Extreme Flight 60"" laser ARF Instruction Manual

60" Laser ARF

Instruction Manual

Copyright 2013 Extreme Flight RC

1

Please take a few moments to read this instruction manual before beginning assembly. We

have outlined a fast, clear and easy method to assemble this aircraft and familiarizing

yourself with this process will aid in a quick, easy build.

Please read the following paragraph before beginning assembly

of your aircraft!

THIS IS NOT A TOY! Serious injury, destruction of property, or even death may result

from the misuse of this product. Extreme Flight RC is providing you, the consumer, with

a very high quality model aircraft component kit, from which you, the consumer, will

assemble a flying model. It is beyond our control to monitor the finished aircraft you

produce. Extreme Flight RC will in no way accept or assume responsibility or liability for

damages resulting from the use of this user assembled product. This aircraft should be

flown in accordance with the AMA safety code. It is highly recommended that you join

the Academy of Model Aeronautics in order to be properly insured and operate your

model at AMA sanctioned flying fields only. If you are not willing to accept ALL liability

for the use of this product, please return it to the place of purchase immediately.

Extreme Flight RC, Ltd. guarantees this kit to be free of defects in materials and

workmanship for a period of 30 DAYS

must be accompanied by the original dated receipt. This warranty is extended to the

original purchaser of the aircraft kit only

aircraft against flutter. We have put these aircraft through the most grueling flight tests

imaginable and have not experienced any control surface flutter. Proper servo selection

and linkage set-up is absolutely essential. Inadequate servos or improper linkage set up

may result in flutter and possibly the complete destruction of your aircraft. If you are not

experienced in this type of linkage setup or have questions regarding servo choices, please

contact us at info@extremeflightrc.com or 770-887-1794. It is your

ensure the airworthiness of your model.

from the date of purchase. All warranty claims

. Extreme Flight RC in no way warranties its

responsibility to

2

Congratulations on your purchase of the Extreme Flight RC 60 inch Laser EXP ARF!

I am a huge fan of the Laser 200 and the late airshow legend Leo Loudenslager. I always

knew that at some point Extreme Flight would have to produce a model of this iconic

airframe. My goal was to honor the unique legacy of Leo and his Laser while bringing the

model up to date to match the performance we have all come to expect from an Extreme

Flight EXP series aircraft.

One of the last modifications that Leo made to the Laser was to install a more streamlined

canopy. This canopy was installed on the Laser and flown by Leo prior to his tragic death

in a motorcycle accident. I much prefer the look of this canopy to the original and decided

to incorporate it into the Laser EXP design. In my research I found photos of the Laser

Z230, Laser 300 and 2000 that had all started incorporating much more streamlined

modern cowlings. I decided to incorporate a similar cowl into the Extreme Flight EXP

version as well. As such this model can't really be designated as any particular variant,

so I decided to simply call it the Laser EXP. Like all of the EXPs, the Laser excels at both

3D and precision maneuvers. It shares the long tail moment of the Extra and Edge which

gives it great stability in high speed precision maneuvers and it also features that famous

EXP elevator that allows for crazy pitch authority and great stability in high alpha

maneuvers. When the CG is properly set the Laser has minimal coupling and is a very

neutral aircraft.

The Laser EXP shares many of the attributes of the previous EXP airframes along with

some new features. Due to customer feedback we have changed the wing retention

method to make it much easier to attach the wings to the fuselage. The wings are also

slightly recessed into the fuselage sides which provide a much cleaner appearance and

insures the wings will appear flush with the fuselage sides. The Laser EXP incorporates

carbon fiber and G10 composites into the structure of the airframe, resulting in a

lightweight, yet twist free structure capable of handling extreme aerodynamic loads.

Carbon and G10 are used in high stress areas such as the landing gear mounting structure

and fuselage longerons to provide enormous strength and durability. A true piece of

carbon fiber art, the landing gear is airfoiled and has just enough "give" to cushion those

not so perfect landings. All control surfaces are pushrod driven with short linkages and

use ball links for slop free actuation with no binding. Optional Side Force Generators are

included and add to the already generous side area, increasing yaw axis authority and

adding stability in all angles of sideslip. Expertly painted fiberglass cowl and wheel pants

and 2 gorgeous high visibility Ultracote color schemes add the finishing touches and make

this an airplane that you will be proud to show up at the flying field with.

3

Items needed for completion:

Masking tape.

Hobby knife with #11 blades.

Thin and medium CA. We highly recommend Mercury M5T thin and M100XF

medium formulas as well as the Mercury glue tips.

30 minute epoxy. Mercury Adhesives Epoxies have worked very well for us.

Blue Loctite.

Electric drill with an assortment of small drill bits.

Small flat head and Phillips head screw drivers.

Standard and needle nose pliers.

Side cutter.

Metric ball driver or allen key set.

Sanding block and sandpaper.

4 x METAL GEARED servos with a minimum of 76oz of torque. All flight testing

was performed with Hitec HS-7245MH.

Dubro Long Super Strength servo arm set. (Dubro part #670 for Futaba, #671 for

JR and #672 for Hitec).

2 x 6” Servos Extensions for the Ailerons.

2 x 24” Servo Extensions for the rudder and elevator servos

Torque 4016T/500 MKII Brushless Outrunner.

Airboss Elite 80 Amp ESC.

6S 3300-4000 mah LiPo battery.

16 x 7 prop.

The Ultracote colors used on the Laser are as follows:

Red color scheme

#HANU885 and Gold #HANU879

Yellow/White/Blue color scheme

Midnight Blue #HANU885, Silver #HANU881

: True Red #HANU866, White #HANU870, Midnight Blue

: Bright Yellow #HANU872, White #HANU870,

4

Tips for Success:

1. Before starting assembly, take a few minutes to read the entire instruction manual

to familiarize yourself with the assembly process.

2. Please take a few minutes and go over all the seams on the aircraft with a covering

iron on a medium heat setting. Also, due to climate changes, wrinkles may develop

in the covering. These are easily removed with a little bit of heat. Use a 100%

cotton tee-shirt and your heat gun and heat the covering while gently rubbing the

covering onto the wood with the t-shirt. Be careful not to use too much heat as the

covering may shrink too much and begin to lift at the edges. Take your time, and a

beautiful, paint-like finish is attainable.

3. Apply a bead of Pacer Formula 560 Canopy Glue at the intersection of the plastic

canopy and its wooden frame.

4. Take a few minutes and apply CA to high stress areas such as servo mounting trays,

landing gear mounts, anti-rotation pins, and motor box joints.

5. By the time your aircraft arrives at your door step, it will have been handled by a lot

of people. Occasionally, there are small dings or imperfections on some of the

surfaces. An effective method to restore these imperfections to original condition is

to use a very fine tipped hypodermic needle and inject a drop of water under the

covering material and into the ding in the wood. Apply heat to the area with a

sealing iron and the imperfection will disappear. Deeper marks may require that

this process be repeated a couple of times to achieve the desired result, but you will

be surprised at how well this technique works.

6. Use a high quality epoxy for installing the composite control horns. We highly

recommend the new Mercury Adhesives 30 minute Epoxy or Pacer Z-poxy. We are

very pleased with the results and ease of application and cleanup of these products.

7. When applying decals, first clean the area where the decal will be applied with

alcohol. Mist the area lightly with Windex or Rapid Tack before applying the decal

which will allow you to properly position it, and then use a rubber squeegee to push

all of the liquid from under the decal. This will result in very few air pockets

trapped under the decal.

8. Take the time to properly balance and trim your aircraft and set up rates and

exponential values. Your flying experience will be greatly enhanced once your plane

is properly dialed in.

5

Let's begin!

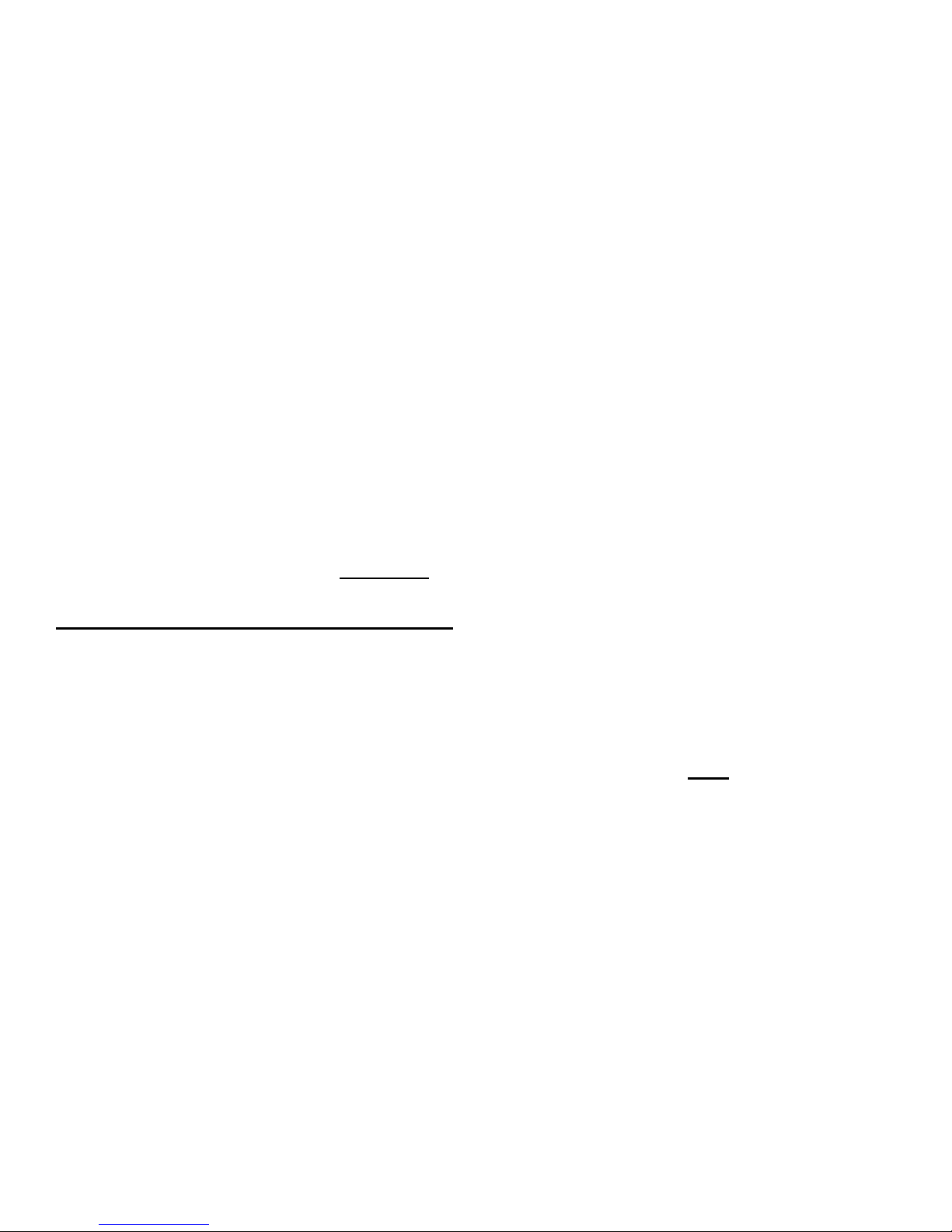

1. Locate the 2 wing panels as well as the composite aileron control horns and base

plates. Use a soldering iron or sharp hobby blade to remove the covering over the

slot for the aileron horn. Make sure you are doing this on the bottom of the aileron!

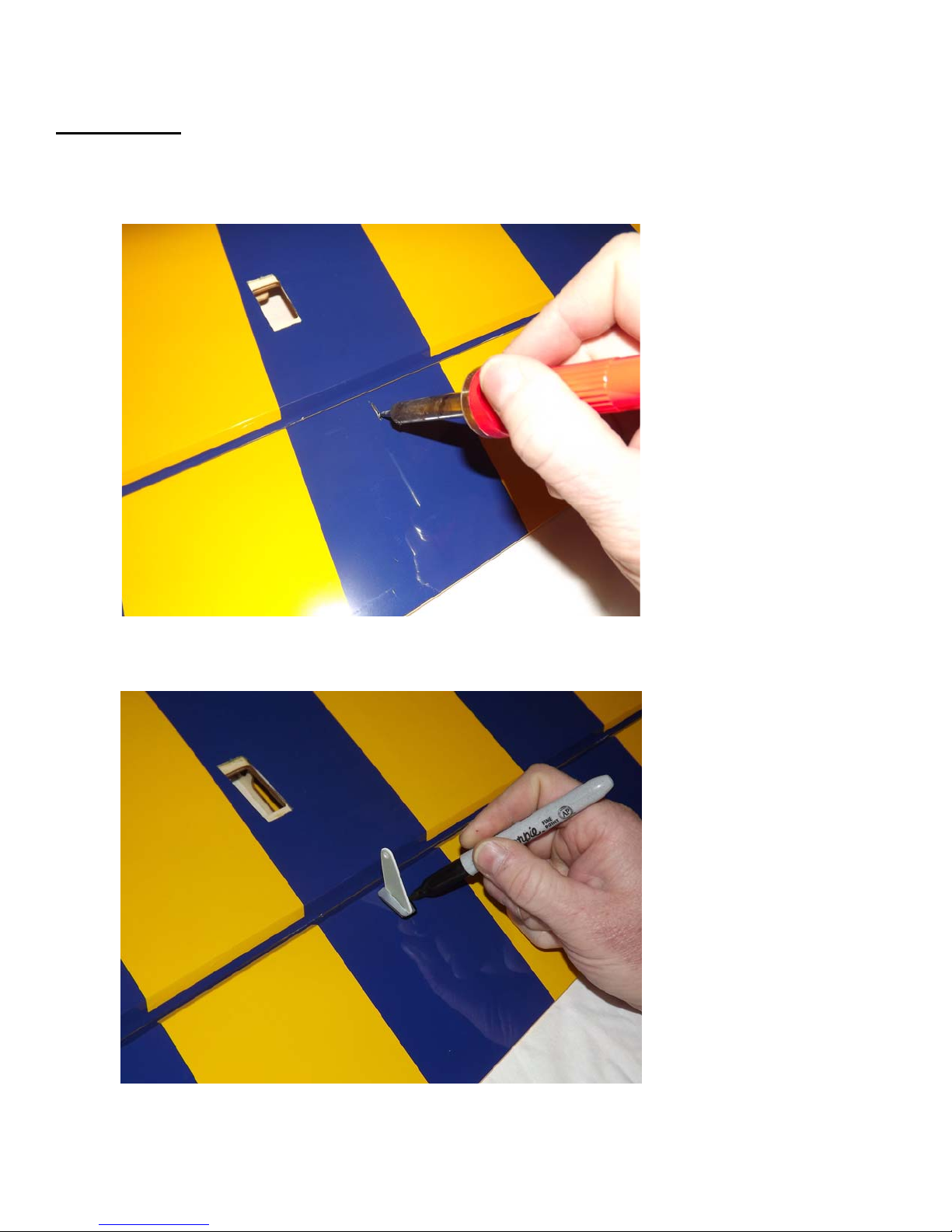

2. Insert the horn into the base plate and into the slot in the aileron. Use a fine

tipped felt marker to trace the base plate.

6

3. Remove the horn assembly and use a #11 blade to remove the covering from inside

the ink line you traced around the control horn base. Wipe away the ink line with a

cotton cloth or paper towel soaked in denatured alcohol.

4. Use sandpaper to scuff the portion of the horn that will be inserted into the aileron as

well as the bottom of the base plate.

7

5. Insert the control horn into the base plate and apply 30 minute epoxy to the slot

in the aileron and the scuffed potion of the control horn that will insert into the

aileron. Use a zip tie to ensure the slot is completely filled with epoxy.

6. Install the aileron horn into the aileron slot and wipe away any excess epoxy with a

paper towel or cloth soaked with denatured alcohol.

8

7. Remove the aileron from the wing to ensure all hinges are centered between the

wing and aileron. One way to ensure the hinges are centered is to fold them in half

and re-install into the aileron using the crease as a reference point.

8. Making sure the aileron is properly aligned between the wing root and wing tip,

hold the aileron fully deflected and apply a drop of thin CA to each hinge. Flip the

wing over and repeat.

9

Loading...

Loading...