Extreme Networks E4G-200, E4G-200-12x, E4G-400 Installation Manual

E4G Routers Hardware

Installation Guide

121150-00

Published April 2016

Copyright © 2016 Extreme Networks All rights reserved.

Legal Notice

Extreme Networks, Inc. reserves the right to make changes in specifications and other information

contained in this document and its website without prior notice. The reader should in all cases

consult representatives of Extreme Networks to determine whether any such changes have been

made.

The hardware, firmware, software or any specifications described or referred to in this document

are subject to change without notice.

Trademarks

Extreme Networks and the Extreme Networks logo are trademarks or registered trademarks of

Extreme Networks, Inc. in the United States and/or other countries.

All other names (including any product names) mentioned in this document are the property of

their respective owners and may be trademarks or registered trademarks of their respective

companies/owners.

For additional information on Extreme Networks trademarks, please see:

www.extremenetworks.com/company/legal/trademarks/

Support

For product support, including documentation, visit: www.extremenetworks.com/documentation/

For information, contact:

Extreme Networks, Inc.

145 Rio Robles

San Jose, California 95134

USA

Table of Contents

Preface......................................................................................................................................... 5

Audience....................................................................................................................................................................................5

Conventions.............................................................................................................................................................................5

Getting Help............................................................................................................................................................................ 6

Providing Feedback to Us.................................................................................................................................................7

Related Publications............................................................................................................................................................ 7

Chapter 1: Extreme Networks E4G Series Routers................................................................9

E4G-200 Cell Site Routers..............................................................................................................................................10

E4G-400 Cell Site Aggregation Router................................................................................................................... 14

Pluggable Interfaces for E4G Series Routers.........................................................................................................21

Stacking Options for E4G Series Routers.............................................................................................................. 22

Chapter 2: Site Preparation.................................................................................................... 23

Planning Your Site..............................................................................................................................................................23

Meeting Site Requirements........................................................................................................................................... 24

Evaluating and Meeting Cable Requirements...................................................................................................... 29

Meeting Power Requirements......................................................................................................................................34

Following Applicable Industry Standards.............................................................................................................. 36

Chapter 3: Installing an E4G Series Router..........................................................................38

Pre-installation Requirements...................................................................................................................................... 38

Installing an E4G-200 Cell Site Router....................................................................................................................38

Installing an E4G-400 Cell Site Aggregation Router....................................................................................... 46

First-Time Startup..............................................................................................................................................................63

Chapter 4: Maintaining Your Equipment..............................................................................64

Replacing an AC Power Supply.................................................................................................................................. 64

Replacing a DC Power Supply.....................................................................................................................................66

Replacing a Fan Module...................................................................................................................................................71

Replacing Optional Ports................................................................................................................................................72

Replacing a Clock Module..............................................................................................................................................73

Replacing a T1/E1 Module...............................................................................................................................................74

Removing an E4G-200 Router from an Equipment Rack..............................................................................75

Removing an E4G-400 Router from an Equipment Rack............................................................................. 76

Appendix A: Safety Information............................................................................................78

Safety Considerations Before Installing...................................................................................................................79

General Safety Precautions...........................................................................................................................................79

Maintenance Safety...........................................................................................................................................................80

Cable Routing for LAN Systems.................................................................................................................................80

Installing Power Supply Units and Connecting Power......................................................................................81

Selecting Power Supply Cords.................................................................................................................................... 82

Battery Replacement and Disposal...........................................................................................................................83

Fiber Optic Ports and Optical Safety.......................................................................................................................83

Safety Information for the E4G Series Routers...................................................................................................84

Sicherheitshinweise...........................................................................................................................................................84

Überlegungen vor der Installation............................................................................................................................. 84

Allgemeine Sicherheitshinweise..................................................................................................................................85

E4G Routers Hardware Installation Guide 3

Table of Contents

Sicherheit bei Wartungsarbeiten................................................................................................................................86

Kabelverlegung für LAN-Systeme............................................................................................................................. 86

Installation der Netzteile und Netzanschluss........................................................................................................87

Auswahl der Netzkabel....................................................................................................................................................89

Wechseln und Entsorgen der Batterie.....................................................................................................................89

LWL-Ports und optische Sicherheit.......................................................................................................................... 89

Sicherheitsinformationen für Router der Serie E4G.........................................................................................90

Appendix B: Technical Specifications................................................................................... 91

E4G-200 Cell Site Router Technical Specifications............................................................................................91

E4G-400 Cell Site Aggregation Router Technical Specifications.............................................................. 96

Power Supplies for the E4G-400 Router..............................................................................................................103

E4G-200 Connector Pinouts...................................................................................................................................... 106

E4G-400 Connector Pinouts......................................................................................................................................109

Conformity Statements...................................................................................................................................................112

Index..........................................................................................................................................116

E4G Routers Hardware Installation Guide 4

Preface

Audience

This guide is intended for network administrators and equipment installers who are responsible for

installing and setting up network equipment.

This guide assumes a basic working knowledge of:

Standard equipment installation procedures, including remote location and electrical safety

•

practices

Local area networks (LANs)

•

Ethernet concepts

•

Ethernet switching and bridging concepts

•

Routing concepts

•

Time division multiplexing (TDM)

•

Simple Network Management Protocol (SNMP)

•

See the ExtremeXOS User Guide and the ExtremeXOS Command Reference Guide for information about

configuring Extreme Networks E4G series routers.

Note

If the information in an installation note or release note shipped with your Extreme Networks

equipment diers from the information in this guide, follow the installation or release note.

Conventions

This section discusses the conventions used in this guide.

Text Conventions

The following tables list text conventions that are used throughout this guide.

Table 1: Notice Icons

Icon Notice Type Alerts you to...

General Notice Helpful tips and notices for using the product.

Note Important features or instructions.

Caution Risk of personal injury, system damage, or loss of data.

E4G Routers Hardware Installation Guide 5

Table 1: Notice Icons (continued)

Icon Notice Type Alerts you to...

Warning Risk of severe personal injury.

New This command or section is new for this release.

Table 2: Text Conventions

Convention Description

Preface

Screen displays

The words enter and

type

[Key] names Key names are written with brackets, such as [Return] or [Esc]. If you must press two

Words in italicized type Italics emphasize a point or denote new terms at the place where they are defined in

This typeface indicates command syntax, or represents information as it appears on the

screen.

When you see the word “enter” in this guide, you must type something, and then press

the Return or Enter key. Do not press the Return or Enter key when an instruction

simply says “type.”

or more keys simultaneously, the key names are linked with a plus sign (+). Example:

Press [Ctrl]+[Alt]+[Del]

the text. Italics are also used when referring to publication titles.

Platform-Dependent Conventions

Unless otherwise noted, all information applies to all platforms supported by ExtremeXOS software,

which are the following:

ExtremeSwitching® switches

•

Summit® switches

•

SummitStack

•

When a feature or feature implementation applies to

the heading for the section describing that implementation in the ExtremeXOS Command Reference

Guide. In many cases, although the command is available on all platforms, each platform uses specific

keywords. These keywords specific to each platform are shown in the Syntax Description and discussed

in the Usage Guidelines.

™

specific platforms, the specific platform is noted in

Terminology

When features, functionality, or operation is specific to a switch family, such as ExtremeSwitching or

Summit, the family name is used. Explanations about features and operations that are the same across

all product families simply refer to the product as the switch.

Getting Help

If you require assistance, you can contact Extreme Networks using one of the following methods:

E4G Routers Hardware Installation Guide 6

Global Technical Assistance Center (GTAC) for Immediate Support

•

Phone: 1-800-872-8440 (toll-free in U.S. and Canada) or 1-603-952-5000. For the Extreme

•

Networks support phone number in your country, visit: www.extremenetworks.com/support/

contact

Email: support@extremenetworks.com. To expedite your message, enter the product name or

•

model number in the subject line.

GTAC Knowledge — Get on-demand and tested resolutions from the GTAC Knowledgebase, or

•

create a help case if you need more guidance.

The Hub — A forum for Extreme customers to connect with one another, get questions answered,

•

share ideas and feedback, and get problems solved. This community is monitored by Extreme

Networks employees, but is not intended to replace specific guidance from GTAC.

Support Portal — Manage cases, downloads, service contracts, product licensing, and training and

•

certifications.

Before contacting Extreme Networks for technical support, have the following information ready:

Your Extreme Networks service contract number and/or serial numbers for all involved Extreme

•

Network products

A description of the failure

•

A description of any action(s) already taken to resolve the problem

•

A description of your network environment (such as layout, cable type, other relevant environmental

•

information)

Network load at the time of trouble (if known)

•

The device history (for example, if you have returned the device before, or if this is a recurring

•

problem)

Any related Return Material Authorization (RMA) numbers

•

Preface

Providing Feedback to Us

We are always striving to improve our documentation and help you work better, so we want to hear

from you! We welcome all feedback but especially want to know about:

Content errors or confusing or conflicting information.

•

Ideas for improvements to our documentation so you can find the information you need faster.

•

Broken links or usability issues.

•

If you would like to provide feedback to the Extreme Networks Information Development team about

this document, please contact us using our short online feedback form. You can also email us directly at

internalinfodev@extremenetworks.com.

Related Publications

Hardware Documentation

ExtremeSwitching X8 Series Switches Hardware Installation Guide

•

Summit Family Switches Hardware Installation Guide for Switches Using ExtremeXOS 21.1

•

Summit Family Switches Hardware Installation Guide for Switches Using ExtremeXOS 16 and Earlier

•

E4G Routers Hardware Installation Guide 7

E4G Series Routers Hardware Installation Guide

•

Extreme Hardware/Software Compatibility and Recommendation Matrices

•

Extreme Networks Pluggable Transceivers Installation Guide

•

Preface

E4G Routers Hardware Installation Guide 8

1 Extreme Networks E4G Series

Routers

E4G-200 Cell Site Routers

E4G-400 Cell Site Aggregation Router

Pluggable Interfaces for E4G Series Routers

Stacking Options for E4G Series Routers

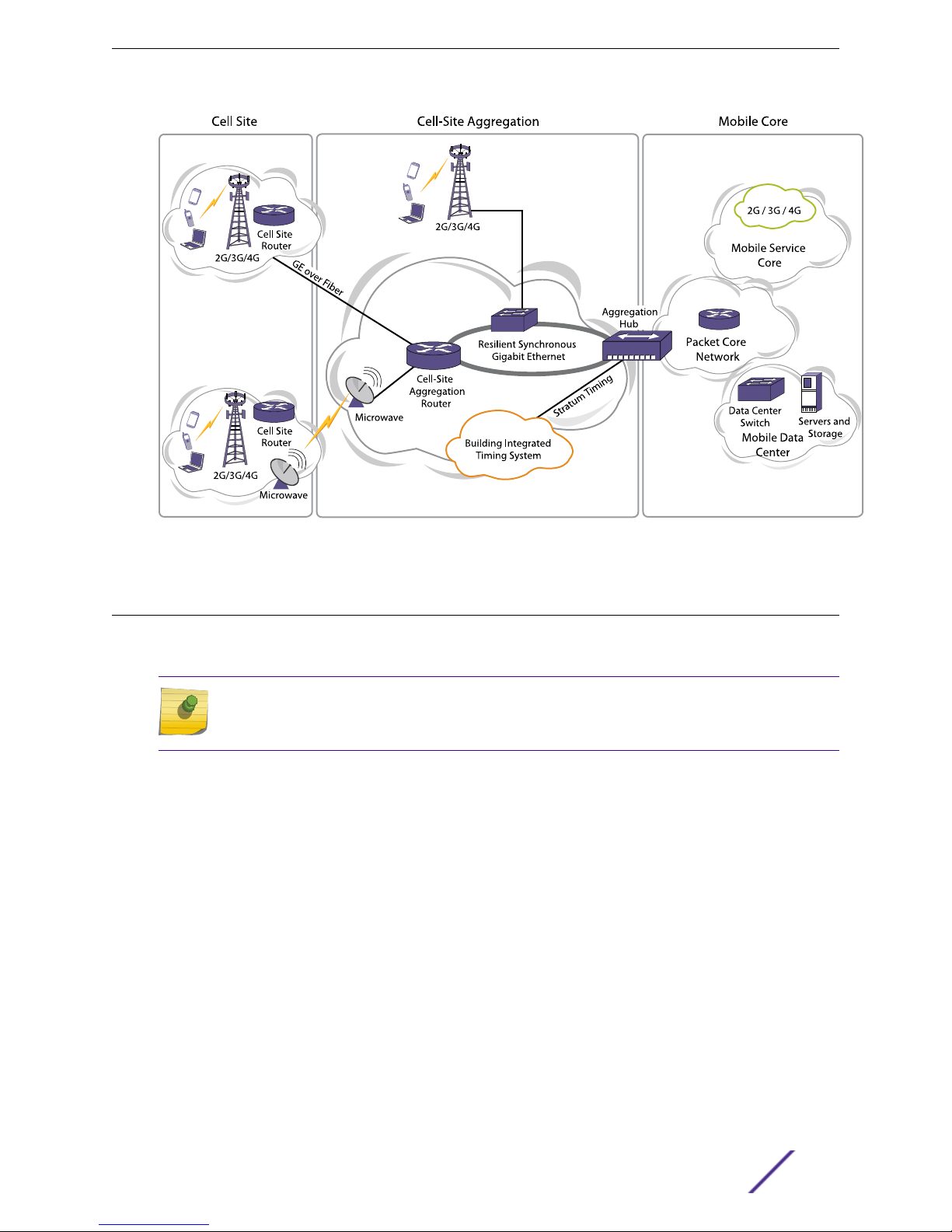

The Extreme Networks E4G router family consists of the E4G-200 cell site routers (models E4G-200

and E4G-200-12x) and the E4G-400 cell site aggregation router.

These routers provide high-bandwidth capacity, highly accurate and

Administration and Maintenance (OAM) capabilities that support service level agreement (SLA) metrics.

They support time-division multiplexing pseudowire end-to-end emulation (TDM PWE3). PWE allows

the simultaneous support of multiple generations of services (2G, 3G, and 4G) over the same Ethernet

backhaul network without having to remove legacy T1/E1 equipment and incur associated costs.

Note

Unless otherwise noted, the term E4G-200 refers in this document to both models in the

E4G-200 series: the E4G-200 and the E4G-200-12x.

The E4G-200 cell site router collects trac from cell site towers for hando to the mobile backhaul

network. The E4G-200 router connects to the E4G-400 cell site aggregation router, which aggregates

T1, E1, and Ethernet trac for hando to the mobile core.

flexible timing, and Operations

E4G Routers Hardware Installation Guide 9

Extreme Networks E4G Series Routers

Figure 1: Mobile Backhaul Architecture

E4G-200 Cell Site Routers

The Extreme Networks E4G-200 routers provide 12 resilient synchronous Gigabit Ethernet ports and 16

T1/E1 ports in a compact (1RU or 1.75 inches high) unit.

Note

Unless otherwise noted, the term E4G-200 refers in this document to both models in the

E4G-200 series: the E4G-200 and the E4G-200-12x.

The Ethernet ports support both IEEE 1588v2 and Synchronous Ethernet (SyncE) timing, and the T1/E1

ports support time division multiplexing (TDM) timing. The router provides high-performance

pseudowire capability, supporting both CESoPSN (channelized) and SAToP (unframed and

unchannelized) TDM services. Deployed at the cell site, the E4G-200 cell site router collects trac from

2G, 3G, and 4G radio towers for hando to the mobile backhaul over fiber or microwave.

The E4G-200 extended temperature range of -40°C to +65°C allows service providers to deploy the

E4G-200 router at sites without climate control.

Features:

Management and console ports

•

Eight 10/100/1000BASE-T (RJ-45) dedicated ports

•

Four 100/1000BASE-X (SFP) ports

•

These ports require Extreme Networks optical modules that are designed for use within the

temperature range of the router.

Slot for clock module

•

E4G Routers Hardware Installation Guide 10

Extreme Networks E4G Series Routers

Slot for T1/E1 module with 16 ports

•

Grounding lug

•

Redundant DC input power connectors

•

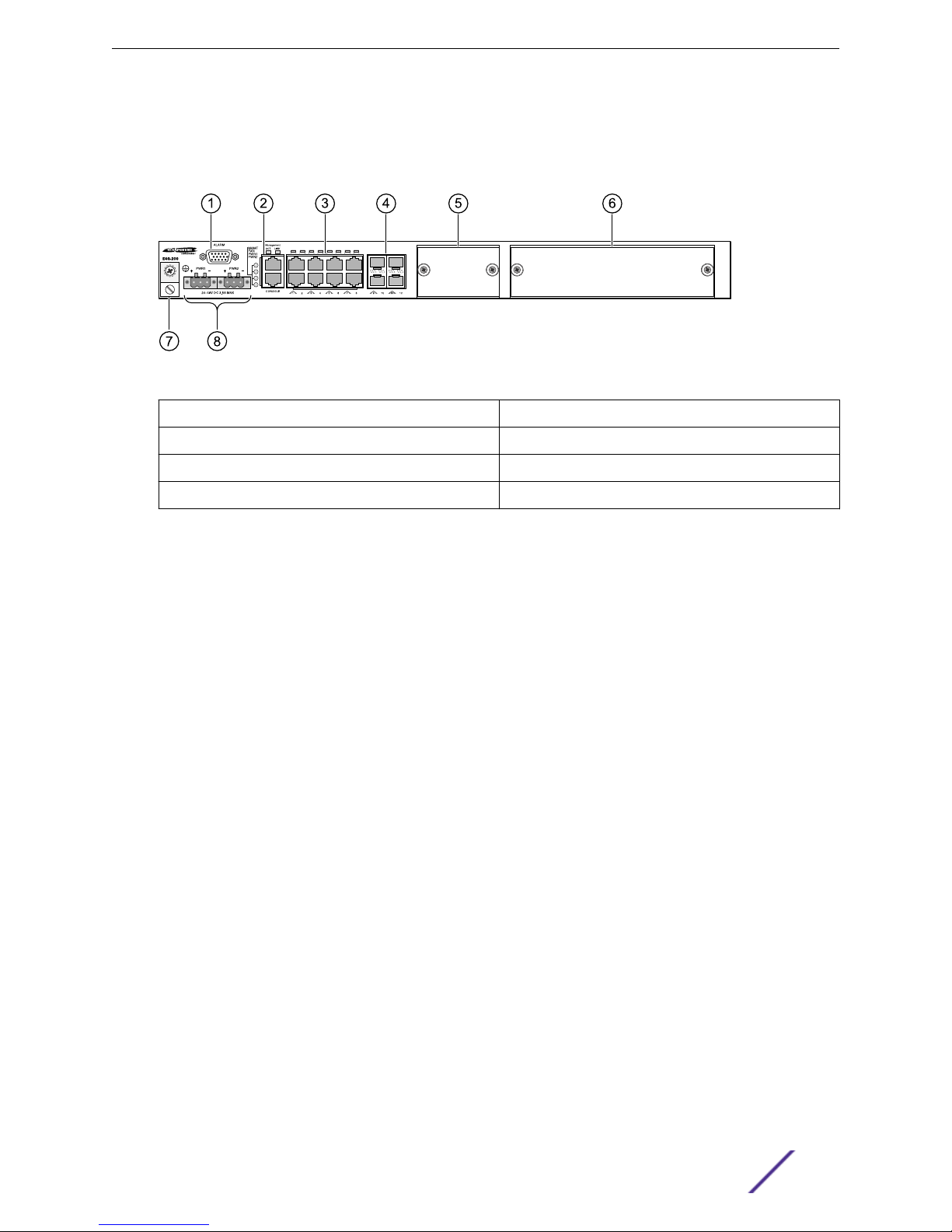

Figure 2: E4G-200 Cell Site Router Front Panel

1 = Alarms connection (inactive) 5 = Slot for E4G-200 CLK module

2 = Management and console ports 6 = Slot for F16T1E1 module

3 = RJ-45 dedicated ports 7 = Grounding lug

4 = SFP ports 8 = DC input power connectors

The E4G-200 router has an integrated DC power supply with dual feeds on the front panel. Power feed

A can be connected to one power source and power feed B can be connected to a dierent power

source to provide protection should either source of power fail. The power supply is not field-

replaceable.

The back panel of the E4G-200 router provides an alternate attachment point for the grounding lug.

Status LEDs on the E4G-200 router are described in Table 3: System LEDs on page 13.

E4G-200 Power Supply

The E4G-200 router has an integrated DC power supply with dual feeds on the front panel. Power feed

A can be connected to one power source and power feed B can be connected to a dierent power

source to provide protection should either source of power fail. The power supply is not field-

replaceable.

The back panel of the E4G-200 router provides an alternate attachment point for the grounding lug.

E4G-200 Clock (CLK) Module

An optional clock module for the E4G-200 router provides timing. Timing is based on either:

ITU-T Synchronous Ethernet (SyncE) protocol

•

Precision Time Protocol based on the IEEE specification 1588v2

•

The clock module has four mini-BNC connectors providing Sync In/Sync Out timing interfaces and an

RJ-45 connector that provides an RS-422 BITS-IN interface. Clock modules can be installed or removed

without powering down the router, although a system reboot is required to initialize the module.

E4G Routers Hardware Installation Guide 11

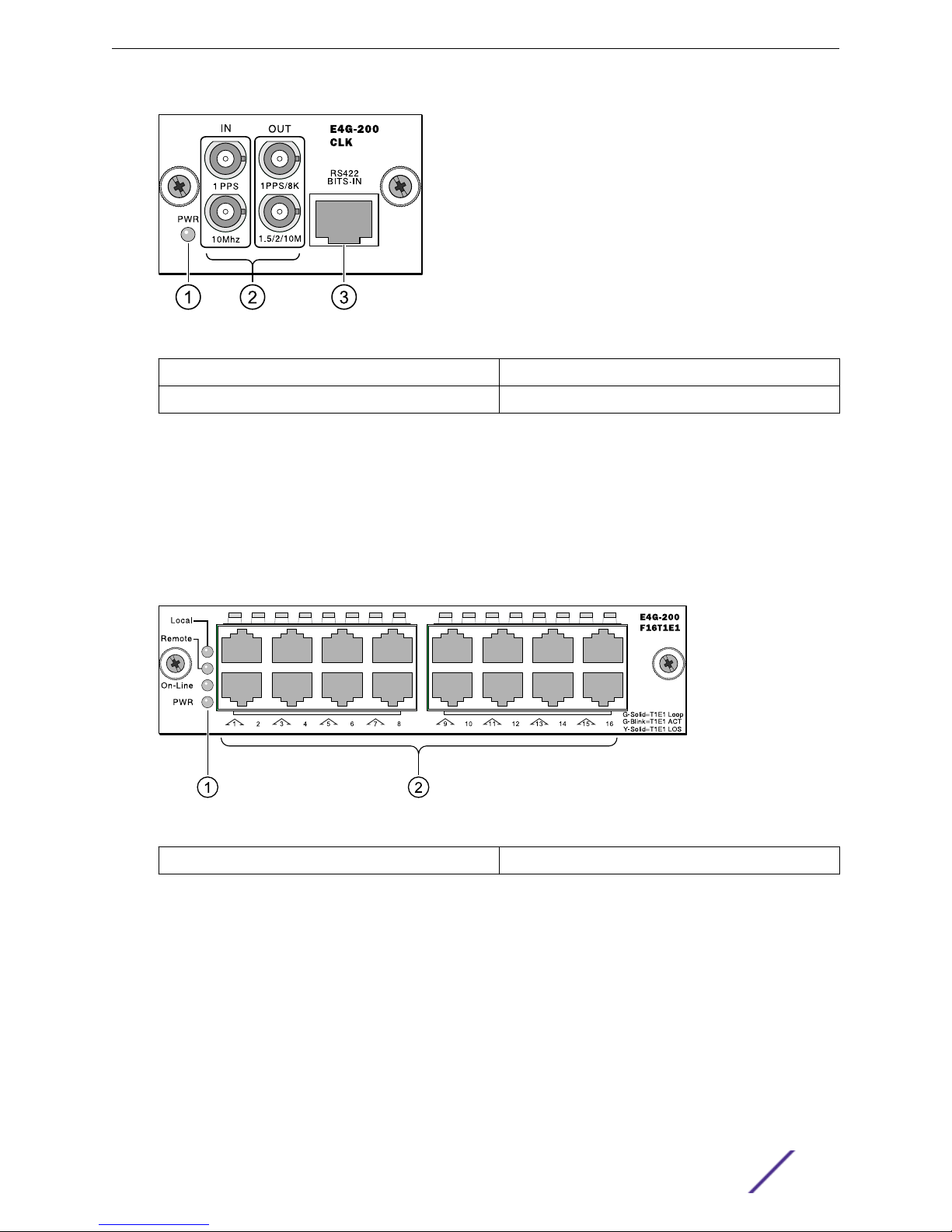

Figure 3: E4G-200 Clock Module

1 = LED 3 = BITS IN interface

2 = Sync In/Sync Out interfaces

E4G-200 F16T1E1 Module

Extreme Networks E4G Series Routers

The F16T1E1 module for the E4G-200 router provides 16 T1/E1 ports implemented as RJ-45 connectors.

These ports support circuit emulations over industry-standard pseudowires, allowing the transformation

of TDM cell sites to Ethernet/IP/MPLS cell sites. T1/E1 modules can be installed or removed without

powering down the router, although a system reboot is required to initialize the module.

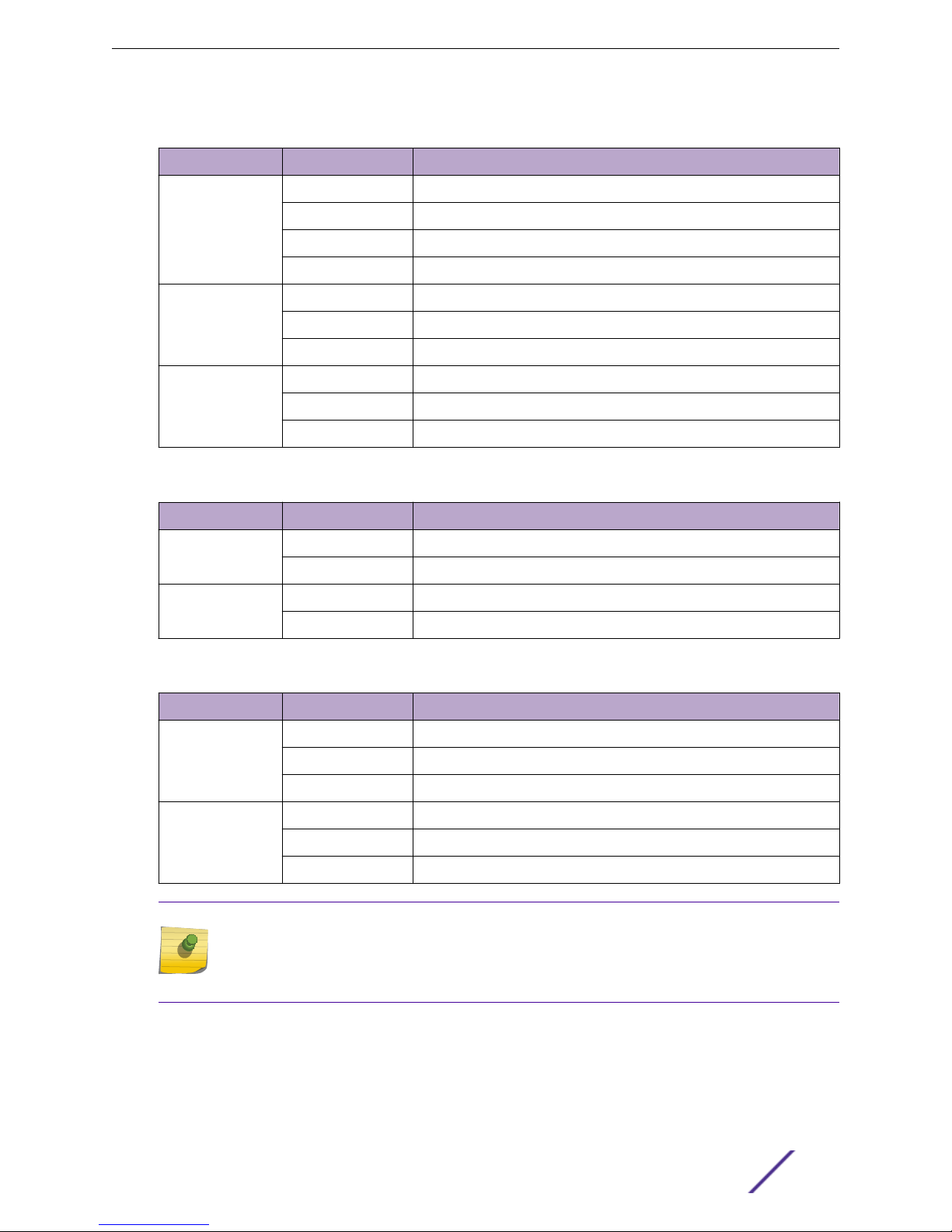

Figure 4: E4G-200 F16T1E1 Module

1 = LEDs

2 = T1/E1 ports

E4G-200 LEDs

The following tables describe the LEDs on the E4G-200 cell site router (models E4G-200 and

E4G-200-12x).

E4G Routers Hardware Installation Guide 12

Extreme Networks E4G Series Routers

Table 3: System LEDs

Label/type Color/State Meaning

MGMT Steady green Power-on self- test (POST) passed, normal operation

Blinking green POST in progress

Amber POST failed or system has overheated

O No power

FAN Steady green Normal operation

Blinking amber Failure

O No power

PSU-1, PSU-2 Steady green Normal operation

Blinking amber Power failure

O No power attached to this connector

Table 4: MGMT Port LEDs

Label/type Color/State Meaning

ACT Blinking green Packet transmitting or receiving

O No packet transmitting or receiving

LINK Blinking green Link up

O No link or port disabled

Table 5: Port LEDs

Label/type Color/State Meaning

Ports 1 – 8

(see note)

Ports 9 – 12

(see note)

Steady green Link exists

Blinking green Activity occurring

O No link or port is disabled

Steady green Link exists

Blinking green Activity occurring

O No link or port is disabled

Note

On model E4G-200 routers, LEDs for ports 1 – 8 are located above the ports and LEDs for

ports 9 – 12 are located on SFP cages.

On model E4G-200-12x routers, LEDs for ports 1 – 12 are located on SFP cages.

E4G Routers Hardware Installation Guide 13

Table 6: Clock Module LED

Label/type Color/State Meaning

PWR Steady green 3.3 V power OK

O No power

Table 7: F16T1E1 Module LEDs

Label/type Color/State Meaning

Extreme Networks E4G Series Routers

Local

(Alarm LED)

Remote

(Alarm LED)

On-Line Steady green On line

PWR Steady green Normal operation

Port LEDs (1 – 16) Steady green Link OK

Steady green Local alarm active

Blinking green Local alarm active but silenced

O No local alarm active

Steady green Remote alarm active

Blinking green Remote alarm active but silenced

O No remote alarm active

O O line

O No power

Blinking green Activity

O No link, or port is disabled

E4G-400 Cell Site Aggregation Router

The E4G-400 cell site aggregation router is a compact unit (1RU or 1.75 inches high) that enables

networks to aggregate multiple Ethernet links from various cell sites and route the trac to the mobile

core.

The E4G-400 router provides 28 Gigabit Ethernet ports and port options for up to six 10-Gigabit

Ethernet ports, as well as a 16-port T1/E1 module with pseudowire capability. The T1/E1 module is used

where 2G and 3G radios are co-located at the aggregation site, and eliminates the need for separate cell

site routers.

The Gigabit and 10-Gigabit Ethernet ports on the E4G-400 router support Synchronous Ethernet

(SyncE) and IEEE 1588v2 timing. Integrated timing connectors on the front panel provide timing based

on either the ITU-T Synchronous Ethernet (SyncE) protocol or the Precision Time Protocol based on

IEEE specification 1588v2. Four mini-BNC connectors providing Sync In/Sync Out timing interfaces and

an RJ-422 connector provides a BITS-IN interface.

The E4G-400 router has 4 shared ports. For each pair of shared ports, either the 10/100/1000BASE-T

port (RJ45) or 100/1000BASE-X (SFP) port can be used as needed.

E4G Routers Hardware Installation Guide 14

Extreme Networks E4G Series Routers

The E4G-400 router supports stacking using ports on installed port option cards at the back of the unit.

Up to eight units can be connected into a single management entity that has up to 192 Gigabit Ethernet

ports and up to 32 10-Gigabit Ethernet ports.

At the back of the unit are two bays for either AC or DC power supplies. One 300 W AC or DC power

supply is included with the base unit. A redundant power supply must be ordered separately. You can

mix any combination of 300 W AC and DC power supplies based on the need at the particular site. For

example, you can have a DC main power feed and an AC input backup from an uninterruptible power

supply (UPS).

The front panel of the E4G-400 router has the following features:

Twenty 10/100/1000BASE-T (RJ-45) dedicated ports

•

Four 100/1000BASE-X (SFP) or 10/100/1000BASE-T (RJ-45) shared ports

•

Four 100/1000BASE-X (SFP) dedicated ports

•

Timing interfaces

•

BITS-IN interface

•

Console port

•

Stack number indicator

•

Management and USB ports

•

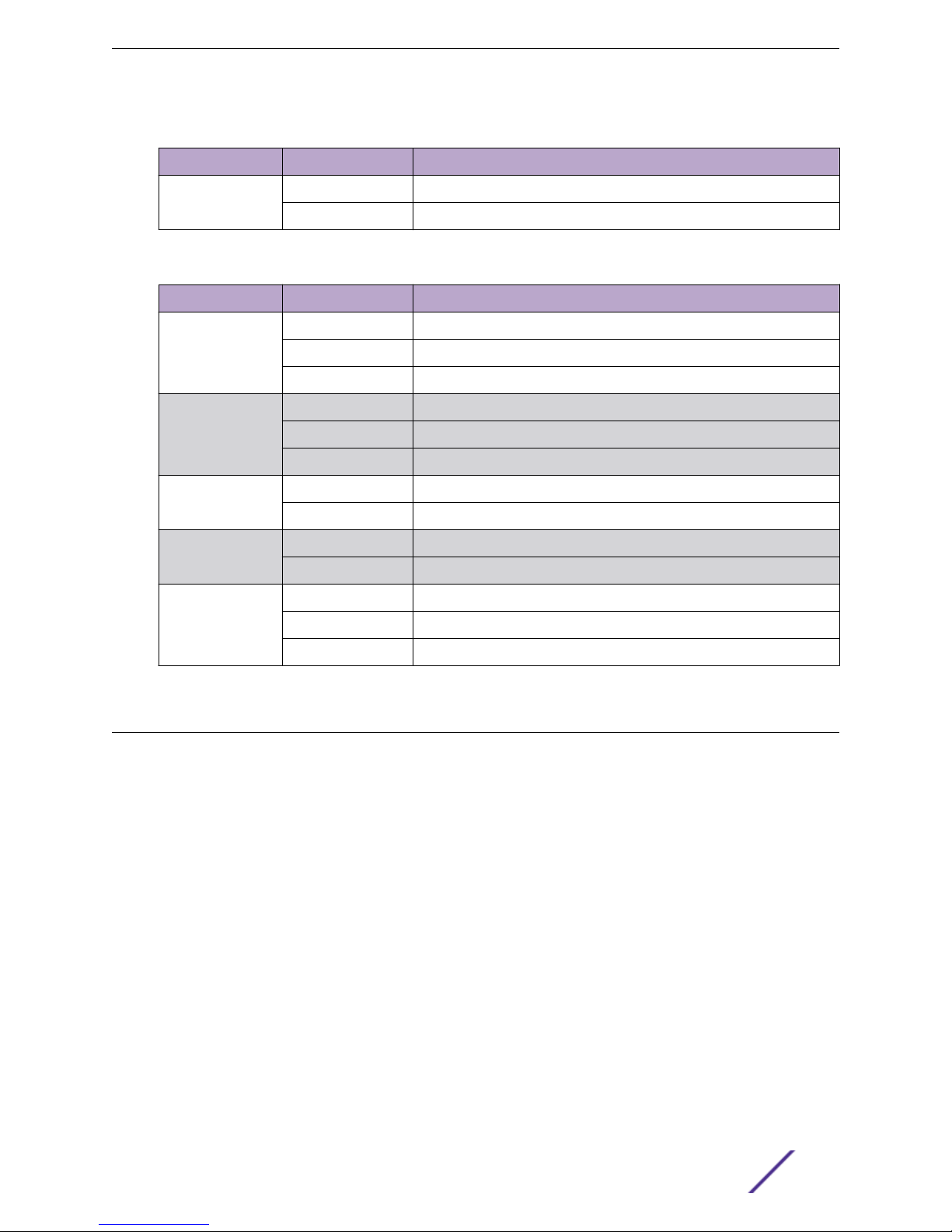

Figure 5: E4G-400 Front Panel

1 = RJ-45 ports

2 = SFP ports 6 = Management and USB ports

3 = Timing connections (Mini-BNC connectors) 7 = Shared ports

4 = BITS IN connector (RJ-45 connector) 8 = Console port

The rear panel of the E4G-400 router (Figure 6: E4G-400 Back Panel on page 16) has the following

features:

Slot A for one of the following optional cards:

•

XGM3S-2xf option card (2 XFP with Sync-E for stacking or data links)

•

XGM3S-2sf option card (2 SFP+ with Sync-E for stacking or data links)

•

Slot B for one of the following optional cards:

•

XGM3SB-4sf option card (4 SFP+ with Sync-E for data links)

•

E4G-B16T1E1 module (2 MRJ21 with 8 TDM ports per MRJ21 connector)

•

Cards in Slot A and Slot B are hot-pluggable.

5 = Stack number indicator

E4G Routers Hardware Installation Guide 15

Extreme Networks E4G Series Routers

Hot-swappable fan tray

•

Two bays for AC or DC power supplies

•

To provide redundant power to the router, you can install two AC power supplies, two DC power

supplies, or a combination of an AC and DC power supply.

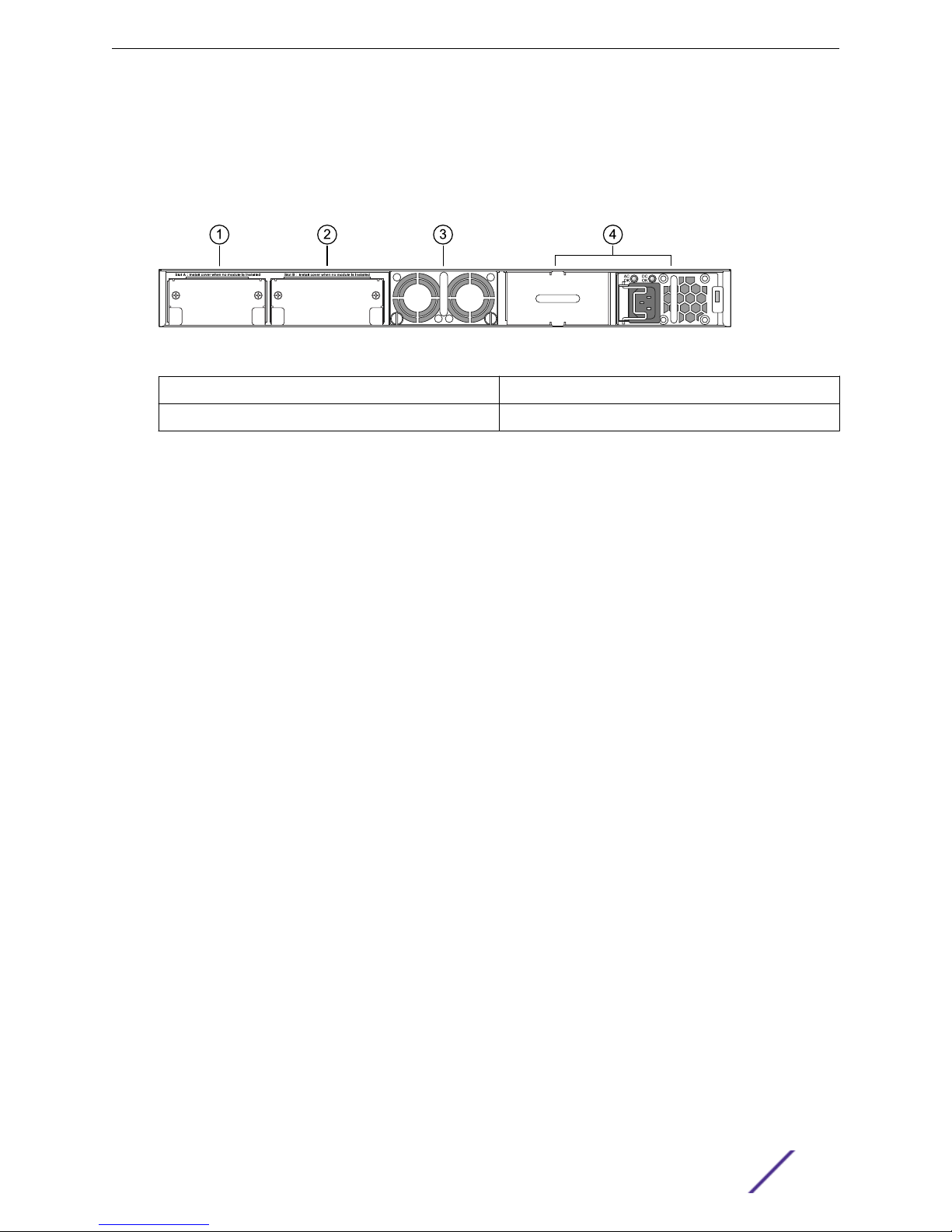

Figure 6: E4G-400 Back Panel

1 = Slot A 3 = Fan tray

2 = Slot B 4 = Power supply bays

E4G-400 Combination Ports

The E4G-400 cell site aggregation router provides four uplink ports implemented as combination ports

that pair a copper port using RJ-45 connectors with an optical port using LC connectors.

The copper port operates as an autonegotiating 10/100/1000BASE-T port. The optical port allows

Gigabit Ethernet uplink connections through Extreme Networks small form factor pluggable (SFP)

interface modules.

The E4G-400 router supports automatic failover from an active fiber port to a copper backup or from

an active copper port to a fiber port. If one of the uplink connections fails, the uplink connection

automatically fails over to the second connection. To set up a redundant link on a combination port,

connect the active 1000BASE-T and fiber links to both the RJ-45 and SFP interfaces of that port.

Gigabit Ethernet uplink redundancy on the E4G-400 router follows these rules:

With both the SFP and 1000BASE-T interfaces connected on a combination port, only one interface

•

can be activated. The other is inactive.

If only one interface is connected, the router activates the connected interface.

•

The router determines whether the port uses the fiber or copper connection based on the order in

•

which the connectors are inserted into the router. When the router senses that an SFP and a copper

connector are inserted, the router enables the uplink redundancy feature. For example, if you first

connect copper ports 21 and 22, and then insert SFPs into optical ports 21 and 22, the router assigns

the copper ports as active ports and the fiber ports as redundant ports.

Hardware identifies when a link is lost and responds by swapping the primary and redundant ports to

maintain stability. After a failover occurs, the router keeps the current port assignment until another

failure occurs or a user changes the assignment using the CLI. For more information about configuring

automatic failover on combination ports, see the ExtremeXOS User Guide.

E4G-400 LEDs

The following tables describe the LEDs on the E4G-400 cell site aggregation router.

E4G Routers Hardware Installation Guide 16

Extreme Networks E4G Series Routers

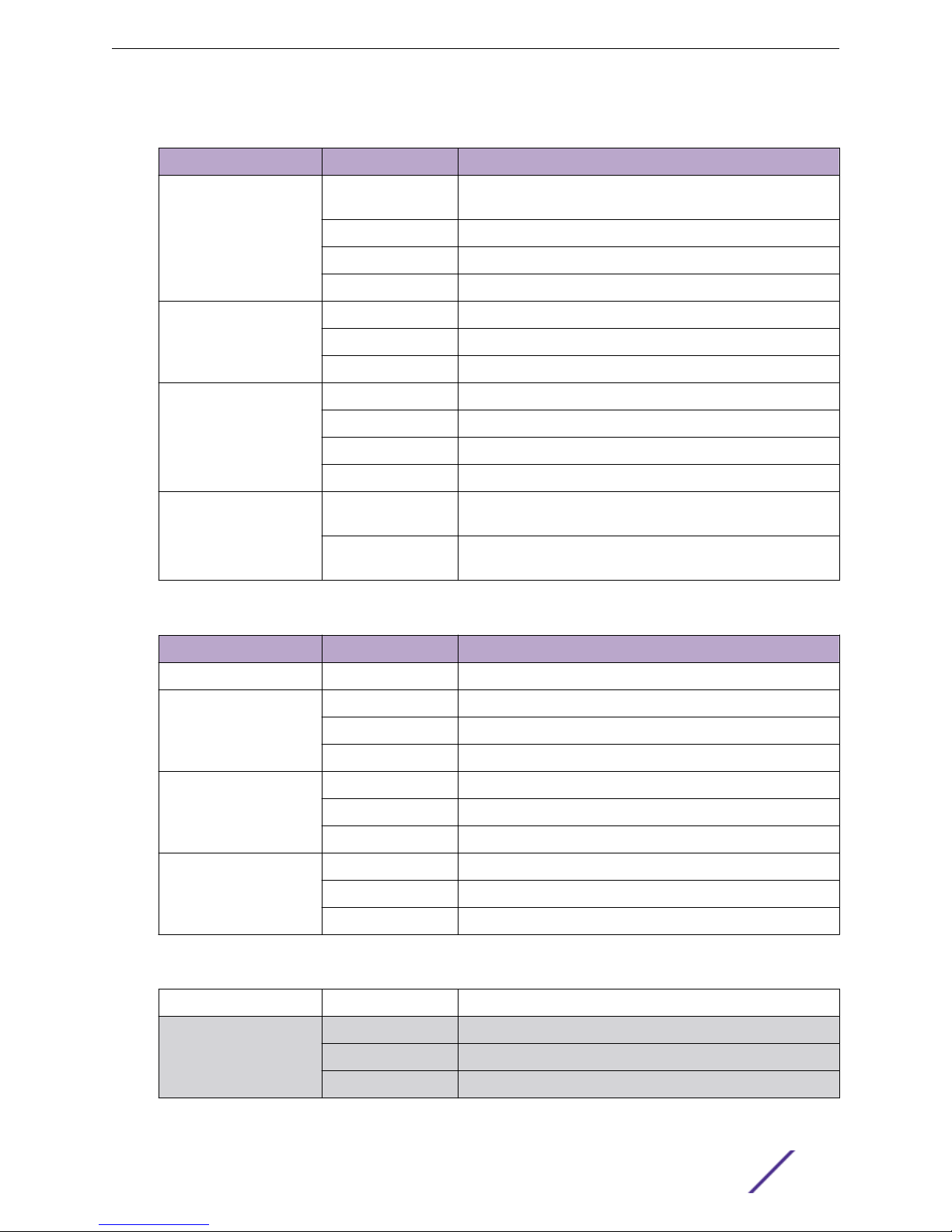

Table 8: Front Panel LEDs

Type/Label Color/State Meaning

MGMT Steady green Power-on self test (POST) completed successfully; normal

operation

Blinking green POST is in progress

Amber POST failed, or the system has overheated

O No external power attached

FAN Steady green Normal operation

Blinking amber Failure

O No power

PSU-1, PSU-2 Steady green Normal operation

Steady amber Power is attached, but no power is on

Blinking amber Failure

O No power is attached

Slot-A, Slot-B Steady green Port option card is installed in the indicated slot at the back of

the router

O No port option card is installed in the indicated slot at the back

of the router

Table 9: 2-digit Stack Number Indicator

Type/Label Color/State Meaning

Left digit (1) NA Reserved for future use

Right digit (1 – 8)

Indicates the position of

this router in a stacked

configuration.

Ethernet Ports 1 – 28 Steady green Link OK

Management Port Steady green Link OK

Upper half blinking This router is the stack master node

Lower half blinking This router is the stack backup node

Lit steadily This router is a standby node in the stack

Blinking green Activity

O No link, or port is disabled

Blinking green Activity

O No link, or port is disabled

Table 10: Back Panel

Type/Label Color/State Meaning

Port LED on installed

XGM3S-2sf option card

E4G Routers Hardware Installation Guide 17

Steady green Link OK

Blinking green Activity

O No link, or port is disabled

Table 10: Back Panel (continued)

Port LED on installed

XGM3S-2xf option card

Steady green Link OK

Blinking green Activity

O No link, or port is disabled

Extreme Networks E4G Series Routers

Port LED on installed

XGM3SB-4xf option card

(S1 – S4)

Port LED on installed

E4G-B16T1E1 module (1 –

16)

Steady green Link OK

Blinking green Activity

O No link, or port is disabled

Steady green Link OK

Blinking green Activity

O No link, or port is disabled

E4G-400 Power Supplies

The E4G-400 router is compatible with the following power supplies:

300 W AC power supply (model number 10930A)

•

300 W DC power supply (model number 10934A)

•

300 W DC power supply (model number 10933)

•

An E4G-400 router accommodates one or two 300 W power supplies. You can combine AC and DC

power supplies in the same E4G-400 router. In a redundant power configuration, both power supplies

are fully fault-tolerant and load-sharing. You can remove one power supply without interrupting router

operation.

Note

An AC power input cord is not provided with a 300 W AC power supply. You can order an

appropriate cord from Extreme Networks or from your local supplier. The power cord must

meet the requirements listed in Power Supplies for the E4G-400 Router on page 103.

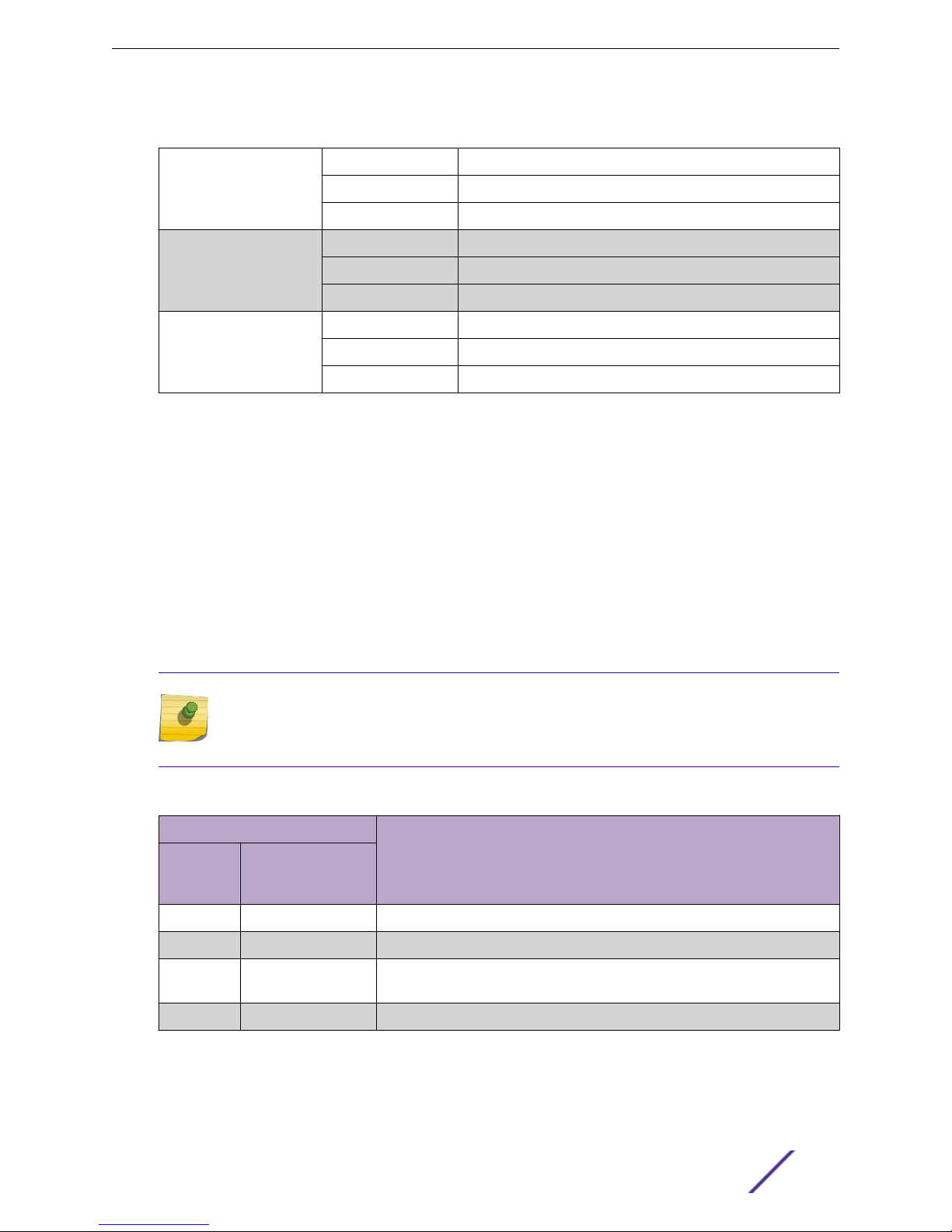

Table 11: 300 W AC Power Supply LEDs

LED Label and Color Meaning

AC IN

OK

Green

O O No AC input power

O Steady red No AC input power; receiving standby output from system

On O AC input good; 12 V output is disabled

On Steady red AC input good; fault in 12 V output

E4G Routers Hardware Installation Guide 18

DC Out

OK

Green/red bicolor

Standby output is ON

Table 11: 300 W AC Power Supply LEDs (continued)

LED Label and Color Meaning

Extreme Networks E4G Series Routers

AC IN

OK

Green

On Flashing green and

On Steady green AC input good; DC outputs good

DC Out

OK

Green/red bicolor

red

AC input good, 12 V output good

Power supply alert: power supply is likely to fail because of a developing

fault, such as abnormal thermal conditions or poor fan performance

Note

The model 10933 is the recommended DC power supply.

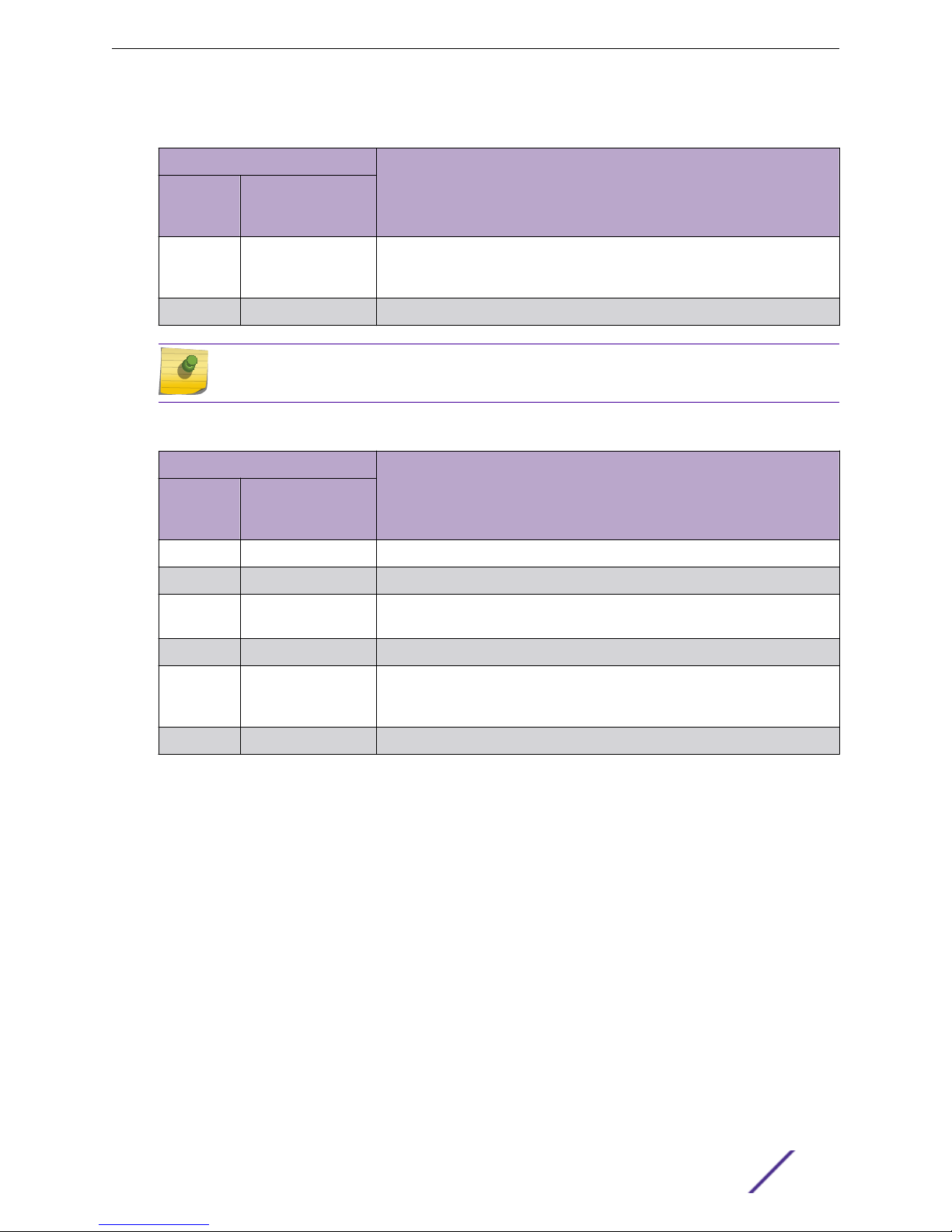

Table 12: 300 W DC Power Supply (models 10934A and 10933) LEDs

LED Label and Color Meaning

AC IN

OK

Green

O O No DC input power

O Steady red No DC input power; receiving standby output from system

On O DC input is good; 12 V output is disabled

DC Out

OK

Green/red bicolor

Standby output is ON

On Steady red DC input is good; fault in 12 V output

On Flashing green and

red

On Steady green DC input is good; DC outputs are good

DC input is good, 12 V output is good

Power supply alert: power supply is likely to fail because of a developing

fault, such as abnormal thermal conditions or poor fan performance

Optional Port Cards for the E4G-400 Router

The rear panel of the E4G-400 router has two slots for installing optional port cards.

Slot A accommodates either of the following option cards:

XGM3S-2sf Option Card on page 19

•

XGM3S-2xf Option Card on page 20

•

Slot B accommodates either of the following option cards:

XGM3SB-4sf Option Card on page 20

•

E4G-B16T1E1 Module on page 21

•

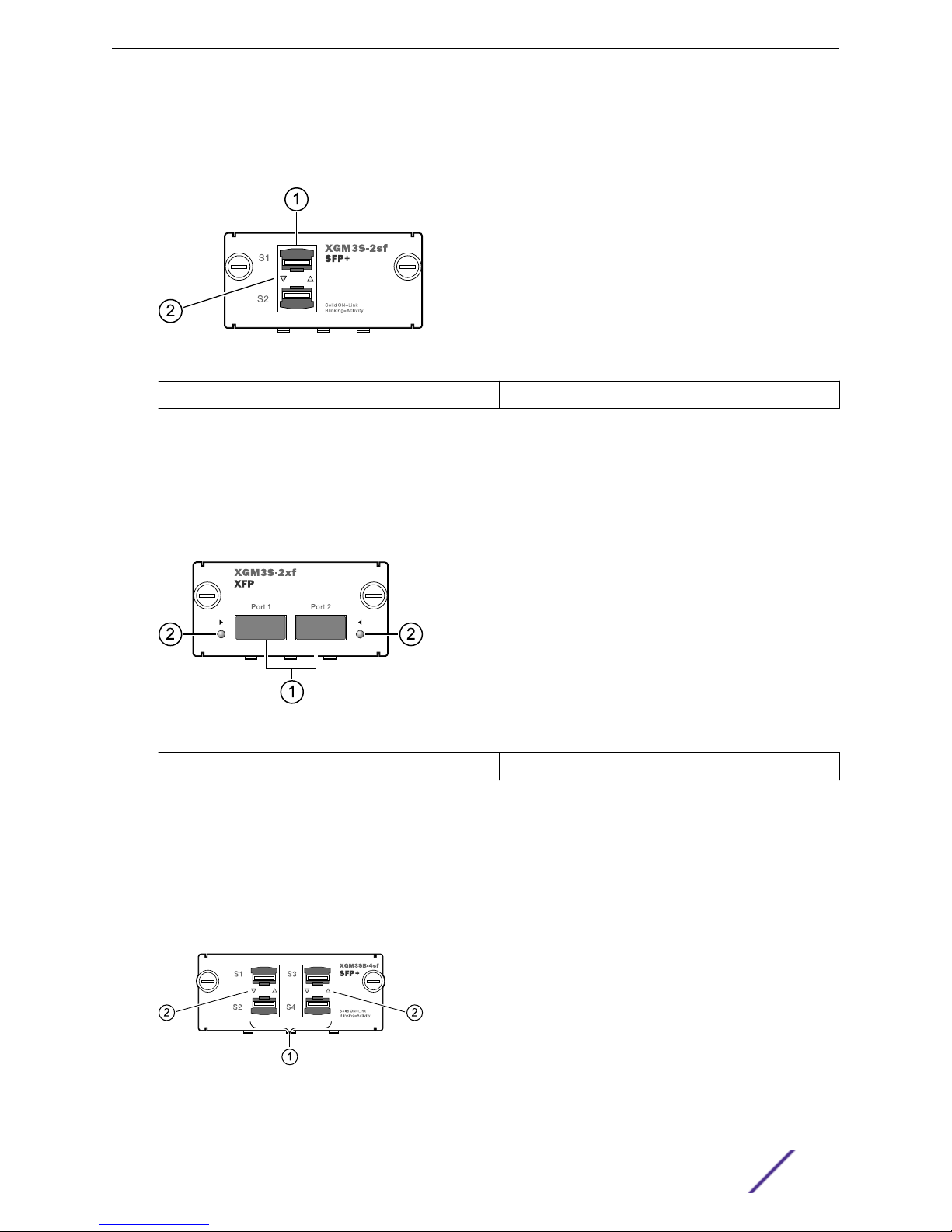

XGM3S-2sf Option Card

The XGM3S-2sf option card allows you to add one or two 10-Gigabit SFP+ optical ports to slot A on the

rear panel of an E4G-400 router.

E4G Routers Hardware Installation Guide 19

Extreme Networks E4G Series Routers

These ports support synchronous Ethernet and can be used for stacking connections or data links. The

XGM3S-2sf option card supports either SFP+ optical modules or an SFP+ direct-attach passive copper

cable.

Figure 7: XGM3S-2sf Option Card

1 = SFP+ ports 2 = LEDs

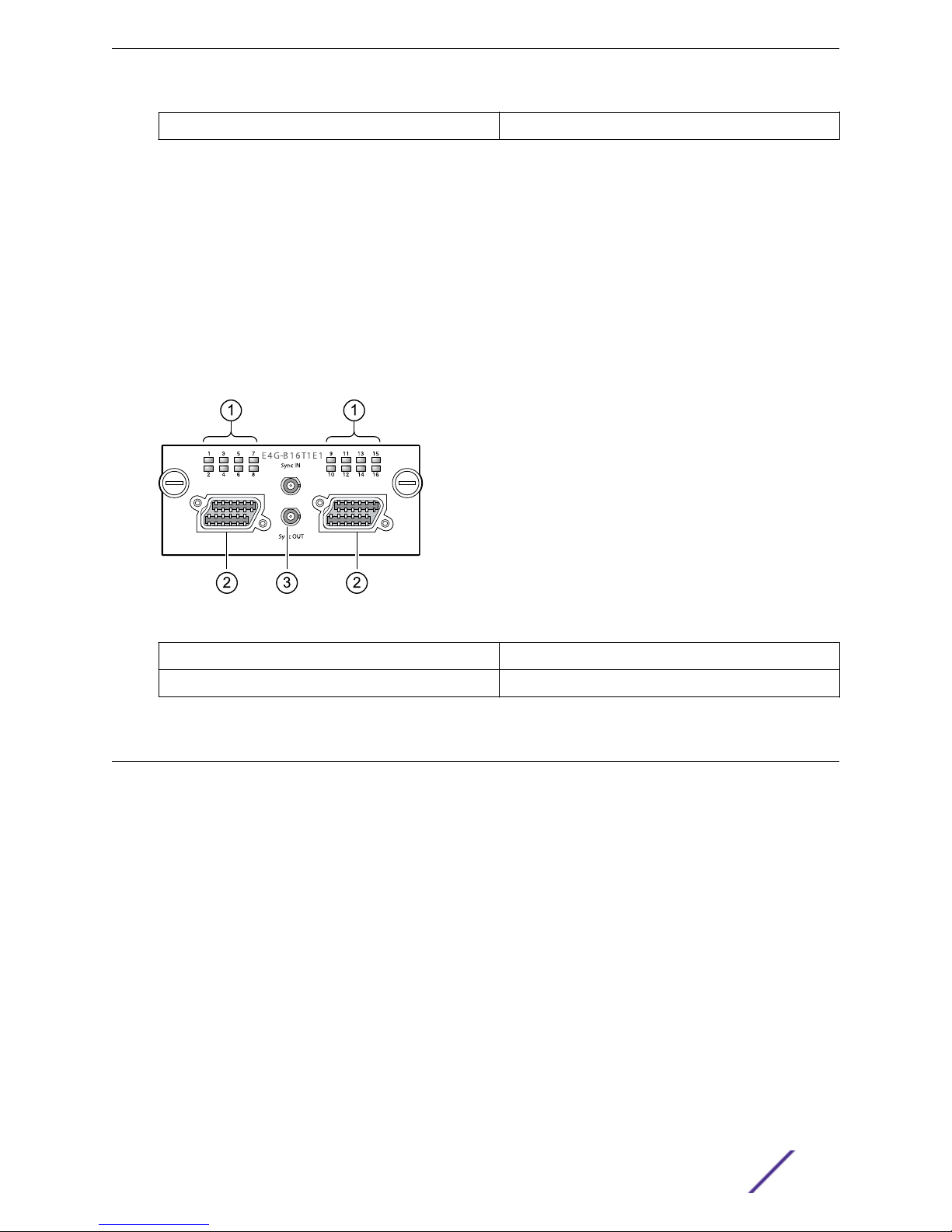

XGM3S-2xf Option Card

The XGM3S-2xf option card allows you to add one or two 10-Gigabit XFP optical ports to Slot A on the

rear panel of the E4G-400 router.

These ports support synchronous Ethernet and can be used for stacking connections or data links.

Figure 8: XGM3S-2xf Option Card

1 = XFP ports

2 = LEDs

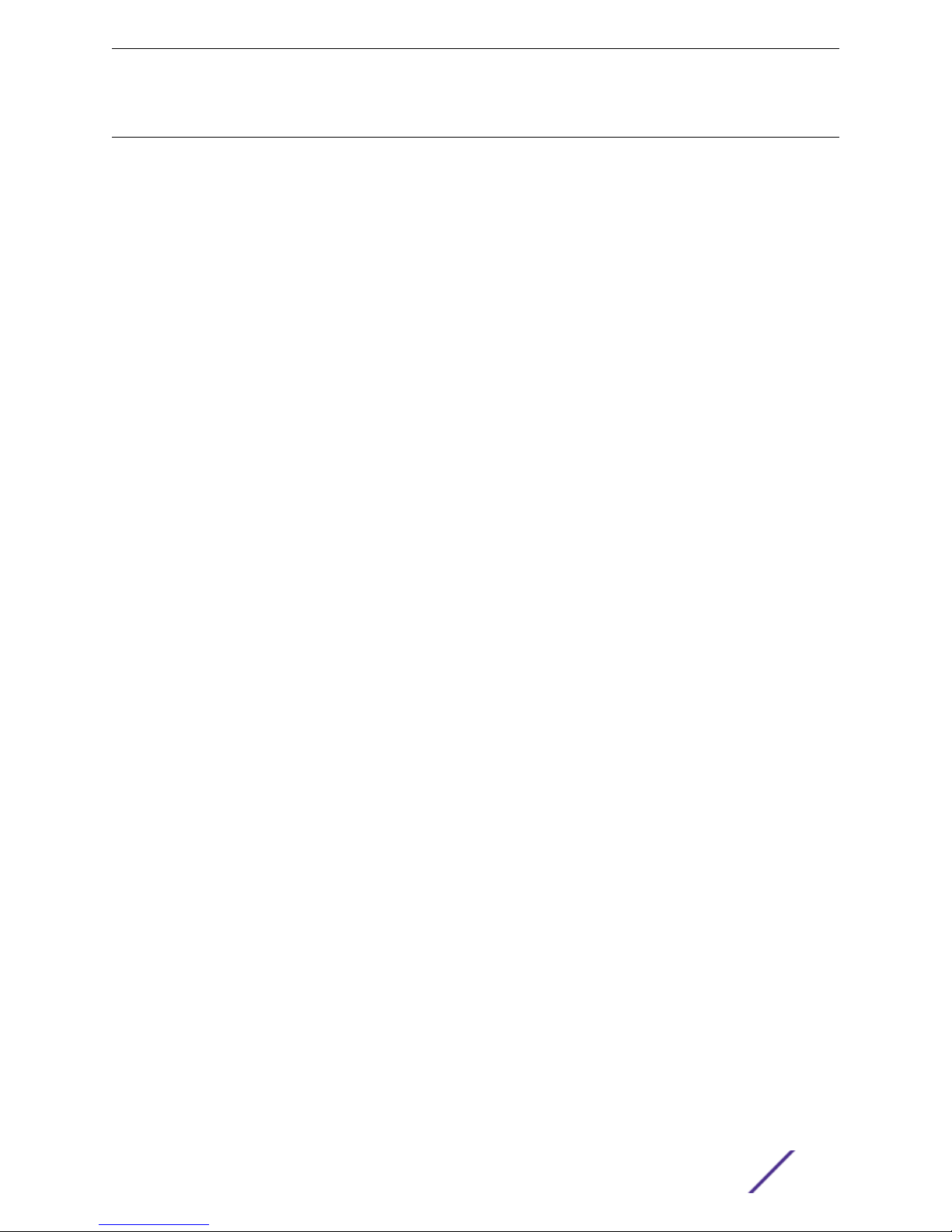

XGM3SB-4sf Option Card

The XGM3SB-4sf option card allows you to add up to four 10-Gigabit SFP+ optical ports to Slot B on the

rear panel of the E4G-400 router.

These ports support synchronous Ethernet and can be used for data links. The XGM3SB-4sf option card

supports either SFP+ optical modules or the SFP+ direct-attach passive copper cable.

Figure 9: XGM3SB-4sf Option Card

E4G Routers Hardware Installation Guide 20

Extreme Networks E4G Series Routers

1 = SFP+ ports 2 = LEDs

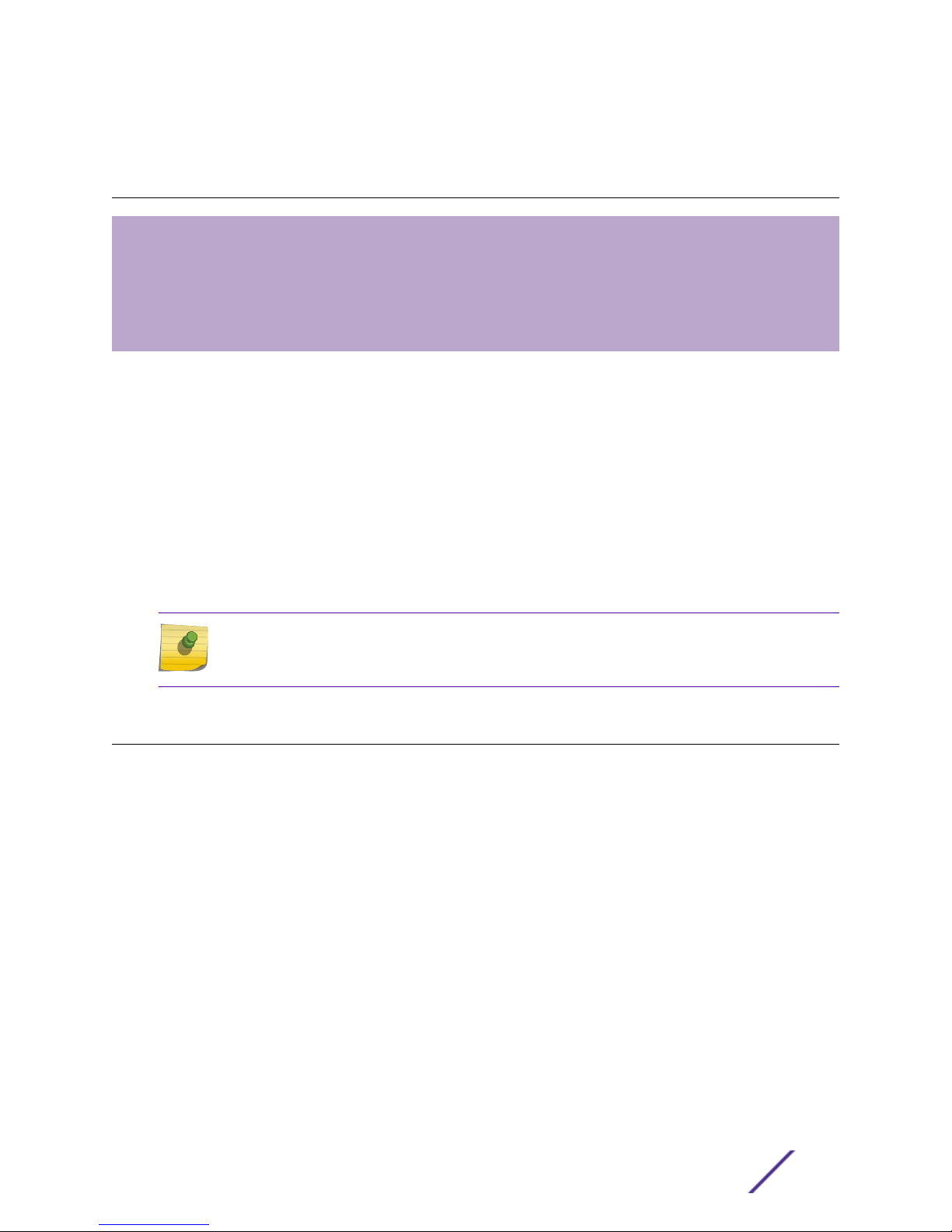

E4G-B16T1E1 Module

The E4G-B16T1E1 module allows you to add 16 T1/E1 ports with pseudowire emulation to slot B on the

rear panel of the E4G-400 router.

This module has two MRJ21 connectors, each one providing eight ports. Connections to these

connectors are made in either of the following ways:

A special fan-out cable that connects to the module and provides eight separate RJ-45 connectors

•

at the other end. (See E4G-400 Connector Pinouts on page 109 for more information about this

cable.)

A straight MRJ21-to-MRJ21 cable that connects to a breakout panel

•

Figure 10: E4G-B16T1E1 Module

1 = T1/E1 ports

2 = MRJ21 connectors

3 = Sync In/Sync Out interfaces

Pluggable Interfaces for E4G Series Routers

Ports on E4G series routers are compatible with a variety of optical modules, including SFP, SFP+, and

XFP modules.

Extreme Networks optical modules are tested to work in all supported Extreme Networks devices. We

recommend that all customers use Extreme Networks optical modules in their Extreme Networks

devices. Extreme Networks assumes no liability for third-party optical modules. Although Extreme

Networks does not block third-party optical modules, we cannot ensure that all third-party optical

modules operate properly in all Extreme Networks devices. The customer assumes all risks associated

with using third-party optical modules in Extreme Networks devices.

For details about which optical modules are supported for use with E4G series routers, see the Extreme

Hardware/Software Compatibility and Recommendation Matrices.

E4G Routers Hardware Installation Guide 21

Extreme Networks E4G Series Routers

Stacking Options for E4G Series Routers

The E4G-400 can be stacked with Summit family switches and other E4G-400 units that are running

the same version of ExtremeXOS. SummitStack-V and SummitStack-V80 connections are made using

10-Gbps Ethernet data ports on either of the following port option cards:

XGM3S-2sf (SFP+ port)

•

XGM3S-2xf (XFP port)

•

E4G Routers Hardware Installation Guide 22

2 Site Preparation

Planning Your Site

Meeting Site Requirements

Evaluating and Meeting Cable Requirements

Meeting Power Requirements

Following Applicable Industry Standards

By carefully planning your site, you can maximize the performance of your existing network and ensure

that it is ready to migrate to future networking technologies.

The information in this chapter is intended for the system administrator, network equipment technician,

network manager, or facilities manager responsible for installing and managing the network hardware.

The chapter assumes a working knowledge of local area network (LAN) operations, and a familiarity

with communications protocols that are used on interconnected LANs.

Only

qualified service personnel should install, maintain, or remove Extreme Networks equipment.

Qualified service personnel have had appropriate technical training and experience that is necessary to

be aware of the hazards to which they are exposed when performing a task and of measures to

minimize the danger to themselves or other people.

Note

Before installing or removing any components of the system, or before carrying out any

maintenance procedures, read Safety Information on page 78.

Planning Your Site

For successful installation and operation of your equipment, plan the site carefully.

The site planning process has three major parts:

1 Meet site requirements.

Building and electrical code requirements

•

Environmental, safety, and thermal requirements for the equipment you plan to install

•

Equipment rack requirements

•

2 Evaluate and meet cable requirements.

Compare existing cabling with the requirements of the Extreme Networks equipment to determine if

you need to install new cables.

3 Meet power requirements.

To run your equipment safely, you must meet the specific power requirements for each router and

external power supply unit installed in the system. For power specifications of the router and power

supplies, see the specific router models listed in Technical Specifications on page 91.

E4G Routers Hardware Installation Guide 23

Meeting Site Requirements

By carefully planning your site, you can maximize the performance of your existing network and ensure

that it is ready to migrate to future networking technologies.

The information in this chapter is intended for the system administrator, network equipment technician,

network manager, or facilities manager responsible for installing and managing the network hardware.

Operating Environment Requirements

Virtually all areas of the United States are regulated by building codes and standards. During the early

planning stages of installing or modifying your network, it is important that you develop a thorough

understanding of the regulations that pertain to your location and industry.

Verify that your site meets all environmental and safety requirements.

Building and Electrical Codes

Building and electrical codes vary depending on your location. Comply with all code specifications

when planning your site and installing cable. This section lists resources for obtaining additional

information.

Site Preparation

For information about major building codes, consult the following organization:

International Code Council (ICC)

5203 Leesburg Pike

Falls Church, VA 22041 USA

www.iccsafe.org

www.sbcci.org

The organizations listed in the following table are authorities on electrical codes.

Table 13: Authorities on Electrical Codes

Organization Address Web Site URL

National Electrical Code (NEC) Classification (USA only)

Recognized authority on safe electrical wiring. Federal, state,

and local governments use NEC standards to establish their

own laws, ordinances, and codes on wiring specifications. The

NEC classification is published by the National Fire Protection

Association (NFPA).

Underwriters’ Laboratory (UL) (USA only)

Independent research and testing laboratory. UL evaluates the

performance and capability of electrical wiring and equipment

to determine whether they meet certain safety standards

when properly used. Acceptance is usually indicated by the

words “UL Approved” or “UL Listed.”

NFPA

1 Batterymarch Park

Quincy, Massachusetts

02169

USA

UL

333 Pfingsten Road

Northbrook, Illinois

60062-2096

USA

www.nfpa.org

www.ul.com

National Electrical Manufacturing Association (NEMA) (USA

only)

Organization of electrical product manufacturers. Members

develop consensus standards for cables, wiring, and electrical

components.

E4G Routers Hardware Installation Guide 24

NEMA

1300 N. 17th Street

Rosslyn, Virginia 22209

USA

www.nema.org

Site Preparation

Table 13: Authorities on Electrical Codes (continued)

Organization Address Web Site URL

Electronics Industries Alliance (EIA)

Trade association that develops technical standards,

disseminates marketing data, and maintains contact with

government agencies in matters relating to the electronics

industry.

Federal Communications Commission (FCC) (USA only)

Commission that regulates all interstate and foreign electrical

communication systems that originate in the United States

according to the Communications Act of1934. The FCC

regulates all U.S. telephone and cable systems.

Equipment Location

Observe the following recommendations when locating your equipment.

Note

Extreme Networks recommends that you consult an electrical contractor for commercial

building and wiring specifications.

Be sure that your system is readily accessible for installation and service.

•

See Rack and Cabinet Specifications and Recommendations on page 27 for information.

Use appropriate AC or DC power, power distribution, and grounding for your specific installation.

•

Use a vinyl floor covering in wiring closets or other indoor equipment locations.

•

Concrete floors accumulate dust, and carpets can cause static electricity.

Prevent unauthorized access to equipment locations by providing door locks.

•

Install the equipment in a secured, enclosed, and restricted access location, ensuring that only

qualified service personnel have access to the equipment.

Provide adequate overhead lighting for easy maintenance.

•

Be sure that each equipment location has a suitable ground.

•

All equipment racks and equipment installed in the closet should be grounded.

Be sure that all system environmental requirements are met, such as ambient temperature and

•

humidity.

Refer to the following topics for details.

EIA

2500 Wilson Boulevard

Arlington, Virginia 22201

USA

FCC

445 12th Street S.W.

Washington, D.C. 20554

USA

www.eia.org

www.fcc.gov

Temperature

It is important to keep installed equipment within the thermal operating specifications for optimum

performance and safety.

E4G Routers Hardware Installation Guide 25

Install the E4G-400 cell site aggregation router only in a temperature-controlled and humiditycontrolled indoor area that is free of airborne materials that can conduct electricity. Too much humidity

can cause a fire. Too little humidity can produce electrical shock and fire.

Note

As with all electrical equipment, Extreme Networks product lifetimes degrade with increased

temperature. If possible, temperatures should be kept at approximately 25°C (78°F) or lower.

Be sure that the ventilation in the installation site is adequate to maintain a temperature below 50°C

•

(113°F) for the E4G-400 router or below 65°C (149°F) for the E4G-200 router.

Install a reliable air conditioning and ventilation system for indoor locations.

•

Keep the ventilation in wiring closets running during non-business hours to prevent overheating of

•

the equipment.

Maintain an ambient operating temperature range of -10° to 50°C (14° to 122°F) for the E4G-400

•

router or a range of -40° to 65°C (-49° to 149°F) for the E4G-200 router.

Maintain a storage temperature of -40° to 70°C (-40° to 158°F).

•

Humidity

Site Preparation

Keep operating humidity between 50% and 70% relative humidity (non-condensing) during typical

operation.

The equipment can operate at between 10% and 95% relative humidity (non-condensing) for short

intervals.

Spacing Requirements and Airflow

Be sure that cables and other equipment do not block the air intake or outflow on an Extreme Networks

router.

Depending on other conditions in the equipment room, it may be possible to install the routers closer to

each other; consult your Extreme Networks Customer Support representative for guidance.

Leave at least 3 inches (8 cm) of clear space in front of the air intake and outflow vents on the sides of

the router.

Airflow moves from side to side. For proper airflow through an E4G series router, leave clear space on

the left and right sides of the router.

Electrostatic Discharge (ESD)

Your system must be protected from static electricity or electrostatic discharge (ESD). Take the

following measures to ensure optimum system performance:

Remove materials that can cause electrostatic generation (such as synthetic resins) from the wiring

•

closet.

Check the appropriateness of floor mats and flooring.

Connect metal chassis, conduit, and other metals to ground using dedicated grounding lines.

•

Use electrostatically safe equipment.

•

If you are working with pluggable interface modules, wear an ESD-preventive wrist strap and

connect the metal end to a grounded equipment rack or other source of ground.

E4G Routers Hardware Installation Guide 26

Rack and Cabinet Specifications and Recommendations

Racks and cabinets should conform to conventional standards.

In the United States, use EIA Standard RS-310C: Racks, Panels, and Associated Equipment.

In countries other than the United States, use IEC Standard 297. In addition, verify that your rack meets

the basic mechanical, space, and earthquake requirements that are described in this section.

Mechanical Recommendations for the Rack

Use equipment racks that meet the following mechanical recommendations:

Use an open style, 19-inch rack to facilitate easy maintenance and to provide proper ventilation.

•

Use a rack made of steel or aluminum.

•

The rack should use the universal mounting rail hole pattern that is identified in IEC Standard 297.

•

The rack should have designated earth grounding connections (typically on the base).

•

The rack must meet earthquake safety requirements equal to that of the installed chassis.

•

The mounting holes should be flush with the rails to accommodate the chassis.

•

Site Preparation

Protective Grounding for the Rack

Use a rack grounding kit and a ground conductor that is carried back to earth or to another suitable

building ground.

Use a rack grounding kit and a ground conductor that is carried back to earth or to another suitable

building ground.

Before you install an E4G series router in an equipment rack, clean the rack and mounting bracket

surfaces and apply an antioxidant. When you secure an E4G series router to the rack, use threadforming mounting screws that remove any paint or non-conductive coatings and establish metal-tometal contact.

Extreme Networks equipment is designed with mounting brackets that provide solid metal-to-metal

connection to the rack.

Note

Because building codes vary worldwide, Extreme Networks strongly recommends that you

consult an electrical contractor to ensure proper equipment grounding for your specific

installation.

At a minimum, follow these guidelines to ground equipment racks to the earth ground:

CAD weld appropriate wire terminals to building I-beams or earth ground rods.

•

Use a minimum 14 AWG stranded copper wire for grounding an E4G-200 router or a DC-powered

•

E4G-400 router.

An AC-powered E4G-400 router does not need separate chassis grounding.

E4G Routers Hardware Installation Guide 27

Position the earth ground as close to the equipment rack as possible to maintain the shortest wiring

•

distance possible.

Use a ground impedance tester or micro-ohm meter to test the quality of earth ground connection

•

at the chassis. This will ensure good grounding between the chassis, rack, and earth ground.

Note

Because building codes vary worldwide, Extreme Networks strongly recommends that you

consult an electrical contractor to ensure proper equipment grounding for your specific

installation.

Space Requirements for the Rack

Provide enough space in front of and behind the switch so that you can service it easily.

Allow a minimum of 48 inches (122 cm) in front of the rack and 30 inches (76 cm) behind the rack.

When using a relay (two-post) rack, provide a minimum of 24 inches (61 cm) of space behind the

mounted equipment. Extra room on each side is optional.

Securing the Rack

Site Preparation

The rack should be attached to the wiring closet floor with 3/8-inch (9.5 mm) lag screws or equivalent

hardware.

The floor under the rack should be level within 3/16-inch (5 mm). Use a floor-leveling cement compound

if necessary or bolt the racks to the floor as shown.

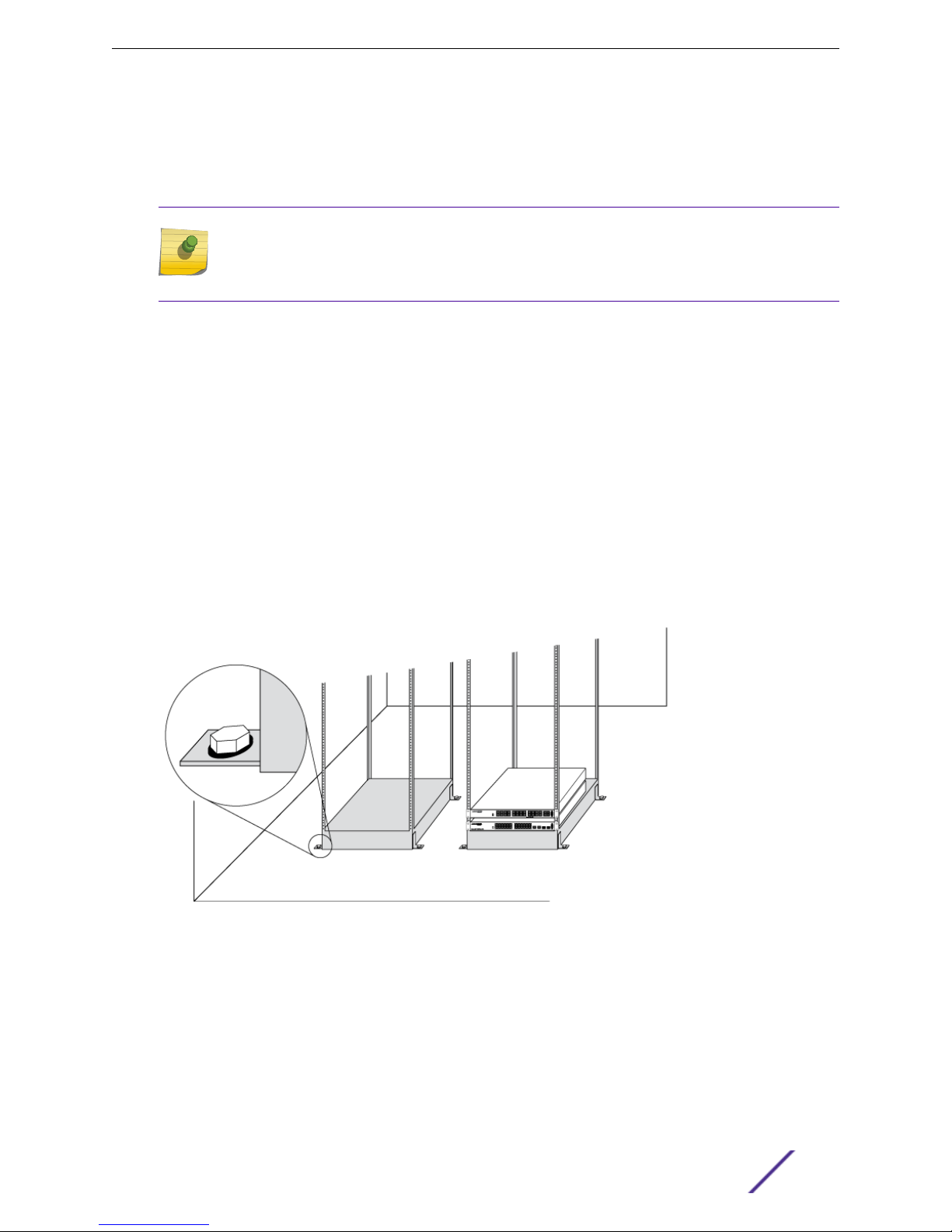

Figure 11: Properly Secured Rack

Brace open equipment racks if the channel thickness is less than 1/4 inch (6.4 mm).

Outdoor Installation

The E4G-200 router can be installed in locations outside of buildings.

E4G Routers Hardware Installation Guide 28

Site Preparation

Prevent unauthorized access to equipment locations and make sure that only qualified service

•

personnel have access to the equipment.

Take reasonable precautions to prevent animals from gaining access to the equipment.

•

Be sure that the ventilation in the installation site is adequate to maintain a temperature below 65°C

•

(149°F) for the E4G-200 router.

For proper airflow through the router, leave clear space on the left and right sides of the router.

•

Evaluating and Meeting Cable Requirements

Use professional consultants for site planning and cabling.

Extreme Networks recommends using the Building Industry Consulting Service International (BICSI)

Registered Communications Distribution Designer (RCDD), which is globally recognized as a standard in

site planning and cabling.

For information, visit www.bicsi.org.

Cable Labeling and Record Keeping

A reliable cable labeling system is essential when planning and installing a network.

Maintaining accurate records helps you to:

Relocate devices easily.

•

Make changes quickly.

•

Isolate faults in the distribution system.

•

Locate the opposite end of any cable.

•

Know the types of network devices that your cabling infrastructure can support.

•

Follow these guidelines when setting up a cable labeling system suitable for your installation:

Identify cables by securely attaching labels to all cable ends.

•

Assign a unique block of sequential numbers to the group of cables that run between each pair of

•

wiring closets.

Assign a unique identification number to each equipment rack.

•

Identify all wiring closets by labeling the front panel of your Extreme Networks equipment and other

•

hardware.

Keep accurate and current cable identification records.

•

Post records near each equipment rack. For each cable drop, include information about the cable

•

source, destination, and jumper location.

Installing Cable

When you connect cable to your network equipment, keep the following things in mind.

Examine cable for cuts, bends, and nicks.

•

Support cable using a cable manager that is mounted above connectors to avoid unnecessary

•

weight on the cable bundles.

E4G Routers Hardware Installation Guide 29

Site Preparation

Use cable managers to route cable bundles to the left and right of the network equipment to

•

maximize accessibility to the connectors, as shown in the following figure.

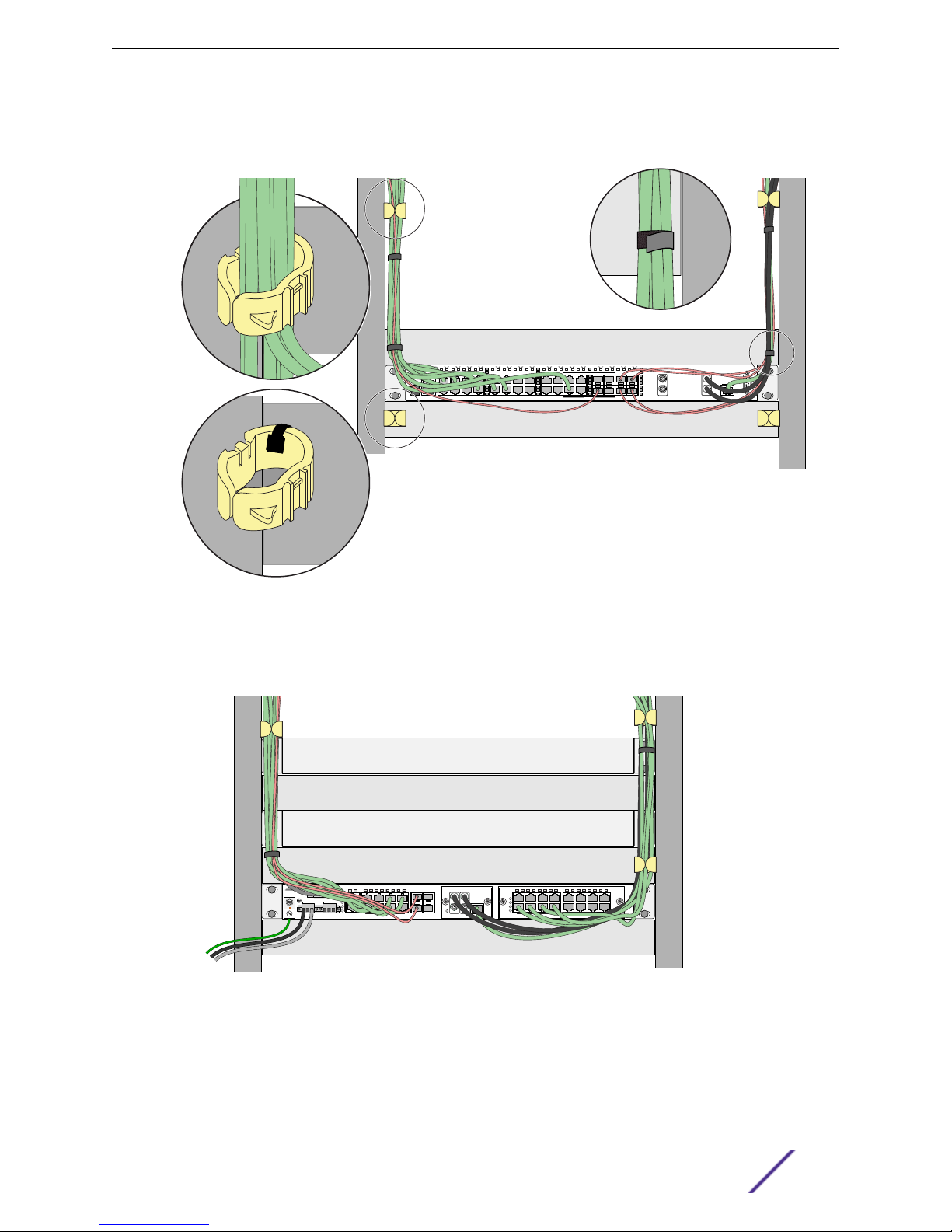

Figure 12: Properly Installed and Bundled Cable for an E4G-400 Router

Provide enough slack, approximately 2 to 3 inches (5 to 8 cm), to provide proper strain relief as

•

shown in the following figure.

Figure 13: Properly Installed Cables, Showing Slack for Proper Strain Relief

Bundle cable using hook-and-loop straps to avoid injuring cables.

•

If you build your own cable, be sure that connectors are properly crimped.

•

When installing a patch panel using twisted pair wiring, untwist no more than 1 inch (2.54 cm) of the

•

cable to avoid radio frequency (RF) interference.

E4G Routers Hardware Installation Guide 30

Loading...

Loading...