Page 1

OFFICE LINE

USER MANUAL

UM_EN

Date: 150525_02

R

Page 2

OFFICE LINE

2

CONTENT .....................................................................................................................................................................2

SYMBOL DESCRIPTION .......................................................................................................................................4

Hazard intensity levels ........................................................................................................................................................ 4

GENERAL ........................................................................................................................................................................5

Introduction .......................................................................................................................................................................... 5

General instructions ............................................................................................................................................................ 5

Warnings ................................................................................................................................................................................ 5

Precautions ............................................................................................................................................................................ 6

Intended use .......................................................................................................................................................................... 6

TECHNICAL SPECIFICATIONS ........................................................................................................................7

Leva ......................................................................................................................................................................................... 7

Accessories............................................................................................................................................................................ 7

Control/Pulser & Control/Pulser with grinder ............................................................................................................. 8

Accessories............................................................................................................................................................................ 8

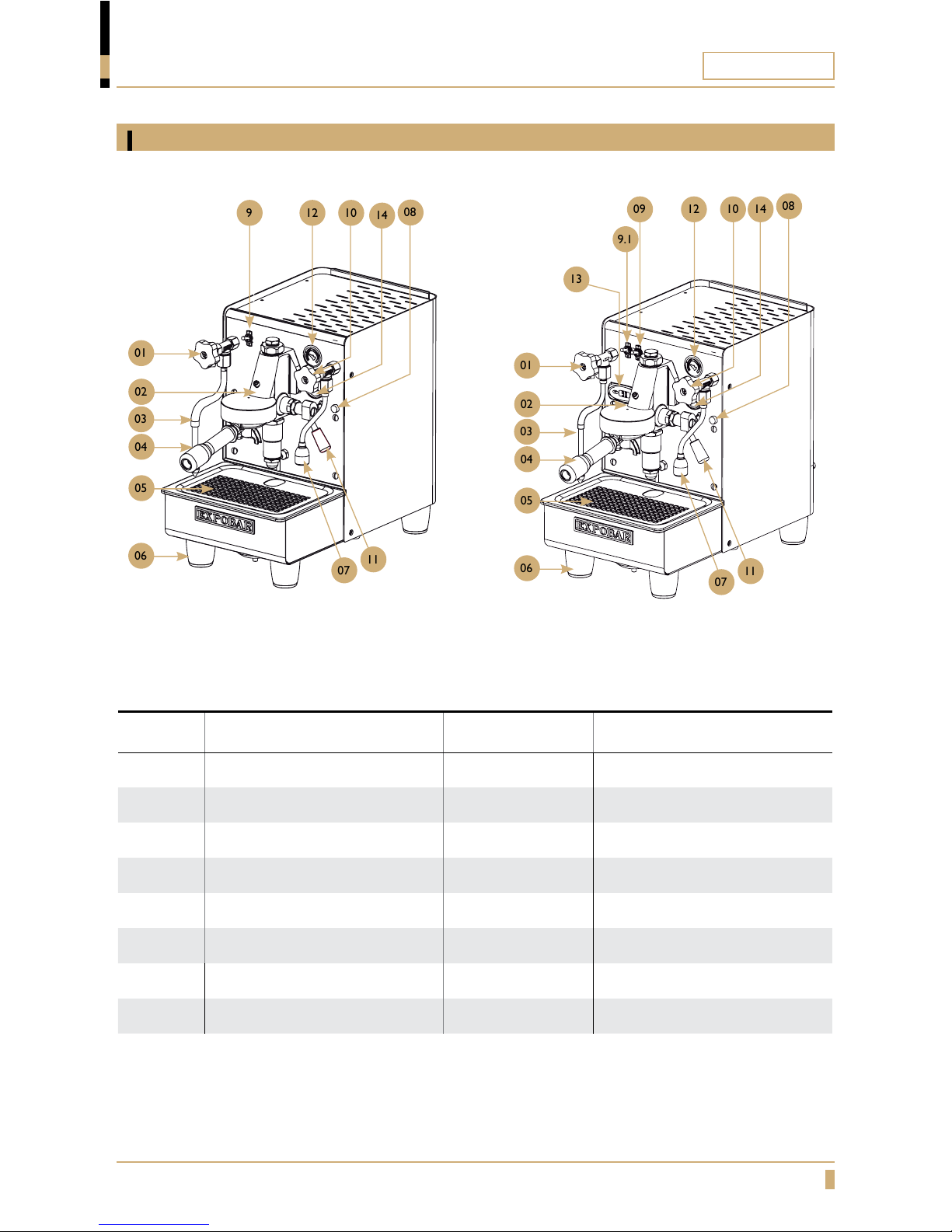

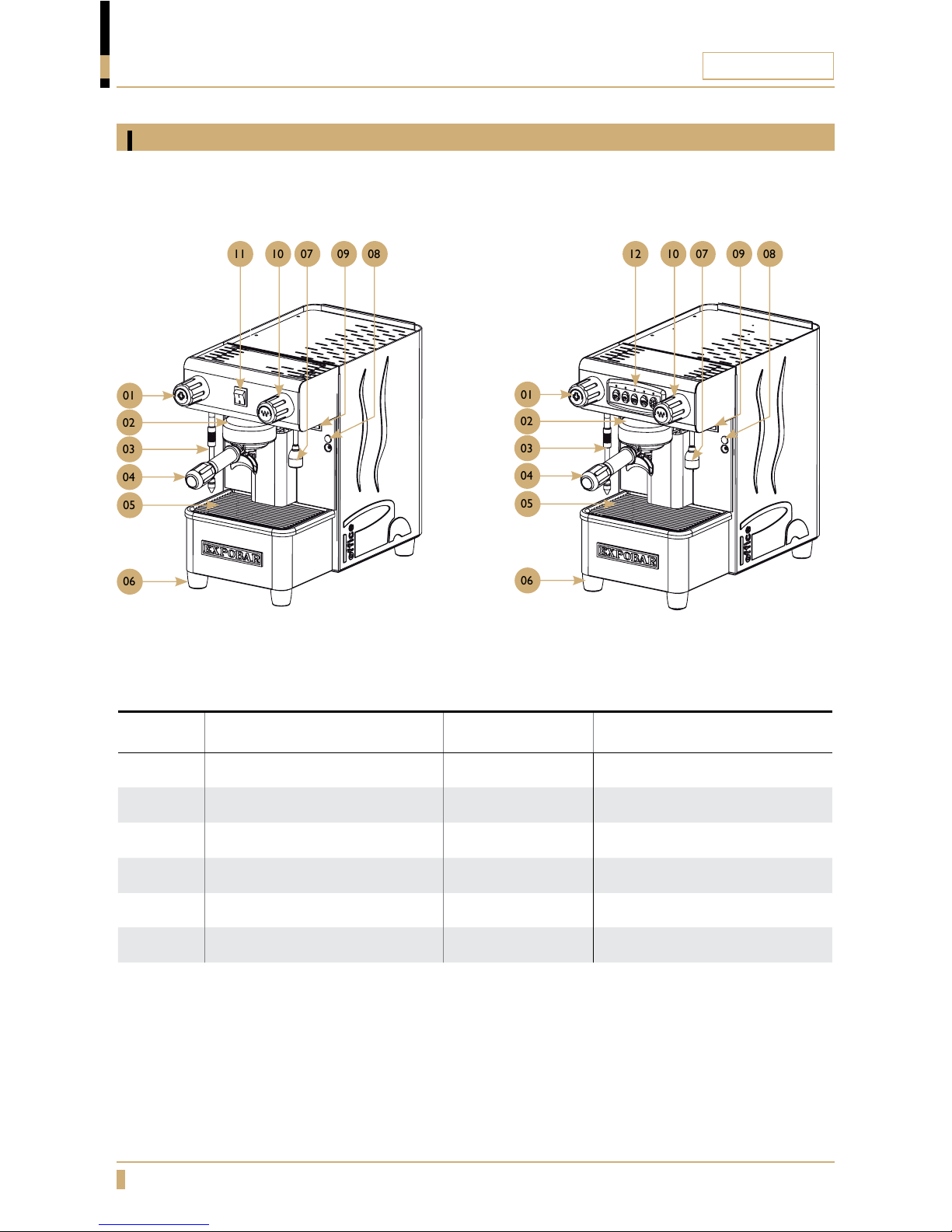

OVERVIEW OF COMPONENTS ....................................................................................................................9

Leva ......................................................................................................................................................................................... 9

Control/Pulser .................................................................................................................................................................... 10

Control/Pulser with grinder ............................................................................................................................................ 11

DIMENSION SKETCH .......................................................................................................................................... 12

Leva ...................................................................................................................................................................................... 12

Control/Pulser ................................................................................................................................................................... 12

Control/Pulser with grinder ........................................................................................................................................... 13

TRANSPORT .............................................................................................................................................................14

Packaging .............................................................................................................................................................................. 14

Delivery inspection ............................................................................................................................................................ 14

INSTALLATION ....................................................................................................................................................... 14

Positioning ...........................................................................................................................................................................14

Electrical installation .......................................................................................................................................................... 15

Electrical connection types .............................................................................................................................................. 15

Water connection .............................................................................................................................................................16

Pressure and temperature ............................................................................................................................................... 16

Hydraulic connection types ............................................................................................................................................. 16

Filling the water tank ......................................................................................................................................................... 17

Connecting to the water mains ...................................................................................................................................... 18

Starting the machine ..........................................................................................................................................................18

The portalter set .............................................................................................................................................................19

Inserting the portalter in the group ............................................................................................................................19

Original Instructions

CONTENT

Page 3

OFFICE LINE

3

CONTENT

OPERATION ............................................................................................................................................................... 20

Espresso brewing ................................................................................................................................................................ 20

Steaming and frothing milk ............................................................................................................................................... 21

ESPRESSO MACHINE WITH BUILT-IN GRINDER ............................................................................ 22

Hot water dispensing ......................................................................................................................................................... 22

Before using the coffee grinder ....................................................................................................................................... 22

Adjusting the grinder coarseness .................................................................................................................................... 23

Dispensing a ground coffee dose .................................................................................................................................... 23

CLEANING AND MAINTENANCE ............................................................................................................ 24

Recharging the water softener ........................................................................................................................................ 24

Coffee machine cleaning .................................................................................................................................................... 25

Daily cleaning ....................................................................................................................................................................... 25

Weekly cleaning .................................................................................................................................................................. 25

Cleaning the brewing group and portalter ................................................................................................................. 26

Cleaning the gasket and shower plate ........................................................................................................................... 27

Additional handling of the machine................................................................................................................................. 28

STORAGE AND DISPOSAL OF MACHINE ..........................................................................................28

Storing the machine ............................................................................................................................................................ 28

Disposal of the machine .................................................................................................................................................... 28

PROGRAMMING ..................................................................................................................................................... 29

Touchpad .............................................................................................................................................................................. 29

Dosage programming of the drink buttons (Control models only). ....................................................................... 29

Normal mode ...................................................................................................................................................................... 30

Turning the thermostat and group boiler off/on ......................................................................................................... 30

Adjusting the group boiler temperature ....................................................................................................................... 30

Reset temperature to factory default ............................................................................................................................ 31

Thermostat alarms ............................................................................................................................................................. 31

TROUBLESHOOTING ......................................................................................................................................... 32

Quick Troubleshooting Guide ......................................................................................................................................... 32

Page 4

OFFICE LINE

4

SYMBOL DESCRIPTION

Hazard intensity levels

i

There are four different levels of notication intensity within this manual, as identied by signal words

DANGER, WARNING, IMPORTANT, and NOTE. The level of risk and importance of the notication

is determined by the following denitions. Always observe the warnings to ensure safety and prevent

potential injury and product damage.

Important:

Alerts against unsafe practices. Observe Important notications to ensure food safety, prevent

possible minor personal injury, or damage to the machine.

WARNING:

Indicates a potentially hazardous situation which, if the WARNING is ignored, could result in

serious injury or even death.

DANGER:

INDICATES A IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL

LIKELY RESULT IN SERIOUS INJURY AND EVEN DEATH.

Note:

Gives additional information which may be helpful during the operation, routine maintenance,

and cleaning of the machine.

Page 5

OFFICE LINE

5

GENERAL

Introduction

Thank you for choosing an OFFICE LINE espresso machine from EXPOBAR.

We hope you enjoy it !

Machine installation and certain maintenance

operations should only be performed by

qualified service personnel.

All safety instructions and warnings contained

in this manual should be observed to ensure

safe installation, use and maintenance.

Do not attempt to open or repair the machine

or access the interior. Repair should be

performed by an authorised workshop, by a

service centre, or by qualified service staff.

Do not remove operational or protective parts

requiring use of tools for removal.

Purchasers are liable for ensuring that users

have been trained to operate the machine

and have been informed of the potential risks

involved.

The installer will be held liable for all non-

authorised modification of the machine.

Non-authorised alteration or modification of

the machine will exempt the manufacturer of

all liability for damages and will invalidate the

warranty.

This manual refers to the machine as at the

time of sale. The commercial availability of

subsequent versions featuring modifications,

upgrades or adaptations does not oblige

the manufacturer to apply the same to this

machine, nor does it oblige it to update the

documentation supplied.

The manufacturer reserves the right to

withdraw currently available manuals whenever

it considers appropriate and reasonable.

General instructions

Warnings

Read this user manual carefully before starting

to use the machine.

This manual contains important instructions

regarding safe intended use of the machine.

Do not discard this manual, it will be useful for

future reference. If damaged or lost, request a

copy from the manufacturer.

Install the machine in a horizontal position and

away from heat sources and flammable objects.

This machine should only be installed on a

water-resistant work surface that is capable of

adequately supporting the machine’s weight.

Place the machine in a location accessible only

to personnel trained to operate it.

Keep all hazardous packaging materials, such as

plastic bags, styrofoam, and staples, out of reach

of children.

Plug the machine into a properly installed, earth

grounded electrical outlet with line voltage that

matches the specifications for the machine.

Ensure that the power supply voltage does not

fluctuate by more than 6%.

Position the power cable so that users cannot

trip over it. Keep the power cable away from

sharp edges and heat sources.

Children should never be allowed to play with

the machine.

This appliance is not suitable for installation in

an area where a pressure washer may be used.

Do not use the machine outdoors, where

it would be exposed to severe weather or

extreme temperatures..

If the power cable is damaged, it may only be

replaced by the manufacturer or its approved

service technician.

Do not remove or disable any of the

mechanical, electrical, or thermal protection

safety equipment.

Note:

The manufacturer is not liable for damage to persons or property resulting from failure to

follow the instructions and warnings listed below when installing and using this machine.

Page 6

OFFICE LINE

6

GENERAL

Precautions

Intended use

In case of emergency, (e.g., the machine catches

fire or becomes unusually hot or noisy),

disconnect the power immediately and turn off

the water supply.

If the machine is not going to be used for an

extended period of time, disconnect the power.

When disconnecting the power, pull the plug

rather than the cable.

When packed for storage, store the machine

in a dry place with an ambient temperature

above 5ºC. Boxes may be stacked up to three

units high of the same model. Do not place

other heavy items on top of the box.

If the machine is likely to be exposed to

temperatures below 0ºC during handling and

transport, make sure that service personnel

empty the boiler and water system. (The

machine’s boiler and water system is empty

when delivered from the factory.)

To ensure fault-free machine operation, only

use manufacturer-approved replacement parts

and accessories.

The coffee machine has been designed and

manufactured to make espresso coffee and

other hot drinks (e.g., steaming and frothing

milk). Do not use it for any other purpose.

The machine is intended to be used by trained

personnel for preparing foodstuffs.

This machine is not intended for use in

industrial kitchens, domestic kitchens, or similar

locations.

The manufacturer will not be held liable

for damage to persons or property due

to incorrect, improper or negligent use by

nonprofessional personnel.

To ensure optimal performance, install the

machine in a location where these parameters

will not be exceeded:

- Maximum permissible inlet water pressure:

600 KPa (6 Bar)

- Minimum permissible inlet water pressure:

200 KPa (2 Bar)

- Maximum inlet water temperature: 40ºC

- Ambient temp. maintained between:

+10ºC / (min.) and +40ºC (max.).

Before performing maintenance and/or moving

the machine, disconnect the machine from the

power supply and wait for it to cool down.

Do not place any liquids on the machine.

This appliance must not be cleaned with a

pressure washer.

Never immerse the machine, plug or power

cable in water, as there is a risk of electric

shock.

Do not touch the machine’s hot surfaces or

dispensing equipment.

Do not touch the machine if your hands or feet are

wet.

Do not operate the machine if any part except

the dispensing equipment is wet.

Place the machine out of reach of children.

This appliance can be used by children from

age 8 and above and persons with reduced

physical, sensory, or mental capabilities or lack

of experience and knowledge if they have been

given supervision or instruction concerning use

of the appliance in a safe way and understand

the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be

made by children without supervision.

Do not use the machine if the power cable

or plug is damaged, or the machine has been

dropped. Contact a service technician for

repairs or to ensure that it is safe for use.

Do not block the vents with rags or other

objects.

Do not insert foreign objects into the vents.

Check the drain regularly to make sure that

waste water is emptying properly.

Page 7

OFFICE LINE

7

Accessories

TECHNICAL SPECIFICATIONS

Leva

MODEL

2-spout

portalter

Filter

basket

Coffee

spoon

Inlet

hose

Cleaning

membrane

Drain tube Tamper

Water

softener

cartrge.

Leva

-

Leva

2 boiler

1 unit

1 unit

each

1 unit

1 unit

(mains

connection

models

only)

1 unit

1 unit

(mains

connection

models

only)

1 unit 2 units

7 grams

14 grams

SPECIFICATIONS

MODEL

Leva 1 boiler Leva 2 boilers

Steam wand

1 unit

Hot water outlet

1 unit

Group

1 unit

Built-in grinder

No

Temperature control

Pressurestat regulated Pressurestat & PID regulator

Width, height, depth

16.9x10.2x18.1 in. / 430x260x460 mm

Boiler volume (L)

1.5 1.5 + 1.5

Water tank volume (L)

2.75

Power supply options

120V~ 1200W 60Hz

240V~ 1950W 60Hz

Water connection

Female 3/8” thread

Machine weight

55.8 lbs / 25.3 kg 62.4 lbs / 28.3 kg

Steam boiler operating press

11.6-18.8psi / 0.8-1.3 bar

Ambient noise

< 70 dB

21 in. /

55 cm

59 in. /

150 cm

Page 8

OFFICE LINE

8

Accessories

TECHNICAL SPECIFICATIONS

Control/Pulser & Control/Pulser with grinder

SPECIFICATIONS

MODEL

Control & Pulser

1 boiler

Control & Pulser

1 boiler w/ grinder

Steam wand 1 unit

1 unit

Hot water outlet 1 unit

1 unit

Group 1 unit

1 unit

Built-in grinder

No Yes

Temperature control

Pressurestat

regulated

Pressurestat

regulated

Width, height, depth

21.9x10.2x18.1 in.

555x260x460 mm

26.8x16.5x18.1 in.

680x420x460 mm

Boiler volume (L)

1.5 1.5

Water tank volume (L)

2.75 2.75

Power supply options

120V~ 1200W 60Hz 120V~ 1310W 60Hz

240V~ 1950W 60Hz 240V~ 2050W 60Hz

Water connection Female 3/8” thread Female 3/8” thread

Machine weight

37.5 lbs / 17.0 kg 59.5 lbs / 27 kg

Steam boiler operating press Between 11.6 and 18.9 psi /

0.8 and 1.3 bar

Ambient noise

< 70 db

MODEL

2-spout

portalter

Filter

basket

Coffee

spoon

Inlet

hose

Cleaning

membrane

Drain tube Tamper

Water

Softener

Cartrge.

Control

& Pulser

-

Control

& Pulser w/

Grinder

1 unit 2 units 1 unit

1 unit

(mains

con-

nection

models

only)

1 unit

1 unit

(grinder

models

only)

1 unit 2 units

7 grams

14 grams

21 in. /

55 cm

59 in. /

150 cm

Page 9

OFFICE LINE

9

OVERVIEW OF COMPONENTS

Leva

POS. Description POS. Description

1 Steam tap 9 Main switch

2 Brewing group 9.1 Water-steam boiler switch

3 Steam wand 10 Hot water tap

4 Porta lter 11 Brewing lever

5 Removable drip tray 12 Steam manometer

6 Adjustable leg 13 Temperature control display

7 Hot water outlet 14 Brew manometer

8 Heating element light

Leva

Leva 2 boiler

010107

07

11

11

10

14

121309

9.1

08

010102

02

03

03

040405

05

06

06

10129

14

08

Page 10

OFFICE LINE

10

OVERVIEW OF COMPONENTS

Control/Pulser

POS. Description POS. Description

1 Steam tap 7 Hot water outlet

2 Brewing group 8 Heating element light

3 Steam wand 9 Main switch

4 Porta lter 10 Hot water tap

5 Removable drip tray 11 Brewing switch

6 Adjustable leg 12 Electronic control panel

Pulser

Control

01

01

11

12

010102

02

030305

05

06

06

04

04

07070909101008

08

Page 11

OFFICE LINE

11

11111110

10

2

8

4

3

9

6

5

7

OVERVIEW OF COMPONENTS

Control/Pulser with grinder

Pulser with grinder Control with grinder

POS. Description POS. Description

1 Steam tap 7 Hot water outlet

2 Brewing group 8 Heating element light

3 Steam wand 9 Main switch

4 Porta lter 10 Hot water tap

5 Removable drip tray 11 Brewing switch

6 Adjustable leg 12 Electronic control panel

2

8

4

3

9

6

5

7

Page 12

OFFICE LINE

12

DIMENSION SKETCH

Model A B C

Leva & Leva 2 boiler 260 mm 460 mm 430 mm

Leva

A

C

B

Model A B C

Control & Pulser

250 mm 420 mm 410 mm

A

C

B

Control/Pulser

Page 13

OFFICE LINE

13

DIMENSION SKETCH

Control/Pulser with grinder

Model A B C D

Control with grinder

420 mm 460 mm 560 mm 680 mm

Pulser with grinder

420 mm 460 mm 560 mm 680 mm

A

C

D

B

Page 14

OFFICE LINE

14

INSTALLATION

TRANSPORT

Positioning

Packaging

Delivery inspection

MIN. 30 cm

MIN. 10 cm

The machine is shipped in a custom-designed carton which utilizes model-specific polystyrene

cushions to protect it from damage.

The machine’s carton features standardized handling symbols to explain proper shipping and

storage methods.

The machine must remain in a horizontal position during the transport. Do not store or handle the

machine except on its feet.

During transport protect the carton and machine from impact drops, crushing, shocks, moisture

and exposure to extreme temperature.

Upon receipt and delivery ensure that the machine is in the exact condition described in the

enclosed documentation, and that all accessories are included. Missing items should be reported to

the manufacturer or dealer immediately.

Damage caused during transport should be reported to the shipping agent and the machine’s

distributor immediately.

Packaging materials are potentially dangerous and should be kept away from children.

The carton and all packing materials are recyclable and should be returned to a recycling center for

disposal.

i

Install the machine on a level, sturdy, and water-resistant

surface approximately 110cm above floor level for ease of

access and usage.

Adjust the feet to ensure that it dispenses coffee evenly to

all cups.

Ensure enough free space is available above (>30cm) and

behind (>10cm) the machine to ensure easy cleaning and

maintenance and adequate ventilation.

Do not install the machine if it is wet or damp. Allow it to

dry completely and ask a service technician to ensure that

none of the electrical components have been affected.

Note:

Leave an air gap of approximately 30cm above

the machine and 10cm behind it to ensure

adequate ventilation.

Page 15

OFFICE LINE

15

INSTALLATION

Electrical installation

Electrical connection types

The machine should only be connected to the power supply by qualified

personnel. The following safety instructions should be obeyed at all times:

Ensure that the electrical requirements stated on the TECHNICAL

SPECIFICATIONS (pages 7 - 8) match the specifications of the power

supply at the outlet.

Ensure that the domestic electrical supply where the machine is being

installed is rated for and able to provide the power required by the

machine. Insufficient power supply, wiring, grounding, or insulation can result

in overheating and possibility of fire.

The coffee machine must be connected to an earth grounded electrical

outlet that complies with the regulations in force in the country of

installation.

Ensure that a circuit breaker engineered for the power consumption of the

machine is installed to protect the domestic electrical supply, as specified on

the ratings plate located under the drip tray.

Do not connect the machine to the domestic power supply via extension

cords, plug adapters, or shared outlets.

The manufacturer will not be held liable for damage to persons, animals or

property resulting from incorrect installation of the coffee machine.

DANGER!

If the power cable or plug is damaged, it must be replaced by the manufacturer, distributor, or

its approved service technician in order to avoid RISK OF SERIOUS INJURY OR DEATH!

Connect the machine per the instructions and voltage information shown on the ratings plate.

NEUTRAL

PHASE

Supply

Blue

Brown

Yellow/Green

VOLTAGE TYPE:

220-240Vac Ph+N

PHASE

PHASE

Supply

Blue

Brown

Yellow/Green

NEUTRAL

PHASE

Supply

White

Black

Green

VOLTAGE TYPE:

220-240Vac 2Ph

VOLTAGE TYPE:

125Vac Ph+N

Page 16

OFFICE LINE

16

INSTALLATION

Water connection

Pressure and temperature

Relationship between boiler pressure and temperature

Standard pressure and temperature

0.7

110

115

120

125

0.8 0.9 1 1.1 1.2

o

C

BAR

Fig. 01

Connecting the machine to the domestic water supply must be performed by a qualied person.

Purge at least 20 liters of water from the domestic water supply before connecting the machine to it to ush

out any debris that may be in the plumbing system that would otherwise accumulate inside the boilers.

The domestic plumbing system should be tted with a brass 3/8” male pipe tting and an in-line

shut-off valve. Connect the 180cm water inlet hose included with the machine to the domestic water

supply and tighten the line ttings with a wrench.

Only use safe drinking water with a hardness rating between 5ºfH and 8ºfH (French hardness

degrees) or 20 to 32 ppm (parts per million as calcium). If the hardness value is below this limit,

corrosion of hydraulic components is likely. If the value is higher, lime-scaling inside the boiler will

occur. In both cases, the proper function of the machine and quality and taste of the coffee will be

negatively affected.

If necessary, connect the machine to a water softener to reduce water hardness using the exible

55cm hose included in the accessory box.

Connect one end of the corrugated drain tube to the drain cup in the machine, connect the other

end to the plumbing drainage system in the installation area.

Boiler pressure is directly related to water temperature (g. 01).

Machines tted with a pressure gauge will display the boiler pressure, while machines is tted with

a digital display it will indicate water temperature.

Important:

Only use the hoses supplied with the machine. Never reuse damaged hoses.

Ensure that the drainage tube is not twisted and that it is below the level of the drain cup.

Hydraulic connection types

This machine is offered with three options for hydraulic connection:

Machine intended for water mains connection.

Machine with internal water tank.

Machine with internal water tank and water mains connection.

Check the machine ratings plate to confirm which arrangement the specific machine is

equipped as.

Page 17

OFFICE LINE

17

INSTALLATION

Filling the water tank

Option 1:

Remove the top panel/cup warming tray.

Remove the water inlet tube and water softener unit, then

remove the water tank.

Fill the tank with clean, fresh drinking water (max. volume = 2.75L).

Replace the water tank in the machine, then replace the softener unit, with

the inlet side pointing down.

Replace the top panel/cup warming tray.

When the boiler is lled and heated, the machine is ready for use.

Option 2:

Remove the top panel/cup warming tray.

Using a pitcher, carefully ll the tank with clean, fresh drinking water (max.

volume = 2.75L). Avoid spills inside the machine.

Replace the top panel/cup warming tray.

When the boiler is lled and heated, the machine is ready for use.

DANGER!

Avoid spills inside the machine. If spills occur, turn the machine off and unplug the

power supply until the machine is completely dry to avoid RISK OF SHOCKS.

i

i

Note:

The machine has a microswitch located below the water tank to automatically stop the

machine’s pump when the tank is empty. Therefore, the water tank should only be removed and

relled when espresso is not being brewed.

Note:

Always use fresh water with a pH water with a hardness rating between 5ºfH and 8ºfH (French

hardness degrees) or 20 to 32 ppm (parts per million as calcium) to ensure great tasting coffee

and to prevent limescaling.

Page 18

OFFICE LINE

18

Attach the included 1/2’ water inlet hose to the bottom of the machine (elbow end to machine,

straight end to mains) and torque both ttings with a wrench.

Open the water valve located on the bottom of the machine (see images below for positioning).

When the boiler is lled and heated, it is ready for use.

Connecting to the water mains

1/2” water

connection elbow

Back of

machine.

1-2 kg bottle,

or similar

Valve set to use

water mains only.

Valve set to use

water tank only.

Important:

To prevent limescale build up in the

boiler and other components, a watersoftening system must be installed in-line

ahead of the machine.

INSTALLATION

This section applies to models with the optional water mains connection.

Starting the machine

Fill the water tank or open the water mains supply valve.

Turn on the main power switch.

Press a drink button at the control panel or raise the group lever then wait until water comes out

continuously. This ensures that the heat exchanger in the machine is being correctly lled.

Open the steam tap to release any air trapped in the boiler.

The red lamp indicates that the boiler is heating. The lamp switches off automatically when the

machine reaches operating temperature and is ready to use.

i

Note:

For models which have both water tank

and water mains connection, the water tank

must be removed and stored and a 1-2 kg

water-proof, heat-resistant object (such as

a sealed, lled plastic bottle) must be put

in its place to ensure the pump-control

microswitch remains on. Failure to weigh

down the microswitch will prevent the

machine from lling the boiler.

Page 19

OFFICE LINE

19

INSTALLATION

The portafilter set

Inserting the portafilter in the group

Filter basket locking spring

Filter basket

Portafilter spring channel

Portafilter & filter basket

for double espresso (14g)

Align the portafilter's two flanges with

the two slots in the group housing.

Insert the portafilter and rotate it counterclockwise until

the handle is approximately perpendicular to the face of

the coffee machine.

Correct

position.

Portalter not

fully inserted.

Group gasket is

worn out, please

replace.

Page 20

OFFICE LINE

20

OPERATION

Espresso brewing

01 02

03 04 05

06

Important:

Always keep the

portalter inserted

in the group to keep

it warm. This is very

important to maintain

an optimal temperature

to make the best

espresso possible.

Unlock and remove the portafilter

from the group head.

Compress the coffee with the

coffee tamper.

Place one or two cups

beneath the outlet spouts.

Select the desired option from the drink buttons or raise the group lever.

Insert the filled portafilter into the

group head and lock it into the

correct position.

Fill the lter basket of the

portalter with espresso

powder (the amount may

differ depending of the lter

basket size). For best result

use freshly ground espresso

beans.

WARNING!

Never try to open the portalter while the machine is in operation! The pressurised hot water

could cause scalding or serious injury. After dispensing has nished, wait at least 3 seconds before

removing the portalter.

Page 21

OFFICE LINE

21

OPERATION

Steaming and frothing milk

01

02

04

03

05

Steaming

Frothing

Place the steam wand over the drip tray

and open the steam tap for a few seconds

to allow condensed water to be ejected.

Close the steam lever when only steam

comes out.

Open the steam tap again to begin steaming or frothing

the milk. Do not remove the milk pitcher while steaming.

Once the milk reaches the

desired temperature, close the

tap and remove the pitcher.

Immerse the steam wand into the milk, making sure

the wand tip is submerged.

After the process is finished, position the steam wand

over the drip tray and open the steam tap for a few

seconds to eject any milk remaining in the wand.

Close the tap and then wipe down the outside of

the steam wand with a damp cloth to prevent nozzle

blockage and to keep it clean. Leaving milk in or on

the wand will affect the taste of later drinks.

WARNING!

Do not allow the steam wand to extend out

of the milk when the lever is open, it may

cause serious burns and injuries.

Page 22

OFFICE LINE

22

OPERATION

Hot water dispensing

Place a jug (or similar) under the hot water outlet.

Open the hot water tap.

Close the tap as soon as the machine has

dispensed the desired amount of water.

WARNING!

Never expose hands and ngers directly

under the water outlet during operation

to avoid scalding or serious burns.

ESPRESSO MACHINE WITH BUILT-IN GRINDER

Before using the coffee grinder

Pos PART NAME

1

BEAN HOPPER LID

2

BEAN HOPPER

3

BEAN STOP

4

GRINDING ADJUSTMENT DISK

5

COFFEE TAMPER

6

GRINDER POWER SWITCH

7

GRINDER COFFEE OUTLET

8

PORTA FILTER HOLDER

9

GRINDER ACTIVATOR

2

1

3

5

8

4

6

7

9

Check that the bean hopper (2) is correctly fitted in place.

Lift up the bean hopper lid (1), fill the bean hopper (2) with coffee beans and close it again.

Open the bean stop (3) to allow the coffee beans to flow into the grinder.

Page 23

OFFICE LINE

23

ESPRESSO MACHINE WITH BUILT-IN GRINDER

Dispensing a ground coffee dose

Adjusting the grinder coarseness

Fine Coarse

Place the portalter on the portalter holder (9), below the

ground coffee outlet.

Press the portalter against the grinder activator (10),

ground coffee will dispense automatically.

Release the pressure on the activator when the desired

amount is reached.

Place the portalter under the coffee tamper (6) and push it

up to compact the coffee.

For a finer grind:

Hold down the grinder trigger while slowly rotating the

adjuster to the right. When the desired grind is achieved

release the trigger.

For a courser grind:

Hold down the grinder trigger while slowly rotating the

adjustment disk (4) to the left. When the desired grind is

achieved release the trigger.

Important:

You should only adjust the coarseness when the grinder is turned off.

i

Note:

If when brewing espresso, if it comes out very slow, the grinder is set too ne. If it comes out too

quickly and coffee appears pale and weak, it is too course. Espresso should come out with a slow,

thin and continuous ow and dark color.

Page 24

OFFICE LINE

24

CLEANING AND MAINTENANCE

Recharging the water softener

Turn the machine off at the main power switch.

Remove the top panel/cup warming tray.

Remove the water inlet hose and water softener unit.

Place the water softener unit in a container of 1% salt water solution (99% clean water + 1% plain

table salt) for 10 minutes. The hose does not need to be disconnected.

After recharging, remove the water softener unit and dry the outside with a clean cloth. The water

inside the unit may remain.

Replace the water softener unit in the water tank and make sure the water tank is filled to dilute

any remaining salt water.

Replace the top panel/cup warming tray and turn on the main power switch. The machine is now

ready for use.

Soak in 1% saltwater

solution for 10 minutes.

i

Note:

This section only

applies to water

tank models.

Page 25

OFFICE LINE

25

Coffee machine cleaning

Important:

To keep the machine looking and working like new, you should always follow the cleaning

and care instructions provided in this manual.

Always turn off the main power switch when cleaning the exterior of the machine.

All external surfaces should be cleaned with a damp, lint-free cloth that will not scratch the

machine.

Do not use aggressive cleaning detergents, solvents or degreasers. These can damage the

surfaces, and plastic and rubber parts, and leave unwanted residue.

Important:

Each day, or 8 hours after dispensing the last coffee, the following cleaning tasks should be

performed to maintain the quality and performance of the water system:

Portafilter: Brew one espresso with the filter empty (around one minute) to flush it out

(dispose of this water).

Steam Wand: Position the wand over the drip tray and open the steam lever for one minute

to flush the wand.

Hot Water Outlet: Place a container under the water outlet and dispense water for 10

seconds (dispose of this water).

Daily cleaning

Weekly cleaning

Clean the brewing group and portafilter with professional cleaning powder (see page 26).

Clean the water tank once per week with detergent and a bottle brush under running water to

prevent bacteria build-up. Rinse thoroughly and dry the outside before refilling and replacing it in

the machine.

Rinse the brewing group, shower plate, and portafilter with hot water for 15 seconds (page 27).

Clean the external surfaces of the machine with a damp cloth, paying special attention to the

stainless steel parts.

Clean the steam wand and the water tap. Be sure that the nozzles are not clogged or partially

blocked with milk or other residue. If it’s necessary to remove them for cleaning, be careful not to

deform or damage any of the components during removal.

Clean the dip tray and the stainless steel insert grid under running water with a brush.

Clean the drain cup by slowly pouring one liter of warm water into it to dissolve and remove the

coffee residue that accumulates inside the drain cup and hose.

CLEANING AND MAINTENANCE

Page 26

OFFICE LINE

26

CLEANING AND MAINTENANCE

Cleaning the brewing group and portafilter

Unlock and remove the portafilter from the group head.

Place the cleaning membrane in the filter basket.

Fill the filter basket with professional cleaning powder for espresso coffee machines.

Lock the portafilter into the group head.

Ofce Control machines: To activate the auto-cleaning program turn off the machine’s main power

switch. Then press and hold the 2 Short Espressos button then turn on the main power

switch. Cleaning will start automatically. Release the 2 Short Espressos button.

Office Pulser machines: To activate the auto-cleaning program simply cycle the Brew button on

for 5 intervals of 10 seconds each.

Leva Pulser machines: To activate the auto-cleaning program simply raise the brew lever for 5

intervals of 10 seconds each.

Cleaning membrane

Espresso-machine

detergent

Note:

Only use professional cleaning

powder for espresso machines.

It’s available from your

distributor. Part no: 1104162

i

WARNING!

Never try to open the portalter while the machine is in operation! The pressurised hot

water could cause scalding or serious injury. After cleaning has nished, wait about 3

seconds before removing the portalter.

Important:

When the cleaning process is nished, remove the portalter and run water through

the group again to rinse out any residue. Repeat the cleaning process this time without

cleaning powder to remove any remaining residue. Store the cleaning membrane in a

convenient location for future use.

Note:

Rinse the group and portalter with hot water (using only the cleaning membrane and

hot water, no cleaning powder) each day that the machine is used.

Clean the group and portalter with cleaning powder once a week.

i

Page 27

OFFICE LINE

27

Cleaning the gasket and shower plate

While making espresso, coffee grounds will naturally accumulate on the group’s sealing surface.

Allowing an excessive amount of grounds to build up can prevent the portafilter from properly sealing

to the group head. In extreme cases, such as leaving a used portafilter in the group head for several

days, water can even become blocked from passing through the shower plate.

To prevent these problems, perform the following cleaning procedures daily:

Place the cleaning membrane in the lter basket (without detergent).

Insert the portalter in the group head, but do not tighten fully (the portalter should be loose).

Press the Continuous Dispensing button for Control machines, or press the brew button

for Pulser machines. For Leva machines, raise the brewing lever for 15 seconds.

Make an opening-closing movement of the portalter in place without closing it. Water will now

ow around the portalter, owing through the closing surface and cleaning it.

CLEANING AND MAINTENANCE

Coffee residue

requiring cleaning

Cleaning the gasket

Cleaning the shower plate

Shower plate

WARNING!

Take special care to avoid scalding when

performing this cleaning operation, as the hot

water used to clean the gasket will spill over

the sides of the portalter.

WARNING!

Do not fully tighten the portalter. If fully

tightened, high-pressure water may spray out

and cause scalding or serious injury.

Remove the portalter from the group head.

Clean the shower plate and group gasket with a soft brush to remove any coffee residue.

Page 28

OFFICE LINE

28

Additional handling of the machine

Storing the machine

Disposal of the machine

CLEANING AND MAINTENANCE

STORAGE AND DISPOSAL OF MACHINE

Always remove and insert the portalters

gently. Never use excessive force to try to

close the portalter. If the portalter does

not turn and lock into place without excessive

force this usually indicates that there is too

much coffee in the lter basket.

Important:

Do not place wet cups directly on the

cup shelf. Allowing water to drip into

the machine can cause mechanical and

electrical damage.

Before storage be sure to:

Perform all weekly and periodic cleaning procedures described in this manual (see pages 25-27).

Disconnect and roll up the power cord (this should be performed by a qualified person).

Disconnect the machine’s water inlet hose from the domestic water supply and drain the boilers (this

should be performed by a qualified person).

Clean the drip tray and exterior of the machine to remove any coffee or other residue.

Cover / re-pack the machine in its original carton and store it in a dry place where it will not be

exposed to extreme temperatures or humidity.

When returning the machine to service after long-term storage perform all weekly and periodic

cleaning procedures before use.

Disconnect and roll up the power cord (this should be performed by a qualified

person).

Disconnect the machine’s water inlet hose from the domestic water supply and

drain the boilers (this should be performed by a qualified person).

Pack up and ship/deliver the machine to an authorized recycling center.

Page 29

OFFICE LINE

29

For machines equipped with an electronic control panel (5 buttons per brewing group), the following

controls are available:

Volumetric control for four different espresso doses.

Time-controlled hot water dosage (on customer’s request).

Automatic filling and level control of the boiler.

Automatic switch off of the heating element at low water level (on customer’s request).

Brewing group auto-cleaning/descaling.

The control panel is by default programmed with 4 standard drink doses (these can be re-programmed

as desired) and one continuous brewing function. The four left-side buttons (1 short espresso – 1

long espresso – 2 short espressos – 2 long espressos) brew the programmed amount and then stop

automatically; the right-side button brews continually until stopped manually by pressing again.

Touchpad

Dosage programming of the drink buttons (Control models only).

PROGRAMMING

1 Long Espresso

1 Short Espresso

2 Short Espresso & Auto-cleaning

Programming &

Continuous Dispensing

2 Long Espressos

Press the Continuous Dispensing button for 4 seconds, it will begin to flash.

Within 5 seconds, press the button of the dispensing option that you want to program: 1 Short

Espresso, 1 Long Espresso, 2 Short Espressos or 2 Long Espressos. The lights on the selected drink

button and the Continuous button will remain on.

The group will start dispensing coffee. When the desired volume is reached in the cup, press the

selected drink button again to stop dispensing. This volume setting will be saved and the button’s light

will turn off. The Continuous button will remain illuminated.

Repeat this process for all of the dispensing options that you wish to reprogram.

If you only need to reprogram one of the dispensing options, follow the steps above and program just

that option. All of the other dispensing options will remain unchanged.

Important:

Always use a portalter lled with fresh coffee grounds for every new dose programmed.

Page 30

OFFICE LINE

30

On Leva Multiboiler machines the temperature of each group boiler can be programmed and adjusted

individually via the digital temperature adjusting system.

The temperature control is performed by a PID thermostat, which provides accurate and stable

temperature management for the group.

During normal mode, the temperature display shows

the current temperature of the group boiler. When

the boiler’s heating element is working and water is

heating up, a small blue dot will illuminate to indicate this

function.

Note:

Adjust the group boiler’s temperature up with the

button and down with button.

To turn the thermostat and its group boiler off, press and hold

the

button for 2 seconds. The thermostat selected will be

disconnected, “OFF” will be displayed, and the group will start to

cool down.

To connect the thermostat:

If the thermostat is “OFF”, press either the or

button. The thermostat will be turned back on and the group’s

current temperature will be displayed as the group boiler

starts to heat up.

To adjust the group operating temperature setting follow the

steps below:

• Pressandholdthe

button until the temperature display

shows “PrG”.

• Within2seconds,pressthe button, the display will show

the current group temperature setting.

• Within2seconds,begintoadjustthetemperaturesettingup

with the button, or down with the button.

• Whenthedesiredtemperatureisdisplayed,wait3seconds.

The thermostat will automatically return to normal mode with

the new temperature setting.

LEVA MULTIBOILER TEMPERATURE CONTROL

Normal mode

Turning the thermostat and group boiler off/on

Adjusting the group boiler temperature

i

i

90.

off

PrG

92

Note:

The instructions on this page apply to Leva Multiboiler machines only.

Buttons

Heating

Element

Lamp

Group Boiler Temp.

Page 31

OFFICE LINE

31

If the thermostat’s operating program is lost, or if an abnormal

group temperature setting appears, reset the system to the factory

defaults. Follow the steps below:

• Turn off the machine, press and hold down the

button, then turn the machine on at the power switch.

• Release the button when the system displays the “PrS”

message.

• Turn the machine off and on again at the power switch to

restart the thermostat.

If the temperature gauge in the group’s boiler has short-circuited,

the system will display the “A1” error message. Call a service

technician to replace or repair it.

If the temperature gauge cable is disconnected, the system will

display the “A2” error message. Call a service technician to repair

it.

LEVA MULTIBOILER TEMPERATURE CONTROL

Reset temperature to factory default

Thermostat alarms

PrS

a1

a2

Page 32

OFFICE LINE

32

TROUBLESHOOTING

Quick Troubleshooting Guide

Coffee-grinding issues

Coffee dispensing is very fast:

The coffee grind is too coarse. Adjust the

coffee-grinder to a ner setting.

Coffee dispensing is very slow:

The coffee grind is too ne. Adjust the coffeegrinder to a coarser setting.

Problem Possible cause Solution

The machine does not

start up

The plug is not correctly

inserted into the power socket

Check that the plug is correctly

inserted and that the power

socket is operational.

The circuit breaker and/or

differential are disconnected.

Ensure that they are connected

and operational.

The cable and/or plug are

damaged.

Call a service technical to

replace it.

The steam wand does not

dispense steam

The steam wand is clogged by

milk

Clean the wand and, if

necessary, remove the nozzle

and unclog it using a pin or

needle.

Water is found

underneath the machine

The drainage tube is blocked. Clean the drainage tube.

The following checks can be carried out by users only after the machine has been turned off and

disconnected from the power supply. For all other nonspecific machine faults, disconnect the machine

from the power supply and immediately contact authorised and qualified service personnel.

Faults produced by limescale

Coffee not dispensed at right temperature:

Heat-exchanger outlet pipes clogged by

limescale.

Brewing groups do not dispense water: Water system is clogged by limescale.

90% of faults are due to limescaling inside the coffee machine (due to not softening the

water). To avoid these faults, maintain the water softener regularly.

Page 33

Your Dealer

FOR SERVICE

Please contact your dealer

www.creminternational.com

For the warranty to be valid the conditions for maintenance must have been

followed according to our instructions, proper precautions have been taken, and

warranty claim has been issued without delay.

The affected equipment shall not be used while awaiting service if there is any risk

that the damage or defect could worsen.

The warranty shall not cover consumable supplies such as glassware, or normal

maintenance such as cleaning of filters. Additionally, damages of an external nature,

such as contaminants in the water, limescaling, incorrect voltage or power surges,

and water supply issues such as pressure changes or service disconnection are not

covered by this warranty.

The warranty will not cover damages or defects caused by incorrect handling or

operation of the appliance.

Loading...

Loading...