Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

User’s Guide

Models 475040 and 475044

Visit us at www.TestEquipmentDepot.com

Back to the Extech 475040 Product Page

13

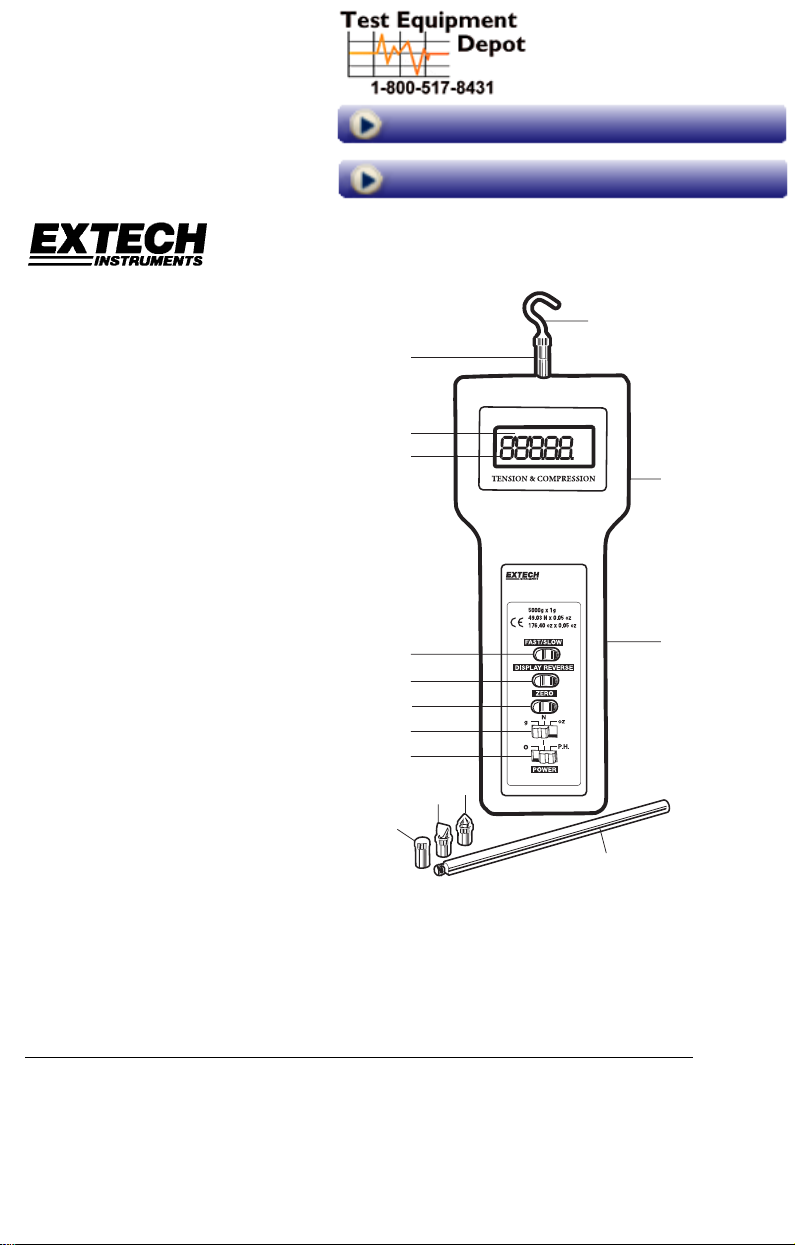

Digital Force Gauge

10

15

1

FORCE GAUGE

3

2

8

475040

4

5

6

7

11

12

14

9

1. Universal sensing head

2. LCD Display

3. Fast response indicator

4. FAST / SLOW response selection

5. LCD reverse display button

6. Zero/Tare button

7. Units select switch

8. Mounting Holes (on rear)

9. Battery compartment cover (on rear)

10. Flat Head adapter

11. Cone adapter

12. Chisel adapter

13. Hook adapter

14. 5” (120mm) extension rod

15. OFF/ON/PEAK HOLD button

Introduction

Congratulations on your purchase of Extech’s Digital Force Gauge. This professional meter,

with proper care, will provide years of safe reliable service. Measure Tension or Compression

(Push or Pull) to 5kg (475040) or 20kg (475044), reversible display indicates readings in

grams, ounces, or newtons. This meter offers Peak Hold and a Zero function.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 2

Specifications

A

475044 475040

Range 44 lbs, 20kg,196 Newtons 176oz, 5000g, 49 Newtons

Accuracy (23oC) ±(0.5%rdg + 2 digits) ± (0.4%rdg + 1 digit)

Resolution 0.01lbs, 0.01kg, 0.05 Newtons 0.05oz, 1g, 0.01 Newtons

Overload Capacity 30kg 10kg

Circuit Custom LSI microprocessor circuit

Zero adjust Button for Peak Hold and normal display zero

Display 5 digits, 0.4” (10 mm) LCD display

Update Rate Fast mode 0.2 secs; Slow mode 0.6 secs.

Overrange Indicator Displays “--------“

Zero Control Maximum capacity

Full Scale Deflection 2.00mm

Transducer type Load cell

Peak Hold Freezes Max reading on display

Operating Temperature 0 °C to 50 °C (32 °F to 122 °F).

Operating RH Max. 80% RH.

Power Supply 6x 1.5V AA (UM-3) size battery or DC 9V adapter (not included)

Weight 1.2 lbs/551g

Size 8.9 x 3.3 x 1.5” (227 x 83 x 39 mm)

Mounting Holes Located on rear of gauge for optional test stand

Accessories Tension adapter (hook), compression adapters (flat, cone, and

chisel), 5" extension rod, 6 x 1.5V AA batteries, case

Operation

Preparation for Measurement

1. The 475044 or 474040 automatically determines TENSION or COMPRESSION

(Push or Pull) force during use. Compression displays as a negative value and

Tension displays as a positive value.

2. Select units of measure (grams/kilograms, ounces/pounds, or newtons) via the

units select button.

3. Attach the desired adapter (tension – hook; compression.- flat, cone or chisel head)

to the Universal Sensing Head.

4. Select FAST or SLOW response. The FAST setting permits the capture of fast

measurement changes and the SLOW setting provides an averaged reading

display.

5. Zero the display before each measurement via the Zero button.

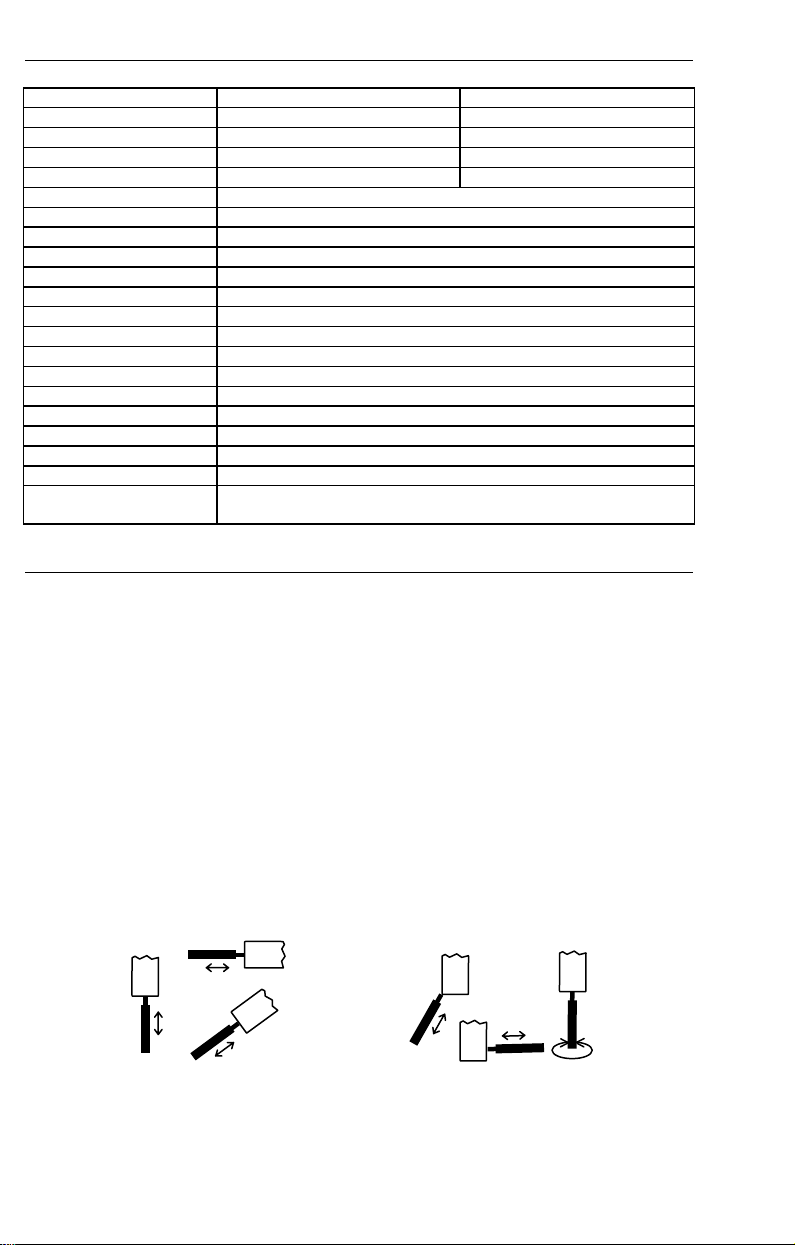

Note: The sensing head with adapter must be in line with the object being measured.

Avoid rotating the sensing head. Refer to the figure below.

Figure 1 ─ Correct and Incorrect Angles of Measurement

cceptable

2

Not Acceptable

475040 and 475044 Ver. 1.9 12/04

Page 3

Normal Measurement Mode

1. Slide the POWER switch to the ON position. Reverse the LCD display if desired via

the Reverse key.

2. Zero the meter before each measurement.

3. Touch the adapter to the object being measured in a straight line. Refer to Fig.1.

4. Begin measurement by applying force (Push or Pull). Read the LCD display.

5. After completing the measurement, the display will indicate "0.00" if the position

and angle of the Force Gauge have not changed.

6. If the position or angle of the Force Gauge changes during a measurement, the

display may show one of the following:

a) The display overranges because the initial force of the transducer decreases

due to a change in the position or angle of the Gauge after measurement.

b) The display indicates any value such as "12", "25", etc. This occurs because

the initial force of the transducer increases due to a change in the position or

angle of the Gauge after measurement.

Note: Be sure to press "ZERO" before taking any new measurements.

Peak Load Measurement

1. Slide the POWER switch to the PEAK position...

2. Touch the adapter to the object being measured in a straight line, refer to Fig. 1.

3. Zero the meter before each measurement.

4. Begin measurement by applying force (pull or push). The LCD will display the peak

value, which is the highest reading encountered.

5. After completing the measurement, the display will hold the peak load value if the

position and angle of the Force Gauge have not changed.

6. After completing the measurement, the display will overrange if the position or

angle of the Force Gauge has changed. This occurs because the initial force of the

transducer decreases due to a change in the position or angle of the Gauge after

measurement.

Note: Be sure to press "ZERO" before taking any new measurements.

Fast/Slow selection

Press the FAST/SLOW key to select the desired display update rate. The “((•))” symbol will

appear in the display when FAST is selected.

Mounting

For best results, mount the Digital Force Gauge to a test stand (optionally available, contact

Extech for details). Mounting holes are provided on the rear of the meter.

Maintenance

Battery Replacement

The low battery indication appears as a "LO" on the display when battery voltage is less than

6.8V. To replace the battery:

1. Remove the two screws from the battery compartment cover.

2. Lift off the battery cover.

3. Replace with 6x 1.5V AA (UM-3) batteries. Observe polarity carefully.

4. Replace compartment cover and screws.

3

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

475040 and 475044 Ver. 1.9 12/04

Loading...

Loading...