ALT-03

LINE TRIMMER ATTACHMENT

OPERATOR’S MANUAL

1

2

8

3

1

5

7

6

9

4

Fig. 1

11

12

13

10

Fig. 3Fig. 2

Fig. 5Fig. 4

16

15

17

15

16

21

18

19

17

14

20

19

Fig. 7Fig. 6

22

Fig. 9Fig. 8

17

21

Fig. 10

23

24

25

1

Fig. 11

Important!

It is essential that you read the instructions in this

manual before mounting and operating this machine.

Subject to technical modifications

SAFETY RULES

WARNING

Read and understand all instructions. Failure

to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

GENERAL SAFETY RULES

■ For safe operation, read and understand all

instructions before using the straight shaft trimmer

attachment. Follow all safety instructions. Failure to

follow all safety instructions listed below, can result in

serious personal injury.

■ Do not allow children or untrained individuals to use

this unit.

■ Wear safety glasses or goggles that are marked to

comply with ANSI Z87.1 standards and hearing

protection when operating this unit.

■ Wear heavy long pants, boots, and gloves. Do not

wear loose fitting clothing, short pants, jewelry of any

kind, or go barefoot.

■ Secure long hair so it is above shoulder level to

prevent entanglement in any moving parts.

■ Keep all bystanders, children, and pets at least

15 m away.

■ Do not operate this unit when you are tired, ill,

or under the influence of alcohol, drugs, or medication.

■ Do not operate in poor lighting.

■ Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or

exposure to hot surfaces.

■ Keep all parts of your body away from any moving part.

■ Do not touch areas around the muffler or cylinder of

the power head, these parts get hot from operation.

Failure to do so could result in possible serious

personal injury.

■ Always stop the engine and remove the spark plug

wire before making any adjustments or repairs except

for carburetor adjustments.

■ Inspect unit before each use for loose fasteners,

damaged or missing parts. Correct before using the

straight shaft trimmer attachment. Failure to do so can

cause serious injury.

■ Check for damaged parts. Before further use of the

appliance, any part that is damaged should be

carefully checked to determine that it will operate

properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard

or other part that is damaged should be properly

repaired or replaced by an authorized service center.

■ Use only original manufacturer’s replacement parts.

Failure to do so, may cause poor performance,

possible injury, and will void your warranty.

■ Do not, under any circumstance, use any attachment

or accessory on this product which was not provided

with the product or identified as appropriate for use

with this product in the Operator’s Manual.

SPECIFIC SAFETY RULES FOR TRIMMER USE

■ Replace string head if cracked, chipped, or damaged

in any way. Be sure the string head is properly

installed and securely fastened. Failure to do so can

cause serious injury.

■ Make sure all deflectors and handles are properly and

securely attached.

■ Use only the manufacturer's replacement string in the

cutting head. Do not use any other cutting attachment

unless specifically noted in operator’s manual.

■ Never operate string trimmer without the grass

deflector in place and in good condition.

■ Maintain a firm grip on both handles while trimming.

Keep string head below waist level. Never cut with the

string head located over 76 cm or more above

the ground

1

English

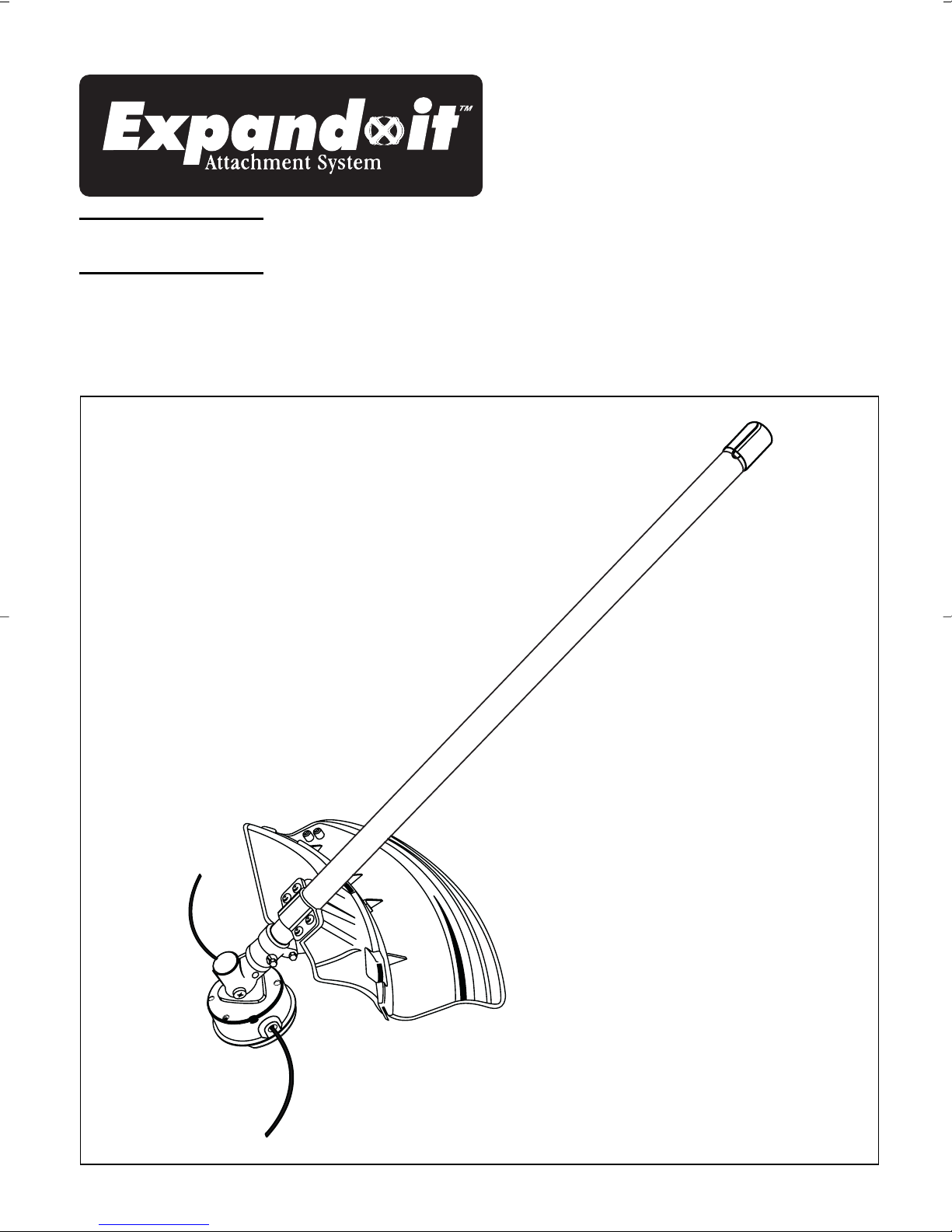

DESCRIPTION

1. Attachment Shaft

2. End Cap

3. Gear Head

4. String Head

5. Guard

6. Knob

7. Coupler

8. Guide Recess

9. Positioning Hole

10. Best Cutting Area

11. Dangerous Cutting Area

12. Cut-off Blade

13. Spool Retainer

14. String Head

15. Spring

16. Spool

17. Slots

18. Eyelets

19. First String

20. Anchor Hole

21. Arrows On Spool

22. Second String

23. Hanger Cap

24. Button

25. Secondary Hole

ASSEMBLY

JOINING THE POWER HEAD TO THE

STRAIGHT SHAFT TRIMMER ATTACHMENT

(Fig. 1)

WARNING

Never attach or adjust any attachment while

power head is running. Failure to stop the engine

may cause serious personal injury

The straight shaft trimmer attachment connects to the

power head by means of a coupler device.

■ Loosen the knob (6) on the coupler (7) of the power

head shaft and remove the end cap (2) from the

attachment shaft (1).

2

English

SYMBOLS

Important: Some of the following symbols may be used on your tool. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and more safely.

SYMBOLS NAME EXPLANATION

Safety Alert Symbol Indicates danger, warning or caution. it means attention!!!

Your safety is involved.

Read Your Operator's Manual Your manual contains special messages to bring attention to

potential safety concerns as well as operating and servicing

information. Please read all the information carefully to ensure

satification and safe use.

Wear eye and hearing protection Wear eye, and hearing protection when operating this

equipment.

Keep bystanders away Keep all bystanders at least 15m (50 ft) away.

Ricochet Danger of Ricochet.

Do not use toothed blade This unit is not intended for use with a toothed saw type blade.

ASSEMBLY

■ Push in the button located on the straight shaft

trimmer attachment shaft. Align the button with the

guide recess (8) on the power head coupler and slide

the two shafts together. Rotate the straight shaft

trimmer attachment shaft (1) until the button locks into

the positioning hole (9).

NOTE: If the button does not release completely in

the positioning hole, the shafts are not locked into

place. Slightly rotate from side to side until the button

is locked into place

■ Tighten the knob securely

WARNING

Be certain the knob is fully tightened before

operating equipment; check it periodically for

tightness during use to avoid serious injury or

product damage

REMOVING THE ATTACHMENT FROM THE

POWER HEAD

For removing or changing the attachment:

■ Loosen the knob.

■ Push in the button and twist the shafts to remove and

separate ends.

OPERATION

OPERATING THE TRIMMER (Fig. 2)

Hold the trimmer with the right hand on the rear handle

and the left hand on the front handle. Keep a firm grip

with both hands while in operation. Trimmer should be

held at a comfortable position with the rear handle about

hip height.

Always operate trimmer at full throttle. Cut tall grass from

the top down. This will prevent grass from wrapping

around the shaft and string head which may cause

damage from overheating. If grass becomes wrapped

around the string head, stop the engine, disconnect the

spark plug wire, and remove the grass. Prolonged cutting

at partial throttle will result in oil dripping from the muffler.

ADVANCING THE STRING

String advance is controlled by tapping string head on

grass while running engine at full throttle.

■ Run engine at full throttle.

■ Tap string head on ground to advance string.

String advances each time the head is tapped.

■ Several taps may be required until string strikes the

cut off blade.

■ Resume trimming.

NOTE: If the string is worn too short you may not be

able to advance the string by tapping it on the ground.

If so, stop the engine, disconnect the spark plug wire,

and manually advance the string.

ADVANCING THE STRING MANUALLY

Push the spool retainer down while pulling on string(s) to

manually advance the string.

CUTTING TIPS (Fig. 3)

■ Keep the trimmer tilted toward the area being cut;

this is the best cutting area (10).

■ Do not cut in dangerous cutting area (11).

■ Use the tip of string to do the cutting; do not force

string head into uncut grass.

■ Wire and picket fences cause extra string wear, even

breakage. Stone and brick walls, curbs, and wood

may wear string rapidly.

■ Avoid trees and shrubs. Tree bark, wood moldings,

siding, and fence posts can easily be damaged by

the string.

OPERATION

GRASS DEFLECTOR LINE TRIMMING CUT-OFF

BLADE (Fig. 4)

This trimmer is equipped with a line trimming cut-off

blade on the grass deflector. For best cutting, advance

string until it is trimmed to length by the cut-off blade (12).

Advance string whenever you hear the engine running

faster than normal. This will maintain best performance

and keep string long enough to advance properly.

WARNING

Do not, under any circumstance, use any

attachment or accessory on this product which

was not provided with the product, or identified

as appropriate for use with this product in the

Operator’s Manual.

MAINTENANCE

WARNING

Use only original manufacturer's replacement

parts, accessories and attachments. Failure to do

so may cause poor performance, possible injury

and may void your warranty.

3

English

MAINTENANCE

You may make adjustments and repairs described in the

maintenance section. For other repairs, have the unit

serviced by an authorized servicing dealer.

SPOOL REPLACEMENT

NEW PREWOUND SPOOL (Fig. 5 & 6)

Use only 2.4 mm diameter monofilament string.

Use the manufacturer's replacement parts for best

performance.

■ Stop the engine, hold the string head and unscrew

the spool retainer (13). Turn clockwise.

■ Remove the empty spool from the string head (14).

Use the spring (15) from the empty spool if one is not

provided with the new spool and string.

■ To install the new spool (16), make sure the two

strings are captured in the slots (17) opposite each

other on the new spool. Make sure the ends of each

string is extended approximately 6 in. (152 mm)

beyond each slot.

■ Thread the strings into the eyelets (18) in the string

head. Carefully push the spool into the string head

(gently pull the strings to the outside if necessary).

When the spool is positioned in the string head, grasp

the strings and pull sharply to release them from the

slots in the spool.

■ Push down and turn the spool counterclockwise until

it no longer turns. Hold the spool down and rotate

clockwise a small amount. Release the spool.

The spool should be locked down in the string head. If

not, hold down and rotate until locked.

■ Make sure the string head and the spool retainer are

installed on the shaft by turning the retainer

counterclockwise to tighten.

■ Pull the strings again to rotate the spool into cutting

position. Push the spool retainer down while pulling

on string(s) to manually advance the string and to

check for proper assembly of the string head.

STRING REPLACEMENT (Fig. 8 - 11)

■ Stop the engine, disconnect the spark plug wire.

Hold the string head and unscrew the spool retainer.

Turn clockwise.

■ Remove the spool from the string head.

NOTE: Keep the spring attached to the spool.

Remove any old string remaining on the spool.

■ Cut two pieces of string, each being approximately

2.7 m long.

■ Insert the first string (19) into the anchor hole (20)

in the upper part of the spool. Wind the first string

around the upper part of the spool counterclockwise,

as shown by the arrows on the spool (21).

Place string in the slot on upper spool flange, leaving

about 152 mm extended beyond the slot. Do not

overfill. After winding the string, there should be at

least 6 mm between the wound string and the outside

edge of the spool.

■ Repeat above step with second string (22), using the

bottom part of spool. Do not overfill.

■ Replace the spool and the spool retainer. Refer to

"Spool Replacement" earlier in this manual.

STORING THE STRAIGHT SHAFT TRIMMER

ATTACHMENT

Store the straight shaft trimmer attachment in a well

ventilated place that is inaccessible to children.

Keep away from corrosive agents such as garden

chemicals and deicing salts.

To remove the straight shaft trimmer attachment from the

power head for storage:

■ Loosen the knob on the coupler device.

■ Push the button in, then twist the shafts to remove

and separate the power head from the

attachment.

MAINTENANCE

ATTACHING THE STORAGE HANGER (Fig. 11)

There are two ways to hang your attachment for storage.

■ To use the hanger cap (23), push in the button (24)

and place the hanger cap over end of the straight

shaft trimmer attachment shaft. Slightly rotate the cap

from side to side until the button locks into place.

■ The secondary hole (25) in the straight shaft trimmer

attachment shaft can be used for hanging purposes

as well.

4

English

RYOBI TECHNOLOGIESAUSTRALIA PTY. LTD.

GUARANTEE

Subject to the guarantee condition below, this Ryobitool

(hereinafter called “the product”) is guaranteed byRyobi

(hereinafter called “the Company”) to be free from

defects in material or workmanship for a period of 24

months from the date of originalpurchase covering

both partsand labour. Under the terms of this

guarantee, the repair or replacement of any part shall

be the opinion of the Company or itsauthorised agent.

Should service become

period, the owner should contact the

1300 361 505 or contact the retailer from whom the

product was purchased.

In order to obtain guarantee service, the owner must

present the sales docket and Guarantee Certificate

to confirm date of purchase. This product issold bythe

dealer or agent as principal and the dealer has no

authority from the Company to give any additional

guarantee on the Companyí sbehalf except as herein

containedorhereinreferredto.

Guarantee Conditions

This guarantee only applies provided that the Product

has been used in accordance with the manufacturer’s

recommendationsunder normal use and reasonable

care (in the opinion of the Compa ny) and such

necessary during the warranty

RYOBI HELPLINE

guarantee does not cover damage, malfunction or

failure resulting from misuse, neglect, abuse, or used

for a purpose for which it was not designed or is not

suited and

have been attempted by other than anAuthorised

Service Agent. This guarantee will not apply if the tool is

damaged by accident or if repairsarisefromnormal

wear and tear.

The Company accepts no additionalliability pursuant to

this g uarantee for the cos t s of travelling or

transportation

service dealer or agent - such costsare not included in

this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territoriallaws

give rights to the buyer and imposeliability on the seller in

certaincircumstances. Nothing herein shall have theeffect

of excluding, restricting

guarantee, right or liability imposed, to the extent only

that such exclusion, restriction or modification

would render any term herein void.

no repairs, alterations or modifications

of the Product or parts to and from the

or modifying any con dition,

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

SYDNEY: Building B, Rosehill Industrial Estate, 3-5 Shirley Street, Rosehill N.S.W. 2142

Contact during normal business hours.

Tel: - Fax: 1800 807 993 - www.ryobi.com.au

1300 361 505

BRISBANE : All enquiries Te l : 1 300 361 505

TOWNSVILLE: All enquiries Te l : 1 300 361 505

MELBOURNE:

All enquiries Tel : 1300 361 505 33-35 Sorbonne Cres. Canning Vale, W.A. 6155

HOBART: All enquiries Te l : 1 300 361 505

ADELAIDE: All enquiries Te l : 1 300 361 505

PERTH:

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 27 Clemow Drive, Mt Wellington, N.Z.

Tel: (09) 573 0230-FreeCall: 0800 279 624 - Fax: (09) 573 0231 - www.ryobi.co.nz

Contact during normal business hours.

This Guarantee Form Should Be Retained By The Customer At All Times

For yourrecordand to assistinestablishing date of purchase(necessary for in-guarantee service)

pleasekeepyourpurchase docket and this form completed with the following particulars.

Address Of Dea ler

Date Model No SerialNo

Present This Form With YourPurchase Docket When Guarantee Service Is Required.

Tel : (08) 9455 7775

Loading...

Loading...