Page 1

User's Manual

Heavy Duty Pressure Meter

Model 407495

Page 2

Introduction

Congratulations on the purchase of the Extech Heavy Duty Pressure Meter, Model

407495. This meter measures and displays pressure in eight (8) measurement units. Up to

three (3) interchangeable transducers (sold separately) in varying ranges can be used with

this meter. Special features include RS-232 PC Interface, Min/Max Memory, push-button

Zero, Data Hold, and Auto Power-Off. This meter is shipped fully tested and calibrated

and, with proper use, will provide years of reliable service.

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects

in parts and workmanship for three years from date of shipment (a six month limited

warranty applies to sensors and cables). If it should become necessary to return the

instrument for service during or beyond the warranty period, contact the Customer Service

Department at (781) 890-7440 ext. 210 for authorization or visit our website

www.extech.com for contact information. A Return Authorization (RA) number must be

issued before any product is returned to Extech. The sender is responsible for shipping

charges, freight, insurance and proper packaging to prevent damage in transit. This

warranty does not apply to defects resulting from action of the user such as misuse,

improper wiring, operation outside of specification, improper maintenance or repair, or

unauthorized modification. Extech specifically disclaims any implied warranties or

merchantability or fitness for a specific purpose and will not be liable for any direct, indirect,

incidental or consequential damages. Extech's total liability is limited to repair or

replacement of the product. The warranty set forth above is inclusive and no other

warranty, whether written or oral, is expressed or implied.

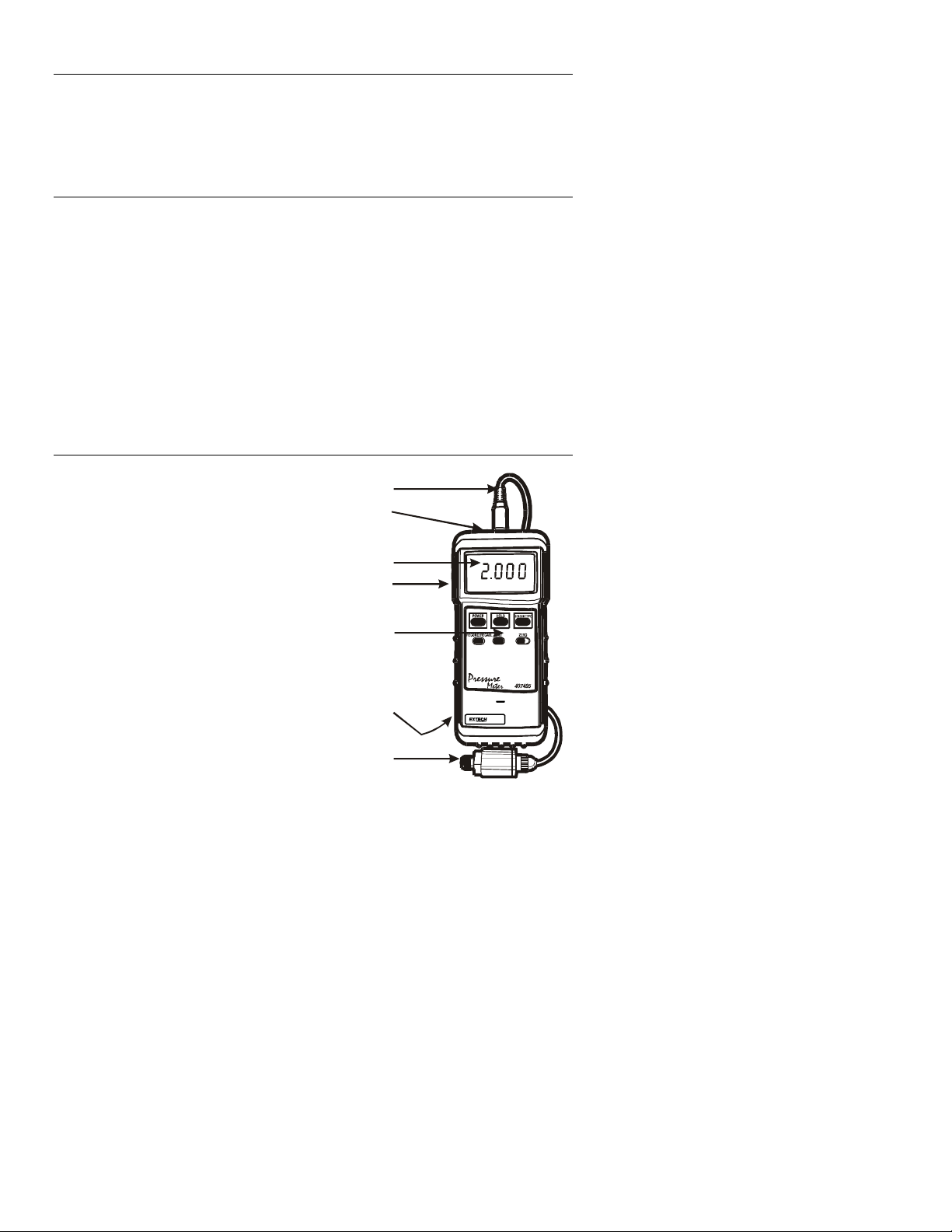

Meter Description

1. Transducer cable shown plugged into meter

input jack

2. RS-232 Output Jack

3. LCD Display

4. Protective rubber holster

5. Keypad

6. Battery compartment on rear of meter

7. Transducer shown attached to meter cable

2

1

2

3

4

5

6

7

407495 V2.1 11/2007

Page 3

Preparation for Use

Measurement Procedure Overview

The following list provides an overview of pressure measurement steps. Each step is

discussed in subsequent paragraphs. Note that the first 4 steps should only be performed

the first time the meter is used and each time the transducer is changed.

1. Select a Transducer model that covers the desired range

2. Plug the Transducer into the meter's input jack

3. Program the Transducer range

4. Select the measurement units

5. Zero the meter

6. Connect the Transducer to the process under test

7. Apply pressure to the process under test

8. Read pressure reading on the meter's LCD

Selecting Transducer Range

1. With the meter turned OFF, simultaneously press and hold the HOLD, SENSOR, &

RECORD buttons down.

2. While holding the three buttons down, press the POWER key momentarily. Release

the 3 buttons when the LCD display switches on.

3. A number will appear on the LCD that represents the Transducer type. Select the

Transducer type by pressing the SENSOR TYPE key until the desired transducer

number appears. Select the transducer from the list below in step 5.

4. Press the ZERO button to store the new transducer type. The meter will memorize the

new type even when the meter is turned OFF.

5. Select the transducer from the following list:

• Select 2 for the 30 psi (2 bars) transducer

• Select 10 for the 150 psi (10 bars) transducer

• Select 20 for the 300 psi (20 bars) transducer

NOTE: The meter does not

Connecting the Transducer to the Meter

1. Press the POWER button to turn the meter OFF.

2. Remove the existing transducer, if necessary, by unplugging it from the meter’s input

jack (top of meter).

3. Plug the new transducer into the meter’s input jack.

Selecting the Unit of Measure

Press the UNIT key to select the desired unit of measure: Bar, psi, Kg/cm

O, inch H2O, or Atmospheres (ATP).

mH

2

need to be recalibrated each time the transducer is changed.

2

, mmHg, inHg,

3

407495 V2.1 11/2007

Page 4

Operation

Push-button Zero

1. Attach a transducer to the meter, turn the meter ON, and select the range that matches

the attached transducer as described in the 'Preparation for Use' section.

2. With the transducer attached to the meter (but not attached to the process) press the

ZERO button. Note that the ZERO button should always be pressed after swapping

transducers.

3. If the display reads zero after pressing the ZERO button proceed to the next section. If

the display does not zero, the transducer may be defective.

Connect Transducer Port to Process

1. Ensure that the process under test is not pressurized

2. Connect the Transducer's ¼” PS, 19 teeth per inch threaded port to the process under

test.

3. Apply pressure to the process.

4. Read the pressure on the meter's LCD.

Data Hold

1. When a reading is on the display that you wish to hold, press the Data Hold button.

2. The reading will freeze and the HOLD icon will appear on the display.

3. Press the Data Hold button again to release the reading and return the meter to normal

operation.

Minimum/Maximum Reading Memory

1. Press the RECORD/RECALL button to start tracking the highest (MAX) and lowest

(MIN) readings. The REC indicator will appear on the LCD.

2. Take pressure measurements.

3. When pressure measurements are complete, press the RECORD/RECALL button to

recall the Maximum reading recorded (the MAX indicator will appear on the LCD).

4. Press the RECORD/RECALL button again to recall the Minimum reading recorded (the

MIN indicator will appear on the LCD).

5. To exit this mode and return the meter to normal operation, press and hold the

RECORD/RECALL button until the REC indicator goes out.

Auto Power-Off

In order to conserve battery life, the meter automatically shuts off after 10 minutes. To

defeat this feature put the meter in the Record mode by pressing the RECORD/RECALL

button; the REC indicator will appear. As long as the REC icon is displayed, the meter will

stay on indefinitely.

RS-232 PC Interface

This meter is equipped with an RS-232 PC Interface output port (meter top). A Data

Acquisition kit that includes Windows

meter-to-PC interface cable can be obtained from Extech for use with this meter. The Part

Number for the kit is 407001A. Instructions for use are supplied with the kit.

TM

95 / 98 / ME / NT / 2000 compatible software and a

4

407495 V2.1 11/2007

Page 5

Specifications

General Specifications

Display Multi-function LCD

Transducers 30, 150 and 300 max. psi (sold separately)

Transducer signal Full scale: 100mVDC

Display units Bar, psi, Kg/cm

Atmosphere

Zero adjust Front panel push-button

Data Hold Displayed reading can be held by front panel push-button

Min/Max Memory Lowest/Highest readings can be stored for later recall

PC Interface kit Built-in RS-232 port for use with optional Windows

acquisition software

Auto Power-Off To conserve battery life, the meter turns OFF automatically

after approx. 10 minutes (programmable over-ride).

Sampling time 0.8 seconds approx.

Power supply 9V Battery

Low battery indication Rectangular battery-life box appears on the left side of LCD.

Power consumption Approx. 7mA

Operating Temperature 32 to 122

Operating Humidity Less than 80% RH

Dimensions 7.1 x 2.8 x 1.3" (180 x 72 x 32mm)

Weight Approx. 0.76 lbs. (345g)

Accessories Protective rubber holster and 9V battery

2

, mmHg, inches Hg, meters H2O, inches H2O,

o

F (0 to 50oC)

TM

data

Transducer Range, Resolution, and Accuracy Specifications

psi bar Kg/cm

2

mm Hg in Hg m H2O in H2O atm

30 2 2.040 1500 59.05 20.4 802 1.974 Range

Resolution

0.02 0.002 0.002 2 0.05 0.02 1 0.002

150 10 10.19 7500 295.2 101.9 4010 9.87 Range

Resolution

0.2 0.01 0.01 10 0.2 0.1 5 0.01

300 20 20.40 15000 590.5 204.0 8020 19.74 Range

Resolution

0.2 0.02 0.02 20 0.5 0.2 10 0.02

Accuracy: Meter only: ± (0.5% reading + 1 digit)

Transducer only: ± 2% full scale

Combined: ± (2.5% full scale + 1 digit)

Accuracy note: Specified accuracy applies to meter at 23

o

C (±5oC)

Calibration note: Re-calibration is not required each time a new transducer is attached.

5

407495 V2.1 11/2007

Page 6

Transducer Specifications

Model Maximum Capacity

PT30 30psi (2 BAR)

PT150 150psi (10BAR)

PT300 300psi (20 BAR)

Overload protection 150% of max capacity

Diaphragm Ceramic

Supply voltage 5V

Thread ¼” PS, 19 teeth per inch

Span (full scale) ± 1% (10 to 40ºC) includes linearity, hysteresis & repeatability

Zero ± 2% Full Scale (10ºC to 40ºC)

Operating Temperature 32ºF to 140ºF (0ºC to 40ºC)

Operating Humidity Max 80% RH

Output Full capacity output = 100 mV DC

Size 30 mm diameter x 85mm

Weight 5.65oz. (160g)

Cable length 39” (1m)

Calibration and Repair Services

Extech offers repair and calibration services for the products we sell. Extech also

provides NIST certification for most products. Call the Customer Service Department for

information on calibration services available for this product. Extech recommends that

annual calibrations be performed to verify meter performance and accuracy.

All rights reserved including the right of reproduction in whole or in part in any form.

Technical Support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Extech Instruments Corporation, 285 Bear Hill Road, Waltham, MA 02451

Support line (781) 890-7440

Extech Instruments Corporation.

Copyright ©

2007

6

407495 V2.1 11/2007

Loading...

Loading...