Page 1

R

TM_EN

Part No.: 1764198_04

QUARTZ

ONE TOUCH

TECHNICAL MANUAL

Page 2

2

QUARTZ

ONE TOUCH

CONTENT

CONTENT ................................................................................................................................................................................2

SYMBOL DESCRIPTION ..................................................................................................................................................4

Hazard intensity levels ...................................................................................................................................................................................................................... 4

TECHNICAL SPECIFICATIONS ...................................................................................................................................5

OVERVIEW OF COMPONENTS ................................................................................................................................6

DIMENSION SKETCH ........................................................................................................................................................7

TRANSPORT ...........................................................................................................................................................................8

Packaging .............................................................................................................................................................................................................................................. 8

Delivery inspection ........................................................................................................................................................................................................................... 8

Positioning ........................................................................................................................................................................................................................................... 8

INSTALLATION AND START-UP ................................................................................................................................9

Electrical connection ......................................................................................................................................................................................................................... 9

Pressure and temperature ............................................................................................................................................................................................................... 9

Connecting to the domestic water supply .................................................................................................................................................................................10

Installing the drip tray drain...........................................................................................................................................................................................................11

Starting the machine ........................................................................................................................................................................................................................12

USER PROGRAMMING .................................................................................................................................................13

Button functions ...............................................................................................................................................................................................................................13

Display functions ..............................................................................................................................................................................................................................14

Machine status ..................................................................................................................................................................................................................................14

Accessing the user menu functions .............................................................................................................................................................................................14

Programming the drink dosages ...................................................................................................................................................................................................15

Accessing the display day and time ..............................................................................................................................................................................................15

Machine automatic ON/OFF .........................................................................................................................................................................................................16

Day off ................................................................................................................................................................................................................................................16

Cappuccino ON/OFF ......................................................................................................................................................................................................................16

Cappuccino dispensing order ........................................................................................................................................................................................................17

Cappuccino milk frothiness ...........................................................................................................................................................................................................17

Cappuccino milk steam timing ......................................................................................................................................................................................................18

Cappuccino end wash .....................................................................................................................................................................................................................18

Cafe Crema .......................................................................................................................................................................................................................................19

Black coffee .......................................................................................................................................................................................................................................19

Prebrewing time ...............................................................................................................................................................................................................................20

Prebrewing pause time ...................................................................................................................................................................................................................20

Cleaning interval ...............................................................................................................................................................................................................................21

Initial flushing .....................................................................................................................................................................................................................................21

Advanced cleaning ON/OFF ..........................................................................................................................................................................................................22

Advanced cleaning times - T1, T2, T3, T4 .................................................................................................................................................................................22

Timed flushing ...................................................................................................................................................................................................................................23

Accessing and resetting the partial counter, accessing the total counters.........................................................................................................................24

Exiting the User Menu ....................................................................................................................................................................................................................24

STORAGE AND DISPOSAL ........................................................................................................................................ 25

Storing the machine .........................................................................................................................................................................................................................25

Machine disposal ..............................................................................................................................................................................................................................25

Original instructions

Page 3

3

QUARTZ

ONE TOUCH

CONTENT

SERVICE PROGRAMMING ....................................................................................................................................... 26

Accessing the service menu functions .....................................................................................................................................................................................26

Language selection ........................................................................................................................................................................................................................26

Editing the greeting message ......................................................................................................................................................................................................26

Setting the service phone number ............................................................................................................................................................................................27

Enable/disable user programming ..............................................................................................................................................................................................27

Adjusting the boiler level probe sensitivity .............................................................................................................................................................................27

Maintenance cycles .......................................................................................................................................................................................................................28

Setting the display temperature format ...................................................................................................................................................................................29

Adjusting the boiler operating temperature ...........................................................................................................................................................................29

Adjusting the capsule storage alarm .........................................................................................................................................................................................30

Adjusting the water filter service alarm ..................................................................................................................................................................................30

Resetting to factory default settings .........................................................................................................................................................................................31

Exiting the service programming ...............................................................................................................................................................................................31

Exiting standby mode ...................................................................................................................................................................................................................31

MESSAGES AND ALARMS ........................................................................................................................................ 32

CLEANING AND MAINTENANCE ....................................................................................................................33

Removing the capsule group ......................................................................................................................................................................................................33

Replacing the pinch chamber kit ...............................................................................................................................................................................................37

Replacing the capsule holder kit ................................................................................................................................................................................................37

Replacing the group gasket .........................................................................................................................................................................................................38

SERVICE INTERVALS ..................................................................................................................................................... 39

ELECTRICAL DIAGRAM ............................................................................................................................................40

EXPLODED VIEWS ........................................................................................................................................................ 41

Electrical components ..................................................................................................................................................................................................................41

Machine front .................................................................................................................................................................................................................................42

Machine ...........................................................................................................................................................................................................................................44

Water schematic ...........................................................................................................................................................................................................................46

Boiler ...............................................................................................................................................................................................................................................48

Thermic assembly .........................................................................................................................................................................................................................50

Cappuccino distributor ................................................................................................................................................................................................................52

Cappuccino set ..............................................................................................................................................................................................................................54

Manifold system .............................................................................................................................................................................................................................56

Capsule group chassis ..................................................................................................................................................................................................................58

Capsule group Caffitaly................................................................................................................................................................................................................60

Capsule group Lavazza .................................................................................................................................................................................................................62

Tank inlet ........................................................................................................................................................................................................................................64

Vibration pump ..............................................................................................................................................................................................................................65

Water tank .....................................................................................................................................................................................................................................66

Water tap .......................................................................................................................................................................................................................................68

Steam wand ....................................................................................................................................................................................................................................70

Page 4

4

QUARTZ

ONE TOUCH

SYMBOL DESCRIPTION

There are three different levels of hazard intensity, identied by the signal words DANGER, WARNING and

IMPORTANT. The level of hazard is determined by the following denitions.

Additionally, NOTE indicates useful information that all users should be aware of.

Observe these statements to ensure user safety and prevent injury and/or material damage.

Important:

Alerts against unsafe practices. Observe to ensure drink quality, machine performance, food

safety, to prevent minor personal injury or damage to the machine.

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could result in scalding, serious

injury and even death.

DANGER!

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, WILL RESULT IN SERIOUS INJURY AND EVEN DEATH.

Note:

Gives additional information which may be helpful during the cleaning procedure or operation of

the machine.

i

Hazard intensity levels

Page 5

5

QUARTZ

ONE TOUCH

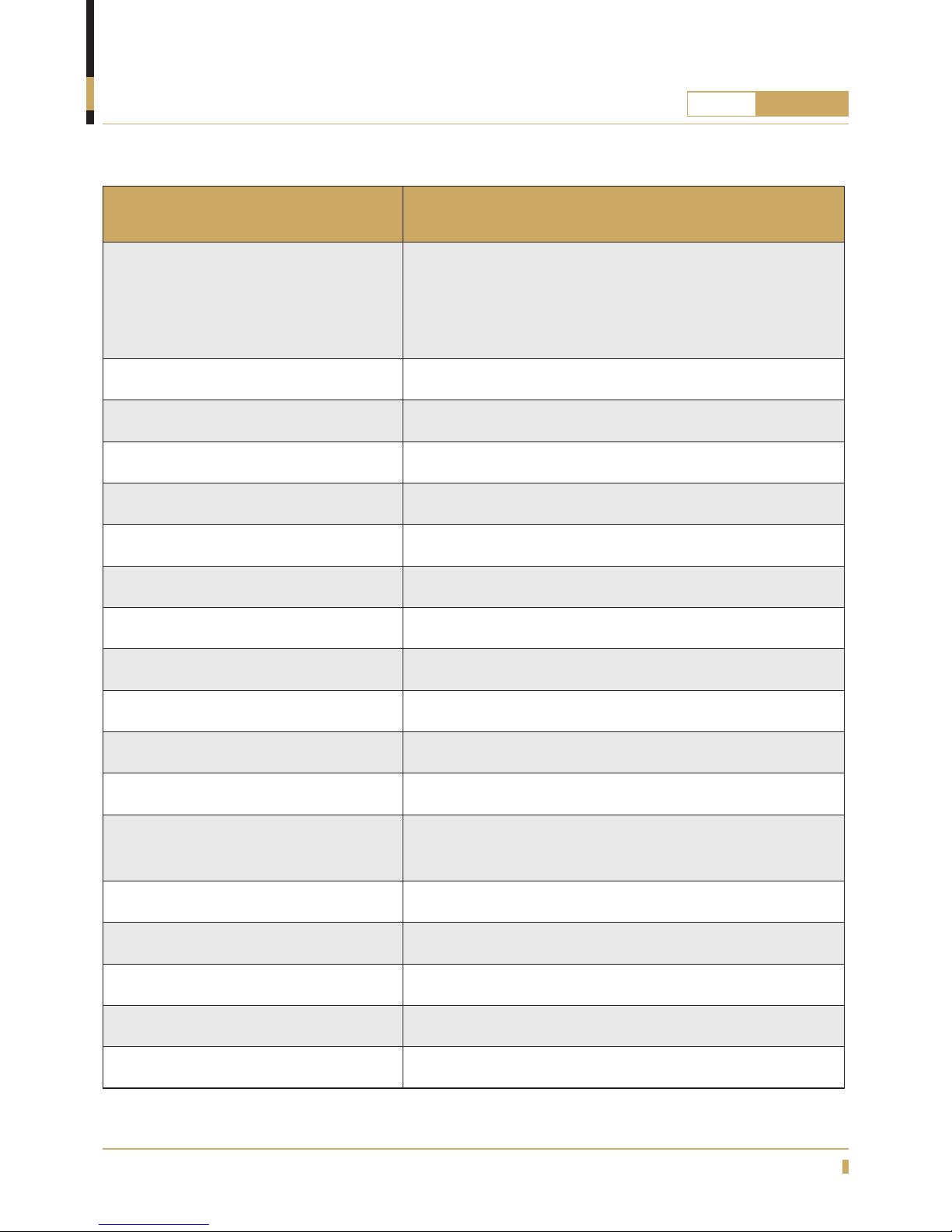

TECHNICAL SPECIFICATIONS

Data sheet

FACTS QUARTZ ONE TOUCH

Drink selection options

Continuous Brewing

Short Espresso

Long Espresso / Cafe Crema

Cappuccino / Long Espresso

Coffee with Milk / Black Coffee

Brewing mechanism Capsule

Capsules supported Caftaly, Lavazza

User interface Capacitive touchpad with display

Temperature control PID regulation

Height adjustable outlet Adjustable from 65 to 110mm

Used capsule drawer

15 capsules with sensor

Energy saving mode Yes

Dimension (height, width, depth) 410, 260, 400mm

Internal water tank 1.8 L with water lter

Minimum inlet water pressure 1 bar

Boiler volume 1,7 L

Power rating

220-240 V 1N ~ 1950W 50-60Hz

(EAEB-B71C-13AL)

Cold water connection

1

/2" external thread or water tank

Drip tray Level viewer & option for drainage connection

Dispenser Automatic cappuccino, water/ steam manual taps

Ambient noise < 70 dB

Machine weight 16 kg

Page 6

6

QUARTZ

ONE TOUCH

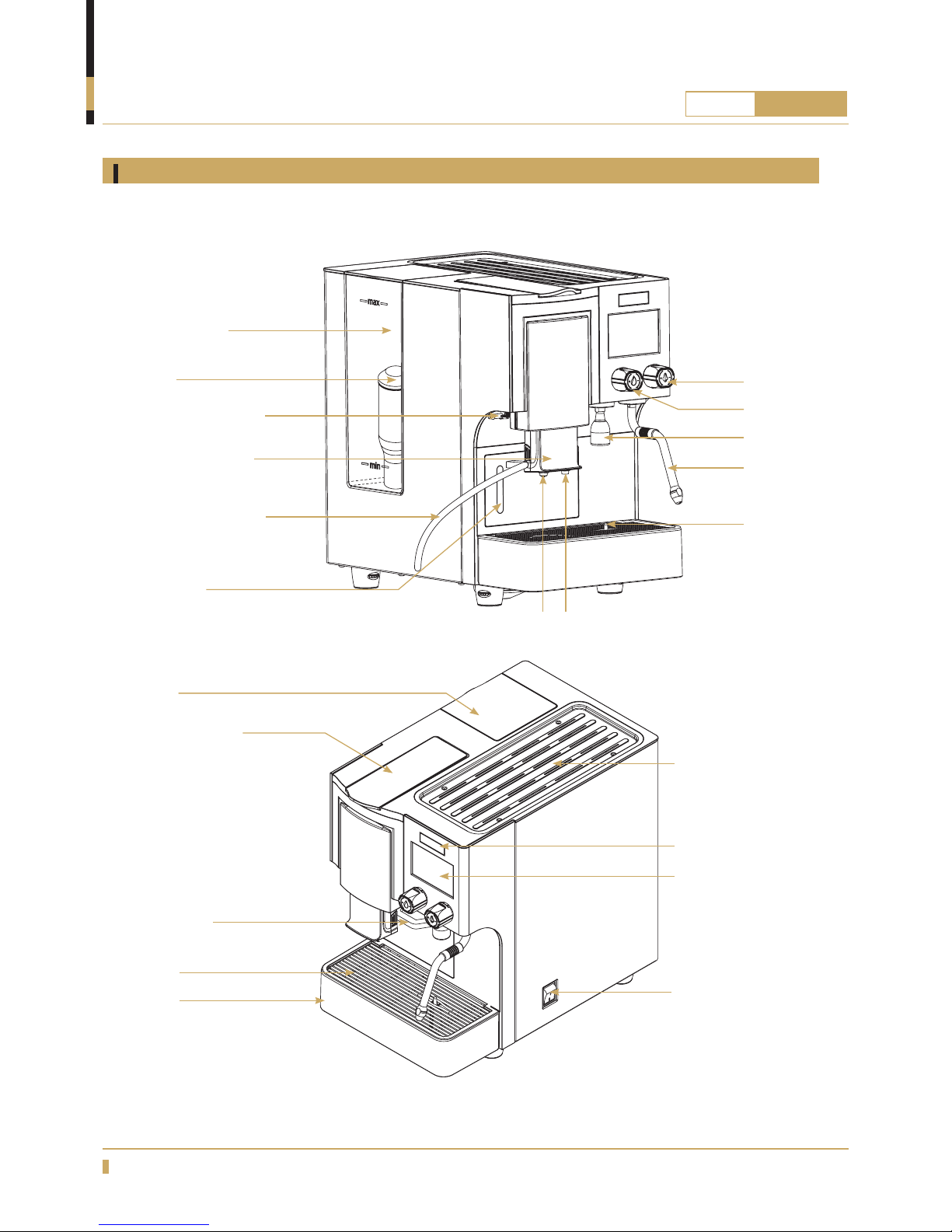

OVERVIEW OF COMPONENTS

Front view

Cup shelf

Capsule group lever

Tank lid

Internal water tank

Display

Touch pad

Steam tap

Steam pipe

Main switch

Drip tray

level float

Drip tray

Drip grid

Coffee outlet Milk outlet

Hot water outlet

Hot water tap

Water filter

(optional)

Milk system cleaning inlet

connector

Height-adjustable outlet

Capsule drawer

with window

Cappuccino milk inlet tube

Drawer handle

Page 7

7

QUARTZ

ONE TOUCH

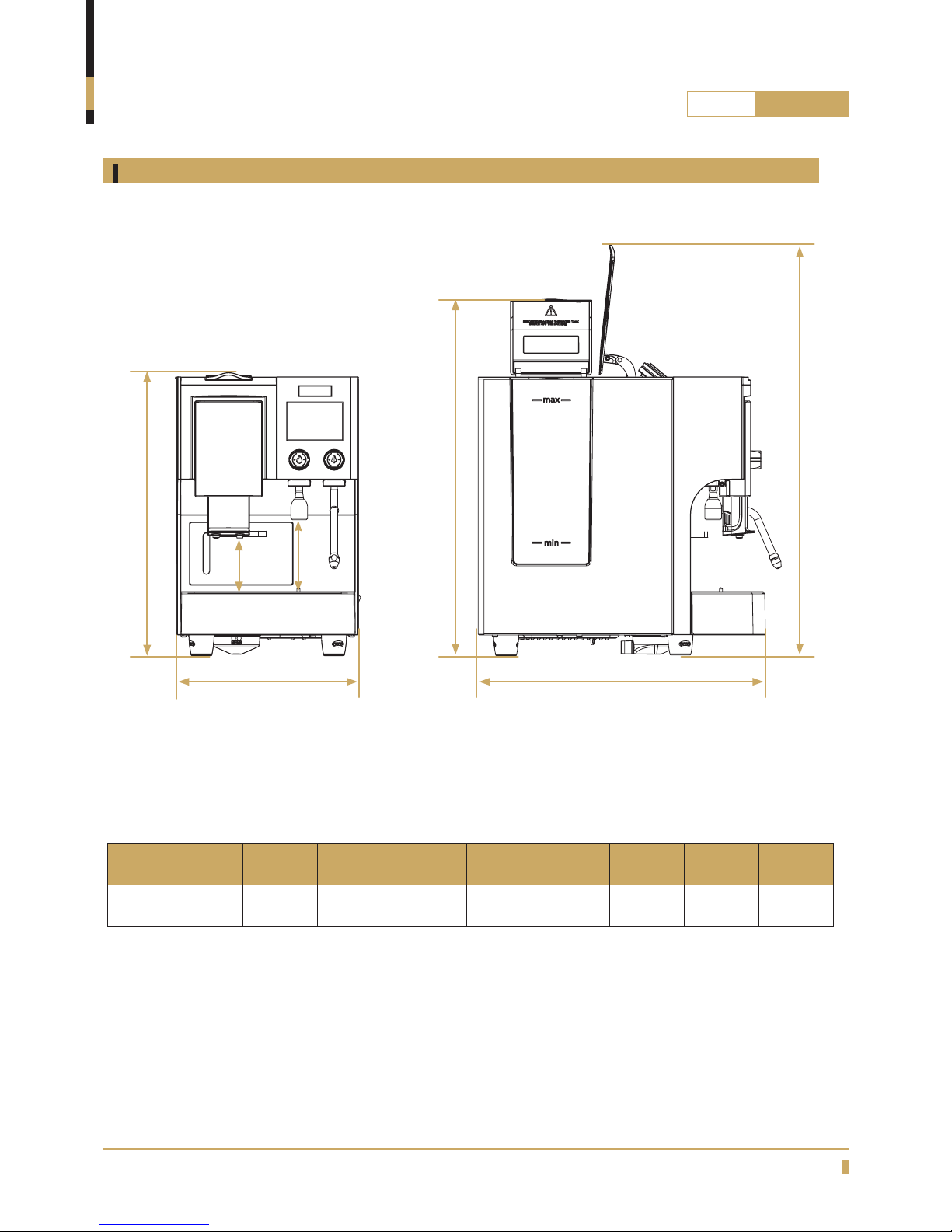

DIMENSION SKETCH

QUARTZ

D

A

F

G

B

C

Model A B C D (Min~ Max) E F G

ONE TOUCH 400 mm 260 mm 410 mm 65 mm ~ 110 mm 92 mm 510 mm 590 mm

E

Page 8

8

QUARTZ

ONE TOUCH

Packaging

Delivery inspection

Positioning

INSTALLATION AND START-UP

TRANSPORT

The machine is shipped in a custom-designed carton which utilizes model-specic polystyrene

cushions to protect it from damage.

The machine’s carton features standardized handling symbols to explain proper shipping and storage methods.

The machine must remain in a horizontal position during the transport. Do not store or handle the machine

except on its feet.

During transport protect the carton and machine from impact drops, crushing, shocks, moisture and exposure

to extreme temperature.

Upon receipt and delivery ensure that the machine is in the exact condition described in the enclosed

documentation, and that all accessories are included. Missing items should be reported to the manufacturer or

dealer immediately.

Damage caused during transport should be reported to the shipping agent and the machine’s distributor

immediately.

Packaging materials are potentially dangerous and should be kept away from children.

The carton and all packing materials are recyclable and should be returned to a recycling center for

disposal.

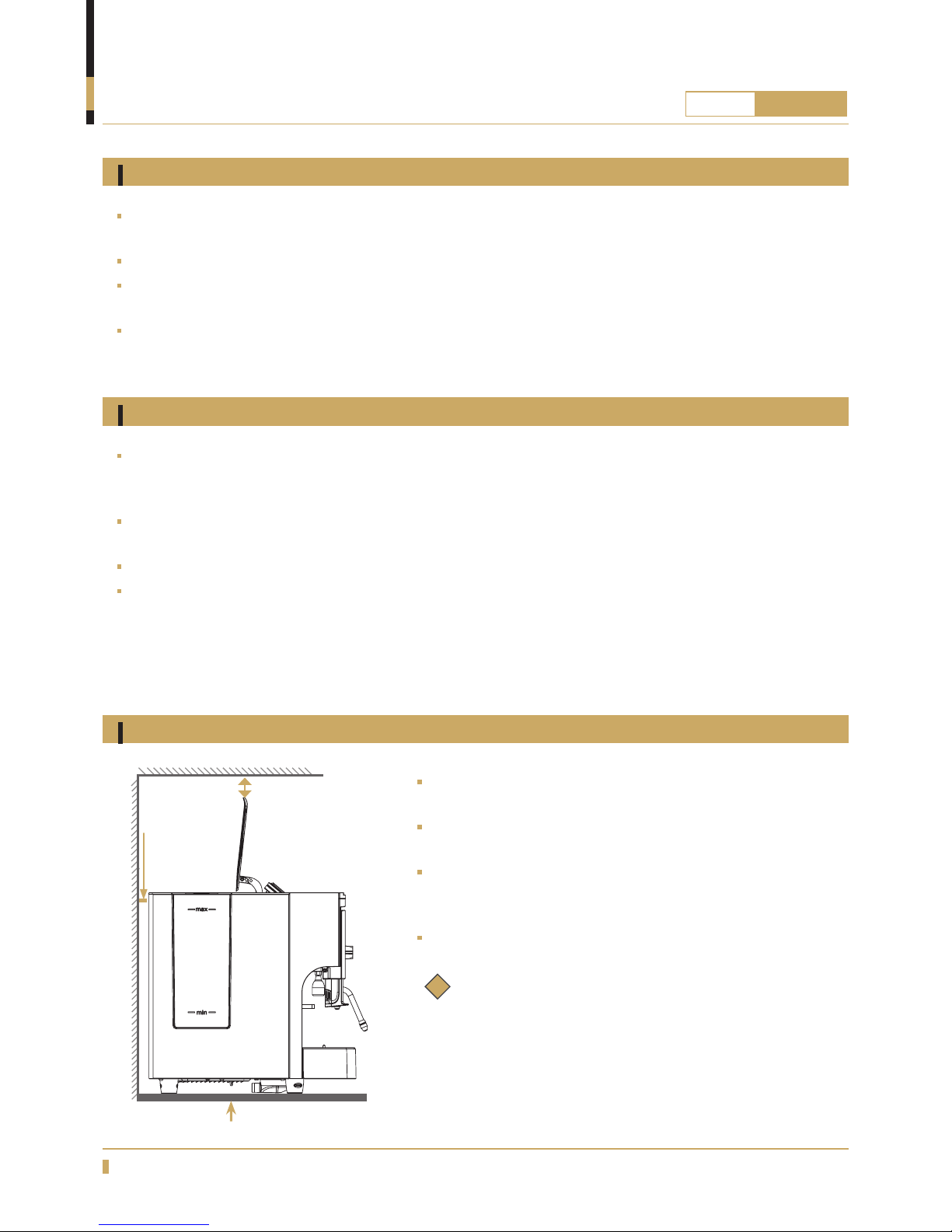

MIN. 10cm

MIN. 30cm

Minimum dimensions for machine placement are 360 mm

wide x 510mm depth x 890mm high.

Position the machine on a at, stable surface and away from

water and heat sources.

This machine should only be stored and used in a dry

environment, since excessive humidity will damage the

machine.

Do not cover the machine with plastic lm or rags.

Install within 0-3º horizontal.

i

Note:

Leave an air gap of at least 30cm above the machine

and 10cm behind it to ensure adequate ventilation. The

machine must be installed within 3º of horizontally level

front-to-back and side-to-side to ensure proper hydraulic

function and drainage. Conrm with a spirit level or digital

angle gauge.

Page 9

9

QUARTZ

ONE TOUCH

INSTALLATION AND START-UP

Electrical connection

Pressure and temperature

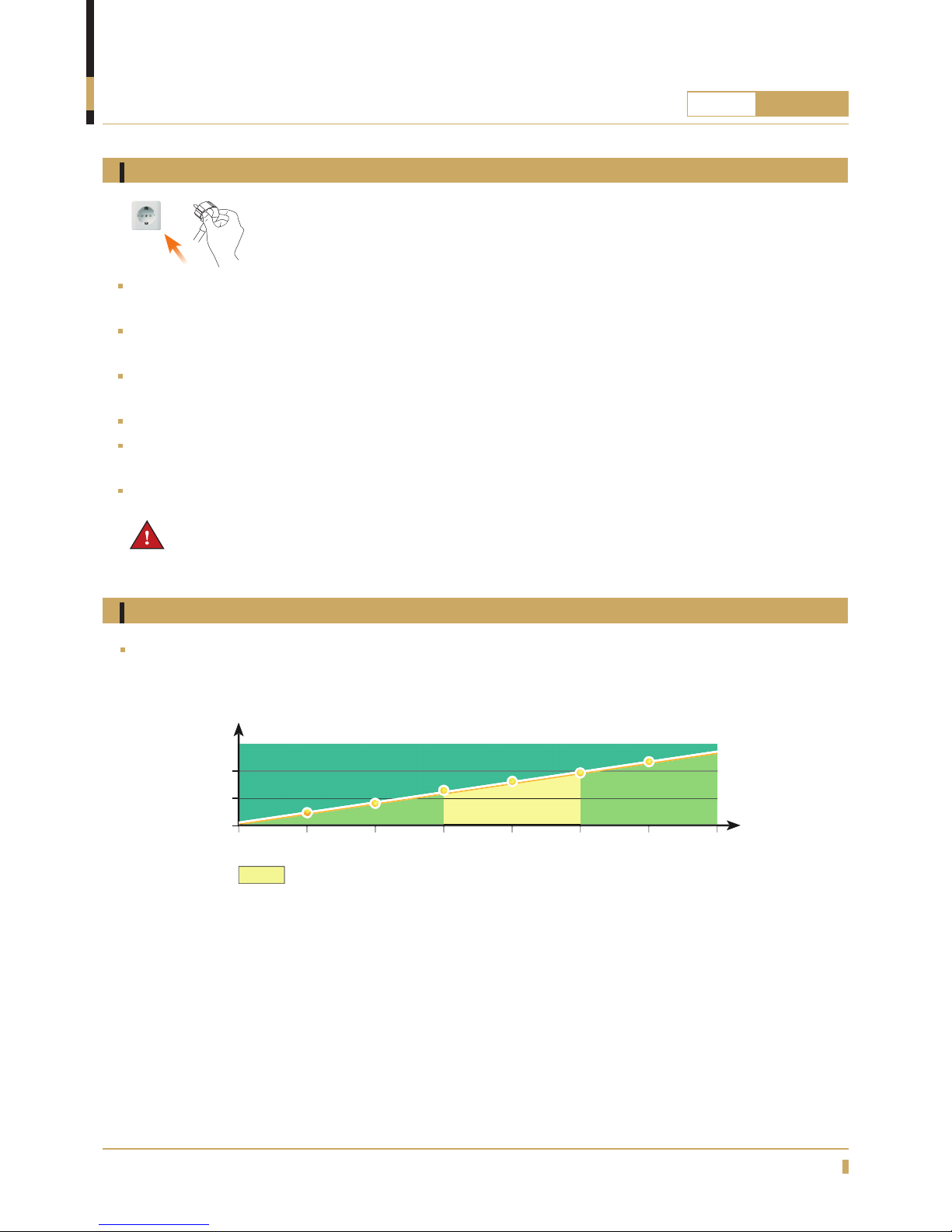

Boiler pressure is directly related to water temperature. The chart below demonstrates pressure

increase as a result of temperature rise:

Standard pressure and temperature

Pressure to temperature relationship within boiler

110

115

120

125

0.7 0.8 0.9 1.0 1.1 1.2

BAR

O

C

This machine must be connected to an earth grounded wall socket. See page 5 of

this manual for electrical specications.

Verify that the electrical specications on the nameplate are compatible with the operating conditions of the

area where you will install the machine.

This machine must be connected to a earth grounded wall socket. Ensure that the grounding system is

sufcient and conrms with local regulations.

This machine must be connected to an electrical supply protected by a circuit breaker appropriate for the

power consumption of the machine, specied on its nameplate.

A residual current circuit breaker must be installed in accordance with local regulations.

Ensure that the power rating of the installation location and the electrical system are suitable for the power

demands of the machine.

Do not use an extension cord, plug adapter or multi-socket device to power this machine.

DANGER!

If the power cable or plug is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualied person to avoid

SERIOUS INJURY OR DEATH!

Page 10

10

QUARTZ

ONE TOUCH

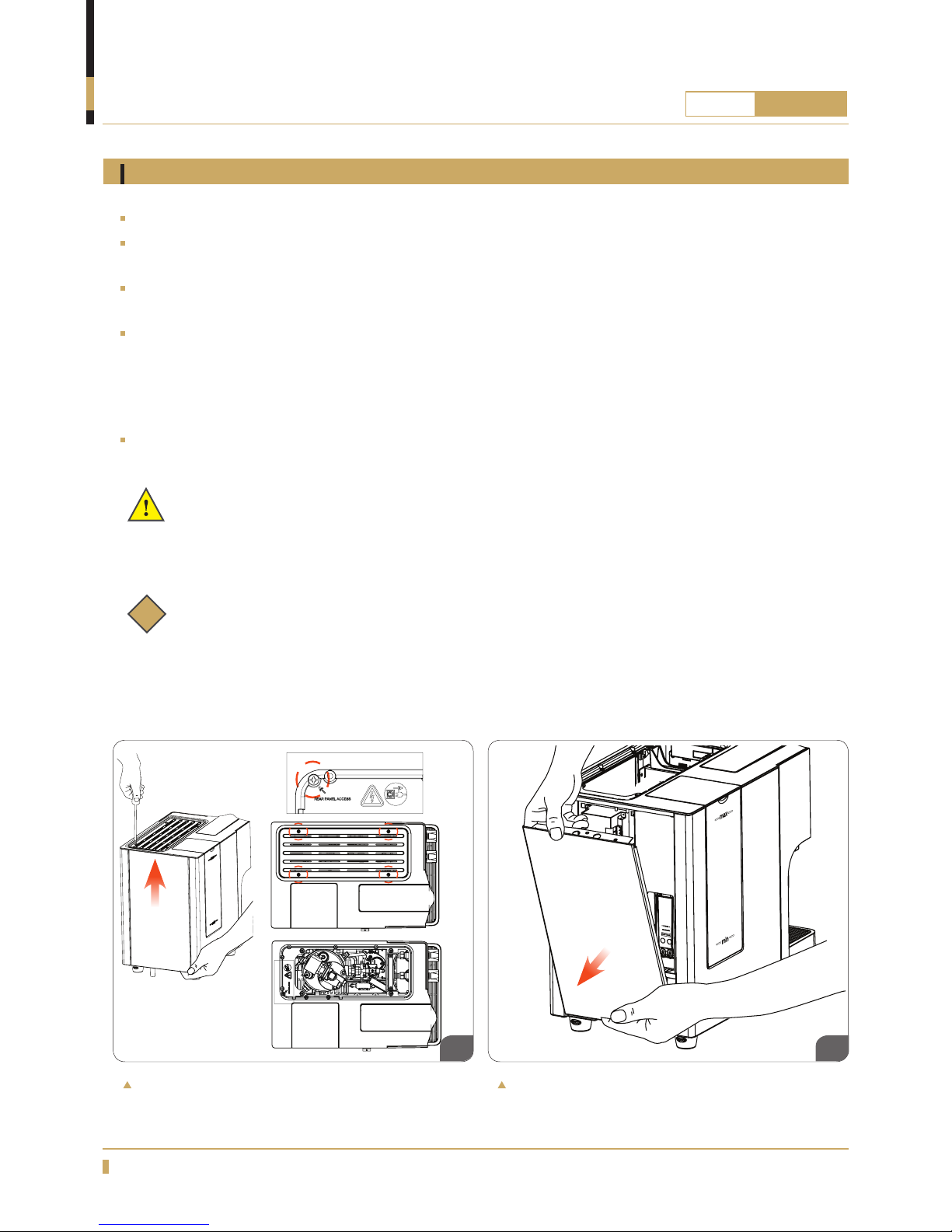

Important:

Be careful to not damage any panels and electronic components while disassembling the machine.

The power cord must be unplugged when disassembling the machine.

Remove the four screws form the cup shelf. Remove the screw at the top of the rear panel,

then remove it.

INSTALLATION AND START-UP

Note:

If you want to disconnect the machine from the mains water supply and start using only the internal

water tank again, make sure to replace the inlet valve cover plug. The machine will leak if this plug is

not reinstalled.

01 02

i

To prepare the machine for connection to an external water supply follow the connection procedure

explained below.

Connecting the machine to the domestic water supply must performed by a qualied person.

Run about 20 liters of water from the domestic water supply before connecting the machine to make sure

there are no contaminants in the plumbing system.

Connect the exible inlet hose (included in the accessory box) to the domestic water supply and tighten it

with a wrench. The hose only connects to a ½” male connection.

Only use safe drinking water with a hardness rating between 5 - 8ºTH (French hardness degress) / 2.8 -

4.5ºdH (German hardness degrees ) / 3.5 - 5.6ºe (English hardness degrees) / 50 - 80 ppm (parts per million)

of calcium. If the hardness value is below this limit, corrosion of hydraulic components is likely. If the value is

higher, lime-scaling inside the boiler will occur. In both cases, the proper function of the machine and quality

and taste of the coffee will be negatively affected.

If you choose to connect the machine to an external water connection, it is strongly recommend to connect

the drip tray to an external drain. See page 11 for more information.

Connecting to the domestic water supply

Page 11

11

QUARTZ

ONE TOUCH

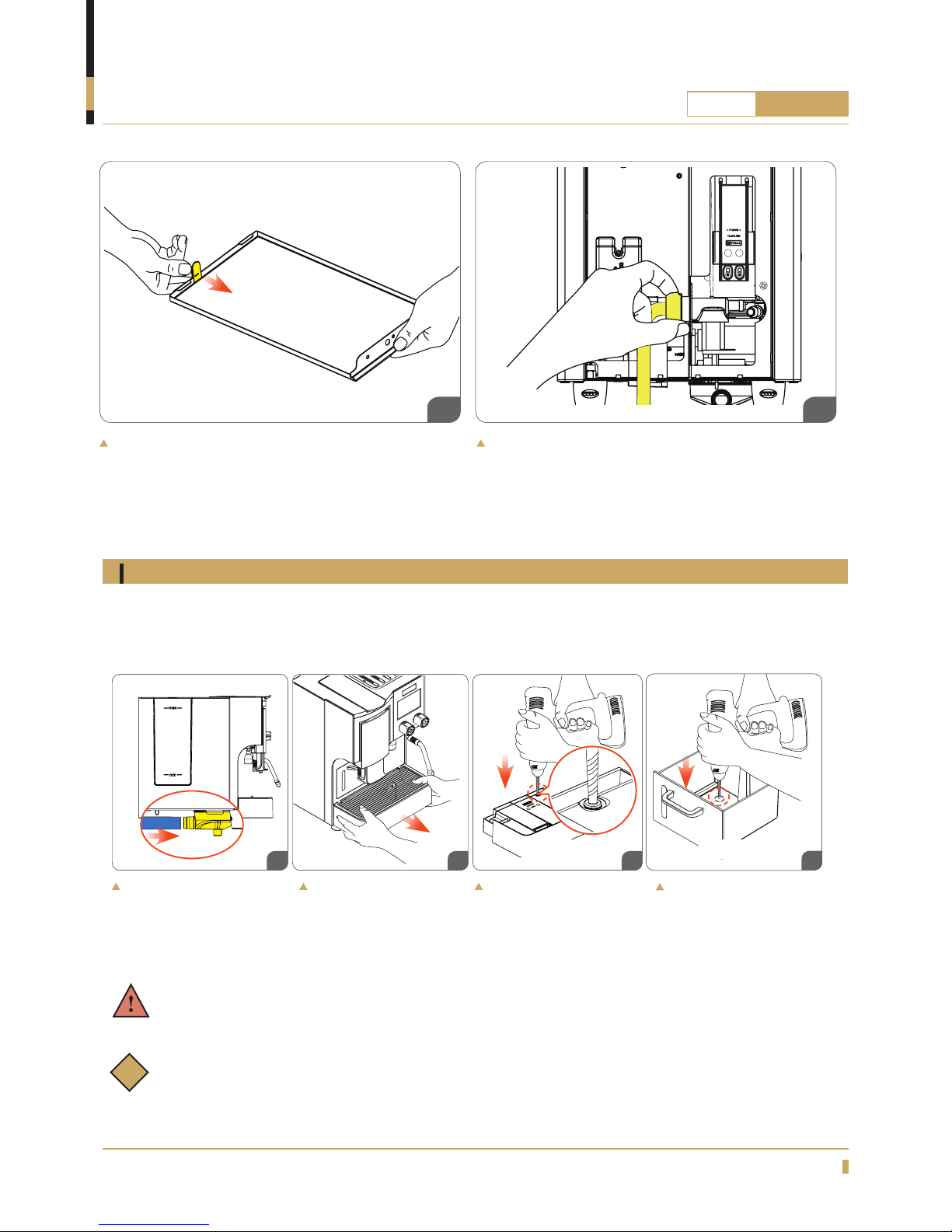

Remove the cover plug for the inlet valve and connect

the included inlet hose. The machine will now

automatically ll the internal water tank to

minimum level + 40mm, when water goes below

minimum level it will rell again, etc.

Bend the ange (shown in yellow) inward to make

room for the inlet tube.

03 04

INSTALLATION AND START-UP

Installing the drip tray drain

The drip tray can be connected to a plumbing drain, allowing the tray to be emptied much less frequently

(a domestic drain connection is required for this). To use this feature, follow the connection procedure

explained below.

Note:

The drain pipe system can be used when the machine is connected to the domestic water supply

or the internal water tank.

WARNING!

The holes drilled in the drip tray or capsule drawer should be ≤3mm to avoid leaks.

Remove the drip tray.

Drill a 3mm hole in the

bottom of the capsule

box as shown above.

Reinstall the capsule

box when nished.

Connect the included

corrugated drain tube

to the drain cup.

Drill a 3mm hole in

the bottom of the drip

tray as shown above.

Reinstall the drip tray

when nished.

01 02 03

04

i

Max. Ф: 3mm Max. Ф: 3mm

Page 12

12

QUARTZ

ONE TOUCH

INSTALLATION AND START-UP

Starting the machine

Note:

Keypad functions and explanations are found on page 13.

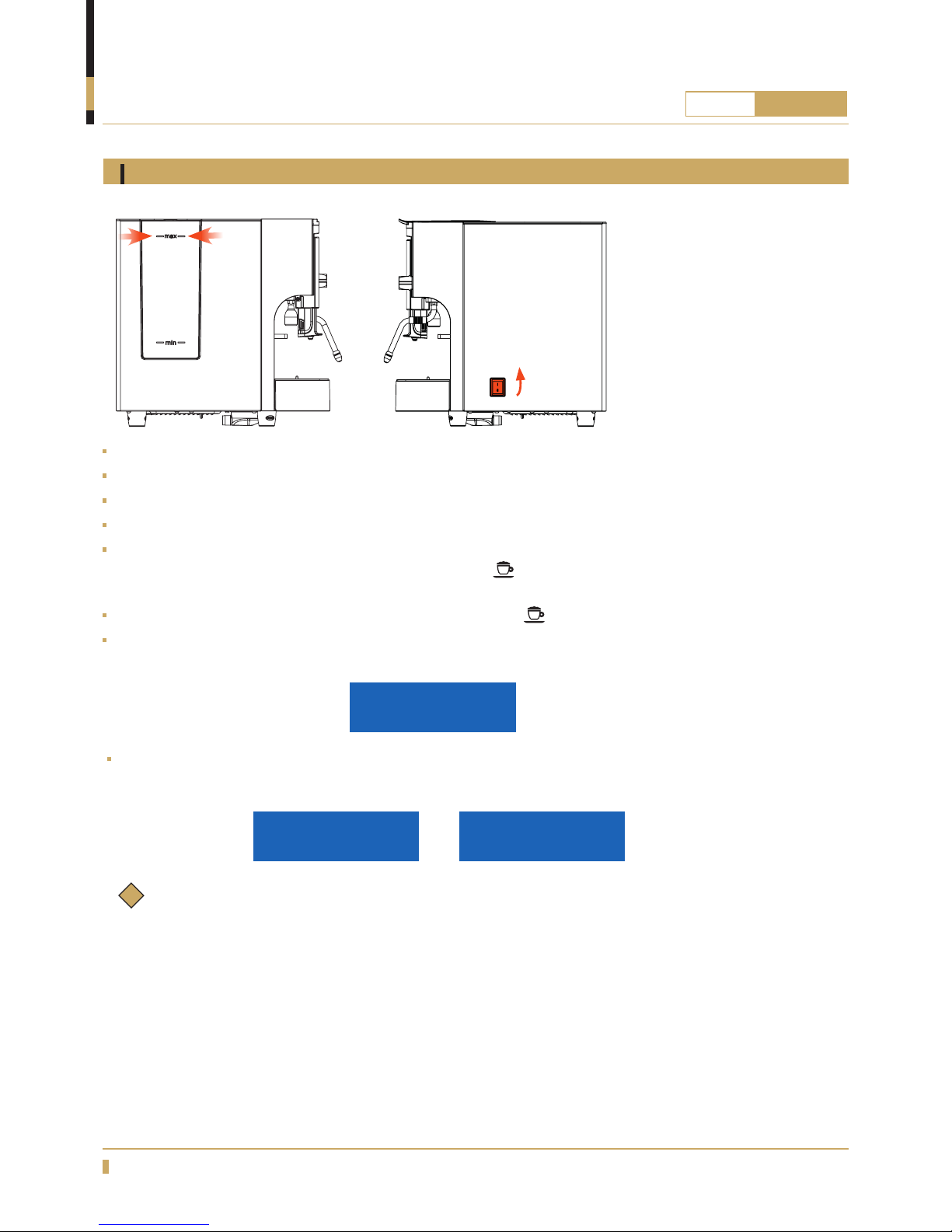

Fill the water tank to the max level (A).

If the machine is connected to the domestic water supply, water lling will begin automatically.

Connect the machine’s plug to the electrical outlet (this should be done by a qualied person).

Turn on the main power switch (B).

When the machine is switched on, it may automatically go into STANDBY mode. To determine if the machine

is in STANDBY mode, conrm if the OK and Cappuccino

buttons are ashing simultaneously. If this is the

case, the machine must be changed to ON

mode.

To change to ON mode, simply press the OK and Cappuccino buttons simultaneously.

When the machine is in ON mode, ve of the buttons will light up and the one remaining unlit button will begin

to cycle. The display will show PREHEATING XXX

o

C until the boiler reaches operating temperature (C).

When all the drink buttons are lit continuously (none ashing) the machine is ready for use.

The display will show the water temperature, time, (D) and EXPOBAR QUARTZ ONE TOUCH (E).

A

B

i

C

D

E

PREHEATING

XXX

o

C

118oC 07:53

ENJOY YOUR DRINK

EXPOBAR

QUARTZ ONE TOUCH

Page 13

13

QUARTZ

ONE TOUCH

USER PROGRAMMING

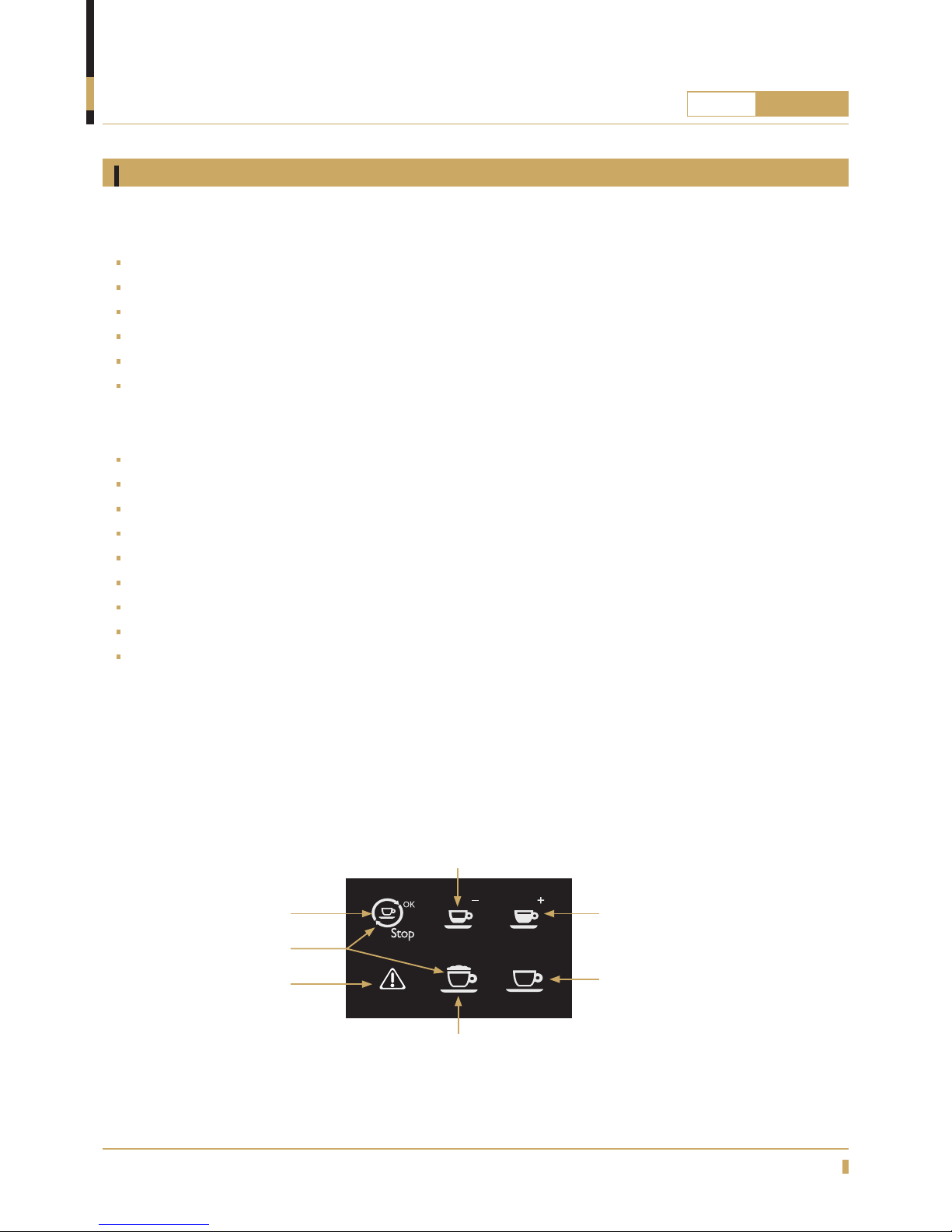

Button functions

OK / Stop /

Continuous Brewing

& Programming menu

Standby (simultaneously

press for standby off & on)

Alarm

Cappuccino / Long Coffee

Coffee with Milk / Black Coffee

Long Espresso / Cafe Crema &

Move up in program menu

Short Espresso &

Move down in program menu

From the touch pad you can perform the following functions-

User Programming:

Volume control for four different espresso drinks.

Automatic lling and level control of the boiler.

Automatic lling and level control of the water tank (for machines with external water supply).

Automatic switch off of the heating element when water level is low.

System supervision through alarms.

Semi-automatic cleaning of the milk system.

Service Programming:

Set the display language.

Edit the greeting message.

Input the service phone number.

Enable and disable the user programming function.

Adjust the boiler and drip tray sensor sensitivities.

Set the maintenance cycle, water lter service, and empty capsule box alarm intervals.

Control the display temperature units.

Adjust the boiler operating temperature.

Restore all settings to factory defaults.

The control panel is by default programmed with 4 standard drinks (these can be reprogrammed as desired) and

a continuous dispensing option. The four drink buttons (Short Espresso, Long Espresso / Cafe Crema, Coffee

with Milk / Black Coffee, Cappuccino / Long Coffee) brew the programmed volume and then stop automatically,

the button (Continuous/OK/Stop) brews continuously until the user stops it by pressing it again.

Page 14

14

QUARTZ

ONE TOUCH

XXX ºC HH:MM

STANDBY

XXX ºC HH:MM

USER PROGRAMMING

Display functions

Machine status

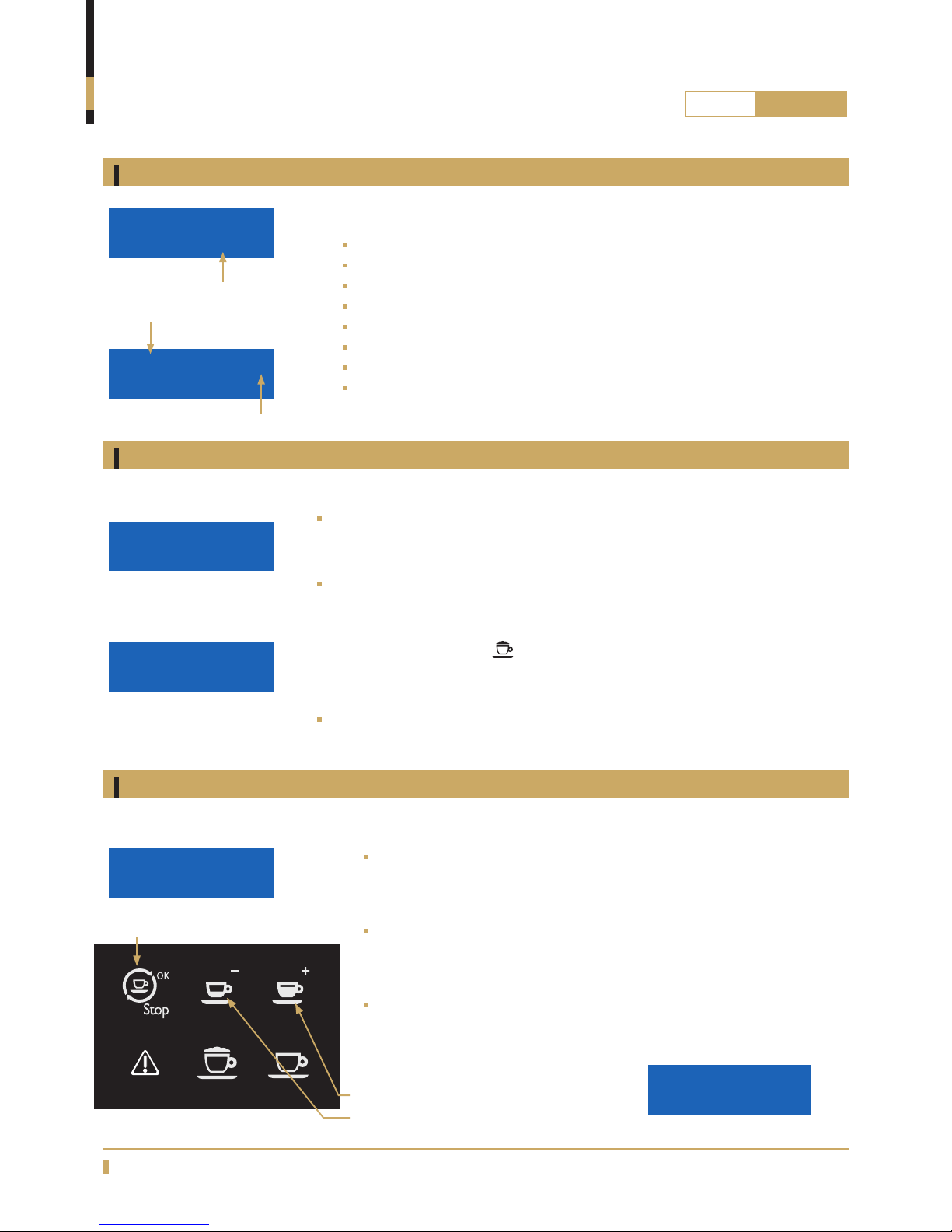

Accessing the user menu functions

Fig. 01

Fig. 02

Fig. 03

Fig. 05

Scroll forward within the Service Menu

Scroll back within the Service Menu

Adjust automatic daily on/off timer (stand-by).

Adjust clock settings (current time and date).

Change display greeting message.

View the number of coffees dispensed.

View digital boiler-temperature display and control.

Access programming and settings help system.

Reset visual water-softener regeneration alarm.

Change display language.

The machine has three operating statuses:

ON:

The machine is ready for use. This is the normal machine status after turning

on the power switch after the boiler is heated up. (see Fig. 01).

STANDBY:

The power switch is on, but the display shows STANDBY (see Fig. 02). This

means that the machine is in energy-saving mode. To enter this mode, press

OK and the Cappuccino

button simultaneously for at least 5 seconds.

To exit this mode and turn the machine back on, press the same two buttons

simultaneously again. (They will be ashing already.)

OFF:

The coffee machine is turned off at the main power switch.

Press OK for 5 seconds, or until the button starts to ash and the

display shows DOSE PROGRAMMING, (see Fig. 03), then press OK

again to enter the User Menu.

Within the User Menu, press + to scroll through the menu’s functions

and press OK to enter your desired menu option, or press

- to scroll

back (See Fig. 04).

To exit the User Menu, scroll to the end, the display will show

EXIT (See Fig. 05), then press OK. The display will show DOSE

PROGRAMMING (See Fig. 03). Wait 30 seconds and the machine will

return to normal use ON mode.

XXX ºC HH:MM

EXPOBAR

QUARTZ ONE TOUCH

DOSE PROGRAMMING

IN 30 SEC.

EXIT

Greeting message

Current time

Boiler temperature

Fig. 04

Via the machines display you can read or control the following functions:

Follow the steps below to access the machine’s User Menu functions:

Enter

Page 15

15

QUARTZ

ONE TOUCH

USER PROGRAMMING

Accessing the display day and time

Programming the drink dosages

TIME ADJUST

XX:XX / DAY

Fig. 03

1. Within the User Menu (see Fig. 02), press

+ and - to scroll through the menu’s

functions until TIME ADJUST XX:XX / DAY OF WEEK is shown (see Fig. 03), then

press OK to begin adjusting the time.

2. Press OK to begin to edit the hours, minutes and date. The number will ash

when it is ready to be edited. Press

+ or - to change the time or date’s number,

then press the OK to accept the input and move to the next number.

3. When the desired times are set press OK to save your setting. When no elds are

ashing press

+ to return to the User Menu.

Follow the steps below to adjust the time on the machine’s display:

Fig. 02

DOSE PROGRAMMING

IN 30 SEC.

Important:

Use always a new capsule when programming each new dose, a used or missing capsule during

programming will affect the strength, volume and avor of subsequent drinks.

Note:

For Coffee with Milk and Cappuccino drinks, you can set the milk and coffee

dosages separately. This is easiest when the machine is set to rst dispense

coffee then milk (see Cappuccino Dispensing order on page 18 for instructions

on how to congure this setting). Then start the DOSE PROGRAMMING and

pay attention to the coffee dosage rst and stop it at your desired volume by

pressing OK, then the machine will continue the drink. Simply watch the milk

volume and press OK again to set the stop the milk and save the new drink

dosage.

i

Follow the steps below to change the dosage for each of the machine’s programmed drink buttons:

1. Insert a new coffee capsule into the capsule group, and place a clear coffee cup under the outlet.

2. Press OK for 5 seconds, or until the button starts to ash and the display shows DOSE PROGRAMMING (see

Fig. 01 below)

3. Press the drink button you want to program: Short Espresso, Long Espresso/Cafe Crema, Cappuccino or Coffee

with Milk/Black Coffee (see page 13 for drink button diagrams). The selected drink’s button and the OK button

will light up.

4. The machine will begin dispensing coffee. When the desired volume is reached in the cup, press the OK button

to stop dispensing. This dosage will be saved for all drinks using this button.

5. Repeat this process for all of the drink buttons that you want to reprogram. Then press OK to access

the User Menu, or simply wait 30 seconds for the machine to return to normal mode.

Fig. 01

DOSE PROGRAMMING

IN 30 SEC.

Page 16

16

QUARTZ

ONE TOUCH

1. Within the User Menu (see Fig. 01), press + and - to scroll through the menu’s

functions until the currently programmed ON - OFF times are shown (See Fig.

02), then press OK to begin adjusting the time.

2. Press OK to begin to edit the ON hour and minute. The number will ash

when it is ready to be edited. Press

+ or - to change the ashing input, then

press the OK to accept and move to the minute input.

3. When the desired times are set press OK to save your setting. When no elds

are ashing press

+ to return to the User Menu.

1. Within the User Menu (see Fig. 03), press

+ and - to scroll through the

menu’s functions until ON-OFF DAY OFF and the current day off is shown

(See Fig. 04).

2. Press OK, the current day off will start to ash. Press

+ or - to scroll to the

desired day you want to set as the day off.

3. Press OK to save your setting then press

+ to return to the User Menu.

Machine automatic ON/OFF

Day off

USER PROGRAMMING

ON - OFF

--:-- --:--

ON-OFF DAY OFF

WEEKDAY

Fig. 02

Fig. 04

Fig. 01

Fig. 03

DOSE PROGRAMMING

IN 30 SEC.

DOSE PROGRAMMING

IN 30 SEC.

Follow the steps below to adjust when the machine automatically turns ON and OFF everyday:

Follow the steps below to set one day per week that the machine does not automatically turn ON:

Cappuccino ON/OFF

CAPPUCCINO

YES / NO

Fig. 06

1. Within the User Menu (see Fig. 05), press

+ and - to scroll through the menu’s

functions until CAPPUCCINO YES or NO is shown (See Fig. 06), then press

OK to enter the menu.

2. Press

+ or - to select YES or NO. The default setting is YES

3. Press OK to save your setting then press

+ to return to the User Menu.

Follow the steps below to turn the ability to make cappuccinos on or off:

Fig. 05

DOSE PROGRAMMING

IN 30 SEC.

i

Note:

The ability to deactivate cappuccinos as a drink option can be useful if the drinks desired includes Short

Espresso, Cafe Crema, Long Coffee, and Black Coffee (Americano), since the Long Espresso button will

default to Cafe Crema, the Coffee with Milk button will default to a Black Coffee (Americano) button, and the

Cappuccino button will default to a Long Coffee button. The dose volumes can then be adjusted using the Dose

Programming to create the perfect ratio of espresso to hot water for each drink.

i

Note:

To deactivate the automatic ON/OFF function simply set the clock to read ON --:-- and OFF --:-- as shown

in Fig. 02. This will force the machine to stay on whenever the main power switch is turned on, with the only

exception being if the machine is programmed for a day off.

Page 17

17

QUARTZ

ONE TOUCH

USER PROGRAMMING

Cappuccino milk frothiness

1. Within the User Menu (see Fig. 04), press + and - to scroll through the menu’s

functions until CAPP. STEAM XX % is shown (see Fig. 05), then press OK to

enter the menu.

2. Press

+ to increase the amount of air in the froth, or - to reduce it. The

default setting is 50%.

3. Press OK to save your setting then press

+ to return to the User Menu.

i

Note:

The higher the percentage (%) setting, the more air is concentrated in the milk and the frothier it will be. This

programming function is not available when the cappuccino function is turned off.

CAPP. STEAM

XX %

Fig. 05

Fig. 04

DOSE PROGRAMMING

IN 30 SEC.

Follow the steps below to set your preferred amount of milk froth for cappuccinos:

Cappuccino dispensing order

DOSE PROGRAMMING

IN 30 SEC.

CAPPUCCINO MODE

CAPPUCCINO MODE

COFFEE -> MILK

CAPPUCCINO MODE

MILK -> COFFEE

CAPPUCCINO MODE

COFFEE <--> MILK

Fig. 01

Fig. 02

Fig. 03

There are 3 milk and coffee dispensing options for

cappuccinos:

Dispense coffee rst, then add milk.

Dispense milk rst, then add coffee.

Dispense coffee and milk simultaneously.

Follow the steps below to program the milk and coffee dispensing order for

cappuccinos:

1. Within the User Menu (see Fig. 01), press

+ and - to scroll through the menu’s

functions until CAPPUCCINO MODE is shown (see Fig. 02), then press OK

to enter the menu.

2. Press

+ or - to scroll to the desired milk and coffee dispensing order; coffee

then milk, milk then coffee, or coffee and milk simultaneously (see Fig. 03).

3. Press OK to save your setting then press

+ to return to the User Menu.

Note:

This programming function is not available when the Cappuccino function

is turned off.

Note:

Coffee with Milk drinks will always be dispensed as milk rst, then coffee.

This function is not adjustable.

i

i

Page 18

18

QUARTZ

ONE TOUCH

USER PROGRAMMING

Cappuccino milk steam timing

1. Within the User Menu (see Fig. 01), press + and - to scroll through the

menu’s functions until PUMP & STEAM TIMES X,X S is shown (see Fig. 02),

then press OK to enter the menu.

2. Press

+ to increase the pump cycle time, or - to reduce it (time is

adjustable from -2.0 to 2.0 seconds). Default is 0.0 seconds.

3. Press OK to save your setting then press

+ to return to the User Menu.

i

Note:

Selecting a longer (positive) pump time will create a foamier cappuccino, selecting a shorter (negative/delayed)

time will create in a milkier, less foamy cappuccino. Your specic milk fat/cream content, viscosity, temperature

and storage methods all impact foaming characteristics, so trying a few different pump times until you nd your

perfect foam/hot milk ratio is recommended. This programming function is not available when the Cappuccino

function is turned off.

PUMP&STEAM TIMES

X.X s

Fig. 02

Fig. 01

DOSE PROGRAMMING

IN 30 SEC.

Follow the steps below to set the ratio of foam/hot milk for cappuccinos:

Cappuccino end wash

1. Within the User Menu (see Fig. 03), press + and - to scroll through the menu’s

functions until CAPP. END WASH X,XX S is shown (see Fig. 04), then

press OK to enter the menu.

2. Press

+ to increase the amount of end wash time, or - to reduce it in 0.25

second intervals from 0.00 (no end wash) to 1.00 second. Default is 0.50.

3. Press OK to save your setting then press

+ to return to the User Menu.

i

Note:

The end wash should be made longer if your machine only receives limited use each day (just one or two

cappuccinos or coffees with milk per hour) to ensure the milk system stays clean. If it is used regularly all day

long, then the end wash can be adjusted shorter or turned off. This programming function is not available when

the Cappuccino function is turned off.

CAPP. END WASH

0,XX s

Fig. 04

Fig. 03

DOSE PROGRAMMING

IN 30 SEC.

Follow the steps below to set the preferred amount of wash time after each cappuccino or coffee with milk:

Page 19

19

QUARTZ

ONE TOUCH

USER PROGRAMMING

Cafe Crema

Black coffee

1. Within the User Menu (see Fig. 01), press + and - to scroll through the

menu’s

functions until CAFE CREMA NO or XX % is shown (see Fig. 02), then

press OK to enter the menu.

2. Press

+ and - to set the desired amount of crema (choose none, or

between 60 and 100%).

3. Press OK to save your setting then press

+ to return to the User Menu.

1. Within the User Menu (see Fig. 03), press

+ and - to scroll through the

menu’s functions until BLACK COFFEE NO or XX % is shown (see Fig. 04),

then press OK to enter the menu.

3. Press

+ and - to set the desired amount of pre-extraction (choose none,

or between 60 - 100%).

4. Press OK to save your setting then press

+ to return to the User Menu.

i

Note:

The higher the percentage (%) setting, the more pre-extraction there will be in the brew and the more crema

there will be on the top of the nished coffee.

i

Note:

The higher the percentage (%) setting, the more pre-extraction there will be and the stronger the brew will taste.

CAFE CREMA

NO / XX %

BLACK COFFEE

NO / XX %

Fig. 02

Fig. 04

Fig. 01

Fig. 03

DOSE PROGRAMMING

IN 30 SEC.

DOSE PROGRAMMING

IN 30 SEC.

Follow the steps below to set your preferred amount of crema for espressos:

Follow the steps below to set your preferred amount of pre-extraction for the black coffee:

Page 20

20

QUARTZ

ONE TOUCH

USER PROGRAMMING

Prebrewing time

Prebrewing pause time

1. Within the User Menu (see Fig. 01), press + and - to scroll through the

menu’s functions until PREBREWING ON is shown (see Fig. 02), then press

OK to enter the menu.

2. Press

+ to increase the amount of prebrewing desired, or - to reduce it in

0.5 second intervals from 0.00 (no prebrewing dosing) to 5.00 seconds.

Default is NO.

3. Press OK to save your setting then press

+ to return to the User Menu.

1. Within the User Menu (see Fig. 03), press

+ and - to scroll through the

menu’s functions until PREBREWING OFF is shown (see Fig. 04), then

press OK to enter the menu.

2. Press

+ to increase the amount of prebrewing desired, or - to reduce it

in 0.5 second intervals from 0.00 (no prebrewing pause) to 5.00 seconds.

Default is NO.

3. Press OK to save your setting then press

+ to return to the User Menu.

i

Note:

Prebrewing allows the coffee/espresso to develop a little more avor by moistening the grounds for a few

seconds (depending on the setting) before pressurizing the capsule and nishing the brew. Different coffee

brands and roasts will taste best with different prebrew dose times. Test a few times with your favorite coffee to

nd the prebrew time that tastes best to you.

i

Note:

Prebrewing pausing allows the coffee/espresso to extract maximum avor by soaking the grounds for a few

seconds after the prebrewing cycle, then repressurizing the capsule and nishing the brew. Different coffee

brands and roasts will taste best with different prebrew pause times. Test a few times with your favorite coffee

to nd the prebrew time that tastes best to you.

PREBREWING ON

NO / 0X, X s

PREBREWING OFF

NO / 0X, X s

Fig. 02

Fig. 04

Fig. 01

Fig. 03

DOSE PROGRAMMING

IN 30 SEC.

DOSE PROGRAMMING

IN 30 SEC.

Follow the steps below to set the preferred amount of prebrewing dosing for stronger avor extraction:

Follow the steps below to set the preferred amount of prebrewing pause time for stronger avor extraction:

Page 21

21

QUARTZ

ONE TOUCH

USER PROGRAMMING

Cleaning interval

1. Within the User Menu (see Fig. 01), press + and - to scroll through the

menu’s functions until CLEAN INTERVAL XX is shown (see Fig. 02), then

press OK to enter the menu.

2. Press

+ to increase the number of drinks between cleanings, or - to

reduce the reminder interval from 0 (no cleaning reminder) to 50 drinks.

Default is 50.

3. Press OK to save your setting then press + to return to the User Menu.

i

Note:

The advanced cleaning should be done everyday (or every 2-3 hours if ambient temperature is very warm) to

prevent milk spoilage inside the machine.

CLEAN. INTERVAL

XX

Fig. 02

Fig. 01

DOSE PROGRAMMING

IN 30 SEC.

Follow the steps below to set the preferred cleaning interval (number of milk-based drinks between reminders

to perform the milk system cleaning):

Initial flushing

1. Within the User Menu (see Fig. 03), press + and - to scroll through the menu’s

functions until INITIAL FLUSH NO or XX S is shown, then press OK to

enter the menu (see Fig. 04).

2. Press

+ to set the desired ushing time, between 5 and 20 seconds. Default is

10 seconds.

3. To turn the initial ush off, press

- until the display reads INITIAL FLUSH NO.

4. Press OK to save your setting then press

+ to return to the User Menu.

Follow the steps below to adjust or deactivate the initial ush function:

Note:

Initial ushing should only be set to OFF if the machine receives very heavy usage. For lighter usage

a longer ushing time should be selected, for moderate usage a shorter one can be used. Insufcient

ushing will negatively affect the taste of the drinks due to an unsanitary coffee spout.

i

DOSE PROGRAMMING

IN 30 SEC.

INITIAL FLUSH

NO / XX s

Fig. 03

Fig. 04

Page 22

22

QUARTZ

ONE TOUCH

Note:

When performed daily, the pump times are recommended to be

set at 5 seconds each.

Note:

If you select YES to activate the Advanced Cleaning function, you must follow the instructions on the

display when the machine reminds you to do the Milk Cleaning starting from the next scheduled cleaning

cycle. Alternatively, if you select NO then the advanced cleaning will be disabled and the system will only

be periodically ushed with hot water, so it is important that you perform the cleaning steps found in the

User Manual at least once per day to ensure the coffee spout and milk system are clean.

Advanced cleaning times - T1, T2, T3, T4

Advanced cleaning ON/OFF

Fig. 04

Fig. 02

Fig. 06

Fig. 07

i

i

1. Within the User Menu (see Fig. 01), press + and - to scroll through the menu’s

functions until ADVANC. CLEAN T1 Xs is shown, then press OK to enter

the menu (see Fig. 04).

2. Press

+ or - to set the desired ushing time (between 5 and 20 seconds, the

machine is set to 5 seconds by default).

3. Press OK to save your setting then press

+ to return to the User Menu.

4. After returning to the User Menu, scroll to the ADVANC. CLEAN T2 (see Fig.

05), ADVANC. CLEAN T3 (see Fig. 06), and ADVANC. CLEAN T4 (see Fig. 07)

and repeat steps 2, 3, and 4 to program each pump time conguration.

1. Within the User Menu (see Fig. 01), press

+ and - to scroll through the menu’s

functions until ADVANC. CLEANING YES or NO (See Fig. 02) is shown, then

press OK to enter the menu.

2. Press OK and when the YES or NO option is ashing

+ or - to activate or

deactivate the cleaning function (depending on its current status).

3. Press OK to save your setting then press

+ to return to the User Menu.

If the advanced cleaning option (shown above) is selected, follow the steps below to program the four

cleaning cycle function pump times: (Each time is programmed separately from within the User Menu.)

Follow the steps below to activate or deactivate the machine’s semi-automatic milk cleaning system:

Fig. 03

Fig. 01

Fig. 05

DOSE PROGRAMMING

IN 30 SEC.

DOSE PROGRAMMING

IN 30 SEC.

ADVANC. CLEANING T2

X s

ADVANC. CLEANING T1

X s

ADVANC. CLEANING T1

X s

ADVANC. CLEANING T3

X s

ADVANC. CLEANING T4

X s

The pump times correspond to the following cleaning functions:

T1: initial steam cleaning time

T2: milk cleaning solution intake time (5 seconds = approx. 150ml)

T3: hot water from boiler ush time

T4: air intake time, to dry cleaning system

USER PROGRAMMING

Page 23

23

QUARTZ

ONE TOUCH

i

USER PROGRAMMING

Note:

The timed ushing provides a programmed dose of hot water to prevent milk spoilage inside the

machine. A shorter ushing interval time is advised for locations with warmer ambient temperatures,

and frequent automatic ushes will help reduce the need for frequent advanced cleaning cycles.

Timed flushing

Fig. 02

Fig. 04

Fig. 05

1. Within the User Menu (see Fig. 01), press

+ and - to scroll through the menu’s

functions until TIMED FLUSHING NO / X h is shown (see Fig. 02), then press

OK to enter the menu.

2. Press

+ to increase the ushing interval time, or - to reduce it (time is

adjustable from NO/off to 24 hours) in 1 hour increments. Default is NO.

3. Press OK to save your setting then press + to return to the User Menu or

to set the T STEAM, T WATER, and T AIR times. T STEAM default is 5

seconds, T WATER default is 10 seconds, T AIR default is 5 seconds.

4. If a timed ushing is selected, then the T STEAM, T WATER, and T AIR

settings (see Fig. 03-05) will be activated and can be set from individually

from 1-20 seconds each.

Follow the steps below to set the preferred ushing time interval (amount of time between automatic ushes

to ensure the milk system stays clean):

Fig. 01

Fig. 03

DOSE PROGRAMMING

IN 30 SEC.

T STEAM

X s

TIMED FLUSHING

NO / X h

T WATER

X s

T AIR

X s

The pump times correspond to the following cleaning functions:

T STEAM: milk pump intake run time (5 seconds = approx. 25ml)

T WATER: hot water from boiler internal ush time

T AIR: air intake time (to dry the cleaning system)

Longer pump times provide more thorough cleaning, but are not necessarily

needed if the machine is used heavily, as the milk system will be constantly

refreshed after each use.

Page 24

24

QUARTZ

ONE TOUCH

1. Within the User Menu (see Fig. 01), press + and - to scroll through the menu’s

functions until PARTIAL COUNTERS is shown (See Fig. 02), then press OK to

view each counter for each drink.

2. To reset each drink counter individually press OK for at least 5 seconds until

the drink counter resets to 000000000.

3. Press OK to save your setting then press

+ to return to the User Menu.

4. After returning to the User Menu, scroll to the TOTAL COUNTERS (See Fig.

03) and repeat steps 2 and 4. The total counters cannot be reset.

Accessing and resetting the partial counter, accessing the total counters

PARTIAL COUNTERS

TOTAL COUNTERS

Fig. 02

Fig. 03

Fig. 01

DOSE PROGRAMMING

IN 30 SEC.

Follow the steps below to access and reset the partial drinks counters:

Exiting the User Menu

1. Within the User Menu press + scroll to the end, the display will show EXIT

(See Fig. 04), then press OK.

2. The display will show DOSE PROGRAMMING (See Fig. 05).

3. Wait 30 seconds and the machine will return to normal use ON mode.

DOSE PROGRAMMING

IN 30 SEC.

Fig. 05

Fig. 04

EXIT

Follow the steps below to exit the User Menu:

USER PROGRAMMING

Page 25

25

QUARTZ

ONE TOUCH

Before storage be sure to:

Perform all weekly and periodic cleaning procedures described in this manual (see pages 18-26).

Disconnect and roll up the power cord.

Disconnect the machine’s water inlet hose from the domestic water supply (if applicable) and drain the boiler (this

should be performed by a qualied person).

Clean the drip tray and exterior of the machine to remove any coffee or other residue and empty and clean the

capsule drawer.

Cover / re-pack the machine in its original carton and store it in a dry place where it will not be exposed to

extreme temperatures or humidity.

When returning the machine to service after long-term storage, perform all weekly and periodic

cleaning procedures before use.

Before disposal be sure to:

Perform all weekly and periodic cleaning procedures described in this manual (see

pages 18-26).

Disconnect and roll up the power cord.

Disconnect the machine’s water inlet hose from the domestic water supply

(if applicable) and drain the boiler (this should be performed by a qualied person).

Pack and send the machine to a certied recycling center.

STORAGE AND DISPOSAL

Storing the machine

Machine disposal

Page 26

26

QUARTZ

ONE TOUCH

Accessing the service menu functions

Language selection

Fig. 04

Fig. 05

Fig. 06

Fig. 07

Editing the greeting message

SERVICE PROGRAMMING

1. Set the machine to STANDBY mode by pressing OK and Cappuccino

simultaneously for 5 seconds (see Fig. 01).

2. Within the STANDBY mode, press OK for 8 seconds, the display will

show LANGUAGE XX (see Fig. 03), which is the rst option of the

Service Menu.

Follow the steps below to access the machine’s service menu functions:

XXX ºC HH:MM

STANDBY

LANGUAGE

XX

LANGUAGE

XX

LANGUAGE

XX

MESSAGE 1

EXPOBAR

MESSAGE 2

QUARTZ ONE TOUCH

Fig. 02

Fig. 03

Fig. 01

Press simultaneously.

1. Enter the Service Menu, when LANGUAGE (see Fig. 04) appears press OK.

2. The currently selected language will ash. English is the default.

3. Press

+ to scroll to the desired language, then press OK to conrm and

press + to move to the next menu option. Available languages: English, French,

German, Spanish.

1. Within the Service Menu (see Fig. 05), press + and - to scroll through

the menu’s functions until MESSAGE 1 is shown (see Fig. 06).

2. Press OK to begin to edit the greeting message.

3. Press

+ and - to change each ashing character, then press OK to move the

next one.

4. When the desired message is input, press OK to scroll to the end (no

characters will be ashing) then press + to conrm the new message and

move to the second line of the greeting message (see Fig. 07), Repeat steps

2 and 3.

Follow the steps below to change the display language:

Follow the steps below to change the greeting message:

Page 27

27

QUARTZ

ONE TOUCH

SERVICE PROGRAMMING

Enable/disable user programming

Adjusting the boiler level probe sensitivity

Setting the service phone number

1. Enter the Service Menu menu (see Fig. 01).

2. Press + until the display shows SERVICE PHONE (see Fig. 02),

3. Press OK. The bottom line will be activated. Press

+ to add characters one

at a time. Press OK to move to the next character.

3. When the desired message is input, press OK to scroll to the end (no

characters will be ashing) then press + to return to the Service Menu.

1. Enter the Service Menu menu (see Fig. 03).

2. Press + until the display shows ENABLE PROGRAMM. YES or NO (see

Fig. 04),

3. Press OK. The bottom line will ash. Press

+ or - to change the setting.

3. When the desired setting is input, press OK to conrm then press + to

return to the Service Menu.

1. Enter the Service Menu menu (see Fig. 05).

2. Press + until the display shows BOILER SENSIB. LOW, MEDIUM or HIGH

(see Fig. 06),

3. Press OK. The current setting will ash. Press

+ or - to change it.

3. When the desired setting is input, press OK to conrm then press + to

return to the Service Menu.

SERVICE PHONE

ENABLE PROGRAMM.

YES

BOILER SENSIB.

MEDIUM

Fig. 02

Fig. 04

Fig. 06

Fig. 01

Fig. 03

Fig. 05

LANGUAGE

XX

LANGUAGE

XX

LANGUAGE

XX

Follow the steps below to set the helpline phone number:

Follow the steps below to enable or disable user programming capabilities:

Follow the steps below to adjust the boiler temperature probe sensitivity:

Note:

By default, the boiler sensitivity is set to medium and normally it will not require modication. If your

water is very pure, with very low dissolved salt content then it may need to be adjusted to high.

Conversely, for water with high dissolved content, the setting may need to be adjusted to low.

i

Page 28

28

QUARTZ

ONE TOUCH

SERVICE PROGRAMMING

Maintenance cycles

1. Enter the Service Menu menu (see Fig. 01).

2. Press + until the display shows MAINTENAN. CYCLES NO or X000 (see

Fig. 02).

3. Press OK. The current setting will ash. Press

+ or - to change it. The

maintenance interval is adjustable from NO to 10,000 coffees, at

1,000 coffee intervals.

4. When the desired setting is input, press OK to conrm then press + to

return to the Service Menu.

MAINTENAN. CYCLES

NO

Fig. 02

Fig. 01

LANGUAGE

XX

Follow the steps below to adjust the number of beverages between maintenance alerts: (The machine can still be

used after the alarm sounds simply by silencing the alarm. The alarm is only intended to alert the user that the

routine maintenance is due.)

Note:

By default, the routine maintenance alarm is turned off (setting: NO). The setting should be determined

based on your intended use of the machine (coffees per day, public or wait staff-only accessibility, vendor

leasing or private ownership, etc.) Routine maintenance is intended to include replacement of shower

plates, gaskets, and other wearable items inside the group, and guarantees the machine continues to make

high-quality, well-extracted coffee.

i

Page 29

29

QUARTZ

ONE TOUCH

SERVICE PROGRAMMING

Setting the display temperature format

1. Enter the Service Menu menu (see Fig. 01).

2. Press + until the display shows TEMPERATURE ºC / F

(see Fig. 02),

3. Press OK. The current setting will ash. Press

+ or - to adjust it.

4. When the desired setting is input, press OK to conrm, then press + to

return to the Service Menu.

TEMPERATURE ºC / F

ºX

Fig. 02

Fig. 01

LANGUAGE

XX

Follow the steps below to set the display temperature units (Celsius or Fahrenheit):

Adjusting the boiler operating temperature

1. Enter the Service Menu menu (see Fig. 03).

2. Press + until the display shows BOILER TEMP. XXX ºC / F (see Fig. 06),

3. Press OK. The current temperature setting will ash. Press

+ or - to

change it.

4. When the desired setting is input, press OK to conrm then press + to

return to the Service Menu.

BOILER TEMP.

XXXºC XXXºF

Fig. 04

Fig. 03

LANGUAGE

XX

Follow the steps below to adjust the normal boiler operating temperature:

Note:

By default, the boiler operating temperature is set to 118ºC / 244ºF. Any adjustments should be based

on the elevation that the machine will be used at (higher elevations may require lower temperatures)

and the type/brand of coffee capsule to be used.

i

Page 30

30

QUARTZ

ONE TOUCH

SERVICE PROGRAMMING

Adjusting the water filter service alarm

Adjusting the capsule storage alarm

1. Enter the Service Menu menu (see Fig. 01).

2. Press + until the display shows CAPSULE STORAGE XX

(see Fig. 02),

3. Press OK. The current setting will ash. Press

+ or - to adjust it.

3. When the desired setting is input, press OK to conrm, then press + to

return to the Service Menu.

1. Enter the Service Menu menu (see Fig. 03).

2. Press + until the display shows H2O FILTER NO / XX L

(see Fig. 04),

3. Press OK. The current setting will ash. Press

+ or - to adjust it.

3. When the desired setting is input, press OK to conrm, then press + to

return to the Service Menu.

CAPSULE STORAGE

XX

H2O FILTER

NO

Fig. 02

Fig. 04

Fig. 01

Fig. 03

LANGUAGE

XX

LANGUAGE

XX

Follow the steps below to set the number of capsules required in the box to activate the capsule box alarm:

Follow the steps below to set the required number of liters of water cycled to activate the water

lter service alarm:

Note:

By default, the alarm is set to 15 capsules. This setting is adequate for most standard capsules and should

not be adjusted unless a smaller or larger-than-average capsule is selected (capsules must be compatible

with the machine’s capsule group) or a waste funnel or an aftermarket, oversized capsule drawer is being

used. Adjusting the setting so that the box is very full of used capsules when the alarm is activated is

not advised, since the box will be difcult to remove and empty, will be very messy, and can cause used

capsules to become jammed inside the machine.

If a waste funnel or an aftermarket, oversized capsule drawer is being used then the alarm can be

deactivated by setting the number to 0 (zero). When deactivating the alarm, it is the responsibility of the

user to make sure that the machine is never blocked/clogged by used capsules.

Note:

By default, the alarm is set to NO (turned off). When turned on, the alarm is adjustable from 50 to 500

liters, in 5 liter increments. Adjustment to the number of liters required to activate the alarm should

always take into consideration the cleanliness/quality and pH rating of the local water supply.

i

i

Page 31

31

QUARTZ

ONE TOUCH

SERVICE PROGRAMMING

Resetting to factory default settings

Exiting the service programming

1. Enter the Service Menu menu (see Fig. 01).

2. Press + until the display shows PRESET (see Fig. 02).

3. Press OK for at least 5 seconds until DONE appears on the display (see

Fig. 03).

1. Enter the Service Menu menu (see Fig. 03).

2. Press + until the display shows EXIT (see Fig. 04).

3. Press OK. The STANDBY mode message will show on the display (see Fig.

03).

1. Exit STANDBY mode by pressing OK and Cappuccino

simultaneously for 5 seconds (see Fig. 06).

2. The machine will return to normal operating mode and the boiler

will begin to heat up. Wait until the greeting messages are displayed

before dispensing a coffee.

PRESET

EXIT

XXX ºC HH:MM

STANDBY

PRESET

DONE

Fig. 02

Fig. 04

Fig. 05

Fig. 03

Fig. 01

Fig. 03

LANGUAGE

XX

LANGUAGE

XX

Follow the steps below to reset all machine to factory default settings:

Follow the steps below to exit the Service Menu and return to Standby Mode:

Follow the steps below to exit Standby Mode and return to normal operation:

Note:

Resetting the machine to factory default preset settings affects

all programming menu parameters: User and Service. Any

adjustments made to individual program settings and values

will be reverted back to as-delivered status.

i

Exiting standby mode

Fig. 06

Press simultaneously.

Page 32

32

QUARTZ

ONE TOUCH

MESSAGES AND ALARMS

ALARM POSSIBLE CAUSE SOLUTION

PREHEATING

The machine is not nished lling

up or heating the boiler.

Wait until the boiler is full and reaches

normal operating temperature.

LOADING TIMEOUT

1.) The machine is exceeding the

preset boiler ll time because a

tube is loose and the machine is

leaking water.

Turn OFF and unplug the machine and contact technical support for assistance.

2.) The machine is exceeding the

preset boiler ll time because

there is no water in the tank or

the boiler.

Fill the tank and restart the machine

(switch the machine OFF then back ON).

FILL WATERTANK There is no water in the tank. Fill the water tank.

FAIL FLOWMETER

1.) The capsule’s coffee grind is

too ne.

Change capsule/coffee.

2.) Not enough water to make a

coffee.

Fill the water tank.

3.) There is air inside the water

system.

Switch the machine OFF and use the hot

water tap to empty the boiler and purge

the air. Then ll the water tank and switch

the machine back ON.

STANDBY STANDBY mode is activated.

Press OK and Cappuccino buttons

simultaneously to disable STANDBY mode.

EMPTY CAPS. BOX

The capsule drawer is full. The

maximum number of capsules has

been reached (15 capsules).

Empty the capsule drawer. The capsule

counter will be reset to zero (drawer must

be removed for at least 5

seconds to reset).

NTC DISCONNECTED

The NTC is disconnected or

broken.

Turn OFF and unplug the machine and contact technical support for assistance.

WATER TANK OPEN

1.) The water tank is removed or

not installed correctly.

Remove and replace the water tank.

2.) The water tank sensor is not

functioning correctly.

Call technical support for assistance.

CAPSULE BOX OPEN

1.) The capsule box is

removed or not installed correctly.

Remove and replace the capsule box.

2.) The capsule box sensor is not

functioning correctly.

Call technical support for assistance.

H20 FILTER

The water lter/softener needs

to be changed.

Exchange the water lter with a new one.

Press the Continuous and Alarm buttons

simultaneously for 5 seconds to reset the

counter.

Page 33

33

QUARTZ

ONE TOUCH

Revisiones

Rev Descripción Fecha Aprobado

Removing the capsule group

CLEANING AND MAINTENANCE

Remove the cup warming panel by removing the

four screws seen in the picture above.

Remove the two screws at the top of the rear

panel (A) and remove it.

Raise the group lever and remove the two

caps and screws in the picture above (A). Then

remove the water tank and remove the 2 caps

and screws as shown (B).

WARNING!

The boiler may be very hot, let it cool down and make sure there is no pressure in the boiler by

opening the steam or water tap before any service is performed.

Remove the plastic top frame covering the machine

by removing the screws in the picture above.

01

03

04

02

A

A

B

Important:

The cleaning instructions included in this manual are to serve as a complement to the cleaning instructions

explained in the user’s manual.

Page 34

34

QUARTZ

ONE TOUCH

Remove the screw in position A, then lift

the top panel off (B).

To remove the milk spout

panel simply pull it

forward (it attaches

magnetically).

Release the capsule group by removing the four screws seen

in the picture above.

Revisiones

Rev Descripción Fecha Aprobado

05

06

Push the buttons on both sides

of the panel back(A), and push

down slightly to release it.

Remove the outlet cover by

pulling straight out.

CLEANING AND MAINTENANCE

07

08

A

B

09

Page 35

35

QUARTZ

ONE TOUCH

Wash the coffee spout and milk outlet under

warm running water, using a brush to clean inside

all the small crevices to remove any milk residue.

Do not wash/wipe the lubricating grease off of the

mounting tabs.

12

11

13

Disconnecting the milk tube from the milk outlet.

WARNING!

Make sure the speed fitting is cool before you remove the tube, normally this part is hot and can cause

burns or scalding.

10

CLEANING AND MAINTENANCE

Disconnect the water inlet hose via the 13mm

tting located in the bottom front side of the group.

Lift the capsule group out of the machine then

disconnect the wires to the microswitch located on

the side of the group.

Page 36

36

QUARTZ

ONE TOUCH

Cleaning of the capsule group

CLEANING AND MAINTENANCE

Important:

Once all cleaning and rinsing is complete,

replace all necessary parts according to

the service interval on page 39.

Note:

Reassembly of the group should be

performed in reverse order.

16

17

ii

Clean the complete capsule group by immerse

it in a container with hot water and professional

cleaning agent. Leave it soaked for around 15

minutes.

After all necessary parts have been replaced and

before you reassemble the group in the machine,

apply a light coating of grease to the moving parts

and areas shown in yellow the picture to ensure

smooth operation of the group.

Note:

Only use professional cleaning

powder for espresso machines.

It’s available from your distributor.

Part #: 1104162

Important:

After cleaning, rinse the capsule group thoroughly

with cool water to ensure all remains of cleaning

agent is removed.

The group is now totally disconnected and can be

separated from the machine.

Disassemble the micro switch by removing the

two screws as shown above.

14

15

Page 37

37

QUARTZ

ONE TOUCH

Replacement kits for capsule group

Replacing the pinch chamber kit

Replacing the capsule holder kit

02

03

Remove the screws and then

pull out the axles holding the

pinch chamber.

Remove the old chamber

and replace with a new pinch

chamber kit.

Align the chamber, reinsert the

axles and fasten all screws.

01

Use a small screwdriver to

remove the lock washers on

the guide shafts. Pull the shafts

out on the left side to release

the chamber.

Remove the old chamber and

replace it with a new capsule

chamber kit.

Align the chamber and clip

in the guide shafts to lock it

into position, replace all lock

washers to secure the guide

shafts.

02

03

01

Note:

When removing the screws you must use two torx-drivers, one on each side you to counter the

rotation of the axle when unscrewing the opposite screw.

i

CLEANING AND MAINTENANCE

Page 38

38

QUARTZ

ONE TOUCH

Replacing the group gasket

01 02 03

Push the metal tension ring

back (shown in blue), using

thumbnails or a plastic tool,

until it slides off of the gasket.

After the tension ring releases,

pull the gasket forward from

one edge until it releases from

the capsule holder.

Turn the machine off at the

main power switch and then

open up the capsule group.

i

Note: To remove the group gasket, the

machine must cool to room temperature.

WARNING! Beware of the sharps inside the

capsule holder to avoid injury.

CLEANING AND MAINTENANCE

Page 39

39

QUARTZ

ONE TOUCH

SERVICE INTERVALS

Components Part No.

Months (Cycles)

6 (6000) 12 (12000) 18 (18000) 24 (24000)

Boiler

Group Solenoid Valve C60000112 Replace

Non Suction Valve C65000200 Replace Replace

Capsule group

Main Capsule Group Gasket C50000060 Replace Replace Replace Replace

Capsule Holder Kit

Caftaly: CESC81000

Lavazza: CESC81005

Clean Clean Clean Replace

Capsule Pinch Chamber

Caftaly: CESC82000

Lavazza: CESC82005

Clean Clean Clean Replace

Taps

Steam Tap Body C15000336 Clean Replace

Steam Pipe No Burn C35010086 Clean Clean

Water Tap Body C15000336 Replace

Vibration pump

220V 50HZ Ofce Pump C60000040 Check Check

Inlet/Outlet Assemblies

Slider Spout 1264248 Clean Clean

Silicone Milk Inlet Hose C35021000 Replace Replace