Page 1

PMC-Eight™

Programmer’s

Reference

DOC-ESPMC8-002 Release 2

2019_March 07

Page 2

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

1

Revised by: Jerry Hubbell, Vice President Engineering, Explore Scientific, LLC.

Reviewed by: Alex Sanchez, Director Quality Explore Scientific, LLC.

Reviewed by: Dan Dickerson, APh Technological Consulting

Approved by: Scott Roberts, President Explore Scientific, LLC.

This document is copyright ©2016–2019 Explore Scientific, LLC. All Rights Reserved.

NOTE: This document is provided to our PMC-Eight™ customers for their personal use in developing

applications for the PMC-Eight™ Control System in accordance with the requirements of Explore Scientific

and the PMC-Eight™ OpenGOTO™ Community Steering Committee.

If you have any comments or questions about this document, please contact:

Attn: Vice President of Electrical Engineering

Explore Scientific, LLC

1010 South 48th Street

Springdale, AR 72762

(866) 252-3811

The PMC-Eight™ and OpenGOTO™ Name and Logo are registered trademarks of Explore Scientific, LLC,

All Rights Reserved. The JingHua Optical Corporation (JOC) located in Guangzhou, China is the parent

company of Explore Scientific.

Propeller™ copyright Parallax, Inc. SBIG ST-4 standard copyright Santa Barbara Instruments Group,

Cyanogen, LLC. RN-131 module copyright Microchip, Inc. ESP-WROOM-02 (ESP8266) module copyright

Espressif, LLC. G-11 mount copyright Losmandy Astronomical Products, Hollywood General Machining,

Inc. PHD2 copyright Open PHD Guiding Project.

This is the third in the following series of documents for the PMC-Eight™ System:

Document Number Title

DOC-ESPMC8-001A PMC-Eight™ Owner’s Reference Manual (Customer Use)

DOC-ESPMC8-001B iEXOS 100 PMC-Eight™ Owner’s Reference Manual (Customer Use)

DOC-ESPMC8-002 PMC-Eight™ Programmer’s Reference (Customer Use)

DOC-ESPMC8-003 PMC-Eight™ JOC Command Language Reference (Internal Use)

DOC-ESPMC8-004 PMC-Eight™ Datasheet and Design Basis Document (Internal Use)

DOC-ESPMC8-005 PMC-Eight™ Firmware and Software Design Reference (Internal Use)

DOC-ESPMC8-006 PMC-Eight™ Firmware and Software Flowcharts (Internal Use Only)

DOC-ESPMC8-007 PMC-Eight™ Hardware Reference Schematics and Datasheets (Internal Use)

Page 3

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

2

Document Notes

Revision History

0.0 GRH DRAFT Initial Draft.

0.1 GRH DRAFT Added Sections VI and VII.

0.2 GRH DRAFT Revised Section V to add “ESR!” Communications Reset command.

0.3 GRH DRAFT Revised Section III to correct and expand on Meridian Flip discussion.

1.0 GRH RELEASE 0 Miscellaneous cleanup of text and sections for release.

1.1 GRH RELEASE 1 Revised Section II to add board layout information and LED and test point

information. Miscellaneous revisions and formatting changes.

1.2 GRH RELEASE 2 Revised Sections II–VIII to add information about the iEXOS 100 mount and

other updates. Added Appendix section for miscellaneous information, including

Application Notes. Miscellaneous cleanup of text.

This document uses the following convention for units of measure. Instead of stating: 30 counts/second

or 20 arc-sec/count, or 20 arc-sec per count, the units are stated as: 30 counts sec-1 or 20”arc count-1. The

superscript -1 indicates that the unit is in the denominator. You will see , ‘, and “ for degrees, minutes,

and seconds for angular values.

Motor count values are stated in decimal (115200) and hexadecimal (0x9C40) notation. The terms counts

and microsteps are synonymous depending on the usage. All the values returned by the controller are

hexadecimal strings such as “1F92CA”. Actual commands are shown in Courier New font with quotes

around the command string, i.e., “ESGp0!”. Do not include the quotes when typing the commands at a

terminal connected to the controller. Program names used to communicate with the PMC-Eight™ are

designated in Bold Italic, i.e., Parallax Serial Terminal.

The PMC-Eight™ Control System is warranted by Explore Scientific, LLC. If you have any questions or

issues when using this reference with your PMC-Eight™ system, you should contact Explore Scientific

Customer Support at +1 (866) 252-3811

CAUTION: BOARD FAILURE INDUCED THROUGH PROBING THE CIRCUITRY IS NOT COVERED UNDER THE

PMC-Eight™ LIMITED WARRANTY.

Page 4

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

3

Table of Contents

Document Notes 2

Table of Contents 3

Glossary 3

Acronyms 4

I. Introduction 5

II. System Description 6

III. PMC-Eight™ Controller and Command Language

Theory of Operation 13

IV. PMC-Eight™ ASCII Command Language 20

V. PMC-Eight™ ASCII Command Language Syntax 22

VI. PMC-Eight™ Hardware Interface Specifications 32

VII. PMC-Eight™ System Software Development Kit Information 33

VIII. Miscellaneous System Information 34

IX. Appendices 35

Application Note AN001: Firmware Update Procedure 36

Application Note AN002: Model 2A Switching Communications 39

Application Note AN003: Model 1A Switching Communications 44

Model 2A Analog Autoguider (ST4) Port Calibration Procedure 50

ASCOM Platform Conformance Test – PMC-Eight™ ASCOM Driver 55

Glossary

Axis—The rotational axis that the motor is driving, either RA or DEC.

Right Ascension (RA)—The rotational axis that parallels the Earth’s rotational axis.

Declination (DEC)—The rotational axis that allows the scope to move north or south.

German Equatorial Mount (GEM)—A type of mount that positions the telescope to move on one axis to

counteract the rotation of the Earth.

Hexadecimal—The base 16 number system using characters “0” through “9” and “A” through “F”.

Decimal—The normal base 10 number system used in everyday life using characters “0” through “9”.

Rate—The rotational speed at which the motors are driving the mount.

Position—The number of microsteps the motor has moved since startup.

Direction—The direction of the motor rotation (clockwise, or counterclockwise) when looking at the

shaft end.

Tracking Rate—The precision rotational speed of the RA axis motor at a very slow rate. Used to

counteract the rotation of the Earth.

Tracking—The act of counteracting the rotation of the Earth to keep an object in the center of the

telescope field-of-view (FOV).

North Celestial Pole (NCP)—The point in the Celestial Sphere where the Earth’s rotational axis points in

the Northern Hemisphere. Likewise, with the South Celestial Pole (SCP) in the Southern Hemisphere.

Firmware—The computer instructions installed in the permanent memory of the processor that

communicate directly with the hardware I/O on the system. The firmware is compiled on an external

computer and uploaded via the serial RS232(DB9)/USB communications port.

RS232—A communications hardware standard for serial communications.

Page 5

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

4

Acronyms

DEC Declination

EpW East Pointing West

FOV Field-of-View

GEM German Equatorial Mount

HA Hour Angle

HMI Human-Machine Interface

I/O Input/Output

JOC Jinghua Optical Corporation

LDO Low Drop Out

LMST Local Mean Sidereal Time

NCP/SCP North Celestial Pole/South Celestial Pole

OTA Optical Tube Assembly

PMC Precision Motion Controller

PMGR Programmer

RA Right Ascension

TCP Transmission Control Protocol

UDP User Datagram Protocol

WpE West Pointing East

Page 6

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

5

I Introduction

The Explore Scientific PMC-Eight™ Controller Programmer’s Reference contains the information needed

to understand the controller operation and to communicate and use the base controller command

language. This document contains the system description and other data that can be used to create

programs to control the PMC-Eight™. More information about the PMC-Eight™ controller can be found

on the Explore Scientific website at ExploreScientificUSA.com. Additional information is included in the

Application Notes available on the PMC-Eight™ webpage and in Section VIII: Appendices of this document.

One of the key elements of the PMC-Eight™ System is the Explore Scientific PMC-Eight™ Command

Language. This language is designed to be both flexible and powerful enough to instruct the controller to

perform any task the controller can perform. This language is different from most mount controller

languages in that it does not contain astronomy or telescope mount specific commands. This language

contains more generic motion control commands that enable the user to quickly learn and use the system.

The PMC-Eight™ System also has a built-in JOC Command Interpreter used by the OpenGOTO™ Explore

Stars App available at the Microsoft App Store, Google Play Store, and Apple App Store.

The PMC-Eight™ architecture was driven by the design philosophy of abstracting the astronomical

functions from the hardware/firmware layer and encapsulating them within the software

driver/application layer. This provides several benefits to the overall performance, reliability, and

operation of the control system. The system architecture is very similar to other industrial motion control

systems that are used for single and multiple motor control functions used in robotics, power plants, and

manufacturing facilities.

The model 2A circuit board design includes several features that contribute to the reliability and thermal

performance of the control system, including:

• Simple three-layer circuit assembly design with an internal ground-plane used as the system

electrical common and as a thermal heat sync. This design helps evenly distribute the heat from

the components throughout the board and out through the DB9 connectors and the all-aluminum

enclosure. The on-board LDO voltage regulators also provide a source of heat when operating in

very cold temperatures < 5F (< -15C).

• Electronic components are widely distributed on a single side of the circuit assembly to minimize

the chance of defects arising during manufacturing that could occur when placing components on

both top and bottom layers of the circuit board. This also contributes to the even distribution of

heat throughout the circuit board assembly.

• Wide circuit traces are used to maximize the conductivity between component pins and minimize

the voltage drop between components. This considerably reduces the amount of heat generated

when power from the on-board voltage regulators is delivered to the high-current motor driver

and motors. This greatly contributes to the long expected lifetime of the Model 2A.

• A conformal coating is applied to both sides of the completed circuit board assembly to create a

moisture barrier that protects the components from degradation due to moisture when operating

in high-humidity environments coupled with large temperature changes.

Most of these features are not included in the PMC-Eight™ Model 1A used in the iEXOS 100 mount.

Page 7

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

6

II System Description

The PMC-Eight™ is a high-precision stepper motor controller that very accurately controls the pointing

and tracking of a telescope mount. The design basis for this “industrial strength” Precision Motion

Controller (PMC) includes features to increase the reliability and flexibility of the system. The PMC-Eight™

model 2A includes several electrical and thermal design features and characteristics that provide plenty

of margin to ensure a long product lifetime in terms of individual assembly performance in the field, and

in the life-cycle of the design. The model 1A includes a basic level of thermal design features that help to

distribute and dissipate the heat generated in the system. Additional design elements incorporated in the

model 1A and 2A firmware take full advantage of the deterministic processing inherent in the processor

architecture to prevent complete system lockups. The system is designed to fail gracefully. While

individual functions of the system may fail due to external factors, the whole system should not

experience the lockups that other interrupt driven system may experience.

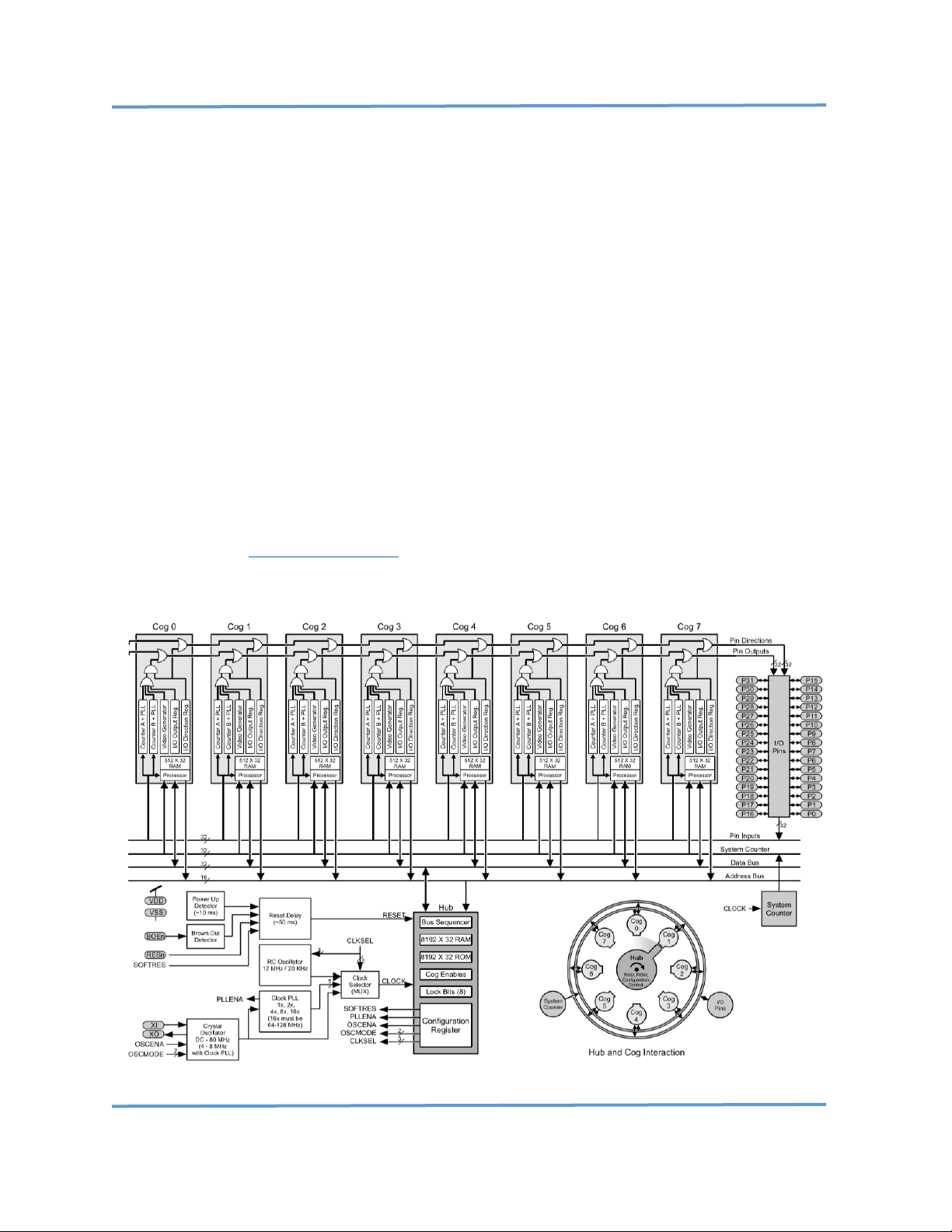

The microcontroller selected is a unique multi-processor design that uses eight processors, all working as

independent units and communicating through shared global memory. Each of these processors is

deterministic in its operation and DOES NOT use interrupts. This ensures that the task assigned to each

processor runs independently, and any failure of any one task does not cause a cascading failure in any of

the other processors; the result is a system that is designed to keep running even with a partial shutdown

of the processor. For more information about the operation of the Parallax Propeller™ Microprocessor

Chip, download the Propeller™ Datasheet . Note that both the model 2A and 1A use the same components

and have nearly identical schematics.

Parallax Propeller™ P8X32A 8-Processor Architecture/Block Diagram

Page 8

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

7

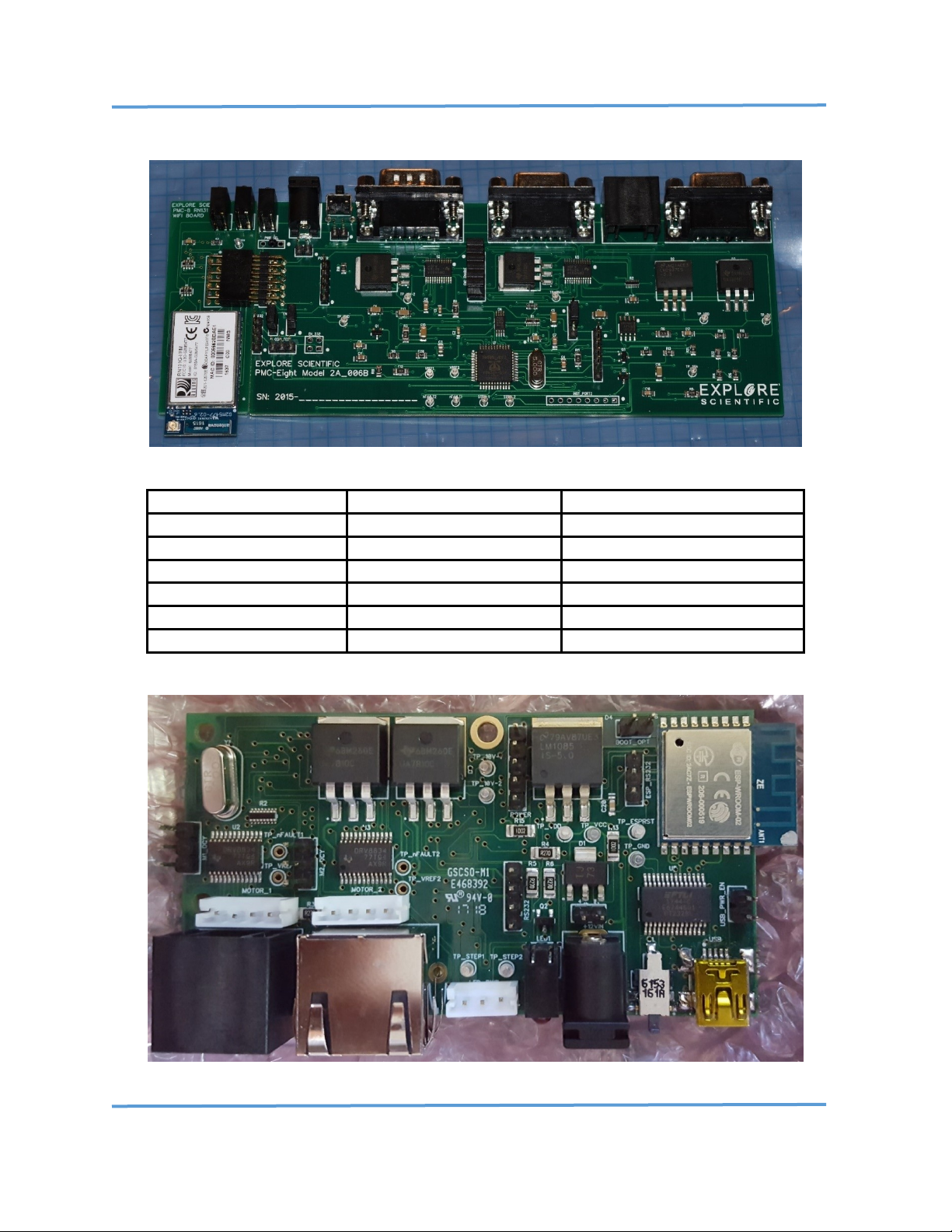

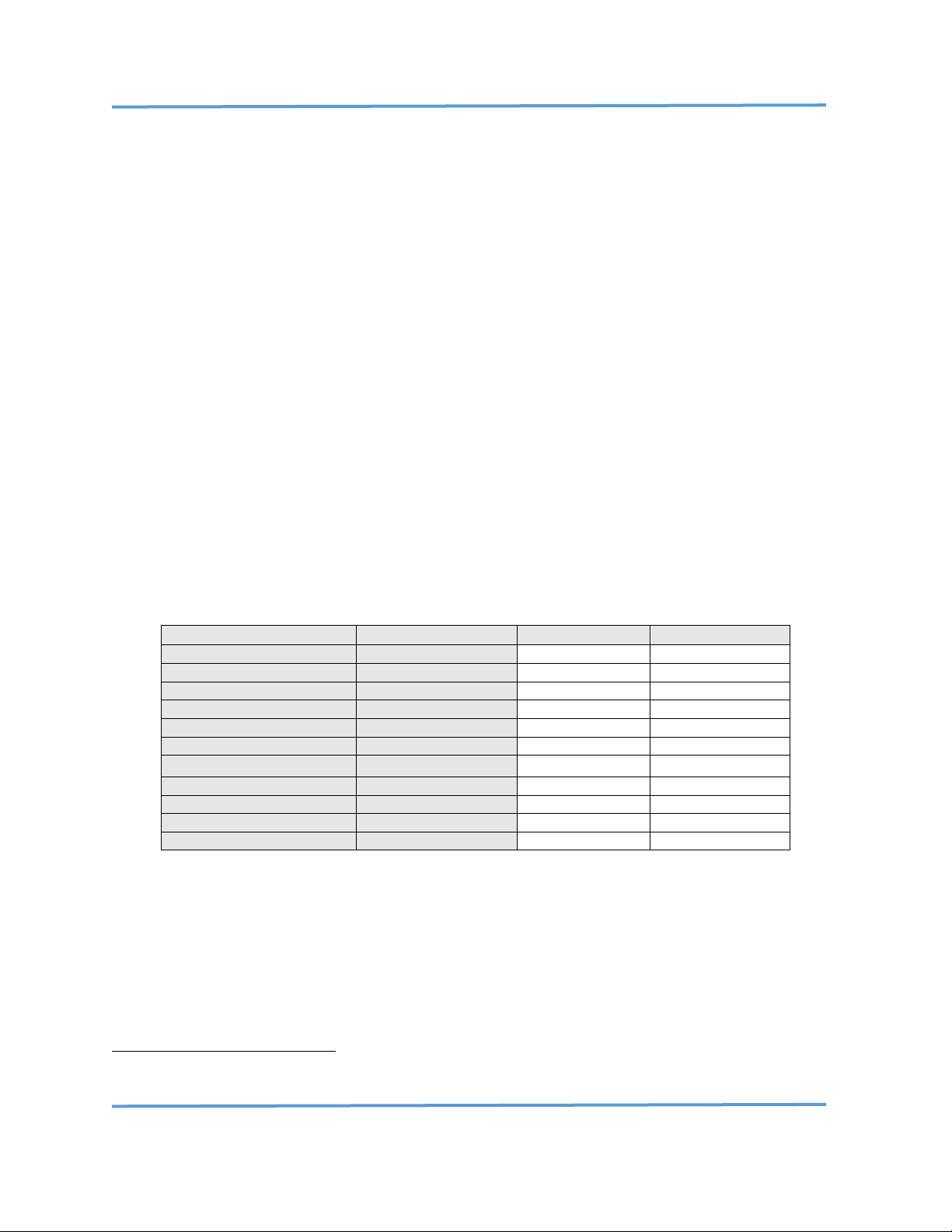

Both the PMC-Eight™ model 2A and 1A use the same components and have nearly identical schematics.

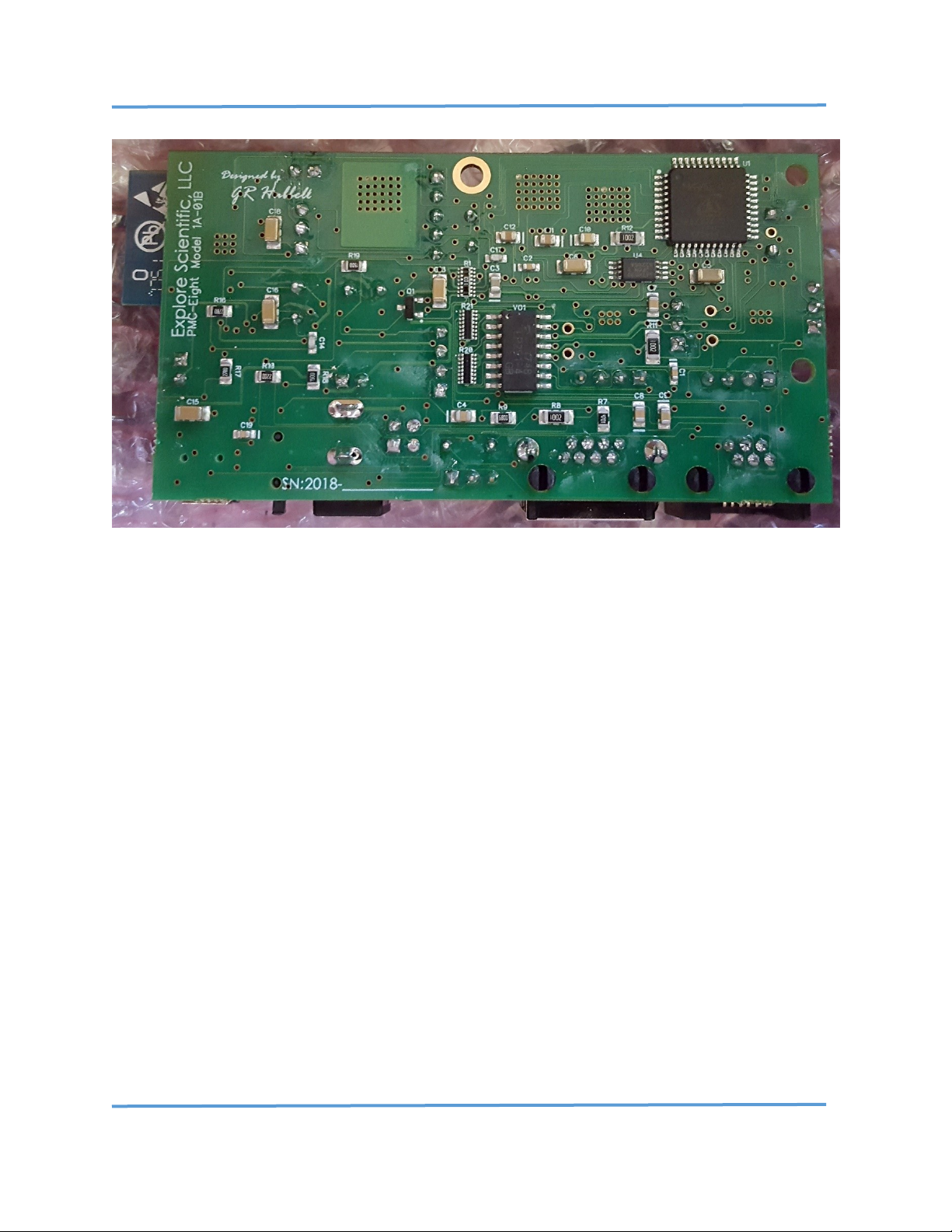

PMC-Eight™ Controller Model 2A-06B

Component

Part Number

Description

1(ea) Microcontroller

Parallax P8X32A-Q44

Propeller 8-CPU Microcontroller

1(ea) 8x64k Memory

Microchip AT24C512C

EEPROM Firmware & Storage

2(ea) Motor Driver

Texas Instruments DRV8835

Stepper Motor Driver Chip

1(ea) 2A-06B WiFi Module

Microchip RN-131G

WiFi Module

1(ea) 1A-01C WiFi Module

Espressif ESP8266

ESP-WROOM-02 WiFi Module

1(ea) 1A-01C USB

FTDI FT232RL

USB Serial Interface Chip

PMC-Eight™ Major Component List

PMC-Eight™ Controller Model 1A TOP

Page 9

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

8

PMC-Eight™ Controller Model 1A BOTTOM

The PMC-Eight™ system consists of several components and is designed to interface with the Host

Computer in several different ways. The primary interface to the PMC-Eight™ Model 2A-06B is through a

dedicated RS-232 interface (DB-9 connector) that serves both as the programmer’s (PGMR) interface for

loading updated firmware into the system and as the interface for sending data request commands and

receiving data. The primary interface to the PMC-Eight™ Model 1A-01C is through a dedicated mini-USB

type B connector that serves both as the programmer’s (PGMR) interface for loading updated firmware

into the system and as the interface for sending data request commands and receiving data. A wireless

network interface (Wi-Fi) is available also for sending data request commands and receiving data. This

wireless interface is the primary HMI interface for the OpenGOTO™ Explore Stars application available for

the Microsoft Windows OS, Google Android OS, and Apple iOS. For details, see Section VII, Miscellaneous

Programming Application Notes. The controller communicates at 115,200 BAUD with No Parity, 8 Bits, 1

Stop Bit over the network, through the RS232 connection and the USB connection.

Page 10

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

9

PMC-Eight™ System Boot Up

When the PMC-Eight™ system boots up, if you are connected to it via the wired PGMR/Serial port, you

will see the following displayed on the Parallax Serial Terminal:

-------------------------------------------------------------

------------------------------------------------------------ PPPPPPP MM MM CCCCCCCC 88888

PP PP MMM MMM CC 88 88

PPPPPPP MM M M MM CC XXXXX 888

PP MM M M MM CC 88 88

PP MM MM MM CCCCCCCC 88888

------------------------------------------------------------Copyright 2013-2018 Explore Scientific LLC., Gerald R Hubbell

1010 South 48th Street, Springdale, AR 72762

PMC-Eight Support 1-866-252-3811

http://www.explorescientificusa.com

------------------------------------------------------------Portions of FIRMWARE covered by MIT LICENSE terms

------------------------------------------------------------Explore Scientific PMC-Eight Controller - Startup

Initializing PMC-Eight Model 1A-01C-FW10B1a 10 AUGUST 2018...

CONFORM TEST VERSION - COMMUNICATIONS TIMEOUT DISABLED

------------------------------------------------------------EEPROM Memory Test - Basic

MEM_TEST1:F0F0F0F0

MEM_TEST2:0F0F0F0F

MEM_TEST3:F0F0F0F0

MEM_TEST4:0F0F0F0F

MEM_TEST5:F0F0F0F0

----------------------------------------------------------Command Processor Started

JOC Controller Command Set: Enabled

PMC-Eight Diagnostic Command Set: Enabled

PMC-Eight ES Command Set: Enabled

System Initialized!

------------------------------------------------------------BAUD Rate Value: P0 115200

Assigned SSID: PMC-Eight-280D

Communications Channel - Enabled: P1 Serial

WiFi Protocol - Disabled: P2 UDP/IP

Assigned WiFi Channel Number: 7

ST4 port Sidereal Rate Fraction: P3 40

Unused Value: P4 0

Unused Value: P5 0

Unused Value: P6 0

Unused Value: P7 0

Unused Value: P8 0

Unused Value: P9 0

-------------------------------------------------------------

PMC-Eight™ Boot-Up Splash Screen

After the copyright information is displayed on the PMC-Eight™ boot splash screen, the current firmware

version installed in the controller is displayed. You can also use the “ESGv!” command to obtain the

current firmware version. The bottom portion of the PMC-Eight™ boot splash screen shows you the

current configuration of parameters P0–P9. The ones to make note of include P1-Communications

Channel, P2-WiFi Protocol, and the value of the Assigned WiFi Channel Number.

Updating/Restoring/Loading Firmware

The firmware on the PMC-Eight™ model 1A and 2A can be updated via the PGMR/Serial port. The

document Explore Scientific PMC-Eight™ Application Note PMC8-AN001: How-To Update the PMC-

Eight™ Control System Firmware (located in the Appendices) explains this process. The firmware files are

in a Knowledge Base Article on the Explore Scientific USA website, just search for “firmware” in the

Knowledge Base search tool.

Page 11

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

10

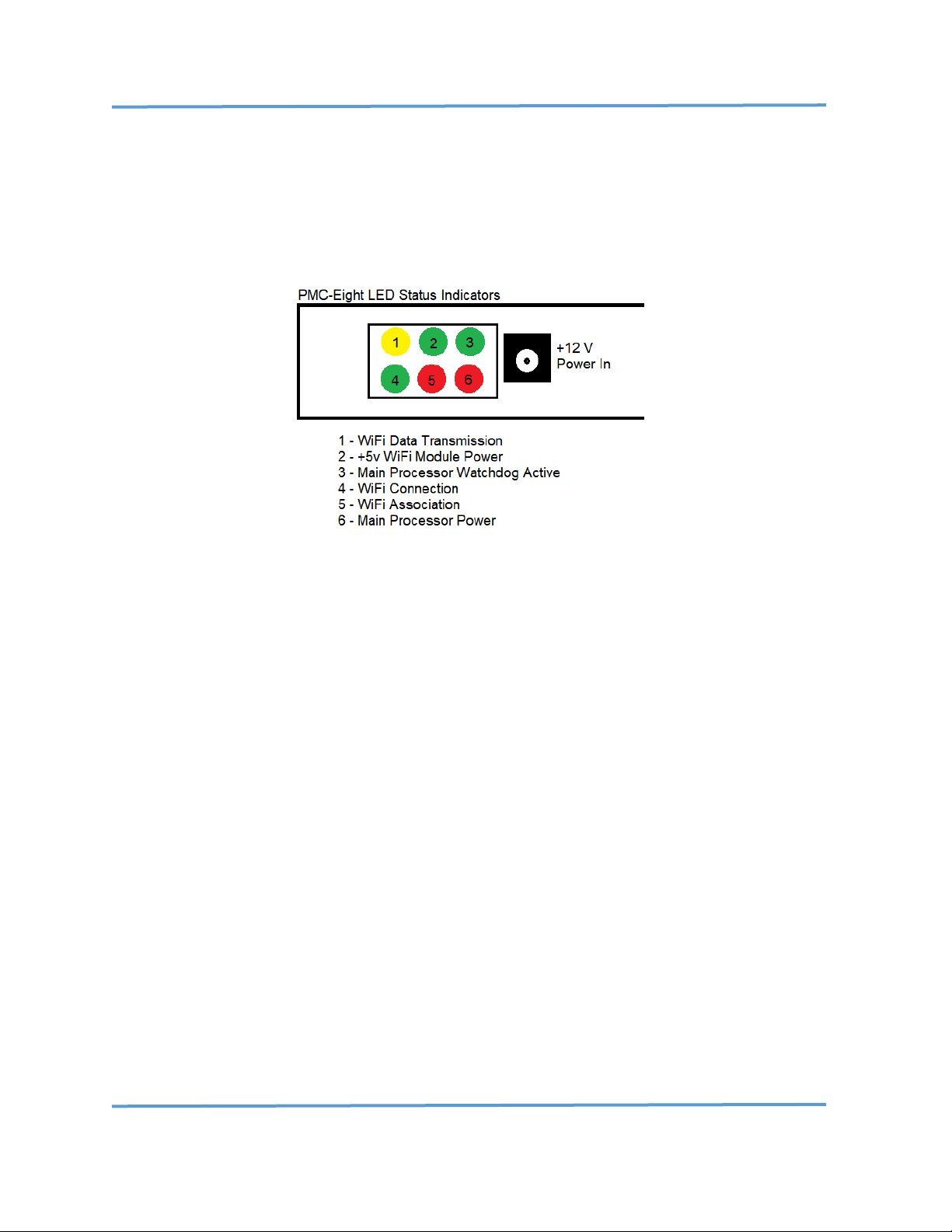

Board Status Indicator LEDs

The model 2A-06B and model 1A-01C PMC-Eight™ processor boards have two LEDs; the RED LED (6) is ON

when power is applied to the board. The GREEN LED (3) is ON indicating the processor status after the

processor firmware boots up and active communications are going on with the processor, and the

watchdog process is active monitoring the communications.

PMC-Eight™ Model 2A-06B Status LEDs

The model 2A-06B PMC-Eight™ RN-131 daughter board has four LEDs; The YELLOW LED (1) is FLASHING

when there is data transmission between the PMC-Eight™ and the host computer application—either the

ExploreStars application or the ASCOM Driver. The RED LED (5) is the WiFi association status and flashes

until a connection to the model 2A-06B SSID (PMC-Eight-xx) of the PMC-Eight™ is made by the host

computer. The GREEN LED (2) is ON when power is applied to the daughter board from the main board.

The GREEN LED (4) FLASHES FAST when a connection is ACTIVE. LED (4) FLASHES SLOW when the module

is waiting on a connection. The model 1A-01C PMC-Eight™ uses the Espressif ESP-WROOM-02 (ESP8266)

WiFi module for wireless communications. There are no communications status lights provided on that

version of the PMC-Eight™.

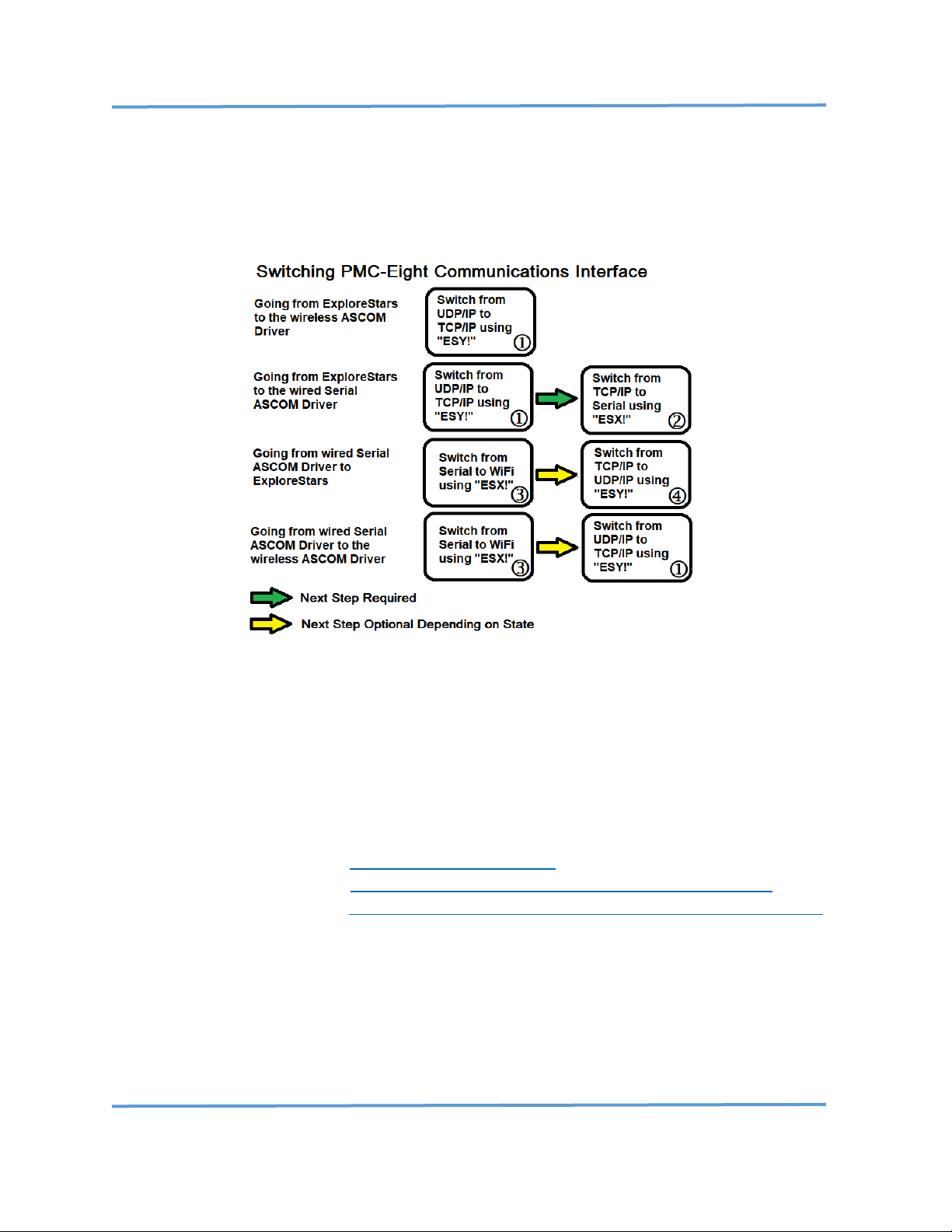

Switching PMC-Eight™ Communications Channels

You can use the document Explore Scientific PMC-Eight™ Application Note PMC8-AN002: Connecting to

the PMC-Eight™ with a Terminal Program to Configure the RN-131 WiFi Interface and Switching

Between the WiFi Interface and the Serial Interface, and the document Explore Scientific PMC-Eight™

Application Note PMC8-AN003: Switching Between the WiFi Interface and the Serial Interface on the

iEXOS 100™ Mount Controller (available in the Appendix at the end of this document) to switch the

communications channel from WiFi (UDP/TCP) to Serial and back again.

Page 12

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

11

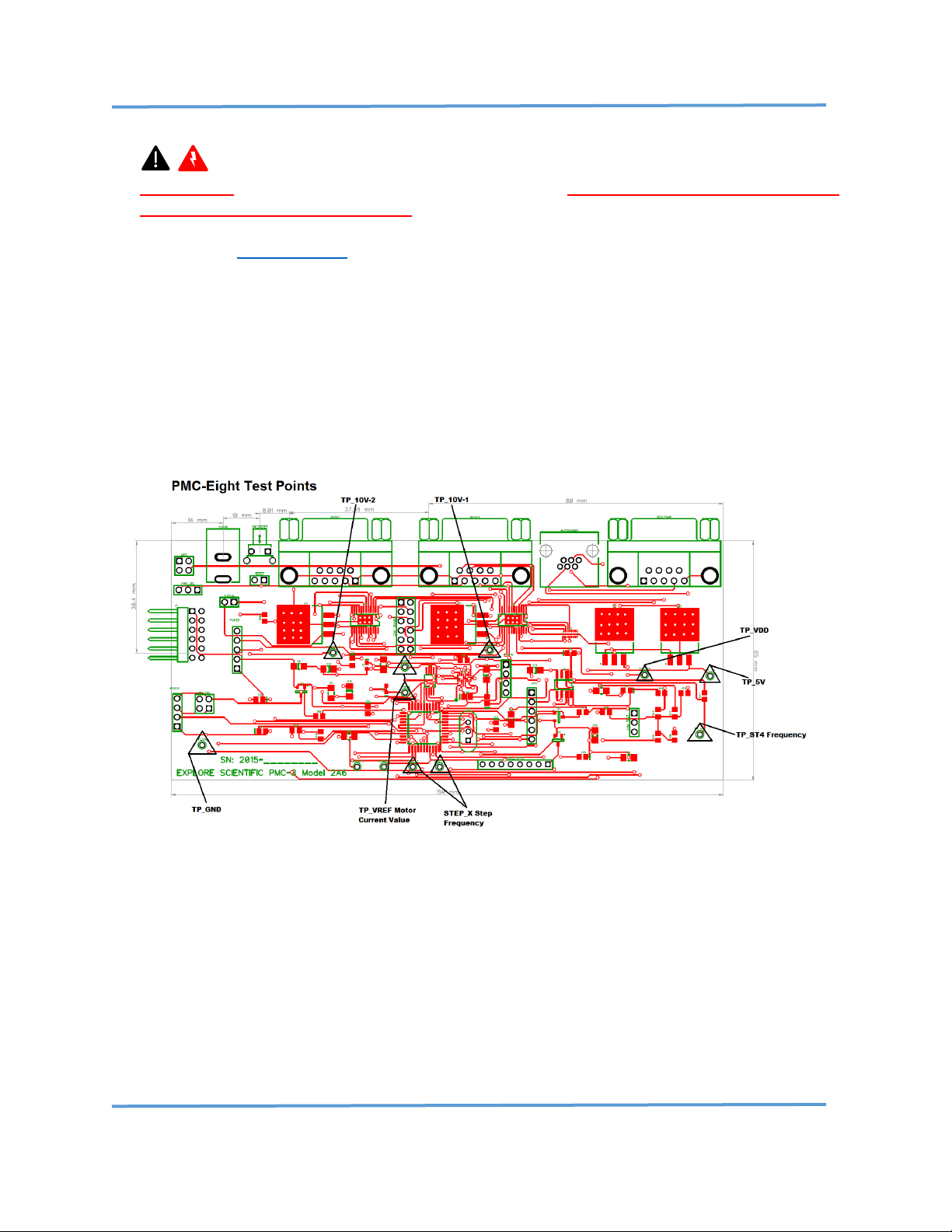

Model 2A Circuit Test Points

WARNING: Prior to opening the PMC-Eight™ enclosure, ensure that you are familiar with all

applicable electrical safety procedures as they apply to working on low-voltage DC circuits. Circuit

failure may occur if proper procedures are not followed when probing the circuitry. See this extensive

discussion on Electrical Safety.

CAUTION: BOARD FAILURE INDUCED THROUGH PROBING THE CIRCUITRY IS NOT COVERED UNDER

THE PMC-Eight™ LIMITED WARRANTY.

There are several test points on the model 2A-06B circuit board assembly (indicated below with a black

triangle) labeled TP_XXXX, such as: TP_GND, TP_VDD, TP_10V-1, TP_10V-2, and TP_5V. There are also test

points to measure the reference voltages for the current limits and the ST4 port frequency and stepper

motor pulses. Headers on the assembly provide access to the RS-232 signals, the power supply voltages

(3.3 Vdc, 5.0 Vdc, 10.0 Vdc, and GND), and the WiFi serial communications signals (COM_TEST header).

PMC-Eight™ Controller Version 2A-06B Test Points

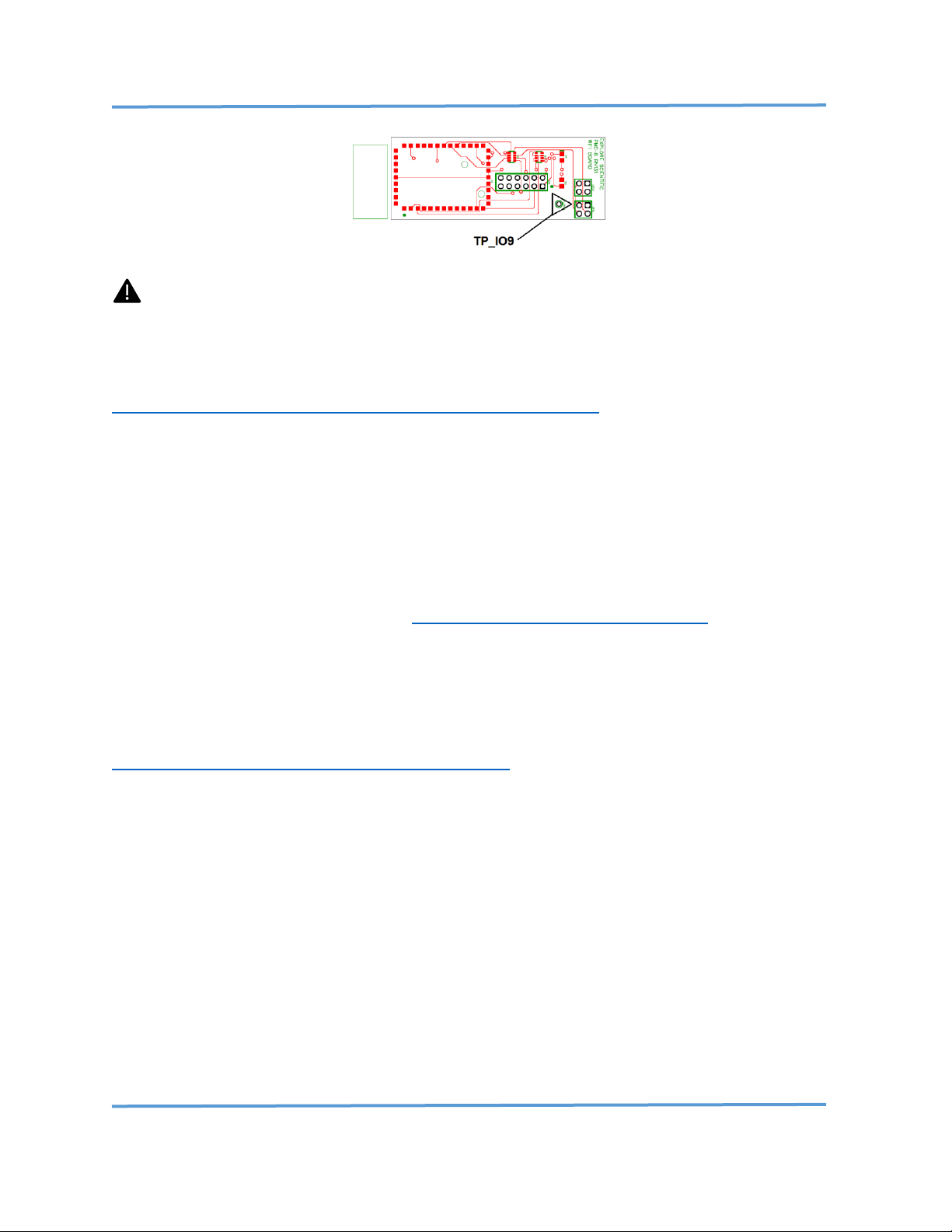

The PMC-Eight™ model 2A-06B WiFi module (Microchip RN-131G) daughter board has a test point

(TP_IO9) used in resetting the module to the Microchip factory defaults. Explore Scientific PMC-Eight™

Application Note PMC8-AN002: Connecting to the PMC-Eight™ with a Terminal Program to Configure

the RN-131 WiFi Interface and Switching Between the WiFi Interface and the Serial Interface (available

in the Appendix at the end of this document) describes in detail how to connect to the Microchip RN-131

Module and restore the PMC-Eight™ default configuration.

Page 13

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

12

PMC-Eight™ Controller WiFi Daughter Board

CAUTION: Changing the WIFI module configuration from the default factory configuration is at

your own risk.

You can also use Application Note AN002 to configure the Microchip RN-131 Module to communicate on

your Local Area Network (LAN). The Microchip RN-131 WiFly Command Reference Manual is located at

http://ww1.microchip.com/downloads/en/DeviceDoc/50002230B.pdf.

WiFi Channel Selection

In some instances, the WiFi environment is very busy with several SSIDs, and if the PMC-Eight™ WiFi

module is configured to use the same channel as others, this can disrupt the communications, regardless

of the signal strength, and may make the PMC-Eight™ WiFi drop out. The default channel configured in

the RN-131 wireless module is channel 6, which is a popular channel for many WiFi devices. The solution

is to change the WiFi channel. You can do this with the ST4 port (RJ12) dongle included with your PMCEight™ system. You can learn more about how WiFi and channels work in the specification document for

IEEE 802.11. An overview is available here: https://en.wikipedia.org/wiki/IEEE_802.11

Here is the procedure to increment the channel number:

NOTE: You can monitor the channel number selected by the channel change procedure by downloading,

installing, and running the program WiFiInfoView available at:

http://www.nirsoft.net/utils/wifi_information_view.html

1. Power up the PMC-Eight™ and it will boot up (the lights will settle out).

2. Insert the dongle into the Autoguider port (ST4 RJ12).

3. Watch the LEDs cycle, as the system reboots.

4. Remove the dongle.

5. Wait until the LEDs settle down, then Reconnect your tablet to the mount’s SSID.

6. Try to connect the ExploreStars or ASCOM Client application to the PMC-Eight™

7. IF you still cannot connect and see the “Please Wait” message, THEN press the reset button.

8. Repeat steps 2 – 7 as needed.

It is recommended to power down the system and then power it back up between steps 3 and 4, but this

shouldn't be necessary. If the new channel still gives problems, the procedure can be repeated (step 8)

until successful. The number (channel) will increment by one each time the dongle is used to change the

channel and will recycle back to 1 after reaching channel 11. There are 11 channels available in total,

channels 1–11.

Page 14

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

13

III PMC-Eight™ Controller and Command Language Theory of Operation

Controller Theory of Operation

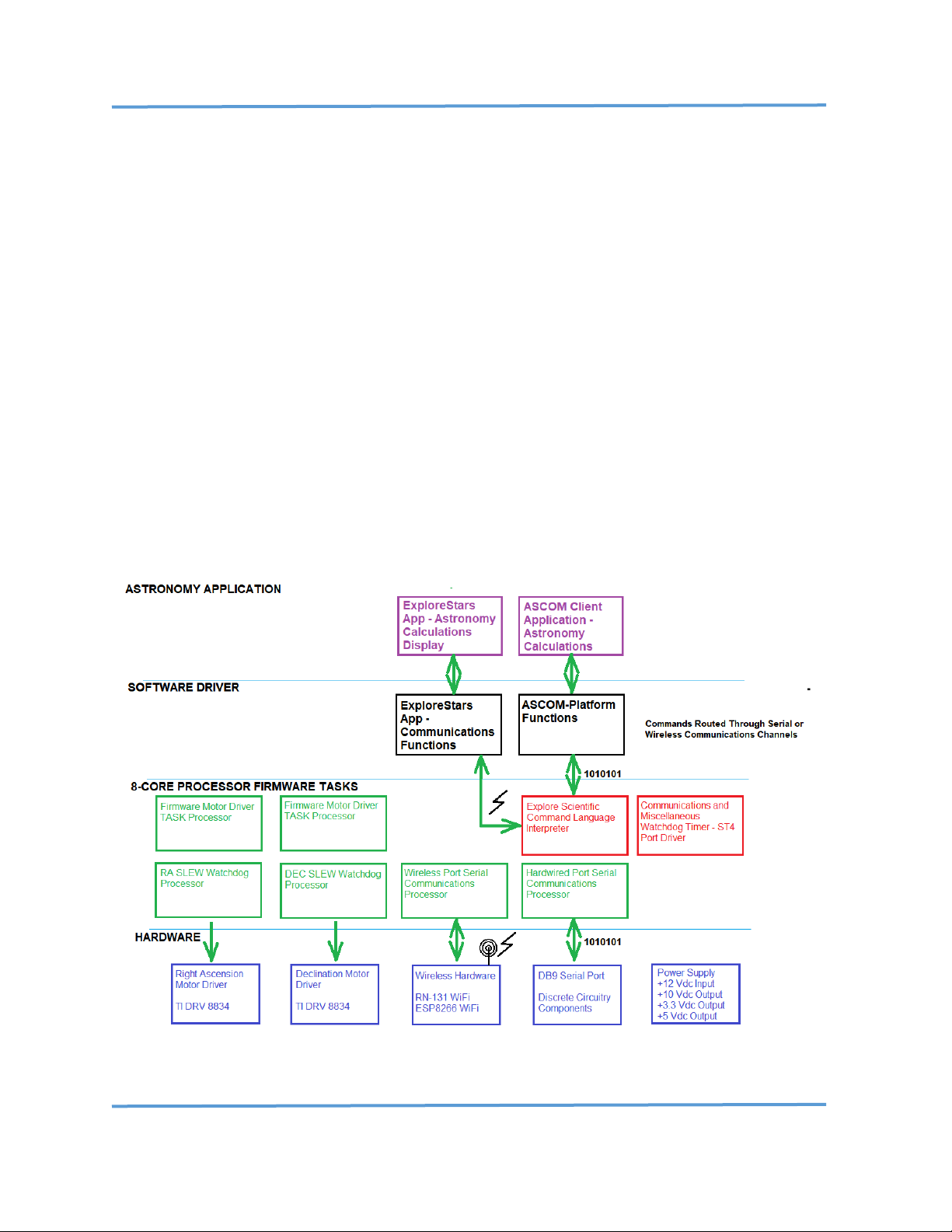

The PMC-Eight™ Precision Motion Controller is designed to enable the quick and reliable movement of

the telescope OTA to point to any object of interest on the celestial sphere. The controller is made up of

three main electronic subsystems: a) Computer Processor and Memory System, b) Motor Driver System,

and c) Communications Interface.

The Computer Processor and Memory System processes and interprets the incoming commands and

provides data output to the communications channels. Eight processors are integrated into the

microcontroller chip (Parallax Propeller Microprocessor P8X32A), each with its own dedicated memory

space and common memory space for sharing information between the processors. There is also a system

RESET/REBOOT momentary push-button switch next to the 12 Vdc Power input. Two processors are

dedicated to communicating with each motor, reading the real-time motor parameters, and generating

the required DIRECTION and RATE motion values real-time to command the motors . One processor is

dedicated to communicating via the RS232 Serial Port via the port driver. One processor is dedicated to

taking the commands and translating them into executable instructions. One processor is dedicated to

monitoring the motor status and reading the Autoguider port. Two processors for the motors are used

only when monitoring the status of the real-time SLEW process. The processors run independently so that

if any one processor fails, it will not affect the operation of the others.

PMC-Eight™ System Architecture

Page 15

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

14

The Texas Instrument DRV8834 Motor Driver integrated circuit chip (one for each motor channel) is

designed to generate the required low-level stepper motor control/drive signals at the proper voltage and

current levels needed to drive the mount as required. A performance margin is built into the system to

enable the mount to operate over a wide temperature range. These motor driver chips are low power and

very efficient in delivering the power to the stepper motors reliably.

PMC-Eight™ Communications

There are three communication interfaces on the system. The first is the base serial interface using the

RS232 hardware specification and the Parallax recommended interface circuitry to provide basic

communications to transfer firmware and data to the permanent memory of the Computer Processor and

to configure the wireless network Wi-Fi processing module.

PGMR/ ST4

Serial Autoguider DEC RA RST PWR LEDS

Model 2A PMC-Eight™ connections.

The model 2A-06B serial command processor/interpreter can be accessed via the RS232 port and via the

second interface, the RN-131 wireless network interface. The model 1A-01C serial command

processor/interpreter can be accessed via the mini-USB Type B port and via the second interface, the ESPWROOM-02 (ESP8266) wireless network interface. The third communications channel is via the RJ 6P6C

connector configured as an SBIG ST4 Autoguider Port. This port is also used to change the WiFi Channel,

when needed, using the supplied ST4 port dongle.

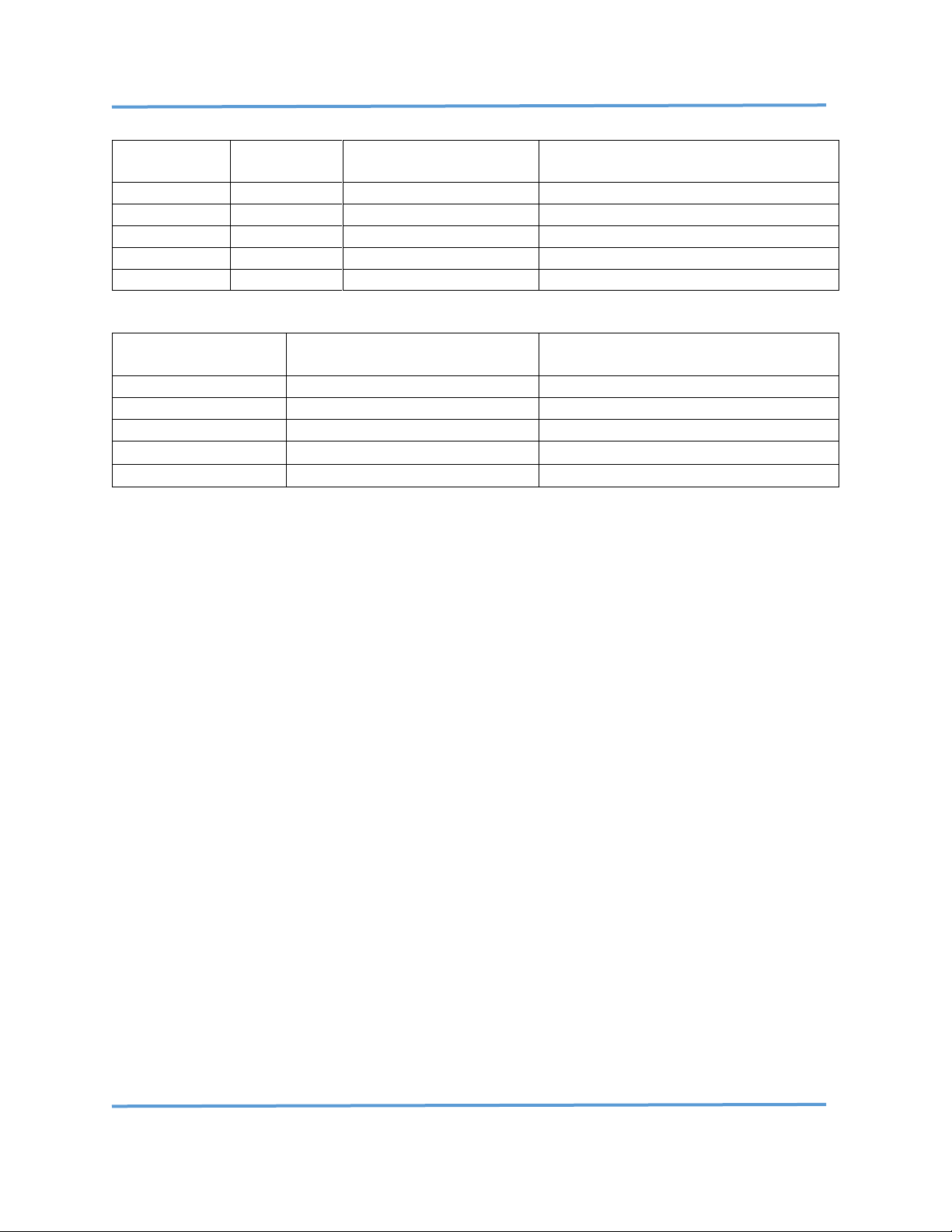

PMC-Eight™ Fixed Tracking Rates

There are several fixed tracking rates available for the PMC-Eight™ ASCOM driver and one fixed rate is

available for selection in the ExploreStars™ application. The Sidereal, Solar, Lunar, and Average King rates

are available for selection. The following tables show the tracking rate values and their corresponding

settings in the customer rate section of the ExploreStars application. These rates are pre-defined in the

ASCOM driver.

NOTE: The different mount rates specified in microstep sec-1 are specified to the nearest 0.04 (± 0.02)”arc

sec-1. This value is based on the internal precision of the firmware integer calculation and setting of the

precision tracking rate value. (See

Page 16

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

15

Application

Object Rate

Solar-Second Rate Value

“arc sec-1

Sidereal-Second Rate Value

“arc sec-1

ExploreStars

Sidereal

15.041

15.000

ASCOM Driver

Sidereal

15.041

15.000

ASCOM Driver

Solar

15.000

14.959

ASCOM Driver

Lunar

14.491

14.451

ASCOM Driver

Average King

15.037

14.996

Fixed Tracking Rate Values

Fixed Tracking Rate

G11 microstep sec-1

@0.28125 arc-sec microstep-1

EXOS 2 & iEXOS 100 microstep sec-1

@0.31250 arc-sec microstep-1

Sidereal

53.32

48.00

Solar

53.20

47.88

Lunar

51.40

46.24

Average King

53.32

48.00

Custom Rate

See Calculation

See calculation

Explore Stars Mount Rate Setting Values

The value of 53.32 microstep sec-1 in the table for the G11 is very close to the actual calculated Average

King rate of 53.3191 microstep sec-1.

The user can also set a custom rate value based on the following equation:

Microstep Rate Value (microstep sec-1) = Sidereal-Second Rate Value (“arc sec-1) / X (“arc microstep-1)

Where X = specific mount’s motor scaling value in “arc microstep-1

For example, if you want to visually observe a comet with the ExploreStars application that is moving

across the sky in RA a little faster than Sidereal, namely at 16.35 “arc sidereal-sec-1 with your G11 mount,

then the calculation would be:

Rate Value = (16.35 “arc sidereal-sec-1/ 0.28125 ”arc microstep-1)

= 58.133 microstep sec-1

= 58.12 microstep sec-1 (rounded to nearest ±0.02 microstep sec-1)

When this value is entered the ExploreStars application would immediately start tracking at that rate.

There would still be a need to move the mount in Declination due to the objects motion in the Declination

axis that is not corrected when in the “square-T” Tracking Mode.

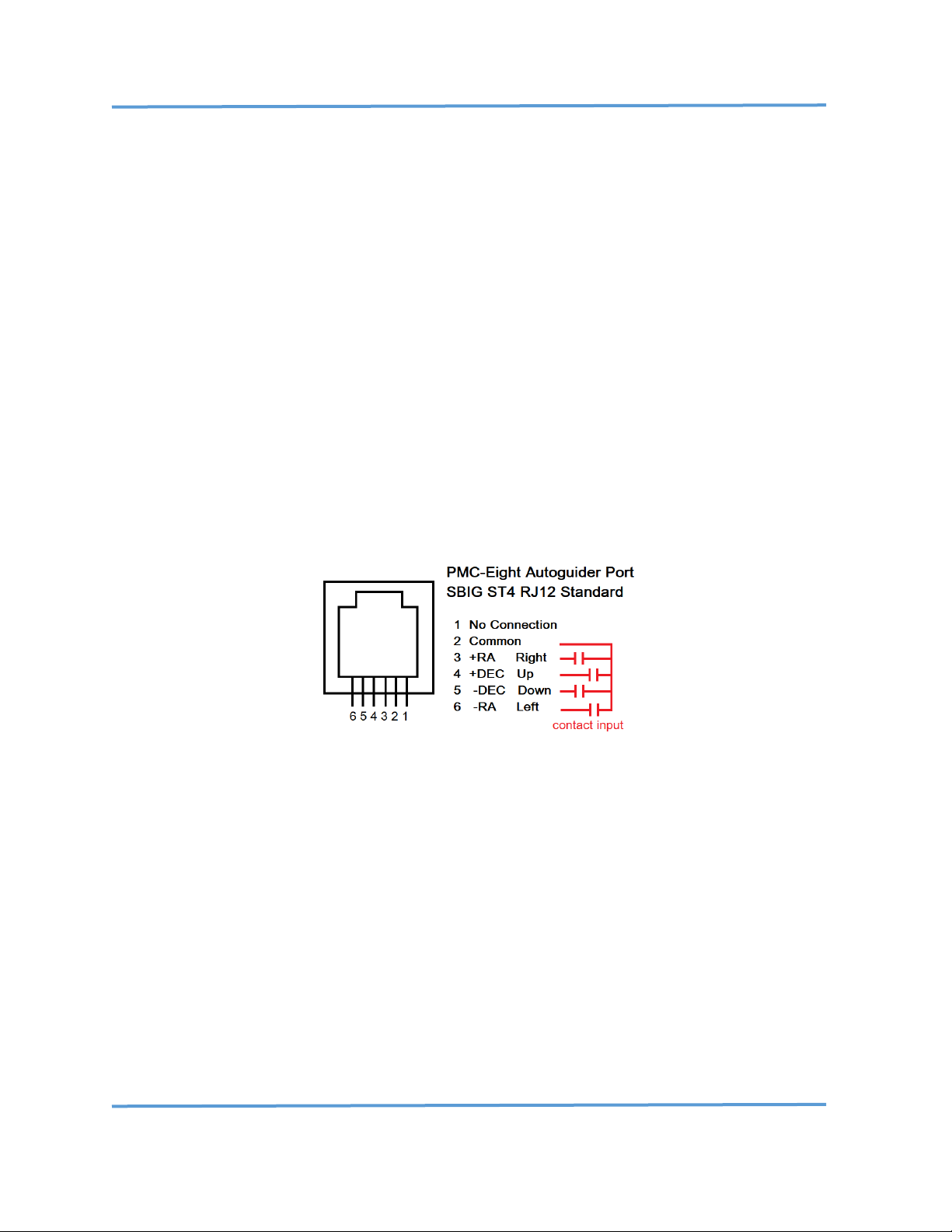

Autoguider (ST4) Port

Both the model 2A and model 1A ST4 port have dedicated interface circuitry to provide contact input

commands into the controller to slowly move the mount in the four cardinal directions to correct for any

tracking errors due to drift in Right Ascension (RA) or Declination (DEC) drift caused by less than perfect

polar alignment.

Page 17

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

16

The ST4 port on the PMC-Eight™ model 2A-06B uses an analog multiplexer design (VCO) to convert the

four contact inputs sent from the Autoguider camera to the controller into numeric values that can be

processed by the firmware into direction values (N, S, E, W). The analog design requires a factory default

calibration that is included in the firmware. The port meets all the SBIG ST4 standard requirements for

processing a “contact closure” input. Contacts are between each direction pin (N, S, E, W) and the

common pin.

Most guide cameras provide an ST4 compliant “contact closure,” or equivalent, via a MOSFET transistor

circuit using a high-quality component. Some cameras, however, do not have a MOSFET transistor that

provides the correct “contact closure” input resistance (shorted input) but instead provides a higher

resistance input that does not work with the PMC-Eight™ ST4 factory default calibration. In this case,

customers must contact Explore Scientific to have their ST4 input calibrated to their specific camera. See

Appendix VIII.4 “Explore Scientific PMC-Eight™ version 2A-006A/B Autoguider (ST-4) Port Calibration

Procedure (Rev 1.3) Firmware Version 9r4 08162015 AND LATER (2015 August 22)” for details on this

procedure.

The ST4 port on the PMC-Eight™ model 1A-01C uses a digital transistor optocoupler circuit design that

provides a reliable and optically isolated input to the controller from the guide camera system. This

updated digital transistor optocoupler circuit design has also been incorporated into the latest Model 2A07A board design. The significance of this design is that it does not require calibration.

Autoguiding (ST4) Port Pinout

Inputs to the Autoguider port are interpreted by the firmware to adjust the rate according to the Sidereal

Rate Fraction, i.e., Percent Sidereal Rate, configured in the PMC-Eight™ ASCOM driver. The factory default

value is set to 40% or 0.4 x 15.00”arc sec-1, or 6.00”arc sec-1. This value is stored in the system EEPROM as

Parameter 3 (P3) so that when using the ST4 port and RJ12 (6P6C) cable to connect directly to an

Autoguider camera, that camera knows what value to use. The Autoguiding software, PHD2™ corrects any

tracking error by sending pulses to the mount that are different time intervals typically from 20 mS to

200+ mS in length, depending on the amount needed to move the mount back to the target star that

PHD2™ is locked onto.

The total movement needed to correct a position error is the product of correction rate and pulse time.

For example, with a measured position error of 1.07”arc and the Sidereal Rate Fraction set to 0.40 or

6.00”arc second-1, the pulse time would equal the position error 1.07”arc / 6.00”arc second-1, or 0.178

seconds (178 mS).

Page 18

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

17

Command Language Theory of Operation

The Explore Scientific Command Language commands are used to send data requests and instructions to

control the motors and receive status data back from the hardware. Four basic types of commands are

used to interrogate the controller, two general purpose commands, and two special purpose commands.

The GET and SET commands are used to get and set real-time motor parameters. These are general

purpose commands to get and set a variety of parameters. The two special purpose commands are the

POINT and TRACK commands. Each of these commands are applied to a given motor axis defined by the

AXIS value. With a telescope mount there are 2 predefined axes: AXIS 0: RA/AZ, AXIS 1: DEC/ALT. This

command language can support multiple axis controllers with any number of axes.

The GET and SET commands have several primary parameters dealing with motor operation: DIRECTION,

POSITION, RATE, and TARGET. The three main parameters, DIRECTION, POSITION, and RATE are statically

set and are fixed until the next time they are changed with a SET command. The SET commands for

DIRECTION and RATE are immediate commands and update the values in real time. The SET POSITION

command is used to adjust the motor position coordinates when calibrating the position in reference to

the celestial coordinate system, or when SYNCING with the celestial coordinates of a given object.

The GET commands allow you to interrogate the controller for various real-time parameters, including:

DIRECTION, POSITION, RATE, and TARGET. Other parameters that are available are FIRMWARE VERSION,

SYSTEM INFORMATION via an Index value, and the current TRACKING RATE value.

NOTE: The SYSTEM INFORMATION command is not implemented in firmware versions 9T10, 11, and 12,

and 10A01.

The controller is designed to handle the requirement for fast slews and very slow, precise tracking rates

by implementing two rate types, like a HIGH and LOW in a four-wheel drive vehicle. Standard Rate (SLEW)

and Precision Track Rate (TRACK) commands are provided. The SLEW Rates are 25x faster than the TRACK

Rates. The rate values can be set to any value between 0 and 40000 (decimal), 0x9C40 (hexadecimal). For

the ES/Losmandy G-11, this equates to SLEW rates up to 3.125 sec-1 on each axis1. This allows the system

to SLEW the telescope 180 across the sky in 60 seconds. The TRACK rate allows for setting the RA motor

rate up to 450.00”arc sec-1 with an accuracy of ±0.006”arc sec-1. The standard GET/SET RATE command

sets the SLEW rates. The TRACK command and GET TRACKING RATE command are used to SET/GET a more

precise tracking rate value. This is an equivalent rate selection range of 1:1000000.

The POINT command is a higher-level FIRMWARE command that automatically calculates the necessary

rates to efficiently SLEW to a TARGET. The process algorithm handles the ramping up and down of the

motor rate to manage the inertial load placed on the stepper motors. In addition, the motor current is

carefully managed to provide enough torque while slewing to accurately position the telescope on the

object desired without exceeding the motor capability. The GET/SET commands for FIRMWARE VERSION

and SYSTEM INFORMATION are used to query and set various values such as communications BAUD rate,

Sync Offset Positions, and Axis Scale values.

1

This angular rate is for the ES/Losmandy G-11 mount. Other mounts will slew faster or slower, depending on the

total motor counts for the drive.

Page 19

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

18

The PMC-Eight™ controller can be remotely rebooted using the BOOT SYSTEM command. This reinitializes

the controller but does not reboot the wireless communications system on the model 2A. You can also

use the BOOT COMMUNICATIONS command to remotely restart the wireless communication system. This

is also independent of the system controller and does not reset the motor drivers or the current motor

counts. To reboot the entire system, you must remove power and reapply power to the controller system.

The Get Motor Position Command returns the motor position string in Hex Value. The string is in the

format “FFFFFF”. The value returned is in the range 0x000000 to 0xFFFFFF, where positive values range

from 0x000000 to 0x7FFFFF and the negative values range from 0xFFFFFF to 0x800000. The scaling of the

motor gear position limits the actual values used to slew the motors. The two motors are on the RA and

the DEC axis of a German Equatorial Mount (GEM). The angular range for counts depends on the motor

count scaling value and is calculated as follows:

NOTE: This example uses the ES/Losmandy G-11 mount.

The ES/Losmandy G-11 uses direct coupled stepper motors whose motor scaling value uses only the wheel

tooth count, the stepper motor steps, and the driver microstep value. The ES/Losmandy G-11 uses a 360tooth wheel and 400-step motors. The driver uses 32 microsteps step-1. The total count for a 360-degree

rotation of both the RA and DEC axis is equal to 360 teeth * 400 steps * 32 microsteps, which is equal to

4,608,000 counts per 360-degree rotation. The angular motion per step in “arc is equal to the total number

of “arc/4,608,000 counts. 360 degrees is equal to 360 x 60 x 60”arc or 1,296,000”arc. The “arc count-1 is

equal to 1,296,000/4,608,000 or 0.28125”arc count-1.

So, in the case of the ES/Losmandy G-11, one rotation in RA, or 24 hours (sidereal time) is equal to

4,608,000 counts or in Hex, 0x465000. The RA value counts positive and negative from the Meridian+6

hours or Local Mean Sidereal Time (LMST)+6 hours. On a GEM mount, the way the telescope is pointing

is an important consideration when determining the motor counts. As the GEM is tracking, when the

telescope gets to the Meridian, a maneuver called a “Meridian Flip” is performed. To help explain, this

here is the sequence of events.

NOTE1: This description is only valid for mounts located in the Northern Hemisphere. The ASCOM driver

detects the hemisphere where the mount is located via the LATITUDE value set in the configuration dialog

box and adjusts the driven RA direction accordingly. The PARK reference position is either the NCP or SCP

(North/South Celestial Pole), with a corresponding motor count on RA and DEC of 0 (0x000000).

NOTE2: This description only applies to the ES/Losmandy G-11 because the description of the motor

counts increasing or decreasing depends on the gear direction for this mount.

1. The mount is pointing the telescope to an object in the EAST. The mount is tracking at

SIDEREAL rate toward the WEST, and the RA motor counts are POSITIVE and INCREASING. The

RA motor counts are in the range 0 (0x000000) moving toward 1152000 (0x119400). The

object the mount is pointing to is also NORTH of the ECLIPTIC or has a positive DEC value

between +0.000 and +90.000 degrees. This is a fixed DEC motor count value between 0

(0x000000) and 1152000 (0x119400) when WpE. The DEC axis counts INCREASE going SOUTH

from the NCP. Objects that are SOUTH of the ECLIPTIC have values between 1152000

(0x119400) and 2304000 (0x232800). These values are from -0.000 to -90.000 degrees. This

pointing position is called “West Pointing East” or WpE. This means that the telescope is WEST

Page 20

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

19

of the PIER and pointing EAST of the MERIDIAN. In the ASCOM driver, this is referred to as

“PierWEST,” where the Hour Angle (HA) is less than zero (HA<0) and DECREASING in value.

2. When the mount RA axis finally arrives at the LMST value of 1152000 (0x119400), then the

mount should execute a Meridian Flip. The flip maneuver SLEWS the RA axis back to the EAST

equal to approximately 12 hours of RA or 180 degrees. This means that the RA motor counts

DECREASE from 1152000 (0x119400) moving toward 0 (0x000000) and then continue to 1152000 (0xEE6C00). At the same time, the DEC axis SLEWS to the NORTH, DECREASING the

motor counts, passing through the NCP while crossing 0 (0x000000) counts and continuing

down toward the object’s DEC motor count value between 0 (0x000000) and -2304000

(0xDCD800) counts.

3. At the completion of the flip maneuver, the RA tracking begins to drive at the SIDEREAL rate

toward the WEST again, with the RA axis counts again INCREASING in value. The RA axis counts

are in the range of -1152000 (0x119400) moving toward 0 (0x000000). In this mode, the DEC

axis counts INCREASE going NORTH from -90.000 to +90.000 degrees or from -2304000

(0xDCD800) to 0 (0x000000) counts when EpW. This position, post Meridian Flip, is called

“EAST Pointing WEST” or EpW. This means the telescope is EAST of the PIER and pointing

WEST of the MERIDIAN. In the ASCOM driver, this is referred to as “PierEAST” where the HA

is more than zero (HA>0) and INCREASING in value.

In summary, the motor count ranges for the different pointing quadrants are defined as specific values

for each quadrant pointed to. The Sidereal Past is defined as object RA values that are LESS than the LMST

value (RA<ST) and is WEST of the MERIDIAN. The Sidereal Future is defined as object RA values that are

GREATER than the LMST value (RA>ST) and is EAST of the MERIDIAN. For example, if the LMST is currently

14:32:26.0, then 14:35:00.0 would be in the Sidereal Future, and 14:30:00.0 would be in the Sidereal Past.

When the telescope is WpE (target object RA is in the Sidereal Future):

1. The counterweight is east of the pier.

2. The telescope is west of the pier.

3. RA motor counts increase, tracking West: 0 < RA < 1152000.

4. DEC motor counts increases from NCP: 0 < N < 1152000 < S < 2304000: SCP.

When WpE, LMST is at motor count value 1152000 and is the position where the counterweight bar is

horizontal to the horizon.

When telescope is EpW (target object RA is in the Sidereal Past):

1. The counterweight is west of the pier.

2. The telescope is east of the pier.

3. RA motor counts increase, tracking West: -1152000 < RA < 0.

4. DEC motor counts increase from SCP: -2304000 < S < -1152000 < N < 0: NCP.

When EpW, LMST is at motor count value -1152000 and is the position where the counterweight bar is

horizontal to the horizon.

Page 21

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

20

IV PMC-Eight™ ASCII Command Language

The 16 base PMC-Eight™ ASCII Commands allow you to control the mount in various ways to set the

tracking rates, slew the mount to a position, and various other functions. Each of the command strings

ends with the “!” (bang/shriek/exclamation) symbol except when entering and exiting the Diagnostic

Mode. The Diagnostic Mode is used to enable the Simple Base ASCII Command Interpreter within the

firmware. These commands are used internally by Explore Scientific employees in troubleshooting lowlevel motor performance functions. The default Command mode enables both the JOC and ES Command

Interpreters when the PMC-Eight™ Controller boots. The Simple Base ASCII Commands are defined further

below.

The JOC Command Language is a BINARY based command system that uses a pre-defined header plus

command and argument values.

NOTE: The JOC command language is only used in the ExploreStars application internal communications

driver. The PMC-Eight™ ASCOM driver uses the Explore Scientific Command Language documented

here.

Enter ASCII Diagnostic Mode:

Command: "%%%"

Response: "Diagnostic Mode ENABLED%"

NOTE: In the current version of the firmware (09T10 or later), entering the ASCII Diagnostic Mode will

continuously display the analog value (Hex) for the ST4 Interface. This is used to acquire the data

for calibrating the ST4 interface with a user’s camera. The other low-level motor commands can

be entered while the display is continuously showing the ST4 values.

Exit ASCII Diagnostic Mode:

Command: "###"

Response: "Diagnostic Mode DISABLED#"

To manually issue commands to the PMC-Eight™ controller, you must follow the instruction in Appendix

VIII.2 (Model 2A-06B) and VIII.3 (Model 1A-01C) of this document. You will use the Parallax Serial

Terminal program to communicate with the controller.

Simple Base PMC-Eight™ Commands

The Simple Base PMC-Eight™ Commands (base commands) deal with the root motor control features and

allow you to start and stop each motor and set the speed, microstep, and direction values.

NOTE: You must enter Diagnostic Mode to enable the base commands. The firmware is set to continuously

display the Autoguider port values. The command interpreter will still process the base commands when

entered.

Page 22

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

21

“B” Command: B <enter>

BOOT Command – Performs a reboot of the controller

“F” Command: FX <enter> where X is the motor channel number 0 (RA), 1 (DEC).

FAULT Command—GETS the status of the DRV8834 motor driver chip fault indicator. The chip

provides a fault indication for a detection of overcurrent, overtemperature, short circuit, and

undervoltage lockout conditions. See the Texas Instruments DRV8834 Datasheet for detailed

information.

“R” Command: RXYYYYY <enter> where X is the RA motor (channel 0) direction and YYYYY is the decimal

motor speed (microsteps/second) internally limited to 40000 microsteps/second.

RA MOTOR Command – SETS the RA motor precision tracking speed in (microsteps/second)/25.

To stop the motor, issue R00 <enter> command.

“D” Command: DYYYYY <enter> where Y is the DEC motor decimal motor speed (microsteps/second).

DEC MOTOR Command—SETS the DEC motor slew speed in (microsteps/second). To stop the

motor, issue D0 <enter> command.

“M” Command: MX <enter> where X is the microstep multiple index value.

MICROSTEP Command—SETS the micro-stepping multiplier value according to the equation:

Multiplier Value = 2X, i.e., for an X value of 3, 23 equals a scaling of 8 microsteps/step.

“X” Command: XX <enter> where X is the direction value for the RA axis.

RA DIR Command—SETS the RA axis direction value, 0 (clockwise), 1 (counterclockwise).

“Y” Command: YX <enter> where X is the direction value for the DEC axis.

DEC DIR Command—SETS the DEC axis direction value, 0 (clockwise), 1 (counterclockwise).

“P” Command: PX <enter>, PXYYYYYY <enter> where X is the parameter number and YYYYYY is the value

to set.

PARAMETER Command—GETS and SETS the stored parameter values where X is 0-9, and YYYYYY

is a decimal value. These parameters are pre-defined. The PX <enter> command GETS the current

value for parameter X, the PXYYYYYY <enter>

command SETS the current value for Parameter X with value YYYYYY.

The current predefined parameters (Firmware 9T10, 9T11, 9T12, 10A01, 10B01) are:

P0—BAUD Rate: 9600-115,200 DEFAULT = 115,200

P1—Communications Channel: 0 (Serial), 1 (Wireless) DEFAULT = 1

P2—Network Protocol: 0 (TCP/IP), 1 (UDP/IP) DEFAULT = 1

P3—Autoguider (ST4) port Sidereal Rate Fraction %: 0-100 DEFAULT = 40

This value should not be changed; values less than 115,200 affect the control response when

using the ExploreStars application and render the application inoperable without modification.

Page 23

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

22

V PMC-Eight™ ASCII Command Language Syntax

The Explore Scientific Controller Command Language is an ASCII based command language system that

can be parsed by a computer program to determine the desired control action and is human readable,

making it easy to interpret and form messages when coding once the syntax is mastered. This language

specification is implemented in the controller FIRMWARE version ES06B9T2 and later.

NOTE1: ASCII Commands are CASE SENSITIVE. Data values are specified as Hex String Values, e.g.,

“FFD47A”. These values are converted to Long Integers (32-bit) within the FIRMWARE. Generally,

when a REQUEST command is sent, the RESPONSE includes the corresponding request syntax so

that future asynchronous capabilities can be accommodated in the FIRMWARE.

NOTE2: The header “ES” is required, items in brackets {} are required, items in parenthesis () are optional

depending on the command, and the “!” or shriek is required as an End-Of-Line (EOL) marker.

ONLY 1 (one) of each command identifier is to be specified in each {} grouping.

Request Syntax:“ES{GSTPBR}{prtdvix}(A)(D) (XXXX)(YYYYYY)(ZZZZZZ)!”

Response Syntax:“ES{GSTPBR}{prtdvix}(A)(D) (XXXX)(YYYYYY)(ZZZZZZ)!”

Header String: “ES” Explore Scientific Language Command

Base Commands: “G” Get command

“S” Set Command

“T” Track Command

“P” Point Command

“B” Boot Command

“R” Reset Communications Command

NOTE3: Command Parameter Codes only apply to the Get “G” and Set “S” Base Commands.

Command Parameter Code: “p” Position value

“r” Slew Rate value

“t” Target value

“d” Direction value

“v” Version value

“i” System Information value

Axis Values: “0” Right Ascension / Azimuth Axis

“1” Declination / Altitude Axis

Direction Values: “0” Clockwise

“1” Counter-Clockwise

NOTE4: Axis Direction value is determined by looking at the motor from the shaft end.

NOTE5: The following System Information Values are not fully implemented in firmware versions 09t10

and previous. Only values “0x00” and 0x01” are implemented but they are not queryable in these

firmware versions.

Page 24

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

23

System Information Values: “0x00” WIRELESS Enabled {True=1, False=0)

“0x01” BAUD Rate {2400,9600…115200}

“0x02” AXIS 0 SCALE Counts (RA/AZ Axis) {0xFFFFFF}

“0x03” AXIS 1 SCALE Counts (DEC/ALT Axis) {0xFFFFFF}

“0x04” AXIS 0 OFFSET Counts (RA/AZ Axis) {0XFFFFFF}

“0x05” AXIS 0 OFFSET Counts (DEC/ALT Axis) {0XFFFFFF}

“06” TBD … “0F” TBD

Not implemented as of Firmware 09T10, 10A01

NOTE6: The AXIS SCALE Counts value is related to the physical configuration of the mount’s gear ratio,

stepper motor configuration, and controller motor driver configuration. The ES/Losmandy G-11

mount’s AXIS SCALE Count values are calculated using the following parameters: Worm/Wheel

Ratio 1:360, Stepper Motor Steps/Revolution 400, Motor Attachment Gear Ratio 1:1, and Motor

Driver Micro-stepping ratio: 1:32. These parameters apply to both the RA and DEC axes on the

ES/Losmandy G-11 mount. The calculation for the RA and DEC AXIS SCALE Counts is: 360 x 1 x 400

x 32 = 4,608,000 (0x465000)2. The mount’s movement in “arc/count can be calculated by dividing

1,296,000 by the AXIS SCALE Counts. In this case, the mount’s resolution is

(1,296,000/4,608,000)”arc count-1 or 0.28125”arc count-1. Because the PMC-Eight™ Controller

uses the Sidereal Second as the standard for internal hardware time-keeping, the Sidereal

Tracking Rate of 15.000”arc sec-1 would be equivalent to a COUNT RATE value of (15.000”arc sec

-

1

) / (0.28125”arc count-1) = 53.333 counts sec-1. The mean Lunar Tracking Rate of 14.451”arc sec

-

1

equates to a COUNT RATE of 51.40 counts sec-1. The mean Solar Tracking Rate of 15.041”arc

sec-1 equates to a COUNT RATE of 53.48 counts sec-1.

Mount

UNITS

ES/Losmandy G-11

EXOS 2 & iEXOS 100

Total Counts

microsteps

4608000

4147200

Motor Counts

steps/revolution

400

200

Motor Model

number

17HM19-1684S

11HS20-0674S

Motor Frame

type

NEMA 17

NEMA 11

Primary Gear Teeth

count

360

144

Secondary Gear Ratio

NA

1

4.5

Motor Current

mA

900

600

Sidereal Tracking Rate

microsteps/second

53.333

48.000

Motor Scale

”arc/micro-step

0.28125

0.31250

Maximum Step Frequency

Hz

40000

40000

Maximum Slew Rate

°/second

3.125

3.472

Mount Stepper Motor Drive Parameters

Firmware version 9T12 increases motor current to 1300 mA

2

See Table on page 16 for the fixed tracking rate count calculation and parameter values for each of the Explore

Scientific mounts.

Page 25

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

24

The following table lists the command language and the command request/response syntax. A description

of all the commands is listed here for your reference and usage. Pay close attention to the command notes

for any special requirements or restrictions on the command’s usage.

GET Command

Name

Parameter

“ESGp!”

Get Axis Current Position

Axis

“ESGr!”

Get Axis Current Rate

Axis

“ESGt!”

Get Axis Current Target

Axis

“ESGd!”

Get Axis Current Direction

Axis

“ESGv!”

Get System Firmware Version

None

“ESGi!”

Get System Information

Value Index

SET Command

Name

Parameter

“ESSp!”

Set Axis Current Position

Axis, Position

“ESSr!”

Set Axis Current Rate

Axis, Rate

“ESSd!”

Set Axis Current Direction

Axis, Direction

“ESSi!”

Set System Information

Value Index

TRACK Command

Name

Parameter

“ESTr!”

Set Precision Tracking Rate

Axis, Rate

POINT Command

Name

Parameter

“ESPt!”

Point to Target Position

Axis, Position

SWAP Command

Name

Parameter

“ESX!”

Swap Primary Serial Interface

None

“ESY!”

Swap Network Protocol

None

RESET Command

Name

Parameter

“ESR!”

Reset WiFi Comm Controller

None

BOOT Command

Name

Parameter

“ESB!”

Reboot Motor Controller

None

List of PMC-Eight™ ASCII Commands

Page 26

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

25

The firmware code modules have the following information as a ready reference to the command syntax.

NOTE: The firmware (version 09T10+, 10A01) source code is Explore Scientific, LLC proprietary and IS NOT

available for inspection.

' -----------------------------------------------------------------------------' Explore Scientific Command Language

' See programmers reference manual for details on command syntax

'

' ES Internal Command Return Strings

' -----------------------------------------------------------------------------' Internally, HEX Return Strings are used for the ES commands to separate out the

' different ones. HEX values from 0x00 to 0x3F are used for the Explore Scientific

' commands. Items in {} are required, items in () are optional depending on the

' command. A=axis, D=direction, XXXX=rate, YYYYYY=position, ZZZZZZZZ=parameter value

'

' ES{G,S,T,P,Y,X,R,B}{p,r,t,d,v,i,x}(A)(D)(XXXX)(YYYYYY)(ZZZZZZZZ)!

'

' G_! 0x00 FUTURE ESG_!

' Gp! 0x01 get current axis position value ESGpA!

' Gr! 0x02 get current axis rate value ESGrA!

' Gt! 0x03 get current axis target value ESGtA!

' Gd! 0x04 get current axis direction value ESGdA!

' Gv! 0x05 get current firmware version ESGv!

' Gi! 0x06 get current system information ESGiZ!

' Sp! 0x11 set axis position value ESSpAYYYYYY!

' Sr! 0x12 set axis slew rate value ESSrAXXXX! (Allows full range of rates)

' Sd! 0x14 set axis direction value ESSdAD!

' Si! 0x16 set system information ESSiAZZZZZZZZ! (A is the parameter index)

' Tr! 0x22 set tracking rate value ESTrXXXX!(Track rate only applies to RA)

' Pt! 0x31 point (slew) to target using ramps ESPtAYYYYYY!

' Y! 0xFC Switch IP Protocol (UDP/TCP) ESY!

' X! 0xFD Switch Communications Mode (WIFI/SER) ESX!

' R! 0xFE Reset Communications Controller ESR!

' B! 0xFF Boot PMC-Eight Controller ESB!

' ------------------------------------------------------------------------------

Page 27

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

26

Command Language Syntax

“G” GET Commands:

“ESGp” GET AXIS CURRENT POSITION VALUE

REQUEST: “ESGpA!”

RESPONSE: “ESGpAYYYYYY!”

Example: Get Current RA Axis Position Value

REQUEST: “ESGp0!”

RESPONSE: “ESGp0FF37DA!”

NOTE: Data values are specified as Hex String Values.

“ESGr” GET AXIS CURRENT RATE VALUE

REQUEST: “ESGrA!”

RESPONSE: “ESGrAXXXX!”

Example: Get Current RA Axis Rate Value

REQUEST: “ESGr0!”

RESPONSE: “ESGr037DA!”

NOTE: Data values are specified as Hex String Values.

“ESGt” GET AXIS CURRENT TARGET VALUE

REQUEST: “ESGtA!”

RESPONSE: “ESGtAYYYYYY!”

Example: Get Current RA Axis Target Value

REQUEST: “ESGt0!”

RESPONSE: “ESGt062E4D7!”

NOTE: Data values are specified as Hex String Values.

“ESGd” GET AXIS CURRENT DIRECTION VALUE

REQUEST: “ESGdA!”

RESPONSE: “ESGdAD!”

Example: Get Current RA Axis Direction Value

REQUEST: “ESGd0!”

RESPONSE: “ESGd01!”

NOTE: Data values are specified as Hex String Values.

Page 28

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

27

“ESGv” GET CURRENT FIRMWARE VERSION VALUE

REQUEST: “ESGv!”

RESPONSE: “ESGvZZZZZZZZ!”

Example: Get Current FIRMWARE Version Value

REQUEST: “ESGv!”

RESPONSE: “ESGvES6B09U0!” (version ES6B09U0)

NOTE1: Data values are specified as character string values.

NOTE2: The returned string is a combination of the hardware version “6B” and the firmware

version “09U0”. This is currently hard coded in the firmware for each firmware release.

“ESGi” GET CURRENT SYSTEM INFORMATION VALUE

NOTE: Not implemented in this version.

REQUEST: “ESGiX!”

RESPONSE: “ESGiXZZZZZZZZ!”

Example: Get Current System Information 1 (BAUD Rate) Value

REQUEST: “ESGi1!”

RESPONSE: “ESGi10001C200!” (decimal 115,200 BAUD)

Example: Get Current System Information 03 (DEC Maximum) Value

REQUEST: “ESGi3!”

RESPONSE: “ESGi300465000!” (decimal 4,608,000 DEC MAX)

NOTE: Data values are specified as Hex String Values.

“ESGx” GET CURRENT PRECISION TRACKING RATE VALUE

REQUEST: “ESGx!”

RESPONSE: “ESGxXXXX!”

Example: Get Current Precision Tracking Rate Value

REQUEST: “ESGx!”

RESPONSE: “ESGx0535!”

NOTE1: Data values are specified as Hex String Values.

NOTE2: The Get Tracking Rate value only applies to Axis 0, or the RA Axis.

The Precision Tracking value is calculated by multiplying the nominal calculated Rate

Counts (for ES/Losmandy G-11) by 25, i.e.,

Rate Counts = rate “arc sec-1/0.28125 count-1

The calculated precision tracking value for a sidereal rate of 15.000”arc sidereal-sec-1 is:

Precision Tracking value = (15.000 / 0.28125) * 25

= 53.333 * 25

= 1333 (decimal)

= 0x0535 (hexadecimal)

Page 29

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

28

The Tracking Rate value is accurate to ±0.02 counts sec-1, so the resulting count rate is

equal to 53.32 counts sec-1. This command accommodates precision count rates from 0.00

to 2621.44 counts sec-1, which is equivalent to precision rate values of 0 to 7.5’ arc sec-1

or about 0.1 sec-1.

“S” SET Commands:

The RESPONSE to the SET Commands in general mimics the value returned when using the GET

Commands. The RESPONSE syntax will be identical to the corresponding GET Command. This is

implemented this way to simplify the coding of any function that is written to process the RESPONSE

string.

“ESSp” SET AXIS POSITION VALUE

REQUEST: “ESSpAYYYYYY!”

RESPONSE: “ESGpAYYYYYY!”

Example: Set RA Axis Position Value

REQUEST: “ESSp0FF37DA!”

RESPONSE: “ESGp0FF37DA!”

NOTE1: Data values are specified as Hex String Values.

NOTE2: Setting the Axis Position Value UPDATES it to a NEW value on the fly without slewing the

mount in any way. This can be used to recalibrate the axis pointing position when syncing the axis

to an external reference point provided by a reference source such as a star catalog or

planetarium program. The Axis Position Value is only set to 0 (zero) when the axis is in its PARK

position. When used in the ASCOM Telescope driver, the Position value is converted back and

forth between the Motor Count Hex Value and the Degrees/Minutes/Seconds System. The

defined PARK position for a GEM mount is the NCP/SCP. This NCP/SCP position has coordinates

RA LST (07:43:22.00) + 06:00:00.00, DEC +90 00m 00.0s (NCP), or DEC -90 00m 00.0s (SCP)

“ESSr” SET AXIS TRACKING RATE VALUE

REQUEST: “ESSrAXXXX!”

RESPONSE: “ESGrAXXXX!”

Example: Set Current RA Axis Rate Value

REQUEST: “ESSr037DA!”

RESPONSE: “ESGr037DA!”

NOTE1: Data values are specified as Hex String Values.

NOTE2: Setting the Axis Tracking Rate Value UPDATES it to a NEW value on the fly without

initiating a ramp to rate process. This can be used to adjust the Tracking Rate for

Sidereal, Lunar, Solar, and any other object that you may want to track (within reason).

The nominal Sidereal Rate for the RA axis is 53.333 counts sec-1 for the ES/Losmandy G-

11. The nominal Lunar Rate for the RA axis is 51.387 counts sec-1. To improve the

resolution for setting the Axis Rate, the floating-point value for counts sec-1 needs to be

multiplied by 25 and rounded to the nearest integer to develop the value used in sending

Page 30

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

29

the REQUEST, e.g., Sidereal Rate = 53.333 Counts sec-1, 25 x 53.333 = 1333.325 or 1333

integer. Finally convert the value 1333 Rate to Hex: 0x0535.

“ESSt” SET AXIS TARGET VALUE

REQUEST: “ESStAYYYYYY!”

RESPONSE: “ESGtAYYYYYY!”

Example: Set Current RA Axis Target Value

REQUEST: “ESSt062E4D7!”

RESPONSE: “ESGt062E4D7!”

NOTE1: Data values are specified as Hex String Values.

NOTE2: Setting the Axis Target Value UPDATES it to a NEW value on the fly and initiates a ramping

rate process. This can be used to reposition the Target in the middle of a POINT command.

When used in the ASCOM Telescope driver, the Target value is converted back and forth

between the Motor Count Hex Value and the Degrees/Minutes/Seconds System. See the

Supplemental Command Discussion section for details.

“ESSd” SET AXIS DIRECTION VALUE

REQUEST: “ESSdAX!”

RESPONSE: “ESGdAX!”

Example: Set Current RA Axis Target Value

REQUEST: “ESSd01!”

RESPONSE: “ESGd01!”

NOTE1: Data values are specified as Hex String Values.

NOTE2: The direction values as looking at the shaft end of the motor are 0x0 for clockwise, 0x1

for counterclockwise.

NOTE3: Setting the Axis Direction Value UPDATES it to a NEW value on the fly. In general, this

should only be done when the motor RATE value is zero or close to zero because it puts

inertial stress on the motor and gear system of the mount and may result in lost motor

counts and slipping of the motor position.

“ESSi” SET CURRENT SYSTEM INFORMATION VALUE

NOTE: Not implemented in versions 09T12, and 10A01 and previous.

REQUEST: “ESSiXZZZZZZZZ!”

RESPONSE: “ESGiXZZZZZZZZ!”

Example: Set Current System Information #1 (BAUD Rate) Value

REQUEST: “ESSi10001C200!”

RESPONSE: “ESGi10001C200!” (decimal 115,200 BAUD)

Example: Set Current System Information #3 (DEC Maximum) Value

REQUEST: “ESGi300465000!”

RESPONSE: “ESGi300465000!” (decimal 4,608,000 DEC MAX)

Page 31

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

30

NOTE: Data values are specified as Hex String Values.

“T” TRACK Command:

“ESTr” SET PRECISION TRACKING RATE VALUE

REQUEST: “ESTrXXXX!”

RESPONSE: “ESGxXXXX!”

Example: Set Precision Tracking Rate Value

REQUEST: “ESTr0535!”

RESPONSE: “ESGx0535!”

NOTE1: Data values are specified as Hex String Values.

NOTE2: The Set Tracking Rate value only applies to Axis 0, or the RA axis. The Precision Tracking

value is calculated by multiplying the nominal calculated Rate Counts (for ES/Losmandy

G-11) by 25, i.e.,

Rate Counts = rate “arc sec-1/0.28125”arc count-1

The calculated precision tracking value for a sidereal rate of 15.000” sec-1 sidereal is:

Precision Tracking value = (15.000 / 0.28125) * 25

= 53.333 * 25

= 1333 (decimal)

= 0x0535 (hexadecimal)

The Tracking Rate value is accurate to ±0.02 counts sec-1, so the resulting count rate is

equal to 53.32 counts sec-1. This command accommodates precision count rates from 0.00

to 2621.44 counts sec-1, which is equivalent to precision rate values of 0 to 7.5’ arc sec-1

or about 0.1 sec-1.

“P” POINT Command:

“ESPt” SET POINT TARGET VALUE

REQUEST: “ESPtAYYYYYY!”

RESPONSE: “ESGtAYYYYYY!”

Example: Set Current RA Axis Target Value

REQUEST: “ESPt006FAE4!”

RESPONSE: “ESGt006FAE4!”

NOTE1: Data values are specified as Hex String Values.

NOTE2: The Point Command is used to slew the mount from the current target to a new target

specified by the YYYYYY value. The command returns the target value immediately. You

must use the Get Motor Position Value command “ESGp0!”, “ESGp1!” while the mount is

slewing to get the current position of the mount. The controller automatically ramps the

slew rate up to the maximum rate commensurate with the distance between the current

position and the target position. The controller also calculates the start of the ramp-down

to stop the mount movement when it reaches the target value. Both axes may be slewed

concurrently as desired because these are independent processes.

Page 32

Explore Scientific PMC-Eight™ Controller Programmer’s Reference

DOC-ESPMC8-002 Rev. 1.2 2019 March 07 (Firmware 09T10, 10A01 and above)

Copyright ©2016-2019 Explore Scientific, LLC. ExploreScientificUSA.com +1 (866) 252-3811, 1010 South 48th Street, Springdale, AR 72762

31

“Y/X” Swap Command:

“ESY” Swap IP Protocol

REQUEST: “ESY!”

RESPONSE: “ESXA!”

NOTE1: Data values are specified as Hex String Values.

NOTE2: The swap IP Protocol command toggles the Protocol between the TCP/IP protocol and

the UDP/IP protocol. The response value “A” is either “0” or “1”, denoting the protocol.

Protocol “0” is the TCP/IP protocol, and Protocol “1” is the UDP/IP protocol.

NOTE3: This command is only applicable to the Espressif ESP-WROOM-02 (ESP8266) WiFi module.

“ESX” Swap Primary Interface

REQUEST: “ESX!”

RESPONSE: “ESXA!”

NOTE1: Data values are specified as Hex String Values.

NOTE2: The swap command toggles the primary interface between the programmer’s hard-wired

serial port and the WiFi network serial interface. The response value “A” is either “0” or

“1”, denoting the port. Port “0” is the programmer’s RS232 port, and Port “1” is the WiFi

wireless port.

“R” RESET Command:

“ESR” Reset Communications Controller

REQUEST: “ESR!”

RESPONSE: “ESR!”

NOTE1: The communications reset command restarts the wireless communications controller.

The system controller is maintained while the wireless communications controller

restarts.

“B” BOOT Command:

“ESB” Reboot System Controller

REQUEST: “ESB!”

RESPONSE: “ESB!”

NOTE1: The system reboot command restarts the controller independent of the wireless