Page 1

User’s Guide

MultiLog™ Digital MultiMeter

With built-in Datalogger

Model ML720

Page 2

1

WARRANTY

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects

in parts and workmanship for three years from date of shipment (a six month limited

warranty applies on sensors and cables). If it should become necessary to return the

instrument for service during or beyond the warranty period, contact the Customer Service

Department at (781) 890-7440 ext. 210 for authorization. A Return Authorization (RA)

number must be issued before any product is returned to Extech. The sender is

responsible for shipping charges, freight, insurance and proper packaging to prevent

damage in transit. This warranty does not apply to defects resulting from action of the

user such as misuse, improper wiring, operation outside of specification, improper

maintenance or repair, or unauthorized modification. Extech specifically disclaims any

implied warranties or merchantability or fitness for a specific purpose and will not be liable

for any direct, indirect, incidental or consequential damages. Extech's total liability is

limited to repair or replacement of the product. The warranty set forth above is inclusive

and no other warranty, whether written or oral, is expressed or implied.

REPAIR AND CALIBRATION SERVICES

Extech offers complete repair and calibration services for all of the

products we sell. For periodic calibration, NIST certification or repair of

any Extech product, call customer service for details on services

available. Extech recommends that calibration be performed on an annual

basis to insure calibration integrity.

Technical support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User’s Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Extech Instruments Corporation, 285 Bear Hill Rd., Waltham, MA 02451

Support line (781) 890-7440

Copyright © 2005 Extech Instruments Corporation. All rights reserved

including the right of reproduction in whole or in part in any form.

ML720 V3.0 2/05

Page 3

2

Introduction

Congratulations on your purchase of Extech model ML720 True rms

datalogging digital multimeter. Properly used, this meter will provide many

years of reliable service.

The MultiLog™ measures AC/DC Voltage/Current, Resistance,

Frequency, Capacitance, Temperature, Diode, and Continuity. The

MultiLog™ offers a built-in datalogger and an optical RS-232 interface.

The meter stores 43,000 data points in internal memory.

Safety

International Safety Symbols

This symbol, adjacent to another symbol or terminal , indicates the

user must refer to the manual for further information.

This symbol, adjacent to a terminal, indicates that, under normal

use, hazardous voltages may be present

Double insulation

Safety Precautions

1. Improper use of this meter can cause damage, shock, injury or death.

Read and understand this user’s manual before operating the meter.

2. Make sure any covers or battery doors are properly closed and

secured.

3. Always remove the test leads before replacing the battery or fuses.

4. Inspect the condition of the test leads and the meter itself for any

damage before operating the meter. Repair or replace any damage

before use.

5. Do not exceed the maximum rated input limits.

6. Use great care when making measurements if the voltages are

greater than 25VAC rms or 35VDC. These voltages are considered a

shock hazard.

7. Always discharge capacitors and remove power from the device

under test before performing Capacitance, Diode, Resistance or

Continuity tests.

Page 4

8. Remove the battery from the meter if the meter is to be stored for

long periods.

9. To avoid electric shock, do not measure AC current on any circuit

whose voltage exceeds 500V AC.

10. Voltage checks on electrical outlets can be difficult and misleading

because of the uncertainty of connection to the electrical contacts.

Other means should be used to ensure that the terminals are not

"live".

11. The product is intended only for indoor use

12. If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

13. Pollution degree: 2

PER IEC1010 OVERVOLTAGE INSTALLATION CATEGORY

OVERVOLTAGE CATEGORY I

3

Equipment of OVERVOLTAGE CATEGORY I is equipment for

connection to circuits in which measures are taken to limit the transient

overvoltages to an appropriate low level. Note – Examples include

protected electronic circuits.

OVERVOLTAGE CATEGORY II

Equipment of OVERVOLTAGE CATEGORY II is energy-consuming

equipment to be supplied from the fixed installation.

Note – Examples include household, office, and laboratory appliances.

OVERVOLTAGE CATEGORY III

Equipment of OVERVOLTAGE CATEGORY III is equipment in fixed

installations.

Note – Examples include switches in the fixed installation and some

equipment for industrial use with permanent connection to the fixed

installation.

OVERVOLTAGE CATEGORY IV

Equipment of OVERVOLTAGE CATEGORY IV is for use at the origin of

the installation.

Note – Examples include electricity meters and primary over-current

protection equipment

Page 5

4

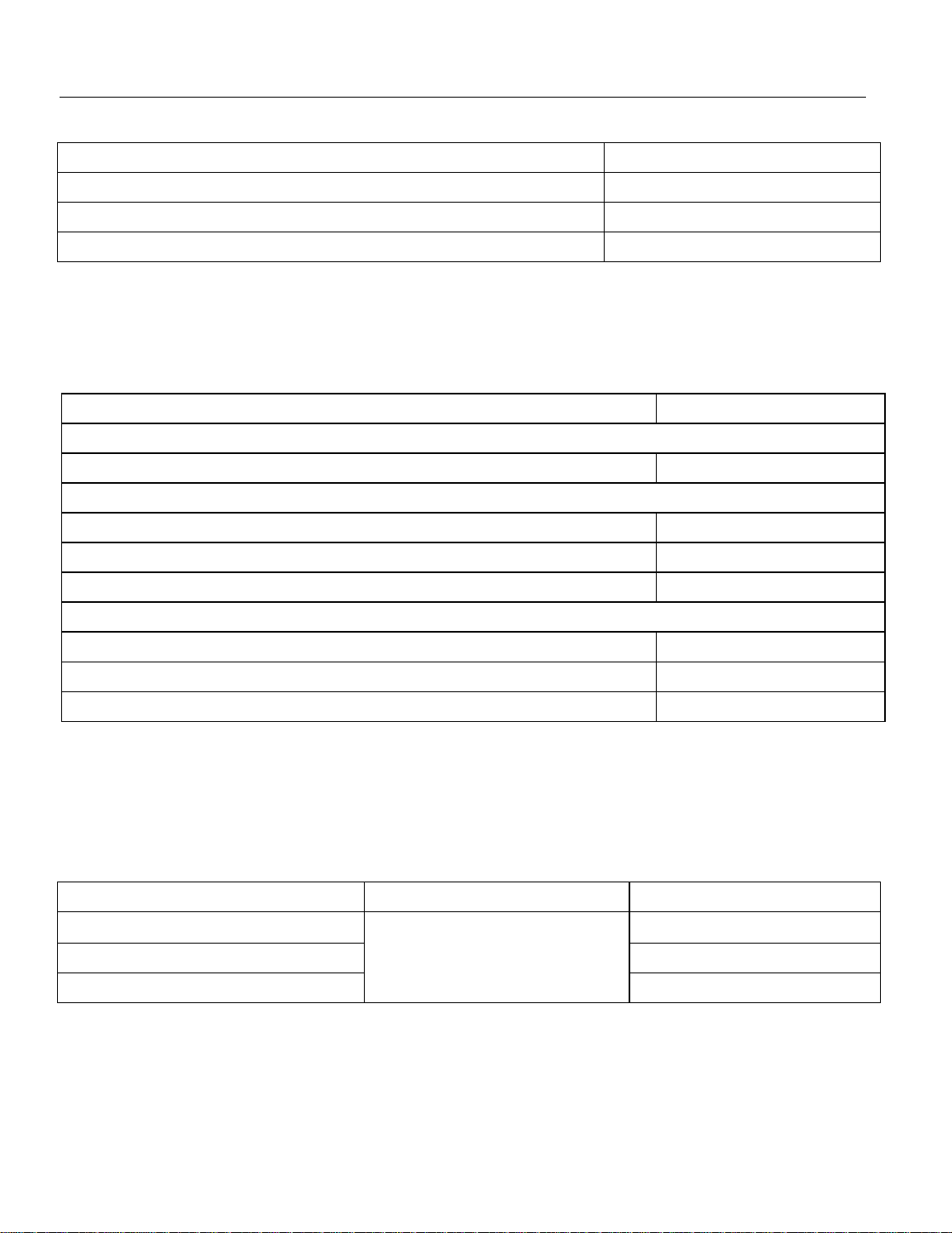

Specifications

DC VOLTAGE

RANGE Accuracy

50.00 mV 0.12% + 2d

500.0 mV 0.06% + 2d

5.000V, 50.00V, 500.0V, 1000V 0.08% + 2d

NMRR: >60dB @ 50/60Hz, CMRR: >120dB @ DC, 50/60Hz, Rs=1kΩ

Input impedance: 10MΩ, 16pF nominal (44pF nominal for 50mV & 500mV

ranges)

AC VOLTAGE

RANGE Accuracy

50Hz/60Hz

50.00mV, 500.0mV, 5.000V, 50.00V, 500.0V, 1000V 0.5% + 3d

40Hz to 500Hz

50.00mV, 500.0mV 0.8% + 3d

5.000V, 50.00V, 500.0V 1.0% + 4d

1000V 1.2% + 4d

Up to 20kHz

50.00mV, 500.0mV 0.5dB*

5.000V, 50.00V, 500.0V 3dB*

1000V Unspecified

*Specified from 30% to 100% of range

CMRR: >60dB @ DC to 60Hz, Rs=1kΩ

Input Impedance: 10MΩ, 16pF nominal (44pF nominal for 50mV &

500mV ranges)

DC CURRENT

RANGE Accuracy Burden Voltage

500.0µA, 5000µA 0.15mV/µA

50.00mA, 500.0mA 3.3mV/mA

5.000A, 10.00A*

0.2% + 4d

0.03V/A

*10A continuous, 20A for 30 seconds max with a 5 minute cool down

interval

Page 6

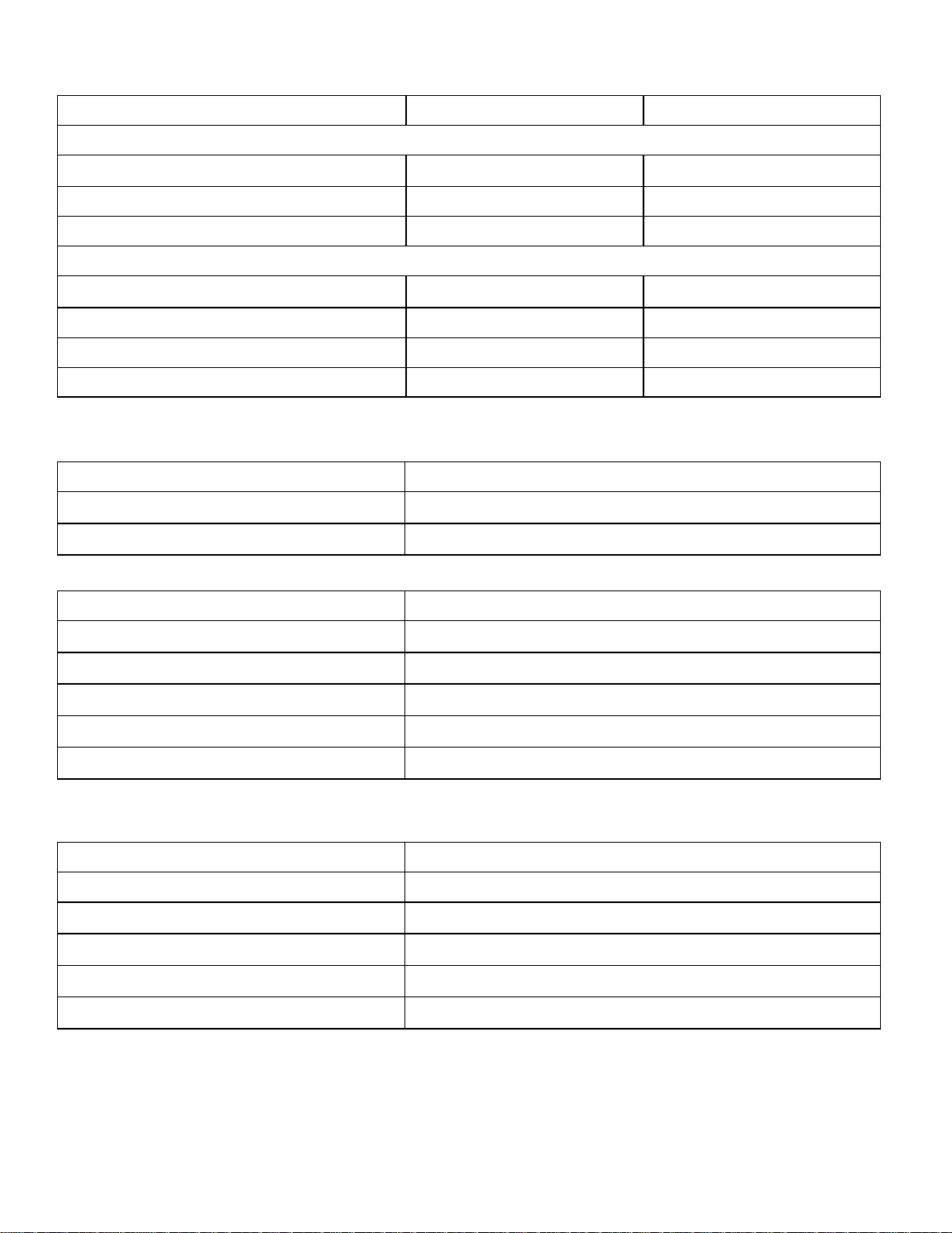

5

AC CURRENT

RANGE Accuracy Burden Voltage

50 / 60Hz

500.0µA, 5000µA

0.6%+3d

0.15mV/µA

50.00mA, 500.0mA 0.6%+3d 3.3mV/mA

5.000A, 10.00A* 0.6%+3d 0.03V/A

40Hz to 1kHz

500.0µA, 5000µA

0.8%+4d

0.15mV/µA

50.00mA 0.8%+4d 3.3mV/mA

500.0mA 1.0%+4d 3.3mV/mA

5.000A, 10.00A* 0.8%+4d 0.03V/A

*10A continuous, 20A for 30-second max with 5 minute cool down interval

TEMPERATURE

RANGE Accuracy

-50°C TO 1000°C

-58°F TO 1832°F

0.3% + 3d

0.3% + 6d

RESISTANCE

RANGE Accuracy

50.00Ω

0.2% + 6d

500.0Ω

5.000kΩ, 50.00kΩ, 500.0kΩ

5.000MΩ

50.00MΩ

0.1% + 3d

0.1% + 2d

0.4% + 3d

1.5% + 5d

Open Circuit Voltage: < 1.3VDC (< 3VDC for 50Ω & 500Ω ranges)

CAPACITANCE

RANGE Accuracy*

50.00nF, 500.0nF 0.8% + 3d

5.000µF

50.00µF

500.0µF

9999µF

1.0% + 3d

2.0% + 3d

3.5% + 5d

5.0% + 5d

*Accuracies with film capacitor or better

Page 7

FREQUENCY

6

Function Sensitivity

Range

(ACrms)

mV 300mV 10Hz - 125kHz

5V 2V 10Hz - 125kHz

50V 20V 10Hz - 20kHz

500V 80V 10Hz - 1kHz

1000V 300V 10Hz - 1kHz

Ω, Cx, diode

µA, mA, A

300mV 10Hz - 125kHz

10% F.S. 10Hz - 125kHz

Accuracy: 0.01% + 2d

Accuracy Notes: Accuracy is ± (% reading digits + number of digits), or

as otherwise specified, at 23°C ±5°C < 75% R.H. True RMS accuracies

are specified from 5% to 100% of range or as otherwise specified.

Maximum Crest Factor <3:1 at full scale & <6:1 at half scale (with

frequency component within the specified frequency bandwidth for nonsinusoidal waveforms).

Audible Continuity:

Measurement threshold: Beeper will sound if measurement is below

20Ω. Beeper will not sound if measurement is above 200Ω. Beeper

may or may not sound if measurement is between 20 and 200Ω.

Response time: < 100µs

Digital Display: 5000-count LCD display; 5 per second

nominal refresh rate

Bar Graph Display: 52-segment bargraph; 60 per second nominal

refresh rate

Datalogging Capacity: 43000 points

oC/o

Datalog Sample Rate: 0.05 (0.2 for

F & Ω, 0.4 for HZ and 1 for

C), 1, 20, 40, 60, 120, 240 & 480 seconds

Low Battery: Below approx. 7V

Operating Temperature: 32° to 113°F (0° to 45°C)

o

Storage Temperature: -4° to 140°F (-20 to 60

C

Relative Humid ity: Max 80% up to 87ºF (31ºC) decreasing

linearly to 50% at 113ºF (45ºC) <80% storage

Altitude: Operating below 2000 meters

Page 8

7

Temp. Coefficient: Nominal 0.15 x specified accuracy per ºC (between

0 and 18

o

C or 28 to 50oC), or as otherwise specified

Power Supply: 9V battery (NEDA1604, JIS006P or IEC6F22)

AC Sensing: True RMS

Auto Power Off: After 17 minutes of inactivity with no input signal

Safety: Intended for indoor use and protected by double insulation per

EN61010-1 and IEC61010-1 2nd Edition (2001) to CAT III

1000V & CAT IV 600V. The meter also meets UL3111-1(1994)*

and CSA C22.2 No. 1010-1-92* to CAT III 1000V.

Terminals (to COM) ratings:

V : CATEGORY III 1000 VOLTS AC & DC, AND

CATEGORY IV* 600 VOLTS AC & DC.

A / MAµA : CATEGORY III AND CATEGORY IV* 500

VOLTS AC AND 300 VOLTS DC.

*Category IV safety standard (for DMMs) was first released in

IEC61010-1 2nd Edition in year 2001, and was yet a UL published

standard at the time this manual was written.

UL Certification: Meters that bear the UL marking have been

investigated by UL headquarter in the USA per UL

standard UL3111-1 1st Ed to its highest CAT III rating

and international standard IEC61010-1 Second Edition

(year 2001) to CAT IV rating. The UL markings on the

meter, where applicable, are marked as “UL Listed Cat

III only” and “UL Classified to IEC61010-1 2nd Ed. Cat

IV”.

E.M.C.: Meets EN61326(1997, 1998/A1), EN61000-4-2(1995) and

EN61000-4-3(1996). Also meets former standards EN55011

(1991) and EN50082-1(1997)

In an RF field of 3V/m: Capacitance function is not specified

Other function ranges: Total Accuracy = Specified Accuracy + 30

digits. Performance > 3V/m is not specified

Overload Protection:

µA/mA Range: 0.63/500V, IR 200kA, F fuse

A Range:

V Range:

1050V rms, 1450V peak

mV, Ω and other:

12.5A/500V IR 20kA, F fuse

600VDC/VAC rms

Power Consumption: 2.7mA typical

Dimension: 7.32 x 3.43 x 1.4" with holster (186mm x 87mm x 35.5mm)

Weight: 15.17 oz. with holster (430g)

Page 9

Meter Description

1. 5000 count Liquid Crystal display

2. Function push-buttons

3. Rotary function switch

4. 10A input jack

5. V/Hz/Ω/Cap/Temp input jack

6. COM input jack

7. mA/uA current input jack

8. RS232 connector (rear)

8

Page 10

Features

Analog Bargraph display

Visual indication of measurement in the tradition of an analog meter

pointer. The bargraph consists of 52 discrete viewing segments. The

bargraph is useful for detecting faulty contacts, identifying

potentiometer gradations, and viewing signal spikes.

True RMS vs. Average Sensing (AC Measurements)

True RMS meters can accurately measure non-sinusoidal waveforms,

as well as distorted sine waves that contain harmonics. Average

Sensing is a fast, accurate and cost effective method of measuring

pure sine wave signals. However, non-sinusoidal waveforms cannot

accurately be measured using Average-sensing techniques.

Backlit display

The MultiLog™ is equipped with a backlight for viewing the LCD

display in poorly lit areas.

9

Data Hold

The HOLD function freezes the reading on the display for later

viewing.

Manual and Automatic Ranging

The MultiLog™ series multimeters are Autoranging, with manual

override.

Smart Power Auto Power Off

Smart Power shuts the meter down automatically after approximately

17 minutes of inactivity.

Audible Beeper

To disable the audible meter tones, press and hold the Hz key while

powering the meter.

Automatic Test Lead Resistance Compensation

Automatically compensates for the resistance of the test leads, as well

as the internal protection circuitry automatically, ensuring greater

accuracy of low resistance measurements.

Datalogging

The MultiLog™ series of multimeters store reading for review on the

LCD display or downloading to a pc using the supplied sof t w ar e.

Page 11

10

Operation

Measurement Considerations

NOTICE: Read and understand all warning and caution statements

listed in the safety section of this operation manual prior to using this

meter.

1. Always move the rotary function switch to the OFF position when the

meter is not in use. This meter has Auto Power OFF that

automatically shuts the meter OFF if 17 minutes elapse without

activity.

2. If "OL" appears on the display during a measurement, the

measurement exceeds the range selected. Change to a higher range.

AC/DC Voltage Measurements

1. Insert the black test lead into the negative COM jack and the red test

lead into the positive V jack.

2. Set the function switch to the "VAC" "VDC" "mV" position. Press the

SELECT key momentarily to toggle between AC and DC.

3. Read the voltage measurement on the display

AC/DC Current Measurements

CAUTION: Do not make current measurements at 20A for longer than

30 seconds. Exceeding 30 seconds may cause damage to the meter

and/or the test leads.

1. Insert the black test lead into the negative COM jack.

2. For current measurements up to 4000µA, set the function switch to

the "µA" position and insert the red test lead into the mA-µA jack.

3. For current measurements up to 400mA, set the function switch to the

"mA" position and insert the red test lead into the mA-µA jack.

4. For current measurements up to 10A, set the function switch to the

"A" position and insert the red test lead into the A jack.

5. Press the SELECT key momentarily to toggle between AC and DC.

6. Remove power from the circuit under test and open the circuit at the

point where you wish to measure current.

7. Touch the black test probe tip to the negative side of the circuit and

touch the red test probe tip to the positive side of the circuit.

8. Apply power to the circuit.

9. Read the current on the display

Page 12

Resistance and Continuity Measurements

1. Insert the black test lead banana plug into the negative COM jack and

the red test lead banana plug into the V/Ω/CAP jack.

11

2. Set the function switch to the "Ω

" position.

3. Press the SELECT key momentarily to select Continuity (if required).

4. Touch the test probe tips across the circuit or part under test. It is best

to disconnect one side of the part under test so the rest of the circuit

will not interfere with the resistance reading.

5. For Resistance tests, read the resistance on the display.

6. For Continuity tests, If the resistance is < 20Ω, an audible tone will

sound

Automatic test lead resistance calibration

When manually entering the 50Ω range (using the RANGE key) the

automatic test lead resistance feature will prompt ("Shrt" in the display)

the user to short the inputs for calibration. Short the test leads for about

3 seconds until the display shows zero. The resistance of the test leads

is now subtracted from the reading. The compensation value can be as

much as 5Ω.

Note: The compensation procedure must be repeated each time the

range or function is changed.

Capacitance Measurements

1. Insert the black lead into the negative COM jack and the red test lead

into the positive CAP jack.

2. Set the function switch to the " CAP" position.

3. Press the SELECT key momentarily to select the Capacitance

function (if required).

4. Touch the test leads to the capacitor to be tested and read the

measured value.

Page 13

Frequency Measurements

1. Connect and make the measurement required as described in the

previous paragraphs.

2. Press the Hz key to select the Frequency (Hz) function.

3. Read the frequency on the display

Notes on sensitivity:

Input sensitivity varies automatically with function range selected. The

mV function has the highest (300mV) and the 1000V range has the

lowest (300V) sensitivity. It is recommended that the user first

measure the signal voltage (or current) level before activating the Hz

function to automatically set the most appropriate trigger level. You

can also press the RANGE button momentarily to select another

trigger level manually. If the Hz reading becomes unstable, select a

lower sensitivity to avoid electrical noise. If the display is zero, select

a higher sensitivity.

Diode Test

12

1. Insert the black lead into the negative COM jack and the red test lead

into the positive jack

2. Set the function switch to " CAP" position.

3. Press the SELECT key momentarily to select the diode function (if

required).

4. Touch the test probe tips to the diode or semiconductor junction you

wish to test. Note the meter reading.

5. Reverse the test lead polarity by reversing the red and black leads.

Note this reading.

6. The diode or junction can be evaluated as follows:

A. If one reading displays a value and the other reading displays "OL",

the diode is good.

B. If both readings display "OL", the device is open.

C. If both readings are very small or 0, the device is shorted.

Temperature Measurements

1. Insert the Temperature Probe into the COM and TEMP input jacks

observing polarity.

2. Set the function switch to the "TEMP" position.

o

3. Use the SELECT key to toggle between

C and oF.

4. Touch the Temperature Probe tip to the device under test.

5. Wait 30 seconds for the measurement to stabilize then read the

display.

Page 14

Smart Power Auto Power Off

Smart Power shuts the meter down automatically after approximately

17 minutes of inactivity. The 17-minute time period is reset any time

the rotary switch is moved or as long as the signal being fed into the

meter is greater than 10% of the range. This prevents auto powering

off during long term tests. To wake the meter, press the SELECT key

or turn the meter off and on again.

Audible Beeper

The audible beeper can be disabled by pressing the Hz key while

turning the meter on.

13

Page 15

14

Datalogging

Datalogging Basics

The ML720 can store up to 43,000 readings automatically. These

readings can be viewed on the LCD display or transferred to a PC using

TM

the PC interface cable and Windows

Datalogging

Note: Each time the datalogging "Strt" process is initiated, existing data

will be erased. Always review or download stored data before beginning a

new recording session.

1. Press the timer key to enter the sample rate mode. The default

setting is 0.05 seconds.

2. Press the up/down arrow keys to select the desired sample rate.

3. Press the timer key to store the selected sample rate.

4. Press and hold the "Strt, PAUS, StoP" key for 1 second until “Strt”

software included.

appears in the display to start the data logging process.

5. The bargraph display will appear with a single oscillating pointer to

indicate the datalogging process is in progress.

6. Press the "Strt, PAUS, StoP" key to pause datalogging. A blinking

"H" will appear in the display.

7. Press again to continue datalogging. "Cont" will appear momentarily

in the display.

8. Press the SELECT key to toggle between the measured value display

and the data list item number display.

9. Press and hold the key for 1 second until “StoP” appears in the

display to stop the data logging process and store the data.

Page 16

Recalling Stored Readings

To recall stored data, press the START, UP or DOWN arrow key

momentarily to “CALL” the logged data. The LCD will show a flashing

“C” (CALL) to indicate that the data shown is logged data. The data can

also be transferred to a PC using the supplied Windows

TM

software and

interface cable. When the datalogger is paused or when the CALL mode

is activated, select from the following activities for datalog viewing:

1. Use the arrow keys to scroll through the data on the meter’s LCD

display.

2. Press and hold the UP or DOWN arrow keys to quickly scan the

logged data. The meter provides an audible tone when the first or last

reading is reached.

3. Press the UP and DOWN arrow keys at the same time momentarily to

display alternately the MINIMUM and MAXIMUM readings.

4. Press the UP or DOWN arrow key momentarily while holding the

HOLD key to search all of the trends in the recorded data list. The

15

LCD will indicate MIN or MAX for each trend in the list.

Datalog Item Numbers

Each logged reading has an item number (0 to n; where n is the

maximum number of records that can be stored) When the logged data

entries exceed 9999, the bargraph display indicates the most significant

digit of the item numbers > 10,000. For example, 1=10,000, 2=20,000,

etc.

Meter Memory Full

When the meter memory is full, the datalogging process ceases

automatically and the meter will enter the Auto Power OFF mode. Note

that while datalogging, the Auto Power OFF mode is disabled.

Low Battery Datalogging

If the 9V battery voltage falls critically low while the meter is datalogging,

the meter automatically ceases logging to ensure the integrity of the

data recorded.

Non-Volatile Data Storage

Data are stored in non-volatile memory shortly after each measurement

is taken to maximize data safety. However, the end-of-data information

can only be stored after a datalog event is complete. Always “StoP” the

datalogger before switching off the meter.

Page 17

Datalogging Sampling Rate

Press the TIMER key momentarily to display the datalogger’s sampling

rate (recording interval). The factory default interval is 0.05 seconds,

meaning that a reading will be logged every 5 hundredths of a second.

Press the UP or DOWN arrow key momentarily to select an alternate

sampling interval. Choose from 0.05 up to 480 seconds. Note that the

fastest sampling interval for Temperature and Resistance readings is 0.2

seconds; For Frequency it is 0.4 seconds; and for Capacitance it is 1

second. Press the TIMER key again to confirm the new setting.

The Sampling Rate cannot be changed while the meter is datalogging.

When a Sampling Rate of 20 seconds or longer is selected, the meter

enters a standby state between readings (to conserve battery life). While

in stand-by, the bargraph will continue to operate. To wake-up meter

from a stand-by state in order to view a real-time measurement, press

the SELECT key momentarily.

16

RS232C PC computer interface capabilities

This device is equipped with an optical isolated interface port located on

the rear of the meter. The data acquisition package includes an interface

TM

cable and Windows

data acquisition software. The software provides

in the format of a digital meter, a analog meter, a comparator meter, and

a graphical display. Refer to the README file on the software disk for

further details.

Page 18

Maintenance

17

WARNING:

To avoid electrical shock, disconnect the meter from any

circuit, remove the test leads from the input jacks and turn OFF the meter

before opening the case. Do not operate with open case. Install only the

same type of fuse or equivalent

Cleaning and Storage

Periodically wipe the case with a damp cloth and mild detergent; do not

use abrasives or solvents. If the meter is not to be used for periods of

longer than 60 days, remove the battery and store it separately

UL List ed

The UL mark does not indicate that this product has been evaluated for

the accuracy of its readings.

Page 19

18

Battery Replacement

Loosen the 2 screws from the battery access door of the case bottom. Lift

the battery access door and thus the battery compartment up. Replace

the battery. Re-fasten the screws.

Battery: Standard 9V Alkaline (NEDA1604, JIS006P, IEC6F22)

Fuse Replacement

1. Remove the four screws from the case bottom and stand using a

Philips head screwdriver.

2. Lift the end of the case bottom nearest the input jacks until it unsnaps

from the case top

3. Replace the battery or blown fuse(s)

4. Replace the case bottom, and ensure that all the gaskets are properly

seated and that the two snaps on the case top (near the display side)

are engaged

5. Re-fasten the screws.

Fuses:

FS1 (µA/mA Range): 0.5/0.63 ampere F, fast acting ceramic.

Preferred: Ferraz C084205 (0.63A)

Acceptable: Bussmann ABC-1/2 (0.5A)

FS2 (A Range): 12 ampere F, fast acting ceramic.

Preferred: Ferraz D085448 (12.5A)

Acceptable: Bussmann ABC-12 (12A)

A fuse kit, Extech P/N FS880, is available that contains one each of the

Ferraz fuses.

Loading...

Loading...