Page 1

User Guide

1Φ/3Φ 1000 Amp True RMS Power Clamp-On

Model 380976

www.GlobalTestSupply.com

Page 2

Introduction

Congratulations on your purchase of the Extech 380976 Power Clamp-On Meter. This device

measures 1Φ/3Φ Power (True, Apparent, and Reactive), Horsepower, Phase Angle, True RMS

Current/Voltage, Resistance, Capacitance, Frequency, & Temperature. Power measurements can

be achieved on 3- or 4-wire configurations. Please read the entire manual to get the most from the

meter’s wide array of capabilities. This meter is shipped fully tested and calibrated and, with

proper use, will provide years of reliable service.

Table of Contents

Warranty .................................................................................................................................. 3

Safety Information .................................................................................................................. 3

Meter Description ................................................................................................................... 4

AC + DC Voltage Measurements ........................................................................................... 5

AC Current Measurements .................................................................................................... 5

1Φ KW, KVA, KVAR, Power Factor & Phase Angle Measurement ..................................... 6

3Φ 3-Wire KW, HP, KVA, KVAR, Power Factor & Phase Angle Measurement .................. 7

3Φ 4-Wire KW, HP, KVA, KVAR, Power Factor & Phase Angle Measurement ................ 10

Resistance and Audible Continuity Measurements .......................................................... 13

Capacitance Measurements ................................................................................................ 14

Diode Tests ........................................................................................................................... 14

Temperature Measurements ................................................................................................ 14

AC and DC µA Current Measurements ............................................................................... 14

Meter Control Keys ............................................................................................................... 15

Automatic Sleep Mode and Battery Replacement ............................................................. 16

Specifications ....................................................................................................................... 17

Calibration, Repair, and Technical Support Services ......... Error! Bookmark not defined.

2

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 3

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects in parts

and workmanship for one year from date of shipment (a six month limited warranty applies to

sensors and cables). If it should become necessary to return the instrument for service during or

beyond the warranty period, contact the Customer Service Department at (781) 890-7440 ext. 210

for authorization or visit our website www.extech.com for contact information. A Return

Authorization (RA) number must be issued before any product is returned to Extech. The sender is

responsible for shipping charges, freight, insurance and proper packaging to prevent damage in

transit. This warranty does not apply to defects resulting from action of the user such as misuse,

improper wiring, operation outside of specification, improper maintenance or repair, or unauthorized

modification. Extech specifically disclaims any implied warranties or merchantability or fitness for a

specific purpose and will not be liable for any direct, indirect, incidental or consequential damages.

Extech's total liability is limited to repair or replacement of the product. The warranty set forth above

is inclusive and no other warranty, whether written or oral, is expressed or implied.

Safety Information

Read the following safety information carefully before attempting to operate or service the

meter.

To avoid damage to the instrument do not exceed the maximum input limits shown in the

technical specifications.

Do not use the meter or test leads if they appear damaged.

Use extreme caution when working around bare conductors or bus bars. Accidental contact

with the conductor could result in electric shock.

Use the meter only as specified in this manual; otherwise, the protection provided by the

meter may be impaired.

Read the operating instructions before use and follow all safety information.

Use caution when working with voltages above 60VDC or 30VAC RMS. Such voltages

represent a shock hazard.

Before taking resistance measurements or testing continuity, disconnect the circuit under test

from the main power supply and remove all loads from the circuit.

Safety symbols

Caution! Refer to this manual before using the meter.

Dangerous voltages.

Meter is protected throughout by double insulation or

reinforced insulation.

When servicing, use only specified replacement parts.

Complies with EN-61010-1, IEC 1010-2-32

3

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 4

Meter Description

1. Transformer Jaws

2. Jaw opening trigger

3. Data Hold & MX/MN button

4. Function Selector

5. Range button

6. Temperature input jack

7. LCD Display

8. ‘COM’ input jack

9. ‘V’ input jack

Ω

µA

10.

input jack

4

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 5

Measurements

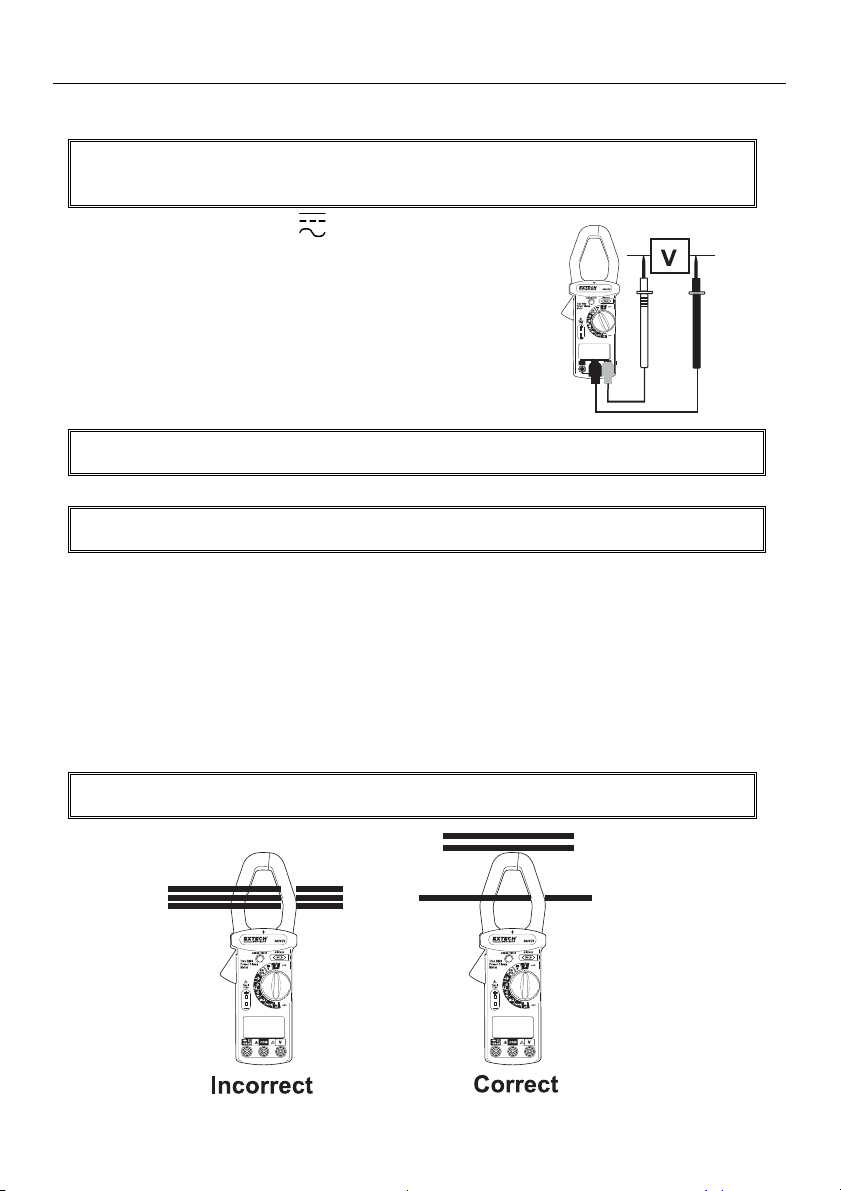

AC + DC Voltage Measurements

WARNING

The maximum input is 600V. Do no attempt voltage measurements above this limit. Exceeding

this limit could cause electrical shock and damage to the meter.

1. Set the rotary switch to the ‘ V’ position.

2. Insert the test leads into the meter’s input jacks. (Black to

‘COM’ and Red to ‘V’)

3. Connect the test leads to the measured circuit.

4. The meter will automatically detect and display AC or DC

voltage. The meter will also automatically select the

appropriate range.

5. Read the voltage (main display) and frequency (upper,

smaller display digits) on the LCD.

NOTE: The sensitivity for Automatic AC/DC Voltage detection is 1V. Voltage below 1V may

indicate DC.

NOTE: The sensitivity for voltage measurements is 1.2V and the frequency range is 40Hz to 1

KHz. If the frequency is less than 40Hz the LCD may display ‘Hz’.

AC Current Measurements

1. Set the rotary switch to the "~A" position.

2. Press the Trigger to open the jaw.

3. Fully enclose the conductor that is being measured in the jaw. No gap should exist between the

two jaw halves. The conductor under test must be a single wire; if there are multiple wires in a

cable the conductor must first be isolated (see diagram below).

4. The meter selects the range automatically.

5. Read the measured current (main display) and frequency (upper display) on the LCD.

NOTE: The sensitivity for current measurements is 6A and the frequency range is 40Hz to

400Hz. If the frequency is less than 40Hz the LCD may display ‘Hz’.

5

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 6

AC Power Measurements

1Φ KW, KVA, KVAR, Power Factor & Phase Angle Measurement

1. Set the rotary switch to the ‘KW/KVA’

position.

2. Insert the test leads to the meter as

follows: Black to ‘COM’ and Red to ‘V’.

3. Connect the black lead to the neutral line.

4. Connect the red lead to the power line

and clamp onto the same lead to which

the red lead is connected.

5. The meter selects the best range

automatically.

6. Select the desired display combination

using the RANGE key. Press RANGE to

scroll through the following combination displays:

kW and HP (horsepower)

kW and PF (power factor)

kW and KVAR (reactive power)

KVA and phase angle (θ)

V and A

Note that LEAD and LAG icons are also displayed on the LCD to inform the user that the voltage is

leading or lagging the current with regard to phase.

Note: Allow 2 seconds after each RANGE key press for the meter to update the display.

1 HP = 746 Watts

KW

PF

= cosθ

KVA

KVA (Apparent Power) = (V*A) / 1000

KVAR (Reactive Power) =

22

(KVA) (KW)

= KVA * sinθ

NOTES

1. The ‘+’ sign printed on the meter must face the power source for best accuracy.

2. If the device under test is a switching mode power supply, the KW, PF, and Phase angle

measurements may not be accurate.

6

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 7

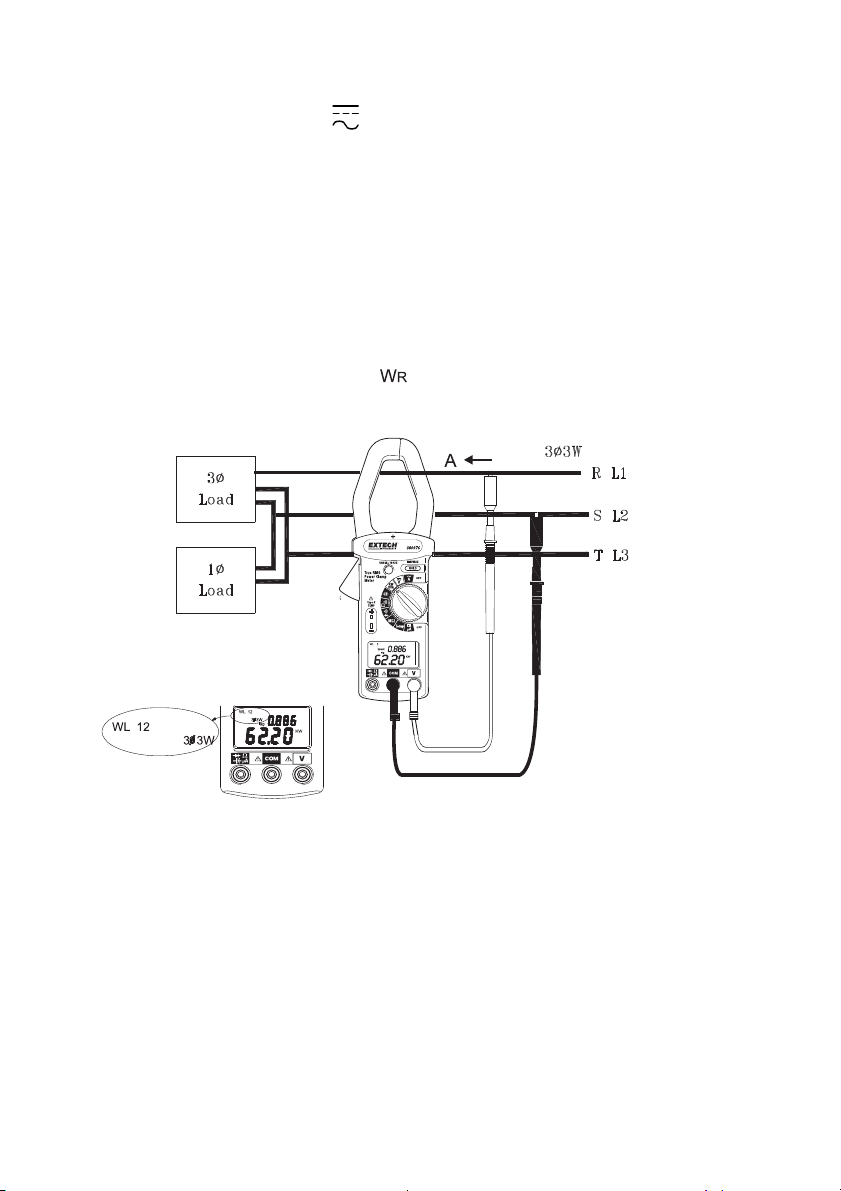

3Φ 3-Wire KW, HP, KVA, KVAR, Power Factor & Phase Angle Measurement

1.

First, measure W

a. Set the rotary switch to the “

(refer to the diagram below).

RS(L1L2)

V ”.

b. Press and hold the “HOLD” key while setting the rotary switch to “KW/KVA”, the 33W and

symbols will appear.

W

L12

c. Insert the test leads into the jacks.

d. Select a phase (e.g. S or L2) as COM and connect the test probe of the COM (black)

terminal to that phase (e.g. S or L2).

e. Connect the test probe of V (red) terminal to the second phase (e.g. R or L1).

f. Clamp the same phase as step e. (e.g. R or L1).

g. The power clamp will automatically select the proper range.

h. Wait until the reading is stable (about 6 seconds). Press the “HOLD” key to store the

measured value. The W

symbol will appear.

L23

2.

Second, measure W

(refer to the diagram that follows the steps below).

TS(L3L2)

a. Disconnect the test probe from the phase where the jaw clamp was set in the previous

measurement.

b. Connect the test probe to the third phase (e.g. T or L3).

c. Clamp the third phase where test probe is connected to (e.g. T or L3)

d. The power clamp will automatically select the proper range.

e. Wait until the reading is stable (about 6 seconds) and then press the “HOLD” key to store

the measured value.

7

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 8

W

3.

The power clamp will process these two sets of data (W

LCD. The W

stored in the meter memory.

symbol will be shown to indicate 33W power. The 33W power (in watts) is

L123

4. To read a single data record, press the “

display then

Factor), KW+KVAR, KVA+θ(Phase Angle) or A+V.

5.

W

33W

press the “RANGE” key to select KW+HP (Horse Power), KW+PF (Power

= W

RS(L1L2)

+ W

TS(L3L2)

L12 , WL23

HOLD

” key to select desired

), and show the result on the

W

, W

L23

or W

L12

L123

2

33

PF

W

33

6. Set the rotary switch to another position to exit this mode and clear the stored data.

KWKVA 33

W

K

KVA

33

33

W

33

W

www.GlobalTestSupply.com

2

8

WKVARW

380976-EU-EN-V3.2 6/12

Page 9

NOTE

Once a phase is selected as COM, users can not change this selection in the

subsequent measurement. For example, if S (or L2) phase is selected, S (or L2)

phase is always connected to the COM during measurement of W

W

(or W

TS

) in 3 3W unbalanced power.

L3L2

(or W

RS

NOTE

1. The "+" sign printed on Panel must face the power source for accurate

measurement.

2. If the device under test is a switching power supply, the meter KW, PF and θ

reading maybe incorrect.

NOTE

For 33W unbalanced power measurements, WRS or WTS could be negative.

Ensure that all connections are correct before accepting a reading as valid.

L1L2

) and

9

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 10

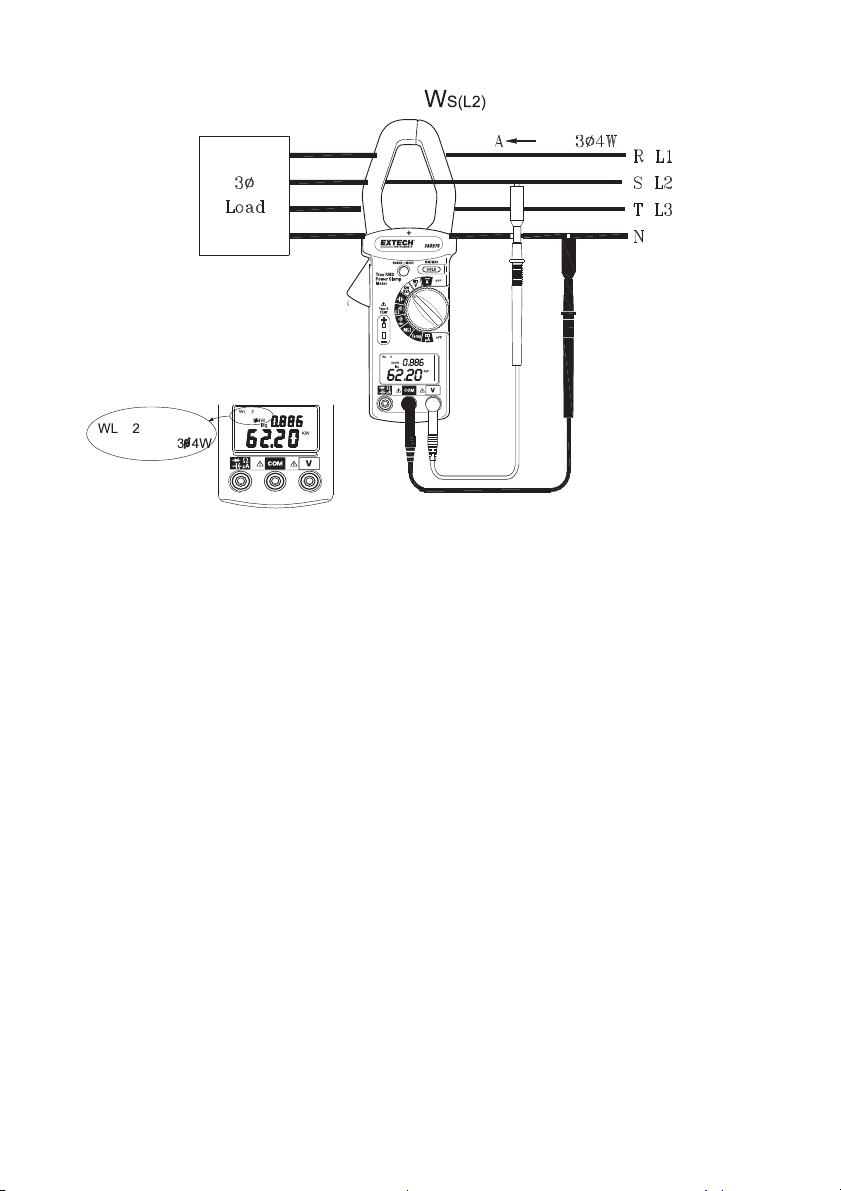

3Φ 4-Wire KW, HP, KVA, KVAR, Power Factor & Phase Angle Measurement

1.

First, measure W

a. Set the rotary switch to the “

(refer to the diagram below).

R(L1)

V ” position.

b. Press and hold the “RANGE” key while setting the rotary switch to the “KW/KVA” position,

the 34W and W

symbols should appear.

L1

c. Insert the test leads into the input jacks.

d. Connect the neutral line to the COM (black) terminal.

e. Connect the test probe of the V (red) terminal to the first phase (e.g. R or L1).

f. Clamp on to the same phase (e.g. R or L1).

g. The power clamp meter will automatically select the proper range.

h. Wait until the reading is stable (about 6 seconds) and then press the “HOLD” key; the W

symbol will clear and the W

symbol will appear in order to instruct users to take the W

L2

measurement.

L1

S(L2)

2.

Second, measure W

(refer to the diagram that follows the steps below)

S(L2)

a. Disconnect the test probe from the phase where the jaw was clamped in the previous

measurement.

b. Connect the test probe of the V (red) terminal to the second phase (e.g. S or L2).

c. Clamp on to the phase where the test probe is connected (e.g. S or L2 phase)

d. The power clamp will automatically select proper range.

e. Wait until the reading is stable (about 6 seconds) and then press the “HOLD” key; the W

symbol will disappear. The W

symbol will appear to instruct users to take the W

L3

T(L3)

L2

measurement.

10

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 11

3.

Third, measure W

(refer to the diagram that follows the steps below)

T(L3)

a. Disconnect the test probe from the phase where the jaws were clamped in the previous

measurement.

b. Connect the test probe of the V (red) terminal to the third phase (e.g. T or L3 phase).

c. Clamp the phase where the test probe is connected to (e.g. T or L3).

d. The power clamp will automatically select the proper range.

e. Wait until the reading is stable (about 6 seconds), and then press the “HOLD” key; The W

symbol will disappear.

L3

11

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 12

4. The power clamp will process these three sets of data (W

The WL

symbol will be shown to indicate the 34W power (refer to diagram).

123

L1, WL2 WL3

The 34W power value in watts is now stored in the meter’s memory.

5. To read a single data record, use the “

display then

press the “RANGE” key to select KW+HP (Horse Power), KW+PF (Power Factor),

HOLD

” key to select WL1, WL2, WL3 or WL123

12

) and show the result on the LCD.

380976-EU-EN-V3.2 6/12

www.GlobalTestSupply.com

Page 13

KW+KVAR, KVA+θ(Phase Angle) or A+V displays.

W

W

6.

W

= W

34W

KVA K

PF

34

+ W

R(L1)

S(L2) WT(L3)

K

W

KVA

7. Set the rotary switch to another position to exit this mode and clear the stored data.

1. The "+" sign printed on meter must face the power source for accurate

measurement.

2. If the device under test is switching power supply, the KW, PF and θ readings

may not be correct.

For 34W power measurements, W

negative power, check the connections.

Resistance and Audible Continuity Measurements

Before taking any in-circuit resistance measurements remove power from the circuit under test

and discharge all capacitors.

1. Set the rotary switch to the

2. Insert the test leads into the input jacks. (Black to ‘COM’ and

3. Connect the test leads to the circuit or component under test.

4. Read the resistance value on the LCD.

5. For measurements < 40

Red to ‘

Ω’

)

2

34

NOTE

NOTE

or WS and WT must be positive. If one shows

R

WARNING

or ‘MΩ

’ position.

34

34

W

2

W

Ω

34

KVARWW W34

‘Ω, ’

’

, the continuity beeper will sound.

13

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 14

Capacitance Measurements

1. Fully discharge the capacitor under test before proceeding.

2. Insert the test leads into the input jacks. (Black to ‘COM’ and

Red to ‘

3. Set the rotary switch to the ‘

’).

’ position.

4. Connect the red and black test leads to the capacitor. For

Electrolytic (polarized) capacitors, connect the red test lead to

the positive side and the black lead to the negative side.

5. Read the capacitance value displayed on the LCD.

Note: Large valued capacitors will take a long period of time to charge and to auto-range to the

correct range. (up to 60 seconds in the worst case). For improved resolution and shortest test

time, manually pre-selecting the proper range is recommended.

Diode Tests

1. Set the rotary switch to the "

2. Insert the test leads into the input jacks. (Black to ‘COM’ and Red to ‘

" position.

’)

3. Touch the test probe tips to the diode or semiconductor junction under test. Note the meter

reading.

4. Reverse the test lead polarity by reversing the red and black leads. Note this reading.

5. The diode or junction can be evaluated as follows:

a. If one reading shows a value and the other reading shows ‘OL’ (overload), the diode is

good.

b. If both readings show ‘OL’, the device is open.

c. If both readings are very small or zero, the device is shorted.

d. Note that the audible continuity function is operational in this mode (<40mV).

Temperature Measurements

1. Set the rotary switch to the "TEMP" position.

2. Press the RANGE button to select the desired unit of measure (C or

F).

3. Insert the Type K Thermocouple into the subminiature input jacks

located to the lower left of the rotary selector switch.

4. Touch the thermocouple sensor to the object under test.

5. Read the temperature value on the LCD.

AC and DC

µA

1. Set the rotary switch to the "

2. Insert the test leads into the input jacks. (Black to ‘COM’ and

Red to ‘

3. Connect the test leads in series with the circuit or device

under test.

4. The meter will automatically select AC or DC and the

appropriate range.

5. Read the current value on the LCD.

Measurements

µA’)

" position.

µA

14

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 15

Meter Control Keys

HOLD - MX/MN Key

Data Hold Function

Press this key momentarily to put the meter into Data Hold mode (HOLD will appear on the LCD).

In this mode, the meter freezes the displayed reading. To exit the Data Hold mode, press the key

again (the HOLD icon will switch off). Note that the Data Hold mode is not available for

Capacitance measurements.

MX/MN (Maximum and Minimum reading mode)

The MX/MN mode permits the user to record and recall the highest and lowest readings. The

MX/MN feature is available for ACA, ACV, DCV, TEMP, and µA functions only. The following

steps outline the MX/MN feature:

1. Take an ACA, ACV, DCV, TEMP, or µA measurement as described earlier.

2. Press and hold the MX/MN key for 2 seconds.

3. The Elapsed Timer (top display) and the MX/MN & ® indicators will appear on the LCD.

4. The Elapsed Timer shows the duration of the measurement session in Minutes and Seconds

(the Elapsed Timer switches to Hours and Minutes after 60 minutes). The maximum

recording time is 100 hours.

5. The ® indicator informs the user that the measurement range is being held. Note that the

AUTO POWER OFF feature is disabled in the MX/MN mode.

6. Press the MX/MN key again to view the highest reading and the time (shown on the Elapsed

Timer) that the reading was taken. The ‘MX’ icon will appear on the LCD.

7. Press the MX/MN key again to view the lowest reading and the time (shown on the Elapsed

Timer) that the reading was taken. The ‘MN’ icon will appear on the LCD.

8. Press again to view the current elapsed time and measurement.

9. To exit this mode, press and hold the MX/MN key until MX/MN indicators switch off.

Using the HOLD button for Power Measurements

Refer to the power measurement section of this manual for details.

RANGE Key

The RANGE Key operation varies from mode to mode. Refer to the information below:

In ACA, ACV, DCV, µA, Capacitance, and Resistance modes:

1. Press RANGE to enter the Manual Range mode (the ® indicator will appear).

2. Press RANGE again to select the desired range manually.

3. Press and hold the RANGE key to exit this mode (the ® indicator switches off).

In KW/kVA mode:

As described earlier, use the RANGE key to select the desired display combination: KW & PF,

KW & KVAR, KVA & Phase angle, or Current / Voltage.

In TEMP mode:

Use the RANGE key to select the desired unit of measure (

o

C or oF).

15

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 16

Automatic Sleep Mode and Battery Replacement

The Meter is powered by a 9V battery. An AUTO SLEEP feature is included to preserve battery life.

Note: The Auto Power OFF feature is disabled when the meter is in the MIN/MAX mode

Note: In the sleep mode the meter continues to draw a small amount of battery current. Always turn

the function switch to the OFF position when storing the meter.

Note: To restore operation after the sleep mode has engaged, turn the function switch to the OFF

position and then back to the function desired.

Auto Sleep Disable

The meter automatically goes to sleep mode after 30 minutes to conserve battery energy. To defeat

this feature:

1. Turn the meter OFF.

2. Press and hold the HOLD key while turning the selector switch to the AC Amps position.

3. Release HOLD when the clock icon appears on the LCD.

Battery Replacement

WARNING

To prevent electrical hazard or shock, turn off the meter and disconnect test

leads before removing the back cover.

When the battery power falls low, the LCD will display the battery icon +.

To replace the 9V battery:

1. Set the Range switch to the OFF position.

2. Remove the back cover by first removing the rear screws and then prying open the housing.

3. Replace the 9V battery.

4. Reassemble the meter housing.

16

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 17

Specifications

General Specifications

Display Dual Display; 4-digit, 10,000 count (0 to 9999) LCD

Jaw Opening 1.6” (42mm)

Max. Input limit Max. voltage between any terminal and ground: 600Vrms

Sampling rate 2.5 times per second (Digital Display); Once every 6 seconds (KW,

Auto Sleep After approx. 30 minutes (feature can be defeated)

Low battery indication Battery symbol appears on the LCD

Power supply 9V Battery

Battery life Approx. 32 hours with alkaline battery

Operating Temperature 32 to 122

Operating Humidity < 80% RH

Operating Altitude 7000 ft. (2000 meters) maximum.

Storage Temperature 14 to 140

Storage Humidity < 70% RH

Temperature coefficient 0.1 x (specified accuracy) /

Dimensions 9.0 x 3.0 x 1.5" (228 x 76 x 39mm)

Weight Approx. 1.0 lb. (465g)

Approvals CE, UL

Safety

This meter is intended for indoor use and protected, against the

UL Listed The UL mark does not indicate that this product has been evaluated

PER IEC1010 OVERVOLTAGE INSTALLATION CATEGORY

OVERVOLTAGE CATEGORY I

Equipment of OVERVOLTAGE CATEGORY I is equipment for connection to circuits in which

measures are taken to limit the transient overvoltages to an appropriate low level. Note –

Examples include protected electronic circuits.

OVERVOLTAGE CATEGORY II

Equipment of OVERVOLTAGE CATEGORY II is energy-consuming equipment to be supplied from

the fixed installation.

Note – Examples include household, office, and laboratory appliances.

OVERVOLTAGE CATEGORY III

Equipment of OVERVOLTAGE CATEGORY III is equipment in fixed installations.

Note – Examples include switches in the fixed installation and some equipment for industrial use

with permanent connection to the fixed installation.

OVERVOLTAGE CATEGORY IV

Equipment of OVERVOLTAGE CATEGORY IV is for use at the origin of the installation.

Note – Examples include electricity meters and primary over-current protection equipment

KVA, and KVAR)

o

F (0 to 50oC)

o

F (-10 to 60oC)

o

C at < 64oF (18oC), > 82oF (28oC)

users, by double insulation per EN61010-1 and IEC61010-1 2nd

Edition (2001) to CAT III 600V; Pollution Degree 2. The meter also

meets UL 61010A-1, First Edition

for the accuracy of its readings.

17

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 18

Measurement Specifications

Accuracy: ± (% of rdg + number of digits) from 18

o

C to 28oC (64oF to 82oF) R.H. < 80%

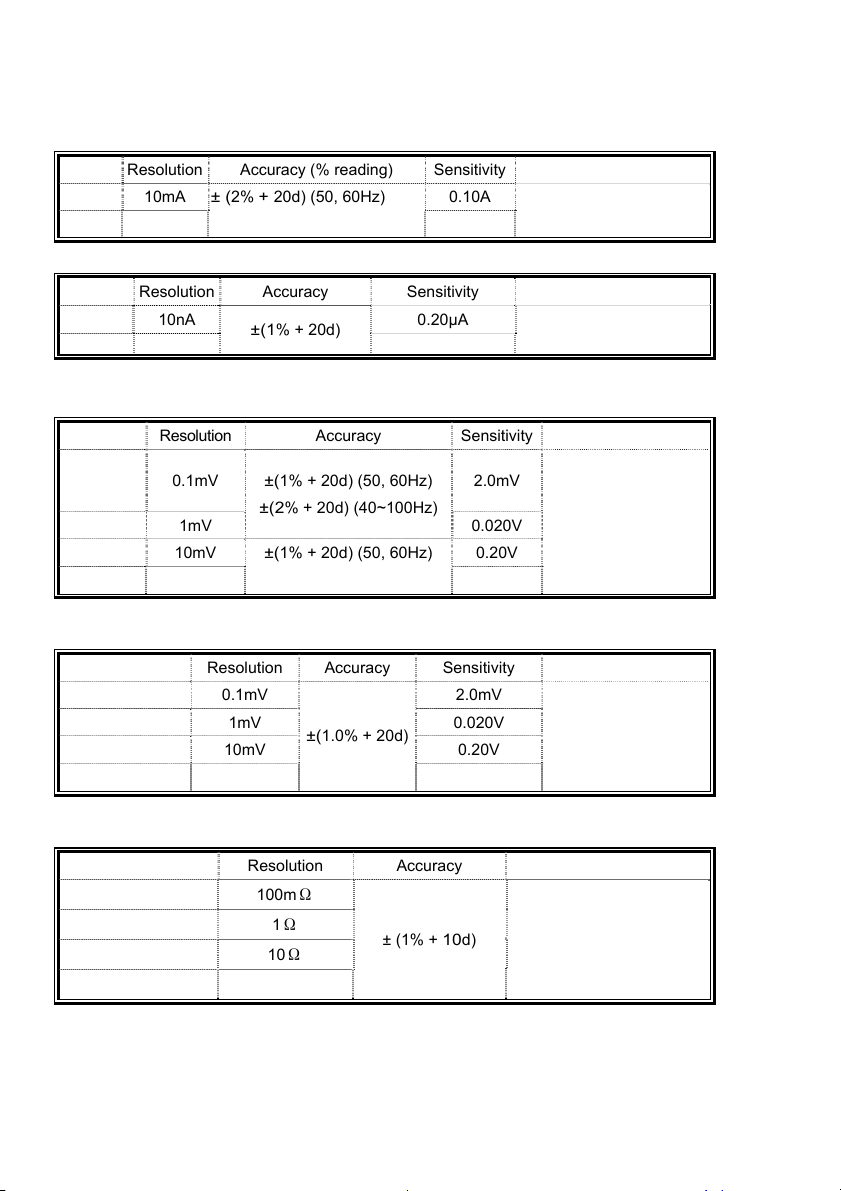

AC Current (50Hz to 400Hz) True RMS

Range Resolution Accuracy (% reading) Sensitivity Overload Protection

99.99A 10mA

999.9A 100mA 1.0A

± (

2% + 20d) (50, 60Hz)

± (4% +

20d) (40~400Hz)

0.10A

1000A

A True RMS (AC+DC)

Range Resolution Accuracy Sensitivity Overload Protection

99.99A

999.9A

10nA

100nA 2.0µA

±(1

% + 20d)

0.20µA

600V

Burden Voltage: 5mV/µA

AC Voltage (50Hz to 400Hz) True RMS

Range Resolution Accuracy Sensitivity Overload Protection

999.9mV 0.1mV

±(

1% + 20d) (50, 60Hz)

±(2

% + 20d) (40~100Hz)

9.999V 1mV 0.020V

99.99V 10mV

600.0V 100mV 2V

Input impedance: 3M

±(

1% + 20d) (50, 60Hz)

±(2

% + 20d) (40~400Hz)

Ω

2.0mV

600V

0.20V

DC Voltage

Range Resolution Accuracy Sensitivity

999.9mV 0.1mV

9.999V 1mV 0.020V

99.99V 10mV 0.20V

±(

1.0% + 20d)

2.0mV

Overload Protection

600V

600.0V 100mV 2V

Input resistance: 3M

Ω

Resistance (Audible Continuity for readings <40on the 999.9 range)

Range Resolution Accuracy Overload Protection

999.9Ω 100mΩ

9.999KΩ 1

99.99KΩ 10Ω

Ω

± (1% +

10

d) 600V

999.9KΩ 100Ω

18

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 19

M(Resistance)

Range Resolution Accuracy Overload Protection

9.999MΩ 1KΩ

99.99MΩ 10KΩ

±(5% +

10

d) 600V

Capacitance

Range Resolution Accuracy

10.000F

100.00F

1000.0F

7000F 1F

1nF

10nF

100nF

±(1.5% +

±(4.5% +

15

5

d)

d)

Overload Protection

600V

Diode (Continuity <40mV)

Range Resolution Accuracy Overload Protection

2.000V 1mV

±(2% + 1

d) 600V

Temperature (K-Type thermocouple)

Range Resolution Accuracy Overload Protection

+

1oC)

-50oC to 900oC 0.1oC

-58oF to 1000oF 0.1oF

1Φ/3Φ TRUE Power (PF > 0.5 or

±(1%

+ 2oF)

±(1%

< 60o) (50/60Hz)

30V

or 60VDC

AC

Range Resolution Accuracy Overload Protection

60.00KW (<100A) 10W

600.0KW (>100A) 100W

1Φ/3Φ

Horse Power (HP) (PF > 0.5 or

±(

5%

+ 20

d)

±(

5%

+ 20

d)

< 60o) (50/60Hz)

600VAC/

1000AAC

Range Resolution Accuracy Overload Protection

80.00HP (<100A) 0.01 HP

800.0 HP (>100A) 0.1 HP

1Φ/3Φ Reactive Power (KVAR) (PF > 0.5 or

±(

5%

+ 20

d)

±(

5%

+ 20

d)

< 60o) (50/60Hz)

600VAC/1000AAC

Range Resolution Accuracy Overload Protection

60.00KVAR (<100A) 10VAR

600.0KVAR (>100A) 100VAR

±(

5%

+ 20

d)

±(

5%

+ 20

d)

600VAC/

1000AAC

19

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Page 20

1Φ/3Φ

Apparent Power (KVA)

Range Resolution Accuracy Overload Protection

60.00KVA (<100A) 10VA

600.0KVA (>100A) 100VA

±(

2.5%

+ 20

d) 600VAC/1000AAC

Phase Angle (

50/60Hz)

Range Resolution Accuracy Sensitivity

-60° ~ 0° ~ +60° 0.1º

±6.0º

ACV>100V, ACA>10A

Frequency

Range Resolution Accuracy Sensitivity

40Hz/1KHz 0.1Hz ±(0.5% + 2d) ACV>5V, ACA>6A

Copyright © 2012 Extech Instruments Corporation

All rights reserved including the right of reproduction in whole or in part in any form.

www.extech.com

20

www.GlobalTestSupply.com

380976-EU-EN-V3.2 6/12

Loading...

Loading...