Page 1

User’s Guide

Waterproof Palm pH Meter

Model PH220

Introduction

Congratulations on your purchase of the Extech PH220 waterproof pH/mV meter. This

microprocessor-based device with tactile buttons is battery operated and ideal for field

use. The PH220 simultaneously displays pH or ORP (mV) and temperature. The rubber

holster which protects the meter has a magnetic backing for convenient mounting.

Careful use of this meter will provide years of reliable service.

Page 2

Specifications

Range (Resolution)

mV (ORP) ± 1999 mV DC (1 mV)

Temperature 32.0 to 212.0oF (0.0 to 99.9oC)

pH 0.00 to 14.00pH (0.01pH)

Temperature Compensation 32 to 212oF (0-100oC) Automatic (ATC)

Power 9 volt battery

Display Dual LCD display for simultaneous pH or mV and

temperature readings

Over-range or open indication Displays " ---- " for over-range or open input

pH Calibration points 4.00, 7.00, 10.00

Auto Power OFF After 10 minutes

Low Battery Indication The icon displays no fill bars

Dimensions / Weight 4.25 x 3.00 x 1.18" (108 x 75 x 30mm) / 0.3 lbs (135g)

Accessories supplied with kit Sample buffers, and battery.

Stick electrode for model PH220-S

Electrode with 39” cable for model PH220-C

Accuracy

± 2mV

± 0.5oF (0.3oC)

± 0.02pH

2

Model PH220 Version 2.0 4/05

Page 3

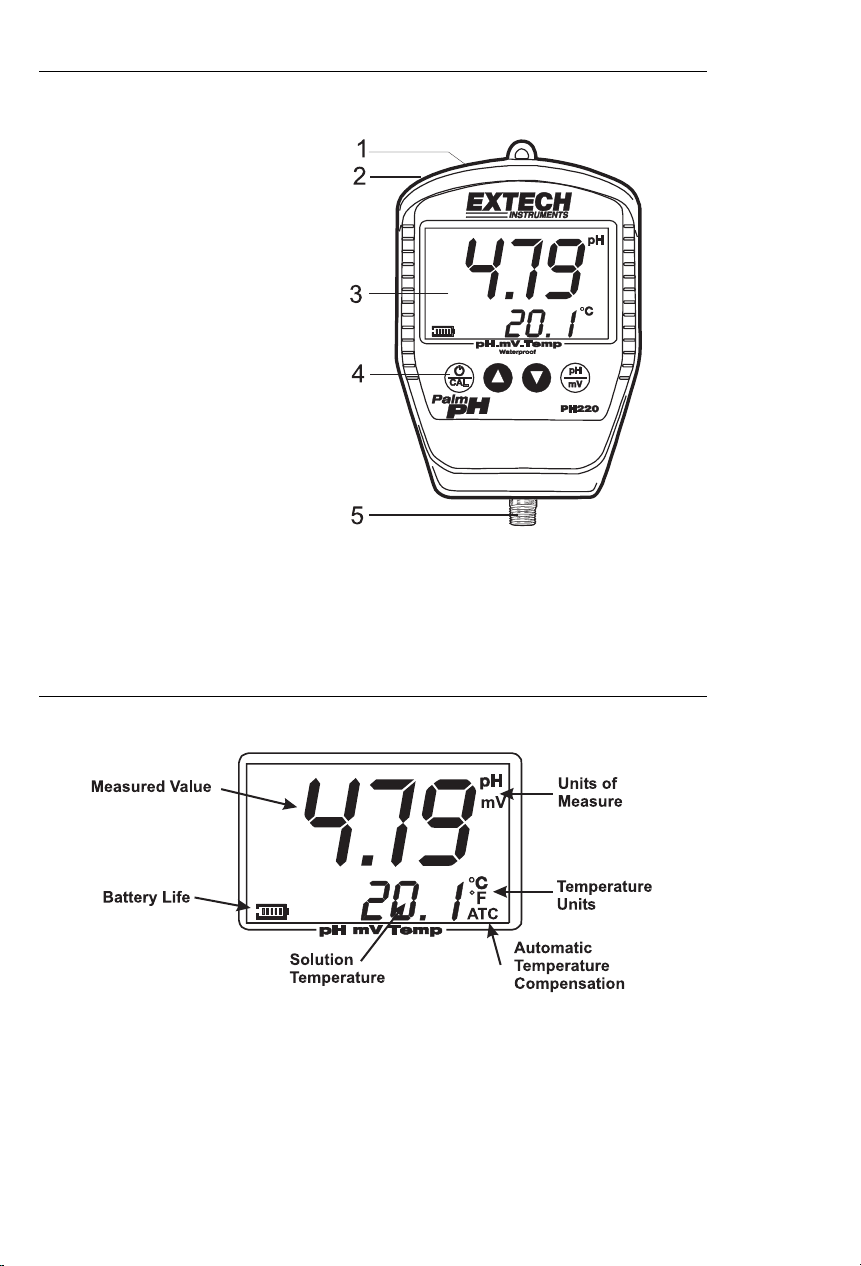

Meter Description

1. Battery Compartment (under holster)

2. Rubber Holster

3. LCD Display

4. Function buttons

5. Electrode input

Display Description

3

Model PH220 Version 2.0 4/05

Page 4

Calibration

pH electrodes are like batteries; they run down with time and use. Because the sensitivity

of a pH electrode degrades over time, it is very important to frequently calibrate the meter

to the electrode.

Calibration is performed using standard buffer solutions at room temperature (78°F, 25°C).

Buffer solutions are solutions of a know pH that have the useful property of resisting

changes in pH. These can be purchased already mixed or in capsule form and are usually

available in three pH values, pH 4.00, pH 7.00 and pH 10.00.

Calibration is always performed using the pH 7.00 buffer first, followed by a second

calibration. Select pH 4 buffer for the second calibration if typical measurements will be

less than pH7 or use a pH 10 buffer if typical measurements will be greater than ph 7.

In order to obtain the most accurate results possible, a pH meter should be

calibrated at least once a day.

2 Point Calibration Procedure

1. Turn the meter on.

2. Use the pH/mV button to select the pH mode. The unit of measure appears on the

LCD.

3. Remove the electrode from its cap and rinse with distilled or deionized water

4. Place the electrode in fresh pH 7.00 buffer solution and stir. Allow 30 seconds for

the electrode/ATC to reach thermal equilibrium with the buffer solution.

5. Press and hold the CAL key for three (3) seconds to enter the calibration mode.

The ‘CAL’ display appears and then the pH value flashes on the LCD.

6. When the pH stops flashing, ‘SA’ (save), and then ‘END’ will appear in sequence.

7. Rinse the electrode with distilled or deionized water.

8. Place the electrode into the second buffer (pH 4.00 or pH 10.00) ands stir. Allow 30

seconds for the electrode/ATC to reach thermal equilibrium with the buffer solution.

9. Press and hold the CAL key for three (3) seconds to re-enter the calibration mode.

The ‘CAL’ display appears and then the pH value flashes on the LCD.

10. When the pH stops flashing, ‘SA’ (save), the Slope percentage, and then ‘END’ will

appear in sequence.

11. The meter is now calibrated and ready for use.

Note: The Slope percentage is an indication of the health of the electrode. Since pH

electrodes vary in performance from one to the next, this meter includes a

feature that displays the electrode’s slope in %. If the slope % is below 75% the

electrode should be replaced (a slope of 100% is ideal).

4

Model PH220 Version 2.0 4/05

Page 5

PH Measurements

1. Connect the pH electrode to the meter.

2. Turn the meter on.

3. Use the pH/mV button to select the pH mode. The unit of measure appears on the

LCD.

4. Rinse the electrode with distilled or deionized water.

5. Place the electrode in the solution. Allow 30 seconds for the electrode/ATC to

reach thermal equilibrium with the buffer solution.

6. When the reading stabilizes, read the pH measurement on the main display.

An out of range reading is indicated by three dashes ( - - - ). The dashes will also

display if the electrode is not connected to the meter.

7. When the test is complete rinse the electrode with distilled or deionized water.

Electrodes should always be rinsed before and between samples

with distilled or deionized water to remove all traces of storage

solution, process medium, or previous test solution..

Temperature Units

To change the unit of measure for temperature (

pH/mV button for 3 seconds. The LCD reflects the unit of measure.

o

C to oF or oF to oC), press and hold the

mV (ORP) Measurements

1. Connect the ORP electrode to the meter.

2. Rinse the ORP electrode

3. Turn the meter on.

4. Use the pH/mV button to select the mV mode. The display will reflect the unit of

measure.

5. Place it into a sample solution. When the LCD stabilizes it will read the redox

potential of the sample in millivolts (mV).

6. When the test is complete rinse the electrode with distilled or deionized water.

5

Model PH220 Version 2.0 4/05

Page 6

Temperature Compensation

Because the millivolt output of a pH electrode varies with temperature, the meter must

compensate for the variations to obtain accurate measurements. The PH220 automatically

compensates for solution temperatures that stray from room temperature using the

thermometer that is built-in to the electrode. Temperature is displayed on the lower LCD

line.

Battery Replacement

The 9V battery requires replacing when all three black bars inside the battery display icon

switch off. Replace the battery per the following:

1. Remove the orange protective jacket holster that surrounds the meter by pulling it

over the top of the meter (ensure that the electrode is disconnected).

2. Pull the battery compartment up from the top of the meter by the two indentations

using two fingers. If necessary, pry the ends of the cover with a coin to release the

watertight seal.

3. Install a fresh 9V battery. Battery polarity is indicated on the battery compartment

cap.

4. To reinstall the battery compartment, align the notch in the cover with the grove in

the meter and press.

5. Reinstall the protective holster.

6

Model PH220 Version 2.0 4/05

Page 7

Electrode Maintenance and Troubleshooting

Most pH measurement difficulties are caused by electrode problems. Careful handling and

proper storage of the electrode will increase measurement accuracy.

Electrodes should be rinsed to remove all traces of storage solution, process medium, or

previous test solution.

Electrode Storage

The electrode should be stored in a soaker bottle or wetting cap filled with pH4 buffer.

Never store an electrode in distilled or deionized water as this will cause migration of the fill

solution from the electrode.

Electrode Cleaning

The type of electrode coating that occurs over time will determine the cleaning method.

Soft coatings can be removed by vigorous stirring or by using a squirt bottle. Organic

chemical coating (hard coatings) should be chemically removed. Only in extreme cases

should the bulb be cleaned mechanically.

Troubleshooting an Electrode

Symptom Cause Recommended Solution

Long response time or

reading drift

Dry Bulb Long term storage without

Static Charge Wiping electrodes Rinse electrode in 7.0 buffer and blot. Do

Same readings in different

buffers and samples

Erratic LCD display Samples have low ionic

Clogged Junction Soak in 4.07 M Potassium Chloride (KCl)

Strong Alkaline measurement Soak in 0.1 M HCL overnight.

Deteriorated Gel layer Replace electrode.

Protein coating on electrode

surface

Oil, paint, dyes, suspended

solids on sensor

Organic solvents are coating

sensor

Dehydrated membrane Read solution for dry bulb below:

wetting

Cracked or broken bulb Replace electrode. Use bulb guard. Avoid

strength (lacks salt); e.g.

distilled, de-ionized, boiled,

lake water (high pressure)

o

@ 60

C for 30 minutes.

Soak in 1 gm Pepsin dissolved in 100ml of

0.1 m HCL for 30 mins. or as needed.

Rinse electrode alternately with a materials

solvent and a buffer 7.00.

Organic mole fraction has to be less than

50% to assure reasonable readings. Limit

time of measurement. Keep probe in the

7.0 buffer between readings.

Soak electrode tip in wetting cap filled with

1ml 7.00 buffer for 24 to 48 hours

no wipe electrode.

plunging electrode to bottom of container

and spinning bars. Wetting cap will protect

bulb between tests.

For each 50 ml of sample add 1 drop

(50uL) of SAT. KCl (No alteration in pH will

occur by inert KCl).

7

Model PH220 Version 2.0 4/05

Page 8

Calibration and Repair Services

EXTECH INSTRUMENTS CORPORATION offers complete repair and calibration services

for all of the products we sell. For periodic calibration, NIST certification or repair on most

Extech products, call customer service for details on services available. Extech

recommends that calibration be performed on an annual basis to ensure calibration

integrity.

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects

in parts and workmanship for one year from date of shipment (a six month limited warranty

applies to sensors and cables). If it should become necessary to return the instrument for

service during or beyond the warranty period, contact the Customer Service Department at

(781) 890-7440 ext. 210 for authorization or visit our website www.extech.com

information. A Return Authorization (RA) number must be issued before any product is

returned to Extech. The sender is responsible for shipping charges, freight, insurance and

proper packaging to prevent damage in transit. This warranty does not apply to defects

resulting from action of the user such as misuse, improper wiring, operation outside of

specification, improper maintenance or repair, or unauthorized modification. Extech

specifically disclaims any implied warranties or merchantability or fitness for a specific

purpose and will not be liable for any direct, indirect, incidental or consequential damages.

Extech's total liability is limited to repair or replacement of the product. The warranty set

forth above is inclusive and no other warranty, whether written or oral, is expressed or

implied.

All rights reserved including the right of reproduction in whole or in part in any form.

Technical support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User’s Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Extech Instruments Corporation, 285 Bear Hill Rd., Waltham, MA 02451

Copyright © 2005 Extech Instruments Corporation

Support line (781) 890-7440

for contact

8

Model PH220 Version 2.0 4/05

Loading...

Loading...