Page 1

User’s Guide

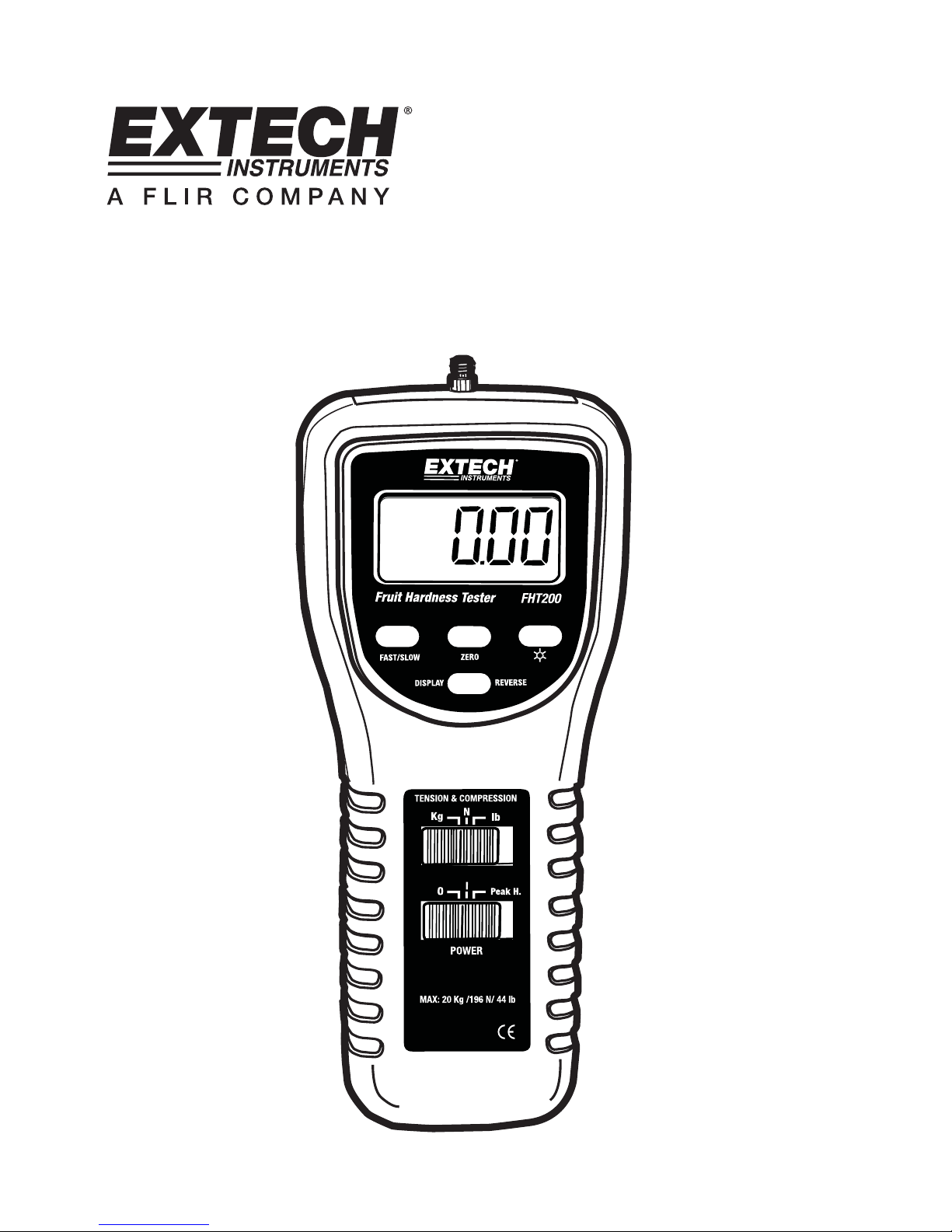

Fruit Hardness Tester

Model

FHT200

Page 2

FHT200-EU-EN-V1.2 5/11

2

Introduction

Congratulations on your purchase of Extech’s Fruit Hardness Tester Model FHT200. The tester is

used to measure the hardness (ripeness) of fruits such as apples, pears, strawberries and grapes.

Users include fruit science research departments, fruit producers, fruit farms and agricultural

colleges and universities to improve the fruit quality, harvest, storage, and product transportations.

The tester helps to judge the fruit's degree of maturity. This professional meter, with proper care, will

provide years of safe reliable service.

Features

• Maximum capacity: 20.00Kg / 44.10lb / 196.10 Newton.

• Units: Kg/lb/Newton

• Includes a high precision load cell sensor

• Digital display with Peak hold function for easy measurement

• Tension or Compression

• Positive/ Reverse display

• Large backlight LCD display

• RS-232/USB computer interface

• Complete set with hard carrying case and 4 tips (3 mm, 6 mm, 8 mm, 11 mm)

• Optional USB cable and data acquisition software

• Peak hold (Max. load) can be held in display during the measurement

• Zero button can operate both for normal mode and "peak hold" mode

• Full capacity zero (tare) control capability

• Fast/Slow response time

• Low power consumption for long battery life

• Microprocessor circuit & exclusive load cell transducer

• Overload protection

• DC 9V power adapter input socket

Page 3

FHT200-EU-EN-V1.2 5/11

3

Meter Description

1. Measurement Tip mounting screw

2. Fast selection indicator

3. LCD display

4. FAST/SLOW button

5. LCD Reverse Display button

6. Kg/Newton/LB unit switch

7. OFF/ON/PEAK HOLD switch

8. RS-232 output terminal

9. LCD Back Light button

10. Zero button

11. Battery Compartment (rear)

12. DC 9V Power Adapter input socket

13. 11mm Tip

14. 8mm Tip

15. 6mm Tip

16. 3mm Tip

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Page 4

FHT200-EU-EN-V1.2 5/11

4

Operation

Preparation for Measurement

1. Select and install the tip most suitable for the fruit to be tested.

2. Slide the Power switch to the “I” position to turn the meter on.

3. If the meter display remains blank or the “Lo” low battery indicator

appears in the display, replace the batteries.

4. Fruit hardness tests utilize the compression function of the meter.

The Tension (pull) function is displayed with a “-“ symbol and is not

normally used for fruit hardness tests.

5. For the most repeatable results, place the fruit against a firm surface

when making measurements.

6. Press the measurement tip perpendicular against the fruit surface.

Do not measure at an angle.

Tip Selection

There are four diameter tips: 3mm, 6mm, 8mm and 11mm. Which tip should be used is based on

the user’s experience, type of fruit or vegetable, location the fruit was grown and ripeness of the

fruit. Always log tip used with measurement results to establish optimum testing results and insure

repeatability of the measurement.

General recommendations are:

3mm Small fruits, berries

6mm Hard fruits, grapes

8mm Firm fruits, pears

11mm Apples

Fruit Preparation

For most measurements, skin removal is recommended.

Page 5

FHT200-EU-EN-V1.2 5/11

5

Peak Measurement

The Peak mode is the most commonly used mode for fruit harness testing.

1. Install a tip.

2. Slide the POWER switch to the “Peak H” position.

3. Select units of measure (grams/kilograms, ounces/pounds, or newtons) using the units select

switch.

4. Press the ZERO button to zero the display.

5. Select FAST or SLOW response. FAST is the preferred speed for fruit harness testing.

6. Properly align the tip and the fruit and then slowly increase the applied pressure against the

fruit..

7. When the tip breaks the surface, the force will release and the peak value, which is the highest

reading encountered, will remain ‘held” in the display.

8. Press the ZERO button to clear the display for the next measurement.

Normal Measurement Mode

1. Install a tip.

2. Slide the POWER switch to the “I” position.

3. Select units of measure (grams/kilograms, ounces/pounds, or newtons) using the units select

switch.

4. Press the ZERO button to zero the display.

5. Select FAST or SLOW response. FAST is the preferred speed for fruit harness testing.

6. Properly align the tip and the fruit and then slowly increase the applied pressure against the

fruit.

7. Observe the display to monitor the applied force.

LCD Backlight

The backlight feature provides display illumination when the meter is used at night or in dimly lighted

areas. Press and hold ( > 2 seconds ) the

button until LCD backlight is turns ON. The backlight

will automatically turn off after approximately 6 seconds

Reverse Display

The Reverse Display feature flips the display upside-down to permit easy reading of the results

regardless of the direction the meter is held during measurement.

Fast-Slow

The Fast-Slow feature selects the meter’s response time. Slow response will average the reading

over a longer time period and Fast response will display more rapid changes.

“FAST” appears in the display when it is selected, no display indication appears for slow.

RS232 PC/USB Interface

Optional software is available to log, graph and save measured data.

Page 6

FHT200-EU-EN-V1.2 5/11

6

Maintenance

Battery Replacement

The low battery indication appears on the LCD as "Lo". Replace the batteries when this symbol

appears.

1. Remove the two screws securing the battery compartment cover.

2. Lift off the battery cover.

3. Replace with 6x 1.5V AA (UM-3) batteries. Observe polarity.

4. Replace compartment cover and screws.

All EU users are legally bound by the battery ordinance to return all used batteries to

collection points in your community or wherever batteries / accumulators are sold!

Disposal in the household garbage is prohibited!

Specifications

Display 5 digits LCD with backlight.

Transducer Load cell.

Units Kg/Newton/LB.

Measure Capacity 20.00Kg / 44.10LB / 196.10 Newton.

Resolution 0.01Kg / 0.01LB / 0.05 Newton.

Min. Display 0.02Kg / 0.07LB / 0.3 Newton,

Accuracy ± (0.5 % + 2 digits), within 23± 5°C, and @ 10 Kg & 20 Kg.

Update time Fast: Approx. 0.2 second, Slow: Approx. 0.6 second.

Over range Indicator " - - - - " is displayed

Data output RS-232 serial computer interface.

Overload Capacity Max. 30kg.

Full Scale Deflection Approx. 0.4mm max.

Data output RS-232 serial computer interface

Mounting Holes Located on rear (thread size: M5 x 0.8mm ISO); mounting screws

included

Power Supply 6 x 1.5 V AA (UM-3) batteries or 9VDCadapter (not included).

Power Consumption Approx. DC 28 mA

Operating Temperature 0°C to 50°C (32°F to 122°F).

Operating Humidity Less than 80% RH.

Dimension 215 x 90 x 45 mm ( 8.5 x 3.5 x 1.8 inch ).

Weight 650g (1.43lb)/with batteries.

Copyright © 2011 Extech Instruments Corporation (a FLIR company)

All rights reserved including the right of reproduction in whole or in part in any form

www.extech.com

Loading...

Loading...