Page 1

Model 3000B - Gravity Feed

Automatic Component Handling System

User’s Manual

Version 3.0.3

June 5, 2001

Exatron, Inc.

2842 Aiello Drive

San Jose, California 95111

(408) 629-7600 Tel

(800) exa-tron Tel

(408) 629-2832 Fax

www.exatron.com

Page 2

Exatron 3000B

www.exatron.com ii TOC

Page 3

Exatron 3000B

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION.................................................................................................................... 1-1

ODEL

M

E

3000B O

XATRON SUPPORT SERVICES

VERVIEW

...................................................................................................................................... 1-1

................................................................................................................................1-3

Toll-Free Telephone Customer Service Line ..................................................................................................... 1-3

Standard Warranty ............................................................................................................................................. 1-3

Customer In-House Service................................................................................................................................1-3

Offshore Warranty Service................................................................................................................................. 1-4

The Model 3000B .............................................................................................................................................. 1-4

The Model 3010B .............................................................................................................................................. 1-5

LSO AVAILABLE FROM EXATRON

A

:........................................................................................................................ 1-5

The Model 2000B .............................................................................................................................................. 1-5

The Model 5000............................................................................................................................................................... 1-5

ARNING/CAUTION

W

ABELS

L

................................................................................................................................... 1-8

Availability of Warning Labels:.........................................................................................................................1-8

CHAPTER 2 INSTALLATION..................................................................................................................... 2-1

XATRON SAFETY FEATURES

E

................................................................................................................................. 2-1

Electrical Hazards .............................................................................................................................................. 2-1

Compressed Air..................................................................................................................................................2-2

Moving Parts......................................................................................................................................................2-2

Overall System Safety........................................................................................................................................ 2-2

NPACKING

U

SSEMBLING

, A

...................................................................................................................................... 2-2

UNPACKING AMBIENT HANDLERS: MODEL 3000B .............................................................................. 2-2

UNPACKING THE POWER SUPPLY........................................................................................................................... 2-3

UNPACKING THE FRED/AMBIENT ASSEMBLY ..................................................................................................... 2-3

UNPACKING HOT RAIL HANDLERS: MODEL 3010B............................................................................... 2-7

UNPACKING THE POWER SUPPLY........................................................................................................................... 2-7

UNPACKING THE FRED/ENVIRONMENTAL ASSEMBLY ..................................................................................... 2-7

UNPACKING THE HOT RAIL HANDLER ASSEMBLY............................................................................................. 2-8

ENERAL OPERATING SPECIFICATIONS

G

................................................................................................................... 2-9

Electrical Requirements ..................................................................................................................................... 2-9

Air Requirements ............................................................................................................................................... 2-9

NVIRONMENTAL OPERATING SPECIFICATIONS

E

.................................................................................................... 2-10

Location ...........................................................................................................................................................2-10

ESD Grounding................................................................................................................................................ 2-10

DUT Materials .................................................................................................................................................2-11

Tilt Mechanism - Table Top Mounting............................................................................................................ 2-11

OWERING UP

P

RACTICE SESSION

P

UNNING DIAGNOSTICS

, R

YCLING SAMPLE DEVICES

: C

................................................................................................................ 2-12

.................................................................................................... 2-14

The Exatron Octoloader................................................................................................................................... 2-15

CHAPTER 3 INTERFACE INFORMATION .............................................................................................3-1

OVERVIEW .......................................................................................................................................................... 3-1

ENERAL INTERFACE OPTIONS AND SET UP

G

........................................................................................................... 3-2

Accessing a Handler Control Interface: ............................................................................................................. 3-2

General Interface RAM Selections:....................................................................................................................3-2

Interface Type: Address 00D2 ........................................................................................................................................ 3-2

Start Test Delay: Address 0097....................................................................................................................................... 3-2

Pick Up Delay: Address 00A9 ........................................................................................................................................ 3-3

Stop On Fail Y/N: Address 00AA.................................................................................................................................. 3-3

Gate Delay: Address 00AB............................................................................................................................................. 3-3

Double Test Sort: Address 00BC.................................................................................................................................... 3-3

www.exatron.com i TOC

Page 4

Exatron 3000B

Handler Binning Setup....................................................................................................................................... 3-4

I. Introduction:............................................................................................................................................................ 3-4

II. Designing Bin Assignments:................................................................................................................................... 3-4

III. Finding Bin Assignment Data:............................................................................................................................ 3-4

IV. Storing Bin Assignments in Handler Memory:................................................................................................... 3-5

ANDLER PORT INTERFACE

H

RS-232 I

NTERFACES

RS-232 Port Options:.......................................................................................................................................3-15

Exatron Super................................................................................................................................................... 3-16

Laser Only Kit:................................................................................................................................................. 3-16

XATRON

E

RS-232:................................................................................................................................................ 3-19

BASIC HANDLER/CPU TEST CYCLE HANDSHAKE ............................................................................................. 3-20

BASIC HANDLER/CPU TEST CYCLE HANDSHAKE ............................................................................................. 3-20

HP RS-232: .......................................................................................................................................................... 3-22

ROGRAMMER

P

ROGRAMMER

P

RS-232: ........................................................................................................................................ 3-23

RS-232 T

CHAPTER 4 HANDLER SET UP................................................................................................................. 4-1

VERVIEW

O

.............................................................................................................................................................. 4-1

CHANGE RAM.....................................................................................................................................................4-5

BLASTING THE RAM ................................................................................................................................................... 4-5

RAM ADDRESS LISTING............................................................................................................................... 4-6

CHAPTER 5 HANDLER DIAGNOSTICS...................................................................................................5-1

.................................................................................................................................... 3-9

............................................................................................................................................. 3-15

ROUBLESHOOTING GUIDE

.............................................................................................. 3-24

OVERVIEW .......................................................................................................................................................... 5-1

ENTERING DIAGNOSTICS MODE ............................................................................................................... 5-1

Diagnostics Quick Reference ............................................................................................................................. 5-2

Test Site Sensors, 0 Through 7 ........................................................................................................................................ 5-6

Shuttle Position Sensors, 1 Through 8............................................................................................................................. 5-7

Tube Full Sensors, 1 Through 8 (Lead-In Sensors) ......................................................................................................... 5-8

Tube Switch, 1 Through 8................................................................................................................................................ 5-9

Solenoid Check.............................................................................................................................................................. 5-10

INTERFACE CHECK: RS-232 Check (Control Panel Check) ..................................................................................... 5-11

INTERFACE CHECK: Output Port

INTERFACE CHECK: Input Sort Check...................................................................................................................... 5-13

ALL MOTOR CHECK: Shuttle Motor Check............................................................................................................... 5-14

ALL MOTOR CHECK: Test Site Plunger Motor

ALL MOTOR CHECK: Octoloader Motor Check ........................................................................................................ 5-16

OCTO/INDEX CHECK: Shuttle Solenoid Check......................................................................................................... 5-17

OCTO/INDEX CHECK: Input Sensor Check .............................................................................................................. 5-18

ODIFIED AUTOMATIC

M

UTOMATIC

A

DJUST QUICK REFERENCE

Z A

DJUST FEATURE

Z A

(Output Cover LED Check)

“Z-Motor” Check

......................................................................................................... 5-19

........................................................................................................... 5-21

.............................................................................. 5-12

............................................................................ 5-15

CHAPTER 6 DISPLAY DICTIONARY....................................................................................................... 6-1

M

ODEL

3000B H

ANDLER STATUS AND ERROR MESSAGES

..................................................................................... 6-1

CHAPTER 7 PREVENTIVE MAINTENANCE.......................................................................................... 7-1

VERVIEW

O

ENERAL SOLENOID MAINTENANCE GUIDELINES

G

IR REGULATOR MAINTENANCE GUIDELINES

A

ACUUM GENERATOR MAINTENANCE GUIDELINES

V

.............................................................................................................................................................. 7-1

................................................................................................... 7-8

......................................................................................................... 7-9

.............................................................................................. 7-12

PARTICLE INTERCONNECT CONTACT MAINTENANCE ..................................................................... 7-16

WHY CLEAN P I CONTACTS?................................................................................................................................... 7-16

P I CLEANING/PREVENTIVE MAINTENANCE PROCEDURE................................................................7-16

PREPARATION - DISMANTLING THE P I CONTACT ASSEMBLY:..................................................................... 7-16

ULTRASONIC P I CLEANING.................................................................................................................................... 7-17

www.exatron.com ii TOC

Page 5

Exatron 3000B

CHAPTER 8 DRAWINGS ............................................................................................................................. 8-1

MECHANICAL..................................................................................................................................................... 8-1

ELECTRICAL ....................................................................................................................................................... 8-1

CHAPTER 9 REPLACEMENT PARTS ...................................................................................................... 9-1

VERVIEW

O

CHAPTER 10 SUPPLEMENT ...................................................................................................................... 10-1

PARTS LISTS ..................................................................................................................................................... 10-1

Overview.......................................................................................................................................................... 10-1

.............................................................................................................................................................. 9-1

www.exatron.com iii TOC

Page 6

Exatron 3000B

www.exatron.com iv TOC

Page 7

Exatron 3000B

Chapter 1 Introduction

This user's guide provides installation, operation and maintenance information for all 3000B Series

Handlers. The E

for a wide variety of package types ~ both surface mount and through-hole technologies ~ using Snap-On

Changeover Kits to convert from one device size to another.

XATRON

Model 3000B Overview

____________________________________________________________________________

XATRON'S

E

temperature programming/test sites, elevated temperature soak tracks and up to eight automatic device

inputs and outputs. The E

(including compatibility with most older 3000 Series Changeover Kits) and incorporates many

technological advances developed from the Series 5000 Production Handling Systems. The improved

performance, reduced size, and classic flat-back bench-top style of the Model 3000B provide the ideal

solution for medium to high volume automated test and programming applications.

Blank/untested devices are loaded in tubes at the top of the handler then indexed to a test contact

mechanism. Among the standard choices, the customer may select special SMD (Surface Mount Device)

test sites which plunge the Device Under Test (DUT) up to 1.5 inches past the back of the handler to a

load board. Programming and testing take place here, using any of several types of programmers and

testers. The devices are sorted by "Pass" and "Fail" categories after each test. After testing, failed

devices are sorted into reject tubes. Devices which pass the test stage are sorted to the output tubes for

retrieval by the operator.

Model 3000B Series of automatic component handlers integrates customer-specified ambient

Model 3000B Handler is a tube to tube, gravity feed, eight-sort handler designed

XATRON

Model 3000B retains the best features of the original Model 3000

Many options are available for the Model 3000B Handler, most of which may be added in the field.

Available options are described in detail at the time of equipment price quote and include:

•

1 Track Hot Rail

•

Upgrade to Automatic Print and Apply Labeler

•

High Frequency Particle Interconnect Contact Sets

•

Extruded Aluminum Output Tubes

•

Output Tube Guard

•

"Live Bug" or "Dead Bug" Operation (Available in most cases)

•

Bowl-feed Input

•

Output Tape and Reel

•

Free-Rolling E

•

Opto-Isolation Interface

•

Status Light Pole

•

Extended Warranties

•

Service Contracts

XATRON

Dolly ("FRED")

Other Options Available as Requested

The Model 3000B handler operation is constantly monitored by its STD Bus CPU. Once a device enters

the handler, it is tracked by sensors as it passes through every step until it is positively placed in the

correct output tube. If a device jam should occur, an appropriate error message will be displayed on the

handler controller's front panel microterminal. Most jams may be cleared by pressing the

[Clear]

buttons on the front panel.

[RUN]

or

www.exatron.com 1-1 Chapter 1 Introduction

Page 8

Exatron 3000B

The handler may be operated in either of two modes: AUTO or MANUAL. MANUAL operation allows for

Handler Diagnostics sequences to be run, Handler Set-Up changes to be entered, and mechanical

adjustments to be made at the operator's convenience before, during, and after automatic Handler

operation.

AUTO operation continuously cycles devices through the handler. The handler will stop when empty but

re-start automatically when more devices are loaded. Each output tube may be filled to any pre-set

amount, with individual counters keeping track of quantities in all outputs. When an output tube fills, the

handler automatically begins to fill any other unfilled tube assigned to the sort signal received from the

tester. When all output tubes are filled, the handler will stop and a message will be displayed, such as,

ALL OUTPUTS FULL

an empty tube. The handler will not cycle devices to outputs which have no tubes or which are full.

Additionally, a continuous subtotal count is maintained for each output, up to a total of 999,999 devices.

Sorting is accomplished by use of a stepper motor and a solenoid released shuttle. Dual positive binning

sensors keep track of the shuttle's position at all times. In the event of a sorting problem, a message will

be displayed on the handler's front panel, and the device will not be binned until the problem is corrected.

The Model 3000B Handler, like all E

during "power down" conditions. E

functions. E

XATRON

Sigma" binning requirements.

Model 3000B Handlers may be configured for all of the following packages:

. The tube counter is automatically reset by removing the full tube and re-inserting

XATRON

XATRON

test handling equipment meets or exceeds the standards set by M

handlers, is guaranteed to properly bin every device even

has been one of the pioneers in the area of positive binning

OTOROLA

"Six

-DIP, D

-SOIC, S

-SOJ,"J

-PLCC, P

-LCC, L

-SIP; SIL, S

ual In-Line Packages: "Live Bug" or "Dead Bug" 0.300", 0.400", 0.600", 0.900" Body Width,

mall Outline Integrated Circuits: "Live Bug" or "Dead Bug" 0.150",

" Lead Shape: 0.170", 0.210", 0.300", 0.330", 0.350", 0.450" Body Width;

lastic, Leaded Chip Carriers: 18, 20, 24, 28, 32, 44, 52, 68, 84 Pin PLCCs, "Live Bug" only.

eadless Chip Carriers: 18, 20, 24, 28, 32, 44, 52, 68, 84 Pad LCCs, "Live Bug" only.

ingle In-Line Packages: D-Pak, D2-Pak, D3-Pak, TO-218, TO-220, TO-247, TO-3P,

-TSSOP

-Small Printed Circuit Boards

- ZIP, Staggered

-SIMM, S

ingle In-Line Memory Modules

Lead Form Single In-Line Package

8 to 48 Pins, Standard Range

4 to 64 Pins, Optional Range

0.070" or 0.100" Pitch Leads

0.100", 0.079", 0.050", 0.039", 0.025", 0.020" Pitch Leads

TO-3PBL, DO-214, SOT23

Custom Hybrid SIPs, Others

-Other Memory Modules

-Numerous Custom Devices

www.exatron.com 1-2 Chapter 1 Introduction

Page 9

Exatron 3000B

Exatron Support Services

Toll-Free Telephone Customer Service Line

For factory technical support, call 1-800-EXA-TRON, between 8:00 A.M. and 5:00 P.M. Pacific time,

Monday through Friday. When calling, please have your E

the following information:

exact wording

z

The

z

A description of what happened and what you were doing when the problem occurred.

z

A description of how you tried to solve the problem.

of any messages that appeared on your handler display.

Standard Warranty

XATRON

equipment close at hand, along with

All E

XATRON

products are under warranty for one year from the date of purchase. E

XATRON

agrees to

repair any mechanical or electrical assembly, subassembly, or entire unit which fails during normal use

within its first year. The Customer agrees to follow the recommended maintenance procedure as defined

in the User's Manual.

XATRON

E

ruined by operator abuse. E

All warranty work must be performed at the E

DOES NOT warrant test contactors. Handler test contactors are fragile and may be easily

XATRON

uses the finest materials available in our contactor designs.

XATRON

factory or at an authorized Representative Service

location. As described on the following page, in-house service by our customers is encouraged.

E

XATRON

1. Damage caused by improper packaging of equipment returned to E

does not warrant the following:

XATRON

for repair.

2. Damage caused by the freight forwarder.

3. Damage caused by acts of God: flood, fire, earthquake, etc.

4. Damage caused by equipment connected to improper power line voltages.

5. Operator abuse.

6. Interface hardware not manufactured by E

XATRON

.

7. Test contactors.

8. Damage caused by equipment connected to improper air supply: contaminated with oil, water,

dirt, etc.

Customer In-House Service

XATRON

XATRON

encourages customer in-house equipment

will even honor the warranty on a unit when an in-house

Except in the case of Laser Marking Systems, E

service and tries to make in-house service as easy as possible to perform. There are no "Void Warranty"

warning stickers on E

XATRON

handlers. E

repair attempt leads to further damage to the unit. By using the built-in diagnostic software and diagnostic

tools, it is usually possible for the operator to isolate a problem quickly and effect a repair.

www.exatron.com 1-3 Chapter 1 Introduction

Page 10

Exatron 3000B

Offshore Warranty Service

XATRON

An E

XATRON

E

with the exception of replacement contactors. In most cases, it will not be necessary to return the worn

part from the offshore user location.

Handler purchased in the United States and then shipped offshore will be warranted through

in California. Replacement parts are furnished for a period of one year from date of purchase

To receive offshore service support, the handler must be purchased through your local E

Representative or an extended warranty agreement must be purchased directly from your local E

XATRON

XATRON

Representative.

Please supply the following information when requesting offshore service or replacement parts:

1. The part number(s) required. If the part number is not known, photocopy the part and fax it to

XATRON

E

.

2. The Model number of the Handler.

3. The type of device being run by the Handler, such as: DIP, SOIC, SOJ, PLCC, LCC, SIP,

PGA, PCB, ZIP, etc.

4. The Handler's serial number.

5. The full shipping address.

6. Any special shipping or customs instructions.

7. Method of shipment, such as: Federal Express, UPS, DHL, U.S. Mail, or the name of your

chosen freight forwarder.

In most cases, faxed requests and shipment of replacement parts orders are processed within twenty-four

hours of receipt by E

XATRON

.

The Model 3000B

with Eight Automatic Inputs

XATRON'S

E

comes equipped with this octoloader which is a moving metal plate holding up to eight tubes of devices,

controlled by the handler's CPU by means of a stepper motor. The plate automatically moves both left

and right, positioning each tube of devices over the handler input track. When the input track is emptied,

the octoloader automatically searches for tubes with devices. The octoloader has a sensor mounted at its

junction with the input track. The octoloader can "see" a device jam and stop its own movement to

prevent breaking the jammed device. The octoloader also has an automatic "wiggle" jam-clearing

operation which it will implement immediately in an effort to remove the jam without operator assistance.

eight-tube Octoloader is an ambient automatic eight-tube loader. The standard Model 3000B

Model 3000B octoloaders use a Snap-On plate which is specifically fitted with tube holders for a given

device application.

All Model 3000B Handlers not intended to be used on a "FRED," (Free Rolling E

XATRON

Dolly) are

supplied with bench-top base plates which must be bolted directly to a bench or table top to secure the

handler. Each plate includes two sets of tilt bars which enable the handler's tilt angle to be altered for

specific applications. The tilt angle is critical for ceramic DIPs and LCCs since too much drop angle may

cause chipping of the packages.

www.exatron.com 1-4 Chapter 1 Introduction

Page 11

Exatron 3000B

The Model 3010B

with One Elevated Temperature Track

The Model 3010B Hot Rail adds a single track hot rail to the input of the handler. This track holds twenty

inches of devices in order to preheat them prior to test. The temperature range of the Hot Rail is ambient

to +125° C. AC heaters are located within the Hot Rail. Exceptional temperature control is maintained by

constantly monitoring four points in the Rail and four points in the Test Site. The guaranteed accuracy is

±3°

C everywhere in the Soak Rail and ±2° C in the Test Site. All four "zones" in the hot rail are controlled

by an E

The input of the Hot Rail has a manually operated two-input tube holder assembly.

XATRON

-designed computerized temperature controller.

All Model 3010B Handlers are supplied with a Free Rolling E

handler is to be mounted onto this floor stand which has four large tires for easy positioning and four floor

jacks to lock it into place.

XATRON

Dolly ("FRED.") For operation, the

Also Available From Exatron:

The Model 2000B

with Two-Tube Manual Input

The Model 2000B is an ambient handler with a manually operated two-input tube holder assembly for low

to mid-volume handling applications. The tube holder must be manually shifted when one tube of devices

empties in order to present another tube of devices to the input track. The Model 2000B uses Snap On

Change Over Kits to accommodate various size packages. The tube holders are custom-machined to a

specific tube size and are included as standard equipment with Model 2000B Snap On Change Over Kits.

All Model 2000B Handlers are supplied with bench-top base plates which must be bolted directly to a

bench or table top to secure the handler. Although smaller and less expensive than our Model 3000B, the

2000B Series handlers are equipped with a broad range of features found in all E

including:

•

Wide Variety of Device Handling Capability

•

Quick Changeovers Using Modified Snap-On Change Kits

•

Variety of Interfaces

XATRON

handlers

•

Positive Binning

•

Plunge to Board Test Contact Mechanism

•

ESD Safeguards

The Model 5000

Series of Production Handling Systems

The 5000 Series of production handlers integrate any combination of customer-specified ambient

temperature programming/test sites, hot chamber(s), elevated temperature test site(s) and a "smart" laser

marking system. In addition, automatic tube loader/reloader components from various manufacturers may

be integrated into E

When equipped with a laser marker, the entire system is controlled by a single 80486/33 computer.

One or more test sites

Model 5000 Series of Heavy-Duty Handling Systems are ideal for automating high-volume program, test,

and mark applications.

www.exatron.com 1-5 Chapter 1 Introduction

XATRON'S

Model 5000 when the laser marking system option is specified.

are available on all of the various Model 5000 configurations. The E

XATRON

Page 12

Exatron 3000B

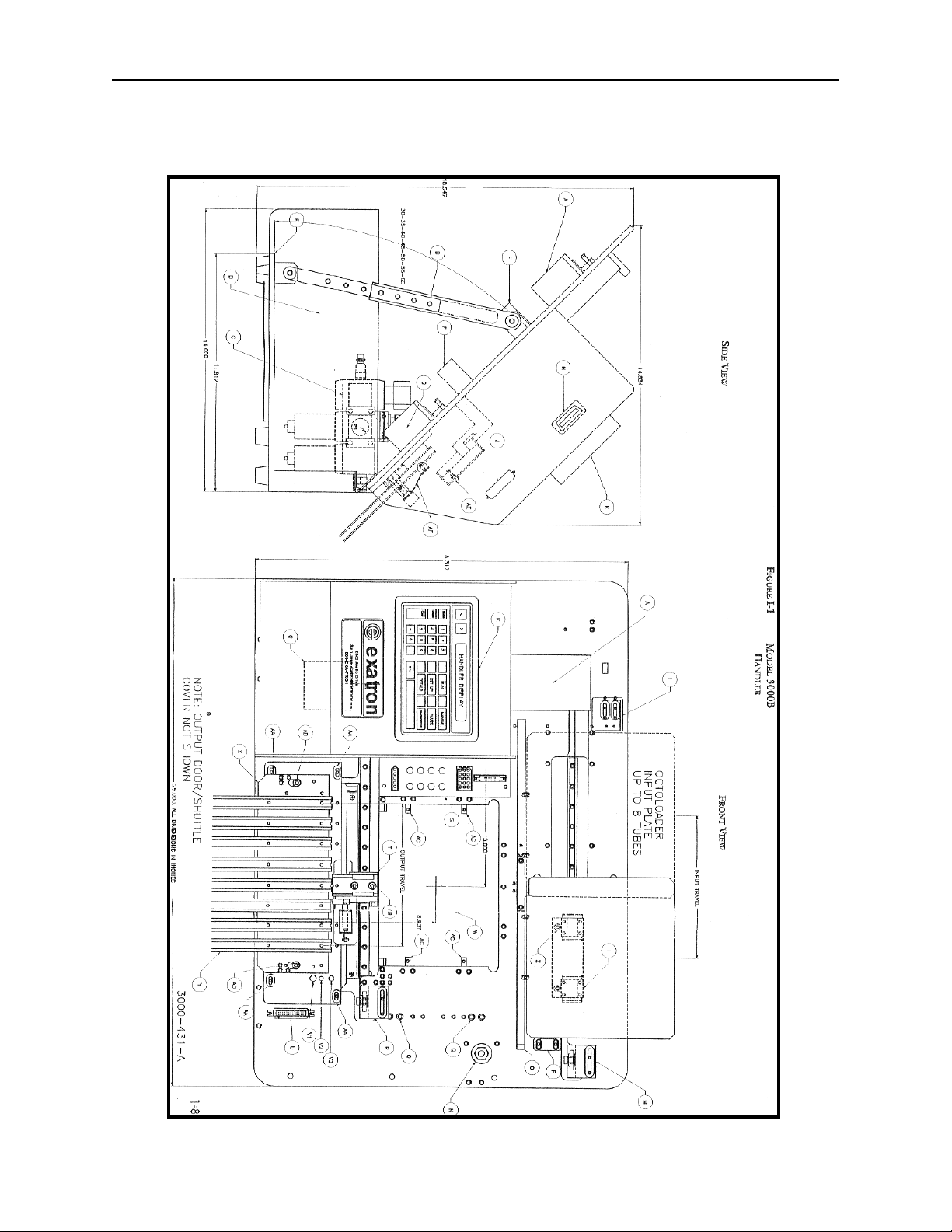

FIGURE 1-1

A. OCTOLAODER MOTOR.

B. TILT MECHANISM.

C. AIR REGULATOR.

D. SERIES 3000B REMOTE POWER SUPPLY.

E. BASE PLATE. Please refer to drawing #3000-215 for base plate bolt-down hole pattern

ALL BENCHTOP HANDLERS MUST BE SECURELY BOLTED TO THE TOP OF THE WORKBENCH.

F. TEST HEAD DOCKING BLOCK.

G. SHUTTLE STEPPER MOTOR.

H. HANDLER PORT INTERFACE.

I. OCTOLOADER SIDE BEARING BLOCK.

J. RS-232 INTERFACE PORT.

K. FRONT PANEL CONTROL.

L. LEFT HAND OCTOLOADER STOP ADJUST BLOCK.

M. OCTOLOADER CHAIN TENSION ADJUST BLOCK.

N. OPTIONAL AIR QUICK DISCONNECT.

O. OCTOLOADER GUIDE BAR.

P. SHUTTLE CHAIN TENSION ADJUST BLOCK.

Q. TEST HEAD MOUNTING BOLT-DOWN HOLE PATTERN.

.

R. RIGHT HAND OCTOLOADER STOP ADJUST BLOCK.

S. CHANGEOVER KIT INPUT / OUTPUT PORTS.

T. SHUTTLE ASSEMBLY. Standard PLCC shuttle assembly shown.

www.exatron.com 1-6 Chapter 1 Introduction

Page 13

Exatron 3000B

FIGURE 1-1

www.exatron.com 1-7 Chapter 1 Introduction

Page 14

Exatron 3000B

Warning/Caution Labels

OUR NEW EXATRON HANDLER WILL ARRIVE WITH SOME OR ALL OF THE FOLLOWING WARNING LABELS ATTACHED

Y

EXATRON

PART NUMBER LABEL TEXT

LAB03-001 DANGER - INVISIBLE LASER RADIATION WHEN OPEN ...

LAB03-004 DANGER - ELECTRICAL HAZARD

LAB03-006 CAUTION - DO NOT OPERATE WITHOUT GUARDS ...

LAB03-007 DANGER - WATCH YOUR HANDS AND FINGERS

LAB03-008 CAUTION - BEFORE CLEANING OR SERVICING ...

LAB06-001 CAUTION - HIGH TEMPERATURE

LAB09-001 THIS UNIT SOLD AND SERVICED BY ...

:

LAB09-002 WARNING! DON'T REMOVE WITH HANDLER POWER ON

(IN-HOUSE ONLY) THIS ORDER CONTAINS PARTICLE INTERCONNECT ...

5000-494 DANGER - DO NOT REMOVE OR DETACH ...

5000-958 CAUTION - HIGH PRESSURE AIR SOURCE

5000-967 CAUTION - CONTAINS HOT SURFACES

Availability of Warning Labels:

Current laws pertaining to the cautionary labels required to be installed on electronic equipment vary from

state to state. E

considerations as they relate to our component handling systems. In effect, virtually every surface of the

handler could be covered with warning signs and labels. For aesthetic reasons, we choose to produce a

machine with a less cluttered appearance, while still providing adequate visual caution indicators.

Individual customers may wish to obtain additional labels to facilitate safe operation and service for this or

other electronic equipment in use at their locations. The labels listed above are shown in detail on the

following pages and may be purchased from the E

number is 1-800-EXA-TRON.

XATRON

makes every attempt to comply with all known labeling laws and safety

XATRON

factory as desired. Our toll-free telephone

www.exatron.com 1-8 Chapter 1 Introduction

Page 15

Exatron 3000B

www.exatron.com 1-9 Chapter 1 Introduction

Page 16

Exatron 3000B

www.exatron.com 1-10 Chapter 1 Introduction

Page 17

Exatron 3000B

www.exatron.com 1-11 Chapter 1 Introduction

Page 18

Exatron 3000B

www.exatron.com 1-12 Chapter 1 Introduction

Page 19

Exatron 3000B

www.exatron.com 1-13 Chapter 1 Introduction

Page 20

Exatron 3000B

www.exatron.com 1-14 Chapter 1 Introduction

Page 21

Exatron 3000B

www.exatron.com 1-15 Chapter 1 Introduction

Page 22

Exatron 3000B

www.exatron.com 1-16 Chapter 1 Introduction

Page 23

Exatron 3000B

www.exatron.com 1-17 Chapter 1 Introduction

Page 24

Exatron 3000B

www.exatron.com 1-18 Chapter 1 Introduction

Page 25

Exatron 3000B

www.exatron.com 1-19 Chapter 1 Introduction

Page 26

Exatron 3000B

www.exatron.com 1-20 Chapter 1 Introduction

Page 27

Exatron 3000B

Chapter 2 Installation

Basic installation of your new Exatron handler will consist of the following three major steps:

I. Unpacking the handling equipment and assembling its peripheral parts.

II. Powering up the handler and running Diagnostics sequences.

III. Cycling sample tubes of devices.

These multi-part steps are described in detail below. After these steps are completed you will be ready to

interface the handler to your tester/prom programmer as described in chapter 3, interface information.

Please read and understand this entire User's Manual before installing or using your Exatron

handler. The following safety procedures must be followed at all times.

Exatron Safety Features

____________________________________________________________________________

Electrical Hazards

High Voltage Testing Applications:

every handler we make prior to shipment. In some cases, the handler will be used to test devices at high

voltages. If your handler will be used to test devices with voltages in excess of 80 VDC or 80 VAC, the

handler will need to be equipped with safety covers.

If Exatron is notified of high voltage requirements as described above on the written purchase order at the

time of order placement, we will equip your handler with safety covers having electrical interlock switches.

These switches are intended to be utilized by the operator by connecting them to the customer-supplied

tester. When the interlock switch is open, the tester will be shut down with no possibility of high voltage at

the handler's contacts. All safety hardware should be verified for proper operation by the customer's own

in-house safety officer.

If you intend to use this handler for high voltage testing, notify Exatron immediately and place an order for

safety covers, if this has not already been done. Added safety covers will be provided at additional cost to

the user.

If your Exatron handler is equipped with safety covers, never operate the handler without them. Never

remove the safety covers. Never defeat any electrical interlock switch supplied with the handler.

High Internal Voltages:

electronics -- with the exception of the Model 3010B Hot Rail.

High voltage from the building line current is present in the Exatron remote 3000B power supply. Only

qualified service technicians should do any repair work on the power supply. Make sure to use qualified

service technicians when attempting to repair any portion of the handler that uses high electrical voltages.

In most cases, there are no high voltages used inside the Model 3000B handler

It is the policy of Exatron to determine the precise application for

www.exatron.com 2-1 Chapter 2 Installation

Page 28

Exatron 3000B

Compressed Air

Your Exatron handler may require a compressed air supply. If your specific changeover kit requires

compressed air, connect the handler to an 80 PSI (+/- 3PSI) air source. Please refer to the "Air

Requirements" section of the Model 3000B General Operating Specifications for further details.

Using compressed air can be hazardous. It is the responsibility of the customer to properly train all

handler operators in every aspect of the safety practices associated with the use of compressed air.

NEVER operate any Exatron equipment which requires compressed air without an approved air

regulator and shutoff valve.

Moving Parts

Most moving parts of the Model 3000B handler have structural covers.

HANDLER WITH ANY COVER REMOVED

on the handler. Keep all loose-fitting clothing away from moving parts, as well. Do not attempt to service

the handler in any way when any part of the handler is in motion. Use the

controller to stop the handler's operation, or turn the handler off before attempting to access any moving

part of the handler.

. Be careful to keep your fingers away from any moving parts

NEVER OPERATE THE

[PAUSE]

button on the handler

Overall System Safety

Typically, the handler is simply one part of a complete test system. It is the responsibility of the user to

properly train all handler operators in all of the safety practices required for every component of the test

system.

Unpacking, Assembling

Your Model 3000B handler has been shipped to you in specially designed containers which should be

safely stored away. If it should become necessary to return the handler to Exatron, these original shipping

containers must be used. Exatron assumes no responsibility for damage during return shipment caused

by improper packing of the handler. If the shipping cartons become misplaced or damaged, new shipping

cartons may be ordered from Exatron.

UNPACKING AMBIENT HANDLERS: MODEL 3000B

Tools required: One standard flat-bladed screwdriver

One Phillips head screwdriver

1. Open the box with the "DELICATE INSTRUMENT" label side up and remove the top

"honeycomb" cardboard cushion panel.

four sides by cardboard cushion panels. Inside the internal carton, the handler is bolted to a wooden

base held in place for shipping by the internal carton which has no bottom. Cut or remove the sealing

tape on the top of the internal carton.

2. Remove this internal carton by pulling straight up on its sides.

bolted to the wooden base. The handler and the wooden base weigh approximately forty-five pounds.

3. Firmly grasp the handler on each side and lift straight up.

table top.

4. Unscrew the bolts to remove the wooden base from the handler.

You will see a sealed cardboard carton surrounded on all

You can now see the handler

Set the handler on a sturdy bench or

www.exatron.com 2-2 Chapter 2 Installation

Page 29

Exatron 3000B

5. Save the bolts and their washers with the wooden base and return them to the shipping

container.

6. Replace the internal carton and the top cushion panel.

7. Carefully examine the space between the container and the four side cushion panels for any

additional parts

spaces.

since Tube Holder extensions and sample devices are often packed in these

8. Replace all packing material and internal boxes.

storage shipping container and re-pack the handler in the reverse order of the unpacking procedure described

above.

DO NOT DISCARD!

If it becomes necessary to return this handler to Exatron, use this

The shipping carton should now be ready for

UNPACKING THE POWER SUPPLY

The power supply is shipped in a separate 20" x 18" x 18" cardboard box.

Open the box with the "DELICATE INSTRUMENT" label side up and remove the top internal box

containing handler peripherals, such as: Octoloader Plate, Air Regulator, Shuttle, User's Manual

and Power Cords.

Open the bottom internal box and remove the power supply using both hands.

supply aside and return the packing material to the empty box. The shipping carton should now be ready

for storage - DO NOT DISCARD! Proceed with the unpacking/assembly instructions. If you have not

purchased a Free Rolling Exatron Dolly, or FRED, skip the following step.

Set these items aside.

Set the power

UNPACKING THE FRED/AMBIENT ASSEMBLY

Tools required: One standard flat-bladed screwdriver

One Phillips head screwdriver

Size 6 Allen wrench

www.exatron.com 2-3 Chapter 2 Installation

Page 30

Exatron 3000B

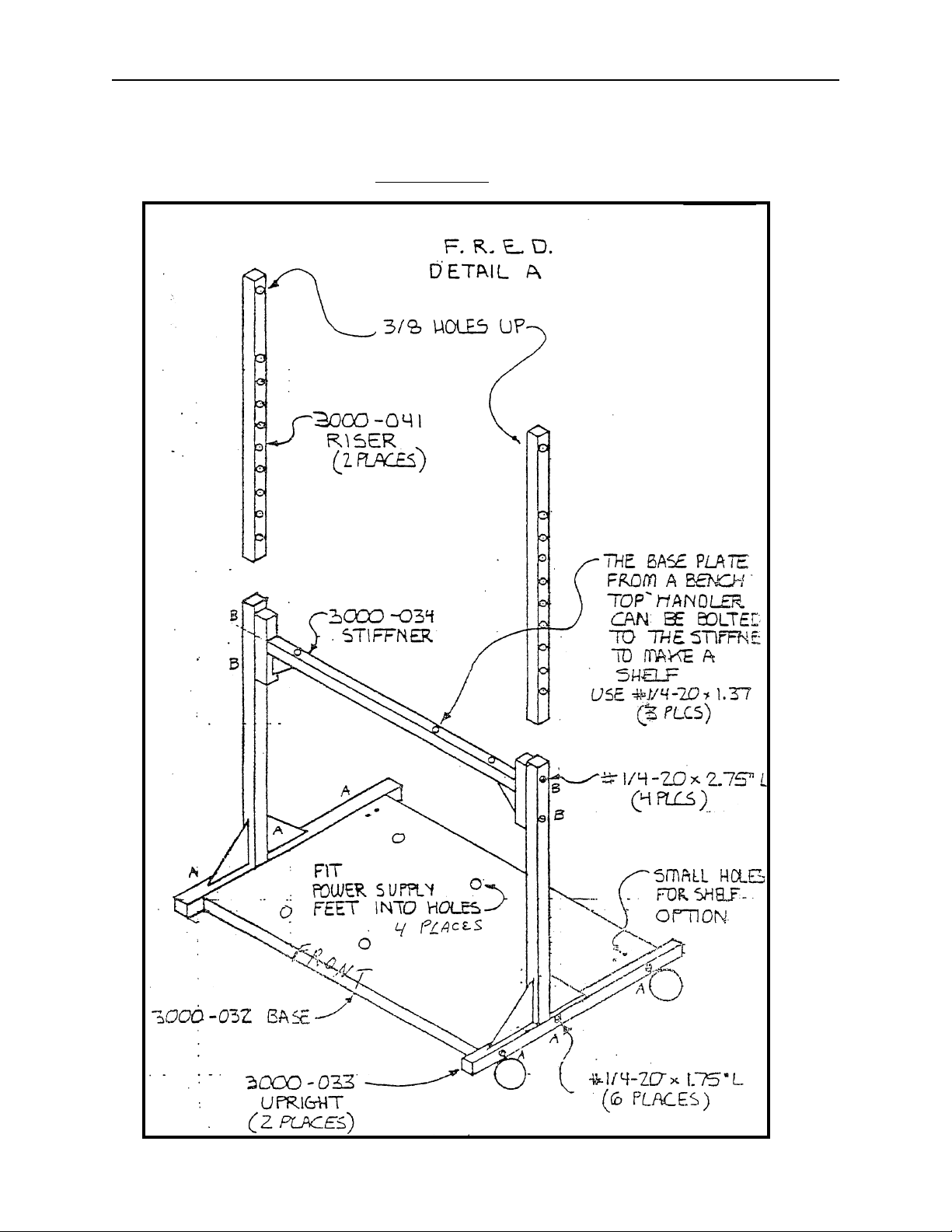

Open the fred shipping box and remove all parts of the metal fred.

additional set of FRED assembly instructions, Detail Figures A, B and C, and one FRED parts list.

Assemble the base of the FRED first. Refer to Detail A.

Inside the box you will find one

www.exatron.com 2-4 Chapter 2 Installation

Page 31

Exatron 3000B

1.

Using six #1/4 - 20 x 1.75" long bolts and six

plate. Note the location of the small holes in the base in relation to the uprights.

2.

Tighten all six bolts.

3.

Locate the two riser bars (#3000-041) and the rigid support bar (#3000-034.) Using four #1/4

- 20 x 2.75" long bolts, four block washers and four #1/4 - 20 hex nuts, attach the risers and

the rigid support bar to the uprights by inserting the bolts through the upright, through the riser

and then through the holes in the rigid support bar. The large holes in the riser should be at

the top. Assemble the riser bar in the lowest position initially and then adjust its height as

needed. Place lock washers and nuts on all bolts. Do not tighten the bolts yet.

4.

Place the handler power supply on the base (#3000-032.) Insert the rubber feet on the power

supply into the pre-cut holes in the base.

Please refer to Figure B. The FRED may be assembled with either of two different pivot points depending

upon your application. The hardware remains the same in both cases. Type A pivot is recommended for

handlers using cable-type test contact interface. Type B pivot is recommended for zero test head

interfaces, or when docking the handler to a manipulator.

NOTE: The maximum slide angle for PLCC devices is 45° from vertical.

1.

Locate the two blue pivot plates (#3000-035.)

2.

Using two #3/8 x 16 x 2.75" long bolts, four

and six #3/8 x 16 hex nuts, attach the pivot plates to the riser bars according to the pivot point

selected. Place lock washers and nuts on all six #3/8 bolts. Do not tighten the bolts yet.

lock washers, attach the two uprights to the base

#3/8 x 16 x 1.75" long bolts, six #3/8 lock washers

www.exatron.com 2-5 Chapter 2 Installation

Page 32

Exatron 3000B

Please refer to Figure C.

3.

Locate the two plate hanger blocks (#3000-037.)

4.

Using two #1/4 x 20 x1.50" long bolts and two

onto the frame, threaded end up. These holes are marked "G" on FRED detail Figure C. Do

not tighten the bolts yet.

5.

Remove the handler main plate (#3000-301) from the base plate (#3000-216). Remove the

hinges and the tilt blocks.

lock washers, mount the plate hanger blocks

6.

Using two #1/4 x 20 x .62" long bolts and two

hanger blocks on the frame through the holes marked "G" on FRED detail Figure C.

7.

Using four #1/4 x 20 x 1.37" long bolts and four

the frame through the four tapped holes on the main plate also used by the base plate hinges.

These holes are marked "E" on FRED detail Figure C.

8.

Verify that the slide angle and handler height are correct for your application then, tighten all

bolts on the frame, risers, rigid support bars and uprights.

9.

TRAY OPTION: Using three #1/4 x 20 x 2.50" long bolts, three

20 hex nuts, bolt the tray extension frame to the bottom edge of the FRED frame. Tighten all

three bolts.

DETAIL C

lock washers, bolt the handler to the plate

lock washers, bolt the handler main plate to

lock washers and three #1/4 x

www.exatron.com 2-6 Chapter 2 Installation

Page 33

Exatron 3000B

UNPACKING HOT RAIL HANDLERS:

Tools required: One standard flat-bladed screwdriver

One Phillips head screwdriver

The Model 3010B Hot Rail is shipped in at least three boxes. The largest box, 46" x 23" x 32" contains the

handler/hot rail as an assembled unit. The FRED box is 5" x 33" x 24" and contains the Free Rolling

Exatron Dolly frame. The third box, 20" x 18" x 18", contains two power supplies. A fourth box may be

included in your shipment containing spare parts or additional handler options. Open these boxes in the

order listed below so that loose parts do not become mixed or misplaced.

MODEL 3010B

UNPACKING THE POWER SUPPLY

The power supply is shipped in a separate 20" x 18" x 18" cardboard box.

Open the box with the "

containing handler peripherals, such as: Octoloader Plate, Air Regulator, Shuttle, User's Manual and

Power Cords. Set these items aside.

Open the bottom internal box and remove the power supply using both hands.

supply aside and return the packing material to the empty box. The shipping carton should now be ready

for storage - DO NOT DISCARD! Proceed with the unpacking/assembly instructions.

DELICATE INSTRUMENT

" label side up and remove the top internal box

Set the power

UNPACKING THE FRED/ENVIRONMENTAL ASSEMBLY

Tools required: One standard flat-bladed screwdriver

One Phillips head screwdriver

Size 6 Allen wrench

Open the fred shipping box and remove all parts of the metal fred.

additional set of FRED assembly instructions, Detail Figures A, B and C, and one FRED parts list.

Assemble the base of the FRED first. Refer to Figure A.

1.

Using six #1/4 - 20 x 1.75" long bolts and six

the base plate. Note the location of the small holes in the base in relation to the

uprights.

2.

Tighten all six bolts.

3.

Locate the two riser bars (#3000-041) and the rigid support bar (#3000-034.) Using

four #1/4 - 20 x 2.75" long bolts, four

attach the risers and the rigid support bar to the uprights by inserting the bolts through

the upright, through the riser and then through the holes in the rigid support bar. The

large holes in the riser should be at the top. Assemble the riser bar in the lowest

position initially and then adjust its height as needed. place lock washers and nuts on

all bolts. Do not tighten the bolts yet.

4.

Place the handler power supply on the base (#3000-032.) Insert the rubber feet on

the power supply into the pre-cut holes in the base.

Please refer to Figure B. The FRED may be assembled with either of two different pivot points depending

upon your application. The hardware remains the same in both cases. Type A pivot is recommended for

handlers using cable-type test contact interface. Type B pivot is recommended for zero test head

interfaces, or when docking the handler to a manipulator.

block washers and four #1/4 - 20 hex nuts,

lock washers, attach the two uprights to

Inside the box you will find one

NOTE: The maximum slide angle for PLCC devices is 45° from vertical.

www.exatron.com 2-7 Chapter 2 Installation

Page 34

Exatron 3000B

5.

Locate the two blue pivot plates (#3000-035.)

6.

Locate two #3/8 x 16 x 2.75" long bolts, four

washers and six #3/8 x 16 hex nuts.

7.

Place the #3/8 x 16 bolts and pivot plates on the risers. push the bolts in just far

enough to hold this assembly together and still leave room for the handler frame to be

placed inside. The bolts can then be pushed quickly into the handler frame while it is

held in position.

8.

Handlers with Hot Rails are shipped pre-assembled on their FRED frames.

#3/8 x 16 x 1.75" long bolts, six #3/8 lock

UNPACKING THE HOT RAIL HANDLER ASSEMBLY

Open the large handler box with the "

two reusable straps on the box. There is no need to cut any tape or remove any staples. lift the top of the

box straight up and remove the inner protective packaging assembly. You should now be able to see the

handler. The handler assembly is very heavy and will require two people to unpack it. With one person at

each end of the unit, pick the handler assembly straight up out of the box.

1.

With two people holding the handler frame assembly by its sides and a third person

ready to push the bolts into place, position the handler assembly horizontally at the

long pivot bolts. Push those pivot bolts into the frame on each side of the handler.

2.

With both people still holding the handler frame assembly by its sides, tilt the handler

to the desired tilt angle and push the remaining four shorter bolts into place. The two

people holding the handler frame should not let go of the handler until all six bolts are

properly inserted.

DELICATE INSTRUMENT

" label side up by carefully removing the

3.

Double-check that the FRED is properly assembled and verify that the tilt angle is

correct. After you have confirmed the assembly is satisfactory, tighten all the bolts.

4.

TRAY OPTION: Using three #1/4 x 20 x 2.50" long bolts, three

three #1/4 x 20 hex nuts, bolt the tray extension frame to the bottom edge of the

FRED frame. Tighten all three bolts.

lock washers and

www.exatron.com 2-8 Chapter 2 Installation

Page 35

Exatron 3000B

General Operating Specifications

Electrical Requirements

Handlers shipped either within the United States or off-shore have built-in electrical supply

capability for 100VAC to 240VAC, 50Hz to 60Hz, except in the case of the Model 3010B Hot Rail.

The Hot Rail thermocouple card contains either a 50Hz crystal or 60 Hz crystal, which must be

specified by the customer.

Model 3010B Hot Rails operating at 240 VAC require an optional step-down transformer for the

handler's heaters.

Connect the power cord to earth-grounded power outlets only.

If the handler is to be used in an electrically noisy environment or near large electromechanical

equipment, Exatron recommends the use of a reliable power conditioner to filter line noise,

surges, and spikes which can cause the handler to operate improperly or become damaged.

Ambient handlers require 3 Amps at 110 VAC. Handlers with Hot Rails require 7 Amps at 110

VAC.

Electricity supplied to the handler must be within the specified operating ranges. If the line voltage drops

too low, the handler may not function properly or may be seriously damaged. Verify that correct operating

line voltage is present. If it is not, contact Exatron for assistance.

SERVICE CALLS MADE TO THE CUSTOMER FACILITY TO CORRECT PROBLEMS CAUSED BY

IMPROPER ELECTRICAL SUPPLY ARE NOT COVERED BY THE EXATRON WARRANTY.

Air Requirements

Depending upon the type of Changeover Kit used, the Model 3000B may require a filtered air

pressure supply of 80 psi/5 cfm (+/- 3 PSI). This air supply must be Clean: containing no

particulate matter greater than 5 microns in size; Dry: having a dew point of 36° F to 38° F; and

free of any oil. To maintain these levels of pressurized air quality, replace the coalescing air filter

(Exatron part #GPA-97-075) in the air regulator of your handler after every 6000 hours or 12

months of operation, whichever comes first; or if your air regulator registers a pressure drop of 15

psi.

Moisture of any kind will travel through external and internal air lines. This moisture will coat these

air lines and the insides of the handler's cylinders, causing them to stick or to stop functioning

altogether. The best defense against this kind of contaminate is to prevent it from occurring in the

first place by maintaining the clean air supply described above.

If the air lines are allowed to become discolored or the moisture traps become overfilled, damage

to the system will occur. The only corrective action to take at that point is to replace all of the air

lines and to completely clean all of the solenoids supplied by those air lines.

due to improper air supply is not covered by the Exatron warranty.

Handler damage

House/Shop vacuum is not required. Changeover kit vacuum requirements are supplied by builtin venturi vacuum generators.

www.exatron.com 2-9 Chapter 2 Installation

Page 36

Exatron 3000B

Environmental Operating Specifications

Location

ALL "BENCHTOP" (ALSO KNOWN AS "TABLE TOP," "PLATE MOUNTED") HANDLERS MUST BE

BOLTED SECURELY TO THE TOP OF THE BENCH.

relation to the benchtop. This makes the handler unstable if not bolted down, which could result in the

handler being knocked over. This can cause serious damage to the handler and injury to the user.

This machine should be installed in a dust-free environment to preclude dust and dirt particles from

contaminating its moving parts, especially those parts which come into contact with the devices being

tested. The life of your handler is greatly enhanced by keeping it as clean as possible.

This Model 3000B handler should be placed as close as possible to your tester test socket, since cable

length from the contactor to the tester is critical in most applications. Please refer to Chapter 3 Interface

Information, for further details.

As specified in the table shown below, Exatron handlers are designed to withstand the impact of virtually

any climate and/or environment that they may be used in. Periodic maintenance as prescribed in Chapter

7 of this manual will ensure that emergency "down time" is kept to a minimum.

The handler's center of gravity is fairly high in

Handler/Hot Rail Handler with Printer

Temperature

Relative Humidity

Airborne dust and moisture, if present, will naturally settle on all surfaces of your handler. If allowed to

build up, dust can eventually block sensors, clog solenoids, fill up the filters of cooling fans, vacuum

generators, air filters and generally inhibit the smooth movement of devices through the handler.

The best defense against this kind of contaminate is to install and use your handler in a dust-free

environment to preclude dust and dirt particles from contaminating its moving parts, especially those parts

which come into contact with the devices being tested. If dust is a factor in your operating environment,

dust the handler off with blasts of compressed air at least every 8 hours. Make sure that the compressed

air is clean, dry and free of any oil.

40° to 115° F,

5° to 45° C

20% to 85%, Noncondensing 20% to 80%, Noncondensing

40° to 105° F,

5° to 40° C

ESD Grounding

All Model 3000B Handlers meet or exceed all known device manufacturers' ESD specifications. All 3000B

Series Handler chassis' are directly connected through the power supply to earth ground. All guide rails,

shuttles, tube holders, hot rails and output trays are connected to earth ground. The handler's power

supply ground is directly connected to earth ground. The handler power supply MUST be connected to a

properly grounded power outlet. NEVER operate the handler with the power line ground removed or

defeated.

All handler main plates, covers and non-trackwork handler parts are plated with conductive finishes.

Exatron uses a very limited quantity of anodizing finishes on handler surfaces.

www.exatron.com 2-10 Chapter 2 Installation

Page 37

Exatron 3000B

DUT Materials

Device Under Test

Component packages vary in the materials from which they're made. The composition and size of

packages can cause wear on the parts of the handler with which they come into contact. Heavy, roughsurfaced DUTs will cause handler wear faster than lighter, smoother materials.

The best defense against the effects of the DUT material on a handler is to ensure that the handler is

properly adjusted for the package it is running. The height of the handler door over the DUT should be as

close as possible. The test site contacts should close on the DUT with enough pressure to provide good

electrical contact, but not press hard enough to force the DUT to the left or the right of the test site rail.

If you have any questions regarding handler adjustment issues, please contact the Exatron Customer

Service Department.

If your handler does experience high levels of wear due to device materials, this will generally occur at

specific points on the handler. If you wish, you may send worn-out equipment parts back to Exatron for

evaluation. In many cases, the excessive wear can be reduced by design changes or material/finish

changes. It is possible that the point which wears out can be modified into an insert which can be easily

replaced as required.

Tilt Mechanism - Table Top Mounting

A tilt mechanism is built into your Model 3000B table top handler. The slide angle may be adjusted from

12° to 60° from vertical. The tilt mechanism is easily removed as needed for large test head interfaces.

The Free Rolling Exatron Dolly (FRED) has its own built-in tilt mechanism.

The slide angle may need to be adjusted when large ceramic devices are to be tested. This is because

ceramic devices may chip or crack upon impact with other devices. Decreasing the slide angle increases

drag and slows the device down as it passes through the handler and into the output tube, which

minimizes chipping from impact. Depending upon the mass and shape of a specific ceramic device, the

angle may need to be reduced.

The handler cycle timing is sensor-controlled, so the cycle speed will be automatically slowed to match

that of the devices. The recommended angle for all plastic devices is 12° from vertical. The maximum

slide angle for PLCC devices is 45° from vertical.

NOTE: Ceramic device damage may be minimized by use of bumpers which attach directly to each

device. Some types of these bumpers will run through a standard Exatron handler. In some cases,

custom rails may be required.

www.exatron.com 2-11 Chapter 2 Installation

Page 38

Exatron 3000B

Powering Up, Running Diagnostics

You may find it beneficial to contact your local Exatron Representative to assist you in setting up your

handler. If you prefer, please feel free to call the Exatron Customer Service Department for assistance as

needed during set up. Our toll-free telephone number is 1-800-EXA-TRON.

After you have unpacked and assembled the handler according to the instructions shown above,

review this entire user's manual before proceeding.

1. Bolt your "benchtop" Model 3000B handler securely to your workbench. If your Model 3000B handler

is mounted on a FRED, verify that it is secure; double-check all mounting bolts.

2. Compare your purchase order to the handler's packing slip and verify that all items ordered have been

received.

3. If your application requires compressed air, bolt the black Wilkerson air regulator, part #NCOD440

onto the right side of the 3000B frame, using two #10-32 x 5/8" bolts. With the orange switch in the

closed position, attach the nozzle of your clean, dry, compressed air supply to the air regulator.

WILKERSON AIR REGULATOR – OFF POSITION

Main Air Flow On/Off

Switch

(On Position Shown)

www.exatron.com 2-12 Chapter 2 Installation

Page 39

Exatron 3000B

DO NOT PLUG THE HANDLER INTO THE POWER SUPPLY YET

4.

into a grounded wall outlet. Turn the power supply on by pressing the red power button and verify that

the +5 volts and +24 volts are operational. If you wish to check/calibrate the power supply output,

please refer to Chapter 7, Preventive Maintenance.

. First plug the power supply only

5. Turn the power supply off again. Now connect the handler power cord to the power supply via the

white Molex connector.

6. If your application requires it, turn the compressed air supply on. Turn the orange switch on the air

regulator to the on position.

7. Move the octoloader plate so that it is flush against the octoloader home switch. Hold the plate in this

position until the power is on.

8. Turn the handler power on by pressing the Red power button on the power supply and observe closely

the display on the handler controller microterminal.

NOTE: Power to the Model 3000B may be turned off and then on again at virtually any time during

handler operation. The only time it is not advisable to turn the power off is within the first 10 seconds

of turning the handler on.

First you will see

firmware revision date. If you have a plunge-type test assembly, the next message to be displayed

JOG UP

will be

The next message displayed is

9. Press the

Diagnostic Tests on your handler and included options. These Diagnostics procedures are detailed

for you in Chapter 5 of this manual. This is your opportunity to become familiar with the handler's

controller and mechanical functions as you observe its self-testing cycles.

[DIAGNOSTICS]

VO1.01 Test Ok

, which tells you that the Z plunger is moving up to locate its top position switch.

displayed, quickly followed by your handler model number and

MOD SET UP ? NO

button on the handler microterminal and perform the complete set of

.

www.exatron.com 2-13 Chapter 2 Installation

Page 40

Exatron 3000B

Practice session: Cycling sample devices

1. Upon completion of all Handler Diagnostics sequences, turn the handler power off, then on again.

When the handler controller displays

message to

2. Make all necessary Set Up Modifications as detailed in Chapter 4, Handler Set Up.

3. Locate a sample set of devices and tubes to use for practice.

4. An Exatron LED Checker, part #3000-052, may be used as a simulator to run sample devices through

the handler. In this case, select the Handler Port Interface during Set Up Modification and switch the

Sort Select Pin 1 to the ON position. This will simulate the tester/programmer. A sort select of 1 will

force all parts cycled to binned to a PASS tube.

MOD SET UP ? YS

MOD SET UP ? NO

.

LED CHECKER

, press the

[SET UP]

button to toggle this

5. Run the sample devices until you are comfortable with the operation of the Model 3000B handler. You

are now ready to interface the handler to your tester or PROM programmer. Please refer to Chapter 3

Interface Information for details on communications interface selection.

www.exatron.com 2-14 Chapter 2 Installation

Page 41

Exatron 3000B

The Exatron Octoloader

XATRON’S

E

automatically load any device supplied in tubes into your E

assembly snaps onto the handler for easy conversion from one device size/type to another.

The Octoloader is a moving plate that holds tubes of devices and is controlled by the handler’s CPU via a

stepper motor. During production, the plate automatically moves from side to side, positioning each tube

above the handler input track. When the input track becomes empty, the Octoloader automatically

searches for tubes with devices. A sensor mounted at the junction of the input track allows the Octoloader

to “see” a device jam, if one occurs. The Octoloader will then stop moving to prevent damage to the

jammed device. In addition, the Octoloader has an automatic “wiggle” cycle that will attempt to clear the

jam automatically, without operator assistance.

TO INSTALL FULL TUBES INTO THE OCTOLOADER:

1. Tubes are installed upside down into the Octoloader.

2. Raise the blue anodized tube gates, if present on the Octoloader, so that they are in the open or “up”

position.

3. Remove the stopper from the top of a full tube of devices. Hold the lower half of the tube in your right

hand and place the index finger of the left hand over the top of the tube to prevent the devices from

spilling.

4. While blocking the open end of the tube with your finger, invert the tube and rest that end of the tube

and your finger against the Octoloader main plate next to the tube gate at an approximately 45° angle.

5. While continuing to hold the tube with your right hand, move the index finger of your left hand out of

the way of the open end of the tube. Keep the open end of the tube resting against the Octoloader to

prevent spilling the devices and raise the bottom end of the tube until it is completely upside down.

Press the tube into place in the track of the Octoloader.

6. Close the tube gate over the tube to complete installation. Repeat this process for each additional

tube.

eight-tube capacity automatic tube loading mechanism, called the Octoloader, will

XATRON

handling system. The Octoloader

OCTOLOADER OCTO / INDEX GAP

www.exatron.com 2-15 Chapter 2 Installation

Page 42

Exatron 3000B

www.exatron.com 2-16 Chapter 2 Installation

Page 43

Exatron 3000B

Chapter 3 Interface Information

OVERVIEW

The test site on the Handler may be interfaced to virtually any programmer and/or tester available. Some

interfaces require custom configuration prior to shipment but the only requirement for a given programmer

or tester is that it be capable of issuing and accepting commands to and from the handler or the system

controller. There are two basic parts to the handler's interface with your programmer/tester.

The first part is the "DUT Interface."

1.

tester's test socket. There are many ways to accomplish this, depending upon application and type of

changeover kit. A direct dock interface which connects the tester directly to the handler contacts

provides the best performance, although other interface methods are available. In most cases, the

hardware required for the DUT Interface will be built and installed at E

Interface will not be discussed in this section of the user's guide.

The second basic part to every interface is the "Control Interface."

2.

the handler to send a Start to the tester and subsequently allows the tester to instruct the handler how

to process the device under test. The handler is equipped with a variety of ways to accomplish this

task using two basic means of access: a parallel port (E

serial port.

The DUT Interface connects the handler's test contacts to the

XATRON’S

XATRON

“Handler Port”) and an RS-232

. Therefore, the DUT

The Control Interface allows

RS-232 PORT

HANDLER

PORT

The handler has a number of operating features which relate to the handler's tester control interface. Both

the Handler Port and RS-232 Port have several distinctive options from which to choose. These various

control interfaces available from E

organized into three categories:

A. General Interface Options

B. Handler Port Interface Options.

C. RS-232 Interface Options

XATRON

, (common to both Handler Port and RS 232 Port)

.

are the subject of the following discussion. They have been

Please read through all of the firmware options in this chapter to determine exactly which interface will

meet your specific application requirements.

www.exatron.com 3-1 Chapter 3 Interface Info

Page 44

Exatron 3000B

General Interface Options and Set Up

Accessing a Handler Control Interface:

When the handler powers up, you will be given the opportunity to,

[Enter]

Listed below are the standard interfaces currently supplied with the handler. N

added to the handler from time to time. Please contact E

telephone number is: 1-800-EXA-TRON.

button, the previously selected interface (or default interface, if RAM was cleared) will be selected.

XATRON

From “PICK INTERFACE?” displayed on the front panel:

[1] Key

[2] Key

[3] Key

[4] Key

Sets the handler to use "HANDLER PORT"

Sets the handler to use “EXATRON SUPER”

Sets the handler to use “H P RS-232”

[

NOTE: FOR “LABEL/TEST

TO THE MODEL

Sets the handler to use “PROGRAM RS-232”

3000B-

,” “

LABEL ONLY

L USER’S MANUAL

PICK INTERFACE?

OTE

for updates as required. Our toll-free

,”

AND “TEST ONLY” OPTIONS, PLEASE REFER

.]

If you press the

: New interfaces are

[5] Key

[Enter] Key

[Clear] Key

Sets the handler to use “EXATRON RS-232”

Sets your choice into the handler.

Rejects selection and returns to

PICK INTERFACE?

.

General Interface RAM Selections:

Listed below are addresses in the handler’s battery backed-up RAM which may be edited to fine tune the

handler for your specific programmer/tester and sorting requirements when using either the Handler Port

(parallel) or the RS-232 serial port. These addresses are not part of the standard power-up selections

may be modified only by “Changing The RAM,”

and

this manual.

Interface Type: Address 00D2

This address allows the user to set the default interface to be used by the handler. The following table

lists available settings:

data setting

data setting

data setting

data setting

data setting

data setting

data setting

21

23

24

25

26

27

28

= EXATRON SUPER

= PROGRAM RS-232

= LASER ONLY KIT

= EXATRON RS-232

= HANDLER PORT

= LOW GOING PULSE

= H P RF RS-232

as described in the Handler Set-Up Chapter of

[

MODEL 5000 ONLY

[

USES SPECIAL PAL A89-2LP

.]

.]

Start Test Delay: Address 0097

For DIP devices only, this delay adds "settling" time to the DUT. The delay allows the DUT more time to

come to rest in the test site before the contacts close. The delay counts down in HEX, in 1 millisecond

steps.

www.exatron.com 3-2 Chapter 3 Interface Info

Page 45

Exatron 3000B

Pick Up Delay: Address 00A9

This delay allows additional time after the handler has detected the device under the plunger before

turning on the vacuum to pick up the DUT at the start of the test cycle. The delay counts down in HEX, in

10 millisecond steps. This feature applies to Plunge-to-Board and Swing Head changeover kits only.

Stop On Fail Y/N: Address 00AA

30 = Stop on Fail

FF = Run Failed Devices, No Stop

This option allows the handler to Stop on Fail, or not. The handler can either automatically cycle a failed

device into an output tube or the handler can be set to stop. If set to

handler will stop on a failure and allow the operator to retest the device again and again, as often as

desired. This is very useful when calibrating test fixtures and programs.

STOP ON FAIL YES

, then the

Gate Delay: Address 00AB

This delay allows additional time for the test site gate to first open and then secondly, allows additional

time after the handler closes the gate at the end of the test cycle. The delay counts down in HEX, in 10

millisecond steps. This feature applies to Plunge-to-Board changeover kits only.

Double Test Sort: Address 00BC

This address tells the handler which test sorts to double test if desired. A setting of “00” will turn

double test for all sorts. A setting of “FF” will set the tester to double test

Pass and all other sorts are to be double tested, set this address to “FE.” Each bit represents a tester sort.

all

devices. Assuming Sort 1 is

off

the

Tester Sort Set Up: Addresses 00C0 to 00C7

ASCII I

1

2

3

4

5

6

7

8

✻✻✻✻

0

NPUT

ORT

S

1 RAM ADDRESS C0

2 RAM ADDRESS C1

3 RAM ADDRESS C2

4 RAM ADDRESS C3

5 RAM ADDRESS C4

6 RAM ADDRESS C5

7 RAM ADDRESS C6

8 RAM ADDRESS C7

= Remote Flush

= Remote Retest

UTPUT BINS

O

URRENT SETTING

C

USED BY EXATRON RS-232

AND H P RS

USED BY EXATRON RS-232

AND H P RS

232 ONLY

-

232 ONLY

-

The handler uses the specifications shown in the table above to assign Output Bins to tester Sorts.

The “Current Setting” column is provided for the customer’s reference purposes. Please enter your

settings in this column.

If the handler does not receive one of the above test Sorts, the handler will pause and display the

message, “