Extraflame EcoLogica Idro, ECOLOGICA, I.C. MINI, I.C. MAXI, BABYFIAMMA Use And Maintenance Manual

...

PELLETS STOVES

Use and maintenance manual

BELLADIVINA

ECOLOGICAIDRO

ECO

LOGICA

I.

C. MAXI

BABYFIAMMA PREZIOSA

BELLA LUX CONTESSA

I.

C. MINI

English

2

Congratulations! You are now the owner of an EXTRA FLAME stove !

The pellet stove EXTRA FLAME is an ideal heating solution. It springs from the most advanced

technology and is manufactured to the highest standards with an up-to-date design, allowing you

to enjoy the fantastic sensation which the heat of a flame can give, in complete safety at all

times.

This manual tells you how to use your stove correctly. Please read it all carefully before using.

IMPORTANT

Ensure that the dealer completes the following box with the details of the authorised specialist

who will help you if you have any problems in using your new pellet stove.

AUTHORISED SPECIALIST

COMPANY

MR./MS.

STREET N.

POSTAL CODE TOWN

PHONE FAX

3

Contents

IMPORTANT ................................................................................................................... 2

1 PRECAUTIONS AND SAFETY .......................................................................….... 4

2 TECHNICAL SPECIFICATIONS........................................................…..............…... 5

3 AIR REQUIRED FOR COMBUSTION..............................................….................…. 11

3.1 External air intake pipe assembly.....................................................................….. 11

4 WHAT PELLETS ARE.........................................................................................…. 12

4.1 Pellet storage.......................................................................................…............. 12

5 SAFETY DEVICES.................................................................................................. 13

5.1 Warm air distribution fan breakdown ................................................................... 13

5.2 Fume extractor breakdown ................................................................................... 13

5.3 Pellet loading motor breakdown ........................................................................... 13

5.4 Lighting failure..................................................................................................... 13

5.5 Temporary power failure ...................................................................................... 13

5.6 Electrical safety.................................................................................................... 13

5.7 Fume exhaust safety............................................................................................. 13

5.8 Safety for pellet overheating ................................................................................. 13

5.9 Safety plant pressure ( Ecologica Idro)…………………………….............……..…... 13

5.10 Safety water boiling (Ecologica Idro)……...............…………………....……………. 13

6 ASSEMBLY & INSTALLATION INSTRUCTIONS.........................................…............ 14

6.1 Assembly............................................................................................................. 14

6.2 Installation ....................................................................................…................... 14

6.3 Fume exhaust....................................................................................................... 15

6.4 Electrical connection............................................................................................. 16

6.5 Canalisation DIVINS PLUS………………………………………………...............…….16

7 INSTALLATION I.C. Maxi and Mini ……..………………………………..…...........….17

8 CONTROL PANEL……………………………………………………………..............… 23

8.1 Description of control panel alarms………………………………............….………… 24

9 USE.............................................................................…................…................. 24

10 LIGHTING......................................................................................……............... 25

11 NORMAL OPERATION – TURNING OFF, REMOTE CONTROL.….................…......... 25

11.1 Normal operation ...............................................................................….…......... 25

11.2 DIVINA PLUS operation………………………………………………............………… 26

11.3 Turning off.................................................................................…....................... 26

11.4 Remote control...........................................................................…....................... 26

12 ROOM THERMOSTAT............................................................................................ 27

12.1 Digital thermostat........................................................................................…...... 27

12.2 Mechanical thermostat (optional)........................................................................... 28

12.2.1 Mechanical thermostat installation (optional).......................................................... 28

12.2.2 Mechanical thermostat operation .......................................................................... 28

12.2.3 Mechanical thermostat operation with energy saving function (Stby)........................ 28

12.2.4 Mechanical thermostat operation for canalis.motor (DIVINA PLUS)……................... 28

12.3 User parameters…………………………………………………………..............……. 30

13 CHRONOTHERMOSTAT……………....................................................................... 31

13.1 “Day/Night” temperature function..................................................................…… 32

13.2 Pellet feeding adjustment…………......................................................................... 32

13.3 Motor parameters for DIVINA PLUS connection ………............…………………..…. 33

13.4 Alarm signalling.................................................................................….......…… 34

14 Operation of the radiofrequency remote control for I.C. Mini…………..............…. 35

15 CLEANING AND MAINTENANCE.....................................................................…. 41

15.1 Cleaning Ecologica,I.C.Maxi, Ecologica IDRO.........................................................42

15.2 Cleaning Bella, Bella Lux, Divina, Contessa,Preziosa, Babyfiamma ……..............…. 44

15.3 Cleaning I.C.Mini................................................................................................. 46

15.4 Chimney connection...........................................................................…............... 46

16 PROBLEMS, CAUSES AND SOLUTIONS................................................................. 47

17 GUARANTEE................................................................……................................. 49

18 QUALITY CONTROL...............................................................……....................... 50

19 APPENDIX…………………………………………………………….…………........…. 51

4

1 PRECAUTIONS AND SAFETY

The stoves manufactured in our works are built

with the maximum dedication to the individual

components so as to protect both the user and

the installer from accidents. The qualified

personnel are therefore advised to pay special

attention to the electrical connections after

every operation on the product, especially with

regard to the stripped part of the wires which

must not protrude in any way from the terminal

block, thereby preventing possible contact with

the live parts of the wire.

Installation must be carried out by qualified

personnel who must issue a declaration of

compliance of the system with good practice

to the purchaser, who shall assume responsibility for the definitive installation and consequent proper operation of the product

installed. Extraflame S.p.A. shall not be

responsible in the event of failure to

observe these precautions.

This instruction manual constitutes an integral

part of the product: ensure that it always

accompanies the appliance, even if passed to

another owner or user or moved to another

installation. If damaged or lost, ask the local

technical service for another copy.

This stove must be used exclusively for the

applications it was expressly designed for.

The manufacturer shall not be responsible

contractually or extra-contractually for any

damage caused to persons, animals or property

by installation, adjustment and maintenance

errors, or by improper use.

After removing the packaging, ensure that the

contents are intact and complete. If this is not

the case, contact the dealer from whom the

appliance was purchased.

Stove maintenance must be carried out at least

once a year, scheduling it sufficiently in

advance with the service centre.

The following safety precautions must be

observed:

The use of the stove by unattended children and

handicapped persons it not recommended.

Do not touch the stove if you are bare-footed or

if parts of your body are wet or damp.

Modifying the safety or adjustment devices

without the manufacturer’s approval or

instructions is forbidden.

Never pull, detach or twist the electric wires

coming out of the boiler even when the electricity

supply is disconnected.

Do not plug or reduce the dimensions of the

aeration apertures of the room in which the

stove is installed.

The aeration openings are indispensable for a

correct combustion.

Never leave the packaging materials within

reach of children or unattended disabled

persons.

ONLY FOR THE MODEL IDRO:

Before installation, we recommend that you

thoroughly wash all the piping in the system to

remove any residues which could affect the

efficiency of the appliance.

During installation, it is necessary to inform

users that:

• If there is any water leakage, they must shut

off the water supply and promptly notify the

technical support service.

• They must periodically check the working

pressure of the plumbing system.

If the stove is not being used for a long period,

users are advised to call the technical

assistance service engineers to carry out at

least the following operations:

• Turn the main switch to position 0

• Close the water cocks of both the heating

and sanitary systems

• Drain the heating and sanitary systems if

there is any risk of freezing

Stove maintenance must be carried out at least

once every year, scheduling it sufficiently in

advance with the service centre.

5

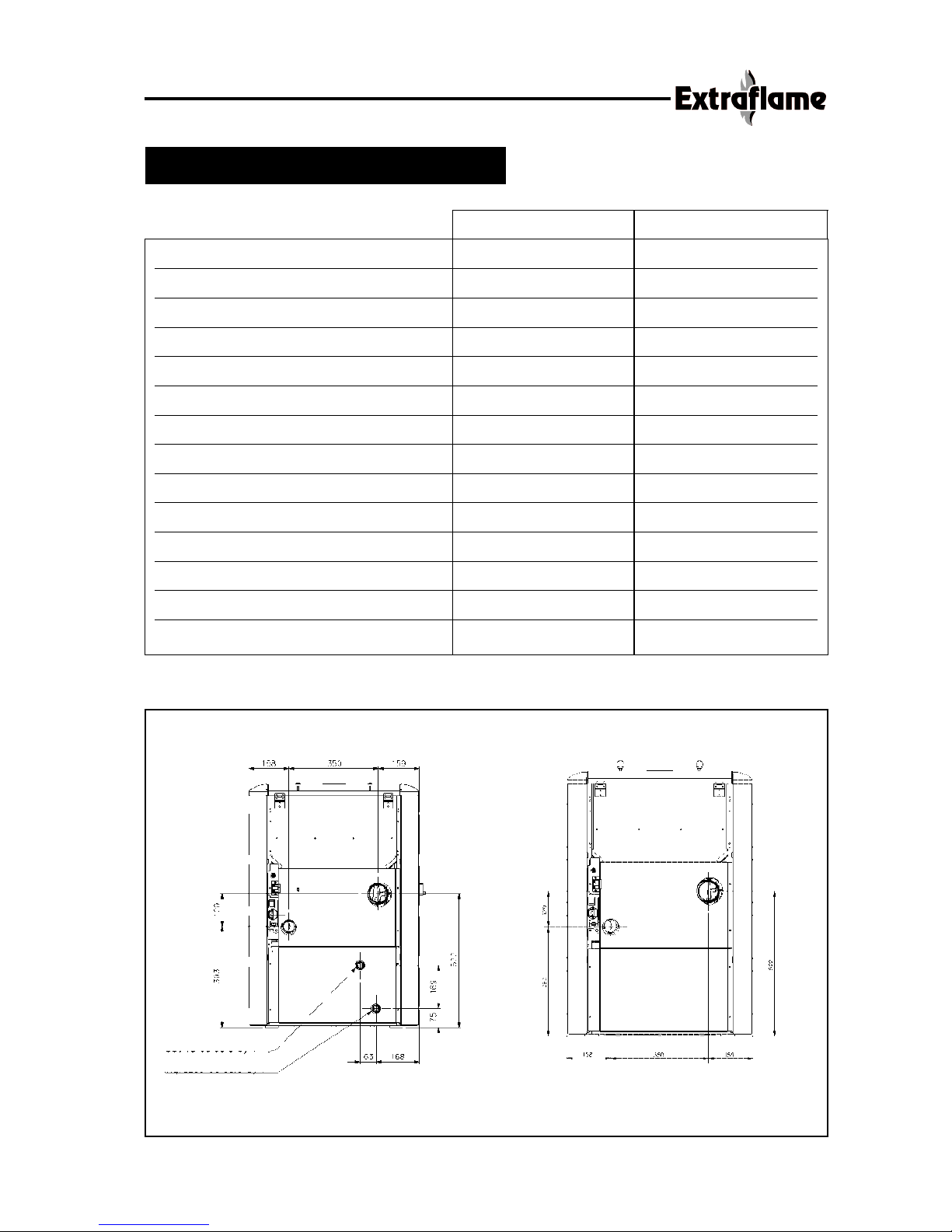

2 TECHNICAL SPECIFICATIONS

All a.m. data are not binding, but valid just as an indication.

The right to make technical modifications for improving the product is reserved.

Height 945 mm. 945 mm.

Width 670 mm. 670 mm.

Depth 670 mm. 670 mm.

Weight 156 Kg. 150 Kg.

Fume exhaust pipe diameter 80 mm. 80 mm.

Max heating volume / m

3

220 m

3

Total power 14,47 kW/h 2,5 - 11 kW/h

Water power 8,5 kW/h / kW/h

Pellet consumption per hour 0,6 - 3,0 Kg/h 0,6 - 2,4 Kg/h

Absorbed electrical power 25 - 190 W 25 - 100 W

Lighting power +280 W +280 W

Power supply 230 V 50 Hz 230 V 50 Hz

Feed box capacity ~30 kg. ~35 kg.

Inlet/outlet water pipe “ 3/4 “ /

EcoLogica Idro

Ecologica

EcoLogica

EcoLogica Idro

B

A

B

A

A: FUMES OUTLET PIPE ø 80

B: AIR INTAKE PIPE ø 50

Boiler outlet “3/4

Boiler inlet “3/4

6

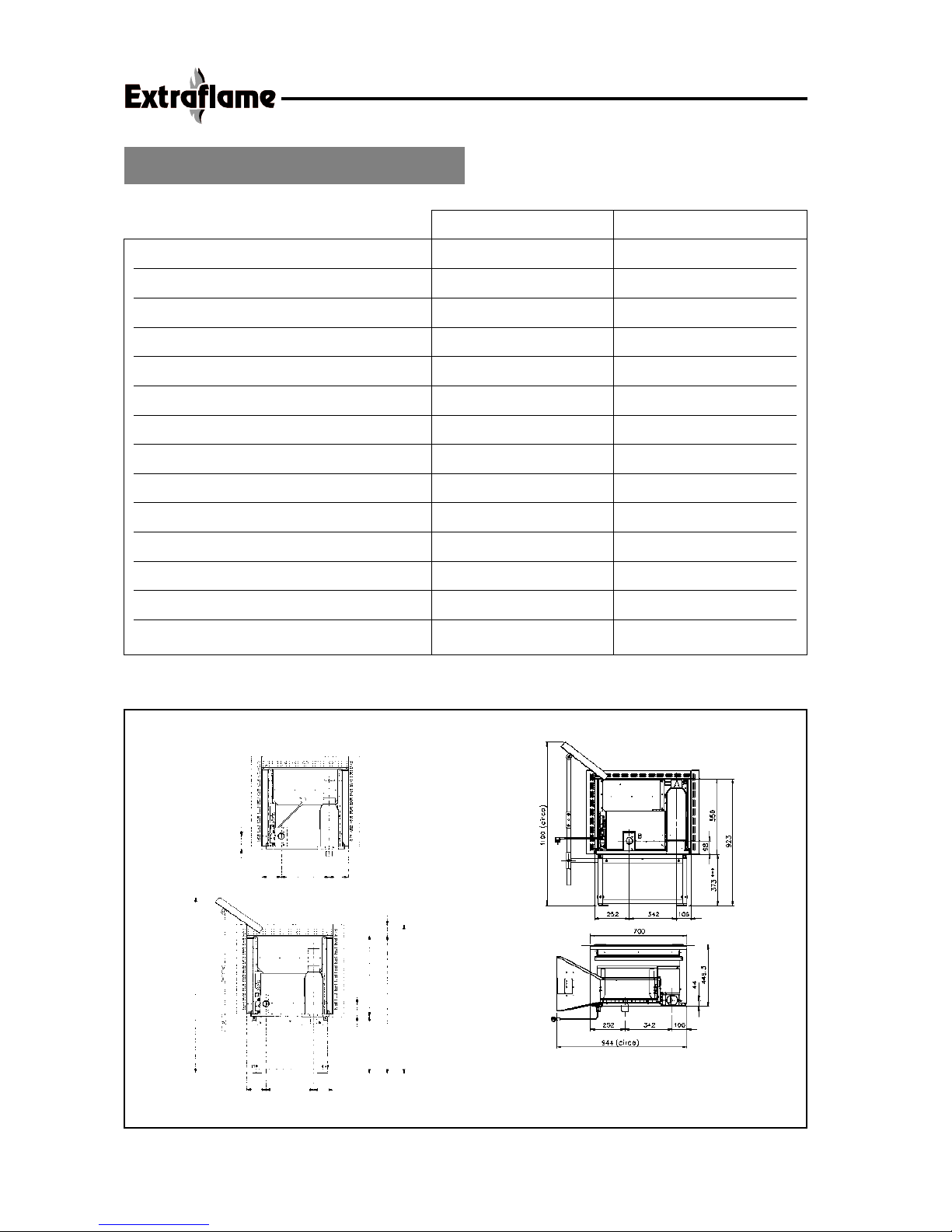

TECHNICAL SPECIFICATIONS

All a.m. data are not binding, but valid just as an indication.

The right to make technical modifications for improving the product is reserved.

Height 606 mm. 550 mm.

Width 640 mm. 700 mm.

Depth 717 mm. 450 mm.

Weight 130 Kg. 110 Kg.

Fume exhaust pipe diameter 80 mm. 80 mm.

Max heating volume 190 m

3

150 m

3

Total power 2,5 - 9,4 kW/h 2,5 - 7,5 kW/h

Water power / kW/h / kW/h

Pellet consumption per hour 0,6 - 2,0 Kg/h 0,6 - 1,6 Kg/h

Absorbed electrical power 25 - 100 W 25 - 100 W

Lighting power +280 W +280 W

Power supply 230 V 50 Hz 230 V 50 Hz

Feed box capacity ~ 28 kg. ~ 12 kg.

Inlet/outlet water pipe “ / “ /

I.C. Maxi

I.C. Mini

I.C. Mini

WITH PELLET FEEDING KIT

355

141

143

97

143 355 141

1310 (circa)

1109

1029

80

97

606

423***

I.C. Maxi

*** Minimum Height

The detail “ adjustment pipe”

is pre-drilled with 3 holes Ø 8,5 : 90-100.

For other adjustments, drill according to needs.

A: FUMES OUTLET PIPE Ø80

B: AIR INTAKE PIPE Ø 50

7

*** Minimum Height

The detail “ adjustment pipe”

is pre-drilled with 3 holes Ø 9 :

90-100-90.

For other adjustments, drill

according to needs.

A: FUMES OUTLET PIPE ø 80

B: AIR INTAKE PIPE ø 50

A

B

I.C. Maxi

8

TECHNICAL SPECIFICATIONS

All a.m. data are not binding, but valid just as an indication.

the right to make technical modifications for improving the product is reserved.

Height 858 mm. 884 mm.

Width 440 mm. 477 mm.

Depth 470 mm. 446 mm.

Weight 100 Kg. 110 Kg.

Fume exhaust pipe diameter 80 mm. 80 mm.

Max heating volume 100 m

3

100 m

3

Total power 1,7 - 5,1 kW/h 1,7 - 5,1 kW/h

Water power / kW/h / kW/h

Pellet consumption per hour 0,4 - 1,2 Kg/h 0,4 - 1,2 Kg/h

Absorbed electrical power 25 - 100 W 25 - 100 W

Lighting power +280 W +280 W

Power supply 230 V 50 Hz 230 V 50 Hz

Feed box capacity ~ 11 kg. ~ 11 kg.

Inlet/outlet water pipe “ / “ /

BabyFiamma

Preziosa

Preziosa

BabyFiamma

WALL DRILLING

SKETCH

AIR INTAKE PIPE

FUMES OUTLET PIPE

FUMES OUTLET PIPE ø 80

FUMES OUTLET PIPE ø 50

9

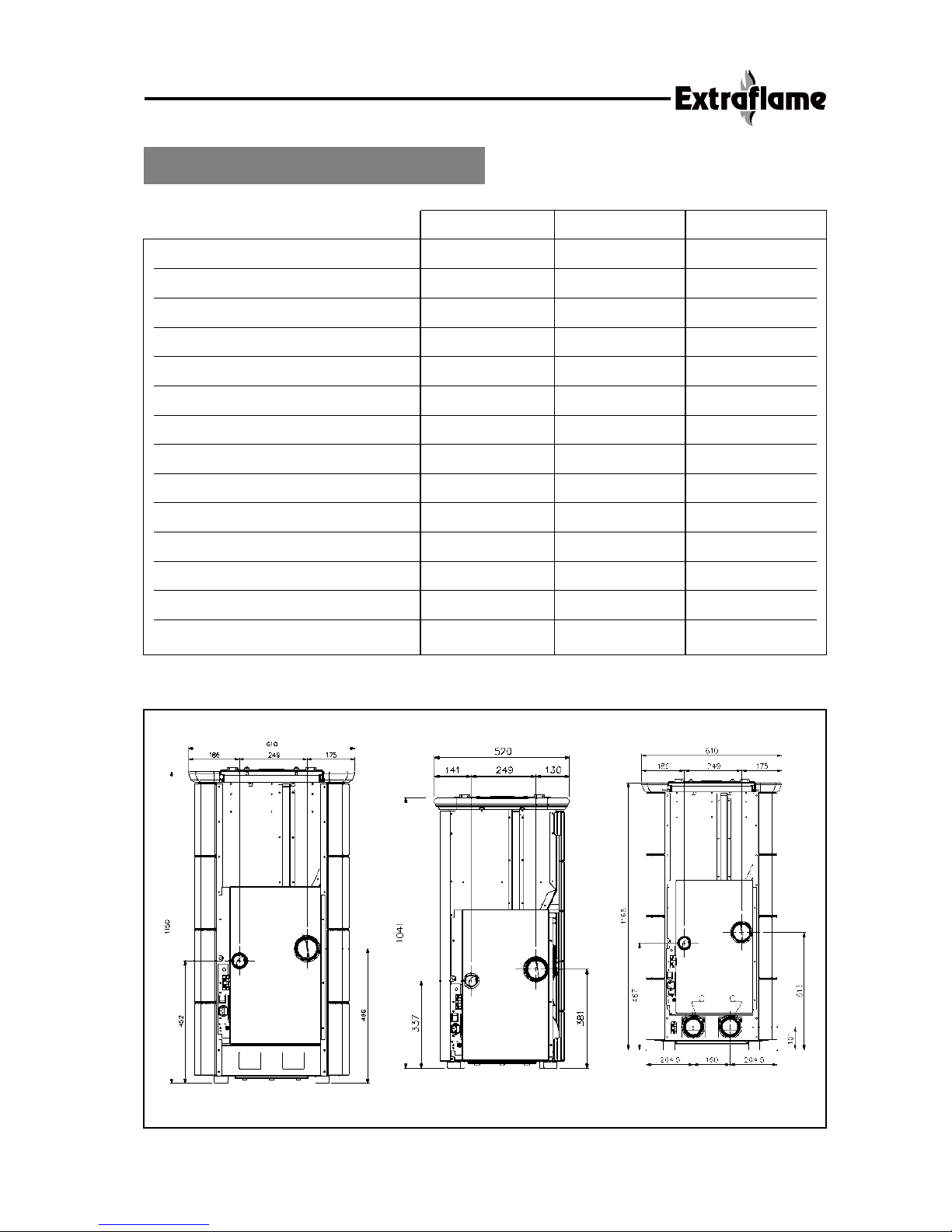

TECHNICAL SPECIFICATIONS

All a.m. data are not binding, but valid just as an indication.

the right to make technical modifications for improving the product is reserved.

Height 1150 mm. 1041 mm. 1150 mm.

Width 610 mm. 520 mm. 610 mm.

Depth 576 mm. 513 mm. 576 mm.

Weight 170 Kg. 130 Kg. 170 Kg.

Fume exhaust pipe diameter 80 mm. 80 mm. 80 mm.

Max heating volume 220 m

3

150 m

3

220 m

3

Total power 2,5 - 11 kW/h 2,5 - 7,5 kW/h 2,5 - 11 kW/h

Water power / kW/h / kW/h / kW/h

Pellet consumption per hour 0,6 - 2,4 Kg/h 0,6 - 1,6 Kg/h 0,6 - 2,4 Kg/h

Absorbed electrical power 25 - 100 W 25 - 100 W 75 - 210 W

Lighting power +280 W +280 W +280 W

Power supply 230 V 50 Hz 230 V 50 Hz 230 V 50 Hz

Feed box capacity ~ 30 kg. ~ 25 kg. ~ 30 kg.

Inlet/outlet water pipe “ / “ / “ /

Divina

Bella Divina Plus

Divina

Bella

Divina Plus

A: FUMES OUTLET PIPE ø 80

B: AIR INTAKE PIPE ø 50

A

B

A

B

A

B

A: FUMES OUTLET PIPE ø 80

B: AIR INTAKE PIPE ø 50

A: FUMES OUTLET PIPE ø 80

B: AIR INTAKE PIPE ø 50

C: CANALISATION PIPE ø 80

10

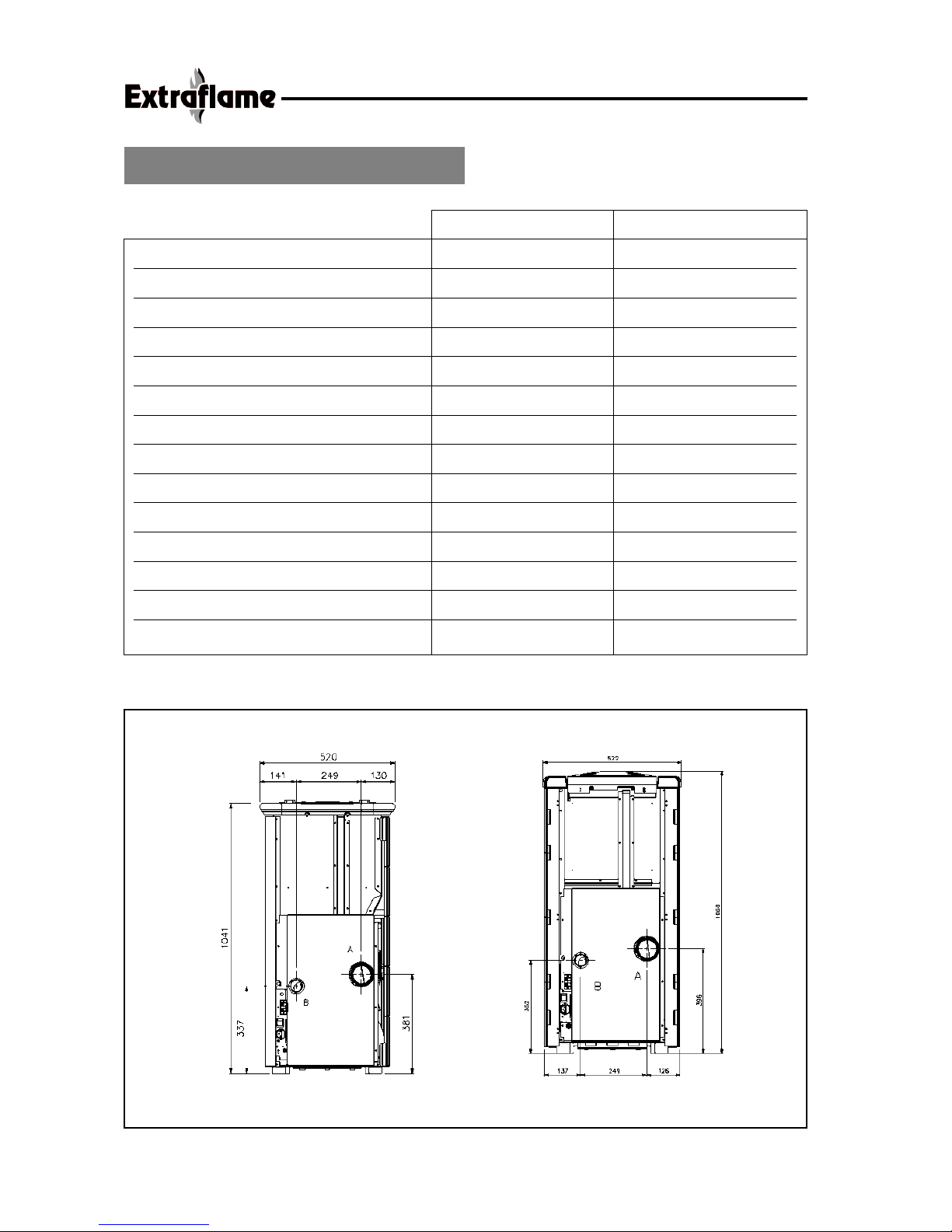

TECHNICAL SPECIFICATIONS

All a.m. data are not binding, but valid just as an indication.

the right to make technical modifications for improving the product is reserved.

Height 1041 mm. 1068 mm.

Width 520 mm. 522 mm.

Depth 513 mm. 500 mm.

Weight 130 Kg. 150 Kg.

Fume exhaust pipe diameter 80 mm. 80 mm.

Max heating volume 150 m

3

180 m

3

Total power 2,5 - 7,5 kW/h 2,5 - 9,4 kW/h

Water power / kW/h / kW/h

Pellet consumption per hour 0,6 - 1,6 Kg/h 0,6 - 2,0 Kg/h

Absorbed electrical power 25 - 100 W 25 - 100 W

Lighting power +280 W +280 W

Power supply 230 V 50 Hz 230 V 50 Hz

Feed box capacity ~ 25 kg. ~ 25 kg.

Inlet/outlet water pipe “ / “ /

Bella Lux

Contessa

Bella Lux

Contessa

A: FUMES OUTLET PIPE Ø80

B: AIR INTAKE PIPE Ø 50

A: FUMES OUTLET PIPE Ø80

B: AIR INTAKE PIPE Ø 50

11

Combustion always requires air (oxygen). Stoves therefore remove air from the room they are

installed in and this must be replaced.

Bad combustion can be caused by poor air circulation in the house and this is often the case

in modern homes, which have sealed windows and doors. On the other hand, there are also

problems when there are draughts in the room (caused for example by kitchen or bathroom

ventilators). To prevent this type of problem, we suggest

a permanent ventilation grill to be

fitted in a window or near the stove. Alternatively, the air can be taken directly from the

exterior or from another sufficiently aerated room (a cellar, for example) by means of a steel

pipe with a diameter of 48 mm.

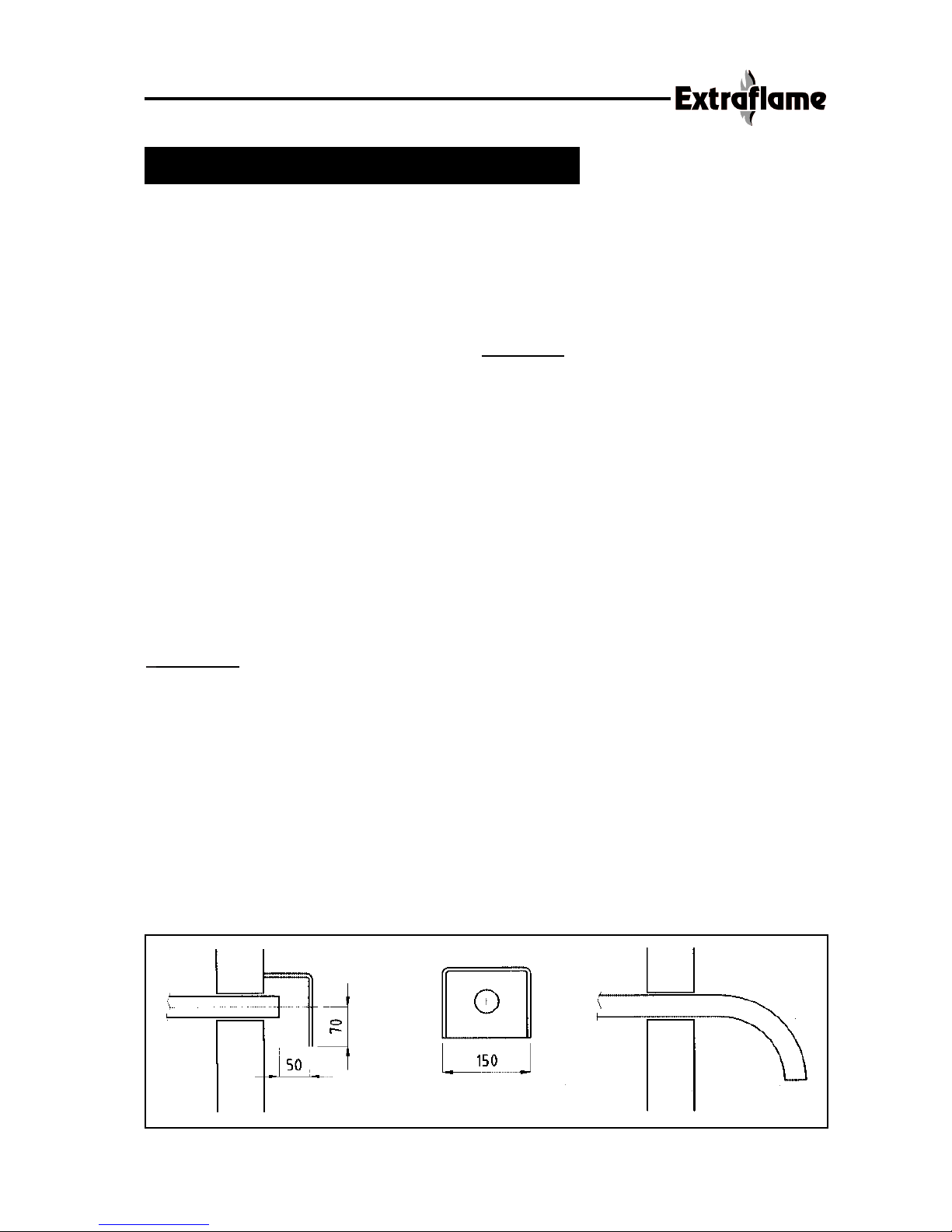

3.1 External air intake pipe assembly

a) Measure and make a hole with a minimum diameter of 5 cm. in the wall for the intake

pipe (see drawing here below).

b) Connect the stove with the exterior by means of a steel pipe.

ATTENTION!

• Only use steel pipes.

• Pipes in synthetic materials or aluminium must not be used.

•To ensure sufficient air intake, the pipe must not be longer than 2 m. and must not have

too many bends.

• If the pipe leads outdoors, it must end with a 90º downward bend and be protected

against the wind (see Fig. Here below).

3 AIR REQUIRED FOR COMBUSTION

11

12

The pellets are made by applying very high

pressure to sawdust, that is pure timber waste

(without paint), produced by sawmills, carpentry

works and other activities associated with the

working and transformation of timber.

This type of fuel is completely environmentally

friendly as no binders of any kind are used to

keep it compact. In fact, the compactness of the

pellets over time is guaranteed by a natural

substance found in the wood itself: the lignite.

As well as being environmentally friendly, as the

wood residues are exploited to the maximum,

pellets also have technical advantages.

While wood has a calorific power of 4.4

kW/kg. (with 15% humidity, after about 18

months seasoning) the power of pellets is 5.3

kW/kg. The density of the pellet is 650 Kg/m3

and the water content is 8% of its weight.

For this reason, the pellets do not need to be

seasoned to obtain an adequate caloric yield.

Their diameter ranges from a minimum of 5

mm to a maximum of 8 mm.

4.1 Pellet storage

To guarantee problem-free combustion, the

pellet must be stored in a dry place.

WARNING

THE USE OF POOR QUALITY PELLETS OR OF

ANY OTHER MATERIAL DAMAGES THE

FUNCTIONS OF YOUR STOVE AND MAY

LEAD TO THE INVALIDATION OF THE WARRANTY

AND ASSOCIATED RESPONSIBILITIES

OF THE MANUFACTURER.

4 WHAT ARE PELLETS ?

13

5.1 Warm air distribution fan breakdown:

If the fan stops for any reason, the stove stops automatically to prevent overheating.

5.2 Fume extractor breakdown:

If the extractor stops, the electronic unit immediately blocks the supply of pellets.

5.3 Pellet feeding motor breakdown:

If the motor stops, the stove continues to operate until the minimum cooling level is reached.

5.4 Lighting failure:

If no flame develops during the lighting stage, the stove automatically makes another attempt to

light and if no flame comes this time either, the stove will show on the display

“ NO ACC”.

While attempting to light the stove , on the display you will read “ATTE” which means “WAIT”.

This function remembers that before lighting the stove , you must be sure that the burning pot,

must be completely free and clean.

5.5 Temporary power failure:

The appliance will re-light automatically after a brief power failure. There may be a minimum

quantity of smoke inside the house when there is no power for a period of 3 to 5 minutes.

THIS DOES NOT GIVE RISE TO ANY SAFETY RISK.

5.6 Electrical safety:

The stove is protected against violent power swings by a master fuse on the rear of the stove

(delayed 2A 250V).

5.7 Fume exhaust safety

An electronic pressure switch stops the loading screw in case the exhaust pipe is obstructed, or

in case the door remains opened for some minutes.

5.8 Safety for pellets overheating

In case of overheating inside the pellet hopper, this safety device stops the functioning of the stove,

the resetting is manual and must be done by a qualified technician.

ONLY FOR ECOLOGICA IDRO:

5.9 Plant pressure safety

A mechanical pressure sensor stops automatically eventually overpressure of the plant. The resetting

of this safety is manual and must be done by a qualified technician.

5.10 Safety for water boiling

In case of water shortage or a minimum water quantity, this safety stops the pellet feeding.

The resetting is manual and must be done by a qualified technician.

5 SAFETY DEVICES

14

6.1 Assembly

An authorised dealer should assemble the

stove.

The assembling of the ceramics in the stoves

which have majolica tiles, must be done by a

qualified technician.

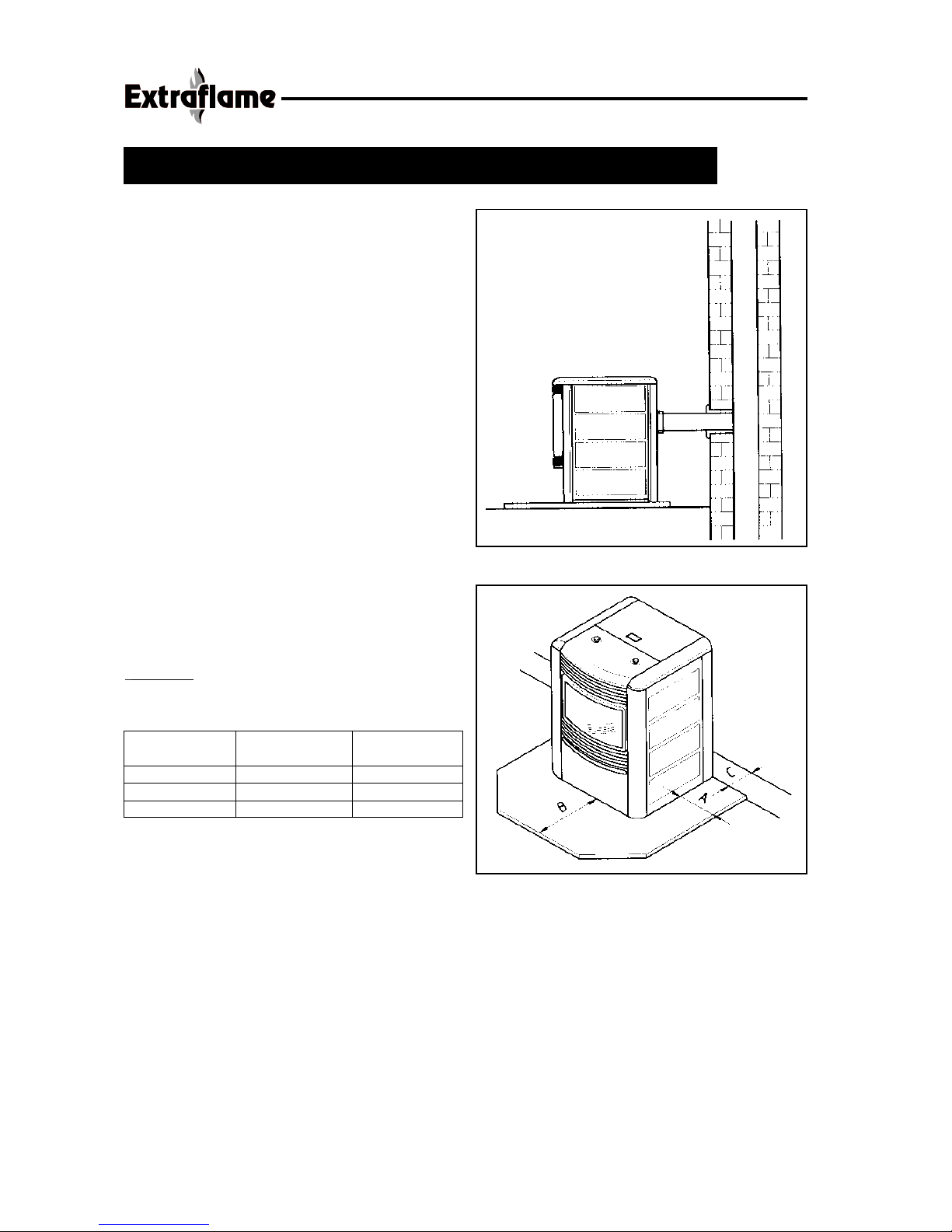

6.2 Installation

a) Paying attention to the dimes of perforation

and taking into consideration a floor pro-

tection plate, if fitted, measure and make

the hole in the chimney for connecting the

fume exhaust pipe with diam. 80 mm.

If the hole has to be done on a wood wall,

the minimum hole diam. must be 130 mm.,

and a min. 20 mm. thickness insulation

material.

b) Connect the stove to the chimney by means

of a steel pipe, sealing it hermetically and

taking care not to obstruct the free section

with the fume pipe. (See fig. 1)

TABLE A: Dimensions of the floor protection

plate and relative safety distances in mm.

6 ASSEMBLY AND INSTALLATION INSTRUCTIONS

REFERENCES

Flammable Not-flammable

objects objects

a* 200 100

b* 800 400

c* 200 100

PRECAUTIONS

1. The appliance must be placed on a flame

resistant floor.

If it is placed on a flammable floor, a floor protection plate must be used. (See table A)

2. The appliance must be connected to a chimney authorised for solid fuels with a minimum

diameter of 130 mm.

3. The fume exhaust system is based on the depression (draught) in the place of combustion

and a light fume exhaust over-pressure (forced exhaust). This makes it essential for the

exhaust pipe to be installed correctly and hermetically.

4. To seal and insulate the pipes, only use heat-resistant materials (up to 300 °C) such as

adhesive tape in aluminium, rock wool or high-temperature silicone.

5. The stove must be placed, so that the electric cord is easy to reach.

fig. 1

fig. 2

*see fig. 4

15

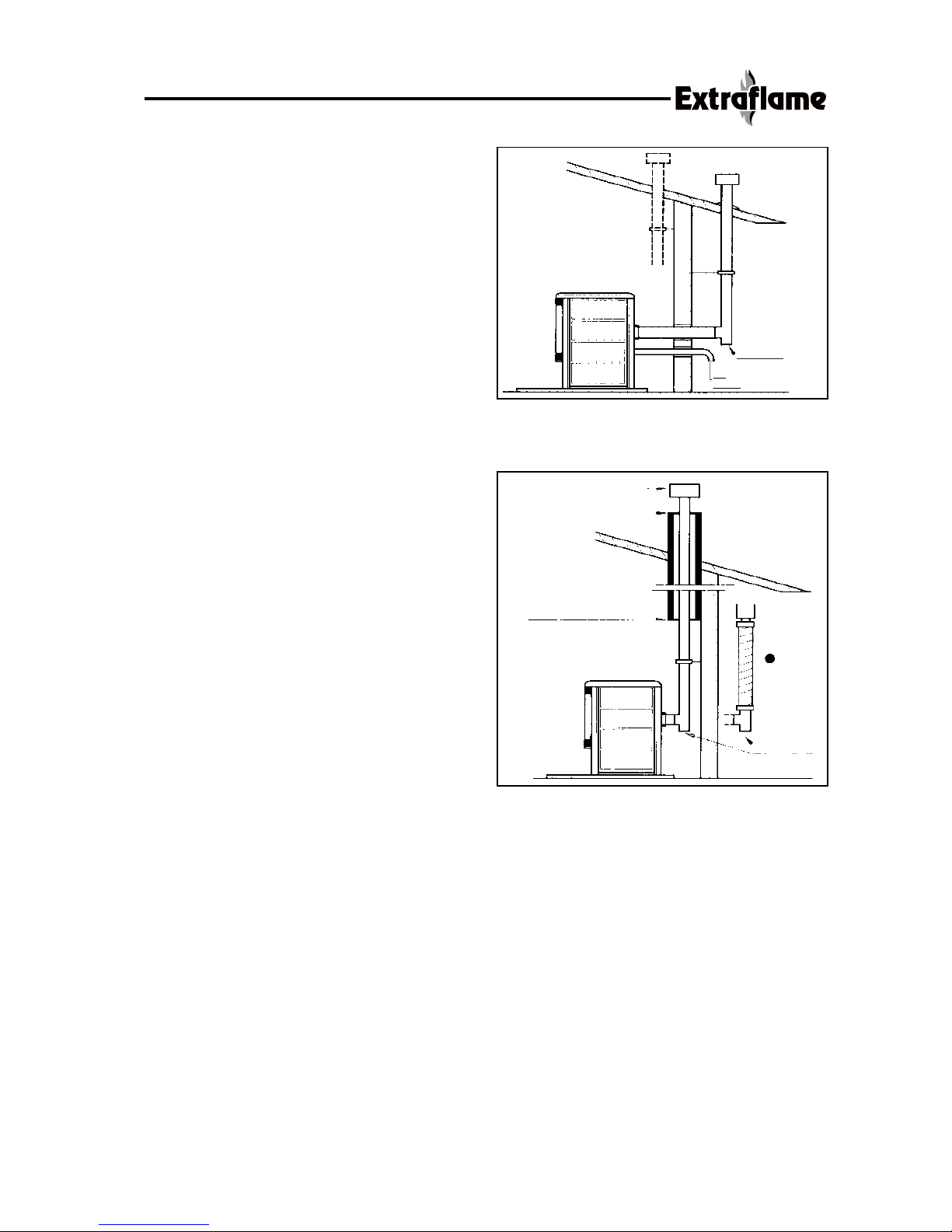

6.3 Fume exhaust

In conformity with DPR 412 and UNI

7129-2001, the allowed installations are:

WITH VERTICAL EXTERNAL OR INTERNAL

FLUE

• The Fig. 3 represents the best solution for

discharging the fumes above the roof.

Proceed as in previous chapter with the

installation of a T-fitting with an inspection

plug. The external or internal flue must

be properly fixed and provided with a

chimney pot for protection from rain.

FUME DISCHARGE THROUGH A CHIMNEY

• Fig. 4 is the classic masonry chimney

system, of course in addition to Fig.1).

Use a T-pipe with an inspection plug and

suitable supporting staffs.

If the chimney is too big, we recommend

reducing it by inserting a porcelain steel

pipe or stainless steel (inox), with a

maximum diameter of 150 mm, and

appropriately sealing the fume inlet and

outlet parts of the fume exhaust from the

part in masonry.

fig. 4

fig. 3

INTERIOR

EXTERIOR

Inspection

Air

intake

Protection from rain

Cover

plate

Airtight sealed

steel plate

Inspection

16

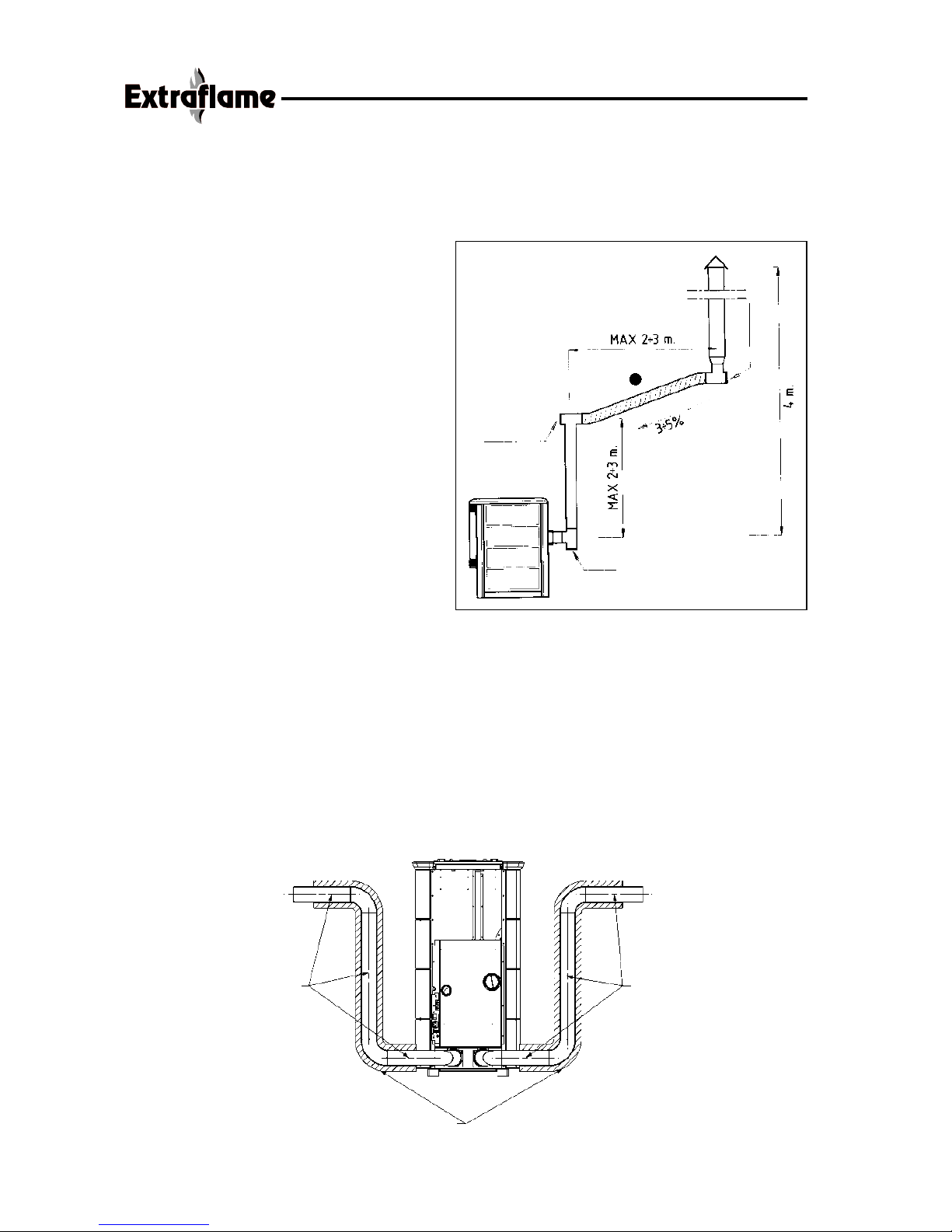

If the fume flue is installed in a fixed way , inspections should be provided for internal

cleaning purposes (ashes), especially in the horizontal sections.

NOTE:

ALL SECTIONS OF THE FUME FLUE MUST

BE EASY TO INSPECT AND TO REMOVE

TO ALLOW THE INTERNAL CLEANING.

( SEE

•)

(SEE FIG. 4 AND 5)

6.4 Electrical connections

The stove is supplied with a power cable

which must be connected to a 230 V /50

Hz socket.

The power absorption is indicated in

chapter 2 (technical specifications).

Make sure that the cable does not come

into contact with the hot surfaces of the

stove.

6.5 CANALISATION DIVINA PLUS

The model DIVINA PLUS is equipped with 2 pipes situated on the back of the stove which

allow the canalisation of the heat issued by the stove. As you can see in the photo here below,

we suggest to make the canalisation by using pipes with the following characteristics:

• Internal diameter 80 mm

• Insulated pipes, that is thermal insulation

• The pipe connection to each nozzle , must not be longer than 2 mt.

fig. 5

Inspection

Inspection

Slope

Height over

Inspection

MAX PIPE LENGTH

2 MT

MAX PIPE LENGTH

2 MT

INSULATING

MATERIAL

Loading...

Loading...