Extraflame LCD User Manual

1

Pellet stoves user manual

lcd

english

2

index

3

We thank you for having chosen our company; our product is a great heating solution developed from the

most advanced technology with top quality machining and modern design, aimed at making you enjoy

the fantastic sensation that the heat of a ame gives, in complete safety.

Extraame S. p. A.

enGLiSH ....................................................................................................................................................................................................................................4

WarninGS ..................................................................................................................................................................................4

Safety ........................................................................................................................................................................................ 4

routine Maintenance .......................................................................................................................................................... 4

Safety deviceS ........................................................................................................................................................................ 5

inStaLLation ............................................................................................................................................................................ 5

InstallatIons allowed ...................................................................................................................................................................................................... 6

InstallatIons not allowed ............................................................................................................................................................................................ 6

ConneCtIon to the smoke evaCuatIon system ................................................................................................................................................... 6

smoke Channel or fIttIngs ............................................................................................................................................................................................. 6

ChImney or IndIvIdual flue ............................................................................................................................................................................................. 7

ChImney Cap ............................................................................................................................................................................................................................... 8

ConneCtIon to external aIr Inlets ........................................................................................................................................................................... 9

InsulatIon, fInIshIngs, CoverIng and safety reCommendatIons ........................................................................................................ 9

PeLLetS and feedinG .............................................................................................................................................................9

Souvenir SPacerS ................................................................................................................................................................10

Hot air ductinG ....................................................................................................................................................................10

grazIosa plus .........................................................................................................................................................................................................................10

souvenIr .....................................................................................................................................................................................................................................11

elIsIr ..............................................................................................................................................................................................................................................11

emma plus and tosCa plus.............................................................................................................................................................................................12

addItIonal thermostat for duCt motor Control ......................................................................................................................................12

controL Board .....................................................................................................................................................................13

dIsplay ICons ...........................................................................................................................................................................................................................13

GeneraL Menu .......................................................................................................................................................................14

BasIC InstruCtIons .............................................................................................................................................................................................................14

tHe reMote controL ........................................................................................................................................................... 15

delayed swItCh-off aCtIvatIon ..................................................................................................................................................................................15

type and replaCement of BatterIes ........................................................................................................................................................................15

coMMiSSioninG SettinGS ...................................................................................................................................................16

adjustIng tIme, day, month and year .....................................................................................................................................................................16

adjustIng language ..........................................................................................................................................................................................................16

functioninG and LoGic .....................................................................................................................................................17

additionaL externaL tHerMoStat (oPtionaL)...........................................................................................................18

uSer Menu...............................................................................................................................................................................18

dIsplay .........................................................................................................................................................................................................................................18

pellet feed adjustment...................................................................................................................................................................................................18

v1-fan ............................................................................................................................................................................................................................................19

stand By ......................................................................................................................................................................................................................................19

keys loCked...............................................................................................................................................................................................................................20

v2 -fan ...........................................................................................................................................................................................................................................21

reset ..............................................................................................................................................................................................................................................21

cHrono .................................................................................................................................................................................... 21

programmIng example .....................................................................................................................................................................................................22

cLeaninG under uSer'S reSPonSiBiLity.........................................................................................................................23

routine Maintenance .......................................................................................................................................................24

diSPLayS ..................................................................................................................................................................................25

aLarMS ....................................................................................................................................................................................26

Warranty conditionS .......................................................................................................................................................27

4

WARNINGS

The instruction manual is an integral part of the product: make sure that it always accompanies the appliance, even if transferred

to other owners or user or is transferred to another place. If it is damaged or lost,request another copy from the area technician.

This product must be destined for the use for which it has been expressly realised. The manufacturer is exempt from any liability,

contractual and extracontractual, for injury/damage caused to persons/animals and objects, due to installation, adjustment

and maintenance errors and improper use. Installation must be performed by qualied sta, which assumes complete

responsibility for the denitive installation and consequent good functioning of the product installed. It is necessary to

bear in mind all laws and national, regional, provincial and town council Standards present in the country the appliance

has been installed.

Extraame S.p.A. cannot be held responsible for the failure to comply with such precautions.

After removing the packaging, ensure that the content is intact and complete. If not so, contact the dealer where the appliance

was purchased.

All electric components that make up the product must be replaced with original spare parts exclusively by an authorised aftersales centre, thus guaranteeing correct functioning.

SAFETY

The stove must not be used by persons (including children) with reduced physical, sensorial and mental capacities or who

are unskilled persons, unless they are supervised and trained regarding use of the appliance by a person responsible for their

safety.

Children must be controlled to ensure that they do not play with the appliance.

Do not touch the stove when you are barefoot or when parts of the body are wet or humid.

The safety and adjustment devices must not be modied without the authorisation or indications of the manufacturer.

Do not pull, disconnect, twist electric cables leaving the stove, even if disconnected from the electric power supply mains.

It is advised to position the power supply cable in a way that it does not come into contact with hot parts of the appliance.

The power supply plug must be accessible after installation.

Do not close or reduce the dimensions of the airing vents in the place of installation. The airing vents are indispensable

for correct combustion.

Do not leave the packaging elements within reach of children or unassisted disabled persons.

The hearth door must always be closed during normal functioning of the product.

When the appliance is functioning and hot to the touch, especially all external surfaces, attention must be paid

Check for the presence of any obstructions before switching the appliance on following a prolonged standstill period.

The stove has been designed to function in any climatic condition (also critical). In particularly adverse conditions (strong

wind, freezing) safety systems may intervene that switch the stove o. If this occurs, contact the technical after-sales service

and always disable the safety system.

If the ue should catch re, be equipped with suitable systems for suocating the ames or request help from the re

service.

This appliance must not be used to burn waste

Do not use any inammable liquids for ignition

During the lling phase do not allow the bag of pellets to come into contact with the product

The majolicas are top quality artisan products and as such can have micro-dots, crackles and chromatic imperfections.

These features highlight their valuable nature. Due to their dierent dilation coecient, enamel and majolica produce

crackling,. which demonstrate their eective authenticity. To clean the majolicas, it is recommended to use a soft, dry cloth. If

a detergent or liquid is used, the latter could penetrate inside the crackles, highlighting the same.

ROUTINE MAINTENANCE

Based on the Decree 22 January 2008 n°37 art.2, routine maintenance means interventions aimed at reducing degradation from

normal use, as well as dealing with accidental events entailing the need of rst interventions, which however do not modify the

structure of the system upon which one is intervening or its intended use according to the prescriptions foreseen by technical

standards in force and by the manufacturer's use and maintenance booklet.

ENGLISH

5

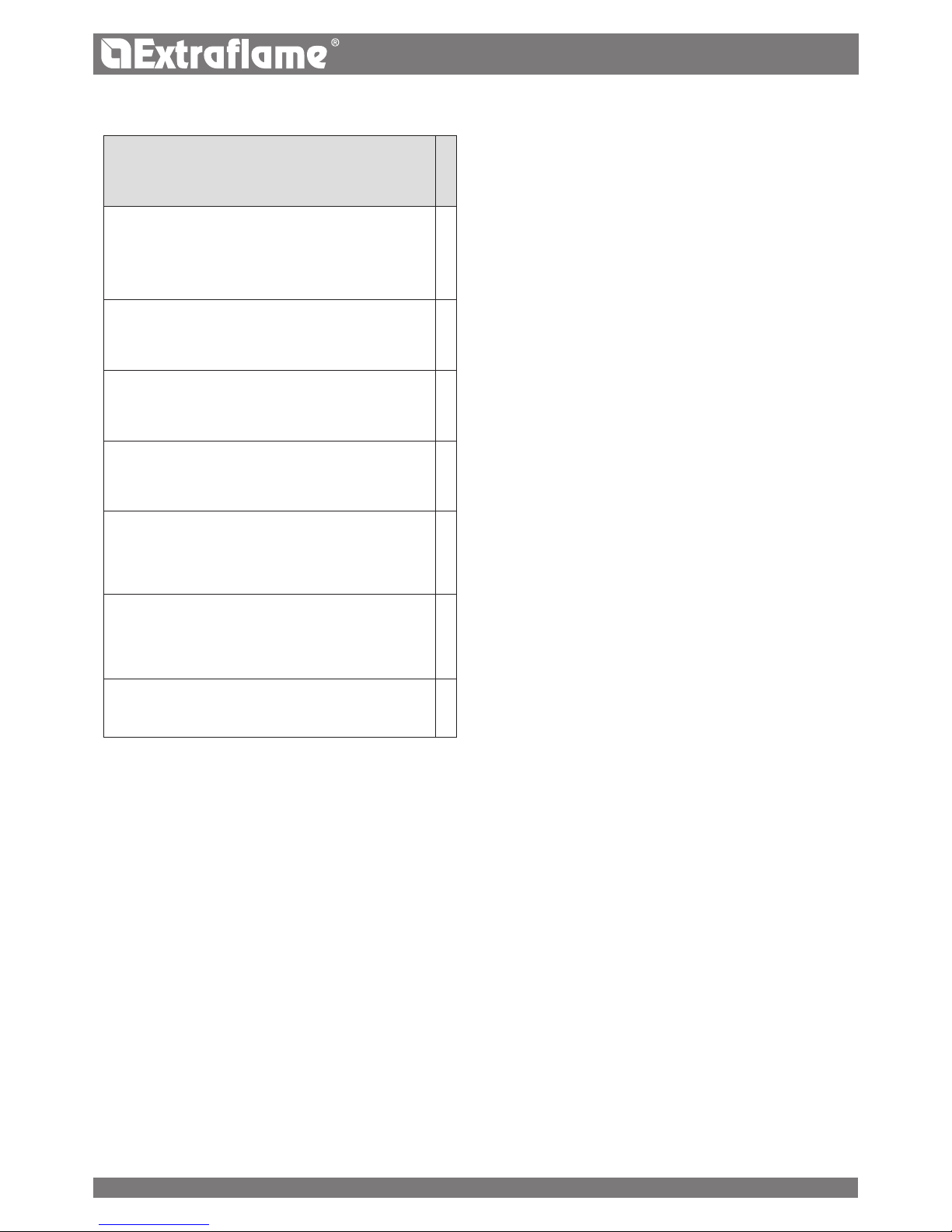

SAFETY DEVICES

SAFETY DEVICES

KEY: * = PRESENT, = NOT PRESENT

STOVES

Circuit board: intervenes directly by sending the product

into alarm conditions until complete cooling, in the case

of: breakage of ue gas motor, pellet feed motor breakage,

black out (if more than 10 seconds), no ignition

*

Insert blocking micro switch: if the end run micro switch

warns that the insert is not blocked, electric energy does

not pass to power it

-

Electronic pressure switch: in the event of inadequate

depression, it takes the machine to alarm conditions

*

F 2.5 A 250 V fuse (stoves): protects the machine from

violent current drops

*

85°C calibrated mechanical bulb with manual rearm:

intervenes by blocking fuel feed whenever the pellet tank

t° reaches the limit of 85°C. Rearm must be performed

by qualied sta and/or the manufacturer's technical

after-sales assistance.

*

Pellet feed-box temperature control probe: if the tank

over-heats, the machine automatically modulates to return

to normal temperature values (* in the models envisioned)

*

Mechanical air pressure switch: blocks the pellet in the

event of insucient depression (in the models envisioned)

*

INSTALLATION

The installation must be in compliance with:

UNI 10683 (2005) heat generators fed with wood and other

solid fuels: installation.

The chimneys must be in compliance with:

UNI 9731 (1990) chimneys: classication based on thermal

resistance.

EN 13384-1 (2006) Thermal and uid dynamic calculation

methods.

UNI 7129 point 4.3.3 Fire Department dispositions, local rules and

prescriptions.

UNI 1443 (2005) chimneys: general requisites.

UNI 1457 (2004) chimneys: clay/ceramic ue liners.

NATIONAL, REGIONAL, PROVINCIAL AND TOWN

COUNCIL REGULATIONS

It is necessary to bear in mind all laws and national, regional,

provincial and town council Standards present in the country

the appliance has been installed.

GLOSSARY

CLOSED HEARTH APPLIANCE

Heat generator which opening is only allowed through the

loading of the fuel during use.

BIOMASS

Biological material, excluding the material incorporated in

geological formations and transformed into fossils.

BIOFUEL

Fuel produced directly or indirectly by biomass.

CHIMNEY

Vertical pipe with the aim of collecting and expelling the fuel

products coming from only one appliance, at a convenient

height from the ground.

SMOKE CHANNEL OR FITTING

Pipe or connecting element between heat generator appliance

and chimney to evacuate combustion products.

INSULATION

Group of set-ups and materials used to prevent the

transmission of heat through a wall that separates rooms with

dierent temperatures.

CHIMNEY CAP

Device positioned at chimney peak to ease the dispersion of

combustion products into the atmosphere.

CONDENSATE

Liquid products that form when the combustion gas

temperature is lower or equal to the water dew point.

HEAT GENERATORS

Appliance which allows to produce thermal energy (heat)

through the rapid transformation, via combustion, of the

chemical energy of the same fuel.

GATE VALVE

Mechanism for modifying the combustion gas dynamic

resistance.

COMBUSTION PRODUCT EVACUATION SYSTEMS

Flue gas exhaust system independent from the appliance

constituted by a tting or smoke channel, chimney or

individual ue and chimney cap.

FORCED DRAUGHT

Air circulation by means of the fan activated by electric motor.

NATURAL DRAUGHT

Draught which is determined in a chimney/ue for eect of

the volume mass dierence existing between smoke (hot) and

surrounding atmosphere air, without any mechanical intake

aid installed inside it or at its peak.

ENGLISH

6

RADIATION AREA

Area immediately near the hearth in which the heat caused by

combustion is diused, where no combustion materials must

be present.

REFLUX AREA

Area where leaking of the combustion products is veried,

from the appliance towards the installation room.

The installation must be preceded by checking the chimneys,

ues or unload terminals positioning of appliances similarly

to:

Installation prohibitions

Legal distances

Limitations disposed by local administrative regulations

or particular authority prescriptions.

Conventional limitations deriving from condominium

regulations, constraints or contracts.

INSTALLATIONS ALLOWED

Only appliances working in a sealed manner respect to the

room or which do not place the room in depression respect to

the external environment, can exist or be installed in the room

where the heat generator will be installed.

Appliances for cooking food and relative hoods without

extractor are only allowed in kitchens.

INSTALLATIONS NOT ALLOWED

In the room where the heat generator will be installed the

following must not pre-exist or be installed:

hoods with extractor.

collective type ventilation pipes.

Should these appliances be in rooms adjacent, communicating

with the installation room, the simultaneous use of the heat

generator is forbidden, where a risk exists of one of the two

rooms being placed in depression respect to the other.

CONNECTION TO THE SMOKE EVACUATION SYSTEM

UNI 10683 (2005) Standard

SMOKE CHANNEL OR FITTINGS

To mount the smoke channels, non-ammable elements will

have to be used, ideal for resisting combustion products and

their eventual condensing.

The use of exible metal and asbestos cement pipes to

connect the appliances to the ue is forbidden, even for preexisting smoke channels.

There must be continuity between the smoke channel and the

ue so that the ue does not lean on the generator. The smoke

channels must not cross rooms where the installation of the

combustion appliances is not allowed.

The mounting of the smoke channels must be carried out in

order to guarantee smoke seal for the appliance functioning

conditions, limit the forming of condensate and avoid it being

transported towards the appliance.

The mounting of horizontal routes must be avoided.

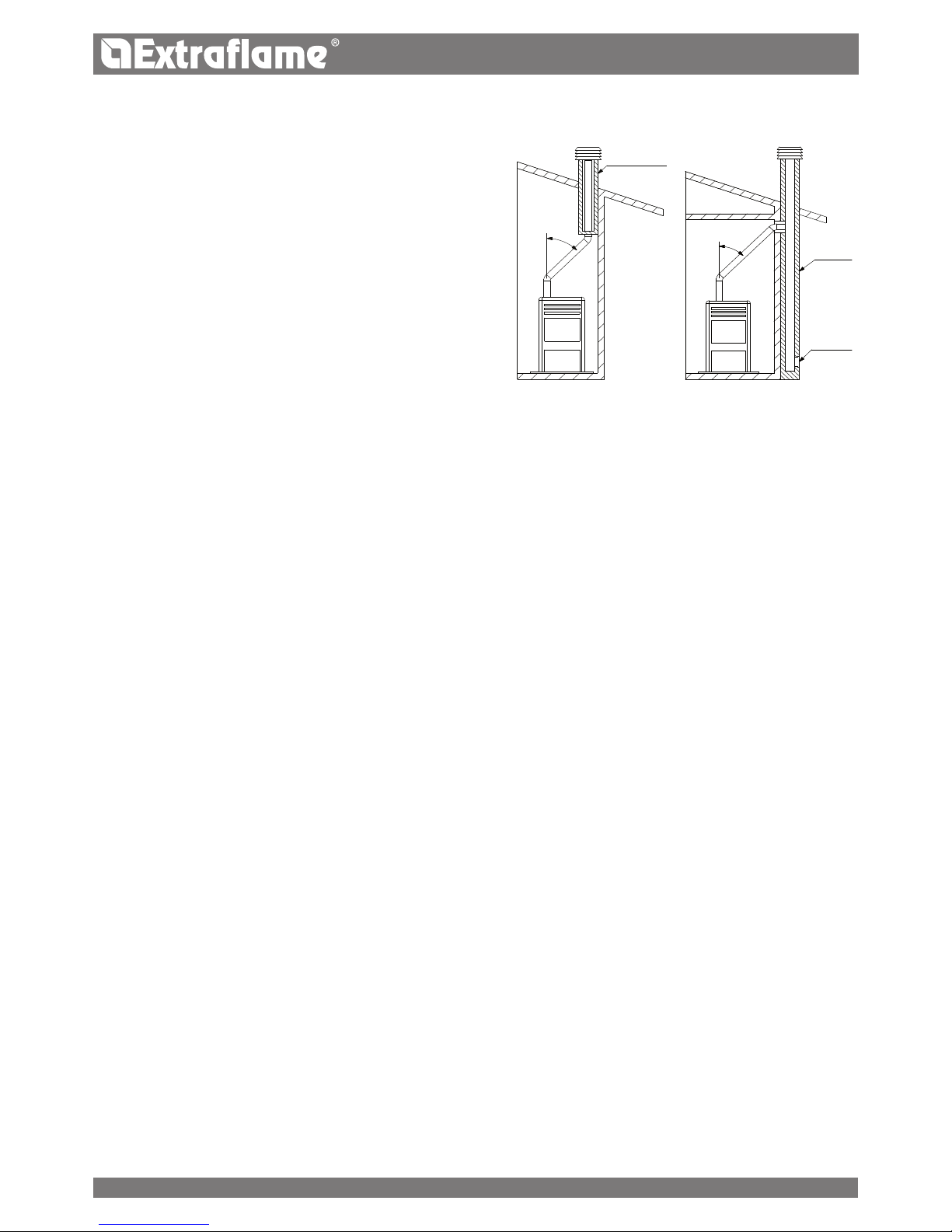

For appliances where ceiling or wall non-coaxial discharges

with respect to the appliance combustion product outlet have

to be reached, the direction changes will have to be realised

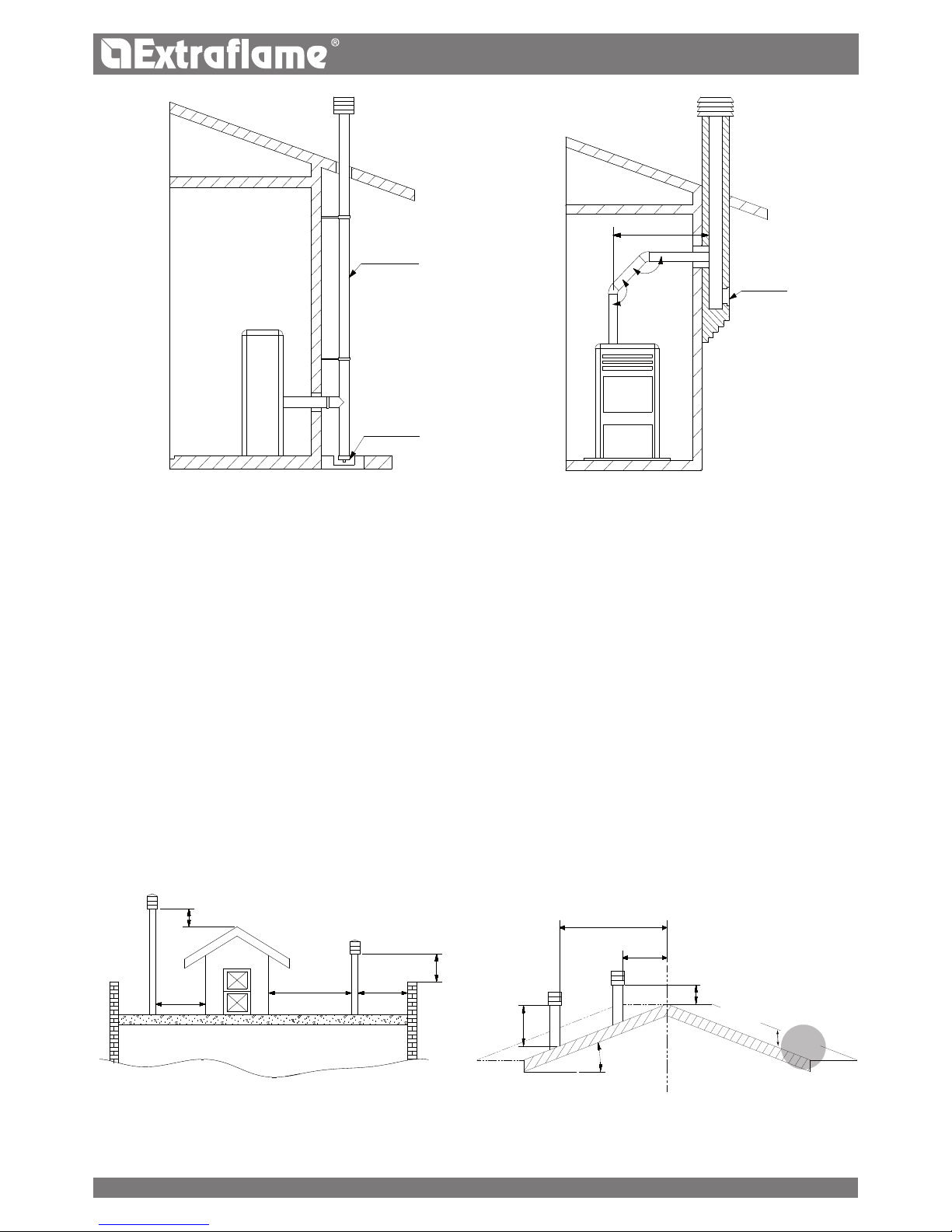

using open bends not greater than 45° (see gures below).

For the heat generator appliances equipped with electric fan

for expelling combustion products, the instructions below

must be followed:

45°

<

45°

<

The horizontal routes will have to have a minimum

upward slope of 3%

The length of the horizontal route must be minimal and,

however, not longer than 3 metres

The number of direction changes including the one for

eect of using the "T" element must not be more than 4.

In any case, the smoke channels must seal the combustion and

condensate products and be insulated if they pass outside the

installation room.

The use of counterslope elements is forbidden.

The smoke channel must allow the recovery of soot or be

brushable.

The smoke channel must have constant section. Any section

changes are only allowed at the ue coupling.

It is forbidden to have other air supply channels and pipes for

plant engineering, especially if over-sized, transit inside the

smoke channels. The mounting of manual draught adjustment

devices on forced draught appliances is forbidden.

Insulating

product

Flue

pipe

Inspection

ENGLISH

B

C

A

S

< 3 m

3 - 5 %

7

CHIMNEY OR INDIVIDUAL FLUE

The chimney or individual ue must respond to the following requisites:

seal the combustion products, be waterproof and adequately insulated in line with the use conditions;

be realised with materials which resist the normal mechanical stress, heat, action of the combustion products and any

condensate;

have mainly vertical progress with deviations from the axis not higher than 45°;

be adequately distanced from fuel or ammable materials through air space or opportune insulation;

have preferably circular internal section: the square or rectangular sections must have round corners with a radius not

lower than 20 mm;

have constant internal section, free and independent;

have rectangular section with max. ratio between the sides of 1.5.

It is recommended that the smoke pipe be equipped with a collection chamber for solid materials and any condensate situated

under the smoke channel inlet, so that it can be easily opened and inspected from airtight door.

REFERENCES INFLAMMABLE OBJECTS NONINFLAMMABLE OBJECTS

A 200 mm 100 mm

B 1,500 mm 750 mm

C 200 mm 100 mm

Minimum 80 cm

2

S= oor protection

Air inlets

Chimney cap

Flue

Inspection

Inspection

Flue

Inspection

ENGLISH

< 3 m

45°

45°

50 cm

< 5 m

> 5 m

< 5 m

50 cm

H min

β

>A

<A

>50 cm

Z

8

External pipe

that is isolated

Inspection

Inspection

Appliance connection to the ue and combustion products evacuation

The ue must receive the discharge from only one heat generator.

Direct discharge towards closed spaces is forbidden, even with clear sky.

The direct discharge of the combustion products must be at roof and the smoke pipe must have the features provided in the

"Chimney or individual ue" section.

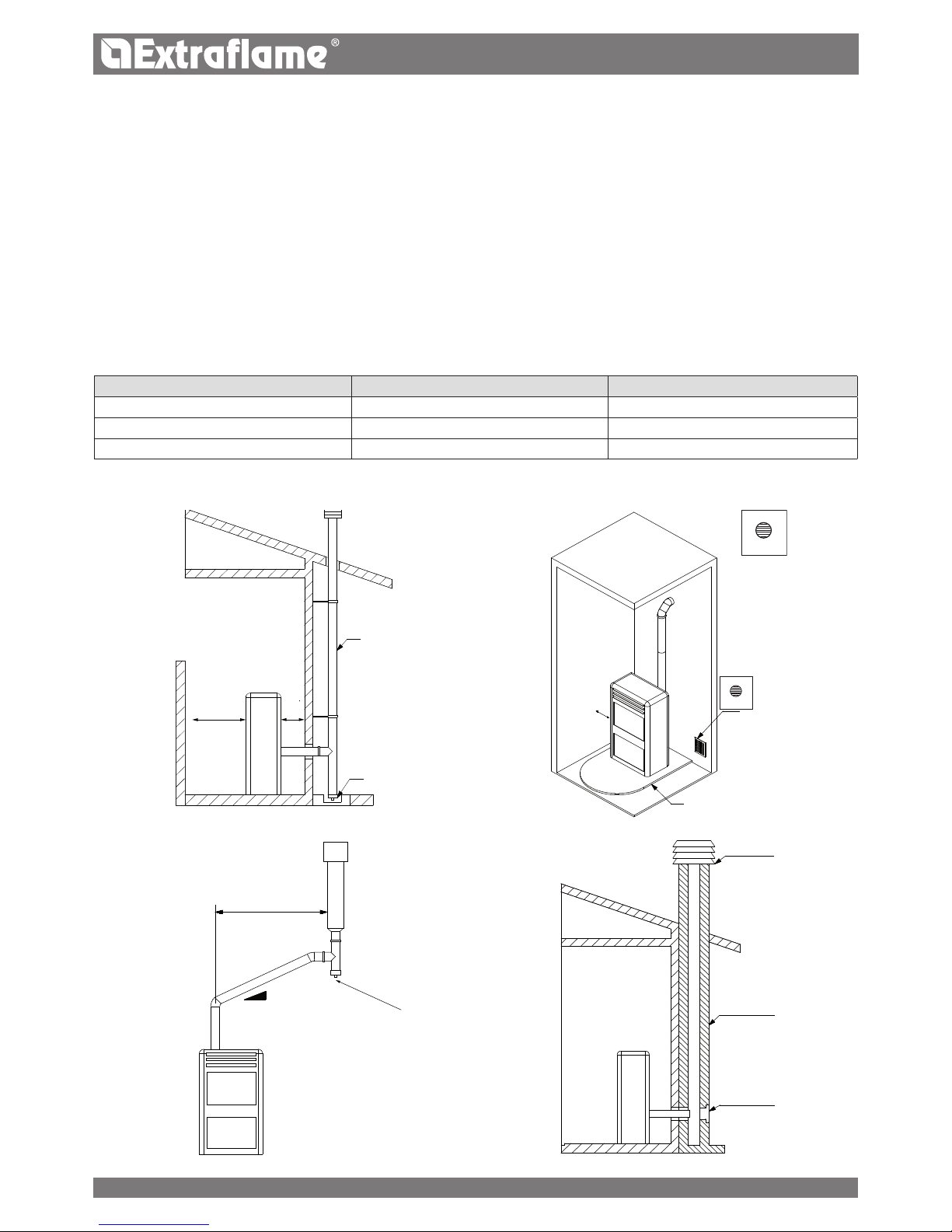

CHIMNEY CAP

The chimney cap must comply with the following requisites:

have an internal section equivalent to that of the chimney;

have useful outlet section not lower than double the chimney internal section;

be built in order to avoid rain, snow, foreign bodies penetrating the chimney and so that, in the event of winds in any

direction and inclination, the discharge of the combustion products is assured.

be positioned in a way to guarantee an adequate dispersion and dilution of the combustion products and, however, outside

the reux area in which the formation of counterpressures occurs. Such area has dierent dimensions and conguration

depending on the covering inclination angle. It is therefore necessary to adopt the minimum heights indicated in the gure

layouts below.

The chimney cap must not have mechanical intake means.

FLAT ROOF

SLOPING ROOF

Z=REFLUX AREA

ENGLISH

9

CONNECTION TO EXTERNAL AIR INLETS

The appliance must be able to use the necessary air to guarantee regular functioning through external air inlet. The air inlets

must comply with the following requisites:

have a total free section of at least 80 cm².

must be protected by grates, metal net or suitable protections as long as they do not reduce the minimum section stated

in the previous point and positioned in order to avoid them being obstructed.

If the combustion agent air is withdrawn directly from outside through a pipe, a downward bend must be mounted outside

or a protection against the wind and no grates or similar must be positioned, (it is recommended that the air vent always

communicates directly with the installation room even if the air is withdrawn from outside through a pipe). The air ow can also

be obtained from an adjacent room, as long as the ow takes place freely through permanent openings communicating with

the outside.

The adjacent room, with respect to the installation room, must not be put in depression with respect to the external environment

by means of reverse draught caused by the presence of another used appliance or intake device in such room. The permanent

openings in the adjacent room must comply with the above-described requisites. The adjacent room cannot be set up as garage,

storage for combustion material or activity with danger of re.

INSULATION, FINISHINGS, COVERING AND SAFETY RECOMMENDATIONS

The coverings, independently from the materials from which they are made, must constitute a self-supporting construction

with respect to the heating block and not be in contact with it.

The cross members and nishings in wood or combustion materials must be positioned outside the hearth radiation area or

adequately insulated.

If coverings in combustion material or sensitive to heat exist in the space above the generator, an insulating and non combustible

protection diaphragm must be inserted.

Elements in combustible or inammable material like wooden furniture, curtains, etc. directly exposed to the hearth radiation,

must be positioned at a safe distance. The appliance installation must guarantee easy access for cleaning the appliance itself,

discharge gas pipe and ue.

CHIMNEY CAPS, DISTANCES AND POSITIONING

Roof inclination Distance between the ridge and the chimney Minimum chimney height (measured from outlet)

β A (m) H (m)

15°

< 1,85 0.50 m over the ridge

> 1,85 1,00 m from roof

30°

< 1,50 0.50 m over the ridge

> 1,50 1,30 m from roof

45°

< 1,30 0.50 m over the ridge

> 1,30 2,00 m from roof

60°

< 1,20 0.50 m over the ridge

> 1,20 2.60 m from roof

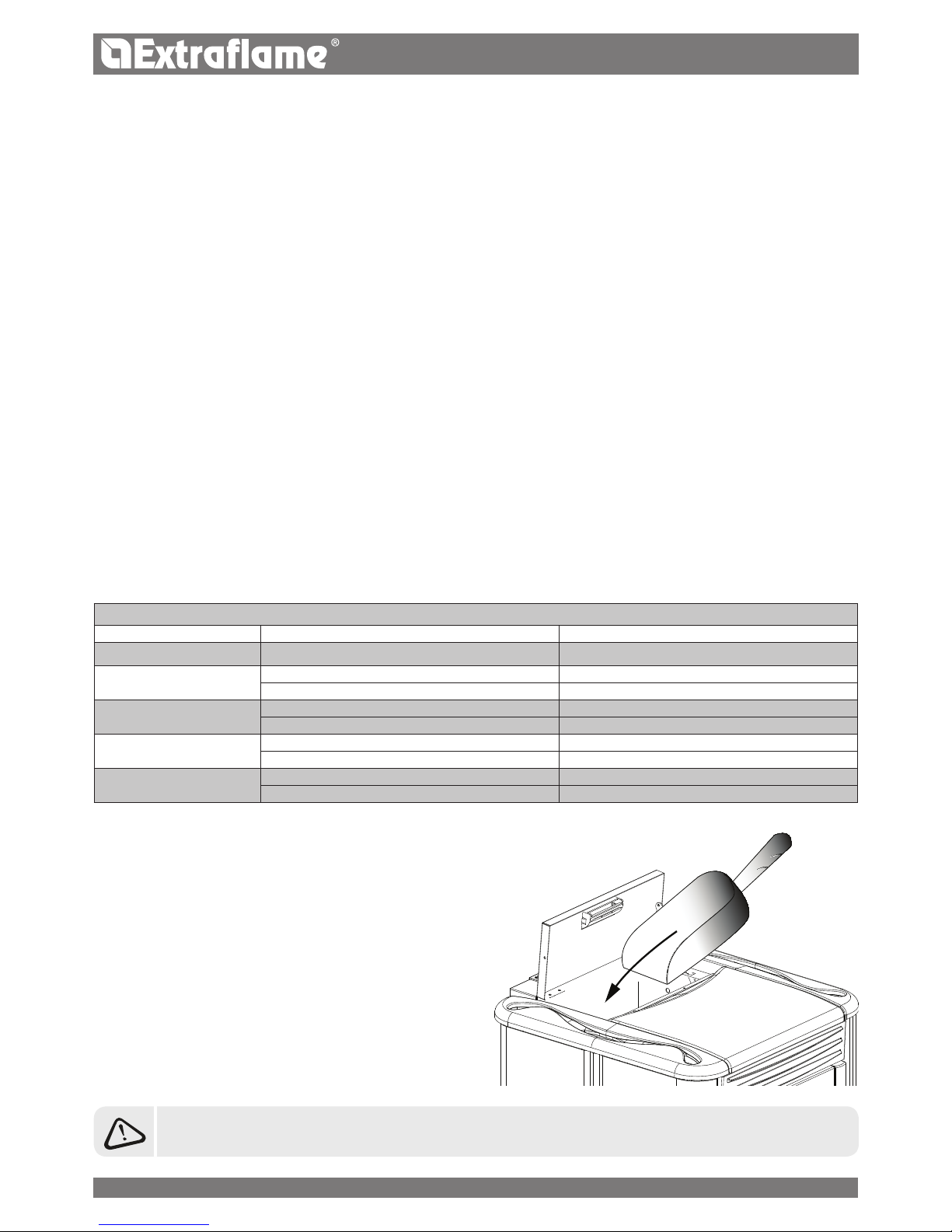

Open the tank lid and load the pellets using a scoop.

PELLETS AND FEEDING

The pellets used must comply with the features described by

the Standard:

Ö-norm M 7135

DIN plus 51731

UNI CEN/TS 14961

Extraame recommends the use of pellets with

a 6 mm diameter for its products.

THE USE OF EXPIRED PELLETS OR ANY OTHER MATERIAL DAMAGES THE FUNCTIONS OF YOUR STOVE AND CAN

DETERMINE THE INVALIDITY OF THE WARRANTY AND THE ANNEXED RESPONSIBILITY OF THE MANUFACTURER.

ENGLISH

Loading...

Loading...