VANQUISH MKII

ELECTRIC ARF

Instruction Manual

©Copyright 2010 EXTREME F LIGHT RC, Ltd.

Thank you for your purchase of the Extreme Flight RC Vanquish MKII Electric ARF. The

original Vanquish released in 2007 was designed to provide maximum performance and fun in a

great looking, lightweight, fully aerobatic park flyer while using an inexpensive and efficient

brushless outrunner motor and speed controller and a single high discharge 4S1P Lithium

Polymer battery. The Vanquish MKII features several notable improvements over the original,

providing even better flight performance and an improved feature set. Among these improved

features are an airfoiled tail group, allowing for even better tracking, a lightweight airfoiled

carbon fiber landing gear and carbon fiber tailwheel assembly. In addition the wing has been

raised and the stab lowered to further reduce coupling and the rudder servo has been moved to

the rear of the aircraft to provide a short direct linkage for rudder actuation.

Great care was taken to design a light weight yet robust airframe. Expert engineering and

modern laser cutting methods in conjunction with a carbon fiber wing tube and composite

control horns keep weight to a minimum. Unique features such as the 2 piece plug in wings, premounted canopy and spring loaded canopy/hatch latch make for quick easy assembly and

instantaneous access to the interior of the plane and battery tray. The Vanquish MKII can truly

be assembled in an evening-buy it one day, fly it the next!

As with all Extreme Flight RC airplanes, the proof is in the flying! The Vanquish MKII flies

precision aerobatics remarkably well and allows you to practice the AMA pattern or FAI F3A

sequence almost anywhere. The long tail moment makes for a plane that tracks like a 2 meter

pattern ship and the lightweight wings minimize over rotation in snaps. On a calm day you’ll be

amazed at how well this thing flies the sequences.

Of course the Vanquish MKII will perform most all of the common 3D moves, but its true

calling is precision aerobatics.

Sport flyers fear not! With reduced rates the Vanquish MKII is a very easy plane to fly. Its

super light wing loading allows it to land at a walk. It will instill confidence and allow you to

improve your flying skills. When you’re ready for more advanced aerobatics, flip the dual rate

switch and hang on!

As with any high performance aerobatic aircraft, great care must be taken to avoid excess

speed. Excess speed will lead to control surface flutter and quite possibly the complete

destruction of your aircraft. Don’t let this happen to you! Always have the motor at idle when

the airplane is pointed down and reserve full throttle for vertical climbs. Make sure you have

adequate mechanical advantage in your control linkage set-up. If you are unsure about this, have

a more experienced flyer look over your set-up before flying. Extreme Flight RC, Ltd. in no way

warranties its aircraft against flutter. As with all of our planes, we put the Vanquish through a

rigorous flight testing regime and have not experienced any control surface flutter. It is your

responsibility to ensure the airworthiness of your aircraft.

The Vanquish MKII was designed around the Torque 2814T/820 Brushless Outrunner motor

and Airboss Elite 45 Amp ESC with SBEC. This is the best choice for powering the Vanquish

MKII, providing plenty of power for any maneuver imaginable. Other outrunner motors in this

class will work as well but may require slight modification to the motor mount.

The Vanquish MKII is very easy to assemble. Take a few minutes to read this manual before

beginning assembly to get familiar with the process.

Tips for Success-Please read before beginning assembly!!!

1. Read the instruction manual thoroughly before starting assembly.

2. We are very pleased with the level of craftsmanship exhibited by the workers in our

factory. However, these are mass produced models. As with any ARF, take a few

minutes to go over the model and add CA to high stress areas or any joints that appe ar to

need more glue. Specific areas to pay attention to are servo mounts, landing gear

mounting plate, firewall to fuselage side joint, wing root rib and motor box joints. A few

minutes and a few drops of CA will help to insure the longevity of your model.

3. Make s ure your prop and spi nner are balanced ! These aircraft perfor m as well as the y do

because they are built light. Excess vibration caused by unbalanced components can

cause damage to the airframe.

4. Buy a Watt meter! For less than the cost of a single battery pack you can purchase one of

these. This will save you a lot of time, money and frustration and p rovide you with a lot

of valuable information about your set up. One battery pack saved is worth this

investment!

5. Observe the C rating of your batteries. If your battery is rated at 2100 mah and 20C

continuous discharge rate then you can safely pull 42000 mah or 42 Amps from it (2100

x 20= 42000 mah=42 Amps). Use a watt meter between your battery and ESC to

determine the number of Amps you are drawing as well as the number of Watts you are

generating. I have found it is best for battery longevity if your maximum amp draw at

wide open throttle is in between the continuous rating and the burst rating of the battery.

Prop your airplane accordingly.

6. We have done a lot of experimenting with various props. Using the Torque 2814T/820 on

4S we like the APC 12x6E. Remember to test each new prop size with a Watt meter

attached to the system to be sure you are not overworking any of the components.

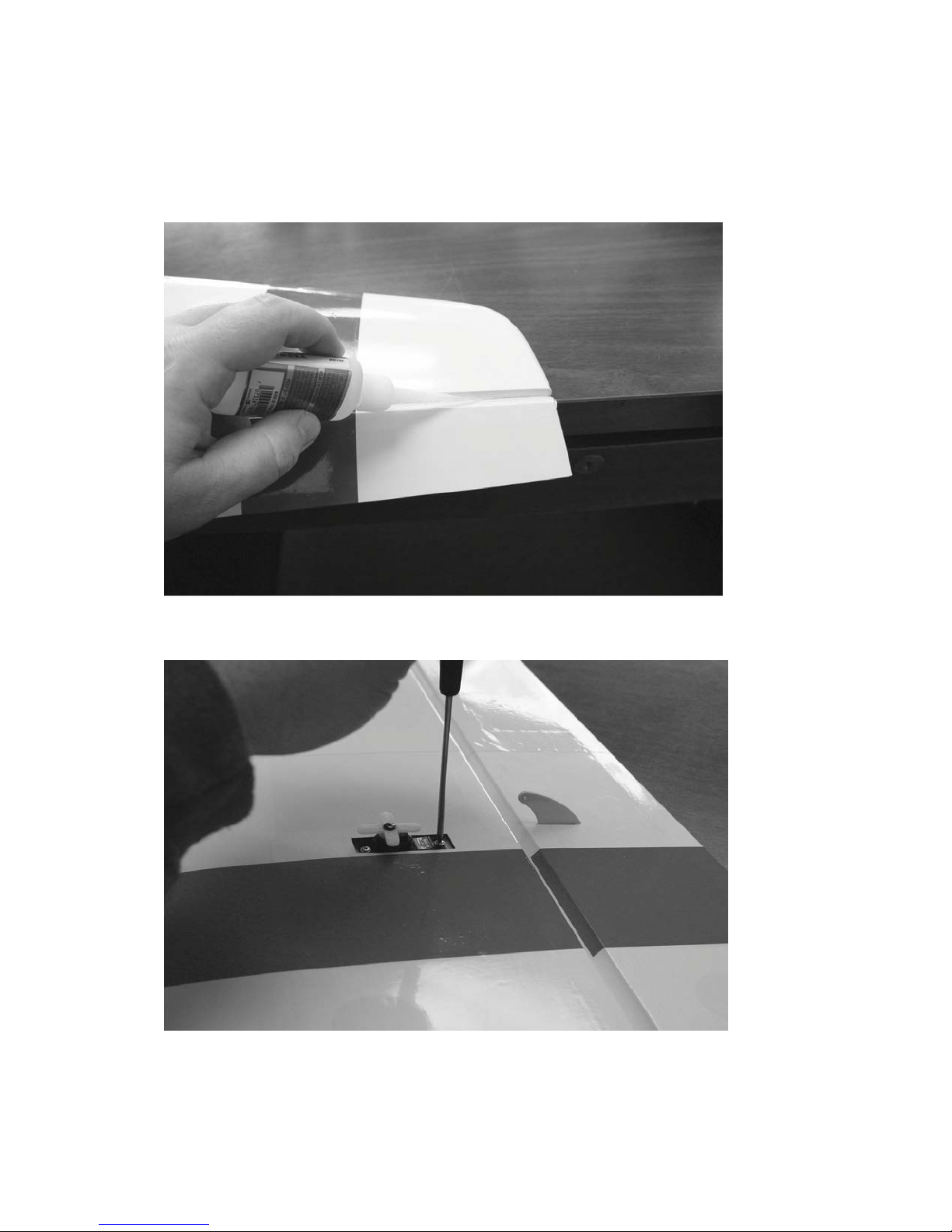

7. Decals- clean your airplane with glass cleaner and a paper towel before st arting to apply

the decals. Mist the area where the decal will be applied with glass cleaner or water

mixed with a little bit of soap. Use scissors to remove the de cal from the s heet. For bes t

results cut as clos e to the edges of the decal as possible. Posit ion the decal in place and

use a credit card or rubber squeegee to push the excess liquid from under the decal and

allow to dry. You may need to secure the edges of the decal with masking tape to

prevent them from rolling up until the solution has dried and evaporated.

PLEASE NOTE-The assembly process for the Vanquish MKII is

virtually identical to that of the original Vanquish. Most of the

pictures in this manual are of the original airframe. Anywhere this

process deviates from the original assembly process photos of the

new assembly method will be provided.

Wing assembly

1. Locate a wing panel. Check to see that all hinges are centered between the wing and

aileron. Hold the aileron fully deflected and apply a drop of thin CA to each hinge.

Flip the wing over and repeat.

2. Use a #11 hobby blade to remove the covering over the servo bay. Install the aileron

servo using the manufacturer supplied mounting screws. You will need to attach a 6

inch extension to the servo lead. Route the servo lead out of the root of the wing.

3. Locate the composite aileron control horn, aileron pushrod, EZ connector, ball link, 2mm

bolt, nut and washer. Remove the covering over the mounting hole for the control horn with

your #11 blade. Scuff the part of the control horn that will glue into the aileron slot with fine

sandpaper. Glue the control horn in place with medium CA. Electronically center your

servo. Thread the ball link onto the pushrod and secure to the glass horn with the 2mm

screw, nut and washer as shown in the photo. Connect pushrod to servo arm with the EZconnector.

4. Repeat this procedure for the other wing.

That’s it! You are done with the wings!

Fuselage Assembly

5. Let’s mount the landing gear first. Locate the carbon fiber landing gear, (4) 3mm machine

screws, (2) park flyer axles, (2) nylon insert lock nuts, (2) wheel collars, (2) wheel pants, (2)

wheels

6. Place the wheel on the axle followed by the wheel collar. Slide the wheel pant over the axle

with the retention ring inside the wheel pant. This ring will keep the wheel pant in place with

friction. Insert the threaded portion of the axle into the hole in the end of the landing gear leg

and secure with the nylon insert locknut. A dab of silicon glue between the pant and gear leg

will keep the pants secure but allow them to move in the event of a rough landing or crash,

minimizing damage.

7. Insert the gear legs through the slots and retain with the (4) 3mm bolts and washers. Make

sure to put a drop of blue Loctite on the bolt threads. The gear legs should sweep toward the rear

of the plane.

8. Attach the radial mount to your motor and install the bolt on prop adapter. Use the included

3mm socket head cap screws and washers to install the motor onto the front of the motor box.

Make sure to apply CA to all joints on both sides of the F1 former as well as all joints in the

motor box.

9. Open the horizontal stabilizer mounting slot in the rear of the fuselage with a sharp hobby

knife (Please note-The elevator slot for the MKII is shaped like the stabilizer airfoil).

10. Insert the elevator into the slot in the rear fuselage side. Insert the carbon fiber wing tube

into the fiberglass sleeve in the fuselage and slide both wings onto the tube. Make sure the

root rib of the wing is flush against fuselage.

11. Insert the horizontal stabilizer into its slot. Compare the horizontal stab to the wing and

insure that they are parallel. Trim or shim the slot as needed to insure proper alignment.

When satisfied with the alignment, glue the horizontal stab in place with CA.

12. Slide the elevator onto the hinges in the horizontal stab and glue in place with thin

. CA. Make sure the elevator is fully deflected when you apply the CA to insure

maximum travel is achievable.

13. Slide the rudder onto the hinges in the vertical stabilizer and secure with thin CA.

14. Locate the carbon fiber tailwheel assembly. Use the 2 supplied wood screws to secure it

to the bottom rear of the fuselage. Use the other wood screw to secure the tiller arm to

the bottom of the fuselage.

15. Locate the elevator control horn. Use a sharp hobby knife to remove the covering from

the elevator horn slot.

16. Glue the elevator horn in place with medium CA or epoxy. Make sure to scuff the

surface of the control horn before gluing.

17. Use a #11 blade to remove the covering from the elevator and rudder servo slots. Soak

the mounting area with thin CA. Install the servos using the manufacturer supplied

mounting hardware. You will need to attach a 24 inch servo extension to each servo

before installation. From the pilot's perspective, the elevator servo mounts in the left

rear side of the fuselage while the rudder servo mounts in the right rear side.

18. Place an ez-connector on the servo arm. Locate the elevator pushrod and thread a ball

link onto the pushrod. Electronically center the servo. Use the 2mm bolt and nut to

connect the ball link end of the pushrod to the elevator control horn. Tighten the set

screw in the ez connector to clamp down on the pushrod, while making sure the

elevator is in the neutral position. Make sure to file a flat spot on the pushrod to

allow the set screw to seat properly and maintain a firm grip on the pushrod wire.

IT IS IMPERATIVE THAT YOU USE A METAL GEAR SERVO FOR THE

ELEVATOR!!!!!!

We highly recommend the Hitec HS-65MG. If you plan to fly

precision aerobatics only, I recommend using the short servo arm to allow for

maximum servo resolution and a very positive and accurate elevator actuation.

19. Use a #11 blade to remove the covering from the rudder control horn slot near the bottom

of the rudder. Locate the composite control horn for the rudder. Scuff the control horn to

remove the glossy finish and glue into place in the slot in the rudder. Assemble the pushrod

assembly and install just as you have for the ailerons and elevator

20. Mount the ESC with Velcro or nylon cable ties on the bottom of the motor box. Insert the

gold bullet connectors from the motor into the female connectors on the ESC. Secure the

wires with a nylon cable tie to prevent them from touching the rotating case of the motor.

21. Place the canopy/hatch in place on the fuselage and make sure it is positioned properly.

Slide the cowling into place. F1 former. Make sure the prop shaft is centered in the. You

may want to install the spinner at this time to insure that the cowl is properly positioned. We

recommend using the 52mm Extreme Flight spinner for the Vanquish View the cowl from

the front, top and sides and when satisfied with the position, secure the cowl with masking

tape. There should be 1/16” space between the spinner backplate and front of the cowl. Use

a small drill bit mounted in a pin vise to drill through the cowl and into the mounting tabs.

You can view through the openings in the front of the cowl to make sure you are drilling into

the center of the tab. Use the 4 small mounting screws with large heads to secure the cowl.

22. Install the receiver at the rear of the battery tray using Velcro. Use Velcro to secure

the battery to the battery tray and use a Velcro strap around the battery.

23. Use the supplied nylon bolts to secure the wings to the fuselage. They insert

from inside the fuselage through the hole behind the wing tube and into the blind nut in

the root rib of the wing. Tighten until snug.

24. The battery should mount right in front of the receiver. Adjust the location of the

battery to achieve proper CG.

This concludes the assembly of the Vanquish MKII.

Radio Set-up and flight tips.

CG range for the Vanquish is from 4.50”- 5.00” from the leading edge of the wing measured

at the wing root. Correct CG should be easy to achieve by moving the battery along the

length of the battery tray. Adjust to fit your flying style.

Control surface recommendations are as follows:

Elevator- 10 degrees low rates, 45+ degrees high rates.

Rudder- 20 degrees low rates, 45+ degrees high rates.

Aileron- 15 degrees low rates, 35+ degrees high rates.

Use exponential function to achieve the best “feel” for your particular flying style. I highly

recommend that you take the time to set up rates for precision flying and separate rates for

3D. The Vanquish is capable of flying very precise maneuvers, and proper rates and CG will

allow you to experience this to the fullest extent. Trying to fly precision aerobatics with 3D

rates is an exercise in futility. Spend some time dialing in and trimming your plane and you

will be rewarded with a great flying experience.

Thanks again for your business!

See you at the flying field!

Loading...

Loading...