Extreme Flight EXTRA 300EXP Assembly Manual

EXTRA 300EXP

Electric ARF

1

Greetings and congratulations on your purchase of the Extreme Flight RC

Extra 300EXP ARF

. Loosely based on our favorite variant of the Extra, the

mid-wing Extra 300, we have taken numerous liberties with this design to

produce an aircraft that is both unique in appearance and flight ability. The

designation 300EXP does not belong to a full scale Extra, but stands for

Experimental Progressive. This name was chosen due to the fact that from its

inception the Extra 300EXP was developed as a test bed for several new

forward thinking design and aerodynamic concepts. Having spent several

months in development, flight testing and refinement, we are very excited

about the end result of our quest.

The Extra 300EXP incorporates carbon fiber and G10 composites into the

structure of the airframe, resulting in a lightweight, yet twist free structure

capable of handling extreme aerodynamic loads. Carbon and G10 are used in

high stress areas such as motor box support, landing gear mounting structure

and fuselage longerons to provide enormous strength and durability. A true

piece of carbon fiber art, the landing gear is airfoiled and has just enough

"give" to cushion those not so perfect landings. The removable wing panels

are mounted on a carbon fiber wing tube and are fastened to the fuselage with

nylon thumbscrews. The large canopy (which is retained by a spring loaded

hatch latch) has been moved forward to place the tallest portion of the aircraft

at the center of gravity, resulting in the best knife edge performance of any

aircraft we've flown to date. The airfoiled tail surfaces are built using a

unique geodetic construction technique which allows the use of less material

while creating a structure that is superior in strength and rigidity to typical

ARF construction methods. All control surfaces are pushrod driven with short

linkages and use ball links for slop free actuation with no binding. Optional

Side Force Generators are included and add to the already generous side area,

increasing yaw axis authority and adding stability in all angles of sideslip.

Expertly painted fiberglass cowl and wheel pants and 2 gorgeous high

visibility Ultracote color schemes add the finishing touches and make this an

airplane that you will be proud to show up at the flying field with. The

combination of these unique elements add up to an aircraft that pushes the

boundaries of modern aerobatic flight.

If repairs become necessary, the Ultracote colors used on the Extra 300EXP

are as follows:

Blue color scheme: Deep Blue/White/Black/Silver

Red color scheme: True Red/White/Black/Silver

2

Tips for Success:

1. Before starting assembly, take a few minutes to read the entire instruction

manual to familiarize yourself with the assembly process.

2. Please take a few minutes and go over all the seams on the aircraft with a

covering iron on a medium heat setting.

3. Use a fresh bottle of thin CA with a fine glue tip when attaching the CA

hinges. This will ensure that the proper amount of CA wicks into the hinge

and surrounding balsa wood and creates a proper bond between the wood and

hinges. We are big fans of the Mercury line of adhesives as well as the glue

tips provided by them.

4. Apply a couple drops of CA to high stress areas such as anti-rotation pins,

landing gear mounts, servo trays and motor box support mounts.

5. All of the G10 control horns are the same with the exception of the elevator

horn. Its base has been shortened to fit the width of the elevator.

6. When applying decals, first clean the area where the decal will be applied

with alcohol. Mist the area lightly with Windex before applying the decal

which will allow you to properly position it, then use a rubber squeegee to

push all of the liquid from under the decal. This will result in very few air

pockets trapped under the decal.

7. Take the time to properly balance and trim your aircraft and set up rates

and exponential values. Your flying experience will be greatly enhanced by

doing this.

3

Items needed for completion

-masking tape

-Thin and medium CA. We highly recommend Mercury M5T thin and M100XF medium

formulas as well as the Mercury glue tips.

-30 minute epoxy. I have used Pacer Z-Poxy for many years and it is a terrific product. It

cures in the allotted time and forms a permanent bond.

-Blue Loctite.

-Silicon based glue (Zap-A-Dap-A-Goo, etc.)

-Electric drill with an assortment of small drill bits.

-Small flat head and Phillips head screw drivers.

-Standard and needle nose pliers.

-Metric balldriver or allen key set.

-4 sub micro metal geared servos. All flight testing was performed with Hitec HS-65MG

and HS-5065MG digital servos and we strongly recommend the use of either of these high

quality servos.

-Torque 2818T/900 or 2814T/820 Brushless Outrunner motor.

-Airboss Elite 45 Amp ESC.

-4S 2100-2700 mah LiPo battery. Our favorite batteries in this aircraft have been the

FlightPower EON Lite 2550. We've also had great success with the Zippy Rhino bargain

LiPos available from www.hobbycity.com in both 2170 mah and 2350 mah sizes.

-APC 12x6 E prop (NOT the slow fly version!).

-52mm Extreme Flight spinner.

-2 18"-24" extensions for the 2 rear servos and 2 6"-8" extensions to go between the

receiver and the aileron servo leads. We recommend the 28 or 32 AWG extensions to save

weight.

-Adhesive backed Velcro and Velcro strap for battery retention.

4

Highlighted text has been changed. Please note new procedure on the right of the page

Let's begin!

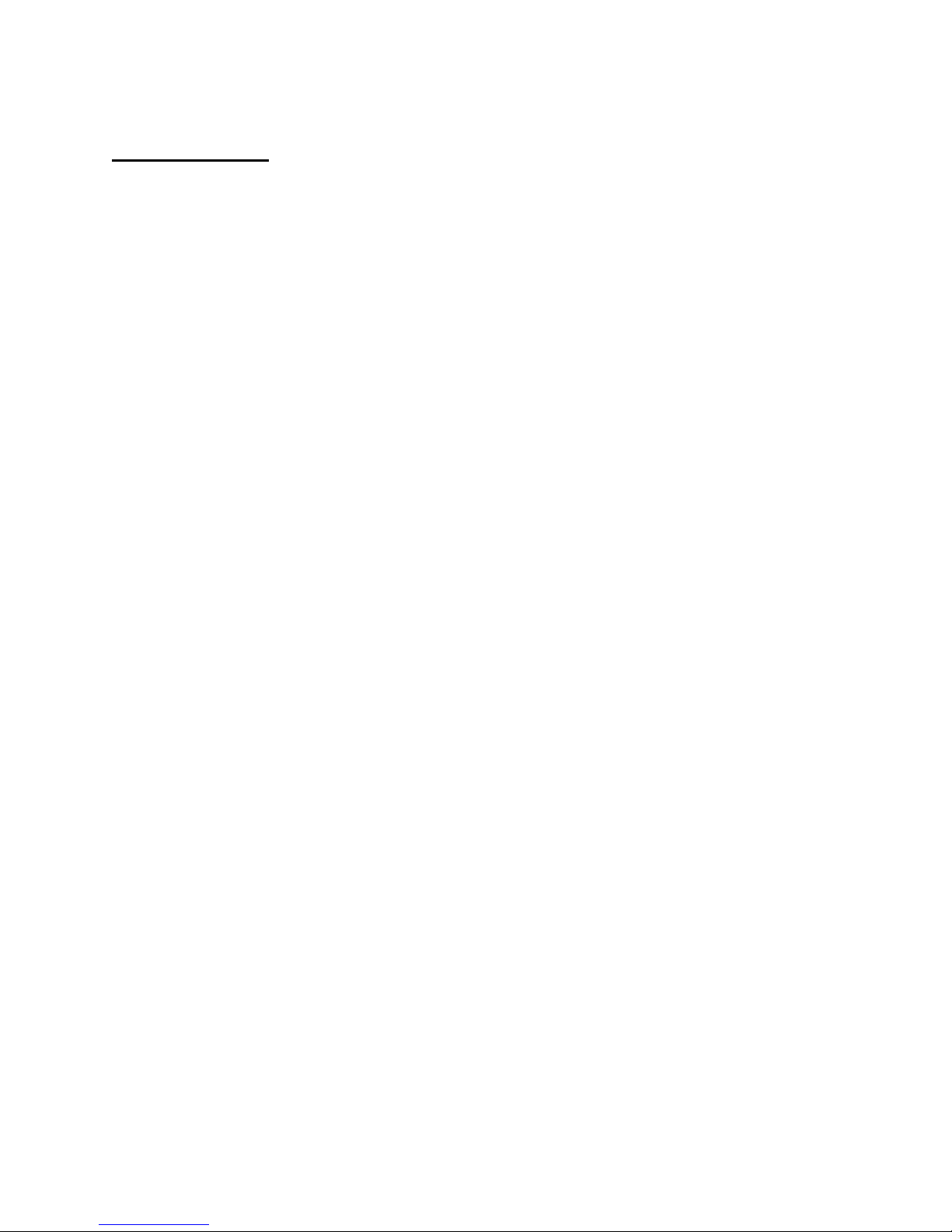

1. So that we don't have to wait for the 30 minute epoxy to dry in a later step,

let's go ahead and prepare the 4 carbon fiber pushrods and ball links for later

use. Locate the 4 carbon fiber pushrods and 4 micro ball links in the

hardware package. Lightly scuff one end of each pushrod.

Note: Based on Customer Feedback

and field testing we have changed the

control rod process. Locate the

threaded pushrods and the micro ball

links along with 2mm screws, nuts

and washers. Thread the ball links

onto each end of the pushrods and

when you reach the appropriate step,

secure to the servo arm and control

horn with the 2 mm hardware. For a

slop free setup we no longer use the

EZ Links

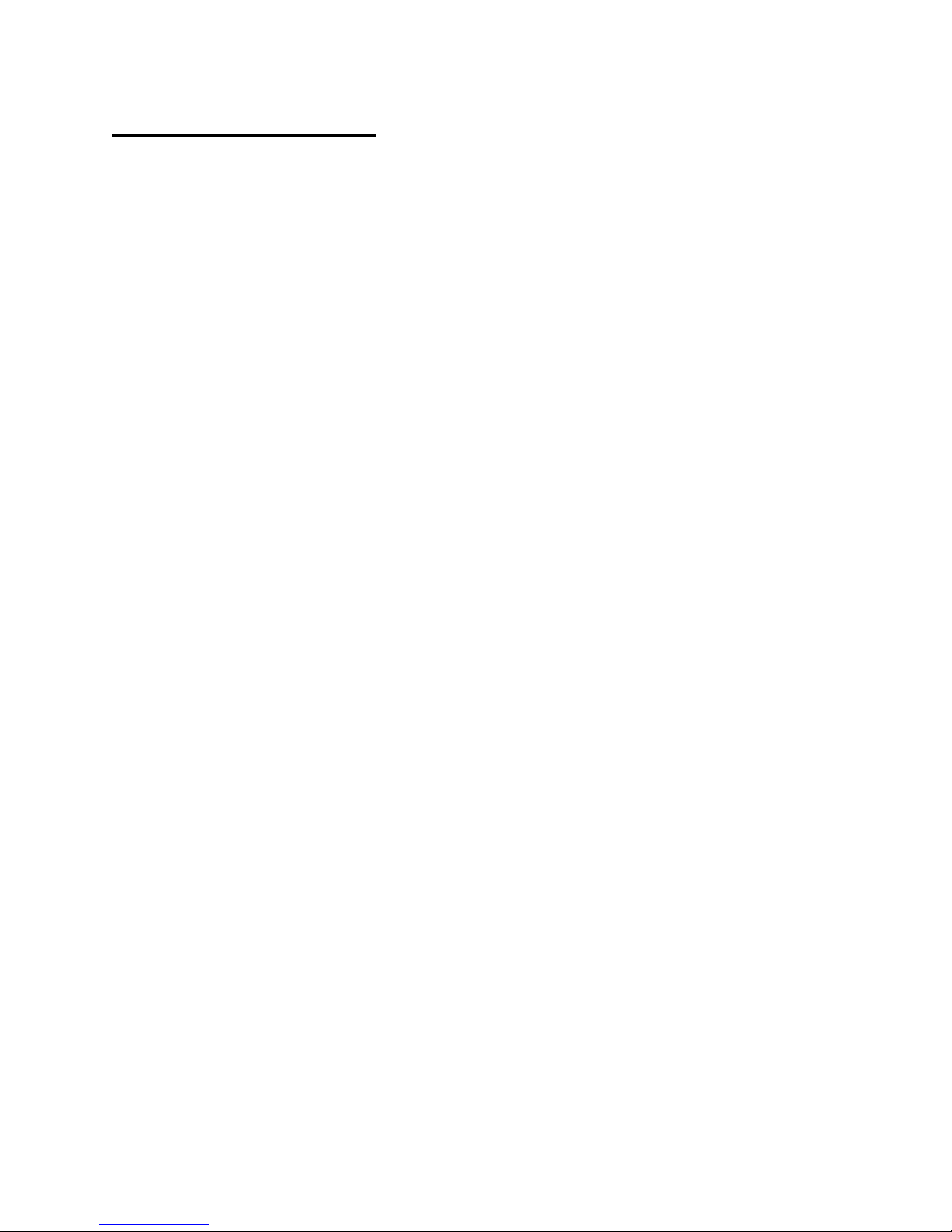

2. Mix up a small batch of 30 minute epoxy. Dip the scuffed end of each

pushrod into the epoxy and i

nsert this end into the ball link with a twisting

motion to make sure the epoxy is evenly distributed inside the ball link. Make

sure the pushrod is completely inserted into the ball link.

5

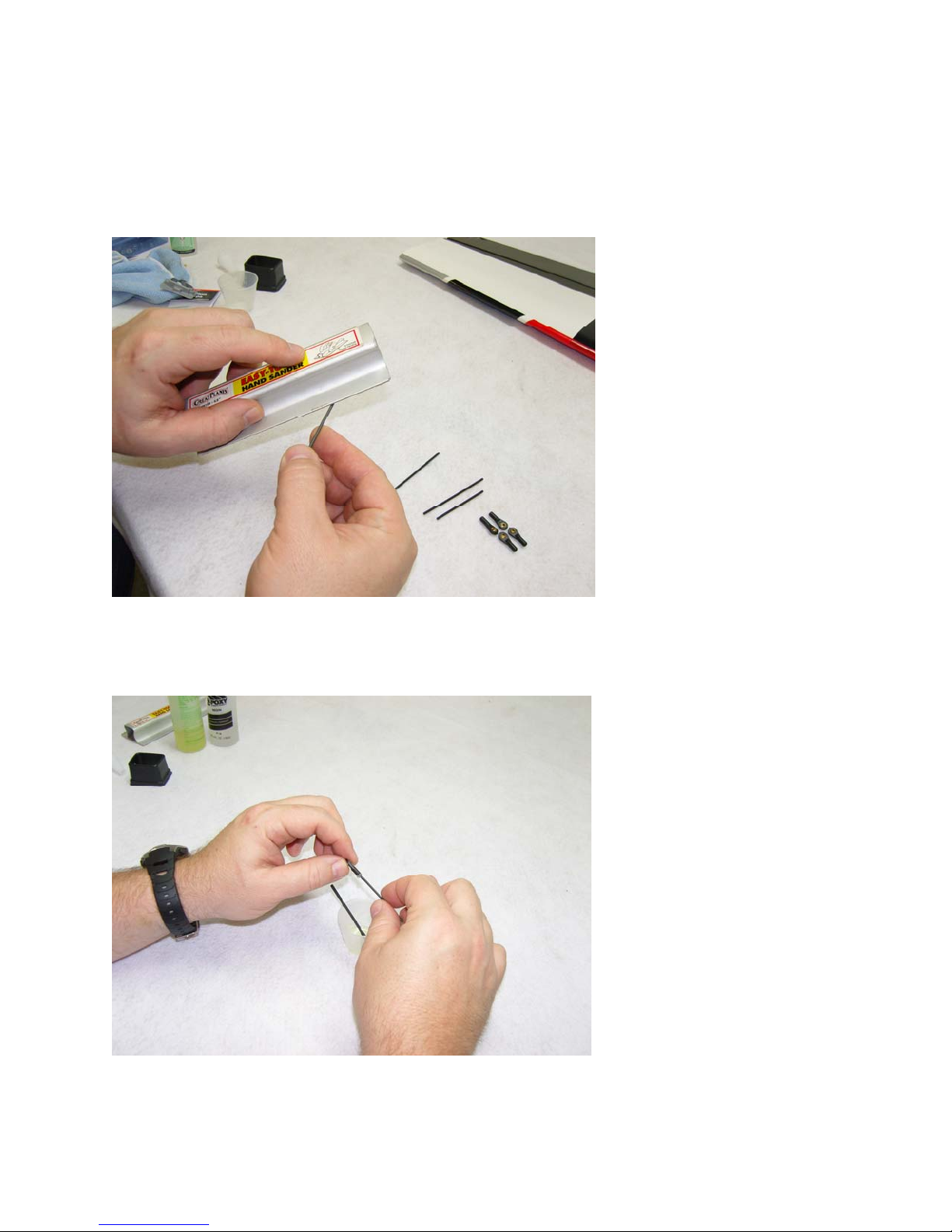

3. Use a paper towel to wipe away most of the excess epoxy, leaving a small

fillet between the carbon pushrod and ball link. Position the pushrods

vertically while they cure as illustrated so the fillet remains in position. DO

NOT use CA for this bond!

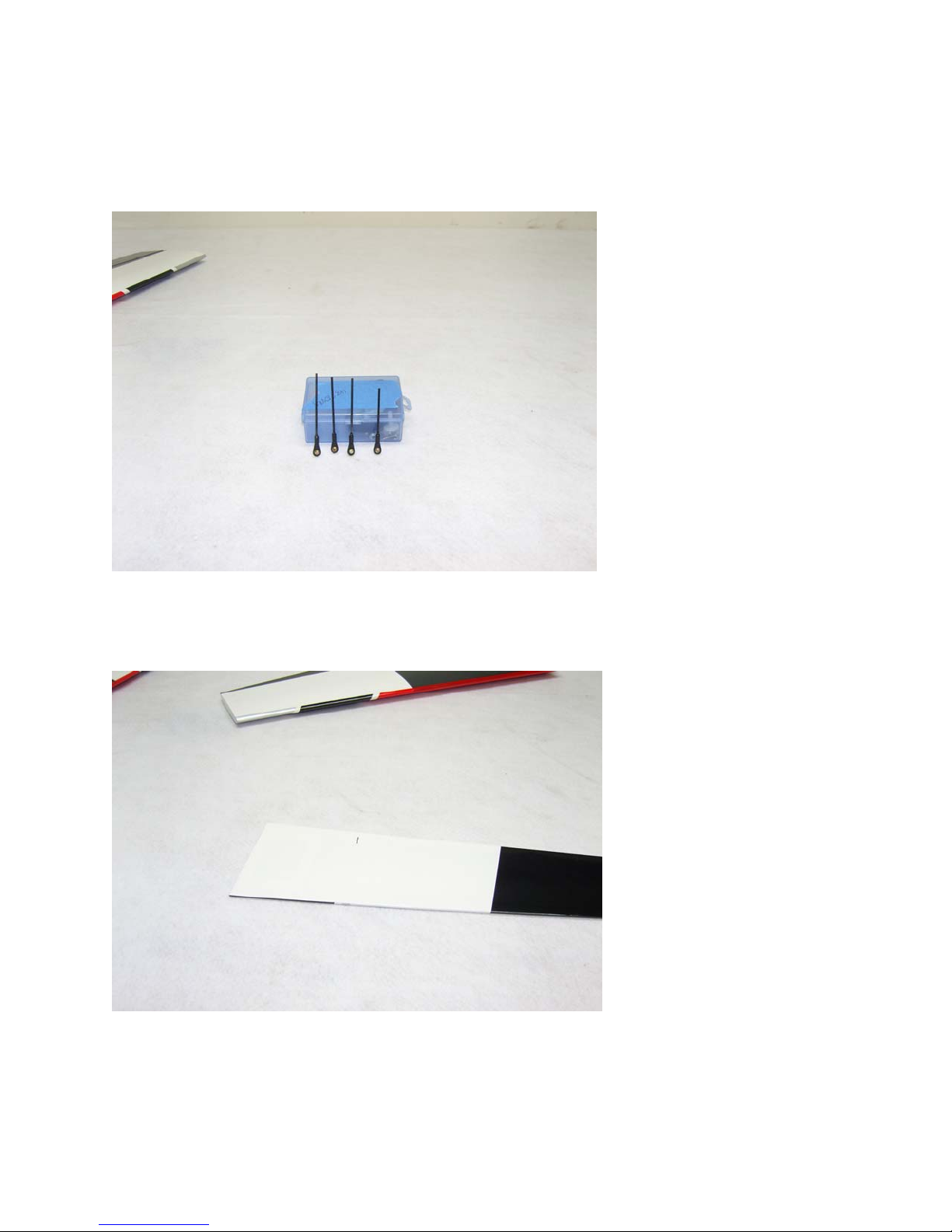

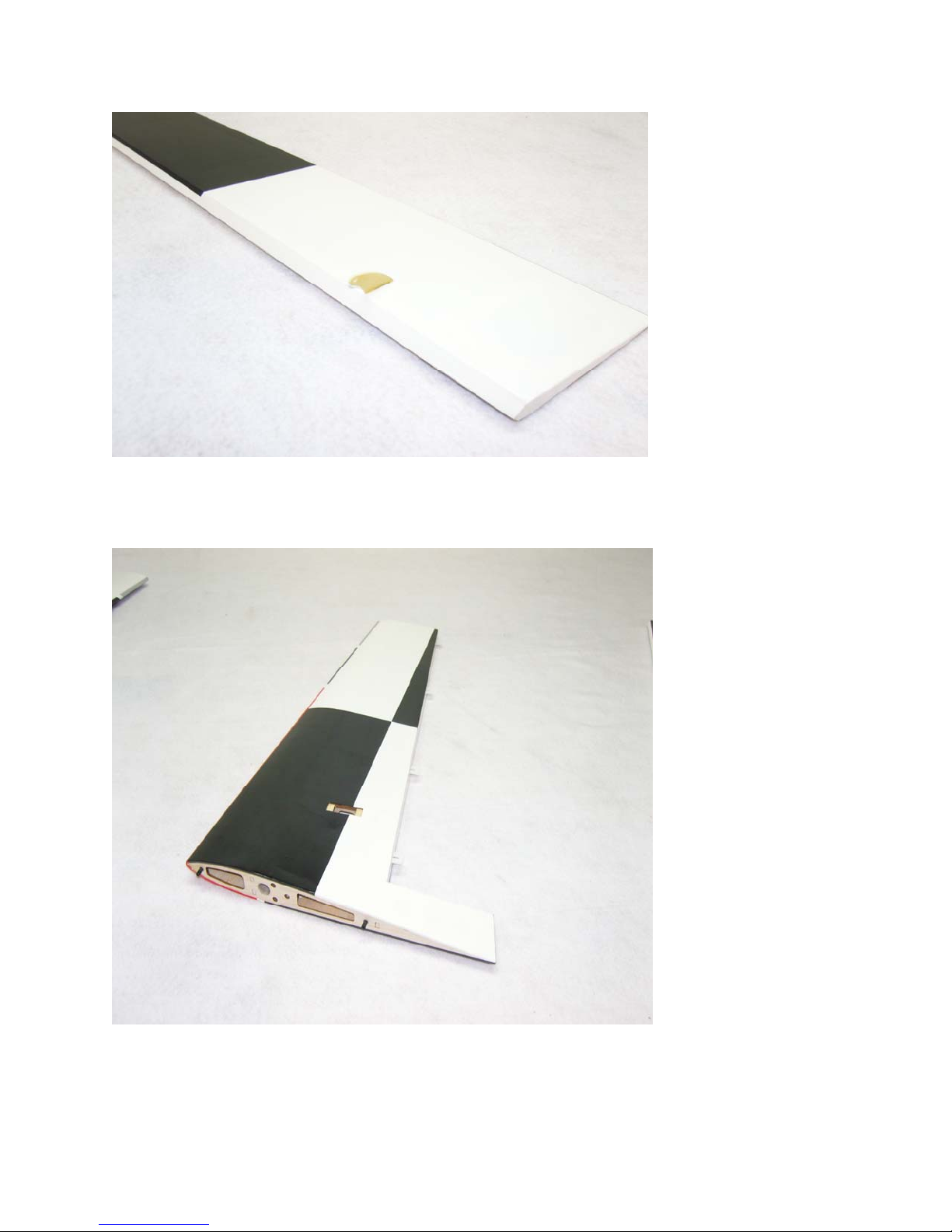

4. Locate the 2 w

ing panels with ailerons as well as the 2 G10 aileron control

horns. Remove the ailerons from the wing and remove the covering over the

slot for the aileron horn on the bottom of the aileron with a sharp hobby

blade. Make sure you are doing this on the bottom of the aileron!

5. Scuff the portion of the control hor

sandpaper.

n that will be glued into the aileron w

6

ith

6. Use a glue tip on your bottle of medium CA and apply glue to the slot as

well as to both sides of the control horn. Insert the control horn into the slot

and make sure it seats properly against the surface of the aileron.

7

7. Remove the covering from the aileron servo location and make sure the

hinges are centered in their slots.

8

8. Slide the aileron into position on the hinges and secure with several drops

of fresh thin CA. This process is much easier and more effective if a fine glue

tip is used. Make sure to deflect the surface as pictured while applying the

CA.

9. Use the screws provided by the servo manufacturer to secure the aileron

servo in the designated location. 1 screw installed in the center hole at each

end of the servo is adequate to secure the servo. Make sure the output shaft is

positioned toward the trailing edge of the wing.

9

Loading...

Loading...