Extreme Networks BlackDiamond 8800 Series, BlackDiamond 10808, BlackDiamond 12800 Series, Summit Family Hardware Installation Manual

Extreme Networks Consolidated ExtremeXOS

Hardware Installation Guide

BlackDiamond 8800 Series Switches

BlackDiamond 12800 Series Switches

BlackDiamond 10808 Switch

Summit Family Switches

Extreme Networks, Inc.

3585 Monroe Street

Santa Clara, California 95051

(888) 257-3000

(408) 579-2800

http://www.extremenetworks.com

Published: 2007

Part number: 100172-00 Rev. 07

AccessAdapt, Alpine, BlackDiamond, ESRP, Ethernet Everywhere, Extreme Enabled, Extreme Ethernet Everywhere,

Extreme Networks, Extreme Standby Router Protocol, Extreme Turbodrive, Extreme Velocity, ExtremeWare,

ExtremeWorks, ExtremeXOS, the Go Purple Extreme Solution, Sentriant, ServiceWatch, ScreenPlay, Summit,

SummitStack, Unified Access Architecture, Unified Access RF Manager, UniStack, Universal Port, the Extreme

Networks logo, the Alpine logo, the BlackDiamond logo, the Extreme Turbodrive logo, the Summit logos, the

Powered by ExtremeXOS logo, and the Color Purple, among others, are trademarks or registered trademarks of

Extreme Networks, Inc. or its subsidiaries in the United States and/or other countries.

© 2006–2007 Extreme Networks, Inc. All Rights Reserved.

Specifications are subject to change without notice.

All other registered trademarks, trademarks and service marks are property of their respective owners.

For safety compliance information, see Appendix A, “Safety Information.”

2

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

Table of Contents

Preface......................................................................................................................................... 15

Introduction .............................................................................................................................15

Conventions..............................................................................................................................16

Related Publications .................................................................................................................16

Part 1: Site Preparation

Chapter 1: Site Preparation............................................................................................................ 21

Planning Your Site ....................................................................................................................22

Meeting Site Requirements ..................................................................................................22

Evaluating and Meeting Cable Requirements..........................................................................22

Meeting Power Requirements ...............................................................................................22

Meeting Site Requirements ........................................................................................................22

Operating Environment Requirements ...................................................................................23

Building and Electrical Codes.........................................................................................23

Wiring Closet Considerations ..........................................................................................24

Temperature .................................................................................................................24

BlackDiamond Family Chassis Spacing Requirements.......................................................25

Summit Family of Switches Spacing Requirements...........................................................25

BlackDiamond Family Chassis Airflow Requirements ........................................................25

Electrostatic Discharge ..................................................................................................27

Humidity ......................................................................................................................27

Rack Specifications and Recommendations ...........................................................................27

Mechanical Recommendations for the Rack .....................................................................28

Protective Grounding for the Rack...................................................................................28

Space Requirements for the Rack ...................................................................................29

Securing the Rack .........................................................................................................29

Evaluating and Meeting Cable Requirements ...............................................................................30

Cabling Standards ...............................................................................................................30

Cable Labeling and Record Keeping......................................................................................30

Installing Cable...................................................................................................................31

Fiber Optic Cable ..........................................................................................................33

Cable Distances ............................................................................................................33

RJ-45 Connector Jackets .....................................................................................................34

Radio Frequency Interference...............................................................................................35

Making Network Interface Cable Connections.........................................................................35

Meeting Power Requirements .....................................................................................................36

LAN Systems ......................................................................................................................36

Power Supply Requirements.................................................................................................36

PoE Devices .......................................................................................................................37

AC Power Cable Requirements..............................................................................................37

Replacing the Power Cable.............................................................................................37

Uninterruptible Power Supply Requirements ..........................................................................37

UPS Features................................................................................................................38

Selecting a UPS............................................................................................................38

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

3

Table of Contents

Calculating Amperage Requirements ...............................................................................38

UPS Transition Time .....................................................................................................38

Applicable Industry Standards....................................................................................................39

Part 2: BlackDiamond Switches

Chapter 2: Overview of the BlackDiamond Switches ........................................................................ 43

Supported Features ...................................................................................................................43

Full-Duplex Support ..................................................................................................................44

Management Ports ....................................................................................................................44

External Compact Flash Memory Card .........................................................................................44

BlackDiamond 8806 Switch Chassis...........................................................................................44

BlackDiamond 8810 Switch Chassis...........................................................................................46

BlackDiamond 12804 Switch Chassis.........................................................................................47

BlackDiamond 12802 Switch Chassis.........................................................................................49

BlackDiamond 10808 Switch.....................................................................................................50

Chapter 3: BlackDiamond 8800 Modules........................................................................................ 53

Management Switch Modules (MSM) ..........................................................................................53

Slots for BlackDiamond 8800 MSMs ....................................................................................53

MSM Activity ......................................................................................................................54

MSM-G8X and MSM-48 Modules..........................................................................................54

MSM LEDs .........................................................................................................................56

I/O Modules..............................................................................................................................56

BlackDiamond 8800 Original Series I/O Modules ...................................................................57

G24X I/O Module ..........................................................................................................57

10G4X I/O Module ........................................................................................................58

G48T I/O Module ..........................................................................................................59

G48P I/O Module ..........................................................................................................59

BlackDiamond 8800 A-Series I/O Modules ............................................................................61

G48Ta I/O Module.........................................................................................................61

G48Xa I/O Module.........................................................................................................62

10G4Xa I/O Module.......................................................................................................63

10G4Ca I/O Module.......................................................................................................63

BlackDiamond 8800 E-Series I/O Modules ............................................................................64

G48Te I/O Module.........................................................................................................64

G48Pe I/O Module.........................................................................................................65

I/O Module LEDs.................................................................................................................66

Module LEDs ................................................................................................................66

Port LEDs on Non-PoE Modules......................................................................................66

Port LEDs on PoE Modules (G48P and G48Pe) ................................................................67

Chapter 4: BlackDiamond 12800 Series Modules ........................................................................... 69

About BlackDiamond 12800 Series Modules ...............................................................................69

BlackDiamond 12800 Series MSMs............................................................................................70

Redundant MSM Activity .....................................................................................................71

MSM LEDs .........................................................................................................................71

MSM-5 and MSM-5R Modules .............................................................................................72

BlackDiamond 12800 Series I/O Modules ...................................................................................73

I/O Module LEDs.................................................................................................................73

4

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

Table of Contents

I/O Port LEDs......................................................................................................................74

GM-20T I/O Module ............................................................................................................74

GM-20T LEDs...............................................................................................................75

GM-20XT and GM-20XTR I/O Modules ..................................................................................75

GM-20XT and GM-20XTR LEDs ......................................................................................76

XM-2X and XM-2XR I/O Modules ..........................................................................................76

XM-2X and XM-2XR LEDs ..............................................................................................77

Distinguishing a BlackDiamond 12800 Series MSM from an I/O Module ........................................77

Module Slot Assignments...........................................................................................................77

Chapter 5: BlackDiamond 10808 Series Modules ........................................................................... 79

About the BlackDiamond 10808 MSMs ......................................................................................79

MSM Activity ......................................................................................................................80

MSM LEDs .........................................................................................................................81

About the BlackDiamond 10808 I/O Modules ..............................................................................82

G60T Module .....................................................................................................................83

G60T LEDs...................................................................................................................83

G60X Module .....................................................................................................................84

Mini-GBIC Ports ............................................................................................................84

G60X LEDs...................................................................................................................85

G20X Module .....................................................................................................................85

Mini-GBIC Ports ............................................................................................................86

G20X LEDs...................................................................................................................86

10G6X Module ...................................................................................................................86

XENPAK Ports ..............................................................................................................87

10G6X LEDs.................................................................................................................87

10G2X Module ...................................................................................................................88

XENPAK Ports ..............................................................................................................88

10G2X LEDs.................................................................................................................89

10G2H Module ...................................................................................................................89

XENPAK Ports ..............................................................................................................90

Mini-GBIC Ports ............................................................................................................90

10G2H LEDs ................................................................................................................90

I/O Module LEDs.................................................................................................................91

Part 3: Installing BlackDiamond Switches and Modules

Chapter 6: Installing the BlackDiamond 8810 Chassis..................................................................... 95

Safety Information ....................................................................................................................95

Unpacking the BlackDiamond 8810 Chassis................................................................................96

Pre-Installation Requirements ....................................................................................................99

Attaching the BlackDiamond 8810 Mid-Mount Rack Brackets.....................................................100

Rack Mounting the BlackDiamond 8810 Chassis .......................................................................101

Grounding the BlackDiamond 8810 Chassis ..............................................................................103

Initial Management Access ......................................................................................................104

Chapter 7: Installing the BlackDiamond 8806 and BlackDiamond 12804 Chassis........................... 105

Unpacking the BlackDiamond 8806/12804 Chassis...................................................................106

Pre-installation Requirements ..................................................................................................109

Attaching the BlackDiamond 8806/12804 Mid-Mount Brackets ..................................................109

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

5

Table of Contents

Rack-Mounting the BlackDiamond 8806/12804 Chassis ............................................................110

Grounding the BlackDiamond 8806/12804 Chassis ...................................................................112

Initial Management Access ......................................................................................................113

Chapter 8: Installing the BlackDiamond 12802 Chassis................................................................. 115

Unpacking the BlackDiamond 12802 Chassis............................................................................115

Rack-Mounting the BlackDiamond 12802 Chassis .....................................................................117

Required Tools and Equipment...........................................................................................117

Front-Mounting a BlackDiamond 12802 Chassis..................................................................117

Mid-Mounting a BlackDiamond 12802 Chassis....................................................................118

Grounding the BlackDiamond 12802 Chassis ............................................................................119

Initial Management Access ......................................................................................................120

Chapter 9: Installing a BlackDiamond 10808 Chassis ................................................................... 121

Safety Information ..................................................................................................................121

Required Tools and Resources..................................................................................................122

Unpacking the Chassis and Preparing the Rack..........................................................................122

Checking the Shipping Status Indicators .............................................................................122

Removing the Accessories Box............................................................................................124

Removing the Carton from the Chassis ................................................................................126

Installing the Chassis ..............................................................................................................128

Standard Rack Installation .................................................................................................129

Mid-Mount Rack Installation ..............................................................................................132

Grounding the BlackDiamond 10808 Chassis ............................................................................134

Initial Management Access ......................................................................................................136

Chapter 10: Extreme Networks Power Supply Units for BlackDiamond Switches.............................. 137

Safety ....................................................................................................................................137

BlackDiamond PSU Compatibility .............................................................................................138

Extreme Networks 1200 W DC PSU ..........................................................................................139

Minimum Software Required ..............................................................................................139

Pre-Installation Requirements ............................................................................................140

Installing the DC Wiring .....................................................................................................140

Installing an Extreme Networks 1200 W DC PSU .................................................................141

Removing an Extreme Networks 1200 W DC PSU.................................................................144

Front Panel LEDs ........................................................................................................145

Extreme Networks 700/1200 W AC PSU ...................................................................................146

Pre-Installation Requirements ............................................................................................146

Installing an Extreme Networks 700/1200 W AC PSU...........................................................147

Removing an Extreme Networks 700/1200 W AC PSU..........................................................149

Front Panel LEDs ..............................................................................................................150

Power Supply Cords.....................................................................................................150

Fuse ..........................................................................................................................151

Specifications...................................................................................................................151

Extreme Networks 600/900 W AC PSU .....................................................................................152

Minimum Software Required ..............................................................................................153

Pre-Installation Requirements ............................................................................................153

Installing an Extreme Networks 600/900 W AC PSU.............................................................154

Removing or Replacing an Extreme Networks 600/900 W AC PSU.........................................155

6

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

Table of Contents

Front Panel LEDs ..............................................................................................................156

Power Supply Cords...........................................................................................................156

Fuse ................................................................................................................................157

Specifications...................................................................................................................157

Extreme Networks 325 W DC Power Supply...............................................................................158

Minimum Software Required ..............................................................................................158

Pre-Installation Requirements ............................................................................................159

Installing the DC Wiring .....................................................................................................159

Installing an Extreme Networks 325 W DC PSU ...................................................................160

Removing an Extreme Networks 325 W DC PSU...................................................................163

LEDs................................................................................................................................164

Fuse ................................................................................................................................164

Specifications...................................................................................................................164

Extreme Networks 325 W AC Power Supply ...............................................................................165

Pre-Installation Requirements ............................................................................................165

Installing an Extreme Networks 325 W AC PSU ...................................................................166

Installing Retaining Brackets and Connecting Power.............................................................168

Removing an Extreme Networks 325 W AC PSU...................................................................170

Front Panel LEDs ..............................................................................................................170

Power Supply Cords...........................................................................................................171

Fuse ................................................................................................................................171

Specifications.........................................................................................................................171

Chapter 11: Installing BlackDiamond Series Modules.................................................................... 173

Module Slot Assignments.........................................................................................................173

Distinguishing a BlackDiamond 8800 or 12800 MSM from an I/O Module ...................................174

Installing a BlackDiamond 8800 or 12800 Series Module ..........................................................175

Connecting and Disconnecting Cables on the 10G4Ca Module.....................................................178

Installing a BlackDiamond 10808 Series Module .......................................................................179

Installing a Backup MSM.........................................................................................................182

Verifying the Module Installation ..............................................................................................182

Displaying Slot Status Information ......................................................................................182

Removing a BlackDiamond 8800 or 12800 Series Module .........................................................183

Removing a BlackDiamond 10808 Series Module ......................................................................184

BlackDiamond Series Blank Front Panels ..................................................................................185

Installing a Blank Front Panel ............................................................................................185

Removing a Blank Front Panel............................................................................................186

Installing or Removing an External Compact Flash Memory Card............................................188

Part 4: Installing BlackDiamond Switch Accessories

Chapter 12: BlackDiamond AC Power Cord Retaining Brackets ...................................................... 191

BlackDiamond 8810 AC Power Cord Retaining Bracket ..............................................................191

Installing the BlackDiamond 8810 AC Power Cord Retaining Bracket.....................................191

Disconnecting a BlackDiamond 8810 AC Power Cord ...........................................................193

BlackDiamond 8806/12804 AC Power Cord Retainer Channel ....................................................194

Pre-Installation Requirements ............................................................................................194

Installing the BlackDiamond 8806/12804 AC Power Cord Retainer Channel...........................194

Removing the BlackDiamond 8806/12804 AC Power Cord Retainer Channel ..........................196

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

7

Table of Contents

Chapter 13: BlackDiamond Cable Management ............................................................................. 197

About BlackDiamond Cable Management ..................................................................................197

Installing the BlackDiamond 10808 Cable Manager ...................................................................197

Using the Cable Holders and Cable Clips...................................................................................202

Connecting Cable Holders ..................................................................................................203

Connecting Cable Clips ......................................................................................................204

Part 5: BlackDiamond Maintenance Procedures

Chapter 14: Replacing the BlackDiamond 12802 PSU/Fan Controller and Fan Tray......................... 209

Safety Information ..................................................................................................................209

Pre-installation Requirements ..................................................................................................209

Replacing the BlackDiamond 12802 Fan Tray ...........................................................................209

Replacing a BlackDiamond PSU/Fan Controller ..........................................................................211

Chapter 15: Replacing a BlackDiamond 8800 Series/BlackDiamond 12804 PSU/Fan Controller ...... 213

Pre-Installation Requirements ..................................................................................................213

Removing a BlackDiamond 8800/12804 PSU/Fan Controller ......................................................213

Installing a BlackDiamond 8800/12804 Spare PSU/Fan Controller..............................................216

Chapter 16: Replacing a BlackDiamond 12804 or 8800 Series Fan Tray........................................ 217

Pre-Installation Requirements ..................................................................................................217

Removing the Fan Tray ............................................................................................................217

Installing the BlackDiamond 8810 Spare Fan Tray.....................................................................219

Chapter 17: Replacing the BlackDiamond 10808 Switch Fan Tray, Air Filter, and

Power Supply Controller .............................................................................................................. 221

Replacing a BlackDiamond 10808 Switch Fan Tray ...................................................................221

Removing the Fan Tray ......................................................................................................221

Installing the Replacement Fan Tray ...................................................................................222

Replacing the BlackDiamond 10808 Air Filter ...........................................................................223

Replacing the BlackDiamond 10808 Power Supply Controller .....................................................224

Pre-Installation Requirements ............................................................................................225

Removing a Power Supply Controller ...................................................................................225

Installing a Power Supply Controller ....................................................................................226

Verifying a Successful Installation.......................................................................................226

Chapter 18: Repacking a BlackDiamond Chassis........................................................................... 227

Safety Information ..................................................................................................................227

Repacking the BlackDiamond 8810 Chassis ..............................................................................228

Repacking the BlackDiamond 8806/12804 Chassis ...................................................................231

Repacking the BlackDiamond 12802 Chassis ............................................................................234

Repacking the BlackDiamond 10808 Chassis ............................................................................235

8

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

Table of Contents

Part 6: Summit Family of Switches

Chapter 19: Summit Family of Switches........................................................................................ 241

Overview of the Summit Switches .............................................................................................241

Summit X250e Series Switches................................................................................................242

Summit X250e-24t Switch ................................................................................................242

Summit X250e-24t Switch Front Panel .........................................................................242

Summit X250e-24t Switch Rear Panel ..........................................................................243

Summit X250e-24p Switch................................................................................................244

Summit X250e-24p Switch Front Panel ........................................................................244

Summit X250e-24p Switch Rear Panel .........................................................................245

Summit X250e-48t Switch ................................................................................................245

Summit X250e-48t Switch Front Panel .........................................................................246

Summit X250e-48t Switch Rear Panel ..........................................................................246

Summit X250e-48p Switch................................................................................................247

Summit X250e-48p Switch Front Panel ........................................................................248

Summit X250e-48p Switch Rear Panel .........................................................................248

Summit X250e-48p Power Supplies..............................................................................249

Internal Power Supply............................................................................................249

External Power Supplies.........................................................................................249

Summit X250e Series Switch LEDs ..........................................................................................250

Summit X450 Series Switches .................................................................................................252

Summit X450-24t Switch ..................................................................................................252

Summit X450-24t Switch Front Panel...........................................................................252

Summit X450-24t Switch Rear Panel............................................................................253

Summit X450-24x Switch..................................................................................................254

Summit X450-24x Switch Front Panel ..........................................................................254

Summit X450-24x Switch Rear Panel ...........................................................................255

Summit X450a Series Switches................................................................................................256

Summit X450a-24t Switch ................................................................................................256

Summit X450a-24t Switch Front Panel .........................................................................257

Summit X450a-24t Switch Rear Panel ..........................................................................257

Summit X450a-24tDC Switch ............................................................................................259

Summit X450a-24tDC Switch Front Panel.....................................................................259

Summit X450a-24tDC Switch Rear Panel......................................................................260

Summit X450a-24x Switch ................................................................................................261

Summit X450a-24x Switch Front Panel.........................................................................261

Summit X450a-24x Switch Rear Panel..........................................................................262

Summit X450a-24xDC Switch ............................................................................................263

Summit X450a-24xDC Switch Front Panel.....................................................................264

Summit X450a-24xDC Switch Rear Panel .....................................................................264

Summit X450a-48t Switch ................................................................................................265

Summit X450a-48t Switch Front Panel .........................................................................266

Summit X450a-48t Switch Rear Panel ..........................................................................266

Summit X450a-48tDC Switch ............................................................................................267

Summit X450a-48tDC Switch Front Panel.....................................................................268

Summit X450a-48tDC Switch Rear Panel......................................................................269

Summit X450e Series Switches................................................................................................270

Summit X450e-24p Switch................................................................................................270

Summit X450e-24p Switch Front Panel ........................................................................271

Summit X450e-24p Switch Rear Panel .........................................................................271

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

9

Table of Contents

Summit X450e-48p Switch................................................................................................272

Summit X450e-48p Switch Front Panel ........................................................................273

Summit X450e-48p Switch Rear Panel .........................................................................274

Summit X450e-48p Power Supplies..............................................................................275

Internal PSU.........................................................................................................275

External PSUs.......................................................................................................275

Summit X450, X450a, and X450e Series Switch LEDs...............................................................276

Chapter 20: Installing Summit Family Switches............................................................................. 279

Safety Information ..................................................................................................................279

Building a SummitStack Configuration ......................................................................................280

Slot Numbers ...................................................................................................................280

About Redundancy ............................................................................................................281

Placing Summit Family Switches for Stacked Operation........................................................281

Connecting the Switches to Form the Stack Ring..................................................................281

Connecting a Stacking Cable to a Stacking Port ...................................................................283

Connecting the Console Port...............................................................................................284

Management Port Cabling ..................................................................................................284

Stacking Port LEDs ...........................................................................................................284

Installing a Summit Family Switch............................................................................................285

Rack-Mounting a Summit Switch........................................................................................285

Free-Standing and Desktop Mounting of Multiple Switches ...................................................286

Removing a Summit Switch from a Rack (AC units only) .......................................................286

Installing and Removing Summit X450a Series DC-Powered Switches..........................................286

Connecting the Internal DC Power Supply to the DC Source Voltage .......................................287

Grounding the Summit X450a-48tDC Switch .................................................................287

Connecting the DC Wiring Harness to the DC Source Voltage ...........................................288

Attaching the DC Wiring Harness to the DC Power Socket on the Switch...........................290

Removing a Summit X450a-48tDC Switch from a Rack ........................................................291

Initial Management Access ......................................................................................................292

Chapter 21: Summit Option Cards.................................................................................................293

Overview ................................................................................................................................293

Safety Information ..................................................................................................................294

XFP and XENPAK Safety Specifications.........................................................................294

Summit XGM-2xn Option Card..................................................................................................295

Mixing ZR XENPAKs with Other Types.................................................................................295

Installing the Summit XGM-2xn Option Card........................................................................296

Summit XGM2-2xn Option Card................................................................................................297

Installing the Summit XGM2-2xn Option Card......................................................................298

Installing or Removing XENPAK Modules...................................................................................300

Installing a XENPAK Module ..............................................................................................300

Removing a XENPAK Module .............................................................................................301

Summit XGM2-2xf Option Card ................................................................................................302

Installing the Summit XGM2-2xf Option Card.......................................................................303

Installing or Removing XFP Modules .........................................................................................304

Installing an XFP Module ...................................................................................................305

Removing an XFP Module ..................................................................................................306

10

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

Table of Contents

Chapter 22: Summit External Power Supplies (EPS) ...................................................................... 307

Overview ................................................................................................................................307

Safety ....................................................................................................................................308

EPS-160 External Power Module (with EPS-T) ...........................................................................309

Installing an EPS-160 External Power Module .....................................................................310

Rack Mounting the EPS-T ............................................................................................310

Installing an EPS-160 into an EPS-T ............................................................................311

Connecting the EPS-160 .............................................................................................311

Removing an EPS-160 from an EPS-T.................................................................................312

EPS-LD External Power Supply Unit..........................................................................................313

Installing an EPS-LD .........................................................................................................313

Rack-mounting the EPS-LD..........................................................................................313

Connecting the EPS-LD to the Switch............................................................................314

Connecting the EPS-LD to Power ..................................................................................316

Removing an EPS-LD ........................................................................................................316

EPS-500 External Power Supply Unit........................................................................................317

Installing and Removing an EPS-500 ..................................................................................318

Rack-mounting an EPS-500 unit ..................................................................................318

Connecting the EPS-500 .............................................................................................319

Removing an EPS-500 unit ..........................................................................................321

EPS-150DC External Power Module (with EPS-T2).....................................................................321

Installing an EPS-T2 .........................................................................................................321

Pre-Installation Requirements ......................................................................................322

Rack Mounting the EPS-T2 ..........................................................................................322

Installing an EPS-150DC ...................................................................................................322

Connecting the DC Wiring Harness to the DC Source Voltage ...........................................323

Installing an EPS-150DC Unit into an EPS-T2 ...............................................................324

Connecting the DC Wiring Harness to the DC Power Socket on the EPS-150DC.................325

Connecting the EPS-150DC to a Switch ........................................................................325

Removing an EPS-150DC ..................................................................................................327

EPS-600LS External Power Module ..........................................................................................328

Power Supply Overview ......................................................................................................328

Single 600-LS Module Configuration: Redundant PoE Power...........................................328

Dual 600-LS Module Configuration: Full Power ..............................................................329

Triple 600-LS Module Configuration: Full Redundant Power............................................329

Internal-to-External PSU Transfer .................................................................................329

Internal PSU failure with single EPS-600LS module.................................................329

Two or Three EPS-600LS modules..........................................................................329

External to Internal PSU Transfer..................................................................................329

Active Internal PSU with single 600-LS module failure .............................................329

Inactive Internal PSU with a dual EPS-600LS configuration and module failure ..........329

Disconnecting the EPS-C/EPS-600LS......................................................................330

Installing an EPS-C Chassis ...............................................................................................330

Pre-Installation Requirements ......................................................................................330

Rack-Mounting the EPS-C............................................................................................330

Installing an EPS-600LS ...................................................................................................332

Removing an EPS-600LS...................................................................................................334

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

11

Table of Contents

Part 7: Optics

Chapter 23: Extreme Networks Optics........................................................................................... 337

Safety ....................................................................................................................................337

GBIC, Mini-GBIC, XENPAK, and XFP Regulatory Compliance.................................................338

Mini-GBIC Interfaces...............................................................................................................338

Mini-GBIC Types and Specifications ...................................................................................338

SX mini-GBIC .............................................................................................................338

LX mini-GBIC..............................................................................................................339

ZX mini-GBIC..............................................................................................................341

Dual-speed 100FX/1000LX mini-GBIC ..........................................................................342

100FX mini-GBIC........................................................................................................343

1000BX mini-GBIC .....................................................................................................345

LX100 mini-GBIC........................................................................................................346

Preparing to Install or Replace a Mini-GBIC .........................................................................346

Installing and Removing a Mini-GBIC ..................................................................................347

Connecting Fiber Cables ..............................................................................................348

100FX/1000LX Mini-GBIC .....................................................................................348

LX100 Mini-GBIC..................................................................................................348

XFP Interfaces ........................................................................................................................349

LR XFP Module .................................................................................................................349

SR XFP Module.................................................................................................................350

Installing an XFP Module ...................................................................................................350

Removing an XFP Module ............................................................................................353

XENPAK Interfaces .................................................................................................................354

SR XENPAK .....................................................................................................................354

LR XENPAK......................................................................................................................355

ER XENPAK .....................................................................................................................356

ZR XENPAK......................................................................................................................357

LX4 XENPAK ....................................................................................................................358

LW XENPAK .....................................................................................................................359

Transmitter Clock Locking Mode ...................................................................................360

Installing and Removing a XENPAK Module.........................................................................361

Part 8: Initial Management Access

Chapter 24: Initial Management Access ....................................................................................... 365

Connecting Equipment to the Console Port ................................................................................365

Logging In for the First Time ....................................................................................................367

Part 9: Appendixes

Appendix A: Safety Information .................................................................................................... 371

Considerations Before Installing ...............................................................................................371

Installing Power Supply Units...................................................................................................372

Maintenance Safety.................................................................................................................373

General Safety Precautions ......................................................................................................373

LAN Systems ....................................................................................................................374

PoE Devices .....................................................................................................................374

12

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

Table of Contents

Uninterruptible Power Supply Requirements ........................................................................374

UPS Features..............................................................................................................374

Calculating Amperage Requirements .............................................................................375

UPS Transition Time ...................................................................................................375

Power Supply Cords Selection ..................................................................................................375

Battery Replacement and Disposal............................................................................................377

Fiber Optic Ports—Optical Safety .............................................................................................377

GBIC, Mini-GBIC, XENPAK, and XFP Regulatory Compliance...........................................377

Appendix B: Technical Specifications .......................................................................................... 385

BlackDiamond 10808 Switch...................................................................................................385

BlackDiamond 8810 Switch.....................................................................................................388

BlackDiamond 8806/12804 Switch..........................................................................................390

BlackDiamond 12802 Switch...................................................................................................393

Power Supplies for the BlackDiamond Family of Switches ...........................................................395

Summit Family of Switches......................................................................................................398

Summit X250e Series Switches..........................................................................................398

Summit X450 Series Switches ...........................................................................................402

Summit X450a Series Switches..........................................................................................404

Summit X450e Series Switches..........................................................................................408

Summit External Power Supplies ..............................................................................................411

Index .......................................................................................................................................... 415

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

13

Table of Contents

14

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

WARNING!

NOTE

NOTE

Preface

This preface provides an overview of this guide, describes guide conventions, and lists other

publications that might be useful.

Service to all equipment should be performed by trained and qualified service personnel only. Before installing or

removing any components of the system, or before carrying out any maintenance procedures, you must thoroughly

read the safety information provided in Appendix A of this guide. Failure to follow this safety information can lea d to

personal injury or damage to the equipment.

Introduction

This guide provides the required information to install Extreme Networks® BlackDiamond® 8800 series

switches, BlackDiamond 10808 switches, BlackDiamond

12800 series switches, and the Summit® family

of switches, including the Summit X250e series, Summit X450 series, Summit X450a series, and Summit

X450e series. This guide also contains information about site preparation, switch functionality, and

switch operation.

The Summit X250e series switches, Summit X450 series switches, Summit X450e series switches, and Summit

X450a series switches are called the Summit family of switches when referred to collectively.

This guide is intended for use by network administrators responsible for installing and setting up

network equipment. It assumes a basic working knowledge of:

● Local area networks (LANs)

● Ethernet concepts

● Ethernet switching and bridging concepts

● Routing concepts

● Simple Network Management Protocol (SNMP)

See the ExtremeXOS 12.0 Concepts Guide and the ExtremeXOS 12.0 Command Reference Guide for

information about configuring Extreme Networks BlackDiamond 8800 series switches, BlackDiamond

10808 switches, BlackDiamond 12800 series switches, or Summit family switches.

If the information in the installation note or release note shipped with your Extreme Networks switch differs from the

information in this guide, follow the installation or release note.

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

15

Preface

Conventions

Tab le 1 and Ta bl e 2 list conventions used throughout this guide.

Table 1: Notice icons

Icon Notice Type Alerts you to...

Note Important features or instructions.

Caution Risk of personal injury, system damage, or loss of data.

Warning Risk of severe personal injury.

Table 2: Text conventions

Convention Description

Screen displays This typeface represents information as it appears on the screen, or command

The words “enter”

and “type”

[Key] names Key names appear in text in one of two ways:

Words in italicized type Italics emphasize a point of information or denote new terms at the place where

syntax.

When you see the word “enter” in this guide, you must type something, and then

press the Return or Enter key. Do not press the Return or Enter key when an

instruction simply says “type.”

• Referenced by their labels, such as “the Return key” or “the Escape key”

• Written with brackets, such as [Return] or [Esc]

If you must press two or more keys simultaneously, the key names are linked with a

plus sign (+). Example:

Press [Ctrl]+[Alt]+[Del].

they are defined in the text.

Related Publications

The Extreme Networks ExtremeXOS™ switch documentation set includes:

●

ExtremeXOS 12.0 Concepts Guide

●

ExtremeXOS 12.0 Command Reference Guide

●

ExtremeXOS 12.0 Release Notes

Documentation for Extreme Networks products is available from the Extreme Networks website at the

following location:

http://www.extremenetworks.com/services/documentation

16

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

Related Publications

You can select and download the following Extreme Networks documentation from the Documentation

Overview page:

● Software User Guides

● Hardware User Guides

You can find archived user guides for software at:

http://www.extremenetworks.com/services/documentation/swuserguides.asp

You can also find archived installation guides for hardware at:

http://www.extremenetworks.com/services/documentation/hwuserguides.asp

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

17

Preface

18

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

1 Site Preparation

WARNING!

1 Site Preparation

This chapter describes:

● Planning Your Site on page 22

● Meeting Site Requirements on page 22

● Evaluating and Meeting Cable Requirements on page 30

● Meeting Power Requirements on page 36

● Applicable Industry Standards on page 39

The requirements described in this chapter are intended for the system administrator, network

equipment technician, or network manager responsible for installing and managing the network

hardware. It assumes a working knowledge of local area network (LAN) operations, and a familiarity

with communications protocols that are used on interconnected LANs. Installation, maintenance, and

removal of a switch, chassis, or its components must be done by qualified service personnel only.

Qualified service personnel have had appropriate technical training and experience that is necessary to

be aware of the hazards to which they are exposed when performing a task and of measures to

minimize the danger to themselves or other people.

By carefully planning your site, you can maximize the performance of your existing network and ensure

that it is ready to migrate to future networking technologies.

To learn more about safety issues and to ensure safety compliance, see Appendix A.

Service to all equipment should be performed by trained and qualified service personnel only! Before installing or

removing any components of the system, or before carrying out any maintenance procedures, you must read the

safety information provided in Appendix A of this guide.

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

21

Site Preparation

Planning Your Site

To install your equipment successfully, you should plan your site carefully. The site planning process

has three major parts:

● Meeting Site Requirements

● Evaluating and Meeting Cable Requirements

● Meeting Power Requirements

Meeting Site Requirements

Your physical installation site must meet the following requirements for a safe and successful

installation:

● Building and electrical code requirements

● Environmental, safety, and thermal requirements for the equipment you plan to install

● Distribution rack requirements

Evaluating and Meeting Cable Requirements

After examining your physical site and ensuring all environment requirements are met, evaluate and

compare your existing cable plant with the requirements of the Extreme Networks equipment to

determine if you need to install new cables (or cabling).

Meeting Power Requirements

To run your equipment safely, you must meet the specific power requirements for each power supply

unit installed in the system.

Meeting Site Requirements

This section addresses the various requirements to consider when preparing your installation site,

including:

● Operating Environment Requirements

● Rack Specifications and Recommendations

22

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

Meeting Site Requirements

Operating Environment Requirements

Verify that your site meets all environmental and safety requirements.

Virtually all areas of the United States are regulated by building codes and standards. During the early

planning stages of installing or modifying your LAN, it is important that you develop a thorough

understanding of the regulations that pertain to your location and industry.

Building and Electrical Codes

Building and electrical codes vary depending on your location. Comply with all code specifications

when planning your site and installing cable. The following sections are provided as a resource to

obtain additional information.

Information on major building codes is located at the following websites:

● International Code Council (ICC); 5203 Leesburg Pike; Falls Church, Virginia 22041 USA.

http://www.iccsafe.org

http://www.sbcci.org

Five authorities on electrical codes are:

● National Electrical Code (NEC) Classification (USA only)—a recognized authority on safe electrical

wiring. Federal, state, and local governments use NEC standards to establish their own laws,

ordinances, and codes on wiring specifications. The NEC classification is published by the National

Fire Protection Association (NFPA). The address is NFPA; 1 Batterymarch Park; Quincy,

Massachusetts 02169 USA.

● Underwriters’ Laboratory (UL) (USA only)—an independent research and testing laboratory. UL

http://www.nfpa.org

evaluates the performance and capability of electrical wiring and equipment to determine whether

they meet certain safety standards when properly used. Acceptance is usually indicated by the

words “UL Approved” or “UL Listed.” The address is UL; 333 Pfingsten Road; Northbrook, Illinois

60062-2096 USA.

● National Electrical Manufacturing Association (NEMA) (USA only)—an organization of electrical

http://www.ul.com

product manufacturers. Members develop consensus standards for cables, wiring, and electrical

components. The address is NEMA; 1300 N. 17th Street; Rosslyn, Virginia 22209.

● Electronics Industries Alliance (EIA)—a trade association that develops technical standards,

http://www.nema.org

disseminates marketing data, and maintains contact with government agencies in matters relating to

the electronics industry. The address is EIA; 2500 Wilson Boulevard; Arlington, Virginia 22201 USA.

http://www.eia.org

● Federal Communications Commission (FCC)—a commission that regulates all interstate and foreign

electrical communication systems that originate in the United States according to the

Communications Act of 1934. The FCC regulates all U.S. telephone and cable systems. The address is

FCC; 445 12th Street S.W.; Washington, D.C. 20554 USA.

http://www.fcc.gov

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

23

NOTE

NOTE

Site Preparation

Wiring Closet Considerations

Be aware of the following recommendations for your wiring closet:

● Be sure that your system is easily accessible for installation and service. See “Rack Specifications and

Recommendations” on page 27 for information.

● Use appropriate AC power, power distribution, and grounding for your specific installation.

● Use a vinyl floor covering in your wiring closet. (Concrete floors accumulate dust, and carpets can

cause static electricity.)

● Prevent unauthorized access to wiring closets by providing door locks. Install the equipment in a

secured, enclosed, and restricted access location, ensuring that only qualified service personnel have

access to the equipment.

● Provide adequate overhead lighting for easy maintenance.

● Be sure that each wiring closet has a suitable ground. All distribution racks and equipment installed

in the closet should be grounded.

● Be sure that all system environmental requirements are met, such as ambient temperature and

humidity.

Extreme Networks recommends that you consult an electrical contractor for commercial building and wiring

specifications.

Temperature

Extreme Networks equipment generates a significant amount of heat. It is essential that you provide a

temperature-controlled environment for both performance and safety.

Install the equipment only in a temperature- and humidity-controlled indoor area that is free of airborne

materials that can conduct electricity. Too much humidity can cause a fire. Too little humidity can

produce electrical shock and fire.

Follow these general thermal recommendations for your wiring closet:

● Be sure that the ventilation in the wiring closet is adequate to maintain a temperature below 104° F

(40° C).

● Install a reliable air conditioning and ventilation system.

● Keep the ventilation in the wiring closet running during non-business hours; otherwise, the

equipment can overheat.

● Maintain ambient operating temperature: 32° to 104° F (0° to 40° C).

● Maintain storage temperature: -40° to 158° F (-40° to 70° C).

Like all electrical equipment, product lifetimes degrade with increased temperature. If possible, temperatures should

be kept at approximately 78° F (25° C) or lower.

24

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

NOTE

Meeting Site Requirements

BlackDiamond Family Chassis Spacing Requirements

Extreme Networks recommends placing no more than three chassis next to each other due to chassis-tochassis heating. The following are some general recommendations for installing your BlackDiamond

10808 switch, BlackDiamond 8800 series of switches, or your BlackDiamond 12804 switch:

● A minimum of one empty 19-inch rack between each set of three adjacent BlackDiamond switches.

or

● Place patch panels between each set of three adjacent BlackDiamond switches. A patch panel does

not require any power and does not generate any heat.

Up to five adjacent switches will continue to function without safety concerns. However, product lifetime may

degrade with continued exposure to high temperatures in close proximity and long term reliability may be

compromised.

Summit Family of Switches Spacing Requirements

Be sure that cables and other equipment do not block the air intake or outflow on an Extreme Networks

Summit family switch. It is best to have at least 3 inches (8 cm) of clear space in front of the air intake

and outflow vents on the sides of the switch; airflow moves from side to side. For proper airflow

through a Summit family switch, leave clear space on the left and right sides of the switch.

Depending on other conditions in the equipment room, it may be possible to install the switches closer

to each other; consult your Extreme Networks Customer Support representative for guidance.

BlackDiamond Family Chassis Airflow Requirements

To ensure proper airflow through a BlackDiamond switch, refer to the following recommendations

when you are installing your switch:

● BlackDiamond 10808 switches require a minimum of 3 inches (8 cm) around both the front and rear

of the chassis from any cabinet wall or other obstruction for proper airflow.

● BlackDiamond 8800 and 12804 switches require a minimum of 1.5 inches (4 cm) around both the left

and right sides of the chassis from any cabinet wall or other obstruction for proper airflow.

● Air temperature measured approximately 1 inch (2.5 cm) from the fan inlet should be less than

104 °F (40 °C).

The airflow of the BlackDiamond 10808 switch, BlackDiamond 8800 series of switches, and

BlackDiamond 12804 switch moves through the power supplies and is independent of the airflow

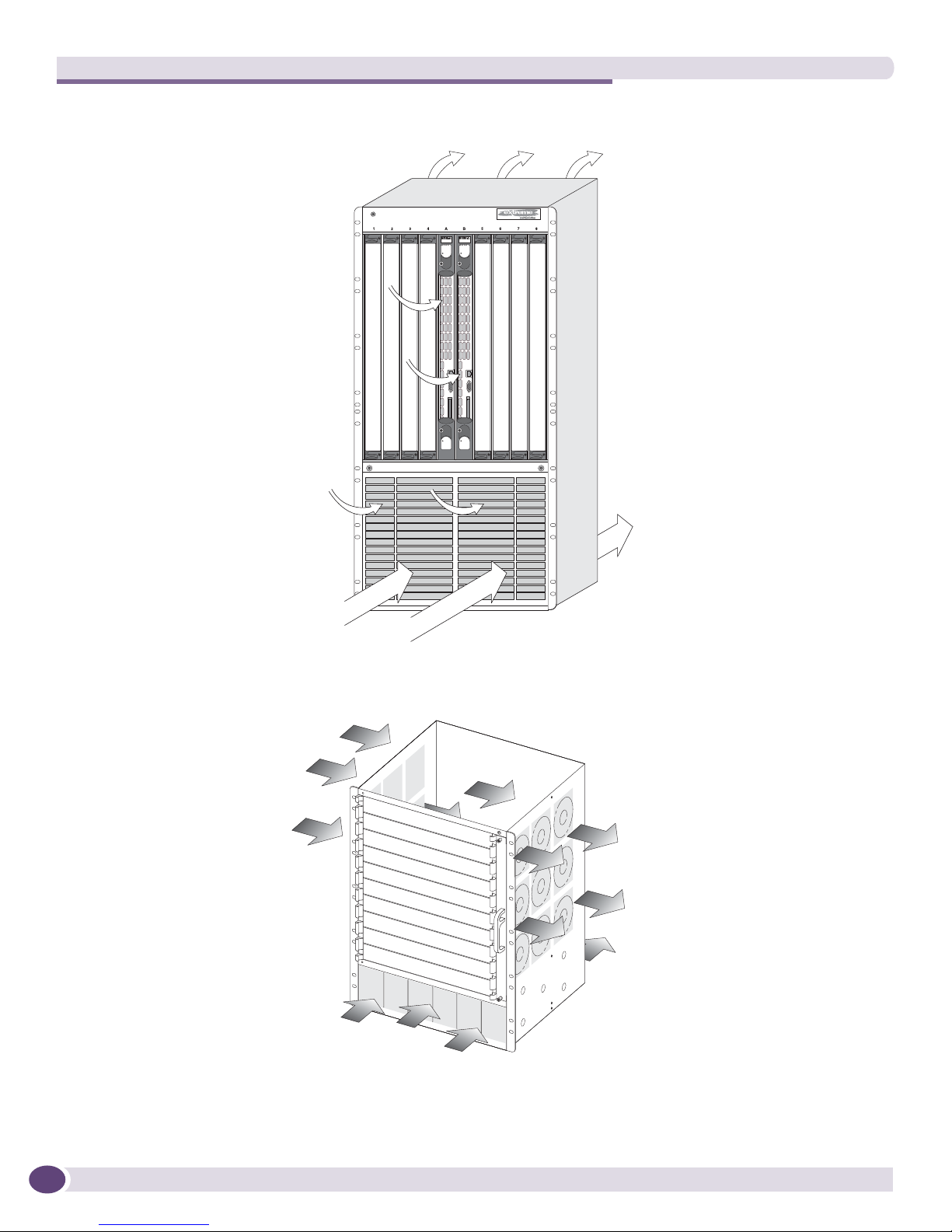

through the modules as shown in Figure 1 and Figure 2.

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

25

Site Preparation

Figure 1: Airflow through the BlackDiamond 10808 system chassis

Airflow

through

chassis

Airflow through

power supplies

Figure 2: Airflow through the BlackDiamond 8810 chassis

Airflow at power

supply level

EX_010

Airflow through

fan tray

ASP045

26

Extreme Networks Consolidated ExtremeXOS Hardware Installation Guide

ESD strap

ESD ground

connection

EX_013

Meeting Site Requirements

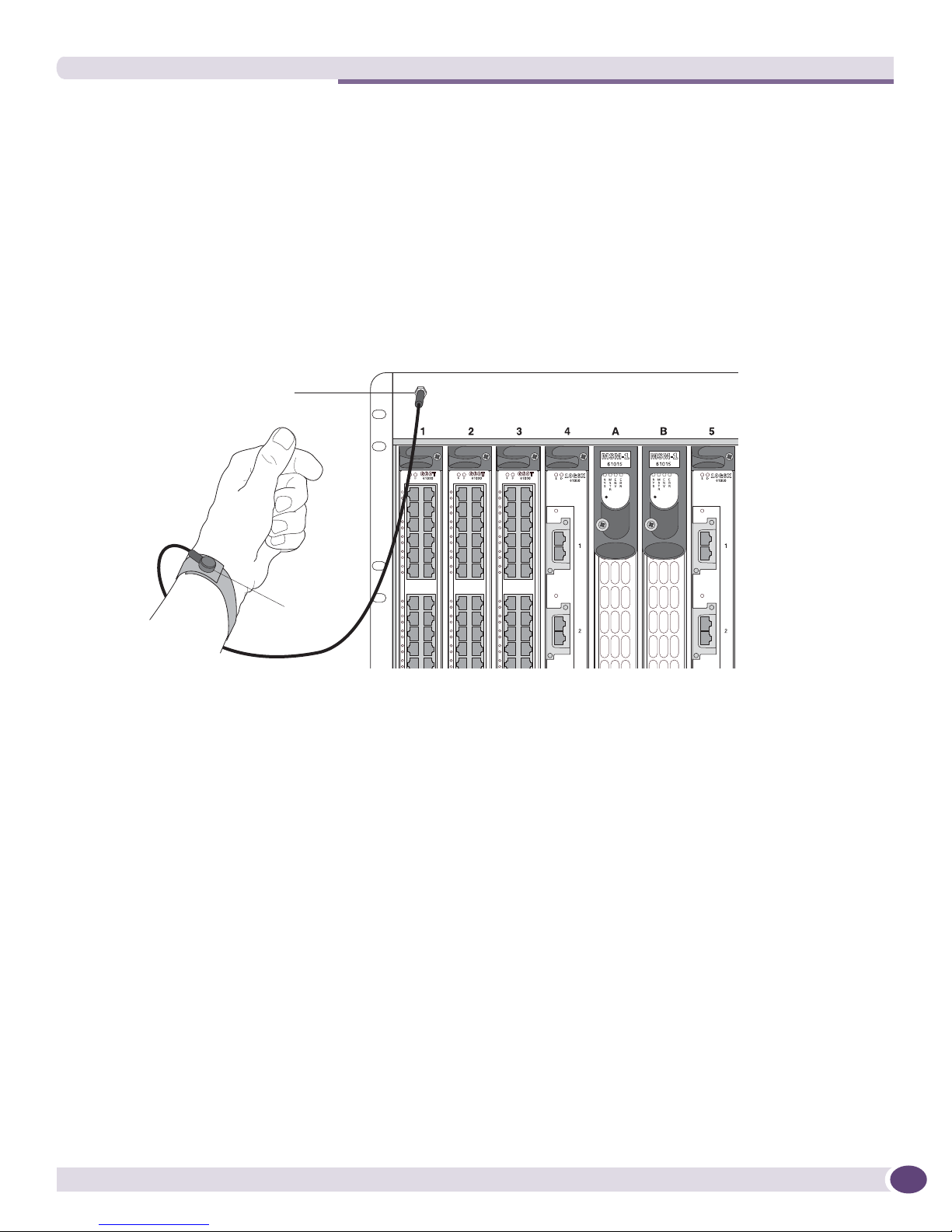

Electrostatic Discharge

Your system must be protected from static electricity or electrostatic discharge (ESD). Take the following

measures to ensure optimum system performance:

● Remove materials that can cause electrostatic generation (such as synthetic resins) from the wiring

closet. Check the appropriateness of floor mats and flooring.

● Connect metal chassis, conduit, and other metals to ground using dedicated grounding lines.