Page 1

1

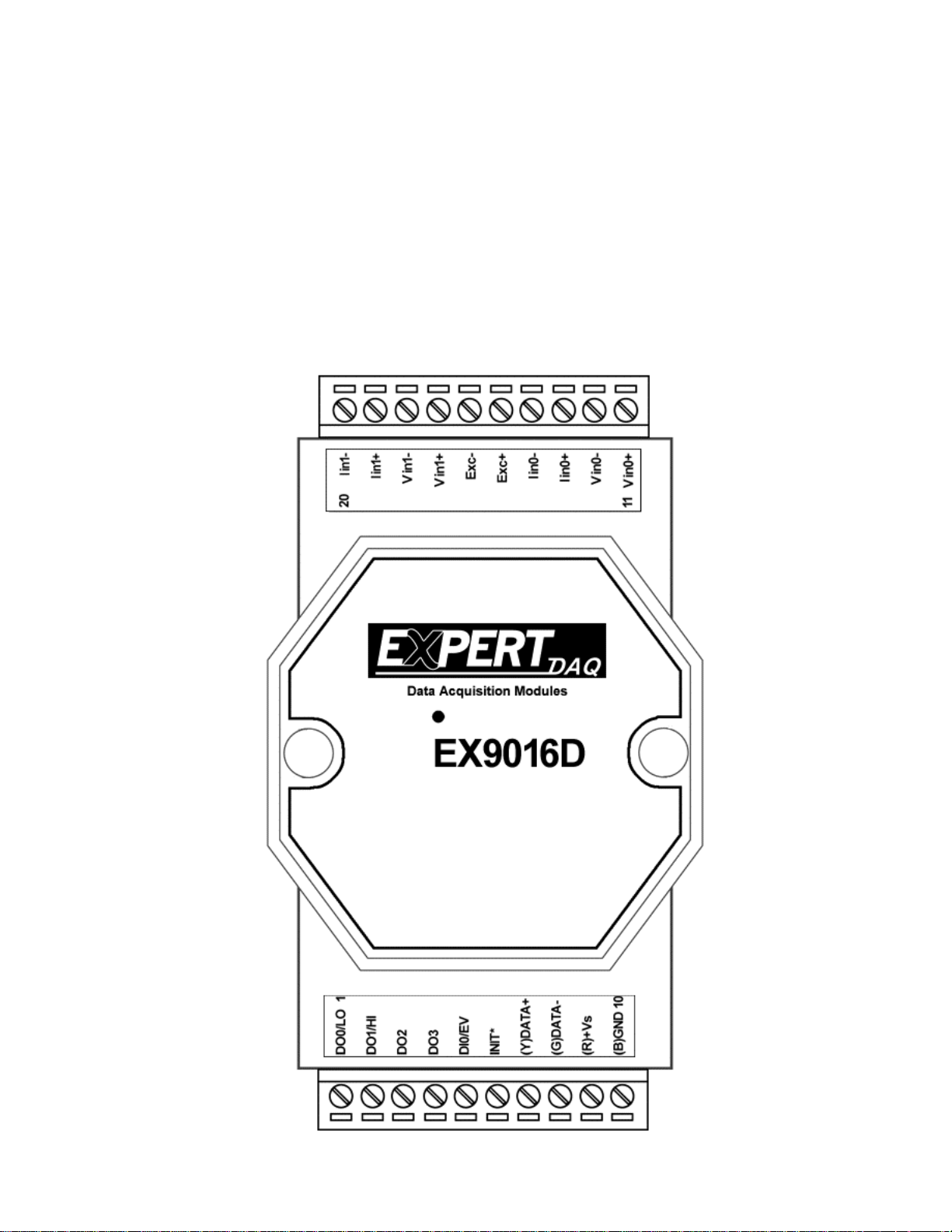

1. Introduction

The common features of the EX-9016 modules is as follows:

1. 3000 VDC isolatied analog input.

2. 24-bits sigma-delta ADC to provide excellent accuracy.

3. 16-bit DAC supply excitation voltage for strain gauge.

4. Software calibration.

5. EX9016D is the EX9016 with 7-segment LED Display.

Page 2

2

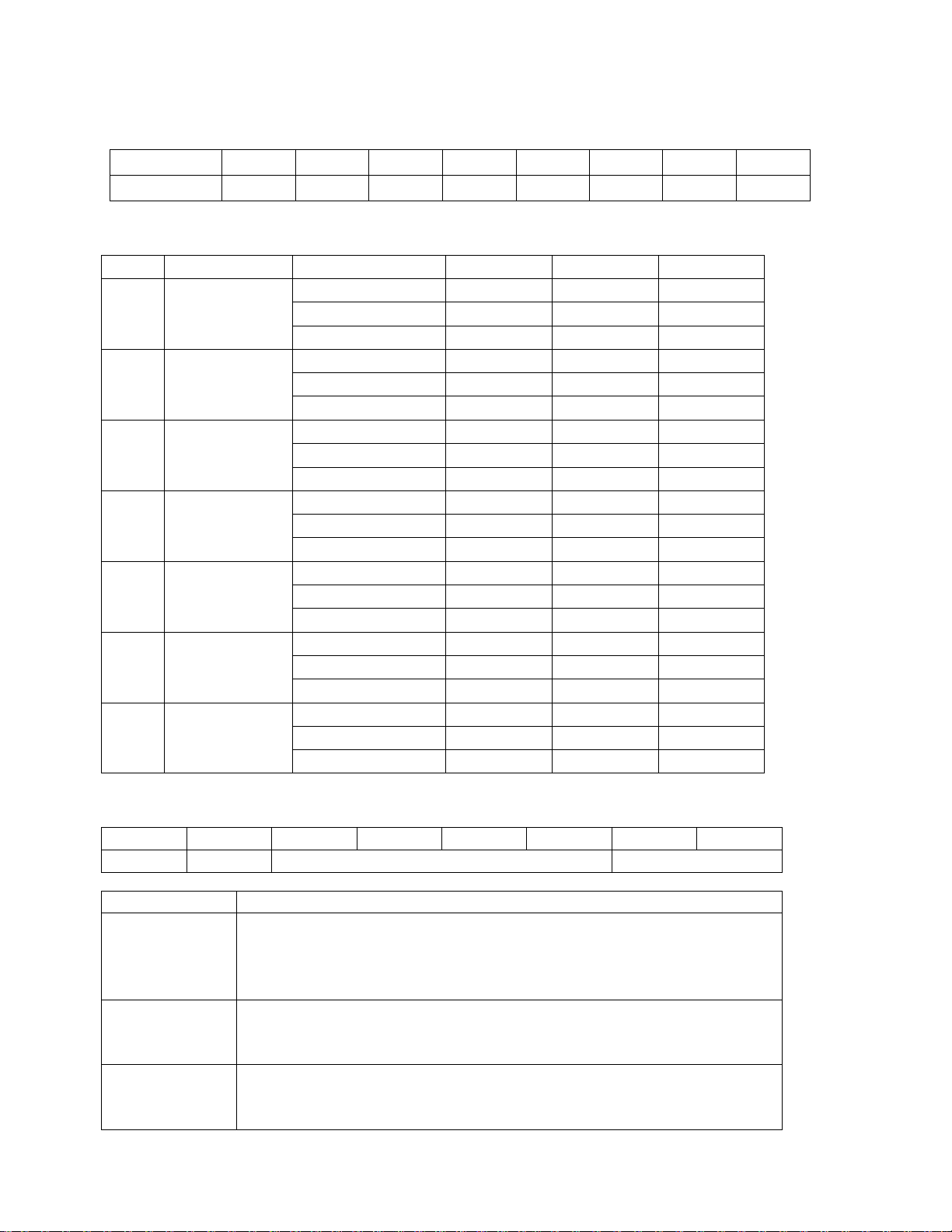

1.1 Specifications

Analog Input

Input Channels

2

Analog Input Type

mV, V, mA

Sampling Rate

10 Samples/Second

Bandwidth

5.25Hz

Accuracy

±0.05%

Zero Drift

0.5µV/℃

Span Drift

25ppm/℃

CMR@50/60Hz

150dB

NMR@50/60Hz

100dB

Input Impedance

20M Ohms

Isolation

3000VDC

Excitation Voltage Output

Output Channel

1

Output Range

0 to +10V

Max Output Load

40mA

Accuracy

±0.05% of FSR

Drift

±50ppm/℃

Output Impedance

12Ohms

Isolation

3000VDC

Digital Output

Output channels

4

Output Type

Open Collector to 30V

Output Load

Sink 30mA max

Power Dissipation

300mW

Digital Input

Input Channel

1

Digital Level 0

+1V Max

Digital Level 1

+3.5~+30V Max

Event Counter

Max Input Frequency

50Hz

Min Pulse Width

1mS

Environment

Power Requirement

+10 to +30 VDC

Power Consumption

2.4 W

Operating Temperature

-25°C to +75°C

Storage Temperature

-30°C to +75°C

Notes: Warm-UP for 30 minutes is recommended!

Page 3

3

Led

Display

EEPROM

Single

Controller

RS485

Interface

Power

Supply

+5V

DI0/EV

Exc+

EX9016D

Data+

Data-

+Vs

GND

Iin0+

Photo-Isolation

ADC

Iin1-

Vin1+

DO1/HI

DO3

Vin1-

Vin0-

MUX

Photo-Isolation

DAC

buffer

DO0/LO

DO2

Iin0-

Vin0+

Iin1+

Exc-

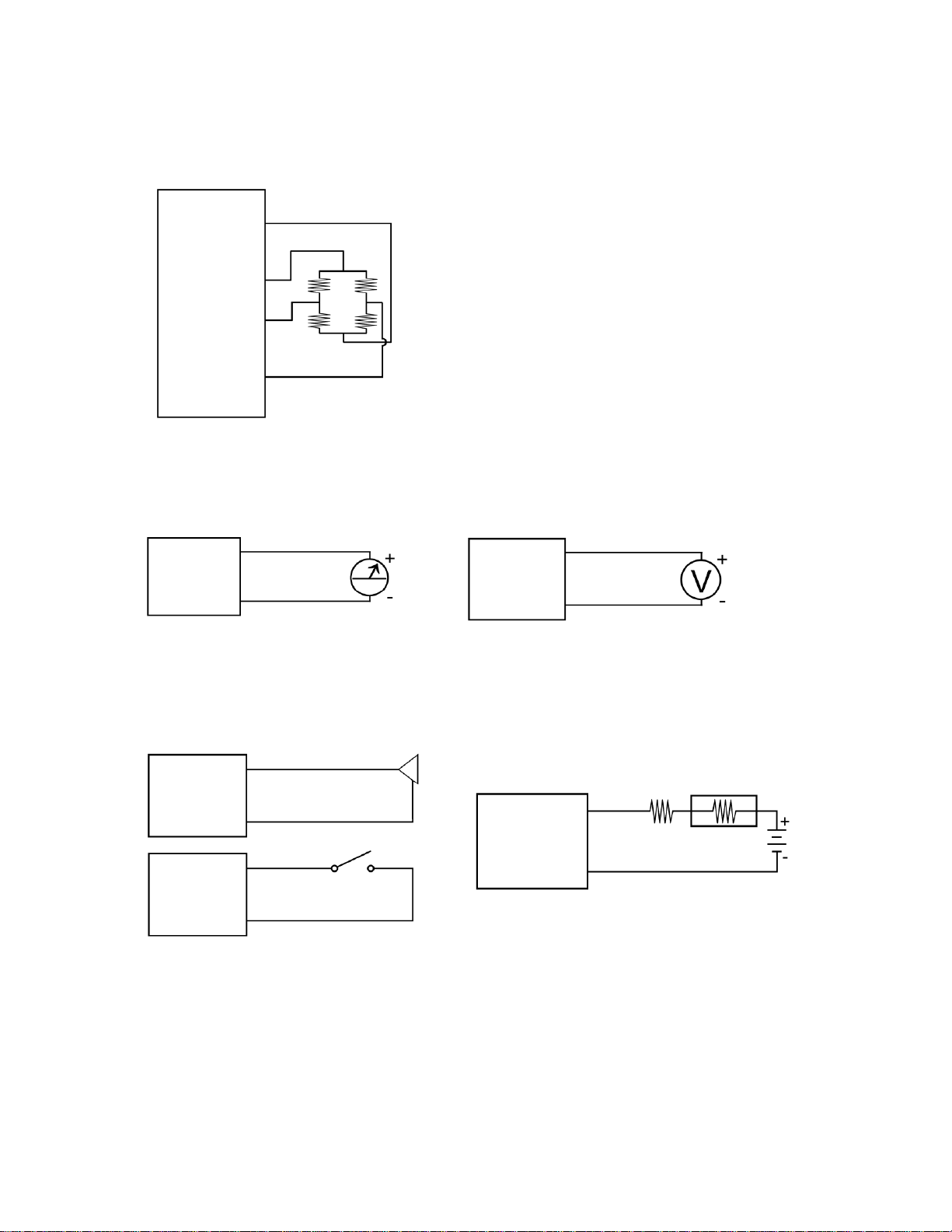

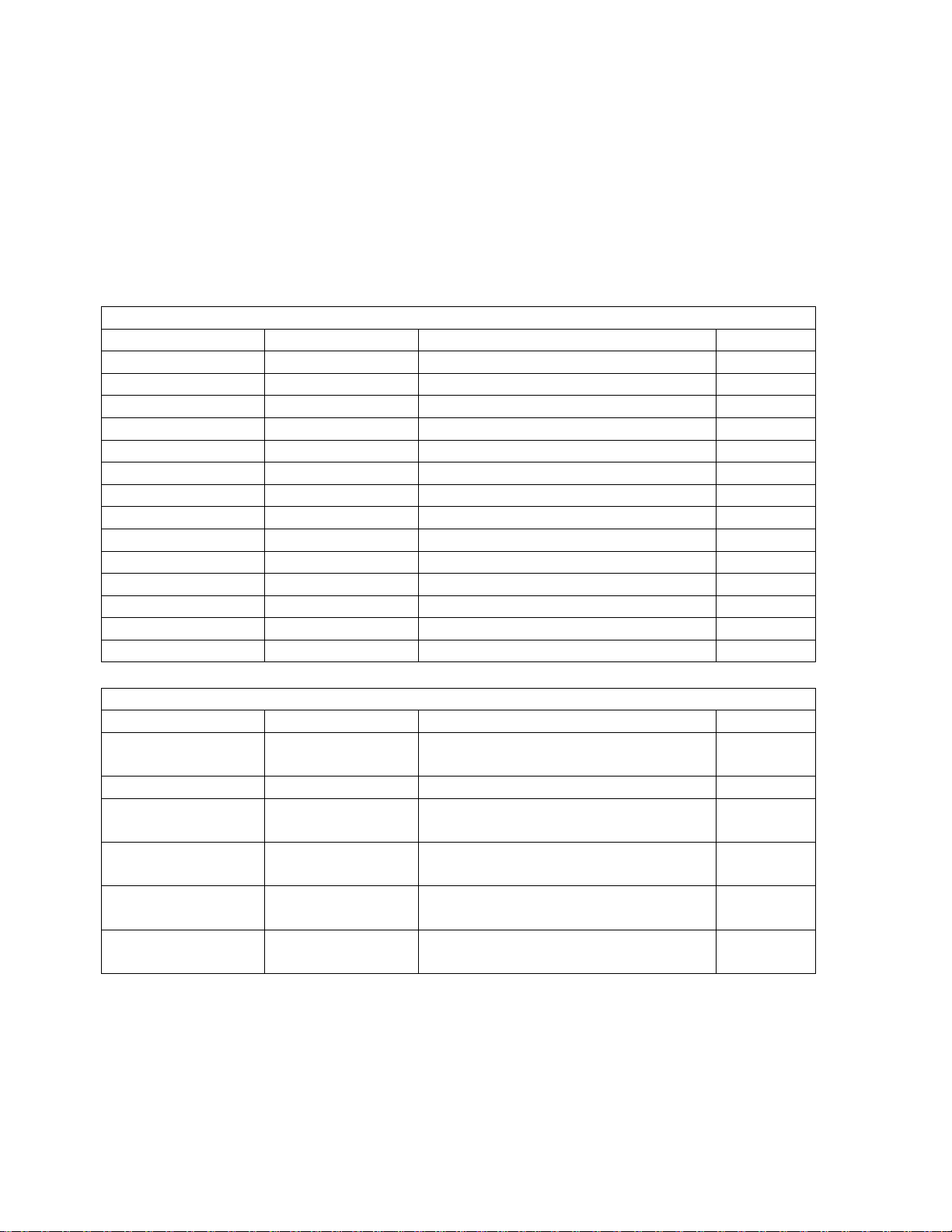

1.2 Wire connection

1.2.1 Block Diagrams

Page 4

4

1.2.2 Wiring diagram for the EX-9016

EXC-

EXC+

Vin-

Vin+

EXC+

EXC-

V

Vin-

Vin+

mV/V

DI0/EV

GND

DI0/EV

GND

TTL.GND

DOx

GND

Bridge Sensor/Load Cell/Strain Gauge Wire Connection

Analog Input Wire Connection: Analog Output Wire Connection:

Digital Input Wire Connection: Digital Output Wire Connection:

Page 5

5

1.3 Default Settings

Default settings for the EX-9016 module are as follows:

. Module Address: 01

. Analog Input Type: Type 05, -2.5 to +2.5V

. Baud Rate: 9600 bps

. Checksum disabled

. Engineering unit format

. Filter set at 60Hz rejection

Page 6

6

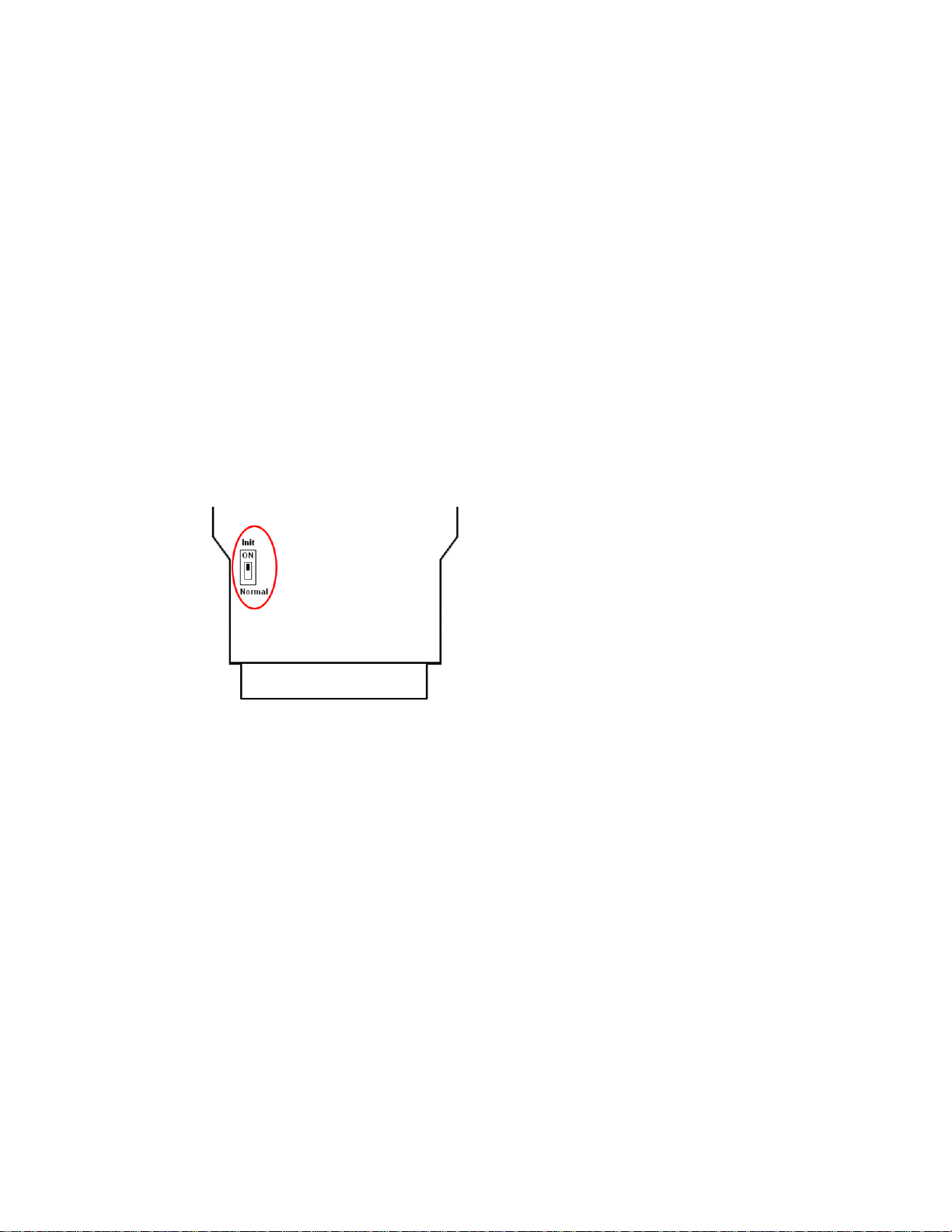

1.4 INIT* Mode Operation

Each EX9000 module has a build-in EEPROM to store configuration

information such as address, type, baudrate and other information.

Sometimes, user may forget the configuration of the module. Therefore,

the EX9000 have a special mode named "INIT* mode" to help user to

resolve the problem. The "INIT* mode" is setting as Address=00,

Budrate=9600bps, no Checksum .

Originally, the INIT* mode is accessed by connecting the INIT*

terminal to the GND terminal. New EX9000 modules have the INIT*

switch located on the rear side of the module to allow easier access to

the INIT* mode. For these modules, INIT* mode is accessed by sliding

the INIT* switch to the Init position as shown below.

To enable INIT* mode, please following these steps:

Step1. Power off the module

Step2. Connect the INIT* pin with the GND pin.

(or sliding the INIT* switch to the Init* ON position)

Step3. Power on

Step4. Send command $002 (cr) in 9600bps to read the

Configuration stored in the module's EEPROM.

There are commands that require the module to be in INIT* mode.

They are:

1. %AANNTTCCFF when changing the Baud Rate and checksum

settings. See Section 2.1 for details.

Page 7

7

1.5 Module Status for DIO, AIO

Power On Reset or Module Watchdog Reset will let all

output goto Power On Value. And the module may accept the host's

command to change the output value.

Host Watchdog Timeout will let all output goto Safe Value.

The module's status(read by command~AA0) will be 04, and the output

command will be ignored.

1.6

Dual Watchdog=Module Watchdog + Host Watchdog

module's operating status. While working in harsh or noisy

environment, the module may be down by the external signal. The

circuit may let the module to work continues and never halt.

operating status. Its purpose is to prevent the network from

communication problem or host halt. When the timeout interval expired,

the module will turn all outputs to predefined Safe Value. This can

prevent the controlled target from unexpected situation.

system more reliable and stable.

Dual Watchdog Operation for DIO, AIO

The Module Watchdog is a hardware reset circuit to monitor the

The Host Watchdog is a software function to monitor the host's

The EX9000 module with Dual Watchdog may let the control

1.7 Reset Status

The Reset Status is set while the module power on or reset by module

watchdog and is cleared while the command read Reset Status ($AA5)

applied. This is useful for user to check the module's working status.

When the Reset Status is set means the module is reset and the output

may be changed to the PowerOn Value. When the Reset Status is clear

means the module is not rested and the output is not changed.

Page 8

8

1.8 Calibration(Warning: Pls don't calibrate before you

Type code

00

01

02

03

04

05

06

Zero Input

0mV

0mV

0mV

0mV

0V

0V

0mA

Span Input

+15mV

+50mV

+100mV

+500mV

+1V

+2.5V

+20mA

really understand.)

Analog Input Calibration sequence:

1. Apply zero calibration voltage.

2. Warm up the module for at least 30 minutes.

3. Set the type code to the type you wish to calibrate.

4. Enable calibration. -> Ref Sec.2.16

5. Perform zero calibration command. -> Ref Sec.2.5

6. Apply span calibration voltage.

7. Perform span calibration command. -> Ref Sec.2.4

8. Repeat steps 4 to 7 three times.

Excitation Voltage Calibration sequence:

1 Connect voltmeter to module’s excitation output pin.

2 Warm-Up for 30 minutes.

3 Output 0V. -> Ref Sec.2.18

4 Trim the output until the value in voltmeter is closest to 0V.

-> Ref Sec.2.20

5 Perform Excitation Voltage Zero Calibration. -> Ref Sec.2.21

6 Output 10V. -> Ref Sec.2.18

7 Trim the output until the value in voltmeter is closest to 10V.

-> Ref Sec.2.20

8 Perform Excitation Voltage Span Calibration. -> Ref Sec.2.22

Page 9

9

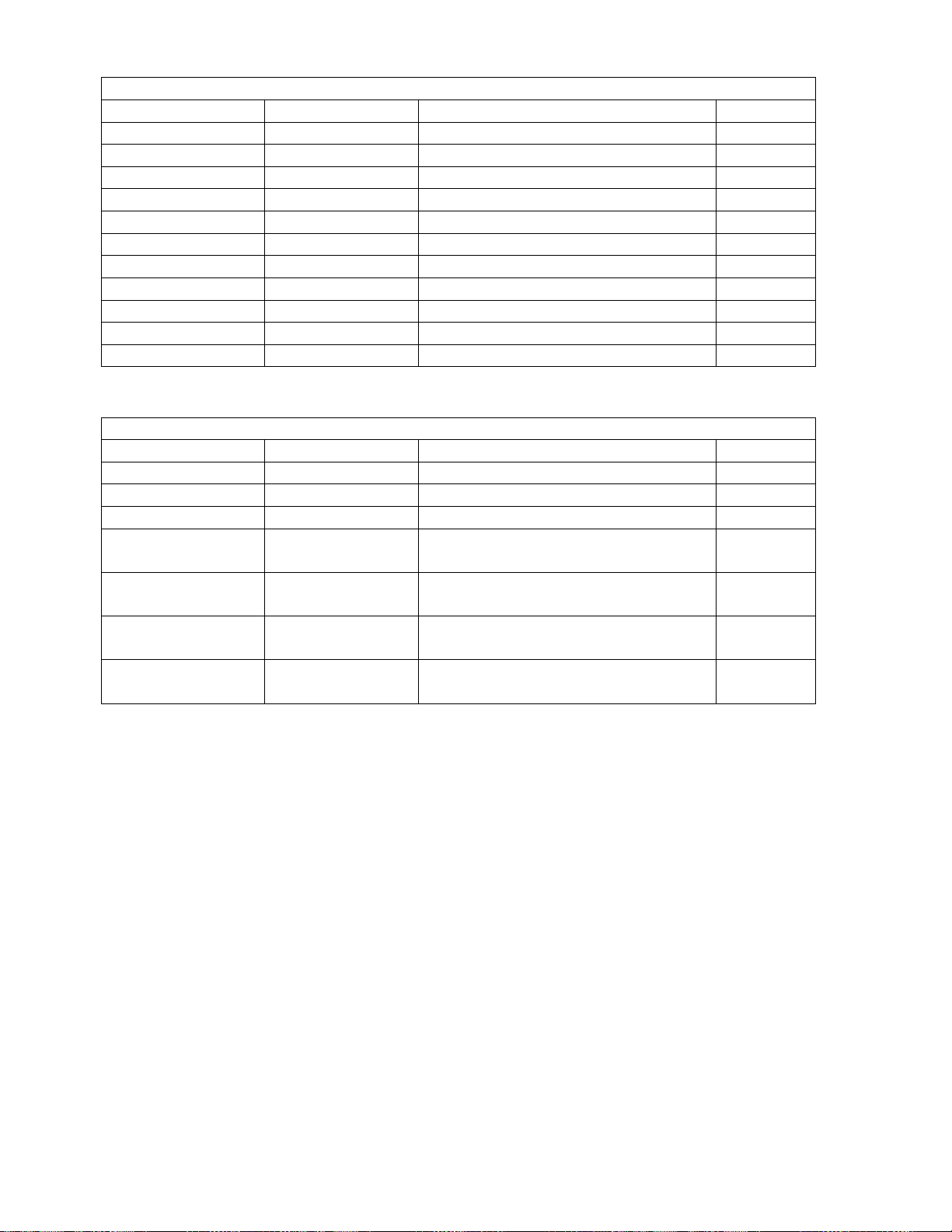

1.9 Configuration Tables

Code

03

04

05

06

07

08

09

0A

Baud rate

1200

2400

4800

9600

19200

38400

57600

115200

Code

Range

Format

+F.S.

Zero

-F.S.

00

-15~+15mV

Engineer unit

+15.000

+00.000

-15.000

% of F.S.R.

+100.00

+000.00

-100.00

2’s complement

7FFF

0000

8000

01

-50~+50mV

Engineer unit

+50.000

+00.000

-50.000

% of F.S.R.

+100.00

+000.00

-100.00

2’s complement

7FFF

0000

8000

02

-100~+100mV

Engineer unit

+100.00

+000.00

-100.00

% of F.S.R.

+100.00

+000.00

-100.00

2’s complement

7FFF

0000

8000

03

-500~+500mV

Engineer unit

+500.00

+000.00

-500.00

% of F.S.R.

+100.00

+000.00

-100.00

2’s complement

7FFF

0000

8000

04

-1~+1V

Engineer unit

+1.0000

+0.0000

-1.0000

% of F.S.R.

+100.00

+000.00

-100.00

2’s complement

7FFF

0000

8000

05

-2.5~+2.5V

Engineer unit

+2.5000

+0.0000

-2.5000

% of F.S.R.

+100.00

+000.00

-100.00

2’s complement

7FFF

0000

8000

06

-20~+20mA

Engineer unit

+20.000

+00.000

-20.000

% of F.S.R.

+100.00

+000.00

-100.00

2’s complement

7FFF

0000

8000

7 6 5 4 3 2 1

0

FS

CS

reserved

DF

Key

Description

DF

Data format

00: Engineering unit

01: % of FSR (full scale range)

10: 2’s complement hexadecimal

CS

Checksum setting

0: Disabled

1: Enabled

FS

Filter setting

0: 60Hz rejection

1: 50Hz rejection

Baud Rate Setting (CC)

Analog Input Type Setting (TT)

Data Format Setting (FF)

Note: The reserved bits should be zero.

Page 10

10

2 Command

General Command Sets

Command

Response

Description

Section

%AANNTTCCFF

!AA

Set Module Configuration

Sec.2.1

#AA

>(Data)

Read Analog Input

Sec.2.2

$AA0

!AA

Perform Span Calibration

Sec.2.3

$AA1

!AA

Perform Zero Calibration

Sec.2.4

$AA2

!AANNTTCCFF

Read Configuration

Sec.2.5

$AA3

!AAN

Read Channel Select

Sec.2.6

$AA3N

!AA

Set Channel Select

Sec.2.7

$AA8

!AAV

Read LED Configuration

Sec.2.8

$AA8V

!AA

Set LED Configuration

Sec.2.9

$AA9(Data)

!AA

Set LED Data

Sec.2.10

$AAF

!AA(Data)

Read Firmware Version

Sec.2.11

$AAM

!AA(Data)

Read Module Name

Sec.2.12

~AAO(Data)

!AA

Set Module Name

Sec.2.13

~AAEV

!AA

Enable/Disable Calibration

Sec.2.14

Excitation Voltage Command Sets

Command

Response

Description

Section

$AA6

!AA(Data)

Get Excitation Voltage Output

Value

Sec.2.15

$AA7(Data)

!AA

Excitation Voltage Output

Sec.2.16

$AAS

!AA

Start-Up Voltage Output

Configuration

Sec.2.17

$AAEVV

!AA

Excitation Voltage Trim

Calibration

Sec.2.18

$AAA

!AA

Excitation Voltage Zero

Calibration

Sec.2.19

$AAB

!AA

Excitation Voltage Span

Calibration

Sec.2.20

Command Format : (Leading)(Address)(Command)[CHK](cr)

Response Format : (Leading)(Address)(Data)[CHK](cr)

[CHK] 2-character checksum

(cr) end-of-command character, character return(0x0D)

Page 11

11

Digital Input/Output, Alarm and Event Counter Command Sets

Command

Response

Description

Section

@AADI

!AASOOII

Read Digital I/O and Alarm Status

Sec.2.21

@AADO(Data)

!AA

Set Digital Output

Sec.2.22

@AAEAT

!AA

Enable Alarm

Sec.2.23

@AAHI(Data)

!AA

Set High Alarm

Sec.2.24

@AALO(Data)

!AA

Set Low alarm

Sec.2.25

@AADA

!AA

Disable Alarm

Sec.2.26

@AACA

!AA

Clear Latch Alarm

Sec.2.27

@AARH

!AA(Data)

Read High Alarm

Sec.2.28

@AARL

!AA(Data)

Read Low Alarm

Sec.2.29

@AARE

!AA(Data)

Read Event Counter

Sec.2.30

@AACE

!AA

Clear Event Counter

Sec.2.31

Host Watchdog Related Command Sets

Command

Response

Description

Section

~**

No response

Host OK

Sec.2.32

~AA0

!AASS

Read Module Status

Sec.2.33

~AA1

!AA

Reset Module Status

Sec.2.34

~AA2

!AATT

Read Host Watchdog Timeout

Interval

Sec.2.35

~AA3ETT

!AA

Set Host Watchdog Timeout

Interval

Sec.2.36

~AA4

!AAPPSS

Read PowerOn Value and Safe

Value

Sec.2.37

~AA5PPSS

!AA

Set PowerOn Value and Safe

Value

Sec.2.38

Page 12

12

2.1 %AANNTTCCFF

%

a delimiter character

AA

address of setting/response module(00 to FF)

NN

new address for setting/response module(00 to FF)

TT

represents the type code. Type code determines the

input range.

If TT=FF the type of all channels keep no change.

CC

new baudrate for setting module.

FF

new data format for setting module.

Example:

Command: %0203050602

Receive: !02

Set module address 02 to 03.

Input type code=05 (-2.5~+2.5V) for all channels

Baudrate=06 (9600)

Dataformat=02 (2’s complement hexadecimal)

Description: Set Module Configuration.

Syntax: %AANNTTCCFF[CHK](cr)

IF the configuration with new baudrate or new checksum setting,

before using this command, the rear slide switch must be in the

ON(INIT*) position. The new setting is saved in the EEPROM and will

be effective after the next power-on reset.

Response: Valid Command: !AA

Invalid Command: ?AA

Page 13

13

2.2 #AA

Description: Read Analog Input

Syntax:#AA[CHK](cr)

# delimiter character

AA address of reading/response module(00 to FF)

Response: Valid Command: >(Data)

(Data) analog input value

Example :

Command: #04 Receive:>+10.234

Read address 04 for getting data is +10.234.

Page 14

14

2.3 $AA0

Description: Perform Span Calibration

Syntax: $AA0[CHK](cr)

$ delimiter character

AA address of setting/response module (00 to FF)

0 command for performing span calibration

Response: Valid Command: !AA

Invalid Command: ?AA

Example :

Command : $010 Receive : !01

Perform address 01 span calibration, return success.

Command : $020 Receive : ?02

Perform address 02 span calibration, return not enable

calibration before perform calibration command.

Warning: Pls don't calibrate before you really understand.

Page 15

15

2.4 $AA1

Description: Perform Zero Calibration

Syntax: $AA1[CHK](cr)

$ delimiter character

AA address of setting/response module (00 to FF)

1 command for performing zero calibration

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: $011 Receive: !01

Perform address 01 zero calibration, return success.

Command: $021 Receive: ?02

Perform address 02 zero calibration, return not enable

calibration before perform calibration command.

Warning: Pls don't calibrate before you really understand.

Page 16

16

2.5 $AA2

type code of the module

baud Rate code of the module

data format, checksum settings and filter

settings of the module

Description: Read configuration.

Syntax:$AA2[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

2 command for read configuration

Response: Valid Command: !AATTCCFF

Invalid Command: ?AA

TT

CC

FF

Example:

Command: $012 Receive: !01200600

Read the configuration of module 01.

Note: check configuration Tables

Page 17

17

2.6 $AA3

Channel selected. The analog input command is

applied to the channel N

Description: Read Channel Select.

Syntax:$AA3[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

3 command for read channel select

Response: Valid Command: !AAN

Invalid Command: ?AA

N

Example:

Command: $013 Receive: !010

Read address 01 channel select, return channel 0 is select.

Page 18

18

2.7 $AA3N

Description: Set Channel Select.

Syntax:$AA3N[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

3 command for read channel select

N channel N is select

Response: Valid Command: !AAN

Invalid Command: ?AA

Example:

Command: $0131 Receive: !01

Set address 01 channel select 1, return success.

Page 19

19

2.8 $AA8 (for EX9016D only)

Description: Read LED Configuration

Syntax:$AA8[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

8 command for read LED configuration

Response: Valid Command: !AAV

Invalid Command: ?AA

V LED configuration

1=module control, 2=host control

Example:

Command: $ 018 Receive: !011

Read address 01 LED configuration, return module control.

Command: $ 018 Receive: !010

Read address 01 LED configuration, return host control.

Page 20

20

2.9 $AA8V (for EX9016D only)

Description: Set LED Configuration

Syntax:$AA8V[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

8 command for read LED configuration

V 1=Set LED to module, 2=Set LED to host

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: $ 0182 Receive: !011

Set address 01 LED to host control, return success.

Command: $ 0181 Receive: !010

Set address 01 LED to module control, return success.

Page 21

21

2.10 $AA9(Data) (for EX9016D only)

Description: Set LED Configuration

Syntax:$AA9(data)[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

9 command for setting LED data

(Data) data display on the LED, range from -19999. to +19999.

The data need sign, 5 digits and decimal point.

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: $ 019+123.45 Receive: !011

Set address 01 LED data to +123.45, return success.

Page 22

22

2.11 $AAF

Description: Read Firmware Version

Syntax:$AAF[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

F command for read firmware version

Response: Valid command: !AA(Data)

Invalid command: ?AA

(Data) Firmware version of module

Example:

Command : $01F Receive : !0120061012

Read address 01 firmware version, return version 20061012

Page 23

23

2.12 $AAM

$

delimiter character

AA

address of reading/response module (00 to FF)

M

address of reading/response module(00 to FF)

Response:

Valid Command:

!AA(Data)

Invalid Command:

?AA

Example:

Command: $01M

Receive: !019016

Read address 01 module name, return name 9016

Command: $03M

Receive: !039016D

Read address 03 module name, return name 9016D

Description: Read Module Name

Syntax: $AAM[CHK](cr)

(Data) Name of module

Page 24

24

2.13 ~AAO(Data)

~

delimiter character

AA

address of reading/response module (00 to FF)

O

command for set module name

(Data)

new name for module, max 6 characters

Response:

Valid Command:

!AA

Invalid Command:

?AA

Example:

Command: ~01O9016

Receive: !01

Set address 01 module name to 9016, return success.

Command: $01M

Receive: !019016

Read address 01 module name, return name 9016.

Description: Set Module Name

Syntax: ~AAO(Data)[CHK](cr)

Page 25

25

2.14 ~AAEV

Description: Enable/Disable Calibration

Syntax:~AAEV[CHK](CR)

~ delimiter character

AA address of setting/response module (00 to FF)

E command for enable/disable calibration

V 1=Enable/0=Disable calibration

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command : $010 Receive: ?01

Perform address 01 span calibration, return the command is

invalid before enable calibration.

Command : ~01E1 Receive: !01

Set address 01 to enable calibration, return success.

Command: $010 Receive: !01

Preform address 01 span calibration, return success.

Warning: Pls don't calibrate before you really understand.

Page 26

26

2.15 $AA6

Description: Get Excitation Voltage Value

Syntax:$AA6[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

6 command for read excitation voltage value

Response: Valid Command: !AA(Data)

Invalid Command: ?AA

(Data) excitation voltage value, engineer unit format

Example:

Command: $ 017+01.234 Receive: !01

Set address 01 excitation +01.234, return success.

Command: $ 016 Receive: !01+01.234

Read address 01 excitation voltage, return +01.234V.

Page 27

27

2.16 $AA7(Data)

Description: Excitation Voltage Output

Syntax:$AA7(Data)[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

7 command for setting excitation voltage

(Data) excitation voltage value, engineer unit format

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: $ 017+01.234 Receive: !01

Set address 01 excitation +01.234, return success.

Command: $ 016 Receive: !01+01.234

Read address 01 excitation voltage, return +01.234V.

Page 28

28

2.17 $AAS

Description: Start-Up Voltage Output Configuration

Syntax:$AAS(Data)[CHK](cr)

$ delimiter character

AA address of reading/response module(00 to FF)

S command for setting Start-Up Voltage

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: $ 017+01.234 Receive: !01

Set address 01 excitation +01.234, return success.

Command: $ 01S Receive: !01

Read address 01 Start-Up Voltage, return success. The

module’s Start-Up Voltage is +01.234V now.

Page 29

29

2.18 $AAEVV

Description: Excitation Voltage Trim Calibration

Syntax: $AAEVV[CHK](cr)

$ delimiter character

AA address of setting module(00 to FF)

E command for performing trim calibration

VV 2’complement hexadecimal to trim the analog output

1 count about 0.2mV

01 to 7F: increase analog output 1 to 127 counts

FF to 80: decrease analog output 1 to 128 counts

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: $01E03 Receive: !01

Trim address 01 excitation voltage +0.6mV, return success.

Page 30

30

2.19 $AAA

Description: Excitation Voltage Zero Calibration

Syntax: $AAA[CHK](cr)

$ delimiter character

AA address of setting module(00 to FF)

A command for excitation voltage zero calibration

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: $017+00.000 Receive: !01

Set address 01 excitation 0V, return success.

Command: $01A Receive: !01

Perform address 01 zero calibration, return success.

Page 31

31

2.20 $AAB

Description: Excitation Voltage Span Calibration

Syntax: $AAB[CHK](cr)

$ delimiter character

AA address of setting module(00 to FF)

B command for excitation voltage span calibration

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: $017+10.000 Receive: !01

Set address 01 excitation 10V, return success.

Command: $01B Receive: !01

Perform address 01 span calibration, return success.

Page 32

32

2.21 @AADI

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

DO0

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

DO1

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

DO2

Off

Off

Off

Off

On

On

On

On

Off

Off

Off

Off

On

On

On

On

DO3

Off

Off

Off

Off

Off

Off

Off

On

On

On

On

On

On

On

On

On

Description: Read Digital I/O and Alarm Status

Syntax: @AADI[CHK](cr)

@ delimiter character

AA address of setting module(00 to FF)

DI command for read digital input and alarm status

Response: Valid Command: !AASOOII

Invalid Command: ?AA

S alarm enable status, 0=alarm disable

1=momentary alarm enable

2=latch alarm enabled

OO digital output status

II digital input status, 00=input low level

01=input high level

Example:

Command: @01DI Receive: !0100001

Read address 01 digital input, return alarm disable, digital

output all off, and digital input high level.

.

Page 33

33

2.22 @AADO(Data)

DO

DO1

DO2

DO3

00

Off

Off

01

On

Off

02

Off

On

03

On

On

10

Off

Off

11

On

Off

12

Off

On

13

On

On

Description: Set Digital Output

Syntax:@AADO(Data)[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

DO command for setting digital output

(Data) output value

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: @01DO00 Receive: !01

Set address 01 digital output 00, return success.

Page 34

34

2.23 @AAEAT

Description: Enable Alarm

Syntax:@AAEAT[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

EA command for enable alarm.

T alarm type, M=momentary alarm, L=latch alarm.

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: @01EAM Receive: !011

Set address 01 enable momentary alarm, return success.

Page 35

35

2.24 @AAHI(Data)

Description: Set High Alarm

Syntax:@AAHI(Data)[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

HI command for setting high alarm value

(Data)

high alarm values, data format is in engineer unit format.

Response: Valid Command: !AA

Invalid Command: ?AA

(Data) high alarm value in engineer unit format

Example:

Command: @01HI+1.2345 Receive: !01

Set address 01 high alarm +1.2345, return success.

Page 36

36

2.25 @AALO(Data)

Description: Set Low Alarm

Syntax:@AALO(Data)[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

LO command for setting high alarm value

(Data)

low alarm values, data format is in engineer unit format.

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: @01LO-1.2345 Receive: !01

Set address 01 low alarm -1.2345, return success.

Page 37

37

2.26 @AADA

Description: Disable Alarm

Syntax:@AADA(Data)[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

DA command for disable alarm

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: @01DA Receive: !01

Disable address 01 alarm, return success.

Page 38

38

2.27 @AACA

Description: Clear Latch Alarm

Syntax:@AACA[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

CA command for clear latch alarm

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: @01DI Receive: !0120101

Read address 01 digital input, return latch alarm mode, low

alarm active.

Command: @01CA Receive: !01

Clear address 01 latch alarm, return success.

Command: @01DI Receive: !0120001

Read address 01 digital input, return latch alarm mode, no

alarm active.

Page 39

39

2.28 @AARH

Description: Read High Alarm

Syntax:@AARH[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

RH command for reading high alarm

Response: Valid Command: !AA(Data)

Invalid Command: ?AA

(Data) high alarm value in engineer unit format

Example:

Command: @01RH Receive: !01+1.2345

Read address 01 high alarm, return +1.2345.

Page 40

40

2.29 @AARL

Description: Read Low Alarm

Syntax:@AARL[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

RL command for reading low alarm

Response: Valid Command: !AA(Data)

Invalid Command: ?AA

(Data) low alarm value in engineer unit format

Example:

Command: @01RL Receive: !01-1.2345

Read address 01 low alarm, return -1.2345.

Page 41

41

2.30 @AARE

Description: Read Event Counter

Syntax:@AARE[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

RE command for reading event counter

Response: Valid Command: !AA(Data)

Invalid Command: ?AA

(Data) event counter value, from 00000 to 65535.

Example:

Command: @01RE Receive: !0112345

Read address 01 event counter, return 12345.

Page 42

42

2.31 @AACE

Description: Clear Event Counter

Syntax:@AACE[CHK](cr)

@ delimiter character

AA address of reading/response module(00 to FF)

CE command for clear event counter

Response: Valid Command: !AA

Invalid Command: ?AA

(Data) event counter value, from 00000 to 65535.

Example:

Command: @01RE Receive: !0112345

Read address 01 event counter, return 12345.

Command: @01CE Receive: !01

Clear address 01 event counter, return success.

Command: @01RE Receive: !0100000

Read address 01 event counter, return 0

Page 43

43

2.32 ~**

Description: Host OK.

Host send this command to all modules for send the

information "Host OK"

Syntax:~**[CHK](cr)

~ delimiter character

** command for all modules

Response: No response.

Example:

Command: ~** No response

Page 44

44

2.33 ~AA0

Description: Read Module Host Watchdog Status.

Syntax:~AA0[CHK](cr)

~ delimiter character

AA address of reading/response module(00 to FF)

0 command for read module status

Response: Valid command: !AASS

Invalid command: ?AA

SS module status, 00=host watchdog timeout status is

clear,04=host watchdog timeout status is set. The status

will store into EEPROM and only may reset by the

command~AA1.

Page 45

45

2.34 ~AA1

Description: Reset Module Host Watchdog Status.

Syntax:~AA1[CHK](cr)

~ delimiter character

AA address of setting/response module(00 to FF)

1 command for reset module status

Response: Valid command: !AA

Invalid command: ?AA

Page 46

46

2.35 ~AA2

Description: Read Host Watchdog Timeout Value

Syntax:~AA2[CHK](cr)

~ delimiter character

AA address of reading/response module(00 to FF)

2 command for read host watchdog timeout value

Response: Valid command : !AAEVV

Invalid command: ?AA

E host watchdog enable status, 1=Enable, 0=Disable

VV timeout value in HEX format, each count is 0.1 second

01=0.1 second and FF=25.5 seconds

Page 47

47

2.36 ~AA3EVV

Description: Set Host Watchdog Timeout Value

Syntax:~AA3EVV[CHK](cr)

~ delimiter character

AA address of setting/response module(00 to FF)

3 command for set host watchdog timeout value

E 1=Enable/0=Disable host watchdog

VV timeout value, from 01 to FF, each for 0.1 second

Response: Valid command: !AA

Invalid command: ?AA

Example:

Command : ~010 Receive : !0100

Read address 01 modules status, return host watchdog

timeout status is clear.

Command : ~013164 Receive : !01

Set address 01 host watchdog timeout value 10.0 seconds

and enable host watchdog, return success.

Command : ~012 Receive : !01164

Read address 01 host watchdog timeout value, return that

host watchdog is enabled, and time interval is 10.0 seconds.

Command : ~** No response

Reset the host watchdog timer.

Wait for about 10 seconds and don't send command~**, the

LED of module will go to flash. The flash LED indicates the

host watchdog timeout status is set.

Page 48

48

Command : ~010 Receive : !0104

Read address 01 module status, return host watchdog

timeout status is set.

Command : ~012 Receive : !01064

Read address 01 host watchdog timeout value, return that

host watchdog is disabled, and time interval is 10.0 seconds.

Command : ~011 Receive : !01

Reset address 01 host watchdog timeout status, return

success And the LED of this module stop flash.

Command : ~010 Receive : !0100

Read address 01 module status, return host watchdog

timeout status is clear.

Page 49

49

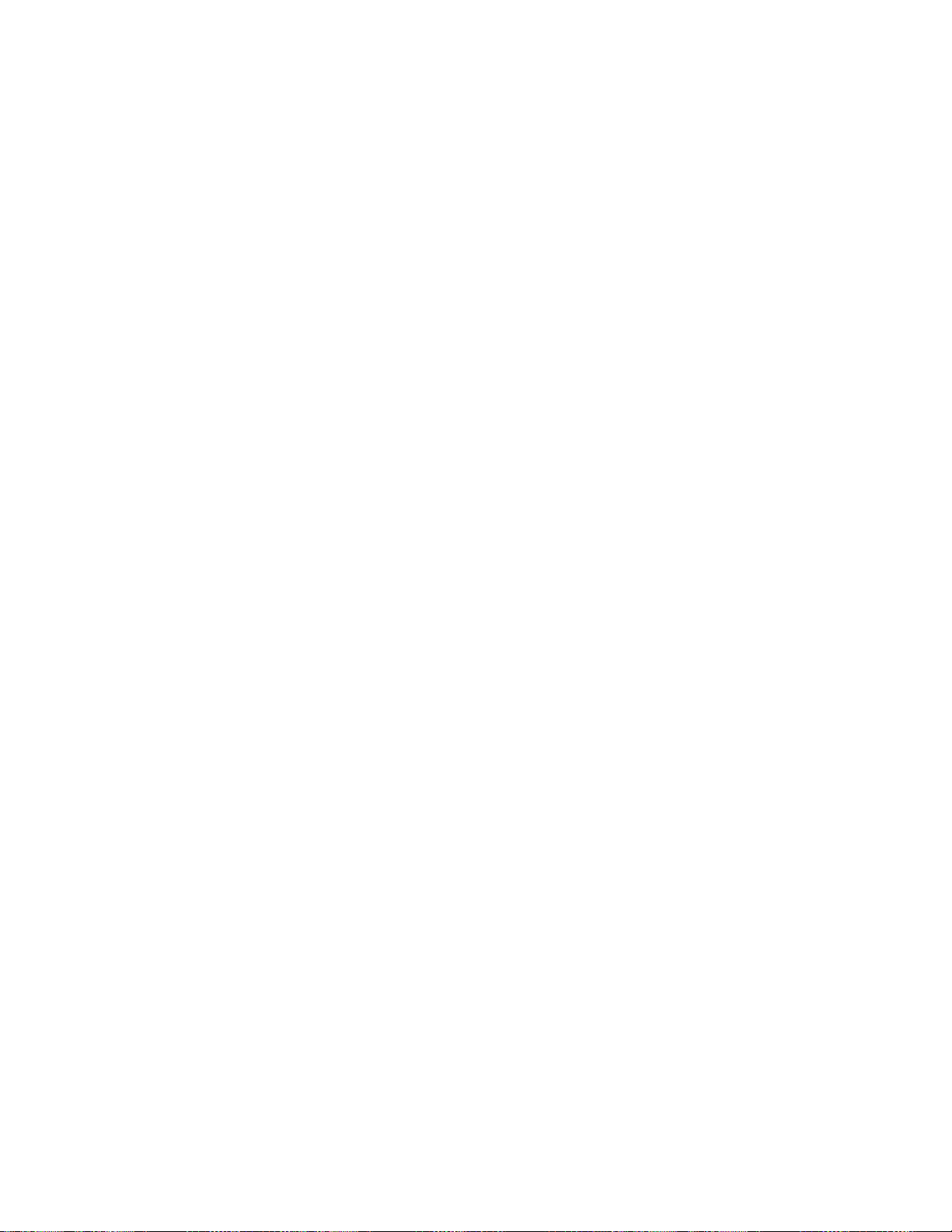

3.37 ~AA4

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

DO0

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

DO1

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

DO2

Off

Off

Off

Off

On

On

On

On

Off

Off

Off

Off

On

On

On

On

DO3

Off

Off

Off

Off

Off

Off

Off

On

On

On

On

On

On

On

On

On

Description: Read PowerOn Value and Safe Value

Syntax: ~AA4[CHK](cr)

~ delimiter character

AA address of setting module(00 to FF)

4 command for reading PowerOn Value and Safe Value

Response: Valid Command: !AAPPSS

Invalid Command: ?AA

PP PowerOn Value, refer table for data format

SS Safe Value, refer table for data format

Example:

Command: ~015FF03 Receive: !01

Set address 01 PowerOn Value is DO0 to DO3 on, Safe Value

is DO0, DO1 on, DO2, DO3 off return success.

Command: ~014 Receive: !01FF03

Read address 01 PowerOn Value is DO0 to DO3 on, Safe Value

is DO0, DO1 on, DO2, DO3 off.

Page 50

50

3.38 ~AA5PPSS

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

DO0

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

DO1

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

DO2

Off

Off

Off

Off

On

On

On

On

Off

Off

Off

Off

On

On

On

On

DO3

Off

Off

Off

Off

Off

Off

Off

On

On

On

On

On

On

On

On

On

Description: Set PowerOn Value and Safe Value

Syntax: ~AA5PPSS[CHK](cr)

~ delimiter character

AA address of setting module(00 to FF)

5 command for reading PowerOn Value and Safe Value

PP PowerOn Value, refer table for data format

SS Safe Value, refer table for data format

Response: Valid Command: !AA

Invalid Command: ?AA

Example:

Command: ~015FF03 Receive: !01

Set address 01 PowerOn Value is DO0 to DO3 on, Safe Value

is DO0, DO1 on, DO2, DO3 off return success.

Command: ~014 Receive: !01FF03

Read address 01 PowerOn Value is DO0 to DO3 on, Safe Value

is DO0, DO1 on, DO2, DO3 off.

Loading...

Loading...