The Extron WMK 100 Wall Mounting Kit is used for hanging PoleVault® System A/V products on a wall near

WMK 100 Installation Notes

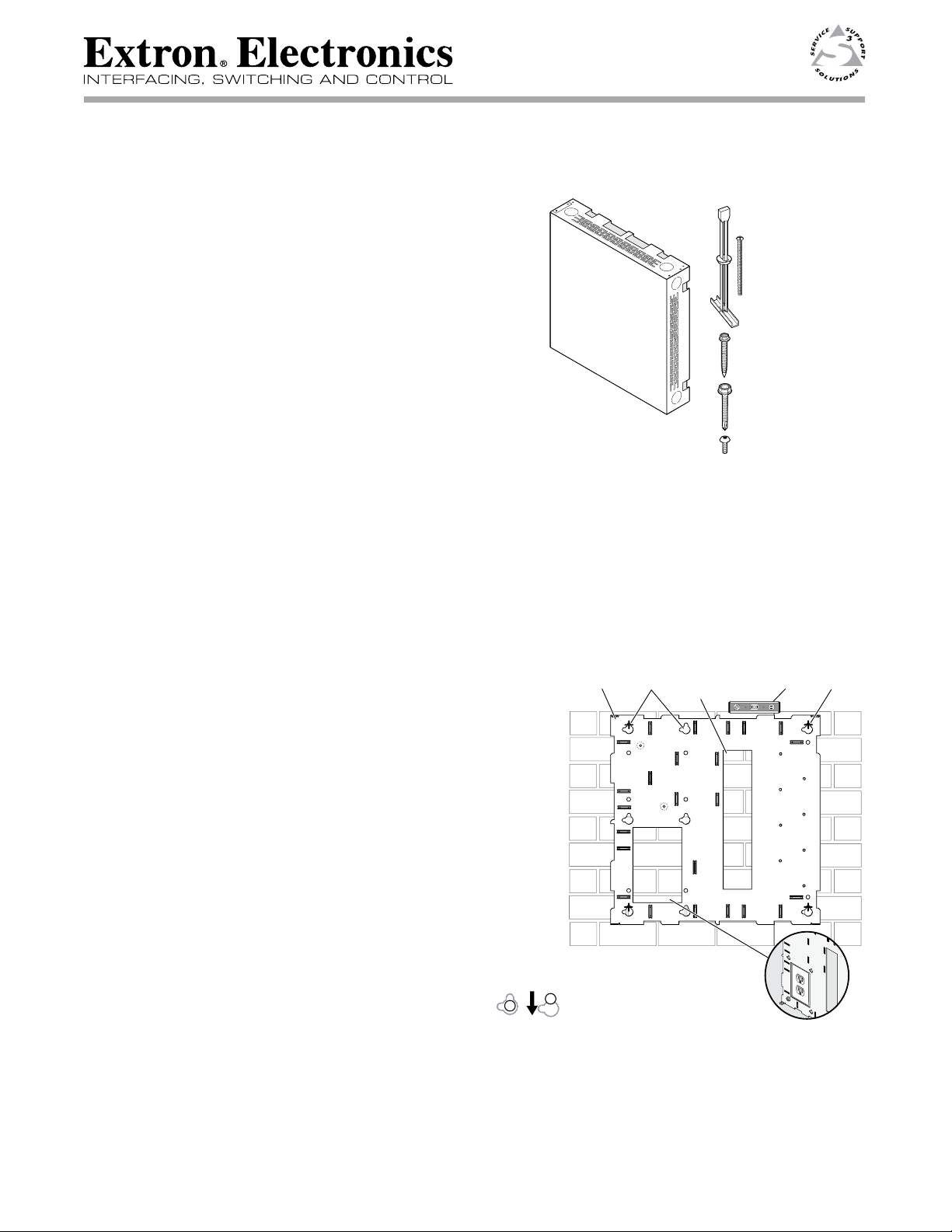

(4) 1/4" x 1 3/4" Masonry Screws

#40-373-01

(4) #14 x 1 3/4" Self-tapping

Metal/Wood Screws

#40-372-01

(4) 1/4-20 x 2"

Pan Head Bolts

#40-375-01

(4) 1/4" Kap Toggle Assemblies

#40-374-01

(4) 6/32" x 1/4" Button Head

Hex Screws

#40-363-17LF

+

+

Cutout for

Electrical

Outlet

Level

Cutout for

Signal Cable

Access

Marker for

Pilot Hole

WMK 100

Base Plate

Mounting

Holes

a flat screen display or short throw projector.

The WMK 100 has a 13" x 13" x 2.5" deep enclosure to mount the

PoleVault switcher and the power supply, with room for cable

management. It also has knockouts on all four sides which allow

external raceways to be used where necessary for cabling.

C

Maximum load for the WMK 100 is 15 lbs (7 kg)

.

The key components (base plate and cover) of the WMK 100 are

shown in figure 1.

Included in the kit are:

(4) ¼-20 x 2" pan head bolts, (4) ¼" Kap toggle assemblies,

(4) ¼ x 1¾" masonry screws, (4) #14 x 1¾" self tapping metal/wood

screws, (4) 6-32 x ¼" button head hex screws.

Not shown but included are (3) 4-40 x ¼" screws, (2) hook-and-loop

straps.

Installation

N

Before installation identify the type of wall (masonry or non-masonry) and the location where the WMK 100 will be

installed. This determines the installation approach and the type of fasteners needed to secure the plate to the wall.

1. Mount the base plate

Follow the steps within 1A or 1B below, as applicable.

N

1A. To mount the WMK 100 onto masonry walls:

N

Proceed to Step 2.

Refer to local building standards and codes to verify that the installation will meet the regulatory

requirements. Observe all local and national building and safety codes, UL requirements, and ADA

accessibility guidelines.

The base plate can be installed over an existing electrical

outlet. The opening fits standard sized 2.75" x 4.5" wall

plates. See figure 2 (inset).

i. Hold the base against the wall, level it, and mark the

positions of four slotted mounting holes (indicated by

+ marks in figure 2). Set the plate aside.

N

Use the top slot position at each mounting hole. Do not use

both top and left slots as this will make it difficult to slide the

plate down (see step iv).

ii. Using a masonry drill bit, drill 1.75" (4.4 cm) deep pilot holes

at the marked locations.

iii. Screw in masonry screws until a gap of 1/8" to 3/8"

(3 to 9 mm) remains between the wall and the screw heads.

iv. Align the base plate's slotted mounting holes over

the installed screws, then slide the plate down so

the screws fit into the slots.

v. At this time, lightly tighten all the screws to secure the plate

to the wall and verify level and position.

Do not over tighten, as the plate needs to be removed to attach the

switcher and power supply before cabling.

Figure 1 — WMK 100 parts

PRELIMINARY

The plate can be aligned over an existing electrical outlet.

Figure 2 — Masonry wall mounting

68-1738-01

Rev A

06 09

1

WMK 100 Installation Notes, cont'd

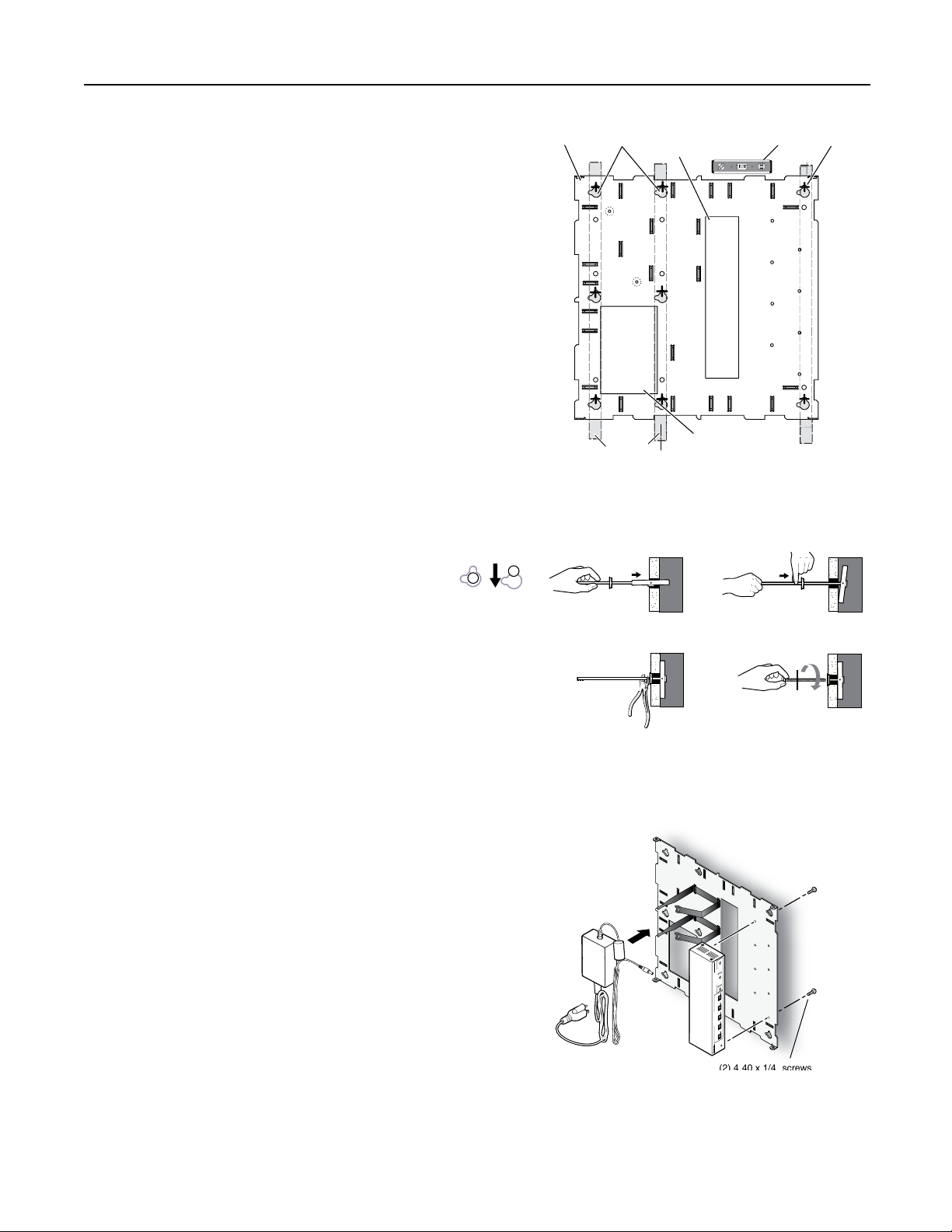

Wall Studs

Cutout for

Electrical

Outlet

Level

Cutout for

Signal Cable

Access

Marker for

Pilot Hole

WMK 100

Base Plate

Mounting

Holes

+

+

(2) 4-40 x 1/4" screws

-

"

PVS 305SA

POLEVAULT SWITCHER

INPUT SELECTION

1

2

PEAK

NORMAL

SIGNAL

CONFIG

3 4

5

AUX AUDIO

AUDIO LEVEL ADJUST

PAGING

SENSOR

SENSITIVITY

VOICELIFT

MIC

PEAK

NORMAL

SIGNAL

INPUT

a. Grasp handle, collapse

toggle and insert into wall.

b. Slide plastic washer

down into pilot hole.

c. Cut off handle close to wall.

d. Hand screw in pan head

bolt until 1/8" gap remains.

1B. To mount the WMK 100 onto a non-masonry wall:

i. At the desired site locate the wall studs and mark their

locations.

N

For ideal installation secure the base plate to at least one

wall stud (see figure 3). Drywall Kap toggles can be used

for holes not aligned with studs.

The base plate can be installed over an existing electrical

outlet. The opening fits standard sized 2.75" x 4.5" wall

plates. See inset on figure 2.

ii. Hold and level the base plate against the wall and mark

the positions of the slotted mounting holes that are on

the stud lines (see figure 3, indicated by + marks). Where

applicable, mark the mounting holes on the wall for

drywall toggles. Set the plate aside.

iii. Drill 1.75" (4.4 cm) deep pilot holes at the marked

locations.

iv. Insert the self tapping screws into the pilot holes, until a

gap of 1/8" to 3/8" (3 to 9 mm) remains between the wall

and the screw heads.

N

If using toggle assemblies see figure 4 for installation

method.

v. Align the base plate's slotted mounting holes

over the installed screws, then slide the plate

down so the screws fit into the slots.

vi. At this time, lightly tighten all the screws to ensure plate

fits flush to the wall and verify level and position.

N

Do not over tighten, as the plate needs to be removed to

attach the switcher and power supply before cabling.

Figure 3 — Non-masonry wall mounting

PRELIMINARY

vii. If the cables are to be run behind the wall to the WMK

viii. Remove the base plate and cut out the marked area.

2. Mount the switcher and power supply

a. Remove the WMK 100 base plate from the wall, and with the

switcher's rear ports facing the cable access hole, align

the two corner holes in the base of the switcher with the two

outermost device mounting holes in the WMK 100 base plate.

Secure with the supplied 440 x ¼" screws.

b. Attach the power supply above the electrical outlet cutout,

with the supplied hook-and-loop straps. Attach it so the cables

are easily and safely routed to the electrical outlet and switcher

alike.

c. Re-attach the plate to the wall and secure firmly.

2

location, mark the cutout area on the wall for the signal

cable access hole (see figure 3).

Figure 4 — Toggle assembly installation

Figure 5 — Attach switcher and power

supply to base plate

Raceway Option

2400

700

Signal Cable Access

Cutout Option

LR

LR

LR

AUX AUDIO

INPUT 5

LINE OUT

VOICELIFT

RECEIVER

PAGING

SENSOR

DO NOT

GROUND

OR SHORT

SPEAKER

OUTPUTS

1B RGB

1A RGB

2B RGB

2A RGB

3B RGB

/VIDEO

4B RGB

/VIDEO

3A RGB 4A RGB

I

N

P

U

T

S

RS-232 MLC/IR

2/4/8

Ohms

CLASS 2 WIRING

AMPLIFIED AUDIO OUT

VOL/MUTE

Tx Rx IR 12V

10V 50mA

POWER

US

LISTED

17TT

AUDIO/VIDEO

APPARATUS

®

RGB

VIDEO

OUTPUTS

CONTROL

N15779

12V

5A MAX

2A RGB

1A RGB

1B RGB

2B RGB

4A RGB

3A RGB

3B RGB

3 VIDEO

4B RGB

4 VIDEO

RGB signal input

(2 CAT 5 cables, A and B

with RJ-45 connectors)

RGB output

to display

RGB #1A

External

Power Supply

(12 VDC, 5 A max.)

d

Composite

video output

to display

Composite video input

(CAT 5 cable with

RJ-45 connector)

b

g

f

a

RS-232 Control

B

A

+12 VDC

Ground ( )

Transmit (Tx)

Receive (Rx)

Ground ( )

Power

Connector

RCA

Connector

Aux Audio

Input 5

e

i

c

j

k

Line out output

(audio)

Red Positive (+)

Black Negative (-)

Wire Color

PVS Terminal

(left and right)

h

VGA

Connector

RGB #1B

VIDEO #3

CONFIG

DISPLAY

VOLUME

MLC 104 IP PLUS

ON

VCR

DVD

PC

OFF

1

2

3

4

PVT RGB D Plus

PVT CV D

COMPUTER IN

AUDIO

IN OUT

MONITOR OUT

IR OUT

S G

AUDIO IN

L

R

VIDEO IN

IR OUT

S G

Paging

Sensor

VoiceLift

Receiver

Audio output

to speakers

MLC Wire Colors PVS Switcher

A (Rx) White A (Tx)

B (Tx) Violet B (Rx)

Ground Drain Wire D (Ground)

Ground Black D (Ground)

12V In Red E +12 V

3. Run cables

Run signal cables from the proposed PoleVault input wall plates,

control device location, and the speakers to the WMK 100 location.

Cables can be routed behind the walls, or through a surface raceway

(e.g., Wiremold 700 or 2400 series) directly to the WMK 100.

3A. If running cable behind the walls:

i. Run all the cables from the various locations to the WMK and

through the access hole.

3B. If using a surface raceway:

i. Attach the WMK cover to the base plate, then identify and

mark the most suitable raceway entrance to the WMK 100.

ii. Run the raceway from the signal source, speaker, and display

locations to the marked raceway entrance at the WMK.

iii Remove the WMK cover, and remove the desired knockout.

iv. Attach the raceway to the wall and run cables from the sources

and outputs through the raceway to the WMK.

Figure 6 — Cabling run options

4. Cable the switcher

a. Connect the cables from the PoleVault transmitters, control device

(MediaLink® Controller), speakers, and optional accessories (VoiceLift, Page Sensor Kit) to the rear ports of the

switcher (see below). Refer to the PVS 305SA Setup Guide for additional details.

N

b. Run VGA and composite video cables from the switcher to the output display device through the wall or

c. Connect the power supply to the switcher and plug it in to the electrical outlet.

N

If using a device other than a PVS 305SA (e.g., PVS 204SA Plus), refer to that device's user manual for details.

where fitted, the raceway.

If the electrical outlet is outside the WMK, pass the IEC power cable out through one of the raceway knockouts.

Cabling the switcher

PRELIMINARY

3

Extron USA - West

Headquarters

+800.633.9876

Inside USA / Canada Only

+1.714 .491.1500

+1.714 .491.1517 FAX

Extron USA - East

+800.633.9876

Inside USA / Canada Only

+1.919.863.1794

+1.919.863.1797 FA X

Extron Europe

+800.3987.6673

Inside Europe Only

+31.33.453.4040

+31.33.453.4050 FAX

Extron Asia

+800.7339.8766

Inside Asia Only

+65.6383.4400

+65.6383.4664 FAX

Extron Japan

+81.3.3511.7655

+81.3.3511.7656 FAX

Extron China

+400.883.1568

Inside China Only

+86.21.3760.1568

+86.21.3760.1566 FAX

Extron Middle East

+971.4.2991800

+971.4.2991880 FAX

12.83"

(32.59 cm)

12.83"

(32.59 cm)

2.5"

(6.35 cm)

13"

(33.02 cm)

13"

(33.02 cm)

Both Sides

Both Sides

Both

Sides

Base

Top View

Side View

Side View

WMK 100 Installation Notes, cont'd

PVS 305SA

POLEVAULT SWITCHER

INPUT SELECTION

1

2

PEAK

NORMAL

SIGNAL

CONFIG

3 4

5

AUX AUDIO

AUDIO LEVEL ADJUST

PAGING

SENSOR

SENSITIVITY

VOICELIFT

MIC

PEAK

NORMAL

SIGNAL

INPUT

5. Final installation.

a. After completion of cabling, place the cover over the installed plate,

and secure at each corner with the provided 6-32 button head screws.

N

b. Switch on the display device, control device, signal sources and

adjust and configure the system as needed.

For full configuration and setup details, refer to the PoleVault System

Installation Manual, the MLC 104 Plus Series Reference Manual, and the

PVS 305SA User's Manual, all available online at www.extron.com.

General Specifications

Mounting

Maximum load capacity ............... 15 lbs (6.8 kg)

Material ........................................... Steel

Dimensions

Product weight .............................. 4 lbs (1.8 kg)

Shipping weight ............................ 6 lbs (3 kg)

Vibration ......................................... ISTA 1A in carton (International Safe Transit Association)

Regulatory compliance

Warranty ......................................... 3 years parts and labor

Ensure any cables exiting the box (e.g., to display device and

external electrical outlet) pass through a raceway knockout.

Wall mount ......................... Yes, with included hardware

Figure 7— Attach WMK 100 cover

Base plate ............................ 12.8" H x 12.8" W x 0.5" D (32.5 cm H x 32.5 cm W x 1.3 cm D)

Cover ................................... 13.0" H x 13.0" W x 2.5" D (33.0 cm H x 33.0 cm W x 6.4 cm D)

Safety ................................... c-UL, UL

N

Specifications are subject to change without notice.

4

2009 Extron Electronics. All rights reserved.

©

Loading...

Loading...