84” Turbo

1

Bushmaster

Copyright 2016 Extreme Flight

Please take a few moments to read this instruction manual before

2

beginning assembly. We have outlined a fast, clear and easy method

to assemble this aircraft and familiarizing yourself with this process

will aid in a quick, easy build.

Please read the following paragraph before beginning assembly of

your aircraft!

THIS IS NOT A TOY! Serious injury, destruction of property, or even

death may result from the misuse of this product. Extreme Flight RC

is providing you, the consumer with a very high quality model aircraft

component kit, from which you, the consumer, will assemble a flying

model. It is beyond our control to monitor the finished aircraft you

produce. Extreme Flight RC will in no way accept or assume

responsibility or liability for damages resulting from the use of this

user assembled product. This aircraft should be flown in accordance

to the AMA safety code. It is highly recommended that you join the

Academy of Model Aeronautics in order to be properly insured, and to

operate your model at AMA sanctioned flying fields only. If you are

not willing to accept ALL liability for the use of this product, please

return it to the place of purchase immediately.

Extreme Flight RC guarantees this kit to be free of defects in materials

and workmanship for a period of 30 DAYS from the date of purchase.

All warranty claims must be accompanied by the original dated

receipt. This warranty is extended to the original purchaser of the

aircraft kit only.

Extreme Flight RC in no way warranties its aircraft against flutter. We

have put these aircraft through the most grueling flight tests

imaginable and have not experienced any control surface flutter.

Proper servo selection and linkage set-up is absolutely essential.

Inadequate servos or improper linkage set up may result in flutter and

possibly the complete destruction of your aircraft. If you are not

experienced in this type of linkage set-up or have questions regarding

servo choices, please contact us at info@extremeflightrc.com or 770887-1794. It is your responsibility to ensure the airworthiness of your

model.

Congratulations on your purchase of the Legacy Aviation Turbo

3

Bushmaster! Our intention with the Legacy line of aircraft is to

provide unique sport-scale aircraft that are easy to assemble and fun

to fly. These models possess gentle flight characteristics for the

novice-to-intermediate sport flyer while also being capable of

advanced aerobatics for the more experienced pilot.

The Turbo Bushmaster is loosely based on the full scale Turbo

Beaver. The Turbo Beaver is a well known and loved aircraft among

bush pilots capable of STOL takeoffs and landings. The Turbo

Bushmaster is capable of these same maneuvers and so much more!

Big and light, the Bushmaster is as gentle and forgiving as any trainer

we've ever flown, making for a very enjoyable and relaxing flying

experience. Flip the rate switches and the model transforms into an

extremely capable aerobat! Experiment with the various flap mixes

that are possible and you open up a whole new envelope of high

lift/high drag maneuvers.

Let’s begin!

4

Wing Assembly

Wing Hardware:

1. Locate the 2 wing panels as well as the composite aileron and

5

flap control horns. Use sandpaper to scuff the portion of the

control horn that will be glued into the surface. For a more

finished look you may wish to paint your control horns before

installation. We used a black Sharpie to perform this task with

great results. Do not paint the portion of the control horn that

will glue into the control surface!

2. Using a soldering iron or a SHARP hobby knife, remove the

6

covering from the slots for the aileron and flap horns.

3. Dry fit the horns into their respective slots and trim any debris

from the slot until the control horn seats properly against the

control surface.

4. Apply 30-minute epoxy to the aileron and flap control horn slots

and to the scuffed area of the control horns. It may be helpful to

use a zip tie to push the epoxy into the slots.

5. Install the control horns into their respective slots and wipe

7

away any excess epoxy with a paper towel or cloth soaked with

denatured alcohol.

6. In these next steps we will install the hinges. Please take a few

moments to familiarize yourself with this process if you have not

installed hinge points before.

There are several ways to do this and several adhesives you can

use. We will describe the way that we do it, as this method has

proven itself over many years of model building. If you are new

to this type of hinging process, then I recommend that you

install a single hinge first just to acquaint yourself with this

method

Before starting you will need to gather a few items to aid you as

you proceed.

A. 30 Minute Epoxy

B. A short length of pushrod or small dowel.

C. A roll of paper towels

D. Denatured alcohol or Acetone

E. Hobby Knife

F. Silicon lubricant

7. Locate a wing panel and separate the control surfaces from the

8

main wing and remove the hinges.

8. Mix up a generous batch of epoxy and use a piece of pushrod or

dowel to apply the epoxy to the hinge hole.

9. Apply epoxy to the barbed section of the hinge on one side and

insert it into the hole until the center of the hinge is centered on the

hinge line. Using a paper towel soaked with acetone or denatured

alcohol wipe away any epoxy that has been squeezed out of the

hole.

10. Make sure the hinge can move freely and that the pin is aligned

9

properly before the epoxy sets! When you are satisfied with the

results set the surface aside so that the epoxy will pool around the

rear of the hinge. When you are comfortable with this process you

should be able to do one side of a surface per batch of epoxy.

Repeat the process to attach the surfaces to each wing. There

should be as little gap as possible while still allowing maximum

movement of the control surface.

11. As a final step before setting the wing aside to dry, do a final

cleaning of the hinge knuckles with a paper towel soaked with

denatured alcohol or acetone to remove any epoxy residue. If you

find any of the hinges are stiff after drying, apply a drop of acetone

to each hinge with a Q-tip and move the surface back and forth

several times to loosen it up. As a final step I typically apply a

couple drops of silicone lubricant to each hinge. This is available

at most home improvement and hardware stores. DO NOT USE A

PETROLEUM BASED LUBRICANT AS IT WILL DEGRADE THE

INTEGRITY OF THE NYLON HINGE!

12. You will need to attach a 12" servo extension to your aileron

10

servo to reach the wing root. The flap servo wire will reach the root

with no extension attached. Secure the extension to the servo lead

with heat shrink tubing or a wire keep.

13. Use the manufacturer supplied mounting hardware to install

the servos with the output shaft toward the LEADING EDGE of

the wing. Electronically center the servo and install 1.25" servo

arms onto the servo spline. The servo arms should be parallel

to the hinge line when centered. It is very important that you

use the same length servo arms for both flap and aileron

servos .

14. Thread the supplied ball links onto each end of the 4 pushrods.

11

Placing the pushrod into your electric drill and using it to thread

the pushrod into the ball link makes this task much easier. Be very

careful not to screw the pushrod in too far and damage the ball

link!

15. Use the supplied 2mm bolts, washers and nuts to affix the

pushrod to the servo arm and control horn. It is imperative to

attach the ball link to the bottom of the servo arm to achieve full

deflection.

16. Locate the wing fences and trail fit on the wing. Some

12

sanding may be required for best fit. While the fences are

temporarily installed on the wing use 2 pieces of painters tape to

mark their location on each side of the fence. This will aid in

alignment and prevent excess glue from getting on the covering.

17. Use 30 min epoxy to attach the fences. Wipe away any excess

13

epoxy with a paper towel soaked in acetone. Be sure to remove

the tape before the epoxy fully cures. Repeat this process for the

other wing panel.

Main Landing Gear Assembly and Installation

14

Tools Required for this step

12mm Wrench

8mm Wrench or Nut Driver

2.5mm Hex Driver

1.5mm Hex Driver

Thread locker

Painters tape

Sharp hobby knife

Welders adhesive or Goop

18. Locate the landing gear fairings and black rubber tubing. You

will need to slice the tubing lengthwise on one side. Use a sharp

hobby knife and starting at one end gently cut through only one

wall of the tubing being careful not to cut through the second side.

Once the tubing has been cut place it around the top of the landing

gear faring and secure it with CA

19. Locate the carbon landing gear, axles, wheels and fasteners

15

from the landing gear hardware package.

20. Attach the landing gear to the fuselage using the supplied

16

bolts and washers. The landing gear has a slight airfoil, make

sure that the thicker part of the gear is facing the nose of the

airframe.

21. Slide the gear fairings into place against the bottom of the

17

fuselage. Use a piece of painters to mark their location.

Remove the fairing and apply a thick bead of Goop to the carbon

gear just above the tape line. Slide the fairing back into place

and secure with tape until dry.

22. Locate the 2 axles, 2 locking nuts, 2 wheels, 4 wheel collars

18

and 2 washers and mount the wheels as shown.

Horizontal Stab and Elevator Assembly

19

Stab/elevator Hardware kit

23. Locate the horizontal stabilizer/elevator assembly. Turn it upside

20

down on the building table and remove the covering from the control

horn slot on the RIGHT side (This will be the Left side when installed).

Glue the control horn in place with 30 minute epoxy.

24. Insert the elevator section Upside-down and backwards into

the Stab/Elevator slot

21

25. Now insert the horizontal stabilizer and check that the hinge

22

holes match the holes in the elevator

26. Check that the horizontal stabilizer is centered and properly

23

aligned with the main wings. It is a good idea to use a tape

measure and triple check all measurements before gluing the

Stabilizer in place. Measure from a fixed point on the wings to the

tip of the Stabilizer on both sides. Adjust the stab until both sides

are the same. Take your time with this step as proper alignment is

critical.

27. Once satisfied with the alignment, glue the horizontal stab in

24

place by applying CA along the joint between the stab and the

fuse. Make sure to apply CA to the top and bottom of the stab.

28. Once the horizontal stab is glued in place, use the same

technique to install the elevator hinges and control horn that we

used for the aileron and flaps.

25

29. Locate the fences for the horizontal stab and attach them

26

with mediu

m CA. Make sure to confirm alignment with the

vertical stab.

30. Locate the lower keel. Note that the small extension piece

27

(top piece in picture) is to be used when building the airframe for

float flying only as it will occupy the space for the tailwheel.

31. Place the fuselage upside-down in a stand (the Extreme

Flight 4-in-1 stand works great!). Locate and remove the

covering from the 3 holes that the lower keel locks into.

32. Dry fit the lower keel in position and when happy with the fit,

28

use 30-minute epoxy to attach it to the fuselage. Use tape to

secure while drying. Be sure to check for proper alignment!

33. Attach an 18” servo extension to your elevator servo and

using the manufacturer supplied hardware install it with the

output shaft towards the rear of the fuselage. Assemble the

pushrod and install as shown in the picture.

Tailwheel Assembly

29

34. Gather the tools and parts required for this step

A. 1.5 mm Hex Driver

B. Phillips head screwdriver

C. Thread locker

D. Tail wheel

E. Tail wheel axle

F. Tail wheel Mounting Bracket

G. Wheel Collar

H. Tiller arm

35. Attach the wheel to the Axle with the supplied wheel collar.

30

NOTE: It is a good idea to file a small flat section on the axle for

the wheel collar set screw to mate up to.

36. Next install the carbon fiber mounting bracket and tiller arm.

31

Make sure to align the screw in the tiller arm with the flat spot on

the tailwheel shaft and use thread lock!

Mounting the Tailwheel Assembly

32

For this step you will need

A. Assembled Tailwheel

B. Small Phillips head screwdriver

C. Thin CA

D. 3 wood screws

E. 5/64” Drill bit and Drill

F. Tailwheel pushrod, Ball link and supplied hardware (not

pictured)

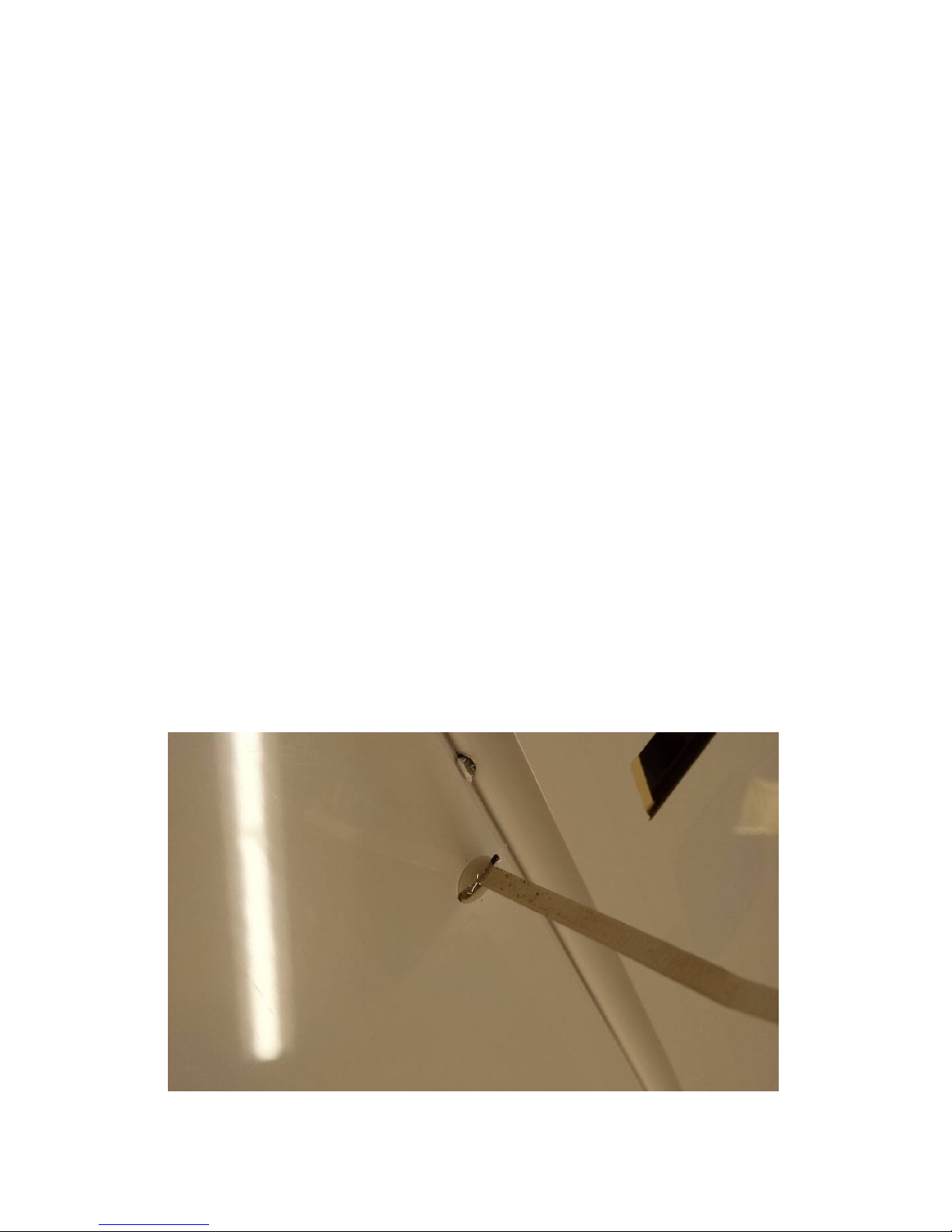

37. Locate the Tailwheel pushrod (29.5” and threaded on one

33

side) and insert it through the hole on the pilot’s upper left side

and into the guide tube, threaded end first.

38. Push the control rod carefully until you feel resistance,

34

locate the area where the control rod is trying to poke thru the

covering and use a sharp hobby knife or soldering iron to

remove the covering from this location. It is easiest to do this

with the fuselage upside down in a stand.

39. Place the tail wheel assembly up against the lower keel and

center it on the bottom of the fuselage . When you are happy

with the placement, use the holes in the tailwheel bracket as a

guide and drill three 5/64” holes. Add a drop of CA to each hole

and then attach the Tailwheel using the supplied wood screws.

Now would be a good time to thread the ball link onto the control

rod and attach it to the center hole of the tiller arm.

Vertical Stab/ Rudder Assembly

35

Rudder hardware kit

o To mount the vertical stab and rudder you will need to locate the

36

following:

A. Vertical stab and rudder assembly

B. Rear vertical stab wedge

C. Carbon fiber vertical stab tube

D. Rudder control horns

E. 4mm cap head screw

F. 30 min epoxy

G. 3mm Hex driver

T

40. Hinge the rudder using the same technique as the flaps and

37

ailerons.

41. Once the epoxy on the rudder hinges has cured, test fit the

rudder control horns. Make sure to scuff the bases of the control

horns. It may be necessary to trim the base of one of the control

horns to ensure that both horns fit properly into the control horn slot.

42. When satisfied with the fit of the control horns, mix up a small

38

batch of epoxy and install the rudder control horns.

43. Insert the carbon fiber vertical stab tube into the vertical stab/

rudder assembly. Then use your hobby knife or soldering iron to

remove the covering from the right side of the vertical stab to reveal

39

the mounting hole.

44. Slide the completed assembly into the vertical stab tube

socket and secure the stab to the fuselage with a 4mm cap head

screw. Don’t forget to use thread lock!

45. Deflect the rudder to one side and install the vertical stab

40

wedge. Wick in a bit of CA to hold it in place.

46. Locate the servo you will be using for the rudder. Using the

41

manufacturer supplied hardware mount the servo in the space

provided on the battery tray and electronically center it. Note

that the output shaft of the servo is towards the rear of the

airframe.

47. Locate the EZ-connector and mount it on the innermost

hole on the pilots left side of the servo arm. Put a drop of thin

CA on the bottom nut to prevent it from backing out.

48. Slide the Tailwheel pushrod into the EZ connector, center

42

the tailwheel and tighten the cap screw. Make sure you use

thread lock!

49. Next install the pull-pull cables and ball links. It is easiest to

build the rear half (rudder side) of the cables and install them

onto the rudder control horn, thread the cables thru the tubes in

43

the rear of the fuselage and then build the front end of the

cables on the servo side. To assemble the pull-pull linkage

follow these steps:

1. Slide one of the aluminum crimps onto the braided wire.

Insert the wire through the hole in the brass fitting and insert the

end of the wire back through the crimp. Loop the wire around

the crimp and insert again into the crimp. Carefully use a pair

of side cutters to crimp the wire in several places.

50. Follow this same method to assemble the linkages in the

forward part of the system that will attach to the servo arm. The

cables should cross in the fuselage for proper function. Adjust

the cables so that there is no slack but do not make them guitar

44

string tight as doing so can overstress the servo.

Windscreen Installation

51. Next we'll install the windscreen. You have the choice of gluing

the windscreen into place with a specialty glue like Pacer Formula 560

canopy glue or sewing it on with screws (not included). Also, a pair

45

of Lexan car body scissors will make this step much easier!

52. Locate the windscreen. Crudely trim it so that you can place it

into position.

53. Use blue tape to mark a cut line with the tape being placed inside

the line where you will trim the canopy. This will help to prevent the

canopy edges from splitting while being cut.

54. Test fit and trim as needed. Attach canopy with a thick bead of

canopy glue and tape in place with painters tape and allow to dry

overnight. Alternately you could sew the canopy in place with

multiple small screws. Photos of both attachment methods are

shown.

46

Motor and Electronic Speed Control Installation

47

55. Locate the following and prepare the motor for mounting

A. Motor (Torque 4016/500)

B. ESC (Airboss 80A)

C. Supplied Torque hardware kit with X mount and Bolt-on Prop

Adapter

D. 2.5mm Hex Driver

E. 3mm Hex driver

F. Small Phillips head screwdriver

G. Thread lock

56. Secure the prop adapter to the motor with supplied socket head

48

cap bolts using blue thread lock on each bolt.

57. Next slide the provided collar over the motor shaft and

49

secure in place with the set screw. Place a small drop of thread

lock on the threads of the set screw to prevent it from backing

out.

58. Attach the Supplied X mount with the 4 Philips head screws.

Again use a drop of thread lock on each screw.

59. Locate the 4mm black cap bolts and washers to attach the

50

assembled motor to the firewall.

60. Using a drop of thread lock on each bolt attach the motor to

the firewall.

61. Using a couple Zip ties and a scrap piece of foam mount the

51

ESC to the bottom of the motor box.

62. Connect the wires of the ESC and the motor and secure

them to the motor box with nylon cable ties.

63. Attach a 12” servo wire extension and a 8-10” battery

extension to the ESC and route them into the fuselage. There are

2 locations in the fuselage for mounting external ESC and BEC

52

switches. If you are going to use a switch go ahead and mount it

now.

Mounting the Cowl

53

64. Locate the following:

A. Cowl

B. Exhaust stacks

C. Contact adhesive or Epoxy

D. Sandpaper

E. Painters tape

F. Drill bit

G. Felt tip pen

65. Scuff the bottom of the exhaust stacks and the indentions

54

on the cowl where they will mount.

66. Using contact adhesive or epoxy glue the exhaust stacks to

55

the cowling and hold them in place with painter’s tape until the

glue is dry.

67. When the glue for the exhaust stacks is fully cured, tear 4

56

short pieces of painter’s tape and place each piece of tape on

the side of the fuselage so that each piece corresponds with one

of the 4 cowl mounting tabs. Use a felt tipped pen to mark the

location of the center of each mounting tab.

68. Slide the Cowl into position. Install the spinner onto the

motor shaft for reference and once satisfied with the cowl

position, roll the tape back into place and secure the cowl. Use a

1/16” drill bit to drill a hole at the location of the dot on each

piece of tape.

69. Remove the tape and cowl and add a drop of CA to each

57

hole. Mount the cowl with the 4 of the small wood screws

included with the kit.

70. Use a sharp hobby knife or soldering iron to remove the

58

covering over the air escape holes in the bottom of the

fuselage.

71. Mount your receiver as shown and tidy up the servo

extensions. Pictured mounted to the battery tray are 2 multiplug extensions to make plugging in your aileron/flap servo

leads easier. Affix a strip of Velcro to the battery tray and retain

your battery with a Velcro strap.

72. Install your prop and spinner.

59

73. Insert the carbon wing tube into the sleeve in the fuselage.

60

Slide the wings into position taking care to insert the servo

extensions into the fuselage. Secure the wings be inserting the

nylon wing bolts into the holes in the fuselage and threading

them into the blind nut in the wing root.

74. Attach the struts using the supplied 3mm cap head screws .

You may find it easiest to start with the wing attachment first.

This concludes the assembly process for the Turbo Bushmaster.

61

Preparing for flight!

With the wing and struts attached, place your battery on the

battery tray and pick up the Bushmaster by the wing tube. Shift

the battery until the plane balances on the tube. This is a safe

location to begin test flying. Adjust CG to your liking, then mark

the tray to know where to position the battery each flight.

Typically the plane balances with the battery centered on the

tray just forward of the wing tube as shown in the photo for step

number 71.

It is recommend you first fly the model in standard configuration

to get used to its flight characteristics before beginning to

experiment with flaps. When deploying flaps you will need to

add an elevator mix that compensates for the flaps and provides

a few degrees of down elevator. A comprehensive and detailed

setup document written by designer Cody Wojcik will cover

various mixes to experiment with and will be posted on the

Extreme Flight website.

Thanks so much for your business and we hope you enjoy flying

your Turbo Bushmaster as much as we have!

Loading...

Loading...