YAK-55SP

Profile ARF

Instruction Manual

©Copyright 2008 EXTREME FLIGHT RC, Ltd.

Thank you for your purchase of the Extreme Flight RC Jeremy Chinn designed

Matchless Yak-55SP profile ARF! We are honored to have worked with Jeremy on this

project to deliver a very high performance, high quality product. Jeremy has been

involved in prototype testing and we have listened to his suggestions and are very excited

about the outcome.

The Chinn Yak (as it is called by the Profile Brotherhood) was released previously as a

kit and quickly became a favorite among the Pro Bros. There are numerous build threads

and videos of this aircraft on the Pro Bro site (www.theprofilebrotherhood.com). When

looking for a new profile to produce the Chinn Yak was at the top of our list and

arrangements were made with Jeremy for Extreme Flight RC to produce an ARF version

of his beloved design.

The Chinn Yak excels at all things 3D! Enormous control surfaces provide extreme

authority in pitch, roll and yaw axis maneuvers. You may want to experiment with

slightly higher exponential values than you are accustomed to until you get used to this

amount of responsiveness. The Chinn Yak is an excellent platform to hone your 3D

skills with and its unlimited performance capability will provide hours of excitement for

the 3D enthusiast.

Tips for Success-Please read before beginning assembly!!!

1. Read the instruction manual thoroughly before starting assembly.

2. We are very pleased with the level of craftsmanship exhibited by the workers in

our factory. However, these are mass produced models. As with any ARF, take a

few minutes to go over the model and add CA to high stress areas or any joints

that appear to need more glue.

3. Take a few minutes and go over the covering with a hot iron. Make sure all edges

are sealed and pay special attention to thin stripes.

4. Decals- clean your airplane with glass cleaner and a paper towel before starting to

apply the decals. Mist the area where the decal will be applied with glass cleaner

or water mixed with a little bit of soap. Use scissors to remove the decal from the

sheet. For best results cut as close to the edges of the decal as possible. Position

the decal in place and use a credit card or rubber squeegee to push the excess

liquid from under the decal and allow to dry. You may need to secure the edges

of the decal with masking tape to prevent them from rolling up until the solution

has dried and evaporated.

2

Assembly

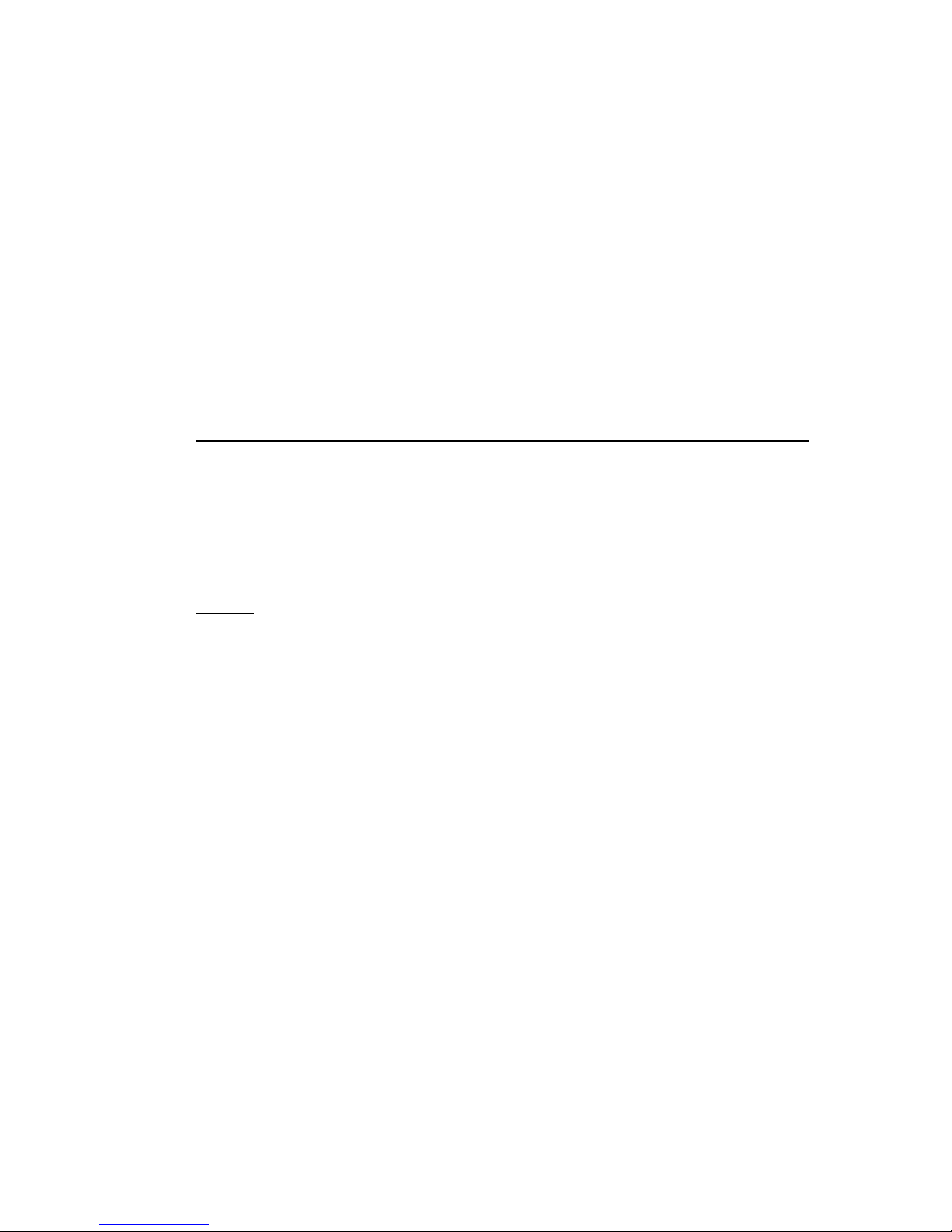

1. The first step is to use a sharp hobby knife to remove the covering from the wing

slot, stab slot and servo openings in the rear of the fuselage as shown in the

pictures.

3

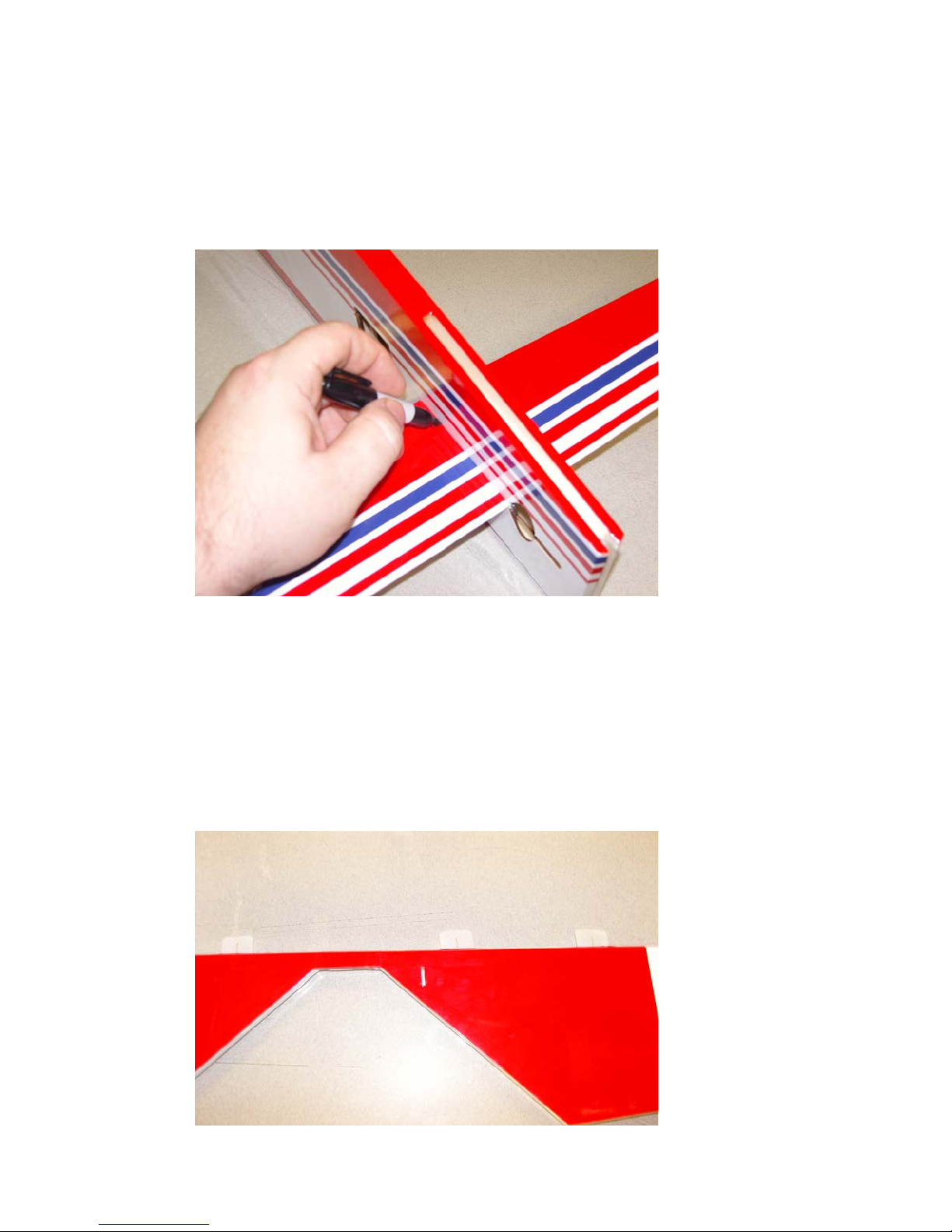

2. Now let’s install the horizontal stab and elevator. First insert the stab into its slot

in the rear of the fuselage. Use a ruler to assure the stab is centered and a square

to make sure it is aligned 90 degrees to the fuselage. Sand or shim the slot as

needed to insure proper alignment. Once satisfied use a fine felt tipped marker to

scribe the covering where it will need to be removed from the stab to allow a

wood-to-wood bond between the fuselage and stab.

3. Remove the stab and use an old soldering iron or sharp hobby blade to remove the

covering from the center of the stab. DO NOT GLUE THE STAB IN AT THIS

TIME!

4. Locate the elevator and the composite control horn and base. Open the slot in the

elevator to accept the control horn and place the base on the horn and insert in the

slot. Use a fine tipped marker to outline the base and then remove the horn

assembly. Use a blade to remove the covering under the base. You will need to

trim and sand the bottom of the horn so that it does not protrude through the top

surface. Scuff the portion of the horn that will be glued into the elevator and then

insert the horn into the base. Glue the horn and base into position with 30 minute

epoxy as shown.

4

5. Slide the elevator through the stab slot oriented as in the picture, upside down

with the counter balances pointing toward the rear of the fuselage. Once in the

slot rotate the elevator into position. Now slide the stab into position. Re-check

alignment and glue in place with 30 minute epoxy. Once dry slide the elevator

onto the hinges and secure with thin CA. Be sure to leave enough gap to get

maximum deflection.

5

6. Locate the vertical fin and place it into the slot in the top rear of the fuselage.

Check to make sure it is properly aligned to the fuselage sides and at 90 degrees

to the horizontal stab, as well as flush with the rear of the fuselage. Sand or shim

the slot as needed for proper alignment. When satisfied glue in place with

30minute epoxy.

6

7. Locate the rudder, composite control horn and base, aluminum bracket, tailwheel

wire, wheel and 2 collars. Remove the covering from the slot for the rudder

control horn and insert the horn into the base and into the slot. Trace around the

base with a fine tipped marker and remove the covering from this area. Glue the

horn and base into position with 30 minute epoxy. You will need to trim and sand

the bottom of the horn to prevent it from protruding through the other side of the

rudder. Be sure to scuff the portion of the horn that will glue into the rudder for

best adhesion.

8. Slide a small wheel collar over the tailwheel wire and insert the tailwheel wire

into the hole in the aluminum mounting bracket. Use a set of pliers to bend the

wire to 90 degrees as shown, making sure the bend is perpendicular to the portion

of the wire where the tailwheel will mount.

9. Drill a hole in the bevel of the rudder to accept the wire just below the bottom

hinge. Slot the bevel to allow the vertical portion of the wire to be embedded.

Trial fit, and then secure with 30 minute epoxy, making sure to thoroughly coat

the wire and balsa. Use a piece of strapping tape to reinforce this area. Once dry

slide the tailwheel onto the wire and secure with a small wheel collar.

7

10. Slide the rudder onto the hinges and into position and secure with thin CA. Be

sure to leave enough gap to be able to get maximum deflection.

11. Secure the aluminum bracket to the bottom of the fuselage with 2 screws and

tighten the collar against the bracket.

8

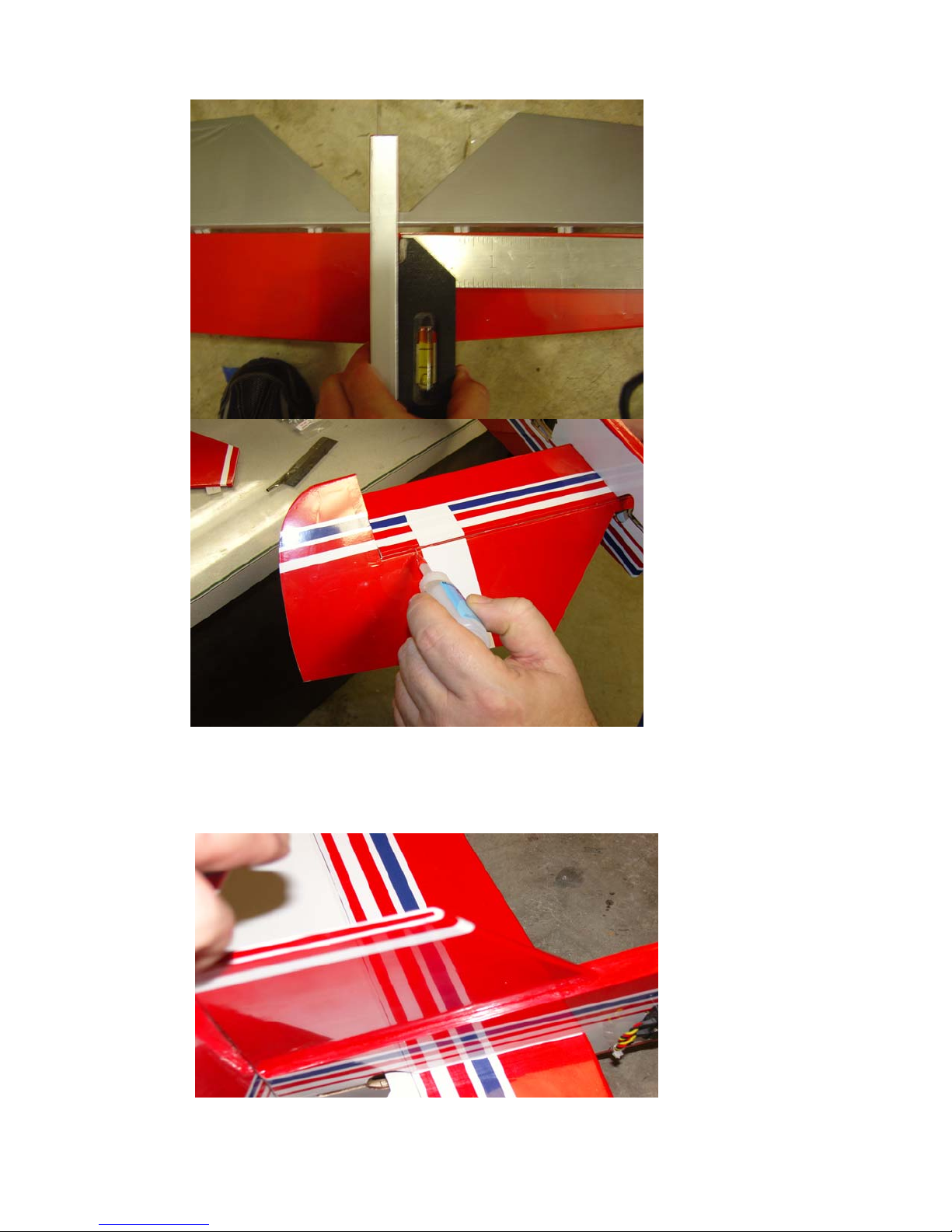

12. Next slide the wing into position and check alignment with fuselage and

horizontal stab. Measure to insure wing is positioned properly and then use a fine

tipped felt marker to mark the area where the covering will need to be removed to

insure a wood-to-wood bond between the wing and fuselage.

13. Remove the wing from the fuselage and use an old soldering iron or sharp hobby

knife to remove the covering from the center of the wing. Use some denatured

alcohol to remove any remaining ink.

14. Slide the wing into position just a few inches short of its proper location. Mix up

some 30 minute epoxy and apply to the exposed wood at the center of the wing

with an epoxy brush.

9

15. Slide the wing into position and check alignment from several angles to make

sure it is correct. Wipe away any excess epoxy with a paper towel soaked in

denatured alcohol. Re-check alignment and then set aside to dry. Once dry fill in

any gaps with thick CA.

16. Locate the 2 ailerons, 2 composite control horns and 2 base plates. Open the

covering over the slot on the bottom of the aileron and insert the control horn into

the base and into the slot. Use a fine tipped felt marker to trace the base plate and

remove the covering from this area.

10

17. You will need to trim and sand the bottom of the control horn so that it does not

protrude through the top surface. Scuff the portion of the control horn that will

glue into the slot and insert the horn into the base plate and secure to the aileron

with 30 minute epoxy. Repeat for the other aileron.

18. Slide the ailerons onto the hinges and into position and secure with thin CA.

11

19. Next let’s assemble the main landing gear and install them on the fuselage. If

flying off of tall grass you may want to forgo the wheel spats. Locate the 2 main

gear legs, 2 wheel spats, 2 axles with retaining nuts, 2 wheels, 2 collars and 2 ply

wood plates as well as 2 4mm bolts, washers and nuts.

20. Scuff the inside of the spats with sandpaper and glue the plywood plate to the spat

with 30 minute epoxy as shown. Repeat for the other spat.

21. Once dry drill a hole through the ply plate and spat as shown to accept the

threaded portion of the axle. Slide the threaded portion of the axle through the

spat and through the landing gear leg and secure with a nylon insert lock nut. The

friction of the washer on the axle will keep the spat in place.

12

22. Slide the wheels onto the axles and secure with wheel collars.

23. There are 2 holes pre-drilled in the outer layer of plywood near the front bottom

of the fuselage for mounting the landing gear. Locate these two holes and drill

completely through the fuselage with a 5/32” bit. Use the 4mm bolts, nuts and

washers to secure the main gear to the fuselage.

13

14

24. Use the manufacturer supplied hardware to install the 2 servos in the rear of the

fuselage as shown with the output shafts positioned toward the rear. It is best to

install the servos and then remove the screws and wick some thin CA into the

mounting holes before reinstalling the screws.

25. You will need to attach 24” extensions to the elevator servos to reach the radio

compartment inside the wing. There is a channel in the bottom of the fuselage

and the extensions are routed through an opening in the lower side of the fuselage

as shown.

15

26. Route the servo leads through the bottom of the fuselage and out of the pre-cut

slot and into the radio compartment in the wing through the pre-cut slot as shown.

27. Locate the provided strip of Ultracote and iron it into position on the bottom of

the fuselage.

16

28. Use the manufacturer supplied mounting hardware to install the 2 aileron servos

as shown. Be sure the output shaft is centered in the pre-cut hole.

29. Now let’s assemble and install the control linkages. Locate the 4 pushrods, 8 ball

links, 8 2mm bolts, nuts and washers. We also recommend the use of the Dubro

Super Strength servo arms. All of the linkages for the ailerons, elevator and

rudder assemble the same way. Electronically center your servos. Thread a ball

link onto each end of the pushrod. Insert a 2 mm bolt into a washer, through the

ball link and into the servo arm or control horn. Secure with another washer and

nut. Be sure to apply a drop of Loctite to prevent the linkage from coming apart

due to vibration. Please see picture for detail.

17

30. Your choice of engine will determine the location for your throttle servo. When

using the Saito .82 I have found it easiest to mount the servo to the hatch on its

side and cut a slot to allow the servo arm to protrude through the top of the hatch.

This provides a straight shot to the throttle arm. Other engines will require

slightly different linkage set-ups. We have provided you with a throttle pushrod

and nylon tube so that you may make a clean effective linkage through the leading

edge of the wing if necessary for your particular installation. Please see the photo

of our Saito .82 installation below.

31. You will want to save the installation of your engine for the last step so that you

can use its position to help achieve proper CG. Lighter engines like the 2 stroke

.46-.50 will need to be mounted further forward on the rails, while heavier

engines like the 4 stroke .82 will need to be mounted further aft. We recommend

installing your receiver and battery in the radio compartment in the wing opposite

the engine. Wrap your receiver battery in foam and place it inside the leading

edge of the wing and secure with Velcro. Once these components are installed

place your engine on the mounting rails with prop and spinner attached. For the

larger engines you may need to slightly trim the rails to make the engine fit

properly. A rotary tool makes quick work of this. Once satisfied with motor

position drill through the mounting lugs and secure engine with the provided 3mm

bolts, nuts and washers as shown. Be sure to place 2 washers between the 2 front

engine mounting lugs and fuselage to provide 2 degrees of right thrust to counter

spiral slipstream effect.

18

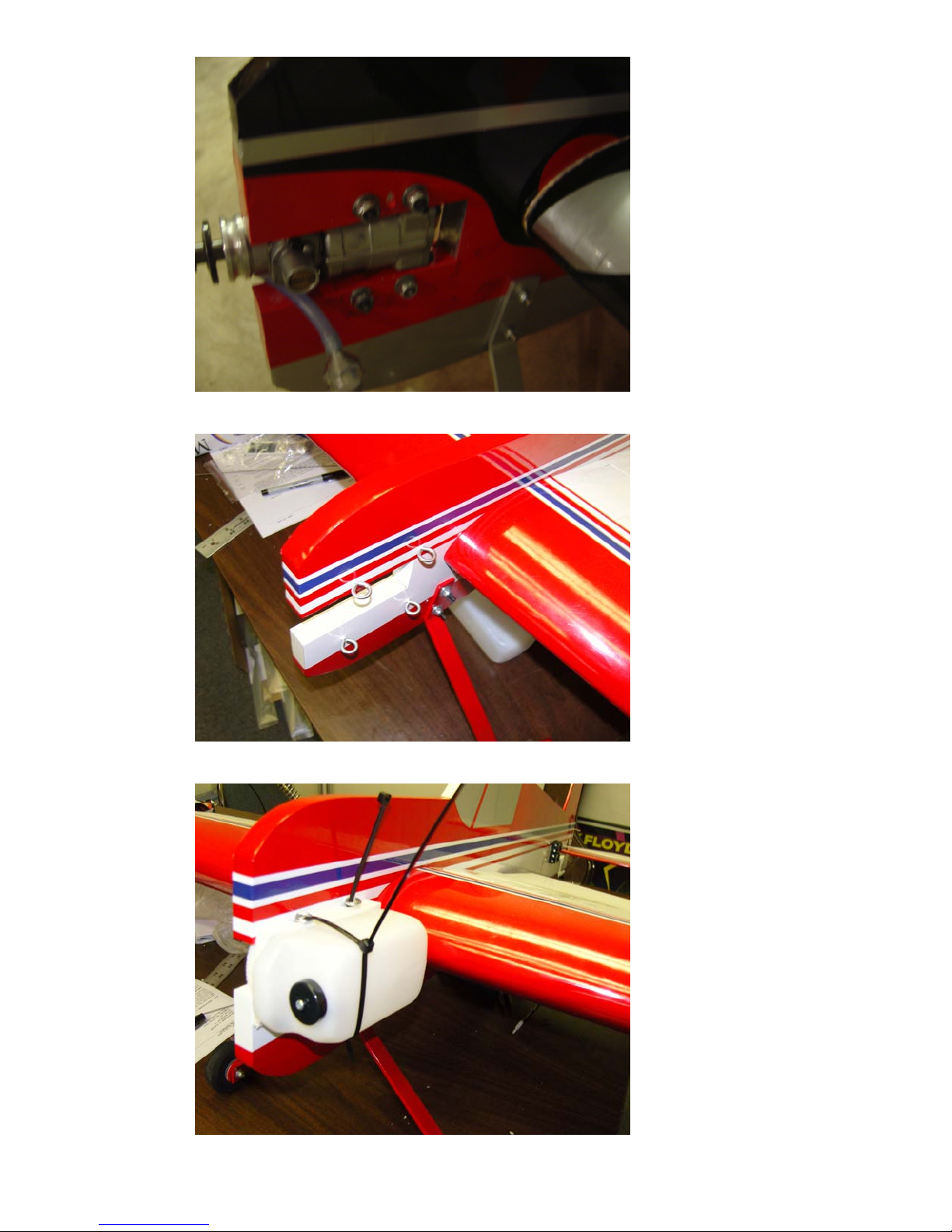

32. Install the 4 provided screw eyes as shown and secure each with a drop of

medium CA.

33. Secure the tank to the fuselage with nylon cable ties or rubber bands. Be sure to

place a piece of closed cell foam between the tank and fuselage side.

19

34. Run you fuel lines from the tank to the engine. We usually drill through the

fuselage to route fuel lines and help keep them out of the propeller.

35. Secure the radio compartment hatches with 4 screws each, installed 1at each

corner.

36. Apply decals, and that’s it! Assembly is done!

Set-up

According to designer Jeremy Chinn the CG range is 5”-5.75” from the leading edge of

the wing measured at the root. Jeremy says the ideal 3D CG is at 5.25”. Below are his

recommended rates and exponential preferences. You may wish to start with a bit more

exponential than this as the control surfaces are extremely effective!

High Rates Low Rates Expo

Elevator 50 degrees 25 degrees 20-40%

Rudder 50-60 degrees 30 degrees 30-50%

Ailerons 50 degrees 30 degrees 20-40%

Thanks again for your purchase of the Extreme Flight RC Yak-55SP Profile ARF. We

hope this airframe provides you with all of the 3D thrills you are looking for and that you

have as much fun flying yours as we have had with ours.

See ya at the flying field!

20

Loading...

Loading...