Page 1

USER GUIDE

TKG100

Digital Ultrasonic Thickness

Gauge

TKG150

Digital Ultrasonic Thickness

Gauge with Datalogger

Page 2

Extech Instruments .

2 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 2

WARRANTY

FLIR Systems, Inc. warrants this Extech Instruments brand device to be free

of defects in parts and workmanship for two years from date of shipment (a six

month limited warranty applies to sensors and cables). If it should become

necessary to return the instrument for service during or beyond the warranty period,

contact the Customer Service Department for authorization. Visit the website

www.extech.com for contact information. A Return Authorization (RA) number

must be issued before any product is returned. The sender is responsible for

shipping charges, freight, insurance and proper packaging to prevent damage in

transit. This warranty does not apply to defects resulting from action of the user

such as misuse, improper wiring, operation outside of specification, improper

maintenance or repair, or unauthorized modification. FLIR Systems, Inc. specifically

disclaims any implied warranties or merchantability or fitness for a specific purpose

and will not be liable for any direct, indirect, incidental or consequential damages.

FLIR‟s total liability is limited to repair or replacement of the product. The warranty

set forth above is inclusive and no other warranty, whether written or oral, is

expressed or implied.

The information in this document is subject to change without notice and describes

only the product defined in the introduction of this documentation. This document

is intended for the use of Extech Instruments customers only (a Flir Systems, Inc.

brand) for the purposes of the agreement under which the document is submitted,

and no part of it may be reproduced or transmitted in any form or means without

the prior written permission. For information address: Flir Commercial Systems,

Inc. 9 Townsend West, Nashua NH, 03063 U.S.A.

The information or statements given in this document concerning the suitability,

capacity, or performance of the mentioned hardware or software products cannot

be considered binding but shall be defined in the agreement made between Flir

Systems and the customer. However, Flir Systems has made all reasonable efforts to

ensure that the instructions contained in the document are adequate and free of

material errors and omissions. Flir Systems will, if necessary, explain issues which

may not be covered by the document.

Other product names mentioned in this document may be trademarks of their

respective companies, and they are mentioned for identification purposes only.

Copyright 2013 Flir Systems, Inc., All Rights Reserved

Printed in the United States of America

Page 3

3

LIABILITY

Ultrasonic testing is a function of using the proper equipment

(electronics, transducer, cable and couplant combination) for the

inspection and a qualified operator who knows how to use this manual,

the instruments and all calibration procedures. The improper use of this

equipment, along with the improper calibration can cause serious

damage to components, factories, facilities, personal injury and even

death.

ALL FLIR SYSTEMS ULTRASONIC THICKNESS GAUGES ARE

NOT INTRINSICALLY SAFE AND SHOULD NOT BE USED IN

ANY HAZARDOUS OR EXPLOSIVE AREAS.

It is understood that the operator of this equipment is a well-trained

inspector qualified by either their own company or another outside

agency to issue Ultrasonic Level I, 40 hour class room training in

Ultrasonic Theory. Flir Systems and any of its employees or

representatives shall not be held responsible for improper use of this

equipment for its intended use. Proper training, a complete

understanding of Ultrasonic wave propagation, thorough reading of this

manual, proper transducer selection, correct zeroing of the transducer,

correct sound velocity, proper test blocks, proper cable length, proper

couplant selection all play a factor in successful ultrasonic thickness

gaging. Special care should be taken when test pieces have rough or

painted surfaces, particularly those applications where the test piece is

thin to begin with as doubling of the echoes is possible even if the

transducer is capable of measuring the desired thickness. As transducers

wear or heat up, results can be either too thin due to a lack of sensitivity

as a result of wear or too thick due to heating up of the transducer,

referred to as “drift.”

Page 4

Extech Instruments .

4 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 4

Table of Contents

Table of Contents ........................................................................................ 4

1 Getting Started ......................................................................................... 7

About the TKG Series ............................................................................. 7

Probe Zero................................................................................................ 8

Keypad Functions .................................................................................. 10

Function Keys ........................................................................................ 11

Display Screen ....................................................................................... 11

Battery Power ......................................................................................... 13

Monitoring the Battery from the Display ........................................ 13

Replacing the Batteries ................................................................... 13

2 Basic Gauge Operations ...................................................................... 14

Power on the Gauge ............................................................................. 14

Performing a Reset (TKG100) ............................................................. 16

Performing a Reset (TKG150) ............................................................. 17

About Screen ......................................................................................... 19

3 Calibrating the Gauge/Making Measurements ................................ 20

Velocity Calibration Only ....................................................................... 20

Velocity and Zero Calibration ............................................................... 21

Zero Calibration Only ............................................................................ 22

Delay Line Calibration ........................................................................... 23

Page 5

5

Automatic Zero ....................................................................................... 24

Measurement Mode with a Datalogger (TKG150) ....................... 26

Measurement Mode without a Datalogger (TKG100) .................. 27

4 Measurement Mode Setup Options ................................................. 29

Using the Clock ...................................................................................... 31

Setting LCD Contrast ............................................................................ 33

Understanding a LOS Reading ............................................................ 33

Using the Hold Option ........................................................................... 34

Using the Fast Option ........................................................................... 35

Using the Gain Option (TKG150 only) ................................................ 38

Using the Diff Option ............................................................................. 39

Using the Alarm Option ......................................................................... 40

‘Vibra’ Alarm (TKG150 only) ........................................................... 44

Using the Echo-to-Echo Option (TKG150 only) ................................. 47

5 Special Gauge Functions ..................................................................... 48

Using the Save Option (TKG150 only) ................................................ 48

Using the Freeze Option ....................................................................... 50

6 Using Datalogger Directory Mode (TKG150) ................................... 55

Selecting a Custom Linear File ...................................................... 63

Selecting a Custom Grid File .......................................................... 63

Reviewing a File .................................................................................... 65

Reviewing a Linear File ................................................................... 66

Reviewing a Grid File ...................................................................... 67

Renaming a File ................................................................ ..................... 67

Page 6

Extech Instruments .

6 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 6

Copying a File ........................................................................................ 71

Deleting a File ........................................................................................ 74

7 Technical Specifications ...................................................................... 76

8 Software Options ................................................................................... 79

B-Scan (TKG150 only) .......................................................................... 80

9 Technical Assistance ............................................................................ 81

Page 7

7

1 Getting Started

About the TKG Series

The TKG100 and TKG150 are portable, digital,

handheld thickness gauges. The TKG series of ultrasonic

thickness gauges are specifically designed to measure the

remaining wall thickness of primarily steel structures.

Vibralarm (vibrates gauge below/above

minimum/maximum thickness value)

Illuminating keypad for easy to view go-no go

thickness values (patent pending)

Automatic transducer replacement intelligence

built in (patent pending)

Unique, programmable left-hand/right-hand

operation (patent pending)

Up to 200 hour battery life with 2 AA batteries

Small, easy to hold, ergonomic, custom molded,

durable case with rubber keypad

Automatic zero capability

Gain boost

Page 8

Extech Instruments .

8 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 8

The TKG100 is a base gauge offering a simple user

interface packaged in the same custom molded highdensity plastic case with rubber keypad as the other more

sophisticated models. This gauge offers reliable, accurate

thickness readings on mostly steel structures with access

to only one side.

The TKG150 contains all the same features of the

TKG100 plus:

50,000 (expandable to 100,000) reading

datalogger capacity with complete setup

tracking

Three pre-set files for linear, grid (row advance)

and grid (column advance)

Echo-to-Echo

B-scan

Probe Zero

When turning on the TKG100 or TKG150 (for the sake

of this manual, with the exception of the datalogger, Bscan, and Echo-to-Echo features, the two model

numbers are interchangeable for the basic operation and

calibration), the gauge does an automatic zeroing of the

transducer (after the user selects the transducer from the

list) thus eliminating the need for an on-block zero. The

TKG100 and TKG150 will electronically zero the

transducer upon power up and at a particular time during

normal operation. This feature ensures the transducer is

Page 9

9

working in accordance with electronic zeroing

procedures. This feature is particularly important on high

temperature materials and when the transducer becomes

worn.

Important Notice: Please make sure the transducer

is not coupled to the test piece when the gauge is first

turned on and that there is no couplant on the end of

the transducer. The transducer should also be at room

temperature, clean without any noticeable wear.

Page 10

Extech Instruments .

10 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 10

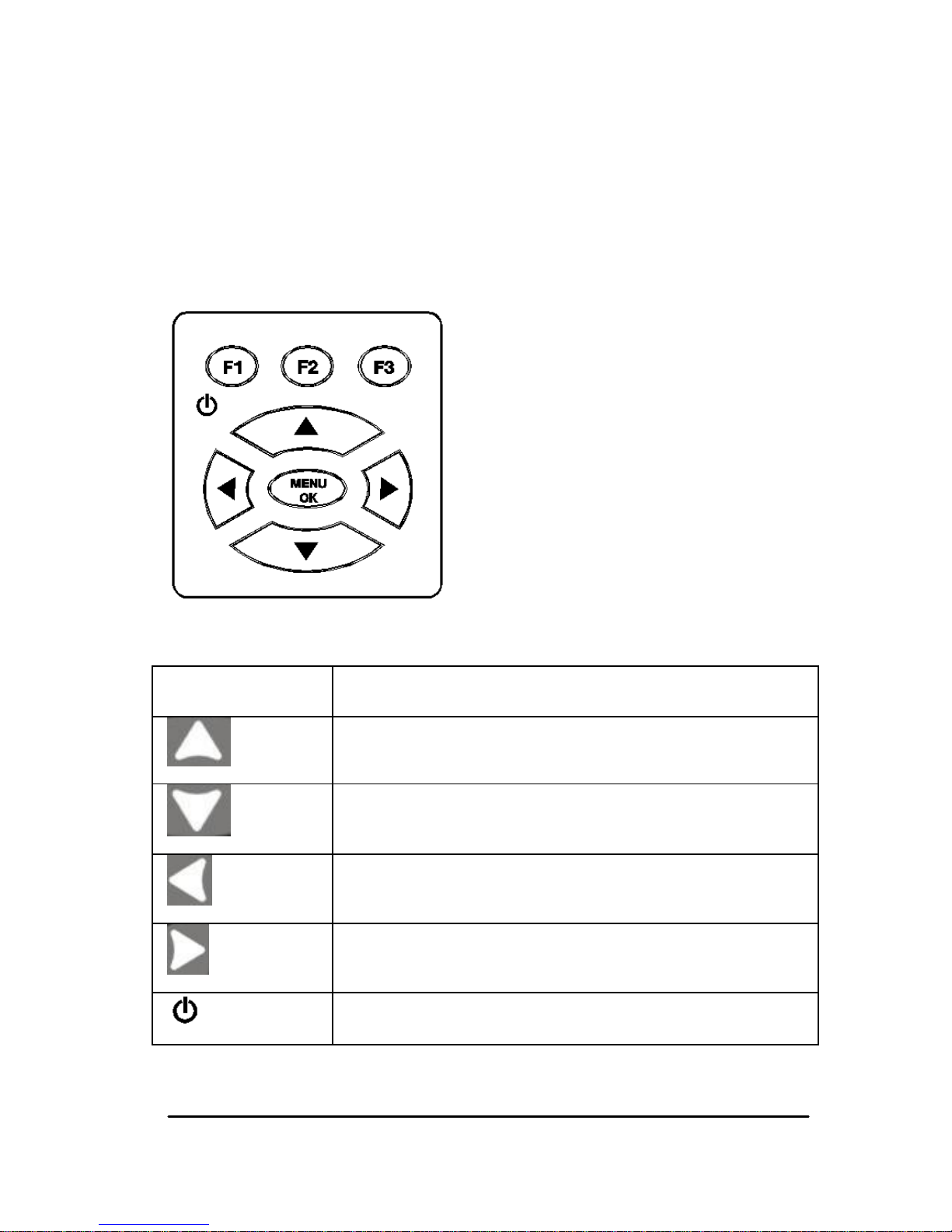

Keypad Functions

The figure below shows the full keypad of the TKG

Series thickness gauges. Refer to the following table that

lists the function of each key on the keypad.

Key

Function

Up arrow key

Down arrow key

Left arrow key

Right arrow key

On/Off symbol (under the F1 key)

Page 11

11

MENU/OK key

F1 key

F2 key

F3 key

Function Keys

Function keys, or F keys, such as F1, F2, and F3 have

various gauge functions and may change depending on

the display screen. View the bottom of the display screen

for the function that corresponds with the appropriate F

key. For example, F1 may correspond with the Save

function, F2 with the Freeze function, or F3 with the

Directory function (Dir).

Display Screen

The gauge has a graphic style Liquid Crystal Display

(LCD). Viewing the screen is best from straight above or

slightly below the surface rather than from side to side. If

external temperatures are below 32F (0C), the display

may be slow to update information.

Page 12

Extech Instruments .

12 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 12

The TKG series is designed to show the parameters

selected in the center of the display screen.

The top part of the display screen for TKG150 model

shows the File name, ID number, AA, and 0001 for grid

column and row. The lower part of the display acts as an

interactive tool that allows you to decide how you want

to proceed with the information that is displayed on the

screen. The middle part of the screen shows the

thickness value, In, mm or usec, Echo-to-Echo symbol,

LOS for loss of signal, Freeze, Fast, Min or Max, Alarm

indicator, Differential mode, Low, Med or High gain and

percent remaining battery life.

F1 F2 F3

F1 F2 F3

Page 13

13

Battery Power

Monitoring the Battery from the Display

The TKG series constantly displays the percent battery

life on the bottom right hand corner of the display

screen. When the gauge gets below 20 %, the indicator

will flash.

Replacing the Batteries

To replace the batteries, unscrew the battery door on the

bottom of the gauge and slide out the two “AA”

batteries. Replace with two new “AA” batteries paying

attention that both positive ends are facing towards the

top of the gauge.

Page 14

Extech Instruments .

14 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 14

2 Basic Gauge Operations

Power on the Gauge

To power on any of the TKG series thickness gauges

follow these steps:

1. Press and hold the F1 key for more than 3

seconds. The power symbol is under the F1 key

printed on the keypad as shown below.

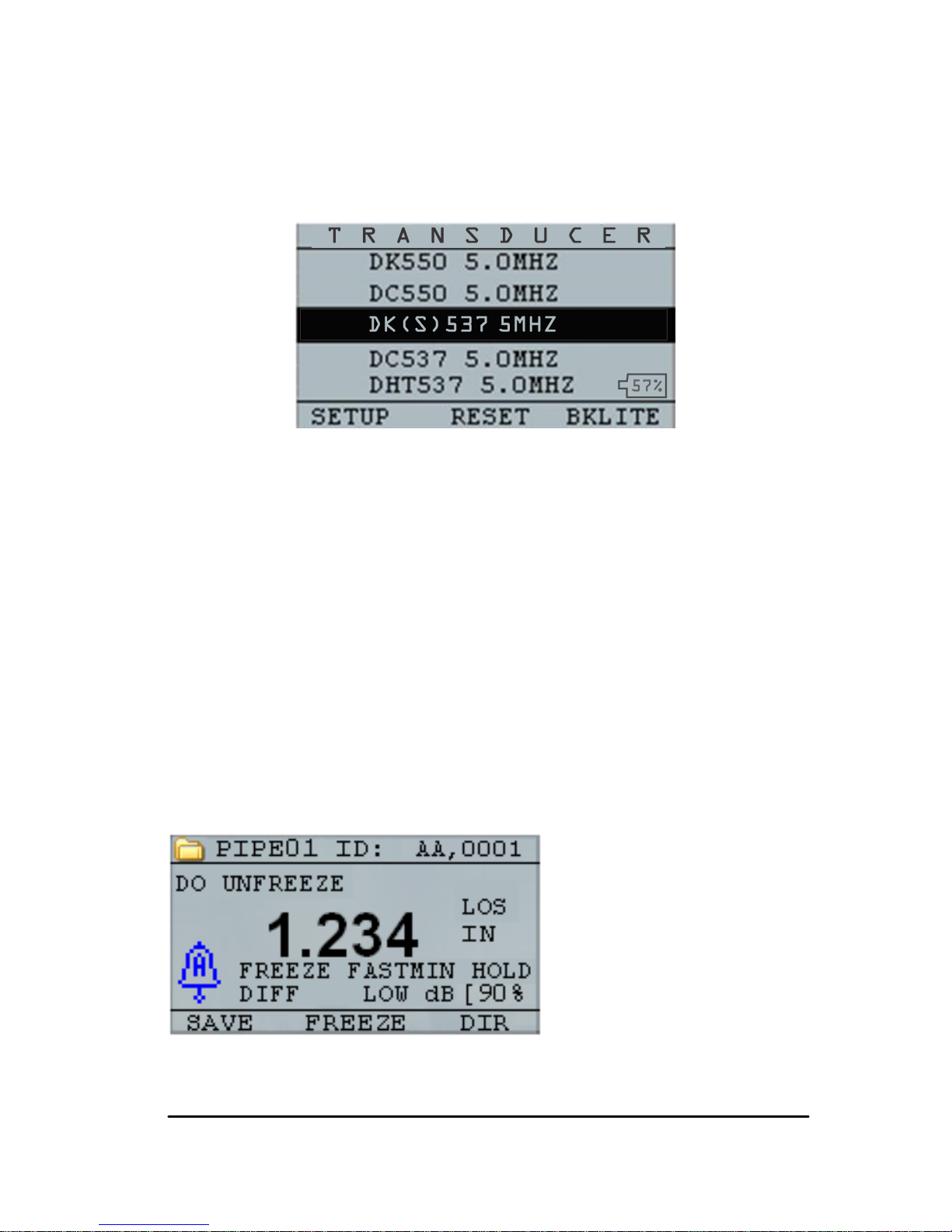

2. The following (or similar) will appear on the

display screen of the thickness gauge:

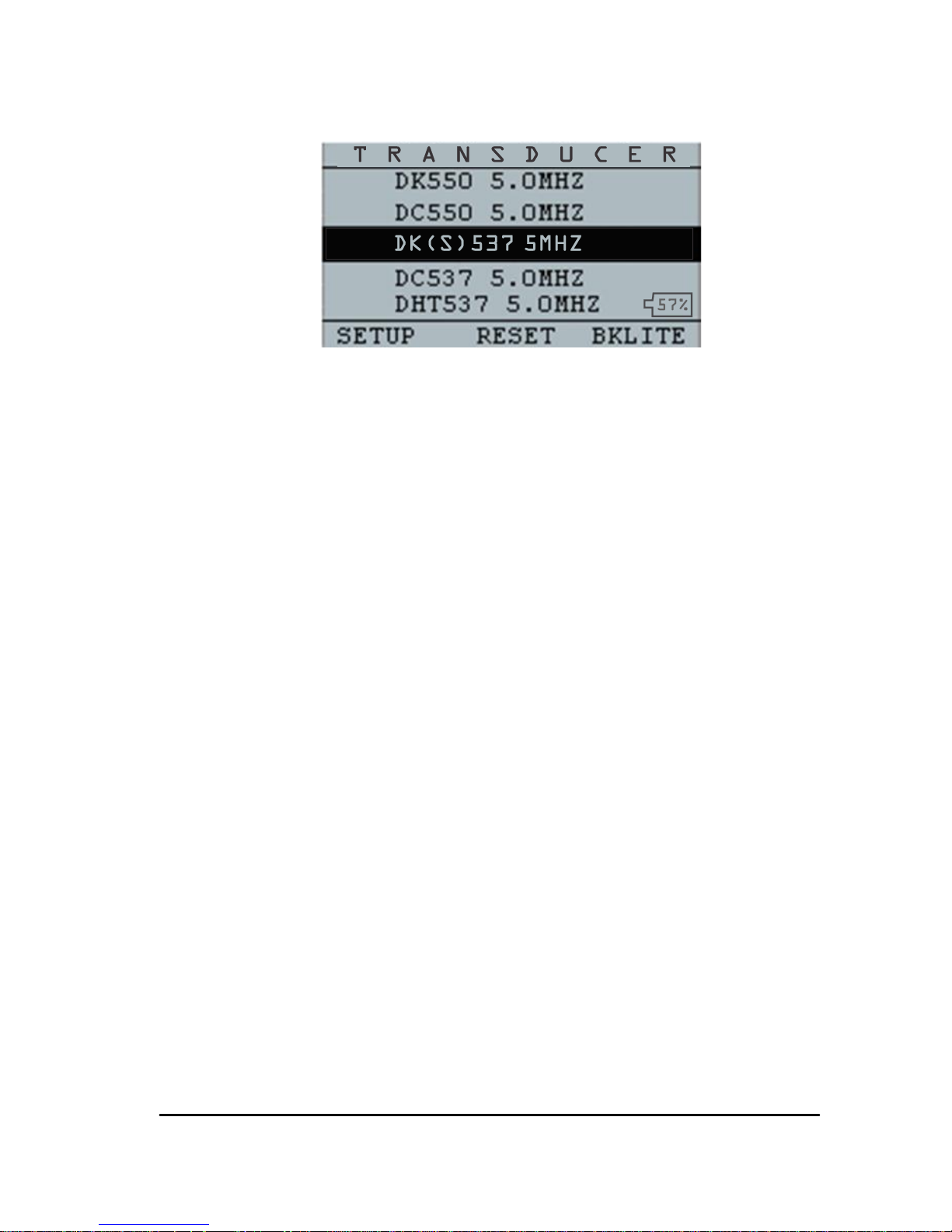

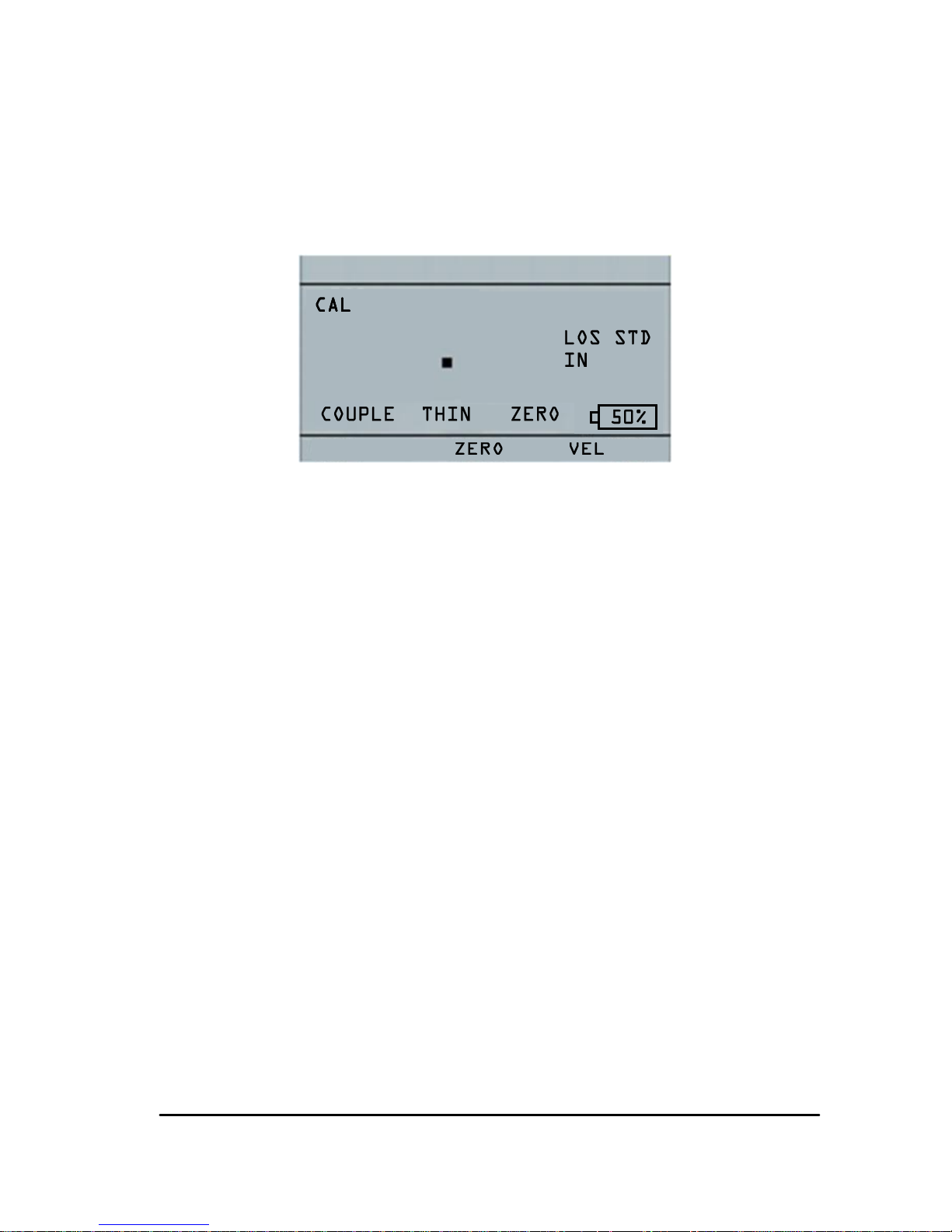

3. The next screen that appears automatically is

the transducer selection screen also referred to

as Home screen in the manual.

Power symbol

under the F1 key

Page 15

15

4. Use the up and down arrow keys to select a

transducer and press OK key. (Please note that

the transducer selection will automatically

display the transducer last used prior to shut

off.

5. Press F1 to select the Setup option.

6. Press F2 to select the Reset option.

7. Press F3 to select the Bklite option.

Page 16

Extech Instruments .

16 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 16

Performing a Reset (TKG100)

You can reset the TKG100 gauge settings back to the

default settings by performing a gauge reset.

Note: Performing a reset permanently deletes all of

the saved parameters from the gauge and replaces the

settings with default values.

To perform a reset, follow these steps:

1. From the Home screen (transducer select

screen), press the F2 Reset key. The following

Reset screen appears:

2. Press the OK button and the ARE YOU

SURE? Prompt will appear. Press YES, NO, or

BACK using the F1 F2 F3 function buttons as

desired.

Page 17

17

Performing a Reset (TKG150)

You can reset both the TKG150 DATABASE and

PARAMETER settings back to their default settings in

one gauge reset or you can reset the PARAMETER and

DATABASE data individually.

Note: Performing a reset permanently deletes all of

the saved parameters from the gauge and replaces the

settings with default values.

To perform a reset, follow these steps:

1. From the Home screen (transducer select

screen), press the F2 Reset key. The following

Reset screen appears:

2. Use the up and down arrow keys to select

DATABASE, PARAMETERS, or ALL and

then press MENU/OK.

3. The ARE YOU SURE? Prompt will appear.

Press YES, NO, or BACK using the F1 F2 F3

function buttons as desired.

Page 18

Extech Instruments .

18 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 18

4. Note that performing a Database Reset clears

all the files in the database and keeps the first

three: Linear, Row increment and Col

increment database files with cleared readings.

All the user created files in the database will be

cleared and deleted.

5. After performing a Reset, the Home screen

appears automatically.

Backlight

The backlight can be turned On or Off by pressing F3 –

Bklite. Backlight can also be turned On, Off or set on

Auto using the Bklight option in the Setup Menu.

Note: Leaving the backlight on will reduce battery life.

If you set the backlight to Auto, the backlight will turn

on during active readings and hold for 15 seconds or

unless otherwise specified.

Note: If the backlight is set to Auto and you have the

gauge in Hold mode, the backlight will shut off after 15

seconds. If you would like the hold to remain lit, then

you must enable the backlight on instead of using

Auto.

Page 19

19

About Screen

You can find information about any of the TKG series

thickness gauges such as the model number, version

number and contact information from the gauge‟s About

screen. To go to the About Screen, follow these steps:

1. From the Home screen (transducer select

screen), press the F2 – Reset key. The Reset

screen will appear.

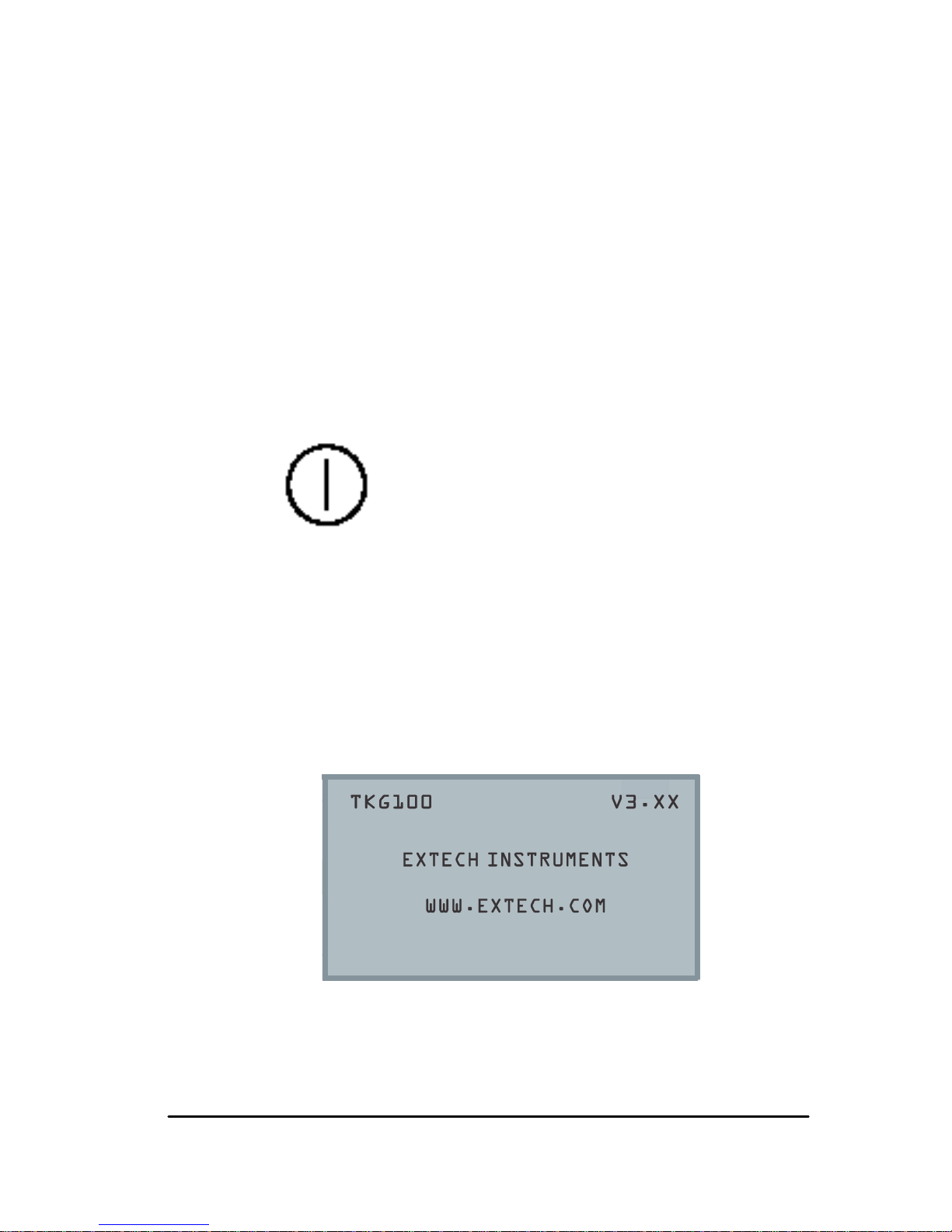

2. Press the F3 – About key. The following About

screen appears.

3. Press the F1 – Exit key to return to the Reset

selection screen.

Page 20

Extech Instruments .

20 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 20

3 Calibrating the Gauge

Calibrating is the process of adjusting the gauge for a

specific material and transducer before testing material to

make sure that all measurements are accurate. You must

always calibrate before measuring material for standard

accuracy.

To measure a thickness of unknown material you need to

know the velocity of the sound in the unknown material.

To find the velocity of the sound you can use one of the

following methods:

Velocity calibration only

Velocity and zero calibration

Zero calibration only

Delay line calibration

Velocity Calibration Only

If you are working with a test piece of known thickness

but unknown material, then you can calibrate the velocity

of the sound in the unknown material by measuring the

time of flight from main-bang to the first back echo. By

using the known thickness you can calculate velocity of

the sound for the unknown material.

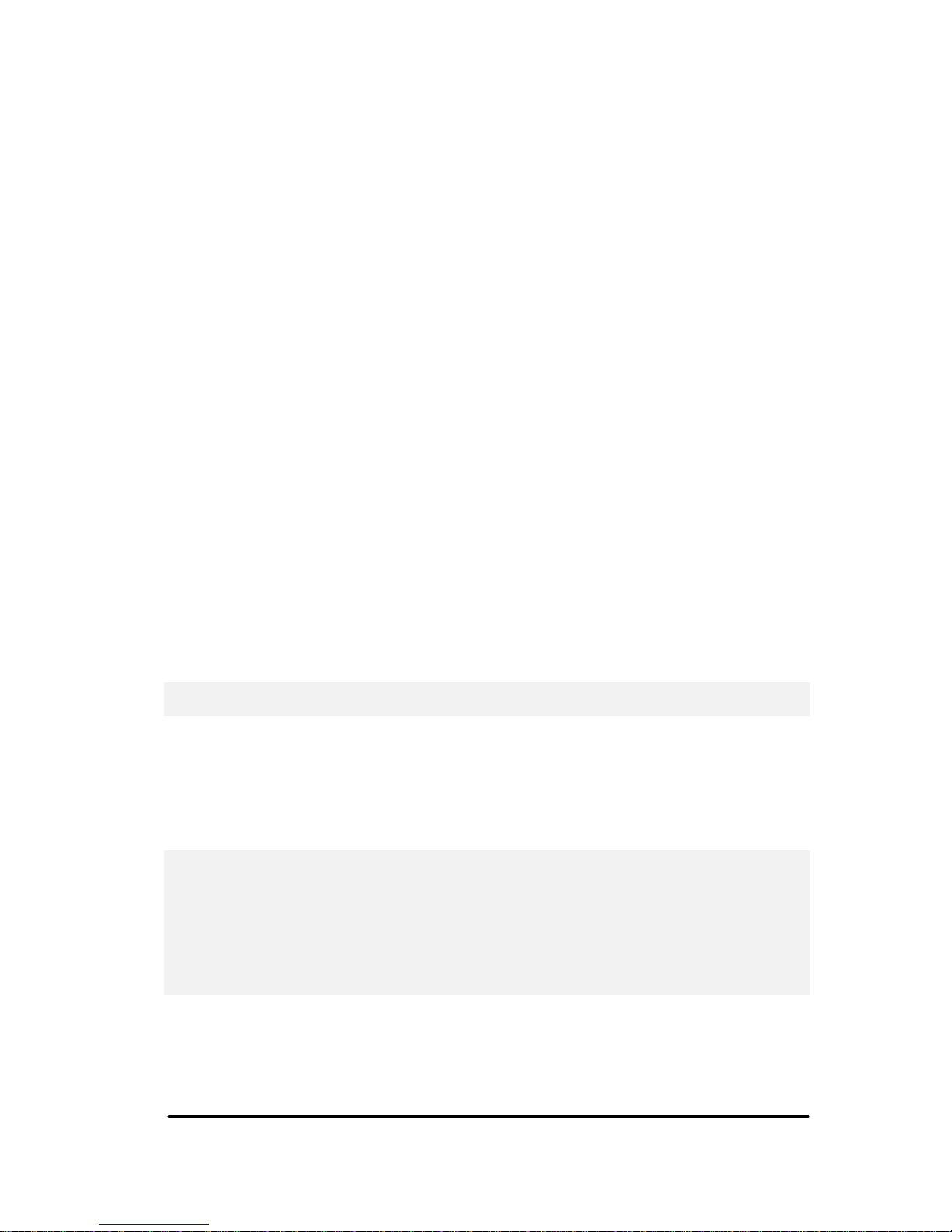

To perform any calibration, first go to the measure mode

and press Menu/OK. Then select the Calibration option

from the Menu screen and press OK. The following

Calibration mode screen (or similar) should appear. To

Page 21

21

exit the calibration screen without performing any

calibration, press OK. To proceed to the Velocity

calibration, follow the following instructions.

Cal screen for TKG100 non-datalogger version

While measuring the thicker step, select VEL by pressing

F3. After selecting VEL, you can take the transducer off

the test block. If the displayed measurement is different

than the known value of the step, use the up or down

arrow key to adjust the displayed value to the known

value of the step. Press OK to perform the calibration.

The unit will briefly display the calibrated velocity value

in the top of the screen and then return to measure

mode.

Velocity and Zero Calibration

If you have a test step block of known thicknesses but

unknown material, then you can calibrate the zero and

velocity of the sound in the unknown material by

measuring the time of flight from the main-bang to the

first back echo for thinner step and thicker step.

Page 22

Extech Instruments .

22 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 22

To calibrate both: velocity and zero at the same time first

go to the Calibration mode as shown in Velocity

Calibration Only section. While measuring the thicker

step, select VEL by pressing F3. After selecting VEL you

can take the transducer off the test block. If the displayed

value is different than the known value of the step, adjust

the value by pressing up or down arrow keys and press

F1/CAL. Then while measuring the thinner step select

ZERO by pressing F2. After selecting ZERO you can

take the transducer off the test block. If measured value

is different than the known value of the step, adjust the

measured value by pressing up or down arrow key and

then press OK. The unit will briefly display the calibrated

zero value and then return to Measure mode. Note that

the order of Velocity and Zero calibration could be

reversed. If Velocity calibration is performed after Zero

calibration, the calibrated velocity value will be displayed

at the end of the calibration process.

Zero Calibration Only

If you have a test step block of known thickness and

known velocity of sound in the material, then you can

calibrate the zero by measuring the time of flight from

main-bang to the first back echo for the thinner step.

The calibrated zero is the calculated zero minus the

measured zero.

To accurately measure a thickness of unknown material

you need to know the velocity of the sound in the

unknown material and the errors introduced by the cable

Page 23

23

and electronics. This is called delay line and zero

calibrated value for the transducer.

To perform a zero calibration, go to the Cal mode as

shown in Velocity Calibration Only section. Then while

measuring the thinner step, select ZERO by pressing F2.

After selecting ZERO, you can take the transducer off

the test block. If the displayed measurement is different

than the known value of the step, use the up or down

arrow key to adjust the displayed value to the known

value of the step. Press OK to perform the calibration.

The unit will briefly display the calibrated zero value in

the top of the screen and then return to measure mode.

Delay Line Calibration

Delay line calibration is done every time the thickness

gauge is powered on and a transducer is selected, or

when a different transducer is selected during normal

operation.

Delay line calibration is performed by measuring the

echo of the transducer itself when it is not placed on any

material and there is no couplant on the transducer

surface.

Under normal usage, the surface of the transducer wears

over time, which reduces sensitivity of the transducer.

When you power on any of the TKG series thickness

gauges and select a transducer, the gauge performs

automatic calculations and warns you (patent pending) if

Page 24

Extech Instruments .

24 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 24

the sensitivity of the transducer is too low and whether

the transducer should be replaced.

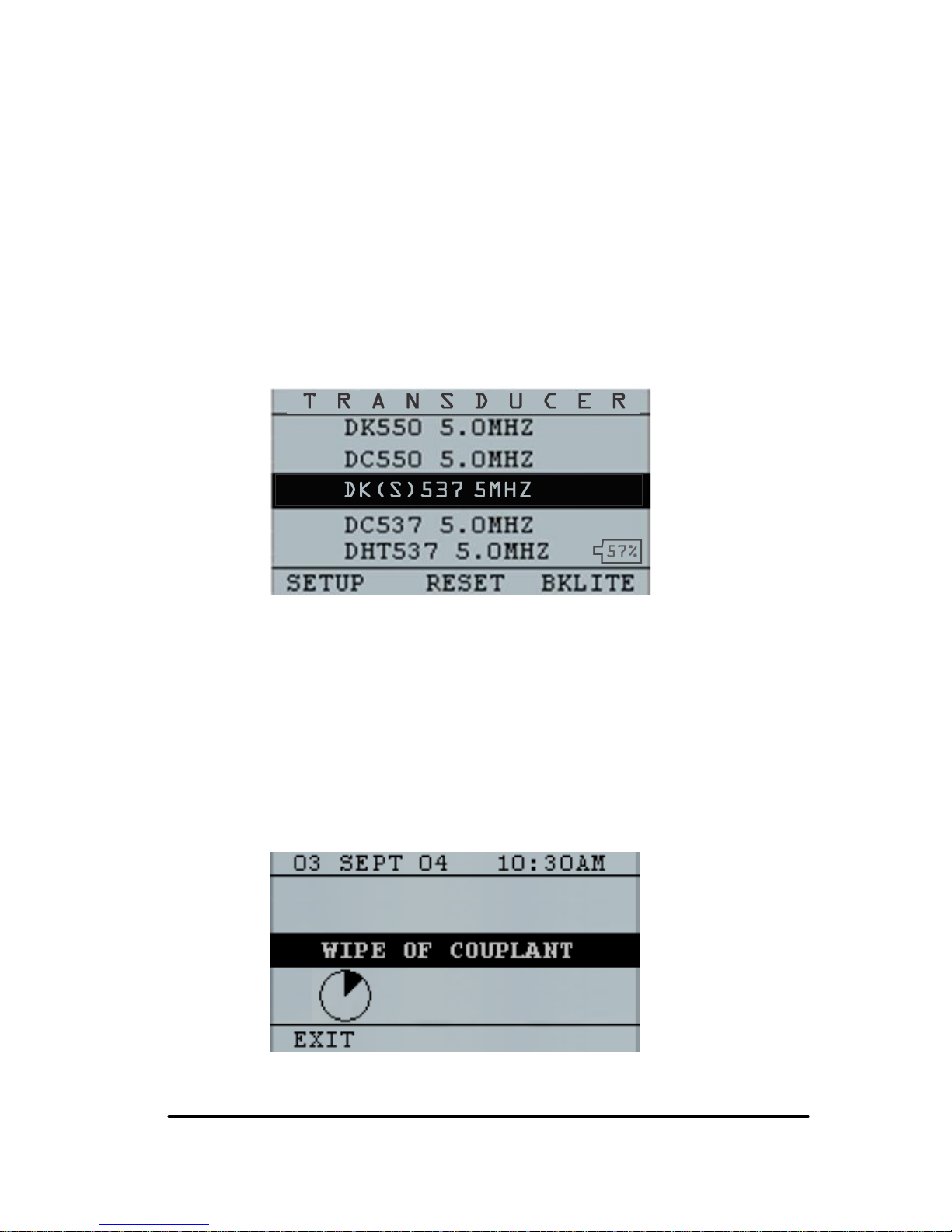

Automatic Zero

To perform an Automatic Zero or Auto Zero, you must

first select a transducer option from the Transducer

selection screen and press the Menu/OK key.

To continue the Auto Zero, follow these steps:

1. Follow the instructions given on each display

screen; the first of which will prompt you to

wipe off any couplant from the transducer and

wait three seconds. The waiting time is shown

in the changing pie-clock graphic on the display

screen.

Page 25

25

2. After three seconds the gauge automatically

begins to zero the transducer. During the delay

line calibration a screen appears displaying the

message “Performing Auto Zero”.

3. A warning message will appear on the display

screen if the delay line is below the acceptable

limit for accurate thickness measurements. You

will need to replace the transducer or select the

F1 key to acknowledge the warning message

and continue using the same transducer, which

may have a worn surface.

4. After three seconds or after acknowledging the

warning message, the display shows the

instrument parameters for 3 seconds before

going to

Measurement

mode.

Page 26

Extech Instruments .

26 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 26

4 Measurement Mode

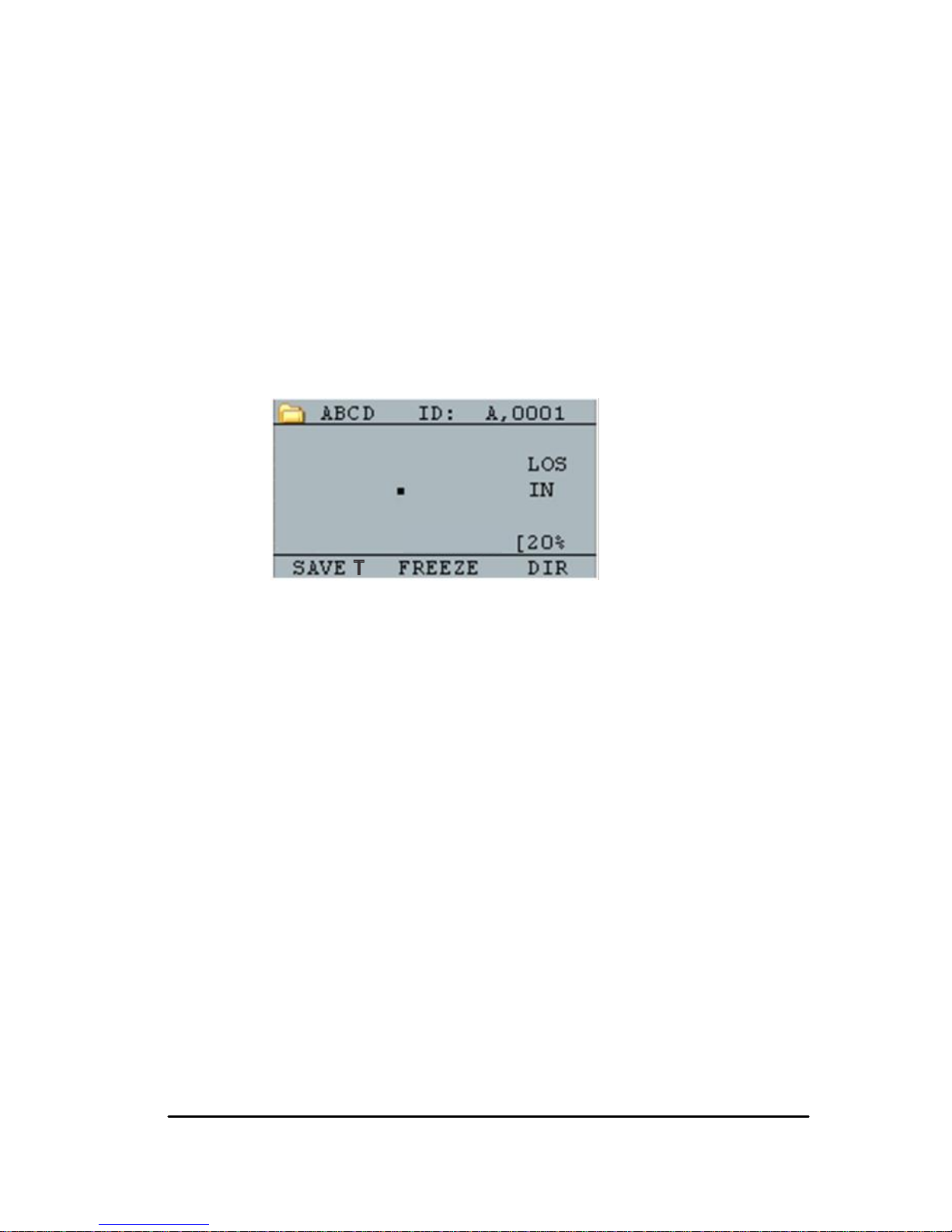

Measurement Mode with a Datalogger

(TKG150)

For the TKG150 series datalogger the display screen in

Measurement

mode will look similar to the screen

below:

To continue in

Measurement

mode, follow these steps:

1. Press the F1 key to select the Save T option.

(See: Save section.)

2. Press the F2 key to select the Freeze option.

(See: Freeze section.)

3. Press the F3 key to select the Dir (Directory)

option. (See: Directory section.)

4. Press the Menu / OK key to select the Menu

option. (See: Menu section.)

Page 27

27

Measurement Mode without a Datalogger

(TKG100)

The TKG100 display screen in

Measurement

mode will

look like the screen below:

To continue in

Measurement

mode, follow these steps:

1. Press the F1 key to select the Alarm option.

(See: Alarm section.)

2. Press the F2 key to select the Freeze option.

(See: Freeze section.)

3. Press the F3 key to control the display

backlight. (See: Display Backlight)

4. Press the Menu / OK key to select the Menu

option. (See: Menu section.)

Note: The available choices for F1, F2, F3 are

different for the TKG100 series thickness gauge.

Page 28

Extech Instruments .

28 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 28

Also, the file symbol, filename, ID: xx,xxxx are not

displayed in the TKG100 series thickness gauge.

Page 29

29

Measurement Mode Setup Options

The following modes are available (please note that in the

TKG100 model the Datalogger mode is not available):

To select the Measurements setup mode, first access

the main MENU (using the MENU/OK button from

the Home screen), and then follow these steps:

1. Use the arrow buttons to highlight

MEASUREMENTS and then press Menu OK.

A screen similar to the one below will appear (a

full list of setup options is shown later in this

section):

2. Use the up and down arrow keys to select any

of the setup parameters available and press the

OK key to change the setting. You can also

change the setting using the “Quick Access

Page 30

Extech Instruments .

30 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 30

mode”. To do this, simply use the left and right

key (indicated in the top right hand of the

display screen) to change the setting of the

highlighted parameter.

3. The entire list of available MEAUREMENT

MODE parameters for the TKG100 and

TKG150 (red items TKG150 only) are as

follows:

FAST OFF

GAIN LOW dB

HOLD OFF

MEAS, TYPE THICKNESS

VEL 0.23596 IN/US

XDUCER DKS537 5.0MHz

ALARM OFF

BSCAN OFF

DIFF OFF

E-TO-E OFF

Page 31

31

Setting the Clock

The TKG series thickness gauges have an internal realtime clock that includes the year, month, day and time.

This option appears under the Initial Settings option.

The entire list of available clock setup options are as

follows:

TIME FORMAT 12 HR

DATE FORMAT MM/DD

MINUTE 21

HOUR 01 PM

DAY 01

MONTH 01

YEAR 2013

To set the time and date, follow these steps:

1. Select CLOCK from the INITIAL SETTINGS

list in the main MENU.

The following is an example of what the clock

setup screen might look like depending on the

Page 32

Extech Instruments .

32 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 32

previous setup.

2. To change the Time Format, select TIME

FORMAT using up/down arrow keys. Use the

left/right arrow keys to select between 12 HR

and 24 HR options.

3. To change the Date Format, select DATE

FORMAT using up/down arrow keys. Use the

left/right arrow keys to select between

MM/DD and DD/MM options.

4. To set Minute, select the MINUTE option

using up/down arrow keys. Use left/right arrow

keys to decrease/increase the minute value.

You can set the minute value from 00 to 59.

5. To set the Hour, select the HOUR option

using up/down arrow keys. Use left/right arrow

keys to decrease/increase the hour value. If

time is set in 12 HR format, the available hour

values are from 00 AM to 11 PM. If time is set

in 24 HR format, the available hour values are

00 to 23.

Page 33

33

6. To set Day, select the DAY option using

up/down arrow keys. Use left/right arrow keys

to decrease/increase the day value. You can set

the day value from 01 to 31.

7. To set Month, select the MONTH option

using up/down arrow keys. Use left/right arrow

keys to select a Month from JAN to DEC.

8. To set Year, select the YEAR option using the

up/down arrow keys. Use left/right arrow keys

to select the year value from 2005 to 2025.

Press Menu to store the changes and to return to the

INITIAL SETTINGS screen. The real-time clock will

automatically update the date and time once the clock

parameters are selected and stored.

Setting LCD Contrast

To change the display contrast, select Contrast from the

Display option under the main MENU. Use left and right

arrow keys to a select contrast value from 1-64. Press

BACK to save the selection and return to the previous

screen.

Understanding a LOS Reading

LOS (Loss of Signal) occurs when the gauge is not

making a valid reading. This can happen for a variety of

reasons, including the ones in the list below:

Page 34

Extech Instruments .

34 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 34

Not enough couplant

Surface is too rough or rusty

Low Transducer sensitivity

Temperature is too high

Dis-bond exists between the coating and the

steel

In the event you try to save a reading in LOS with the

TKG150, the Notes screen will automatically appear so

that a reason is given for saving an LOS. You can scroll

to the appropriate note and press the soft Save key.

Using the Hold Option

If a LOS occurs, the gauge can continue to display the

last measured thickness by “holding” or freezing the

measurement.

Page 35

35

Using the Fast Option

The Fast option is available by accessing the main

MENU, selecting MEASUREMENTS, and then

selecting FAST from the list.

To select the Fast option, follow these steps:

1. Use the up and down arrow keys to highlight

the Fast option and press the OK key.

2. The following parameters are available:

3. Use the up and down arrow keys to select the

desired parameter and press the OK key.

4. Press F1 Back key to return to the

Measurement mode.

Page 36

Extech Instruments .

36 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 36

In the Measurement the selected Fast option setting is

displayed similar to the screen below:

Helpful Hint: When using the FASTMIN mode, if you

press the F2 key “Freeze” prior to LOS, the gauge will

display the last minimum prior to the LOS so that the

actual couplant on the end of the transducer is not

registered as a legitimate minimum reading.

The parameters that you select in the Fast option are

shown as follows in Measure mode:

FAST when On is selected

FASTMIN when Min is selected

FASTMAX when Max is selected

<BLANK> when Off is selected

The Fast option allows you to select fast updates of

measurements at 20 Hz compared to 4 Hz. If you select

the FastMax option, the LOS will display the LAST

MAX measured value, or if you select the FastMin

parameter the LOS will display the LAST MIN measured

Page 37

37

value. If you select the On parameter from the Fast

option, the LOS will work normally and not show the

measured reading.

The screens below reflect different parameters selected

from the Fast option. For example, the top screen shows

the FASTMAX with LAST MAX measurement on LOS,

and the bottom screen shows the FASTMIN with LAST

MIN measurement on LOS.

Note: The LOS flag indicates the LAST MAX or the

LAST MIN value and is shown based on the FastMax or

FastMin setting.

Page 38

Extech Instruments .

38 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 38

To reset the tracking of LAST MAX and LAST MIN

measured value press the OK (Menu) key.

Using the Gain Option (TKG150 only)

Gain refers to an increase in signal power (echo height)

and is typically measured in decibels (dBs). The Gain

function is useful for setting a reference level where by

making it easier to add or subtract gain. There are three

Gain options, which include: LOW dB, STD dB & HI

dB. The Gain selection is available from the

Measurements mode screen in the Main MENU.

1. Use the up and down arrow keys in the

Measurements screen to highlight the Gain

option.

The following Gain parameters are available:

STD (standard), LO, and HIGH

2. Use the left/right arrow keys to select the

desired Gain option.

3. Press the F1 key to accept the parameter and

return to Measure mode.

Page 39

39

In the Measure mode screen the Gain option that you

select is displayed on the center/right side of the display.

Using the Diff Option

There are 3 Diff options:

ABSOLUTE: Absolute, where the gauge will

display a thickness value as an absolute number.

For example, diff abs = 0.500” and the real

thickness is 1.000 inch, the display will show

diff abs 0.500. If the real value is 0.300, the

gauge will display, -0.200”

PERCENT: When this mode is on, the

displayed value will be listed as a percentage of

the value entered into as the diff. For Example,

if the operator set the diff to percentage at

0.500”, a reading of 0.250” will result in 50%

OFF: Diff Option off.

In the Measure mode screen, highlight the DIFF option

and select the desired option using the right/left arrow

keys. Press F1 to exit Measurement mode and save

settings.

Page 40

Extech Instruments .

40 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 40

5 Alarm Options

Using the Alarm Option

The TKG series thickness gauges offers various alarm

settings to alert you of low or high thresholds via audible

sounds, display flashes, vibrations (if on) and illuminating

keypad. There are several alarms options, which include:

Alarm On/Off: Sets the audible alarm either on

or off.

Low Alarm: Audible alarm will occur and

display will flash when the displayed reading is

less than the low alarm reference value.

High Alarm: Audible alarm will occur when the

displayed reading is higher than the high alarm

reference value.

High_Low Alarm: Audible alarm will occur and

display will flash when the displayed reading is

less than the low alarm or greater than the High

alarm reference value.

Low Alarm/Vibra (TKG150 only): Vibration

alarm will occur and display will flash when the

displayed reading is less than the low alarm

reference value.

High Alarm/Vibra (TKG150 only): Vibration

alarm will occur and display will flash when the

Page 41

41

displayed reading is higher than the high alarm

reference value.

High_Low Alarm/Vibra (TKG150 only):

Audible alarm will occur and display will flash

as well as vibrate when the displayed reading is

less than the low alarm or greater than the High

alarm reference value.

The Alarm option is available from the Measurements

screen list.

1. Use the up and down arrow keys to highlight

the Alarm option and press the OK key (or you

can use Quick Access mode by using the right

or left keys once Alarm is highlighted). For the

TKG100 model you can also press the F1

(Alarm) key to go directly to the Alarm option

without having to go through the Main

MENU/Measurement Mode list.

The ALARM selections available are listed on

Page 42

Extech Instruments .

42 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 42

the previous page.

2. Use the up and down arrow keys to select the

desired alarm type and then press the OK key.

The following screen below appears (screens

will differ slightly based on alarm type

selection). Use the up and down arrow keys to

select the high, low, or percent parameters and

then use the left/right arrow keys to change the

Alarm limits. Press the OK key to continue.

Note: The Low Alarm limit will not go beyond the High

Alarm limit.

3. When you are finished adjusting the setting,

press the F1 key to return to Measure mode.

Page 43

43

Visual and Audible Alarm

The Visual Alarm conditions can be viewed from either a

red, yellow or green LED that light up under the F1, F2,

or F3 keys on the keypad.

As an example, when using the 5 step English test block

with thicknesses of 0.100, 0.200, 0.300, 0.400 and 0.500

inches, if you enter alarm high-low you will first need to

enter the high value. Enter 0.500 and press enter. Next

you will need to enter the low value of 0.100 in. The

display will ask you to enter the percent reading of the

high low. The gauge will default to 20% (this can be

changed with the up or down keys), so any reading within

20% of the high value (approaching high, between 0.400

and 0.499 as 0.400 is within the 20% range of 0.500.) will

result in the yellow keypad lighting up. Also, any reading

above the low value of 0.101 and 0.120 will result in the

yellow F2 keypad lighting up as you are approaching the

minimum

So, in Alarm mode, choosing a non-zero percent value

provides the user with warning for readings approaching

the selected percent value of the high or low limits. For

example, if the alarm value is 0.100" and 20% is entered

as the “percent value”, reading from 0.101" to 0.120" will

result in the F2 “yellow” key being illuminated. Also,

reading less than 0.100" will result in the F1 key “Red”

being illuminated and greater than 0.120" will result in

the F3 “Green” key being illuminated.

Page 44

Extech Instruments .

44 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 44

The Audible Alarm turns the beeper on the gauge either

on or off based on the same alarm conditions used for

visual alarm stated above.

‘Vibra’ Alarm (TKG150 only)

The gauge will physically vibrate when the Vibrating

Alarm is active based on the same alarm condition used

for visual alarm. The Vibrating Alarm, noted as ( ( . ) )

on the gauge display, can be enabled with varying alarms

and alarm conditions as shown on the screens below:

Visual and Audible Alarm is enabled.

The letter A (Alarm) appears in the alarm icon

Page 45

45

Visual, Audible, and Vibrating alarm enabled

.)) symbol appears next to the alarm icon. The letter H

(High) appears in the alarm icon

Alarm condition has occurred meaning the

measured reading is greater than the High

Alarm limit. The letter H (High) appears in the

alarm icon. The screen above has the Vibrating

alarm enabled as the .)) symbol appears next to

the alarm icon.

Page 46

Extech Instruments .

46 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 46

Visual, Audible, and Vibrating alarm enabled

.)) symbol appears next to the alarm icon. The letter L

(Low) appears in the alarm icon

Alarm condition has occurred meaning the

measurement reading is less than the Low

Alarm limit. The letter L (Low) appears in the

alarm icon. The screen above has the Vibrating

alarm enabled as the .)) symbol appears next to

the alarm icon.

Note: For the TKG100, the F1, F2, and F3 choices are

different and the file symbol or the filename along with

ID# are not shown.

Page 47

47

6 Using the Echo-to-Echo Option (TKG150

only)

The Echo-to-Echo option allows you to make

measurements between two consecutive back-wall

echoes. Therefore, a good usage of the Echo-to-Echo

option is for measuring through coatings to measure only

the true metal thickness. There are two Echo-to-Echo

options you can select, which are as follows:

Echo-to-Echo On: Enables the Echo-to-Echo

function

Echo-to-Echo Off: Disables the Echo-to-Echo

function

In the Measurements mode screen in the Main menu,

highlight the E-TO-E option and select the desired

option using the right/left arrow keys. Press F1 to exit

Measurement mode and save settings and F1 again to get

back to the measurement mode.

Page 48

Extech Instruments .

48 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 48

7 Special Gauge Functions

The TKG series thickness gauges have many special

functions that go beyond the basics, mainly in the

TKG150 model. This section will discuss these special

gauge functions in detail.

Using the Save Option (TKG150 only)

You are able to save your data via the Save option.

To use the Save option, follow these steps:

1. From the Measurement mode screen, press

[F1] (Save T).

The data saved will depend on your setup

parameters. For example, if the Notes option is

set to Off (Main MENU, DATALOGGER,

NOTES) the saved thickness readings will be

stored at the ID location [Linear], [Row], [Col]

without notes. (See: Directory selection for file

type details.)

Page 49

49

2. If the Notes option is set to Always then the

thickness reading is stored at the ID location

[Linear], [Row], [Col] with notes. To change the

Notes settings, select the Notes option from the

Datalogger screen in the MAIN Menu.

Now when you press Save T (T for Thickness)

to store a reading in measurement mode, the

following Notes options will be presented:

No comments, not sand blasted, pitting, too hot, broken

insulation, couldn’t read scaffold, needs painting,

broken/missed plug, obstruction, port, burner,

metalized, overlay, already cut out, and pad weld

3. Use the up and down arrow keys to select a

note for the reading and press the OK key. The

selected note will be stored at the ID location,

and based on the file type, [Linear], [Row], or

[Col] is incremented. (See: Directory selection

for file type details.)

Page 50

Extech Instruments .

50 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 50

Using the Freeze Option

You can freeze your data via the Freeze option.

To use the Freeze option, follow these steps:

1. From the Measurement mode screen, press

[F2] (Freeze).

The following screen comes up after pressing

[F2] (Freeze) whereby showing the flag

“Freeze” under the thickness reading. You are

now in Freeze mode. The [F2] selection also

changes from Freeze to Unfreeze.

Page 51

51

TKG150 Datalogger version

TKG100 Non-datalogger version

2. Press [F1] (Save) to save the reading. (See

Using the Save Option for more information.)

3. Press [F2] (Unfreeze) to disable the Freeze

mode

4. Press [F3] (Dir) to perform file operations.

(See Using the Directory Option for more

information.)

5. While in Freeze mode the menu options are

disabled. The display will prompt you to

unfreeze the gauge.

Page 52

Extech Instruments .

52 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 52

TKG150 Datalogger version

TKG100 Non-datalogger version

Page 53

53

Using the Menu Option

For the TKG100 and TKG150 models you can operate

in Measure mode.

To use the Measure mode, follow these steps:

1. Press the Menu (OK) key to select the Menu

options from Measure mode.

Measure mode of the TKG150 Datalogger version

Measure mode of the TKG100 Non-Datalogger version

Page 54

Extech Instruments .

54 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 54

The following Menu options are available:

TKG150 Datalogger version

TKG100 Non-datalogger version

Page 55

55

8 Using Datalogger Directory Mode

(TKG150 only)

Note: This section applies only to the TKG150

Thickness Gauge with a datalogger. If you do not have

a datalogger, you may skip this section.

To use the datalogger Directory mode, follow these

steps:

1. From the Measurement mode screen press

[F3] (Dir) to select the Directory mode.

By pressing [F3] (Dir) you will be able to

review, create, delete, select, rename and clear

stored thickness and copy.

2. Use the up and down arrow keys to view the list

of files, and select whichever one is relevant.

Page 56

Extech Instruments .

56 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 56

3. Press the OK key to select a file in the directory

view.

4. To create a custom file see Creating Custom Files

section.

5. To review thickness readings, see Reviewing a File

section.

6. To rename custom file, see Renaming a File

section.

7. To clear an entire file, see Clearing a File section.

8. To clear selected readings from a file, see

Reviewing a File section.

Page 57

57

9. To create copy of the existing file structures, see

Copying a File section.

10. To delete a custom file, see Deleting a File

section.

The first three files cannot be deleted or

renamed. These files are factory default

files available for you to start storing

thickness reading or make a quick copy of

the file structure (Linear or Grid [Col,

Row]) in order to start saving data in the

new file. (See File System for more

information.)

Page 58

Extech Instruments .

58 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 58

Managing the Datalogger File System

The TKG150 supports the following two files types:

Linear file

: Consists of ID# from 0001 to

5000. The extended memory option consists of

ID# from 1 to 500000.

Grid file

: Consists of ID# as COLUMN and

ROW. The COLUMN is single or double digit

capital alpha character from A to Z and AA to

ZZ. The ROW is a four digit number based on

the 5000 / COLUMN.

For example, when you create a new GRID file with

END COLUMN = C, then the maximum ROW you can

slew up to is limited to 1666 calculated by the instrument

as follows:

The total storage space per file is 5000 readings.

For Columns ending at C, this means 3 columns

are required and the maximum Row allowed is

limited to 5000 / 3 = 1666.

If you create a new GRID file with END COLUMN =

Z, then the maximum ROW you can slew up to is limited

to 5000/26 = 192.

If you create a new GRID file with END COLUMN =

AF, then the maximum ROW you can slew up to is

limited to 5000/(26 for A to Z + 6 for AA to AF) = 156

the grids are created as shown below:

Page 59

59

A,1 to A,156 then

B,1 to B,156 then

:

Z,1 to Z,156 then

AA,1 to AA,156 then

AB,1 to AB,156 then

:

AF,1 to AF,156

If a new GRID file with END COLUMN = ZZ, then

the maximum ROW you can slew up to is limited to

5000/(26 for A to Z + 26*26 for AA to ZZ) = 7.

A,1 to A,7 then

B,1 to B,7 then

:

Z,1 to Z,7 then

AA,1 to AA,7 then

AB,1 to AB,7 then

:

AZ,1 to AZ,7 then

BA,1 to BA,7 then

BB,1 to BB,7 then

:

:

ZZ,1 to ZZ,7

Page 60

Extech Instruments .

60 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 60

Note that there are two different types of Grid files:

ROWINC and COLINC. The above two examples show

how the ID locations are incremented in ROWINC type

file only. Here the Row value is incremented first, while

updating ID location. Whereas, in a COLINC type file,

Column value is incremented first.

So for a COLINC file with END COLUMN value AF,

the ID locations will increment as follows:

A,1 to AF,1 then

A,2 to AF,2 then

.

.

A,156 to AF,156

A COLINC file with END COLUMN value ZZ will

have ID increments as follows:

A,1 to ZZ,1 then

A,2 to ZZ,2 then

.

A,7 to ZZ,7

Page 61

61

Creating Custom Files

To create a custom file in the datalogger, follow these

steps:

1. Press [F3] (Dir) from the Measurement mode

screen.

The following screen appears:

2. Use the up and down arrow keys to highlight

the next Empty file in the list.

Page 62

Extech Instruments .

62 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 62

3. Press the OK key and select RENAME, the

following screen appears:

4. Use the up, down, left, and right arrow keys to

select the characters of the filename. Press the

OK key to accept the selected characters. If you

make an error, press [F2] (Del) to delete the

last character of the entered filename.

5. Press [F3] (Done) when you are finished

entering the filename. The following screen

appears:

6. Use the left and right arrow keys to select a file

type. See the next two sections for more

information on selecting file type for the

new file.

Page 63

63

Selecting a Custom Linear File

When you select a LINEAR file format you are

prompted to select START and END file points.

With the extended memory, you can store up to 100,000

readings allowing you more total files.

Pressing the F3 (Done) key again will take you to the

Measure mode displaying the new filename in the top

left corner and the next ID location in the top right

corner.

Selecting a Custom Grid File

When you select a grid file type, the display changes as

shown below. You can now select the number of rows

and columns for your new file.

Page 64

Extech Instruments .

64 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 64

Use the up and down arrow keys to select the END

ROW option. Now press left or right arrow key to

change the END ROW value. Then press down arrow

key to select END COL option. Press left or right arrow

key to change the END COL value. Since the file size is

limited to 5000, the END COL value is limited to

5000/END ROW. Note that the „FILE SIZE‟ will

change depending on the END ROW and END COL

settings.

When you are finished selecting END ROW and END

COL values, press F3 (Done). The display will go back to

Measure mode, showing the new filename and next ID

location in the top row as shown below.

Page 65

65

Reviewing a File

To review a file from the Measurement mode screen in

datalogger version only, follow these steps:

1. Press [F3] (Dir) from the Measurement mode

screen.

The following screen appears:

2. Select the file you would like to review using the

up and down arrow keys and press the OK key.

Based on the type of file you select, a screen will

appear the same or similar to the one shown in

the example below:

Page 66

Extech Instruments .

66 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 66

CLEAR ALL READI NGS

RENAME

DELETE FI LE

COPY

EXI T

REVI EW DETAI LS

ABCD

REVI EW GRI D

The three factory default files have only 3 options: Clear

All Readings, Copy, and Review Details. Custom files

have 5 options: Clear all readings, Copy, Delete file,

Rename, Review details, and Review Grid. Select the

Review option and press the OK key to review the file.

Reviewing a Linear File

The linear file shows the ID# and the stored readings

along with the units. You can browse the readings by

pressing the up or down arrow key. You can also press

F3 (Beg/End) to go to the beginning or end of the file.

To clear a reading from the file, select the reading to be

cleared by pressing up or down arrow key and then press

Page 67

67

F2 (Clear). Note that once a reading is cleared, it cannot

be restored. To store another reading in the file location

that has been emptied by the Clear operation, highlight

that location by pressing up or down arrow key. Then

press OK to go to the measure mode. When you have

the new reading to be stored in the emptied file location,

press F1 (Save). The new reading will be saved in that

location and the display will show the next empty file

location in the top right corner.

Reviewing a Grid File

The grid file shows the ID# as COL, ROW and the

stored reading with the units. Use the F3 function key to

go to the beginning (BEG) or END of a file list.

Renaming a File

To rename a file from the Measurement mode screen in

datalogger version only, follow these steps:

1. Press [F3] (Dir) for the Directory mode.

Page 68

Extech Instruments .

68 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 68

The following screen appears:

2. Use the up and down arrow keys to select the

file you would like to rename and press the OK

key.

Note: The Rename option is not available for the first

three factory default files.

3. Use the up and down arrow keys to select the

Rename option and press the OK key to

rename the file. A screen the same or similar to

the one below appears.

Page 69

69

4. Use the up, down, left, and right arrow keys to

select the characters of the filename. Press the

OK key to accept the selected characters. If you

make an error, press [F2] (Del) to delete the

last character of the entered filename.

5. Press [F3] (Done) when you are finished

entering the filename. The old filename will be

updated with the new filename in the directory

as shown in the example below.

Note: Press [F1] (Exit) to exit the screen without

renaming the file.

Example:

A user erases a file named ABCD by pressing

[F2] (Del) and selects XYZ as the new

filename and presses [F3] (Done) to accept the

entered new filename.

The old filename in the directory is updated

with the new name.

Page 70

Extech Instruments .

70 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 70

Clearing a File

To clear (or delete) a single thickness reading at a time

from a file, see Reviewing a File section. To clear all the

readings from a file, use the clear file option. To do this,

from measurement mode, press [F3] (Dir) for the

Directory mode.

The following screen appears:

1. Use the up and down arrow keys to select the

file you want to clear and press the OK key.

2. Use the up and down arrow keys to select the

Clear All Readings option and press the OK

key to clear all the stored thickness readings in

that file. The meter will prompt for

Page 71

71

YES/NO/EXIT confirmation:

Press [F1] (Exit) to exit without clearing the

thickness readings.

Press [F2] (Yes) to clear the stored thickness

from the entire file.

Press [F3] (No) to exit without clearing the

thickness readings.

If the file is already clear, the unit will show

„NO READINGS TO CLEAR.‟ message.

Copying a File

To copy a file, from the Measurement mode screen in

datalogger version only, follow these steps:

1. Press [F3] (Dir) for the Directory mode.

Page 72

Extech Instruments .

72 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 72

The following screen appears:

2. Use the up and down arrow keys to select a file

and press the OK key. Any file structure

(factory default or custom) can be copied.

Note: When you copy a file only the structure of the

file ID# is copied and not the associated file readings.

3. Use the up and down arrow keys to select the

Copy option and press the OK key. The

following confirmation prompt or a similar

prompt appears with the next Empty file

highlighted as the default choice.

Page 73

73

Press up or down to select an Empty file and

press OK to assign it a new filename. The

following screen appears.

4. Use the up, down, left, right arrow keys to

select the characters of the filename and press

the OK key to accept the selected characters. If

you make an error, press [F2] (Del) to erase

last character before the cursor.

5. Press [F1] (Exit) to exit without copying the

file.

6. Press [F3] (Done) when you are finished

entering the filename. A new file with the

selected name will be added in the directory

with the file structure of the original file.

Page 74

Extech Instruments .

74 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 74

Deleting a File

To delete a file, from the Measurement mode screen in

the datalogger version only, follow these steps:

1. Press [F3] (Dir) for the Directory mode.

The following screen appears:

2. Use the up and down arrow keys to select the

file to be deleted and press the OK key.

Note: Only custom files can be deleted. The factory

default files cannot be deleted.

3. Use the up and down arrow keys to select the

Delete File option and press the OK key. A

Page 75

75

confirmation prompt for YES/NO/EXIT

appears.

Press [F1] (Exit) to exit the screen without

deleting the file.

Press [F3] (No) to exit the screen without

deleting the file.

Press [F2] (Yes) to delete the file and remove

the file from the directory.

Page 76

Extech Instruments .

76 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 76

7 Technical Specifications

Specifications for the TKG100/TKG150 Ultrasonic

Thickness Gauges

Size: 5" (127 mm) (L) x 3" (76.2 mm) (W) x 1.25" (31.75 mm) (H)

Weight: 8 OZ (.23 kg)

Thickness range: 0.008 - 20 inches (0.20 mm - 508 mm), depending on

material, temperature and transducer selection

Material velocity calibration range: 0.200-0.7362 in/μS (0.508-18.699

mm/μS)

Temperature: Gauge Operating: -4° F to 122° F (-20° C to 50° C) Surface

temperature of material: Depending on probe used, from -5° F to 1000°

F (-20° C to 537° C)

Battery life: Up to 200 hours (40 hours with backlight on)

Battery type: 2 "AA" Alkaline

Display: 128 X 64 Graphics LCD monochrome

Information displays: LOS, min, max, large reading while displaying min

at the same time, velocity, zero, calibration, units, freeze, unfreeze, %

battery life remaining, gain - low, std, high, echo-to-echo symbol

(option)

Resolution: 0.001" (0.01 mm), 0.01" (0.1mm)

Accuracy: Basic Accuracy is 0.004” but on clean smooth steel an

accuracy of 0.001” is not uncommon. The more corrosive the

environment, and pitted the surface under test, the closer to the 0.004”

accuracy one can expect to be. As noted, a higher accuracy can be

obtained when measuring on cleaner steel.

Probe recognition: Via pick list from a menu

Delay line zero measurement: Auto at power up with listed numeric

value. Ideal for correcting delay line wear/curvature and for transducer

acoustic drift at elevated temperatures

Package: Custom, splash-proof, high-impact plastic with rubber,

illuminating keypad for go/no-go testing

Bandwidth: 0.5-20 MHz (-3dB)

Units: English/Metric/Microseconds

Gain: Low, Standard and High for varying test conditions

Measurement rate: 4/sec and 20/sec in fast mode

Page 77

77

Differential Mode: Displays the difference from the actual thickness

measurement and a user entered reference value

Alarms: Minimum/Maximum depth, vibralarm, audible/visual

indications as well as keypad illumination

Illuminating keypad: F1 = Red, F2 = Yellow and F3 = Green for easy,

go/no-go testing (Patent Pending)

Automatic probe wear indicator ( Transducer attendant): Automatically

informs the operator to replace the transducer (Patent Pending)

Ergonomics: User selectable left-handed or right-handed display

changes via keypad (Patent Pending)

Backlight: Light Emitting Diode, On/Off or Auto ON based on valid

readings or last key-press

Shut off: Auto, time out (after X minutes user programmable after no

reading, loss of signal LOS, or no key press)

Scan mode: Displays minimum or maximum thickness value at 20

measurements per second (ideal for high temperature thickness reading

and tracking the minimum depth alarm). Press Freeze to capture last

valid minimum thickness readings prior to Loss of Signal (LOS), without

reading the couplant upon lifting probe off the test piece

Carrying case: Custom molded pouch with wrist strap for either lefthanded or right-handed operators (optional)

Shipping case: Hard plastic with high-density molded cut out for all

accessories (optional)

Freeze mode: Freezes display

Hold mode: Holds display to retain last thickness reading in reverse

video display

Standard TKG includes: Ultrasonic thickness gauge, DK-537 potted, 5

MHz 0.375 inch diameter, operational manual, cable, couplant

Warranty: Limited 2 year warranty

Page 78

Extech Instruments .

78 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 78

Specification differences for TKG100 and TKG150 Models

Item

Specification

150

100

Thickness range

0.008-0.20 inches (20mm-508mm)

x

x

Delay line zero measurement

Auto at power up with listed numeric value.

Ideal for correcting delay line

x

x

Scan mode

Displays minimum or maximum thickness

value at 20 measurements per second

x

x

Hold mode

Holds display to retain last thickness reading

with reverse video display

x

x

Freeze mode

Freezes display

x

x

Units

Inches/Millimeters/Microseconds

x

x

Gain

Low, Standard, or High for varying test

conditions

x

o

Differential mode

Reference value

x

o

Alarms

Illumination and vibration

x

o

Illuminating keypad

F1=Red; F2=Yellow; F3=Green for easy,

go/no-go testing (Patent Pending)

x

o

Auto probe wear indicator

Automatically informs operator to replace

transducer (Patent Pending)

x

o

Echo-to-Echo

Measures the thickness only (ignores paint

and coatings)

x

o

Non-encoded B-scan

Displays cross section of test piece

x

o

Datalogger version

Upgrade to datalogger version

x

o

Carrying pouch

Custom molded with belt clip and elastic

strap

x

o

Note: All software options are field upgradable, no need to return the unit to the factory

Page 79

79

8 Software Options

Echo-to-Echo (TKG150 only)

The Echo-to-Echo feature should and can be used within

the thickness range of the chart listed below. To calibrate

in Echo-to-Echo, first press MENU OK, scroll to set up,

press MENU OK and find where E to E is displayed.

Use the right arrow to turn ON or press MENU OK and

scroll to ON. You will see a symbol in the top right

looking like Echo-to-Echo. Next, press MENU OK, turn

on calibration and perform CAL VEL on the thick part

with the coating and CAL ZERO on the think part with

coating, then MENU OK (note that a thickness block

is required for this operation)

Page 80

Extech Instruments .

80 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 80

B-Scan (TKG150 only)

The B-Scan represents a cross sectional view on the test

piece. The simplest example is to show a 5 step test

block. To turn on the B-Scan on the TKG150, press

MENU/OK, scroll to MEASUREMENTS and press

OK, select B-scan and press MENU/OK. First enter the

maximum thickness you expect to scan using the up,

down, left and right keys, then turn on the B-Scan

scrolling down and right arrow (left arrow for off). Press

F3 in lefty or F1 in righty mode when done. The bottom

of the display will read SAVE, START or STOP and

CLEAR. To Start a B-Scan, couple to a test block and

press F2 [START]. If you uncouple the transducer, BScan will stop due to LOS. If you press F2 [STOP] the

minimum thickness will be displayed in the center of the

screen while a vertical cursor allows you to review

readings. During review the thickness value is updated in

the top right of the display. To save all the readings, press

F1 [SAVE]. The amount of saved readings up to the file

size of 5,000 readings or what was pre-determined in the

current file (See Datalogging) set up. Here is a picture of

the B-Scan on a test block.

Page 81

81

Support Lines: U.S. (877) 439-8324; International: +1 (603) 324-7800

Technical Support: Option 3; E-mail: support@extech.com

Repair & Returns: Option 4; E-mail: repair@extech.com

Product specifications are subject to change without notice

Please visit our website for the most up-to-date information

www.extech.com

FLIR Commercial Systems, Inc., 9 Townsend West, Nashua, NH 03063

ISO 9001 Certified

9 Technical Assistance

Call Extech Instruments for specific technical assistance

or troubleshooting questions. See the customer care

information on the following pages or visit the website

www.Extech.com

Calibration, Repair, and Customer Care

Services

FLIR Systems, Inc. offers repair and calibration services for the

Extech Instruments products we sell. NIST certification for most

products is also provided. Call the Customer Service Department for

information on calibration services available for this product. Annual

calibrations should be performed to verify meter performance and

accuracy. Technical support and general customer service is also

provided, refer to the contact information provided below.

Copyright © 2013 FLIR Systems, Inc.

All rights reserved including the right of reproduction in whole or in part in any form

www.extech.com

Page 82

Extech Instruments .

82 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 82

Lignes d’assistance: États-Unis (877) 439-8324

International: +1 (603) 324-7800

Service d‟assistance technique : Option 3 ; E-mail : support@extech.com

Réparations et retours : Option 4 ; E-mail : repair@extech.com

Les spécifications produit sont sujettes à modifications sans préavis.

Pour les toutes dernières informations, veuillez visiter notre site Web.

www.extech.com

FLIR Commercial Systems, Inc., 9 Townsend West, Nashua, NH 03063 USA

Certifié ISO 9001

Calibrage, réparation et services après-vente

FLIR Systems, Inc. offre des services de calibrage et de

réparation pour les produits Extech Instruments que nous

commercialisons. Nous fournissons également une certification NIST

pour la plupart des produits. Contactez notre service client pour toute

information sur les services de calibrage disponibles pour ce produit.

Un calibrage doit être effectué chaque année pour vérifier les

performances et la précision du mètre. Nous offrons également une

assistance technique et un service à la clientèle. Veuillez vous reporter

aux coordonnées fournies ci-dessous.

Copyright © 2013 FLIR Systems, Inc.

Tous droits réservés, y compris la reproduction partielle ou totale sous quelque forme que ce

soit.

www.extech.com

Page 83

83

Servicios de calibración, reparación y atención

a clientes

FLIR Systems, Inc., ofrece servicios de reparación y calibración

para los productos que vendemos de Extech Instruments. Además

ofrecemos certificación NIST para la mayoría de los productos. Llame

al Departamento de Servicio al Cliente para solicitar información de

calibración para este producto. Para verificar el funcionamiento y

precisión se debe realizar la calibración anual. Además se provee

Soporte Técnico y servicios generales al cliente, consulte la información

de contacto en seguida.

Líneas de soporte: EE.UU. (877) 439-8324; Internacional: +1 (603) 324-7800

Soporte Técnico Opción 3; correo electrónico: support@extech.com

Reparación / Devoluciones: Opción 4; correo electrónico: repair@extech.com

Las especificaciones del producto están sujetas a cambios sin aviso

Por favor visite nuestra página en Internet para la información más

actualizada

www.extech.com

FLIR Commercial Systems, Inc., 9 Townsend West, Nashua, NH 03063 USA

Certificado ISO 9001

Copyright © 2013 FLIR Systems, Inc.

Reservados todos los derechos, incluyendo el derecho de reproducción total o parcial en cualquier medio

www.extech.com

Page 84

Extech Instruments .

84 TKG100_TKG150 Ultrasonic Thickness Gauge User Guide v2.8 11/13 84

Loading...

Loading...