Extreme Flight focke-wulf FW-190A Assembly Manual

1

Focke-Wulf

FW-190a

Copyright 2016 Extreme Flight RC

2

Congratulations on your purchase of the AcesHigh Focke-Wulf 190A!

The FW-190 was a backbone of the German Luftwaffe, BMW 801 twin-row radial powered, multi-role fighter. A favorite

of many, it was effectively flown by some of the most successful fighter aces. It wasn’t until the arrival of the Spitfire

that the 190 was challenged for air superiority.

AcesHigh have worked hard to create a model that pays great tribute to the performance of the real thing. As part of the

Extreme Flight family, we have combined the highest level of aircraft manufacture with new technology, and the results

are fantastic. Months of research and effort to create a realistic result without the typical weight problems that go along

with detail. In making the model look real, our objective was to recreate the full size plane as it was in operation. Those

aircraft worked hard, and got very dirty in the process. The details on the scheme are as if the full scale aircraft was

wheeled into a photo booth... there are no pin-stripe panel lines and dots for rivets, because panels aren’t pin-stripes,

and rivets were rivets. This isn’t the “brand new” looking warbird that is typically seen… congratulations on owning the

first ARF that comes dirty out of the box!

We hope that you enjoy the build, love the flying, and appreciate just sitting and looking at it when she’s just sitting

there… waiting for the next sortie.

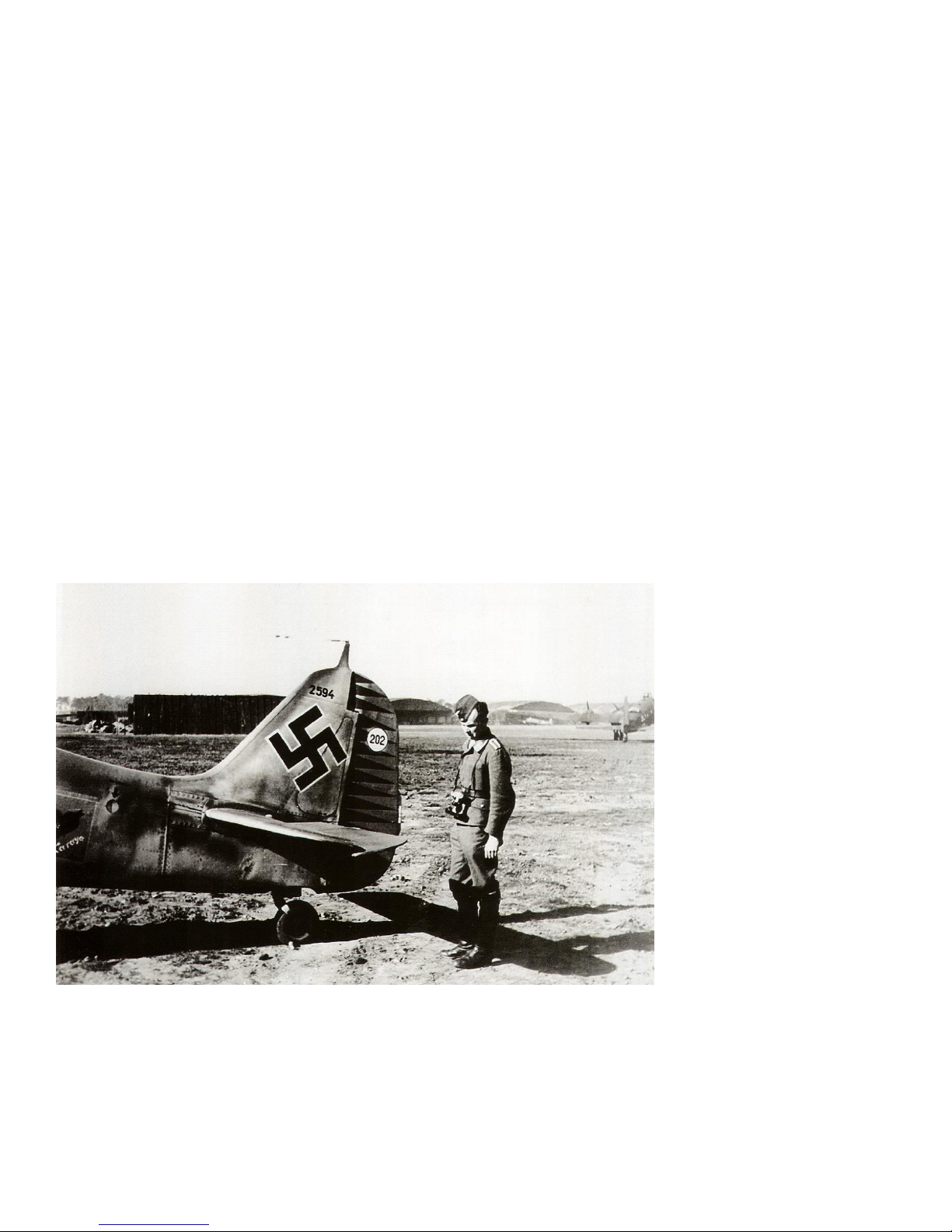

“Red Tulip” – Hermann Graf

When you’re one of the best fighter aces of all time, why not brightly paint your cowling and rudder to something that

can’t be missed? This scheme is depicting the fighter flown by Hermann Graf. Serving on both the eastern and western

front, Graf was the first ace to shoot down more than 200 adversaries; 212 victories and 830 combat missions.

Seen in this photo with 202

victories, Graf was awarded the

highest military decoration at

the time, the Knights Cross of

the Iron Cross with Oak Leaves,

Swords and Diamonds.

An instructor of other aces, an

emblem of his fighter group can

be seen on the right hand side

of the plane; eagle teaching

younger eagles. The emblem on

the left hand side made up of

previous flight groups, the

Karaya-Staffel emblem. The rest

of the markings feature on

many of Hermann’s aircraft.

Research was challenging as Hermann flew more than one FW190, as well as a number of Bf109’s. His technique was

based around getting very close to his prey before firing. He got so close that he was often firing through debris. So

while he was not shot down, he went through a number of aircraft. The recreation of the details on this scheme were

from singling out this exact airplane, and recreating it as closely as possible including the actual reproduction of the

seemingly random camouflage pattern.

3

“Black Eight” - Willi Maximowitz

Willi was more into bombers. Credited with 27 victories, 15 of them were four engine bombers. At least one of these

bombers (though he claimed a second also) was taken by, get this, ramming it. April 20 1945, Willi failed to return from a

combat mission. If you use the airplane itself as a blunt instrument, going out with your boots on was probably a

foregone conclusion. Maximowitz was posthumously awarded the gold German Cross.

4

THIS IS NOT A TOY!

Serious injury, destruction of property, or even death may result from the misuse of this product. Extreme Flight RC is

providing you, the consumer, with a very high quality model aircraft component kit, from which you, the consumer, will

assemble a flying model. It is beyond our control to monitor the finished aircraft you produce. Extreme Flight RC will in

no way accept or assume responsibility or liability for damages resulting from the use of this user assembled product.

This aircraft should be flown in accordance with the AMA safety code. It is highly recommended that you join the

Academy of Model Aeronautics in order to be properly insured and operate your model at AMA sanctioned flying fields

only. If you are not willing to accept ALL liability for the use of this product, please return it to the place of purchase

immediately.

Extreme Flight RC, Ltd. guarantees this kit to be free of defects in materials and workmanship for a period of 30 DAYS

from the date of purchase. All warranty claims must be accompanied by the original dated receipt. This warranty is

extended to the original purchaser of the aircraft kit only. Extreme Flight RC in no way warranties its aircraft against

flutter. We have put these aircraft through the most grueling flight tests imaginable and have not experienced any

control surface flutter. Proper servo selection and linkage set-up is absolutely essential. Inadequate servos or improper

linkage set up may result in flutter and possibly the complete destruction of your aircraft. If you are not experienced in

this type of linkage setup or have questions regarding servo choices, please contact us at info@extremeflightrc.com or

770-887-1794. It is your responsibility to ensure the airworthiness of the model.

Tips for Success

Before starting assembly, take a few minutes to read the entire instruction manual to familiarize yourself with

the assembly process.

Use a fresh bottle of thin CA with a fine glue tip when attaching the CA hinges. This will ensure that the proper

amount of CA wicks into the hinge and surrounding balsa wood and creates a proper bond between the wood

and hinges.

Apply a couple drops of CA to high stress areas such as anti-rotation pins, landing gear mounts, servo trays and

motor box joints.

Take the time to properly balance and trim your aircraft and set up rates and exponential values. Your flying

experience will be greatly enhanced by doing this.

Note that this aircraft is printed using our printed covering technique. Your aircraft has been sealed with a matte

clearcoat. Due to climate changes, wrinkles may develop in the covering. These are easily removed with a little

bit of heat. Use your heat gun or a covering iron with a soft cotton iron sock, medium heat, and a gentle

technique. Just like regular covering, you can remove any wrinkles that develop over the life of your aircraft, but

go a little slower and be a bit more careful for best results. Your iron will feel a bit different gliding over this

sealed covering than regular. Be careful not to use too much heat as the covering may shrink too much and

begin to lift at the edges. Take your time, and the beautiful finish can be easily maintained.

Items Needed For Build

1. Masking tape

2. Thin and medium CA adhesive. We highly recommend Mercury M5T thin and M100XF

3. 30 minute epoxy

4. Blue Locktite thread locker

5. Small and medium Philips head screwdriver

6. Metric hex drivers

7. Needle nose pliers

8. Denatured Alcohol (methylated spirits) for epoxy clean up with paper towels

9. Plastic compatible adhesive/contact adhesive (shoe goo, seal-all work fine)

Required Equipment

1. Torque 4016T-500 brushless motor

2. Airboss Elite 80-Amp ESC

3. External BEC to power radio system

4. QTY 6 mini (~30g) servos (metal gears recommended)

5. 6S 3300 – 4400mah LiPo flight battery

6. 8 channel computer radio

7. 2x 12” servo extensions (ailerons)

8. 2x 6” servo extensions (flaps)

9. Recommended: one three-servo surface mount plug and one two-servo

surface mount plug sets for easy wing equipment connection.

10. Prop and spinner (scale three blade spinner for the FW190 available from

ExtremeFlight)

11. 2x 1” servo arms (ailerons)

12. 2x 3/4" – 1” servo arms (flaps)

13. 2x 3/4" arms (elevator and rudder)

5

6

LET’S BEGIN !!!

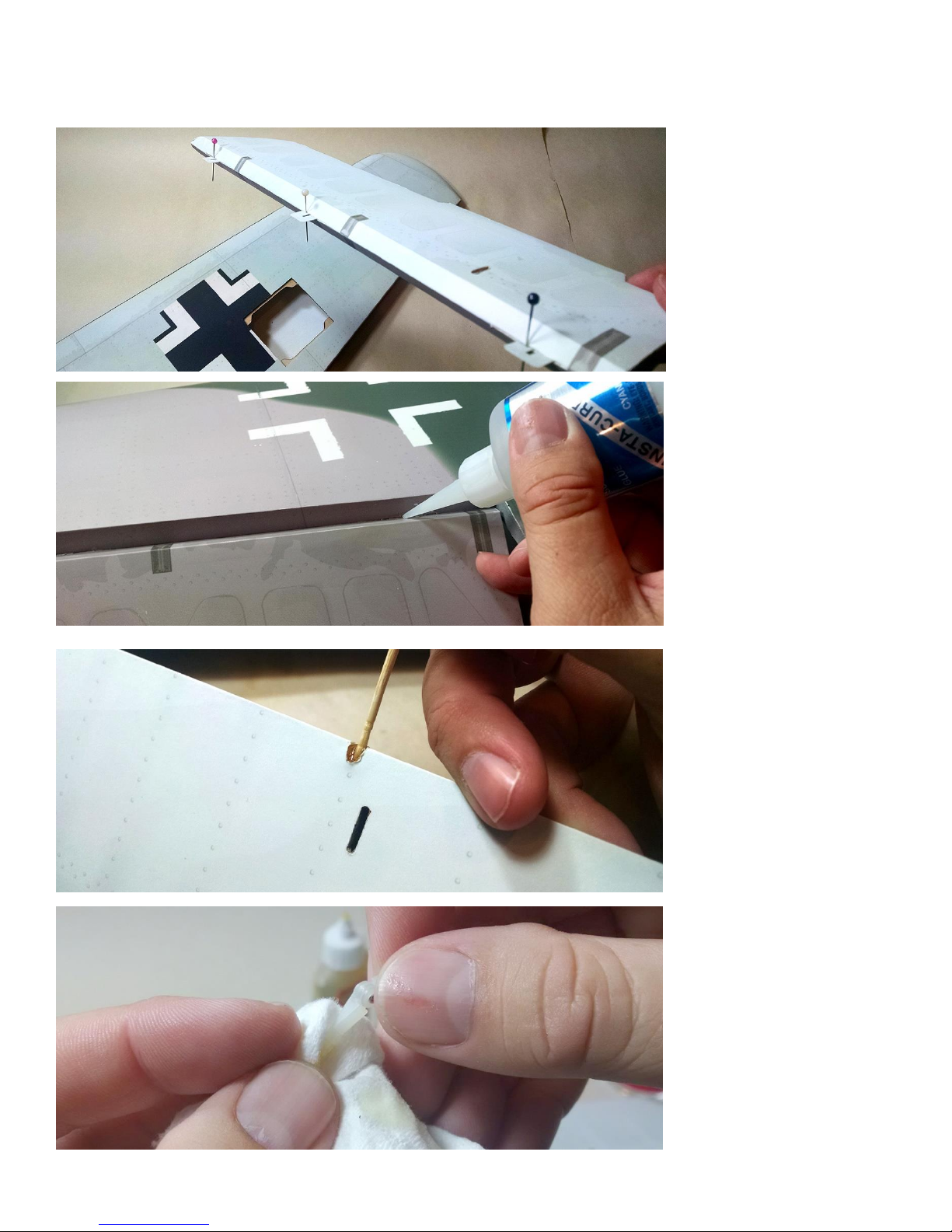

Hinging the aileron. Remove

the aileron, and place some

pins into the center of the

hinges. This will prevent the

hinges from pushing into only

one side of the control surface

of the wing.

Insert the aileron into the wing,

and remove the pins. Make

sure that the aileron is aligned

so that the end of it is in line

with the wing tip. Then holding

it deflected, add a couple of

drops of thin CA to each hinge.

Allow to cure, then flip the wing

over and apply a drop to each

hinge on the opposite side.

Remove the flap from the wing,

and remove the hinges. Mix

some epoxy and use a tool (like

a toothpick) to coat the inside

of the hinge holes with epoxy.

Note: We recommend doing

one side of the hinge at a time.

Gluing the hinges into the flap

and allowing to cure before

gluing into the wing.

Wipe some epoxy onto the

barbed end of the hinge.

Note: One end of the hinges on

the flaps have been shortened.

The shorter end is to go into the

flap surface itself, and the long

end into the wing.

7

Insert hinge into the flap. Wipe

with denatured alcohol

(methylated spirits) to clean

away any excess glue and

ensure the hinge moves freely.

With all hinges glued into the

flap surface, repeat the hinge

gluing steps for the other side

and insert the flap into the

wing.

Note: Before the glue is fully

cured, test that the flap moves

freely. If needed, wipe a drop of

denatured alcohol onto each

hinge to free it up.

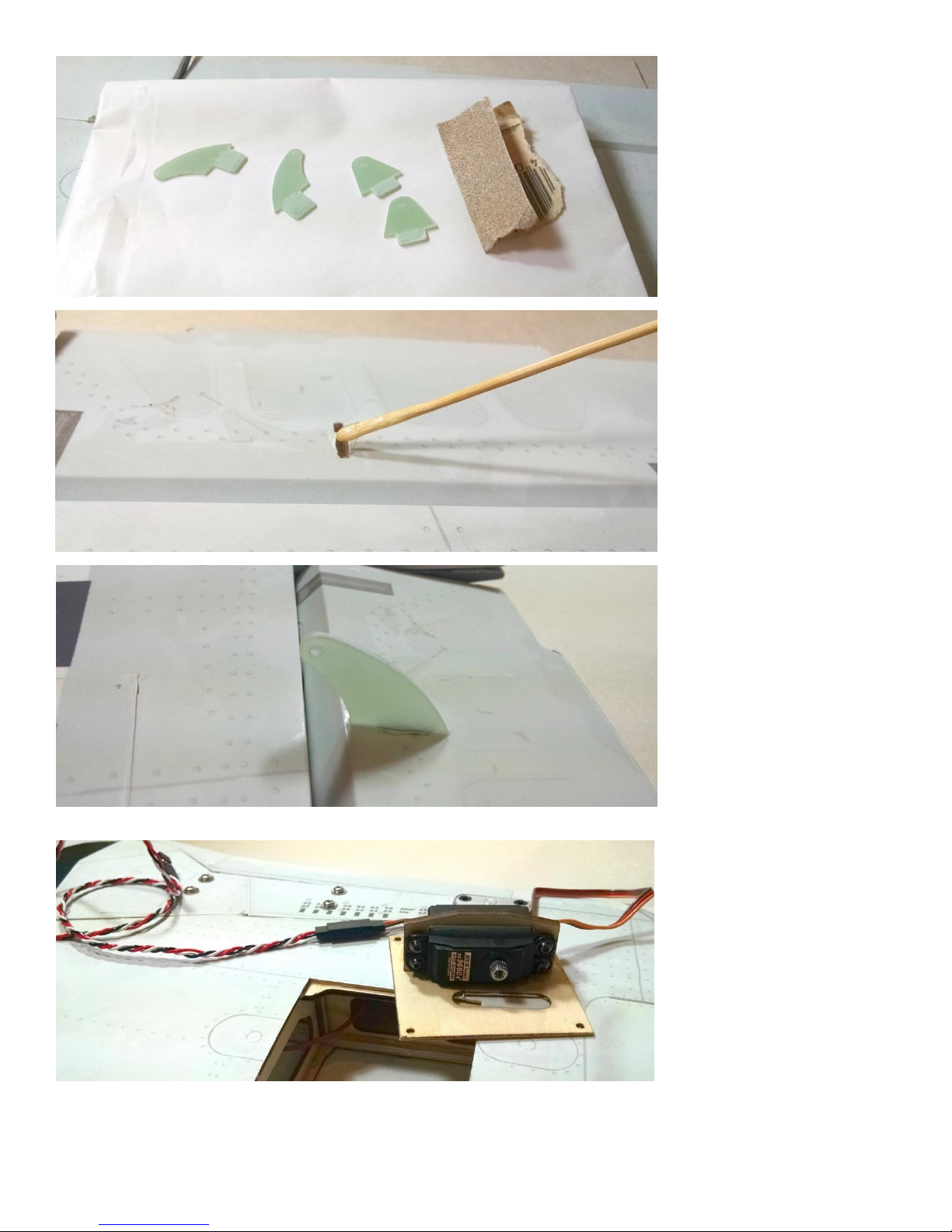

Next are the control surface

horns found in the “Main Wing”

bag.

Using some coarse sandpaper

(100-150 grit is ideal), rough up

the surface of the tabs on the

control horns (the part of the

horn that inserts into the wing).

This will provide better

adhesion for the glue.

8

Note: The curved horns are for

the ailerons, and the triangle

shaped horns are for the flaps.

Mix up some epoxy, and use a

tool/stick to pace into the holes

of the control surface.

Wipe some epoxy onto the

sanded tab area of the horn,

and insert into control surface.

Clean any excess glue with

denatured alcohol (methylated

spirits).

Repeat for all flap and aileron

horns.

Using the hardware that came

with your servo, mount the

servos to the removable servo

access doors as shown.

Note: We recommend screwing

the servo to the mount and

then removing it to apply a drop

of thin CA to the servo screw

holes to make them stronger.

Loading...

Loading...