Page 1

Tech-note

ePALM10 Product Manual

The ePALM10 is a state-of-the-art handheld HMI device with a graphic display and a keypad. The

rugged polyamide enclosure offers a high level of shock and environmental resistance making the

ePALM the ideal choice for use in the factory floor.

Contents

1

2

3

Highlights .......................................................................................................................... 3

Technical data ................................................................................................................... 4

Operation .......................................................................................................................... 6

3.1

Enabling Switches ................................................................................................ 6

3.2

Indicators and Keypad ......................................................................................... 6

3.3

Battery Replacement............................................................................................ 7

3.4

Power Supply and Grounding .............................................................................. 8

3.5

Applicable Regulations ........................................................................................ 9

3.6

Installation Environment ....................................................................................... 9

3.7

Cleaning Faceplates .......................................................................................... 10

3.8

Getting Started ................................................................................................... 10

3.8.1 Serial Communication ........................................................................................ 10

3.8.2 Ethernet Communication ................................................................................... 10

3.9

Troubleshooting ................................................................................................. 10

4

5

Connections .................................................................................................................... 11

4.1

Serial Communication - Types –0061 and –0062 .............................................. 11

4.1.1 Using Optional Fieldbus Modules ...................................................................... 14

4.1.2 Connecting the ePALM to the Simatic S7 MPI network ..................................... 15

4.2

Ethernet Communication - Type –0066 and –0068 ........................................... 16

4.3

Profibus DP Communication - Type –0067 and –0069 ..................................... 19

4.3.1 Termination switch ............................................................................................. 21

4.3.2 Programming connector ..................................................................................... 22

Accessories ..................................................................................................................... 23

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

1

Page 2

www.uniop

.com

Tech-note

Tn202

Ver. 1.02

Copyright 2004-2012 Exor International S.p.A. – Verona, Italy

Subject to change without notice

The information contained in this document is provided for informational purposes only. While

efforts were made to verify the accuracy of the information contained in this documentation, it is

provided “as is” without warranty of any kind.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

2

Page 3

Tech-note

1 Highlights

• Graphical display 120x64 pixels (up to 8 lines

20 characters)

• Highly visible transflective LCD display

• 27-keys keypad with tactile feedback

• Connection to industrial bus systems

• Large memory size (512 KB Flash)

• IP65 protection

• Includes Emergency Stop button

• Includes enabling switches, normal or 3-

positions

• Available in version for connection to Ethernet

and Profibus DP

The ePALM HMI panels are the handheld products of the UniOP family. All of the ePALM products

support the rich common functionality of the UniOP operator panels:

• Versions available for connection to

Ethernet and Profibus DP. Ethernet

version allows connection to field devices

as well as programming the HMI from

Designer.

• Powerful and intuitive programming with

the UniOP Designer 6 software

• Support of more than 130 communication

drivers for industrial devices

• Transflective LCD display ensures

readability under the most critical light

conditions

• Display dynamic data in numerical, text,

bargraph and graphic image formats

• Recipe data storage. Recipe data can be

transferred to a host computer using the

Ethernet connection.

• Multilanguage applications. The number

of runtime languages is limited only by the

available memory. All text information in

the application can be exported in Unicode

format for easier translation.

• Powerful macro editor to configure

keypad operation

• Alarms and historical alarm list. Alarm

and event information can be printed or

transferred to a host computer using the

Ethernet connection.

• Eight level password protection.

• Report printing to serial printer. Reports

are freely configurable using Designer.

• Ethernet-based UniNet network to share

data between UniOP HMIs and to serve

data using UniNet OPC Server.

In addition some unique features make the

ePALM10 a perfect fit for handheld operation.

• Emergency Stop button. Hardwired.

• Enabling switches. Hardwired.

• High-quality polyurethane cable for

mobile applications.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

3

Page 4

Display

Memory

Front panel

Interfaces

Functionality

Replace with same component

Ratings

Environmental

Electromagnetic

Dimensions

Tech-note

2 Technical data

Type Transflective LCD

monochrome

Resolution 120x64 pixel

Active display area 66x33 mm

Backlight LED

Dimming Contrast Software

User memory 512 KB Flash

User memory

expansion

Touch screen Function keys 9

System keys 18

User LED’s 20

System LED’s 5

PC/Printer port See below

PLC port See below

Aux port (fieldbus and

Ethernet)

Serial programming

speed

Vector graphics Dual driver capability Data acquisition and

trends

Recipe memory 16 KB

UniNet network Client/Server

Alarms 1024

Event list 256

Password Yes

Hardware RTC Yes, battery backed

Screen saver Buzzer Battery 3 V 270 mA Lithium, non

-

See below

9600 – 38400 bps

-

rechargeable, user

replaceable, model CR2430.

or equivalent compatible with

the operating temperature of

the product.

Power supply voltage 18 - 30 VDC

Current consumption ~ 300 mA at 24 VDC

Fuse Automatic

Weight ~ 0.5 Kg (not including cable)

Min thickness of cable 7 mm diameter

Max thickness of cable 11 mm diameter

Conditions

Operating temperature

Storage temperature

Operating and storage

humidity

Vibrations

Shock 50 g, 11 ms, 3 pulses per axis

Protection class IP65

Keyboard reliability > 3 million operations

Compatibility (EMC)

Emitted interference Class A

Immunity to radiated

radiofrequency

electromagnetic field

Immunity to conducted

disturbances inducted

by radiofrequency field

Fast transient 2 KV power supply

Electrostatic discharge 8 KV in air

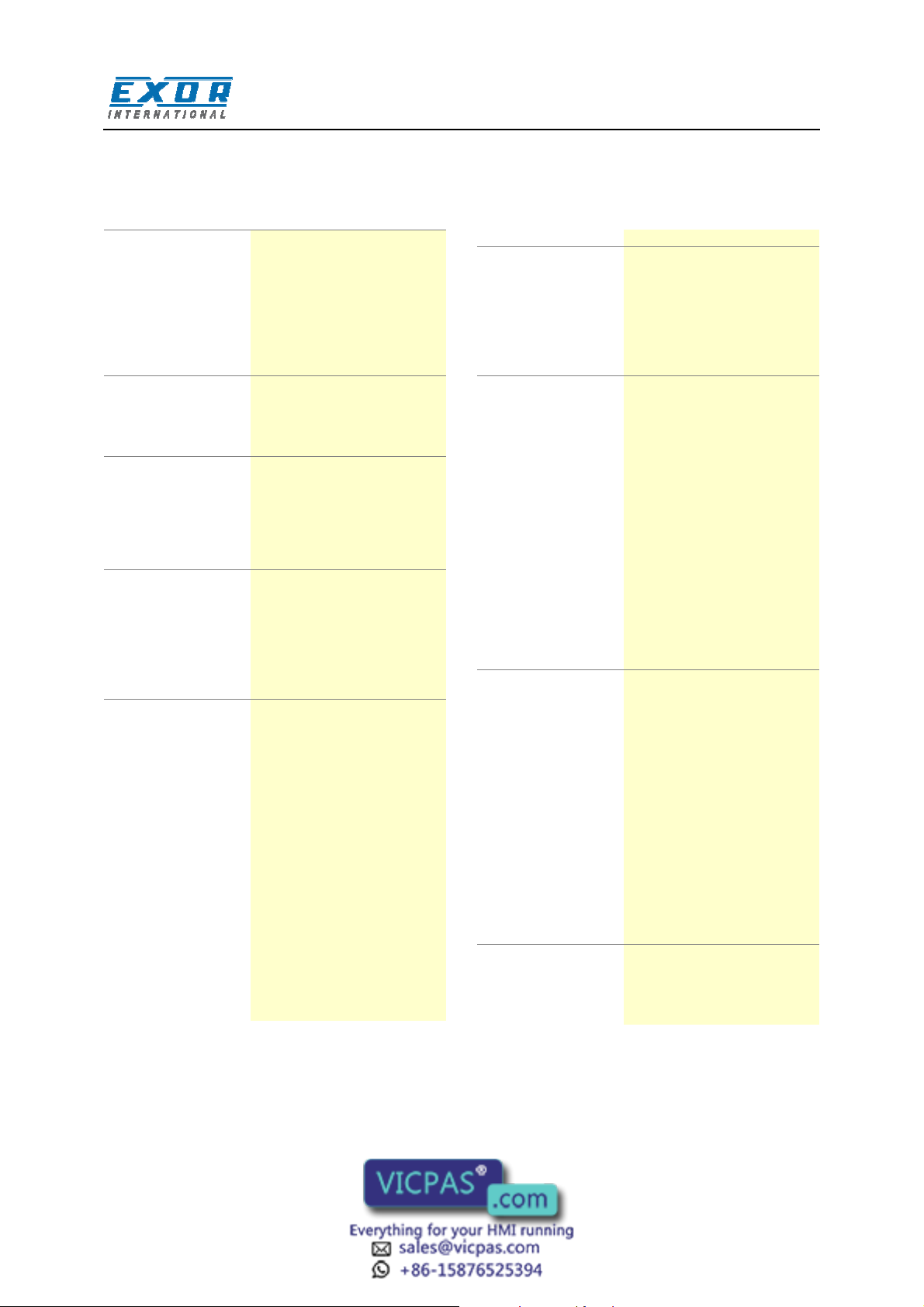

A 116 mm (4.56“)

B 86 mm (3.38“)

C 102 mm (4.01”)

D 239 mm (9.41”)

0 to 50 °C

EN 60068-2-14

-20 to +70 °C

EN 60068-2-14

5 – 85 % RH non-condensing

EN 60068-2-30

10 ÷ 57 Hz, 0,075 mm peak

57 ÷ 150 Hz, 1 G

EN 60068-2-6

EN 60068-2-27

EN 60529

EN 60529

EN 55011

80 MHz ÷ 1 GHz, 10 V/m

EN 61000-4-3

900 MHz, 10V/m

ENV 50204

0.15 ÷ 80 MHz, 10 V

EN 61000-4-6

1 KV signal lines

EN 61000-4-4

EN 61000-4-2

The product is designed for installation in industrial environments in compliance with the regulations:

Emitted interference EN 61000-6-4, 2001

Noise immunity EN 61000-6-2, 2001

All circuits in this handheld product, including the wiring of the emergency stop button and the

enabling switches, must be considered SELV circuits. They will have to be wired in compliance with

EN 60950.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

4

Page 5

Model

Cable Type/Length

PC/Printer Port

PLC Port

Module

Enabling switches

Tech-note

A

D

C

B

Figure 1 – Side and front view

ePALM10-0061 Serial/5m Yes Yes - two normal

ePALM10-0062 Serial/10m Yes Yes - two normal

ePALM10-3P61 Serial/5m Yes Yes - one 3-position

ePALM10-3P62 Serial/10m Yes Yes - one 3-position

ePALM10-0066 Ethernet/5m - - SCM11 one 3-position

ePALM10-0068 Ethernet/10m - - SCM11 one 3-position

ePALM10-0067 Profibus DP/10m Yes - TCM08 one 3-position

ePALM10-0069 Profibus DP/5m Yes - TCM08 one 3-position

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

5

Page 6

Position

Button status

Contacts

Func

tion

Uni

UniUni

Uni

Tech-note

3 Operation

3.1 Enabling Switches

Enabling switches are implemented in two different solutions in the various ePALM models:

Two independent 2-positions switches with NO contacts

One 3-positions switch with two NO contacts

The operator must operate the two independent 2-positions switches simultaneously. The two

normally open contacts are wired directly to the controller.

The 3-positions switch must be operated as described in the table.

1 Released Open Not enabled

2 Pressed Closed Enabled

3 Pressed completely Open Panic

The switch provides two normally open contacts to be wired directly to the controller.

3.2 Indicators and Keypad

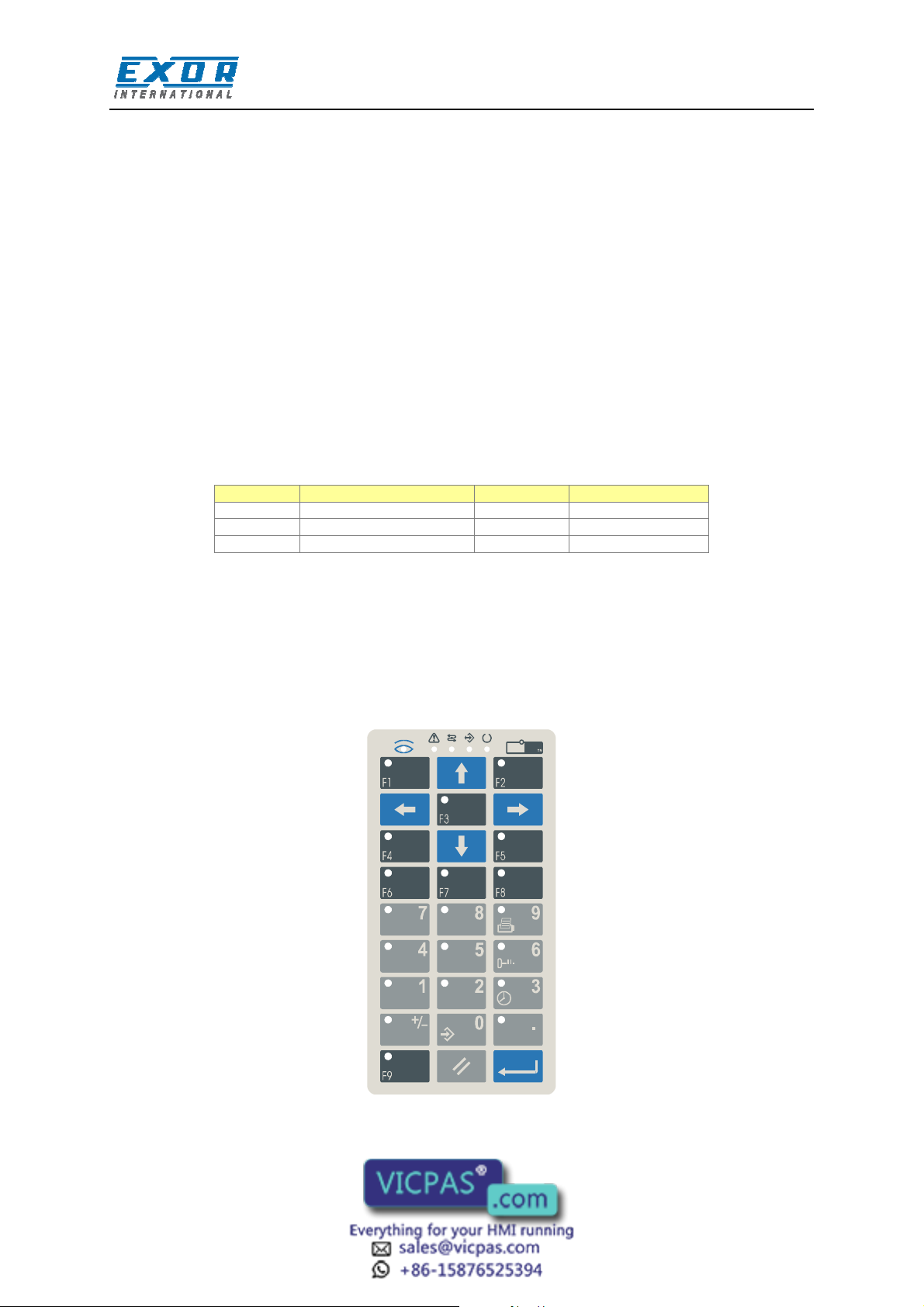

The standard keypad of the ePALM panels is shown in the figure below.

Custom artwork may be designed and produced on request. Please inquire for more information.

OP

OP

OPOP

091A

Figure 2 – Keypad layout

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

6

Page 7

LED Color

Status

Meaning

RDA Bit

LED on Key

RDA Bit

LED on Key

Tech-note

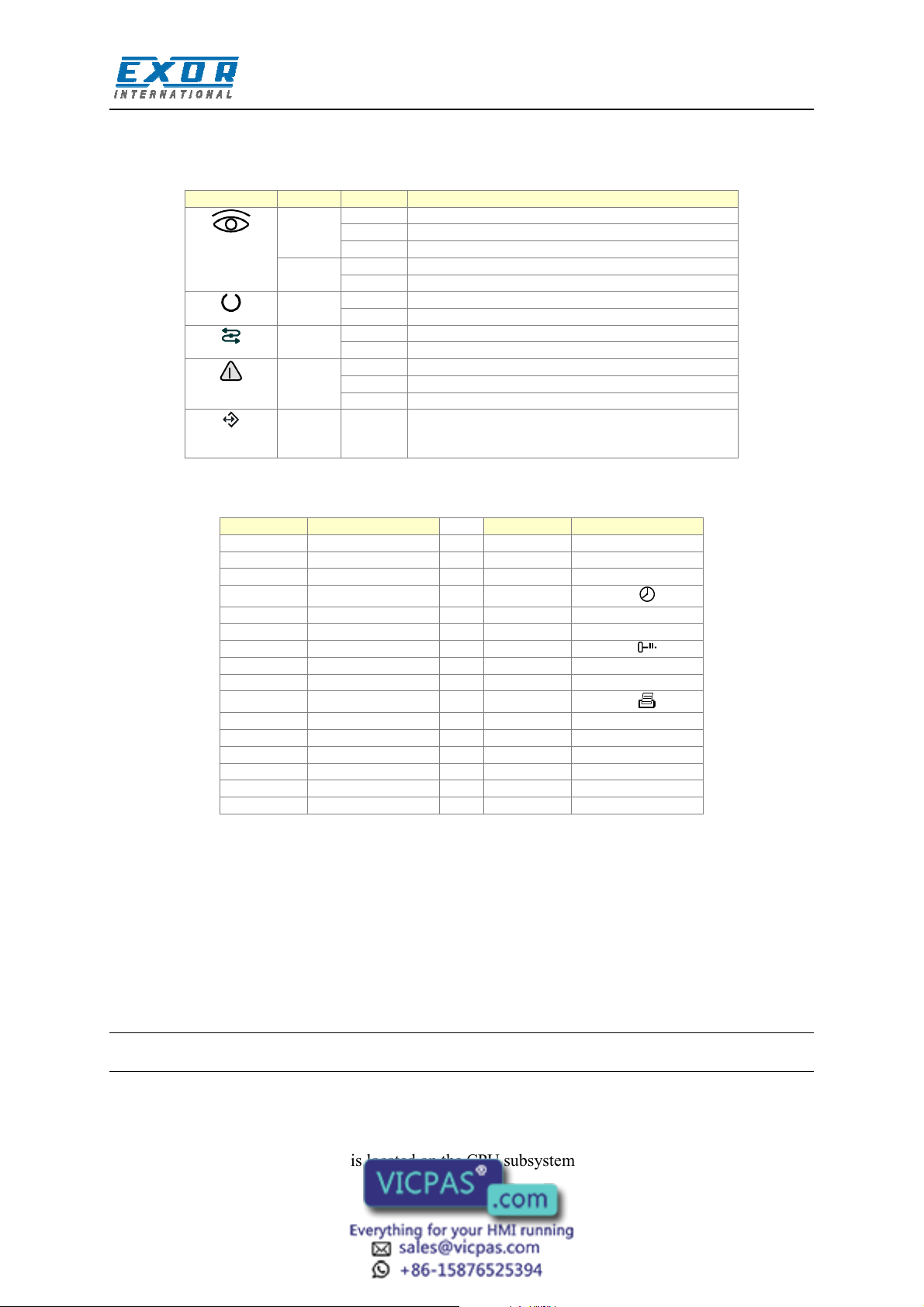

There are several dedicated LED indicators on the front panel of the unit. Functions are described in

the table below.

Red OFF No hardware problems detected

Green OFF No key pressed

Green OFF Hardware fault

Green BLINK Communication error

Red OFF No alarms

Green May be user controlled as LED number 65 using

BLINK Battery low

ON Hardware fault

ON While any key is pressed (visual feedback)

ON Unit in operation

ON Communication OK

BLINK Alarm requires acknowledgment

ON Alarm active

the Macro Editor. Turns ON when recipe/event

backup is being performed.

The RDA mapping of LED indicators is shown in the table below.

L1 F1 L17

L2 F2 L18 1

L3 F3 L19 2

L4 F4 L20

L5 F5 L21 4

L6 F6 L22 5

L7 F7 L23

L8 F8 L24 7

L9 F9 L25 8

L10 L26

L11 L27 .

L12 L28 +/-

L13 L29

L14 L30

L15 L31

L16 L32

3 /

6 /

9 /

The RDA mapping of the keypad is standard.

3.3 Battery Replacement

A Lithium battery is required for data back-up. The battery maintains the following data:

• Hardware real time clock

• Event list

• Recipe data

Note: replacing the battery will cause the loss of the data maintained by the battery.

To replace the battery follow the procedure listed below:

1) turn off the power to the device

2) using a screwdriver loose the 6 screws securing the plastic enclosure

3) open the handheld; the battery is located on the CPU subsystem

4) remove the battery

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

7

Page 8

Tech-note

Warning: danger of explosion if battery is incorrectly replaced. Replace only with the same or

equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

5) replace the battery with a new one

6) close the handheld and tighten the six screws

7) apply power to the handheld and check that the battery good status is reported.

Figure 3 – Battery replacement

3.4 Power Supply and Grounding

The unit must always be grounded to protection earth (PE). Grounding helps limit the effects of noise

due to electromagnetic interference on the control system.

The power supply circuit may be floating or grounded. In the latter case connect to ground the power

source common as shown in figure 4 with a dashed line.

When using the floating power scheme, note that the panels internally connect the power common to

ground with a 1 MΩ resistor in parallel with a 3,3 nF capacitor.

The power supply must have double or reinforced insulation

The suggested wiring for the power supply is shown in figure 4.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

8

Page 9

L1

M

ePALM

L+

Tech-note

N

PE

AC

DC

Figure 4 - Power supply

All the electronic devices in the control system must be properly grounded. Grounding must be

performed according to applicable regulations.

3.5 Applicable Regulations

Regulations and recommendations have been issued in Europe covering the main safety-related issues

in control systems, which include operator interfaces.

EN 60204-1 lists some important guidelines applicable when using operator interfaces.

9.2.4 Suspension of safeguards

9.2.5.3 Stop

9.2.5.4 Emergency stop

9.2.5.6 Hold-to-run controls

9.2.5.7 Two-hand controls

9.4 Control function in case of failure

Do not use operator interface to directly command motors, valves or other actuators not equipped with

safeguards and potentially harmful to persons or equipment in case of fault to the unit.

The service personnel, when operating directly on the powered unit, must be electrostatically

discharged.

All safety related regulations must be observed.

Warning: do not open the rear cover of the device when power is on.

3.6 Installation Environment

The equipment is not intended for continuous exposure to direct sunlight. This might accelerate the

aging process of the front panel film.

The equipment is not intended for installation in contact with corrosive chemical compounds. Check

the resistance of the front panel film to a specific compound before installation.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

9

Page 10

Tech-note

Do not use tools of any kind (screwdrivers, etc.) to operate the keyboard.

3.7 Cleaning Faceplates

The equipment must be cleaned only with a soft cloth and neutral soap product. Do not use solvents.

3.8 Getting Started

ePALMs must be programmed with the Designer software.

To program an ePALM you will have to connect it to a personal computer running the Designer

software; the ePALM must be in Configuration mode to be programmed.

3.8.1 Serial Communication

Make sure that Designer is correctly configured to communicate with the communication port to

which the cable attached.

The serial communication parameters between the panel and the personal computer are:

speed: 9600/38400 baud

parity: None

stop bit: 1

The Designer software defaults to the correct parameters.

3.8.2 Ethernet Communication

When applicable, Designer can use Ethernet to connect to the panel. Make sure all network

parameters are properly set to ensure communication between Designer and the panel.

The version of Designer software must be compatible with the firmware version of the panel to be

programmed. Call technical support for more information on compatibility between firmware and

programming software.

3.9 Troubleshooting

In the case it might be impossible to switch the handheld to Configuration Mode due to problems in

the start-up phase, follow the procedure described below:

1.

Switch off the unit

2.

Press and hold any 3 keys

3.

Turn on the unit and hold the keys pressed until Configuration Mode will be shown on the screen.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

10

Page 11

CN3

CN4

Tech-note

4 Connections

The ePALM10 is available in several versions, featuring different communication cables and different

solutions for the enabling switches.

4.1 Serial Communication - Types –0061 and –0062

ePALM types –0061 and -0062 include all standard UniOP connections and are suitable for all

common serial communication links.

The ePALM10-0061 includes a communication cable with a length of 5 meters.

The ePALM10-0062 includes a communication cable with a length of 10 meters.

The cable does not have a connector at its loose end as it is intended to be wired directly in the control

cabinet.

The following groups of signals are available in the cable:

PC/Printer Port

PLC Port

Aux Port

Power

Emergency Stop button – two NC contacts

Two 2-positions enabling switches – NO contacts

In all the most common configurations, the signals are wired to the cable and there will be no need to

open the unit to access the terminal blocks.

Note: the ePALM10 unit does not include a current loop (20 mA) interface in the PLC port. The

communication modules TCM04 (Interbus), TCM07 (Simatic S7 MPI without optical

insulation), TCM08/TCM18 (Profibus DP) and TCM10/SCM11 (Ethernet) are not supported.

Internally to the product all signals, excluding emergency stop, are wired to a detachable interface

board with five terminal blocks.

The position of the terminal blocks and the numbering of the contacts are shown in the figure below.

CN2

CN1

CN5

Figure 5 – Interface Board

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

11

Page 12

CN1 Aux Port

CN2 PC/Printer Port

CN3 PLC Port

CN4 Power

CN5 Additional Signals

Tech-note

The assignment of the signals on the terminal blocks is shown in the tables below. Terminals

indicated as ‘Reserved’ should not be connected.

1 Aux Port pin 5 1 Reserved

2 Aux Port pin 9 2 Reserved

3 Aux Port pin 4 3 Reserved

4 Aux Port pin 8 4 Reserved

5 Aux Port pin 3 5 +5V output (max 100 mA)

6

Aux Port pin 7

7 Aux Port pin 2 7 RXD

8 Aux Port pin 6 8 CTS

9 Aux Port pin 1 9 TXD

10 Reserved 10 RTS

6 GND

The terminal assignment in CN1 refers to the corresponding assignment in the Aux Port of the

standard panel-mount version of the product. This correspondence will be useful to adapt the normal

cable drawings for use with the handheld device.

1 CHA+ 1 +24 VDC

2 CHA- 2 Common

3 CHB+ 3 Reserved

4 CHB- 4 PE

5 +5V output (max 100 mA)

6 GND

7 RXD 1 Enabling switch R (NO contact)

8 CTS 2 Enabling switch R (NO contact)

9 TXD 3 Enabling switch L (NO contact)

10 RTS 4 Enabling switch L (NO contact)

The Emergency Stop button is hardwired directly to the cable: the corresponding signals are not

available in the connectors.

The wires in the cable are color-coded according to the table below.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

12

Page 13

Signal

Color

S mm

2

AWG (approx)

Power

PC/Printer Port

PLC Port

Additional Signals

Emergency Stop

Tech-note

+24 VDC Red 0.5 20

Common Black 0.5 20

GND Grey 0.14 26

RXD Orange 0.14 26

CTS Brown 0.14 26

TXD White 0.14 26

RTS Pink 0.14 26

+5V Output Green 0.14 26

CHA+ Blue-Red 0.14 26

CHA- Blue-Black 0.14 26

CHB+ Violet-Red 0.14 26

CHB- Violet-Black 0.14 26

+5V Output Red 0.14 26

GND Black 0.14 26

RXD Brown-Pink 0.14 26

CTS Green-Pink 0.14 26

TXD Orange-Pink 0.14 26

RTS Yellow-Pink 0.14 26

ES Right (NO) Cyan-Black 0.35 22

ES Right (NO) Cyan 0.35 22

ES Left (NO) Blue-Black 0.35 22

ES Left (NO) Blue 0.35 22

E-Stop 1 (NC) Green 1 17

E-Stop 1 (NC) Yellow 1 17

E-Stop 2 (NC) Brown 1 17

E-Stop 2 (NC)

Orange 1 17

Note: the wiring of the Emergency Stop button is to be considered a SELV circuit and it is

intended only for connection to low voltage circuits (below 48 VDC).

The standard cable layout of the ePALM10-0061 and ePALM10-0062 includes the signals of the

PC/Printer Port and the signals of the PLC Port. Without modifications it allows to connect to the

handheld device for programming and to set-up a connection to a field device using RS-232, RS-422

or RS-485.

If connection to the Aux Port is required, signals normally wired to the PLC port will have to be

manually moved to the Aux Port. You will have to open the product to perform this operation.

When the RS-422 or RS-485 communication is used, it is recommended not to leave the RXD and the

CTS signals floating, even if they are not used in this configuration. The RXD signal should be

connected to GND; the CTS signal should be connected to the +5V Output.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

13

Page 14

Connect the

Shield Trace

Ferrite Toroid

E

Max Wire Length 10cm

Tech-note

N

G

N

.

C

.

N

E

.

.

.

E

C

C

C

R

.

.

.

N

N

N

G

E

W

N

Y

T

K

I

A

E

O

N

H

R

R

R

I

P

W

B

O

G

To Emergency Stop

Button

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

CYAN-BLACK

CYAN

BLUE-BLACK

BLUE

YELLOW

GREEN

BROWN

ORANGE

Length 25cm

4X1mmq

BLUE-RED

BLUE-BLACK

VIOLET-RED

VIOLET-BLACK

RED

BLACK

BROWN-PINK

GREEN-PINK

ORANGE-PINK

YELLOW-PINK

RED

BLACK

N.C.

SHIELD TRACE

Figure 6 – Wiring layout

The figure shows the standard assembly of the communication cable.

Please note that the ferrite toroid is required for proper operation and should not be removed.

To program the ePALM10 you will need to wire at least the power supply and the programming port

connections. Connect the ePALM10 to the COM port of a PC as indicated in the figure below.

Figure 7 – Programming cable

4.1.1 Using Optional Fieldbus Modules

The ePALM versions –0061 and –0062 are compatible with some of the standard TCM

communication modules for connection to fieldbus systems.

The list of the TCM module currently supported by the ePALM product is the following:

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

14

Page 15

TCM module

Fieldbus

Notes

CN1 Connector (Aux Port)

CN3 Connector (PLC Port)

Pin

Signal

Color

Pin Signal

Tech-note

TCM01 Siemens Simatic S7 MPI Suitable for a point-to-point configuration at the speed

TCM02

TCM03

TCM09 CANopen There are limitations in the bus speed and network

Moeller Suconet K

DeviceNet

of 187 Kb

Suitable for a point-to-point configuration at the

maximum speed of 375 Kb

There are limitations in the bus speed and network

configuration that can be used

configuration that can be used

Other TCM modules are currently not supported for use in these versions of the ePALM product.

The following notes are important:

• The TCM module must be plugged into the unit in the slot available for this purpose. The ePALM

must be opened to allow for the insertion of the TCM module. After plugging the module the

ePALM product must be carefully closed to ensure proper sealing.

• The default wiring of the Aux Port CN1 must be manually changed to connect the appropriate

signals. Fieldbus topologies do not allow long (5-10 meters) drop segments; the wiring must

include incoming and outgoing segments for all bus signals.

• The CA01 interface board does not allow adding terminator resistors to the bus lines. The ePALM

cannot be used a final node in the network topology unless termination resistors are applied

externally.

The most common wiring layouts will be described in detail in this chapter.

4.1.2 Connecting the ePALM to the Simatic S7 MPI network

It is recommended that the signals needed for this connection be moved from the CN3 connector

(PLC Port) to the CN1 connector (Aux Port) as shown in the table below.

The table indicates the wires that must be moved from CN3 to CN1. The signals A and B will have to

be connected to the MPI network.

Please note that it is not possible to connect the termination resistors in the ePALM.

Wires to be removed

4 A Blue-Red 1 CHA+

5 B Blue-Black 2 CHA1 GND Black 6 GND

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

15

Page 16

CN4

CN2

CN3

Ethernet port

Tech-note

4.2 Ethernet Communication - Type –0066 and –0068

ePALM type –0066 and –0068 have been designed exclusively for connection to the Ethernet

network. The products include a special cable suitable for Ethernet communication.

The cable does not have a connector at its loose end as it is intended to be wired directly to the control

cabinet.

The following groups of signals are available in the cable:

Ethernet 10base/T

Power

Emergency Stop button – two NC contacts

One three-positions enabling switch – two independent NO contacts

Please note that this product does not include connections for the following standard ports:

PC/Printer Port,

PLC Port,

Aux Port.

Note: this version of the product does not include the conventionalPC/Printer Port; programming

can be done only via Ethernet.

Internally to the product all signals, excluding emergency stop, are wired to a detachable interface

board with five terminal blocks.

The position of the terminal blocks and the numbering of the contacts are shown in the figure below.

CN7

CN3

CN1

Figure 8 – Interface board

The assignment of the signals on the terminal blocks is shown in the tables below. Terminals

indicated as ‘Reserved’ should not be connected.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

1 RX2 RX+

3 TX4 TX+

16

Page 17

CN1 Additional Signals

CN2 Power

CN4 PLC Port

Signal

Color

S mm

2

AWG (approx)

Power

Ethernet Port

Additional Signals

Emergency Stop

Tech-note

1 Enabling switch A (NO contact) 1 +24 VDC

2 Enabling switch A (NO contact) 2 Common

3 Enabling switch B (NO contact) 3 Reserved

4 Enabling switch B (NO contact) 4 PE

The Emergency Stop button is hardwired directly to the cable: the corresponding signals do not

appear listed in the connectors.

Note: the wiring of the Emergency Stop button is to be considered a SELV circuit and it is

intended only for connection to low voltage circuits (below 48 VDC).

1 CHA+

2 CHA3 CHB+

4 CHB5 +5V output (max 100 mA)

6 GND

7 RXD

8 CTS

9 TXD

10 RTS

Note: the signals in CN4, although fully functional, are not wired to the connection cable and are

not available for applications. The information on CN4 is provided for reference only. The

signals wired to the cable are listed in the table below.

The wires in the cable are color-coded as shown in the table below.

+24 VDC Red 0.75 20

Common Black 0.75 20

TX+ White-Orange 0.5 24

TX- Orange 0.5 24

RX+ White-Green 0.5 24

RX- Green 0.5 24

Enabling Switch A Blue-Black 0.75 22

Enabling Switch A Blue 0.75 22

Enabling Switch B Cyan-Black 0.75 22

Enabling Switch B Cyan 0.75 22

E-Stop 1 (NC) Green 1 17

E-Stop 1 (NC) Yellow 1 17

E-Stop 2 (NC) Brown 1 17

E-Stop 2 (NC) Orange 1 17

The internal layout of the communication cable is shown in the figure. Please note that the ferrite

toroid is required for proper operation and should not be removed.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

17

Page 18

SHIELD TRACE

Tech-note

WHITE-ORANGE

ORANGE

WHITE-GREEN

GREEN

CYAN-BLACK

BLUE-BLACK

CYAN

BLUE

RED

BLACK

N.C.

YELLOW

GREEN

BROWN

ORANGE

Figure 9 – Wiring layout

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

18

Page 19

CN2

CN3

CN4

CN1 Profibus DP

Tech-note

4.3 Profibus DP Communication - Type –0067 and –0069

ePALM type –0067 and –0069 have been designed exclusively for connection to the Profibus DP

fieldbus. The products include a special cable suitable for Profibus DP communication.

The cable does not have a connector at its loose end as it is intended to be wired directly in the control

cabinet.

The following groups of signals are available in the cable:

Profibus DP

Power

Emergency Stop button – two NC contacts

One three-positions enabling switch – two independent NO contacts

Please note that this product does not include connections for the following standard ports:

PLC Port,

Aux Port.

Note: this version of the product has a special connector for programming. See below for

description

Internally to the product all signals, excluding emergency stop, are wired to a detachable interface

board with six terminal blocks.

The position of the terminal blocks and the numbering of the contacts are shown in the figure below.

SW1

CN1

CN5

Figure 10 – Interface board

The assignment of the signals on the terminal blocks is shown in the tables below. Terminals

indicated as ‘Reserved’ should not be used.

1 Reserved

2 Reserved

3 Reserved

4 A

5 B

6 Reserved

7 Reserved

8 Reserved

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

19

Page 20

CN5 Additional Signals

CN4 Power

Signal

Color

S mm

2

AWG (approx)

Tech-note

9 Reserved

10 Reserved

1 Enabling switch A (NO contact) 1 +24 VDC

2 Enabling switch A (NO contact) 2 Common

3 Enabling switch B (NO contact) 3 Reserved

4 Enabling switch B (NO contact) 4 PE

The Emergency Stop button is hardwired directly to the cable: the corresponding signals do not

appear listed in the connectors.

Note: the connection of the Emergency Stop button is intended only for connection to low voltage

circuits (below 48 VDC).

The wires in the cable are color-coded according to the table below.

Power

+24 VDC Red 0.75 21

Common Black 0.75 21

Aux Port (Profibus)

A Green 0.5 24

B Red 0.5 24

Additional Signals

Enabling switch A Blue-Black 0.75 21

Enabling switch A Blue 0.75 21

Enabling switch B Cyan-Black 0.75 21

Enabling switch B Cyan 0.75 21

Emergency Stop

Emergency Stop 1 Green 1 17

Emergency Stop 1 Yellow 1 17

Emergency Stop 2 Brown 1 17

Emergency Stop 2 Orange 1 17

The internal layout of the communication cable is shown in the figure below. Please note that the

ferrite toroid is required for proper operation and should not be removed.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

20

Page 21

SHIELD TRACE

Tech-note

RED

GREEN

CYAN-BLACK

CYAN

BLUE-BLACK

BLUE

RED

BLACK

N.C.

YELLOW

GREEN

BROWN

ORANGE

Ferrite Toroid

Figure 11 – Wiring layout

4.3.1 Termination switch

The ePALM has been designed only for connection at one of the two ends of the Profibus DP

network.

ePALM10

Profibus DP

Figure 12 – Network topology

Profibus-DP requires termination of the bus at both end points; see the Profibus-DP specifications for

details. The ePALM includes the bus terminator resistors. Make sure they are always switched on.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

21

Page 22

Termination

Setting

Switch Position

Pin Signal

Tech-note

Open (not used) Off

On

(Default)

Figure 13 – Termination resistors

4.3.2 Programming connector

On the back of the ePALM a RS-232 serial port is available for programming the device; the drawing

below shows the position and the pin-out of the connector.

7

1

Figure 14 – Programming connector

1 NC

2 +5VDC out

3 RX

4 TX

5 RTS

6 CTS

7 GND

Use cable CA234 to connect the ePALM to a Personal Computer for programming. The cable

diagram is shown in the figure below.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

22

Page 23

Tech-note

Figure 15 – Programming cable

5 Accessories

The following accessories are currently available for the ePALM10 products:

• hooks for hanging the handheld device. Hooks are available in two versions, AHOOK01 without

magnet and AHOOK02 with a magnet.

The hook with the magnet is shown in the figure below.

Figure 16 – Hook with magnet

The hook with magnet cannot be used with type –0067.

tn202-2.doc - 10.01.2012

ePALM10 Product Manual

23

Loading...

Loading...