50cc Extra 300 ARF

Instruction Manual

©Copyright 2007 Extreme Flight RC, Ltd.

Please take a few moments to read this instruction manual before

beginning assembly. We have outlined a fast, clear and easy method to

assemble this aircraft and familiarizing yourself with this process will

aid in a quick, easy build.

Please read the following paragraph before beginning

assembly of your aircraft!

THIS IS NOT A TOY! Serious injury, destruction of property, or even

death may result from the misuse of this product. Extreme Flight RC is

providing you, the buyer with a very high quality model aircraft

component kit, from which you, the buyer, will assemble a flying model.

However it is beyond our control to monitor the finished aircraft you

produce. Extreme Flight RC will in no way accept or assume

responsibility or liability for damages resulting from the use of this user

assembled product. This aircraft should be flown in accordance to the

AMA safety code. It is highly recommended that you join the Academy

of Model Aeronautics in order to be properly insured, and to operate

your model at AMA sanctioned flying fields only. If you are not willing

to accept ALL liability for the use of this product, please return it to the

place of purchase immediately.

Extreme Flight RC, Ltd. guarantees this kit to be free of defects in

materials and workmanship for a period of 90 days from the date of

purchase. All warranty claims must be accompanied by the original

dated receipt. This warranty is extended to the original purchaser of

the aircraft kit only. Please inspect the model immediately upon receipt.

Extreme Flight RC in no way warranties its aircraft against flutter. We

have put these aircraft through the most grueling flight tests imaginable

and have not experienced any control surface flutter. Proper servo

selection and linkage set-up is absolutely essential. Inadequate servos or

improper linkage set up may result in flutter and possibly the complete

destruction of your aircraft. If you are not experienced in this type of

linkage set-up or have questions regarding servo choices, please contact

us. It is your responsibility to ensure the airworthiness of your model.

2

Congratulations on your purchase of the Extreme Flight RC 50cc Extra

300 ARF! Like our previous 50cc Yak-54 release, the Extra is among

the largest aircraft currently available for 50cc gas engine power. Its

light weight yet robust construction allows the Extra to perform

tournament level maneuvers on an economical 50cc power plant,

allowing you to experience the performance and stability of a much

larger aircraft at a considerable savings. The Extreme Flight Extra 300

is loaded with unique features, including all first rate hardware and

components and thorough instructions to ensure a trouble free assembly

and set-up. Weight saving components are used throughout, such as

carbon fiber wing and stab mounting tubes, aluminum landing gear,

titanium pushrods and a carbon fiber tail wheel assembly, all ensuring

the lightest, most high performance aircraft possible. You will notice

there is a box built into the bottom of the Extra’s fuselage. This is a

pipe tunnel and will accommodate most canister mufflers and tuned

pipes sold for the current makes of 50-60cc engines. Also included is a

set of protective wing and stab bags and a canopy/hatch cover to keep

your investment looking great season after season. Add to that one of

our new PILOT X series helmet head figures and a very detailed scale

instrument panel and dash!

The performance ability of the Extreme Flight RC Extra 300 is

phenomenal! This sleek, fast and agile airframe is completely unlimited

in its ability to perform the full range of full stall high alpha maneuvers

and aggressive gyroscopic tumbling maneuvers. The Extra is also a

topnotch precision aerobatic machine. It is capable of performing the

entire FAI catalog of maneuvers and it has the kind of “big plane”

presence in the air that will impress the judges. This makes the 50cc

Extra a great candidate for all classes of IMAC competition.

We have spent a great deal of time and effort to provide you, the

discriminating aerobatic enthusiast, with the highest quality, most

complete package possible. We are very proud of the end result of our

labor and wish you great success with the assembly and flying of your

Extreme Flight RC 50cc Extra 300!

3

A few tips to ensure success and airframe longevity

1. We are very pleased with the level of craftsmanship displayed by the builders

in our factory. Through many grueling test flights containing maneuvers

that no aircraft should be subjected to, our prototypes have remained rigid

and completely airworthy. However, it is impossible for us to inspect every

glue joint in the aircraft. Take a few minutes and apply some medium CA to

high stress areas such as servo mounting trays, landing gear blocks, the

intersection of the wing root rib and wing sheeting, anti rotation pins, etc. A

few minutes spent here inspecting the joints and applying glue where needed

is time well spent

2. Having survived the journey half way around the world while experiencing

several climate changes, it is not uncommon for a few wrinkles to develop in

the covering. Fear not! These are not manufacturing defects, and are easily

removed with a little bit of heat. Use a 100% cotton tee-shirt and your heat

gun and heat the covering while gently rubbing the covering onto the wood

with the t-shirt. Be careful not to use too much heat as the covering may

shrink too much and begin to lift at the edges. Take your time, and a

beautiful, paint like finish is attainable.

3. By the time the aircraft arrives at your door step it will have been handled by

a lot of people. Occasionally there are small dings or imperfections on some

of the surfaces. A neat trick to restore these imperfections to original

condition is to use a very fine tipped hypodermic needle to inject a drop of

water under the covering material and into the ding in the wood. Apply heat

to the area with a sealing iron and the imperfection will disappear. Deeper

marks may require that this process be repeated a couple of times to achieve

the desired result, but you will be surprised at how well this technique works.

4. DO NOT SKIMP ON SERVOS! These aircraft are equipped with very large

control surfaces that deflect over 45 degrees. A lot of servo power is required

to prevent flutter and to maintain the required deflection for maneuvers. We

absolutely recommend the use of high torque METAL GEAR servos. We

have had great success with the Hitec HS-5955 servos in our prototypes. We

recommend this servo or the JR 8611A or new 8711 for all flight surfaces.

5. Use a high quality epoxy for installing the composite control horns and

hinges. We highly recommend the use of Pacer Z-Poxy 30 minute formula.

We have used this glue for many years with zero failures.

4

Hardware

Your new Extreme Flight 50cc Extra 300 includes all necessary hardware with

the exception of main wheels, tailwheel, axles and collars and a 4” spinner.

These items were omitted as I have been unable to source satisfactory versions of

these items in China. I recommend Dubro 5/32” axles and collars and 3.5 inch

main wheels.

You will find a complete pull-pull system, as well as high quality heavy duty ball

links, titanium turnbuckle pushrods and composite control horns, and a carbon

fiber tailwheel assembly. You will also find 3 white ball links. 2 of these are for

use with the included 2mm pushrod for the throttle assembly (this set-up is for

the DA-50-other engines may require a longer pushrod), the other is for the

bottom of the rudder to retain the tailwheel tiller arm.

The bonded sealing washers are used when mounting the cowl and

canopy/hatch. When the bolts used to retain the canopy/hatch and cowl are

tightened against the bonded sealing washer, the rubber on the washer

compresses, preventing the bolt from backing out. The rubber on the washer

also protects the surface of the cowl. Tighten the bolts until the rubber

compresses, but do not allow the metal part of the washer to make contact with

the cowl.

For best results, remove all set screws from the tailwheel assembly and

disassemble the unit. File flat spots on the tailwheel wire so that all set screws

will seat properly. Place a drop of blue Loctite on all set screws and re-insert

them into their holes.

Graphics

The Extra is not supplied with graphics. The “sticker” type graphics included

with our smaller aircraft simply don’t hold up well to gasoline. We recommend

using vinyl graphics. There are several companies that specialize in model

aircraft logos and can supply you with a top notch graphics package that will

really dress up your Extra. Our local graphics guy Jeff Dean of Vital Signs and

Graphics (770-363-2727 or www.vital-signs.biz) has packages available for the

Extra like the ones pictured on our aircraft. He can modify these to suite your

needs as well.

5

Elevator Assembly

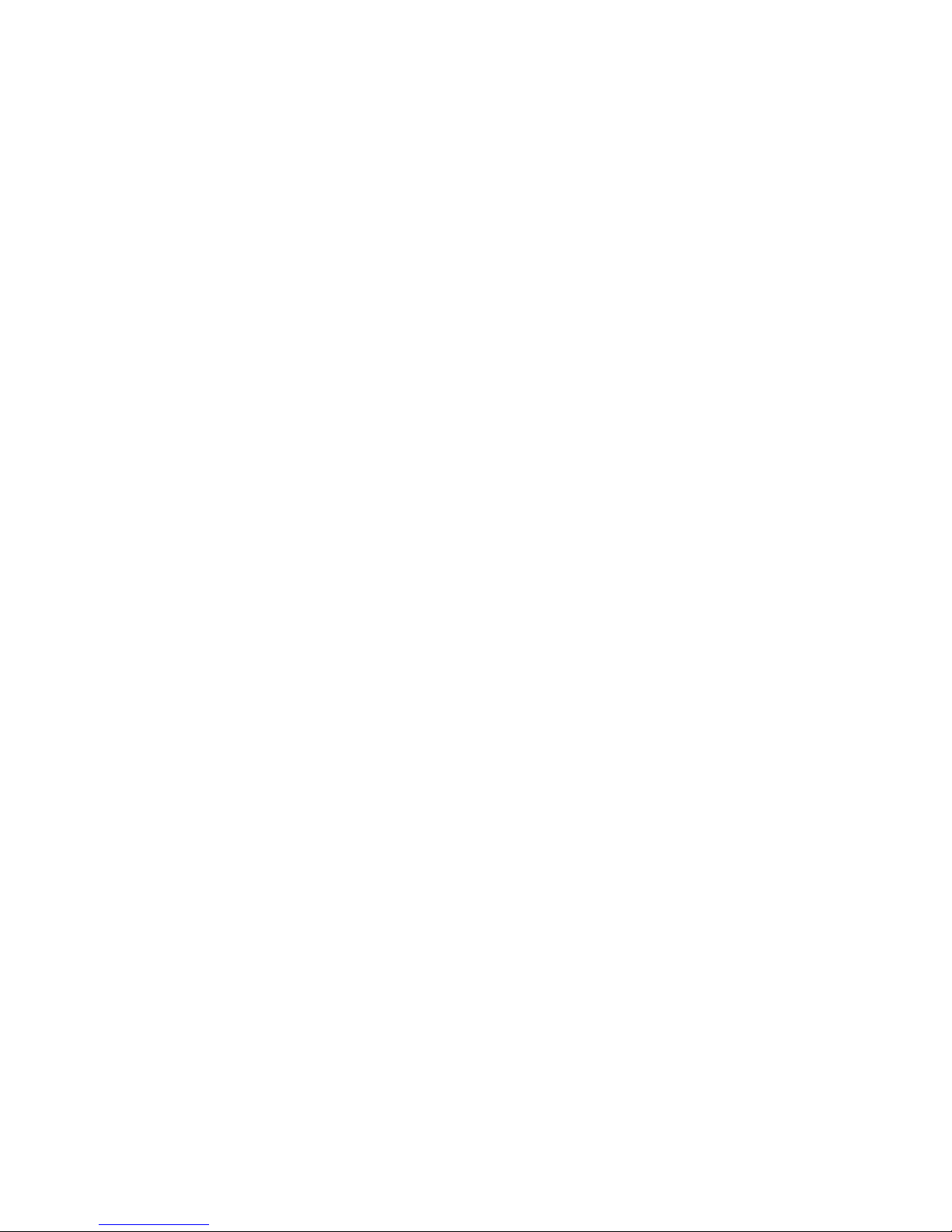

1. Locate the horizontal stabilizer/elevator assemblies as well as the

composite control horns and base pieces from the elevator hardware

package.

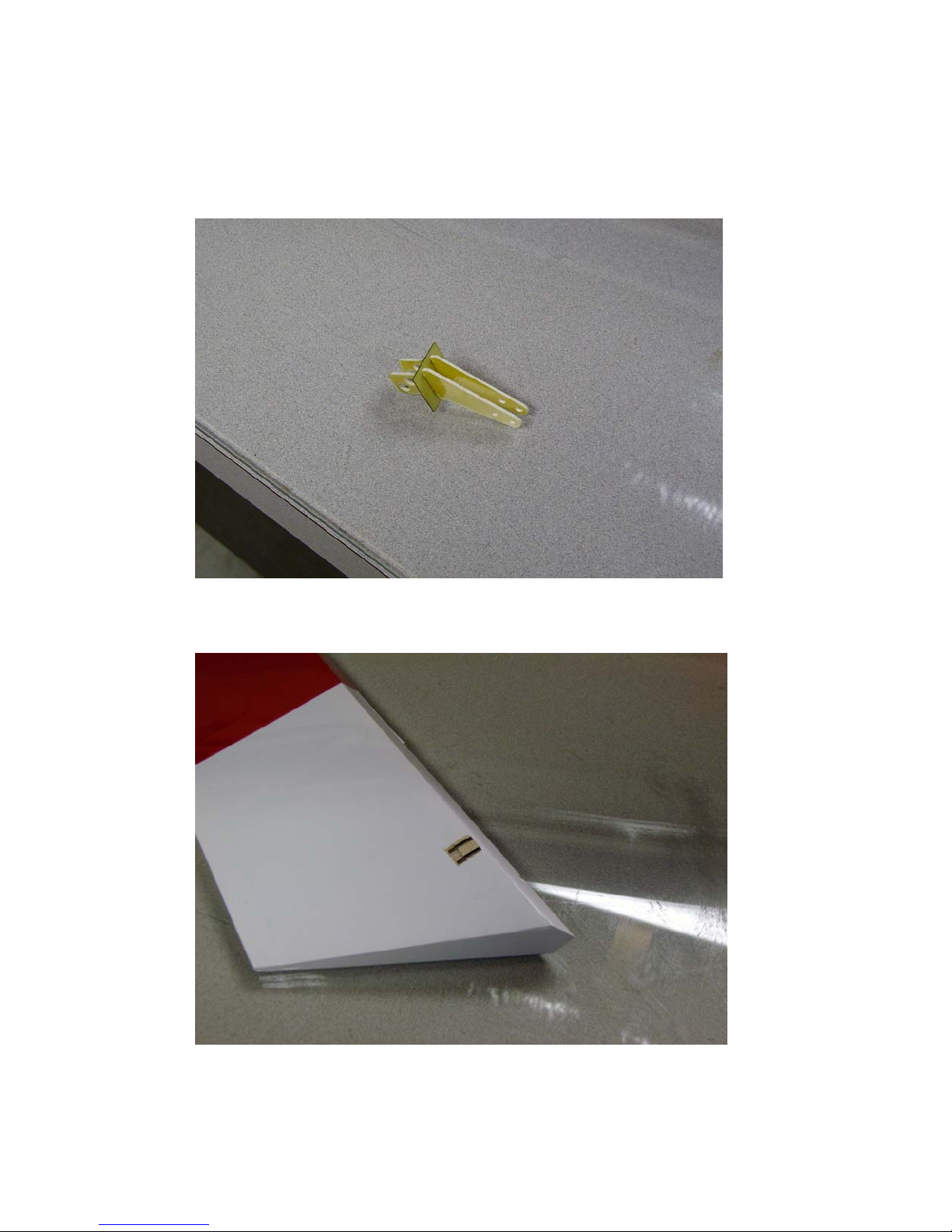

2. Use a sharp #11 blade to remove the covering over the pre-cut control

horn slots near the bottom leading edge of the elevator. Cut the

covering 1/16” from the ends and sides of the slots.

6

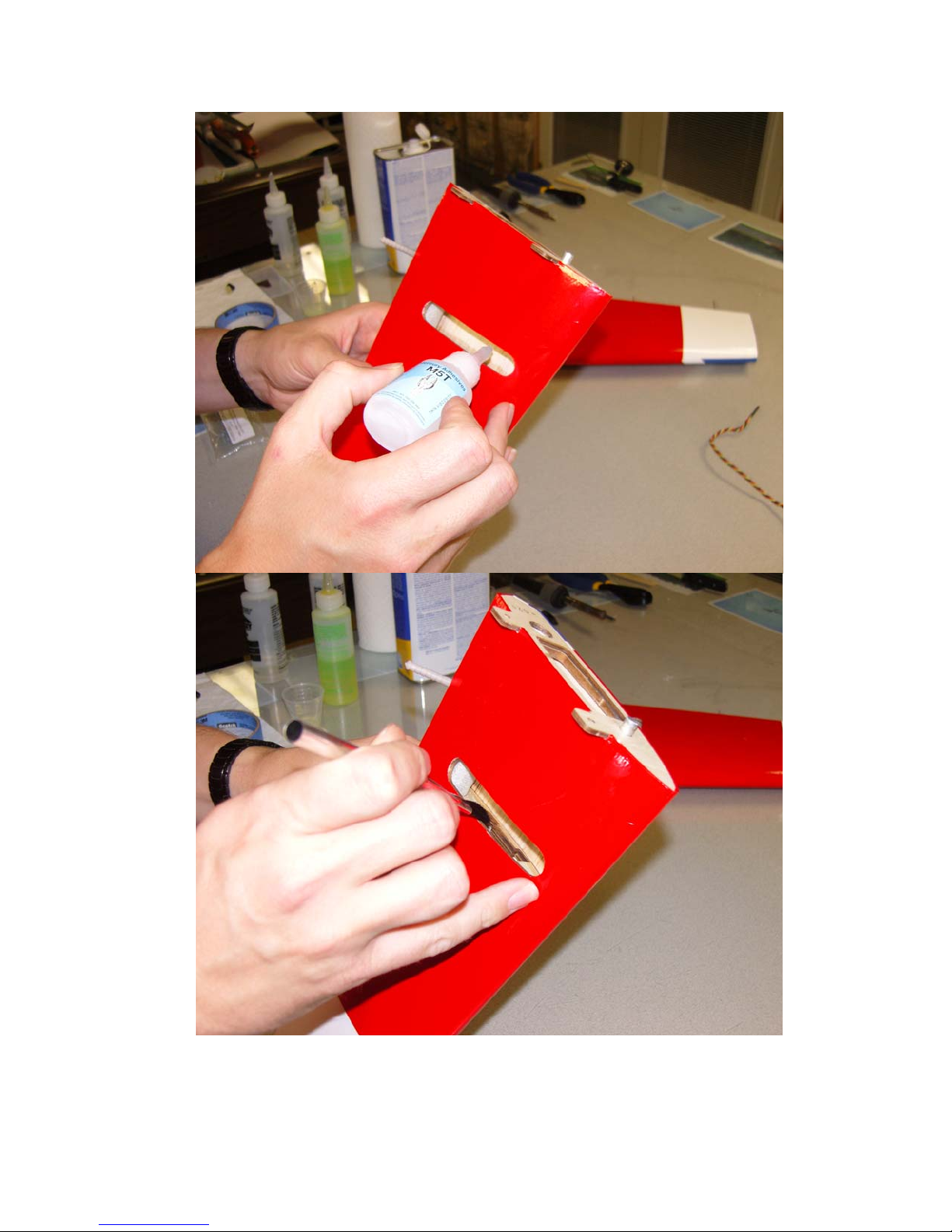

3. Insert the 2 control horns into the base plate and trial fit the

horns into the slot and make sure they seat properly against the

base and elevator surface. You may need to remove 1/16” from the

front of the base plate to prevent it from overhanging the bevel.

Remove the horn assembly and scuff the portion of the horns that

will be inserted into the elevator with sandpaper. Apply 30 minute

epoxy to the slots and thoroughly coat the horns and base plate

bottom. Reinsert the assembly into the elevator and wipe away

any excess epoxy with a paper towel and denatured alcohol. Place

a 3mm bolt through the horns to help insure proper alignment and

set aside to dry. Repeat for the other elevator half.

7

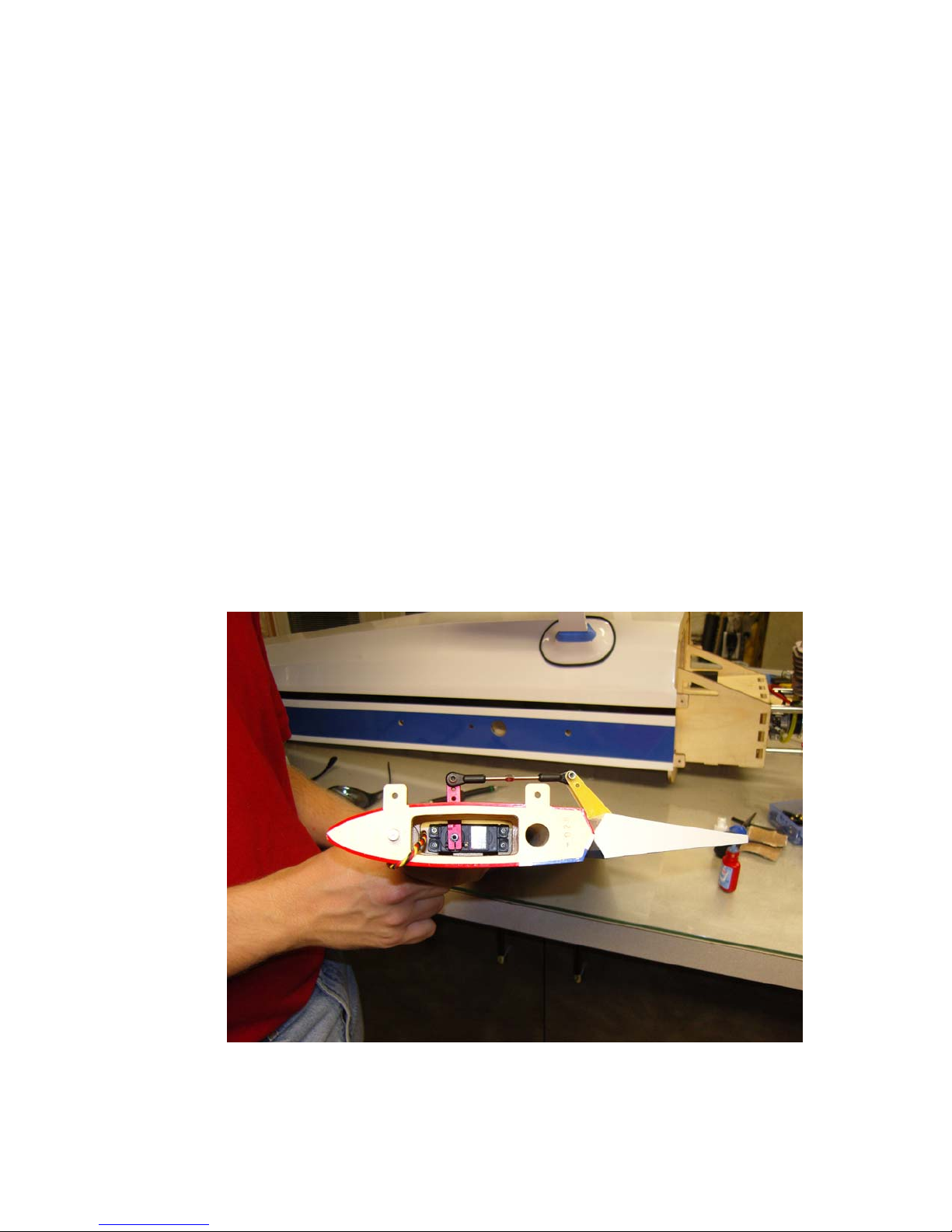

4. Use a sharp #11 blade to remove the covering from the slot for the

elevator servo control horn. You may have to slightly enlarge this

hole to allow for maximum travel.

5. Before installing the elevator servos, I highly recommend that you

take a moment and wick some thin CA (I prefer the Mercury

Adhesives line of CAs) around the servo mounting rib and root rib

where they attach to the sheeting as well as the anti-rotation pin

where it is mounted in the stab. Temporarily install the servo arms

and electronically center the servos. It will be much easier to

match up the servos at this point than when they are installed. I

also recommend that you thin a small amount of epoxy with a few

drops of alcohol and apply a light coat to the inside of the stab and

to the servo mounting rib as well as to the root rib and mounting

tabs. Over time exhaust residue begins to collect here and by

sealing it with epoxy you will prevent degradation of the wood.

8

9

6. Use the manufacturer supplied mounting hardware and install the

elevator servo with the output shaft toward the front of the stab.

Feed the servo wire out of the hole in front of the servo and out of

the root rib. You will need to attach a 36” servo extension to the

servo lead to reach the receiver in the radio compartment. If you

intend to remove your stabs for transport you will need a longer

extension or additional extensions.

7. In this step I will outline the procedure we use to install the hinges.

There are several ways to do this and several adhesives you can

use. We will describe the way we do it, as this method has proven

itself over many years of model building. If you are new to this

type of hinging process then I recommend that you install a single

hinge first just to acquaint yourself with this method. Before

starting the process get a few items together that will aid you as

you proceed. You will need the following items: 30 minute epoxy

(again, we recommend Pacer Z-Poxy), a scrap piece of pushrod or

1/8” dowel, paper towels and denatured alcohol. Locate 3 hinges

per elevator half. You will need to cut 1 hinge just beyond the

second knuckle to clear the fiberglass tube socket in the stabilizer.

Insert the carbon fiber wing tube into the socket while testing for

proper hinge length to avoid damaging the fiberglass sleeve. Mix a

generous batch of 30 minute epoxy. Use the pushrod or dowel to

thoroughly coat and fill the hinge hole with epoxy, then coat the

hinge with epoxy. Push the hinge into its hole until the joint is

10

about a ¼” from its final position and use a paper towel to remove

the excess epoxy that has been forced from the hole. Push the

hinge the rest of the way in and make sure the hinge pin is centered

in the hinge line. Use some denatured alcohol and a paper towel to

remove all excess epoxy, especially on the hinge pin. When you

are satisfied with the result set the surface aside to dry. Position

the drying piece so that any excess epoxy will pool around the rear

of the hinge.

8. When you are comfortable with this process you should be able to

do one side of a surface per batch of epoxy. Glue all hinges into

the stabilizer first. After the glue has set trial fit the elevator to the

stab and adjust if necessary. There should be as little gap as

possible between the stab and elevator. When satisfied with the fit

remove the elevator and repeat the gluing process outlined above.

Be sure to wipe away all excess epoxy! Set aside to dry. Repeat

this process for the other stab/elevator half.

9. After the hinges have dried thoroughly, pull on them to make sure

they are properly installed. The hinges will probably feel a little

stiff as it is almost impossible to get all of the glue out of the joint.

Use a fine tipped hypodermic needle and place one (only one!)

drop of acetone on each side of the hinge pin. Move the elevator

back and forth a few times and you will feel it loosen up.

Be careful to only use one drop as you don’t want to weaken

the glue joint! Add a drop of penetrating oil to each hinge pin and

11

you will ensure a smooth operating surface with no binding. Seal

the bottom of the hinge gap with a strip of Ultracote or Blenderm

tape. Be sure to fully deflect the control surface when applying the

tape or Ultracote to allow full deflection once the gap is sealed.

10. Thread 2 of the heavy duty ball links onto one of the titanium

pushrods. Remember that the ends of the pushrods are reverse

threaded so that they can be adjusted like a turnbuckle without

removing the linkage. Insert a 3mm socket head cap screw into the

ball link and into the servo arm. If using the SWB arms you will

need to drill out the hole to accept the 3mm bolt. Secure with a

3mm nylon insert locknut.

11. Place the servo arm onto the servo (which you should have

electronically centered in a previous step) and make sure the

elevator is in the neutral position. Adjust the ball links until the

linkage fits between the composite control horns and lines up with

the pre-drilled top hole. Insert a 3mm socket cap screw into a

washer, through one side of the composite control horn, through

the ball link, and finally through the other composite control horn.

Secure with a 3mm nylon insert lock nut. Use blue Loctite on all

bolts! See finished set-up below.

12. As mentioned previously, you may need to adjust the size of the

servo arm exit slot to achieve maximum travel. A ¼” Drum sander

in a moto-tool makes quick work of this. Repeat these steps for the

other stab/elevator half. Before you set aside the stabs take a

12

Loading...

Loading...