Extraflame Comfort, Comfort P80, Comfort Mini Crystal, Inserto comfort mini, inserto comfort p80 Mini User Manual

Read these instructions carefully before installation, use and maintenance.

The instruction booklet is an integral part of the product.

User Manual

Comfort

Mini

Comfort

Mini Crystal

Comfort

P80

2

3

Congratulations! You are now the owner of an Extra ame stove!

The Extra ame pellet stove is an ideal heating solution. It utilises the most advanced technology and is

manufactured to the highest standards with a contemporary design, allowing you to enjoy the ambience

and warmth of a natural ame in complete safety.

This manual tells you how to use your stove correctly. Please read the entire manual carefully before using

your stove.

IMPORTANT

Make sure that the dealer completes the following box with the details of the authorised specialist who

will help you if you have any problems in using your new pellet stove.

AUTHORISED SPECIALIST

COMPANY __________________________________________________________________

Full name __________________________________________________________________

Address ______________________________________________ No. __________________

Postal Code ____________ City __________________ County. ______________________

TEL. ________________________________ FAX __________________________________

All Extra ame products are manufactured according to the following directives:

89/106 CEE (Construction Products)

89/366 CEE (EMC Directive)

2004/108 CE (EMC Directive)

2006/95 CE (Low Voltage Directive)

And the following standards:

EN 14785

EN 60335-1

EN 60335-2-102

EN 61000-3-2

EN 61000-3-3

EN 50366

EN 55014-1

EN 55014-2

4

5

Index

WARNINGS AND SAFETY DEVICES.......................................................................................................... 7

Chapter 2

WHAT ARE PELLETS?................................................................................................................................. 8

PELLET STORAGE .....................................................................................................................................................................8

PELLET LOADING .....................................................................................................................................................................8

Chapter 3

SAFETY DEVICES ....................................................................................................................................... 9

BREAKDOWN OF HOT AIR DISTRIBUTION FAN............................................................................................................9

FLUE GAS EXTRACTOR BREAKDOWN ..............................................................................................................................9

PELLET LOAD MOTOR BREAKDOWN ...............................................................................................................................9

FAILED IGNITION ......................................................................................................................................................................9

TEMPORARY POWER CUT ....................................................................................................................................................9

ELECTRICAL SAFETY DEVICE ..............................................................................................................................................9

FLUE GAS EXHAUST SAFETY DEVICE ..............................................................................................................................9

PELLET TEMPERATURE SAFETY DEVICE ........................................................................................................................9

Chapter 4

ASSEMBLY AND INSTALLATION INSTRUCTIONS ................................................................................. 10

GLOSSARY ............................................................................................................................................................................... 10

INSTALLATION ........................................................................................................................................................................ 11

ADMISSIBLE INSTALLATIONS .................................................................................................................................... 11

PROHIBITED INSTALLATIONS ....................................................................................................................................11

CONNECTION TO THE EXHAUST VENTING SYSTEM ...............................................................................................12

EXHAUST CHANNEL OR PIPE ....................................................................................................................................12

CHIMNEY OR SINGLE FLUE ........................................................................................................................................13

CONNECTION TO THE FLUE AND COMBUSTION PRODUCT EXHAUST VENTING ................................ 15

CHIMNEY CAP ................................................................................................................................................................. 15

CONNECTION TO EXTERNAL AIR INTAKES ................................................................................................................. 16

INSULATION, TRIMS, FACINGS, AND SAFETY PRECAUTIONS .............................................................................. 16

NATIONAL, REGIONAL, PROVINCIAL AND MUNICIPAL LAWS ............................................................................ 16

Chapter 5

COMFORT MINI/P80/MINI CRYSTAL INSTALLATION ...........................................................................17

FITTING WITH SLIDING BASE ........................................................................................................................................... 17

INSTALLATION WITH PEDESTAL OPTIONAL ............................................................................................................ 18

INSTALLATION WITH PEDESTAL ...................................................................................................................................... 18

EXTRACTING THE INSERT ..................................................................................................................................................19

FITTING THE FRAMES .......................................................................................................................................................... 19

AIR CIRCULATION DUCTS .................................................................................................................................................. 20

Chapter 6

REMOTE CONTROL OPERATION ............................................................................................................23

GENERAL DESCRIPTION .....................................................................................................................................................23

GENERAL FEATURES ............................................................................................................................................................ 24

KEYPAD ..................................................................................................................................................................................... 24

DISPLAY .................................................................................................................................................................................... 24

Chapter 7

PRODUCT FUNCTIONALITY ...................................................................................................................26

BASIC INSTRUCTIONS ......................................................................................................................................................... 26

6

IGNITION .................................................................................................................................................................................. 26

NORMAL OPERATION .........................................................................................................................................................27

SHUTDOWN ............................................................................................................................................................................ 27

Chapter 8

USER MENUS ...........................................................................................................................................28

SET TEMPERATURE MENU .................................................................................................................................................29

SET CLOCK MENU ................................................................................................................................................................. 29

SET TIMER MENU .................................................................................................................................................................. 29

DAY/NIGHT MENU ................................................................................................................................................................31

PELLET LOAD MENU ............................................................................................................................................................ 32

LANGUAGE MENU ................................................................................................................................................................ 33

Chapter 9

ROOM THERMOSTAT ..............................................................................................................................34

MECHANICAL THERMOSTAT OPTIONAL .................................................................................................................. 34

INSTALLING A MECHANICAL THERMOSTAT OPTIONAL..................................................................................... 34

MECHANICAL THERMOSTAT OPERATION ................................................................................................................... 34

MECHANICAL THERMOSTAT OPERATION IN STANDBY MODE TO BE USED ALSO FOR REMOTE

ACTUATOR ............................................................................................................................................................................. 34

Chapter 10

CLEANING ................................................................................................................................................36

CLEANING THE BRAZIER ....................................................................................................................................................36

USE OF SCRAPERS ................................................................................................................................................................ 36

CLEANING OF ASH COLLECTION COMPARTMENTS ............................................................................................... 36

CLEANING THE HEAT EXCHANGER MONTHLY ....................................................................................................... 36

DOOR, ASH DRAWER AND BRAZIER SEALS ................................................................................................................ 37

CHIMNEY CONNECTION .................................................................................................................................................... 37

BRAZIER PARTITION .............................................................................................................................................................38

Chapter 11

TABLE OF DISPLAY MESSAGES ..............................................................................................................39

Chapter 12

WARRAN TY ..............................................................................................................................................42

WARNINGS AND SAFETY DEVICES

7

Chapter1

The stoves produced by our establishment are built with

attention to the individual components in a way to protect

both the user and the installer from any accidents. It is

therefore recommended that after any intervention on the

product, authorised sta pay particular attention to the

electric connections, especially the stripped parts of the

wires. These must not escape from the terminal board in any

situation, thus preventing possible contact with the live parts

of the wire.

Installation must be carried out by authorised sta , who

must provide the buyer with a declaration of conformity

for the system and will assume full responsibility for nal

installation and as a consequence the correct functioning

of the installed product. It is necessary to bear in mind all

laws and national, regional, provincial and town council

Standards present in the country the appliance has been

installed.

Extra ame S.p.A. cannot be held responsible for the

failure to comply with such precautions.

The instruction manual is an integral part of the product:

make sure that it always accompanies the appliance, even

if transferred to other owners or user or is transferred to

another place. If it is damaged or lost, request another copy

from the area technician.

This stove must be destined for the use for which it has been

expressly realised. The manufacturer is exempt from any

liability, contractual and extracontractual, for injury/damage

caused to persons/animals and objects, due to installation,

adjustment and maintenance errors and improper use.

After the packaging has been removed, check the integrity

and completeness of the contents. If this does not comply,

contact the dealer where the appliance was purchased.

All electric components that make up the stove must be

replaced with original spare parts exclusively by an authorised

after-sales centre, thus guaranteeing correct functioning.

The stove must be serviced at least once a year,

programming it in advance with the technical after-sales

service.

Nota bene: In case of thermo product or boiler, the

product or system venting is not covered by the

warranty.

For safety reasons, remember that:

The stove must not be used by children or unassisted

disabled persons.

Do not touch the stove when you are barefoot or when

parts of the body are wet or humid.

The safety and adjustment devices must not be

modi ed without the authorisation or indications of the

manufacturer.

Do not pull, disconnect, twist electric cables leaving the

stove, even if disconnected from the electric power supply

mains.

Do not close or reduce the dimensions of

the airing vents in the place of installation.

The airing vents are indispensable for correct combustion.

Do not leave the packaging elements within reach of

children or unassisted disabled persons.

The hearth door must always be closed during normal

functioning of the product.

Avoid direct contact with parts of the appliance that

tend to heat up during functioning.

Check for the presence of any obstructions before

switching the appliance on following a prolonged standstill

period.

The stove has been designed to function in

any climatic condition (also critical). In particularly

adverse conditions (strong wind, freezing) safety

systems may intervene that switch the stove o .

If this occurs, contact the technical after-sales service and

always disable the safety system.

If the ue should catch re, be equipped with suitable

systems for su ocating the ames or request help from the

re service.

MAJOLICAS

The company have chosen majolica tiles, which are the

result of high-quality artisan work and therefore the

majolica may present crackles, speckles, and shadings.

These characteristics certify their precious origin.

Enamel and majolica, due to their di erent coe cient

of dilatation, produce microcrackles, which show their

authentic feature.

For the cleaning of the majolica we suggest you use a soft

and dry cloth; if you use a detergent or liquid, the latter

might soak in and make the crackles more visible.

WARNINGS AND SAFETY DEVICES

8

WHAT ARE PELLETS?

Chapter2

WHAT ARE PELLETS?

Pellets are made by applying very high pressure to sawdust; i.e. the residue of raw timber (without paint)

produced by sawmills, carpentry works and other activities involved in processing wood.

This type of fuel is completely environmentally friendly, as no binders of any kind are used to keep it

compact. In fact, the compactness of the pellets over time is guaranteed by lignite, a natural substance

found in the wood itself.

As well as being an environmentally friendly fuel, since wood residues are exploited to the maximum,

pellets also have technical advantages.

The density of the pellet is 650kg/m3 and the water content is 8% of its weight. For this reason, pellets do

not need to be seasoned to obtain a su cient heating yield.

The pellet used must conform to the characteristics of the following regulations:

Ö-Norm M 7135

DIN plus 51731

UNI CEN/TS 14961

Extra ame recommends always using 6 mm pellets for its products.

PELLET STORAGE

To guarantee problem-free combustion, the pellet must be stored in a dry place.

PELLET LOADING

Pellets can either be loaded from the front, by removing the insert, or from the side, by using the chute, if

equipped with the support and loading kit.

WARNING!!!

THE USE OF POOR QUALITY PELLETS OR ANY OTHER MATERIAL MAY DAMAGE THE YOUR

STOVE AND MAY LEAD TO THE INVALIDATION OF THE WARRANTY AND THE RELATED

RESPONSIBILITIES OF THE MANUFACTURER.

9

SAFETY DEVICES

Chapter3

SAFETY DEVICES

BREAKDOWN OF HOT AIR DISTRIBUTION FAN

If the blower stops for any reason, the stove automatically shuts down to prevent overheating.

FLUE GAS EXTRACTOR BREAKDOWN

If the extractor stops, the electronic unit immediately prevents pellet loading.

PELLET LOAD MOTOR BREAKDOWN

If the motor stops, the stove continues to operate until the minimum cooling level is reached.

FAILED IGNITION

If no ame develops during the ignition phase, the appliance automatically attempts a new ignition, this

time, though, without loading pellets.

If, after this attempt, the stove still has no ame, the stove display shows “NO FLAME”. If you attempt to

light the stove again, the display shows “CLEANING WAIT” which means “WAIT”.

This function reminds you that before lighting the stove, you must be sure that the brazier is free of

dirt and debris.

TEMPORARY POWER CUT

The appliance will re-light automatically after a brief power failure. When the power goes o , the stove

may emit a minute quantity of smoke inside the house for a period of 3 to 5 minutes.

THIS DOES NOT POSE ANY SAFETY RISK.

ELECTRICAL SAFETY DEVICE

The stove is protected against violent changes in power by a master fuse on the rear of the stove (2A 250V

delayed).

FLUE GAS EXHAUST SAFETY DEVICE

If the exhaust system fails, an electronic pressure switch stops the stove and an alarm is signalled.

PELLET TEMPERATURE SAFETY DEVICE

In case of overheating inside the pellet tank, this safety device blocks stove operation; resetting is manual

and must be performed by an authorised technician.

10

Chapter5

ASSEMBLY AND INSTALLATION INSTRUCTIONS

Chapter5

ASSEMBLY AND INSTALLATION INSTRUCTIONS

The installation must comply with:

UNI 10683 (2005) heat generators fed with wood and other solid fuels: installation.

The chimneys must comply with:

UNI 9731 (1990) chimneys: classi cation according to thermal resistance.

EN 13384-1 (2006) calculation method of the thermal and uid-dynamic features of the chimney.

UNI 7129 point 4.3.3 provisions, local rules and prescriptions of the re brigade.

UNI 1443 (2005) chimneys: general requirements.

UNI 1457 (2004) chimneys: internal ducts in terracotta and ceramics.

GLOSSARY

CLOSED HEARTH DEVICE

Heat generator that can only be opened to load fuel during use.

BIOMASS

Material of organic origin, excluding the material incorporated in geological formations and fossilised.

BIOFUEL

Fuel produced directly or indirectly from biomass.

FLUE or CHIMNEY

Vertical duct for collecting and expelling combustion products from a single appliance at a suitable height

from the oor.

EXHAUST CHANNEL OR PIPE

Duct or connecting element between the heat generating device and the chimney for extracting the

combustion products.

INSULATION

The series of measures taken and materials used to prevent heat transmission through a wall dividing

rooms at di erent temperatures.

CHIMNEY CAP

Device located at the top of the chimney that facilitates dispersion of the combustion products in the

atmosphere.

CONDENSATE

Liquid products that form when the temperature of the combustion gas is lower than or equal to the dew

point of the water.

HEAT GENERATOR

Device that permits the production of thermal energy (heat) by the rapid transformation of the chemical

energy of the fuel by means of combustion.

AIR LOCK

Mechanism for modifying the dynamic resistance of the combustion gasses.

11

ASSEMBLY AND INSTALLATION INSTRUCTIONS

Chapter5

EXHAUST VENTING SYSTEM

A system for fume exhaust venting that is independent from the appliance, composed of a pipe or channel,

chimney or single ue, and chimney cap.

FORCED DRAUGHT

Air circulation by means of a fan driven by an electric motor.

NATURAL DRAUGHT

Draught resulting in a chimney/ ue due to the di erence in the volume mass existing between the (hot)

fumes and the surrounding atmospheric air, without any mechanical suction aid installed inside or on top

of it.

RADIANCE AREA

Area immediately adjacent to the hearth in which the heat produced by combustion is di used; this area

must not contain any objects made of combustible material.

REFLUX AREA

Area in which the combustion products come out from the appliance towards the room in which it is

installed.

INSTALLATION

Before carrying out installation, it is necessary to check the positioning of the chimneys, ues or exhaust

terminal ducts of the appliance, keeping in mind the following:

Installation prohibitions

Legal clearances

Limitations set forth by local administrative regulations or speci c regulations of the authorities.

Common limitations deriving from building regulations, and easement or contract regulations.

ADMISSIBLE INSTALLATIONS

In the room in which the heat generator is to be installed, any existing or installed appliances must be airtight

to the room and must not cause depression in the room with respect to the external environment.

Appliances used for cooking foods and the related hoods without extractor can only be installed in rooms

used as kitchens.

PROHIBITED INSTALLATIONS

The room in which the heat generator is to be installed must not contain any of the following devices,

either pre-existing or installed:

Hoods with or without extractor;

Ventilation ducts of the collective type.

Should these devices be located in adjacent rooms communicating with the installation room, it is

forbidden to use the heat generator simultaneously where there is the risk that one of the two rooms may

be subject to depression with respect to the other.

45°

<

45°

<

12

Chapter5

ASSEMBLY AND INSTALLATION INSTRUCTIONS

CONNECTION TO THE EXHAUST VENTING SYSTEM

EXHAUST CHANNEL OR PIPE

For the assembly of the exhaust channels it is imperative to use non- ammable materials that are resistant to

combustion products and any condensates.

It is forbidden to use exible metal pipes and asbestos cement for connecting the stove to the ue, also for preexisting exhaust channels.

There must be continuity between the exhaust channel and the ue so that the ue does not lean on the stove.

The exhaust channels must not pass through rooms in which the installation of combustion devices is

forbidden.

The assembly of the exhaust channels must be carried out in such a way as to ensure that they are airtight for

the operating conditions of the appliance, as well as to limit the formation of condensates and prevent them

from being conveyed towards the appliance.

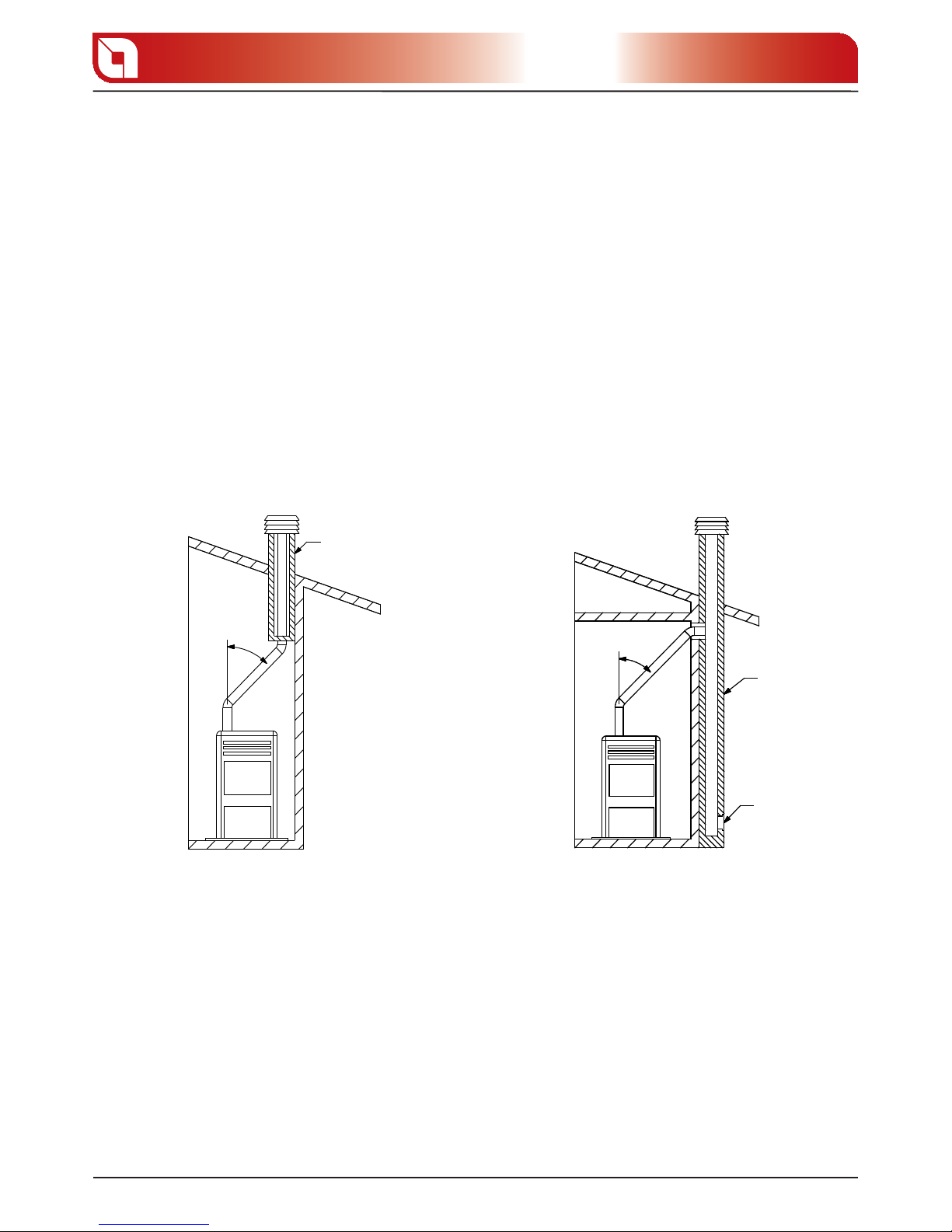

The assembly of horizontal sections must be avoided where possible.

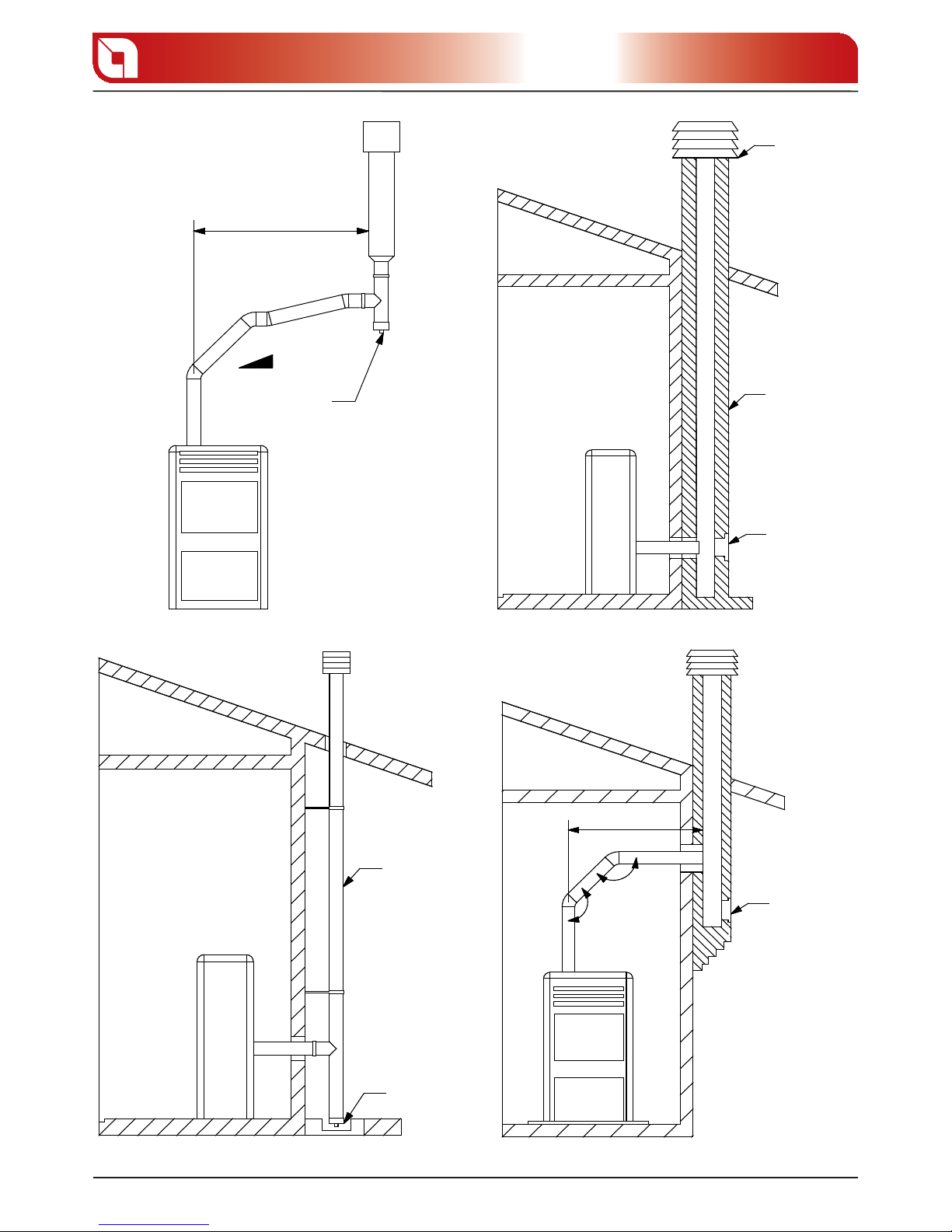

Where roof or wall exhaust outlets have to be reached that are not coaxial in relation to the exhaust outlet

from the appliance, the direction changes must be made using open elbows no greater than 45° (see gures

below).

Insulation

Flue

Inspection

For heat generating devices equipped with an electric exhaust fan, i.e. all products made by Extra ame, it

is necessary to observe the following instructions:

Horizontal sections must have a minimum slope of 3% upwards.

The length of the horizontal section must be as short as possible, and in any case no greater than 3

meters.

No more than four direction changes may be used, including the one resulting from the use of the “T”-

element. (When four bends are used, use double wall piping with a 120 mm diameter.)

In any case, exhaust channels must be sealed in relation to combustion products and condensates, as well

as insulated, if they pass outside the installation room.

It is forbidden to use elements in counter-slope.

The exhaust channel must allow soot recovery and cleaning using a swab.

The exhaust channel must have a constant cross-section. Any changes in cross-section are allowed only at

gure 5.1 gure 5.2

B

C

20 cm

A

13

ASSEMBLY AND INSTALLATION INSTRUCTIONS

Chapter5

the ue connection.

It is forbidden to run other air feed channels or piping for utilities inside the exhaust channels, even if

they are oversized. It is also forbidden to t manual draught adjustment devices on the forced draught

appliance.

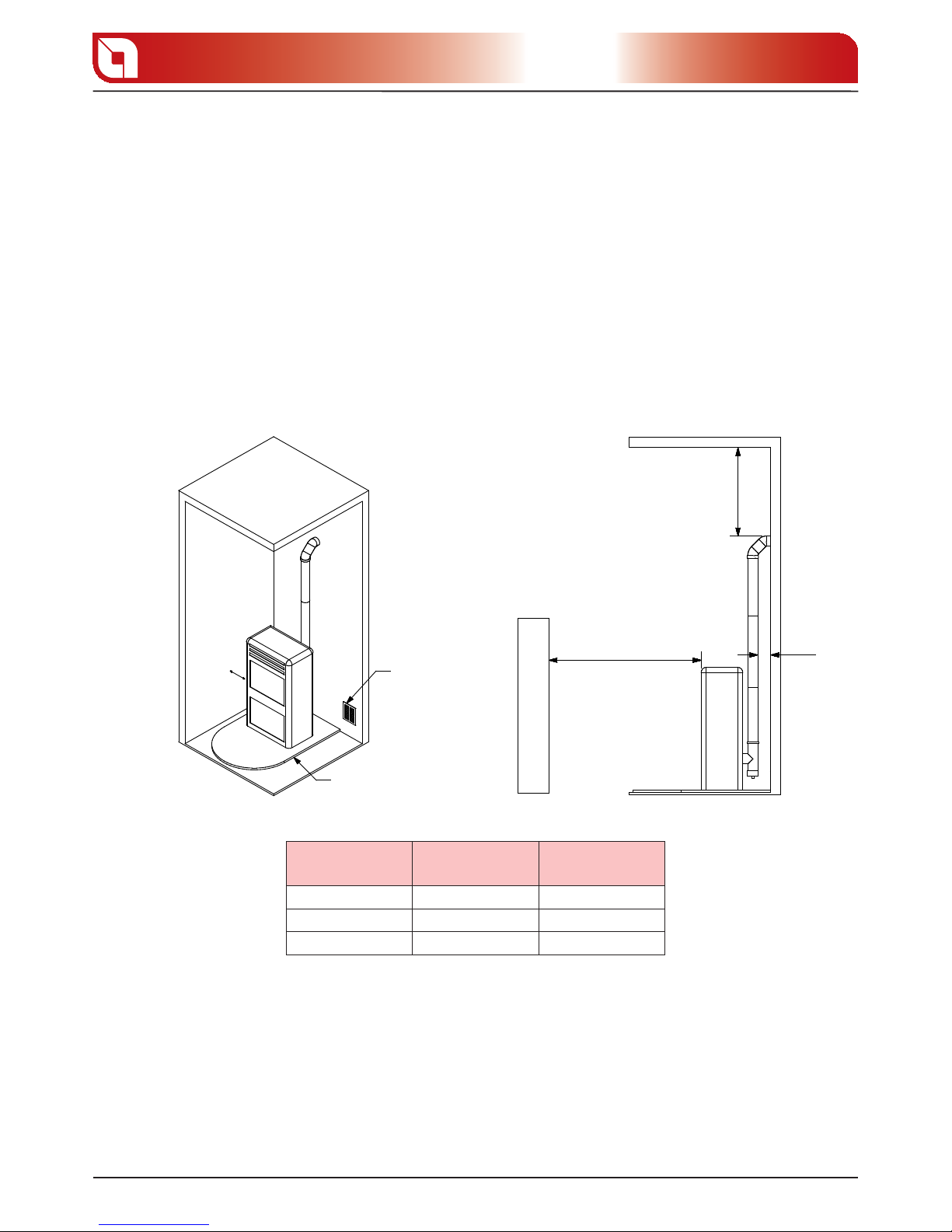

CHIMNEY OR SINGLE FLUE

The chimney or ue must meet the following requirements:

be airtight to combustion products, waterproof and properly insulated according to the usage conditions;

be made of materials suitable to resist normal mechanical stress, as well as heat and the action of combustion

products and any condensates;

have a predominantly vertical layout with deviations from the axis no greater than 45°;

be situated at a proper distance from combustible or ammable materials by means of an air gap or suitable

insulation material;

Minimum80 cm

2

Floor protection

REFERENCES

Flammable

objects

Non- ammable

objects

A 200 100

B 1500 750

C 200 100

preferably have a round internal section: square or rectangular sections must have rounded edges

with radius no less than 20 mm;

have a constant, free and independent internal section;

have rectangular sections with a maximum ratio between sides of 1.5.

The exhaust duct should be equipped with a chamber for the collection of solid materials and any

condensates located below the mouth of the exhaust channel, so that it is easy to open and inspect from

the airtight hatch.

gure 5.3 gure 5.4

< 3 m

3 - 5 %

< 3 m

45°

45°

14

Chapter5

ASSEMBLY AND INSTALLATION INSTRUCTIONS

Inspection

Windproof

chimney cap

Flue

Inspection

External

insulated

duct

Inspection

Inspection

gure 5.5 gure 5.6

gure 5.7 gure 5.8

50 cm

< 5 m

> 5 m

< 5 m

5

0

H min

β

15

ASSEMBLY AND INSTALLATION INSTRUCTIONS

Chapter5

CONNECTION TO THE FLUE AND COMBUSTION PRODUCT EXHAUST VENTING

The ue must receive exhaust from a single heat generator.

Direct discharge towards enclosed areas, even when roo ess, is forbidden.

Direct discharge of combustion products must take place on the roof and the exhaust duct must have the

features set forth in the section “Chimney or single ue”.

CHIMNEY CAP

The chimney cap must meet the following requirements:

have an internal section equivalent to that of the chimney;

have a useful outlet section no less than twice the internal section of the chimney;

be constructed in such a way as to prevent the penetration of rain, snow and foreign bodies into the

chimney, as well as to assure the discharge of the combustion products also in the presence of winds

coming from any direction and at any angle.

be positioned in such a way as to assure proper dispersion and dilution of the combustion products

and, in any case, outside the re ux area in which the formation of counter-pressure is most likely to occur.

This area has di erent sizes and shapes depending on the slope of the roof; therefore, it is necessary to

use the minimum heights indicated in the gures below.

The chimney cap must not have any mechanical suction devices.

SLOPED ROOF

FLAT ROOF

Distance > A

Distance < A

50 cm beyond the ridge beam

REFLUX AREA

Re ux area height

gure 5.9

gure 5.10

Loading...

Loading...