Page 1

User Guide

TM

ExStik

pH (PH100 & PH110) and ORP (RE300)

Waterproof Series Pens

Patent Pending

Page 2

Getting Started

• Remove the cap from the bottom of the ExStikTM to expose the electrode bulb and

reference junction

• Before first use or after storage, soak the electrode (with its cap removed) in a pH 4

solution for about 10 minutes (PH100 only)

• White KCL crystals may be present in the cap. These crystals will dissolve in the soak or

they can be simply rinsed with tap water

• Always calibrate close to the expected measurement value

• Twist off the battery compartment cap to access the battery tab; remove this plastic tab

before first use

• To preserve Electrode life keep the sponge in the protective cap soaked with a pH 4

solution (PH100), deionized, distilled water (RE300) when not in use (store vertically)

Specifications

Display Multifunction LCD with Bargraph

Operating conditions 32 to 122

pH Range and Accuracy 0.00 to 14.99 / ± 0.01pH typical

Temp. Compensation Automatic from 32 to 194

Compensation Accuracy ± 0.9

ORP Range / Accuracy ± 999mV / ± 4mV

Temperature Range 23 to 194

Temperature Resolution 0.1

Temperature Accuracy ± 1.8

± 5.4

Measurement storage 15 tagged (numbered) readings

Power Four (4) SR-44 button batteries (See note on page 6)

Low battery indication ‘BAT’ appears on the LCD

Auto power off After 10 minutes of inactivity

Battery Life 200 to 400 tests, assuming test time of < 10 minutes and use of

SR44 silver oxide batteries. Use of LR44 alkaline will reduce

battery life.

o

F (0 to 50oC) / < 80% RH

o

o

F (0.5oC)

o

F (-5 to 90oC)

o

up to 99.9 then 1o thereafter

o

F / 1oC [from 23 to 122oF (-5 to 50oC)]

o

F / 3oC [from 122 to 194oF (50 to 90oC)]

F (0 to 90oC)

Page 2

ExStikTM (PH100, PH110, & RE300) Version 2.6 02/04

Page 3

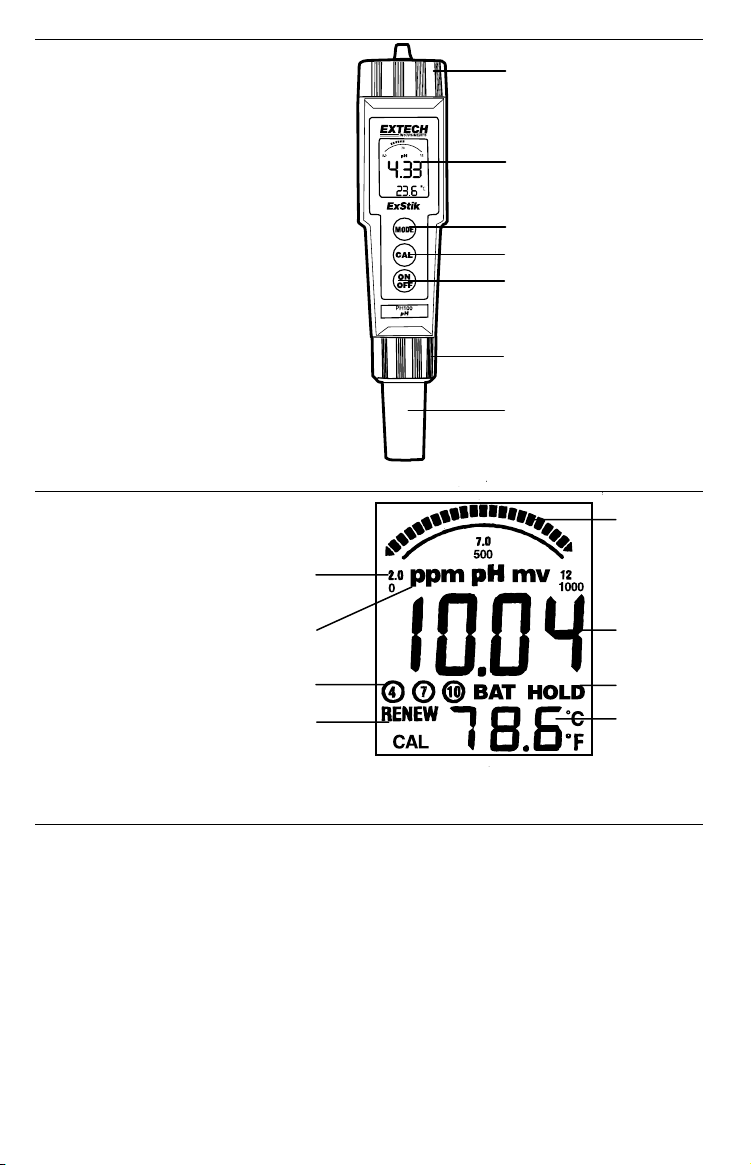

ExStikTM Description

1. Battery compartment cap

2. LCD Display

3. MODE button

4. CAL button

5. ON/OFF button

6. Electrode collar

7. Electrode (refillable on PH110)

(Electrode cap is not shown)

ExStikTM Display

1. Bargraph reading

2. Measurement reading

3. BAT (low battery) and

HOLD (data hold) indicators

4. Temperature display

5. Bargraph scale designations

6. Units of measure

7. Calibration indicators

8. RENEW and CAL indicators

1

2

3

4

5

6

7

5

6

7

8

1

2

3

4

pH Overview

pH is a unit of measure (ranging from 0 to 14pH) indicating the degree of acidity or alkalinity

of a solution. pH tests are the most commonly performed measurements in water analysis,

using the hydrogen ion activity of a solution to determine acidity or alkalinity. Solutions with

a pH less than 7 are considered acidic, solutions with a pH higher than 7 are known as

bases, and solutions with a pH of exactly 7 are neutral.

The pH scale is logarithmic so, for example, if sample A is 1 pH less than Sample B, this

means that Sample A is 10 times more acidic then Sample B. A difference of 1 pH

represents a ten-fold difference in acidity.

Page 3

ExStikTM (PH100, PH110, & RE300) Version 2.6 02/04

Page 4

ORP/REDOX Overview

ORP stands for Oxidation / Reduction Potential and represents the oxidizing or reducing

nature of a solution. The overall “reactive” tendency of a solution can be determined from

ORP measurements. ORP testing is becoming increasingly more common in waste-water

measurement regimens. The unit of measurement for ORP is mV.

Replacing Electrodes

The ExStikTM is shipped with an electrode attached. If the electrode is to be replaced,

follow these steps for removing and connecting electrodes. Note that the PH110 has a

refillable electrode and the PH100 does not.

1. To remove an electrode, unscrew and completely remove the electrode collar (turn the

collar counter-clockwise to remove).

2. Gently rock the electrode from side to side, pulling it downwards, until it disconnects

from the meter.

3. To attach an electrode, carefully plug the electrode into the meter socket (note that the

electrode connector is keyed, ensuring proper connection).

4. Tighten the electrode collar firmly enough to make a good seal (a rubber gasket seals

the electrode with the meter).

Automatic Electrode Recognition

When the ExStikTM is turned on, it recognizes the type of electrode that is connected and

displays the appropriate unit of measure. Attach electrode before turning the ExStik

TM

on.

Powering the ExStikTM

The ExStik

battery compartment must be removed before first use. If the batteries are weak, the ‘BAT’

indicator appears on the LCD. Press the ON/OFF key to turn the ExStik

auto power off feature shuts the ExStik

preserve battery life.

TM

uses four (4) SR-44 batteries (included). The insulating tab located in the

TM

TM

off automatically after 10 minutes of inactivity to

on or off. The

pH Operation

When the electrode is placed in a solution, the main display and bargraph indicate the pH

reading while the lower display reads temperature (readings flash until they have stabilized).

The bargraph is ‘center zero’, i.e. at pH 7 there is no display. As the pH rises, the bar moves

from the center to the right. If the pH drops, the bar moves from the center to the left.

pH Calibration (1, 2, or 3 points)

1. Place the electrode into a buffer solution (4, 7, or 10) and press the CAL key. Typically,

pH 7 is calibrated first then 4 or 10 pH.

2. The ExStik

circled number on the LCD will match the solution). Note that if the solution is more than

1pH off from the 4, 7, or 10pH standard, the ExStik

calibration (CAL and END will be displayed).

3. During calibration, the pH reading flashes on the main display.

4. When calibration is complete, the ExStik

normal operation mode.

5. The appropriate circled indicator (4, 7, or 10) appears on the LCD when a particular

calibration has been completed. When the ExStik

configuration and the calibration data will be memorized.

6. For a two or three point calibration, repeat steps 1-5.

Page 4

TM

automatically recognizes the solution and calibrates itself to that value (the

TM

will assume an error and abort the

TM

automatically displays ‘END’ and returns to

TM

is turned off, the circled indicator

ExStikTM (PH100, PH110, & RE300) Version 2.6 02/04

Page 5

Changing the Displayed Temperature Units

Press and hold the CAL button for approx. 3 seconds. The oC or oF icon will change first and

then the numerical temperature value will change after the button is released. If the

Calibration mode is accidentally accessed (‘CAL’ appears on the LCD) simply turn the

TM

ExStik

off and start again.

ORP Operation

When an ORP electrode is connected and the ExStikTM is turned on, it enters the Automatic

Calibration mode. ‘SELF’ and ‘CAL’ will appear on the LCD while calibration is in progress.

After the calibration is complete, ‘SELF’ and ‘CAL’ will extinguish and both the main display

and bargraph will read ORP in mV units. The bargraph reads 0mV (far left), 500mV (center),

and 1000mV (far right).

Data Hold

Press the MODE button to freeze the current reading. The HOLD display icon will appear

along with the held reading. The held reading will be stored in the next 15-reading storage

location (see below). Press the MODE key to return to normal operation.

15-Reading Measurement Storage

1. Press the MODE button to store the current reading (Data Hold will activate). Press

MODE again to return to normal operation. Repeat step 1 above to store the next

reading and so on.

2. If an attempt is made to store more than 15 readings, the stored readings (starting with

the first reading) will be overwritten.

Recalling Stored Readings

Note: First ensure that the HOLD symbol is not displayed. If it is, exit the HOLD function by

pressing the MODE button.

1. Press the CAL button once and then press the MODE button immediately

displayed; the location number (1 through 15) will flash. If the CAL mode is accidentally

accessed (display flashing), press the CAL button again to exit.

2. The last stored reading taken will be displayed first. To advance through the stored

readings, press the MODE button. The location number is displayed first, followed by the

reading stored in that location.

3. To exit the storage mode, press the CAL button and the ExStik

operation.

TM

will return to normal

after CAL is

CAL Reminder Display

When the ExStikTM is turned on (in pH models) for the 15th time, the ‘CAL’ icon appears on

the LCD indicating that the ExStik

recalibration of the electrode sooner than others. The CAL display is simply a reminder and

will turn off when the pH electrode is recalibrated.

TM

may require calibration. Some applications may require

RENEW Display

A flashing ‘RENEW’ warning indicates that the probe may be nearing the end of its useful

life. If cleaning or recalibration does not cause the RENEW icon to disappear, replace the

probe (see optional accessories below). The RENEW display appears as a result of the pH

electrode slope falling below 75% of a nominal slope.

Page 5

ExStikTM (PH100, PH110, & RE300) Version 2.6 02/04

Page 6

Battery Replacement

TM

1. Twist off the battery compartment cap

2. Replace the four (4) SR-44 button batteries observing polarity

3. Replace the battery compartment cap

Battery Note: For maximum battery life, use battery style SR-44 (Silver Oxide) such

Energizer

TM

Rear

Top View of ExStik

Front (LCD Side)

No. 356 or DuracellTM No. 303/357.

Electrode Refilling

The electrode does not need to be detached from the body of the ExStikTM in order to refill

it as long as the electrode is of the refillable type. Refillable electrodes have a removable

reference junction (slotted) and the word REFILLABLE on the side of the electrode casing.

Instructions for removing the reference junction and filling the electrode are provided with

the refill kit. See ‘Optional Accessories’ below for refill kits and refillable electrodes.

Optional Accessories

• Tripak buffers with 4, 7 & 10 pH capsules (6 each) plus two rinsing solutions (Part

Number: PH103)

• Spare pH Electrode – non-refillable (Part Number: PH105)

• Spare pH Electrode - refillable (Part number PH115)

• Electrode Refill solution (Part number PH113)

• Spare ORP electrode (Part Number: RE305)

• Spare Chlorine electrode (Part Number: CL205)

• Weighted base with 5 solution cups (Part Number: EX006)

Note: If the unit is to be converted for Chlorine use by attaching the chlorine electrode,

please request a CL200 User Guide

Page 6

ExStikTM (PH100, PH110, & RE300) Version 2.6 02/04

Page 7

Measurement and Display Considerations

• If the unit appears to be locked (display frozen). It is possible that the Data Hold mode

has been inadvertently accessed by pressing the MODE button. Simply press the

MODE button again or turn the meter off and restart if the display appears frozen.

• If the meter does latch up and no button presses revive it, remove the batteries and

restart.

• Note that if the batteries are removed, any stored readings will be discarded. Also, the

calibration for pH will be cleared requiring recalibration. Calibration data for ORP or

Chlorine will be retained however.

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects in parts and

workmanship for one year from date of shipment (a six month limited warranty applies on sensors and

cables). If it should become necessary to return the instrument for service during or beyond the warranty

period, contact the Customer Service Department at (781) 890-7440 ext. 210 for authorization or visit our

website at www.extech.com (click on ‘Contact Extech’ and go to ‘Service Department’ to request an RA

number). A Return Authorization (RA) number must be issued before any product is returned to Extech. The

sender is responsible for shipping charges, freight, insurance and proper packaging to prevent damage in

transit. This warranty does not apply to defects resulting from action of the user such as misuse, improper

wiring, operation outside of specification, improper maintenance or repair, or unauthorized modification.

Extech specifically disclaims any implied warranties or merchantability or fitness for a specific purpose and

will not be liable for any direct, indirect, incidental or consequential damages. Extech's total liability is limited

to repair or replacement of the product. The warranty set forth above is inclusive and no other warranty,

whether written or oral, is expressed or implied.

Calibration and Repair Services

Extech offers complete repair and calibration services for all of the products we sell. For periodic

calibration, NIST certification or repair of any Extech product, call customer service for details on services

available. Extech recommends that calibration be performed on an annual basis to ensure calibration

integrity.

Support Hotline (781) 890-7440

Tech support: Ext. 200; Email: support@extech.com

Repair/Returns: Ext. 210; Email: repair@extech.com

Website: www.extech.com

All rights reserved including the right of reproduction in whole or in part in any form.

Copyright © 2003 Extech Instruments Corporation.

Page 7

ExStikTM (PH100, PH110, & RE300) Version 2.6 02/04

Page 8

Notes

Page 8

ExStikTM (PH100, PH110, & RE300) Version 2.6 02/04

Loading...

Loading...