IP65 BattenFit Sensor

MSB1001T - Switching

MSB1001PT - Switching with photocell

Installation and Commissioning

Instructions

Note: QuickSet Pro or HP18* required for commissioning

* Please note that the HP18 offers different/limited programming options

IP65 BattenFit Sensor: MSB1001T - Switching

MSB1001PT - Switching with photocell

Only suitably qualified personnel should install this equipment.

This passive infrared presence detector is designed to be fitted to a batten-style luminaire.

Installation

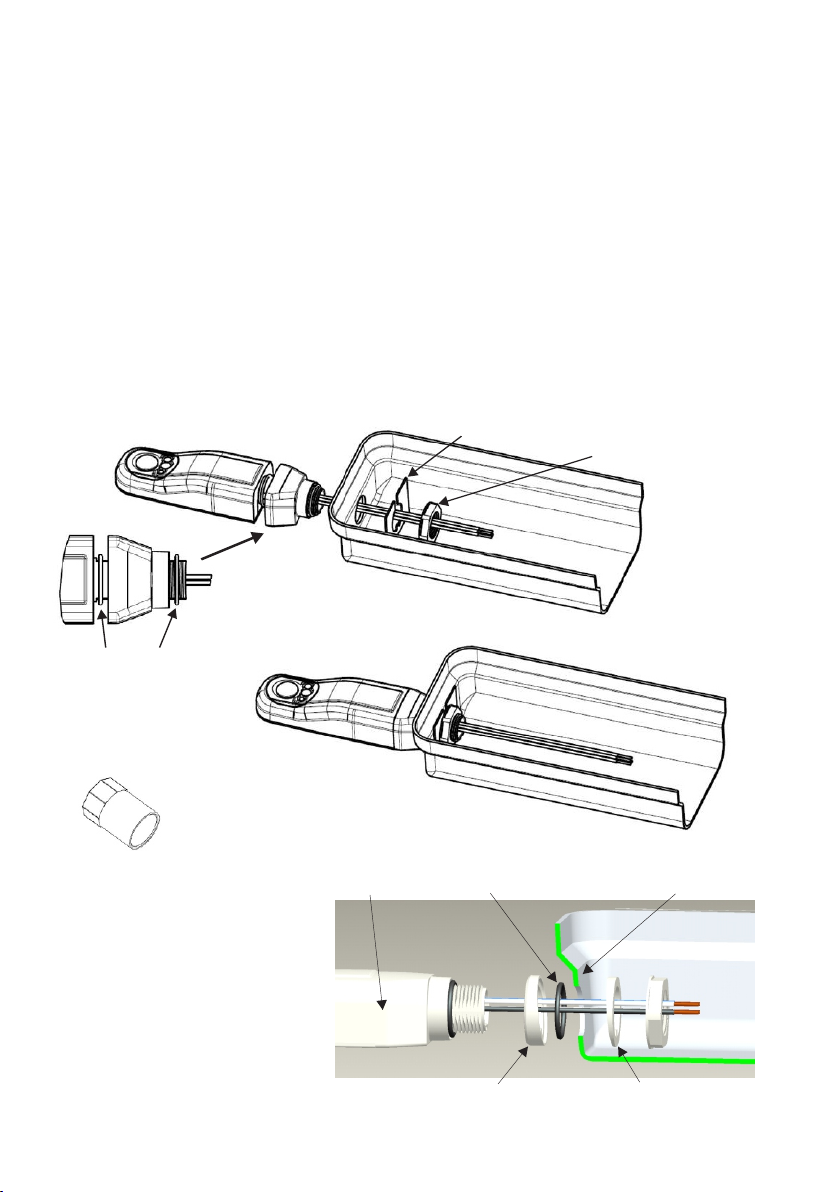

1. Remove the M20 knockout from the end cap of the luminaire.

2. Pass the sensor wires through from the outside and insert the threaded end of the sensor into the hole.

3. A polarising plate can be made in order to prevent rotation of the sensor - an example design is given on

page 3 (Fig.5).

4. If a polarising plate is to be used, pass the wires through the slot and position the polarising plate against

the inside face of the end cap. Ensure that the tab is positioned correctly i.e. at the ceiling side, away from

the lamp.

5. Fit and tighten the locknut.

6. Connect the wires in accordance with the wiring instructions.

OPTIONAL POLARISING PLATE

LOCKNUT

SENSOR

Fig. 1a

ENSURE THAT THE TWO O-RINGS

ARE FITTED AS SHOWN

If there is insufficient space for the locknut,

the adaptor shown below (Fig. 3) can be used.

20mm Female Adaptor

Fig. 3

Angled Washer Kit (supplied)

If the light fitting has an angled (drafted) end

face then use the kit provided as shown

(Fig. 4).

MK part number EFA/2

IP65 LIGHT FITTING

Fig. 2

IP65 SENSOR 20mm O-RING LUMINAIRE WITH ANGLED END FACE

Fig. 4

ANGLED SPACER ANGLED WASHER

Fig. 1

- 2 -

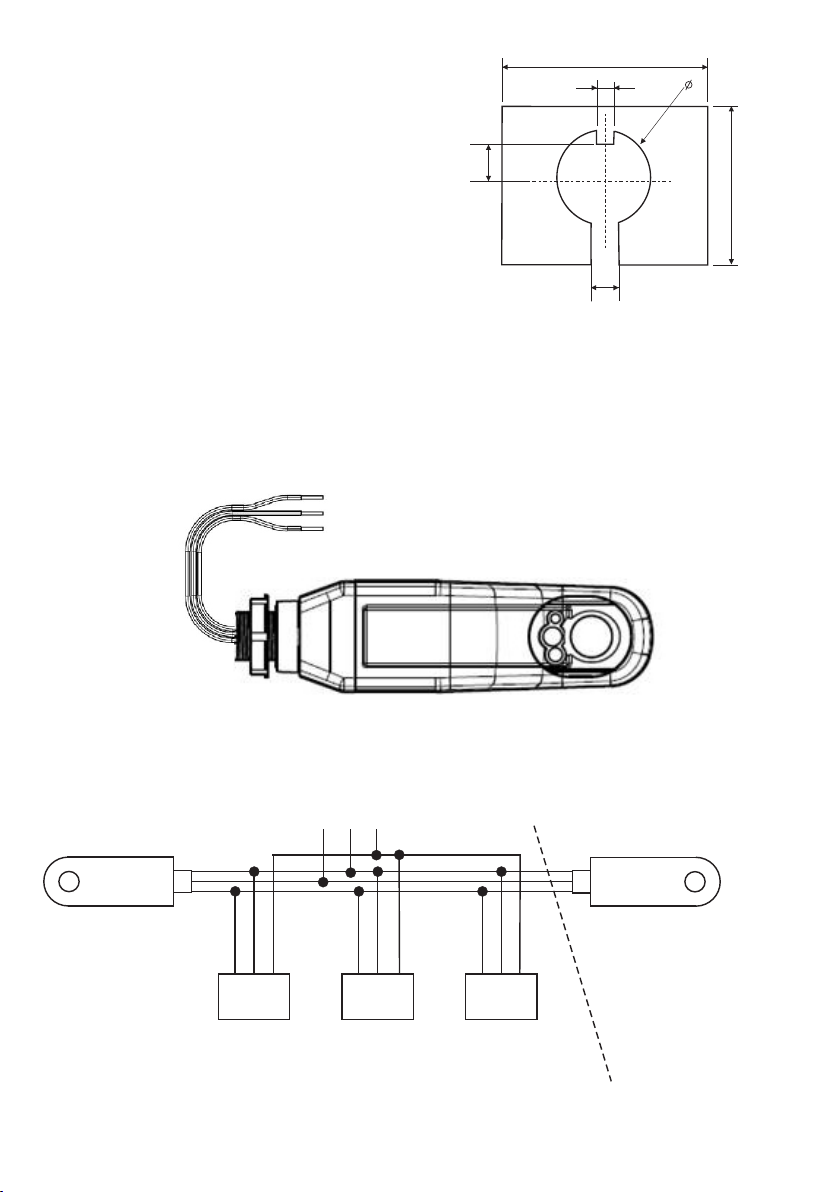

Polarising Plate (not supplied)

The purpose of the polarising plate is to ensure that the sensor does

not rotate from the correct position, i.e. pointing vertically

downwards, during transport or installation.

The two overall dimensions marked ‘SEE TEXT’ need to be made

such that when the plate is positioned against the inner face of the

luminaire end cap, it cannot rotate.

The 3.5mm ‘tab’ should be located closest to the ceiling (away from

the lamp). The 6.0mm slot is optional and is to allow the wires to

pass through for ease of assembly.

Material can be plastic sheet, minimum thicknesss 1.0mm,

recommended thickness 1.5-2.0mm, or mild/stainless steel sheet,

minimum thickness 0.6mm, recommended thickness 1.0-1.6mm.

Electrical Connections

Brown - Live

Blue

- Neutral

- Switched live

Black

SEE TEXT

3.5

7.3

6.0

20

SEE TEXT

Fig. 5

Fig. 6

Fig. 7

Blue

Brown

Black

SUPPLY

L N E

L N E

LOAD

L N E L N E

LOAD

Maximum Total Load not to exceed

that specified for a Single Detector

- 3 -

Always check product label before connecting.

Blue

Brown

Black

Multiple Detectors

may be connected

in parallel, as is

shown above, to

LOAD

control the same

Maximum Load

Loading...

Loading...