Exodraft EHC20 Mounting, Installation And Operating Manual

EHC20

Mounting, installation

and operating manual

Read and save these instructions!

GB

2

3110086 EHC20 UK 110515

A. SUMMARY of assembly, installation and oper-

ating instructions. . . . . . . . . . . . . . . . . . . . . . 4

A.1 Description .......................... 4

A.2 About the automatic controller ....... 4

A.3 Scope of delivery..................... 4

B. Installation ........................ 5

B.1 Wall mounting ....................... 5

B.1.1 Housing base.......................5

B.1.2 Housing cover ......................5

B.2 Electrical connection ................. 6

B.3 Temperature sensor installation....... 6

C. Terminal plan and connections ..... 7

C.1 Terminal housing..................... 7

C.2 Terminal plan for electrical connection 7

D. Pin-out diagram ................... 8

D.1 Program 6.1.7 Heat exchanger with bypass

damper, one buer memory and mixer. .... 8

E. Installation note for 3-way mixing valve

10

E.1 SM230 with MV20/25/32 installation note

10

F. Service and start-up ..............11

F.1 Display and entry................... 11

F.2 Initial start-up with the start-up assistant

12

G. Lock menu .......................12

G.1 Activate/deactivate the lock menu .. 12

H. Option for heat quantity counter SE 20/SE 25/

SE 32 ................................13

H.1 Assembly and connection .......... 13

H.2 Start-up and set-up................. 14

I. SD card ..........................15

I.1 SD card ............................ 15

I.2 Logging............................ 15

I.3 Free storage........................ 15

I.4 Load conguration ................. 15

I.5 Save conguration ................. 15

I.6 Firmware update ................... 15

I.7 Ejection ............................ 15

J. Error messages ................... 16

J.1 Replacing a fuse .................... 16

J.2 Maintenance ....................... 17

K. Product information .............. 18

K.1 Description ........................ 18

K.2 About the controller................ 18

K.3 Items supplied ..................... 18

L. Controller description .............19

L.1 Technical data...................... 19

M. Installation ....................... 20

M.1 Wall mounting ..................... 20

M.1.1 Housing base......................20

M.1.2 Housing top .......................21

M.2 Electrical connection ............... 21

M.3 Installing the temperature sensors:.. 22

N. Terminal plan and connections .... 23

N.1 Terminal box ....................... 23

N.2 Terminal plan for electrical connections 23

N.3 Hydraulic variants / overview / systems 24

O. Connection diagrams .............26

O.1 Program 6.1.1. Heat exchanger without bypass

damper. With one storage tank. . . . . . . . . . . 26

O.2 Program 6.1.2. Heat exchanger without bypass

damper. With two storage tanks. ......... 28

O.3 Program 6.1.3 Heat exchanger without bypass

damper. With one storage tank and a mixer. 30

O.4 Program 6.1.4. Heat exchanger without bypass

damper. With two storage tanks and a mixer. 32

O.5 Program 6.1.5. Heat exchanger with bypass

damper. With one storage tank. . . . . . . . . . . 34

O.6 Program 6.1.6. Heat exchanger with bypass

damper. With two storage tanks. ......... 36

O.7 Program 6.1.7. Heat exchanger with bypass

damper. With one storage tank and a mixer. 38

O.8 Program 6.1.8. Heat exchanger with bypass

damper. With two storage tanks and a mixer. 40

O.9 Program 6.1.1. Heat exchanger with VFS sensor

for power measurement.................. 42

P. Operation ........................ 44

P.1 Display and entry system ........... 44

P.2 Setup wizard . . . . . . . . . . . . . . . . . . . . . . . 44

P.3 Unassisted setup ................... 45

P.4 Menu sequence and structure ...... 45

1. Measurements ...................46

2. Statistics .........................47

2.1 Operating hours.....................47

2.2 Heat quantity .......................47

2.3 Graphic overview....................47

2.4 Reports .............................47

2.5 Reset / delete .......................47

3. Operating mode .................. 47

3.1 Automatic...........................48

3.2 Manual..............................48

3.3 O ..................................48

4. Settings .......................... 48

4.1 Tmin S (X) ...........................48

4.2 Tmax S (X)...........................48

4.3 Priority S(X) .........................49

4.4 T priority ............................49

4.5 Filling time ..........................49

4.6 Temperature rise ....................49

5. Protective functions .............. 49

5.1 Anti-seize protection ................49

6. Special functions ................. 50

6.1 Program selection ...................50

6.2 Rotational speed control.............50

6.2.1 Rotational speed modes ...........50

6.2.2 Pump type ........................51

6.2.3 Pump settings .....................51

6.2.4 Purging time ......................53

6.2.5 Control time.......................53

6.2.6 Max. rotational speed ..............53

6.2.7 Min. rotational speed ..............53

6.2.8 Setpoint value .....................54

6.3 R2 rotational speed control ..........54

6.4 Relay functions ......................54

6.4.1 Thermostat........................54

6.4.2 Thermostat 2 ......................55

6.4.3 Cooling............................55

6.4.4 Return ow temperature rise.......56

6.4.5 Anti-Legionella function ...........56

6.4.6 Transfer ...........................57

6.4.7 Dierence .........................58

6.4.8 Solid fuel boiler....................59

6.4.9 Error messages ....................59

6.4.10 Pressure control ...................60

6.4.11 Booster pump .....................60

6.4.12 Parallel operation R (X) .............60

6.4.13 Parallel operation R2 ...............61

6.4.14 Permanently on ...................61

6.4.15 Heating circuit.....................61

6.5 Heat quantity .......................62

6.5.1 Forward ow sensor (X) ............62

6.5.2 Return ow sensor.................62

6.5.3 Glycol type ........................62

6.5.4 Proportion of glycol................62

6.5.5 Forward throughow (X)...........62

6.5.6 Oset ∆T ..........................62

6.5.7 VFS (X) ............................62

6.5.8 VFS position .......................63

6.5.9 Reference sensor ..................63

6.6 Pressure monitoring.................63

6.6.1 Pressure monitoring ...............63

6.7 Sensor calibration ...................63

6.8 Setup ...............................64

6.9 Factory settings .....................64

6.10 SD card .............................64

6.10.1 Logging ...........................

6.10.2 Free storage space.................64

6.10.3 Load conguration ................64

6.10.4 Save conguration.................64

6.10.5 Firmware update ..................64

6.10.6 Eject ..............................64

6.11 Time and date.......................65

6.12 Summer time .......................65

6.13 Power saving mode .................65

6.14 Ethernet ............................65

6.14.1 Ethernet...........................65

6.14.2 MAC address ......................65

6.14.3 TCP/IP address.....................65

6.14.4 Network mask . . . . . . . . . . . . . . . . . . . . .65

6.14.5 Gateway...........................65

6.14.6 Login..............................65

6.15 Temperature unit....................65

7. Menu lock ........................ 66

8. Service Data ...................... 66

9. Language ........................ 66

Q. Faults with error messages ........ 67

Q.1 Replace fuse ....................... 67

Q.2 Maintenance ....................... 68

R. Useful information / tips and tricks 69

64

3110086 EHC20 UK 110515

Legend for symbols: The following symbols are used throughout the manual as warnings. They indicate potential

hazards or refer to important information relating to the product.

3

Prohibitory symbol:

Hazard symbol: Failure to observe information marked with a hazard symbol can result in injuries

Attention symbol: Information that is particularly important for the functioning and optimum use of

Failure to observe information marked with a prohibitory symbol can result in

serious injuries – or even death!

and/or damage to the device.

the device and the system.

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCKS OR PERSONAL INJURIES,

THE FOLLOWING RULES MUST BE OBSERVED:

• The device should only be used in the manner specied by the manufacturer. If you have any questions,

please contact the manufacturer. The address and telephone number of the manufacturer can be found

in the list at the end of this manual.

• Before maintaining or cleaning the device, switch it o at the service panel and lock the service panel so

that it cannot be turned on again accidentally.

• Installation work and work on the electrical connections should be carried out by specialists in

accordance with the laws and regulations in place.

• Observe the device manufacturer's guidelines and safety regulations as well as the ocial provisions in

force in the particular country.

• The device must be earthed.

No special requirements. The device must be disposed of in accordance with the ocial provisions

concerning the disposal of electronic waste.

4 • Product information

3110086 EHC20 UK 110515

A. SUMMARY of assembly, installation and operating instructions

A.1 Description

The automatic controller was produced and tested while taking into account all requirements for high-quality and safety.

A two-year warranty from the date of sale applies to the device in accordance with the law.

However, the warranty and liability are not valid regarding damage to persons or property that, for example, are ascribed

to one or more of the following causes:

• Failure to follow these assembly instructions and service guide

• Incorrect assembly, start-up, maintenance or servicing

• Improper repairs carried out

• Unauthorised structural modications made to the device

• Installation of additional components that were not tested with the device

• Any damage resulting from continued use of the device in spite of an evident defect

• Failure to use original repair parts and accessories

• Failure to use the device as intended

• Exceedance of or failure to meet the limit values in the technical data

• Force majeure

A.2 About the automatic controller

The EHC temperature dierence controller enables you to eciently use and check the function of your heat exchanger.

Above all, the device gives you condence through its functionality and simple, almost self-explanatory, operation.

The individual entry keys are assigned to each dierent useful function and explained step-by-step. In the automatic

controller menu, help texts and clear graphics are also available in addition to keywords for measured values and

settings.

The EHC temperature dierence controller can be used with dierent systems.

A.3 Scope of delivery

• EHC20 temperature dierence controller

• Threescrews (3.5x35 mm) and threerawl-plugs (6mm) for wall mounting

• 12 strain relief clamps with 24 screws, replacement fuses 1x T2 A / 250 V

• Micro SD card + adapter

• EHC assembly and service guide

• Thermal compound

• One Pt1000 ue gas temperature sensor

• One Pt1000 pipe surface temperature sensor

• One Pt1000 Buer tank sensor with sleeve

Please use thermal compound with the temperature sensors to ensure better heat transfer.

Optionally included, depending on design/order:

• Flowsensor for energy measurement

3110086 EHC20 UK 110515

161

11,8

195,4

9

R4.5

4.4

3333

139,3

n

3.5

169.3

B. Installation

B.1 Wall mounting

1. Loosen cover screw completely

2. Carefully remove the terminal cover from the bottom part. Loosen the two screws on the top part and

remove the top part from the base.

3. Mark the three mounting holes (see ”C.1.1 Housing base”). Make sure that the wall surface is as even as

possible so that the housing is not warped when attached.

4. Drill three holes in the wall at the marked places using a drill and #6 bit and insert the rawl-plugs.

5. Set the automatic controller on the upper screw.

6. Insert and screw in the two lower screws.

Only install the automatic controller in dry rooms and under the environmental conditions as

described in B.1 ”Technical Data”.

The automatic controller must not be accessible from the back!

Installation• 5

B.1.1 Housing base

B.1.2 Housing cover

Terminal housing cover

Cover screw

6 • Installation

B.2 Electrical connection

Disconnect the power supply before working on the device and make sure that it cannot be

reconnected! Check that the power is o!

The electrical connection must only be carried out by qualied personnel in compliance with

the applicable laws. The automatic controller must not be put into operation if any damage is

visible on the housing, such as cracks.

Low-voltage cables such as temperature sensor cables must be routed separately from mains

voltage cables. Only put temperature sensor cables into the left side, and the mains voltage

cable into the right side of the device.

Safe isolation of the voltage supply to the automatic controller has been provided, such as

provision for an overheating emergency stop switch.

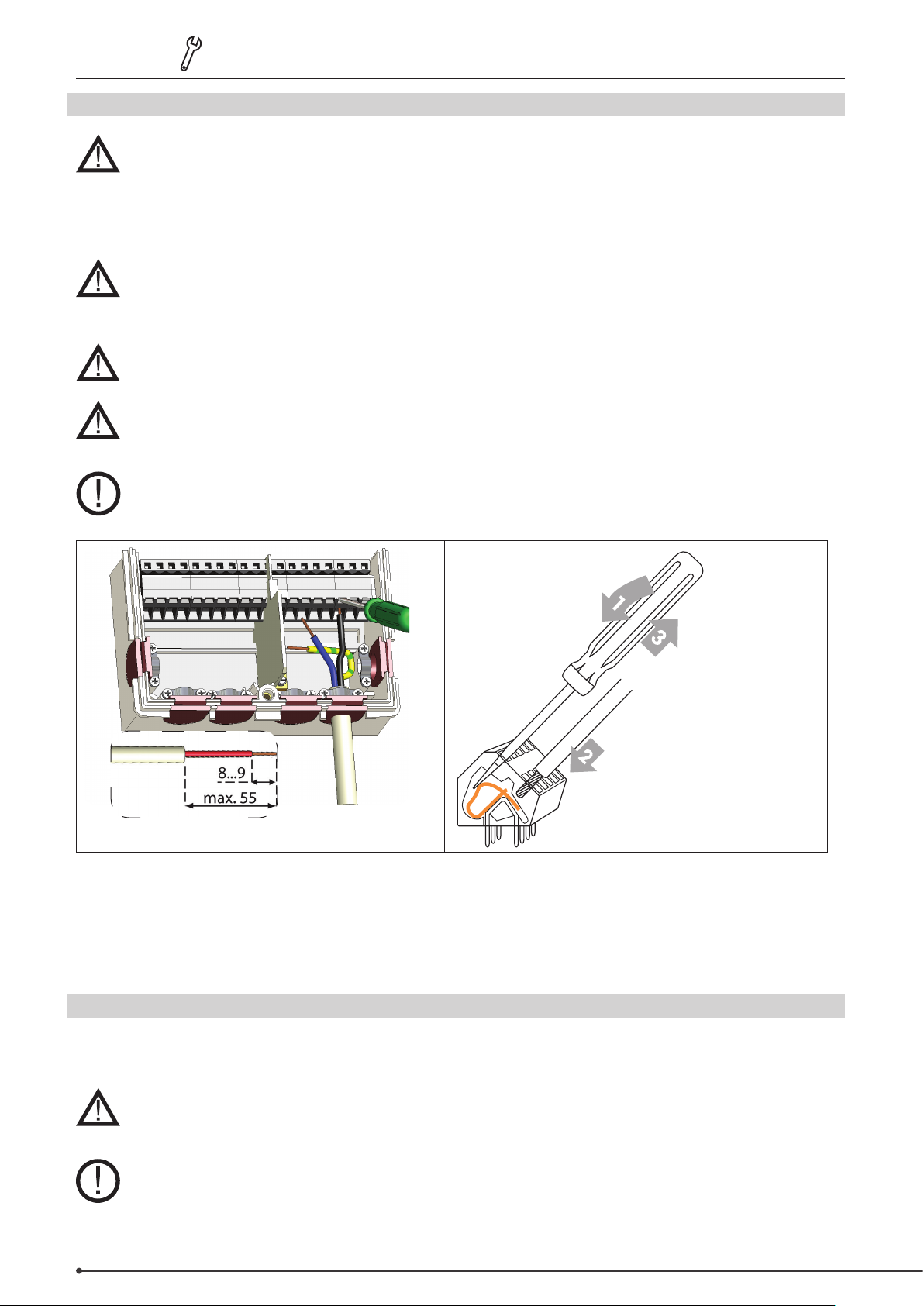

The cables to be connected to the device may be stripped up to maximum of 55mm and the

sheath should reach into the housing to exactly behind the strain relief.

The automatic controller and VFS sensor must have the same earthing potential. The VFS

sensor has a functional earthing (PELV). The peripheral unit terminal of the automatic

controller must be connected to the the piping system near the sensor.

3110086 EHC20 UK 110515

Terminal instructions

1. Insert a suitable screwdriver into the upper opening and press the lock handle down.

Leave the screwdriver in the opening.

2. Insert the cable into the lower opening.

3. Remove the screwdriver.

B.3 Temperature sensor installation

The automatic controller works with Pt1000 temperature sensors to ensure that the temperature is precisely recorded

so that the unit functions under technically optimal conditions.

The temperature sensor cables must be placed separately from the mains cables and must not,

for example, be placed in the same cables duct!

Place the sensors precisely in the area to be measured! Only use the feeder, tube or ush

sensor for the applicable area of use with the allowed temperature range that corresponds to

each. The thermal conductor must be used during assembly!

3110086 EHC20 UK 110515

The sensor cables to S7/S8 may be extended to a maximum total length of 30 metres with a

cable that has a diameter of at least 0.75mm². The sensors from S1 to S6 may be extended to a

maximum total length of 10metres with a cable that has a diameter of at least 0.75mm².

Pay attention that no contact resistance occurs while joining the cables!

Connect the VFS direct sensors with the corresponding plug. In order to avoid damage to the

direct sensors, we strongly recommend only placing them in the return ow! Pay attention to

the correct ow direction when assembling the (VFS) direct sensors!

C. Terminal plan and connections

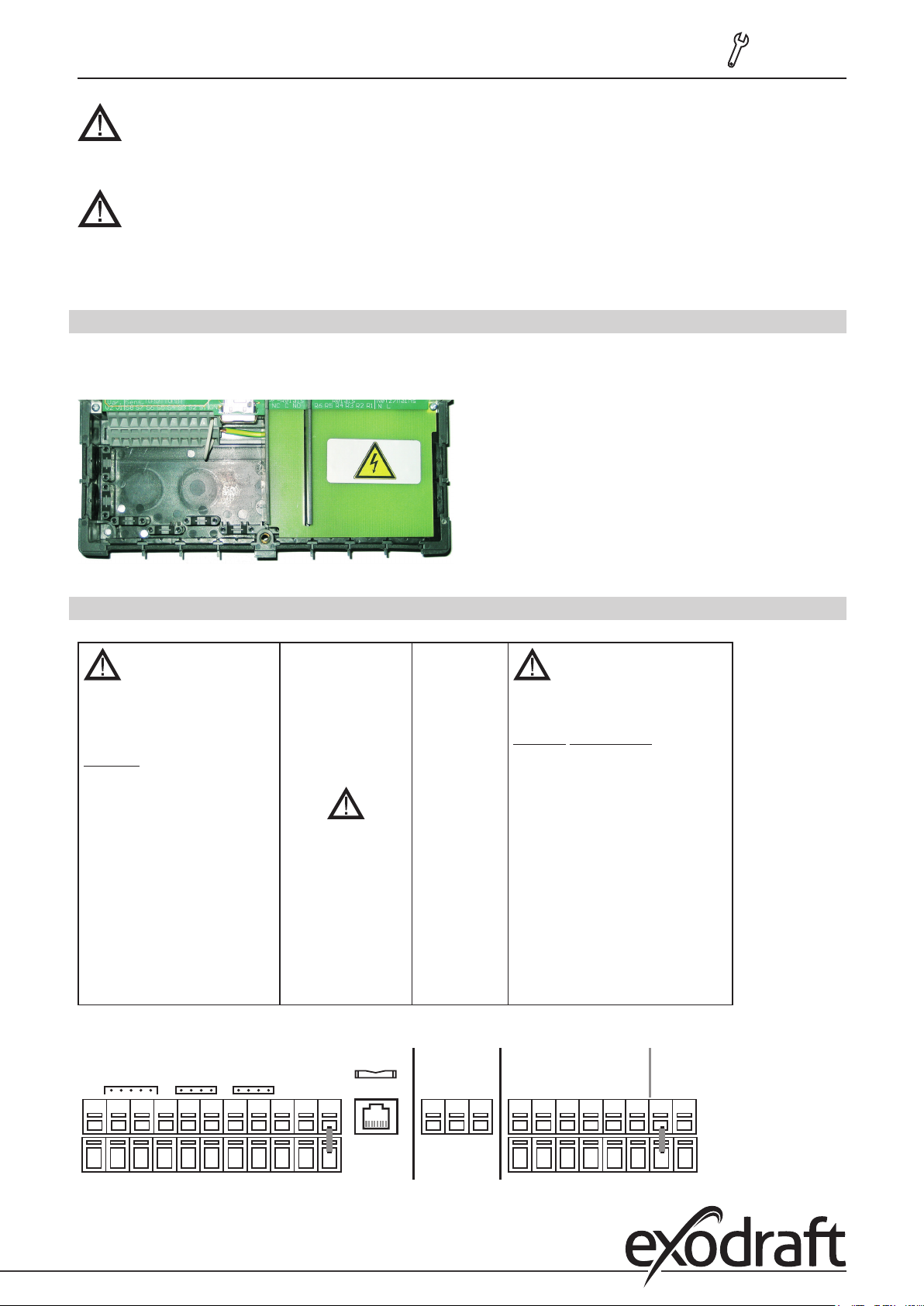

C.1 Terminal housing

The mains side of the terminal housing is protected on the right side by an additional plastic plate.

Before removing the plate, check that the power to the automatic controller has been switched o.

Installation• 7

C.2 Terminal plan for electrical connection

max. 12 V

Extra-low voltages

max. 12 VAC/DC

Terminals Connection for

S1 Sensor 1

S2 Sensor 2

S3 Sensor 3

S4 Sensor 4

S5 Sensor 5

S6 Sensor 6

S7 Sensor 7

S8 Sensor 8

V1 0-10 V/PWM

V2 0-10 V/PWM

VFS1 Grundfos Direct Sensor

VFS2 Grundfos Direct Sensor

RC Room controller

VFS2RC VFS1

SD card slot

for data storage and

updates

Ensure you insert

the card correctly!

The card must

enter without any

resistance, do not

force it into the

slot!

Ethernet (optional)

for linking to an LAN

SD Card

Potentially

free relay

NO

Normally

open

(closer)

C

Common

(Voltage)

NC

Normally

closed

(opener)

Mains

230 VAC

Mains voltages 230 VAC 50-60 Hz

Terminals Connection for

R1 Switch output 1 (speed)

R2 Switch output 2 (speed)

R3 Switch output 3

R4 Switch output 4

R5 Switch output 5

R6 Switch output 6

N Mains neutral cable N

L External mains line conduc

tor L

The peripheral unit protective earth

must be connected at the peripheral

unit of the metal terminal block!

Netz / MainsRelaisPF-RelaisKleinspannungen

-

V2 V1 S8 S7

S6 S5 S4 S3 S2 S1

GND

Ethernet

R6NC C NO R5 R4 R3 R2 R1 N L

8 • Connection diagrams

R1

S1

R6

S8

R4

R5

VFS

S3

A1

V2 V1 S8 S7

VFS2RC VFS1

SD Card

Ethernet

S6 S5 S4 S3 S2 S1

GND

R6NC C NO R5 R4 R3 R2 R1 N L

S8 S3 S1 R4/R5 R1R6

ForsyningRelePF-ReleSvagtstrøm

3110086 EHC20 UK 110515

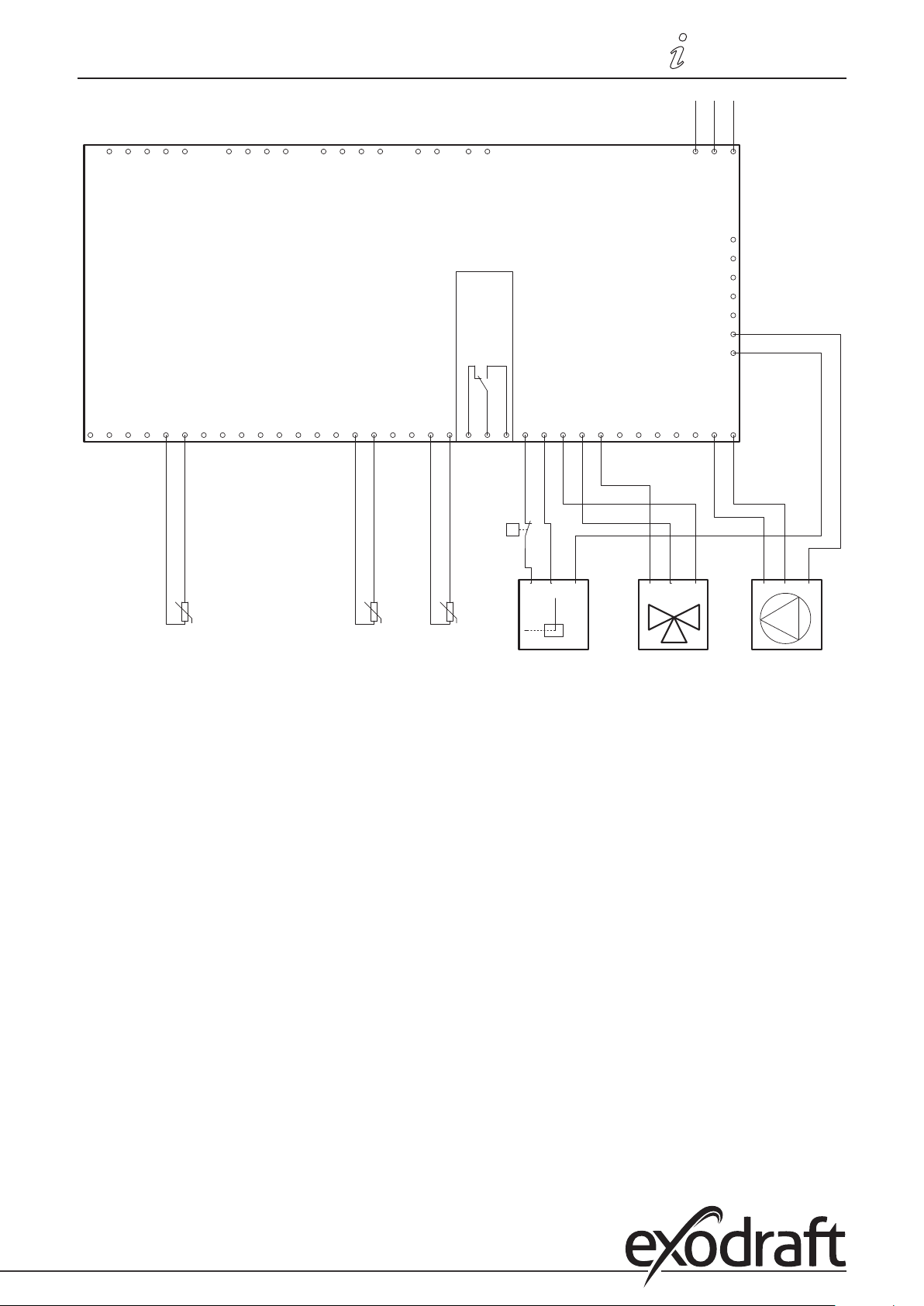

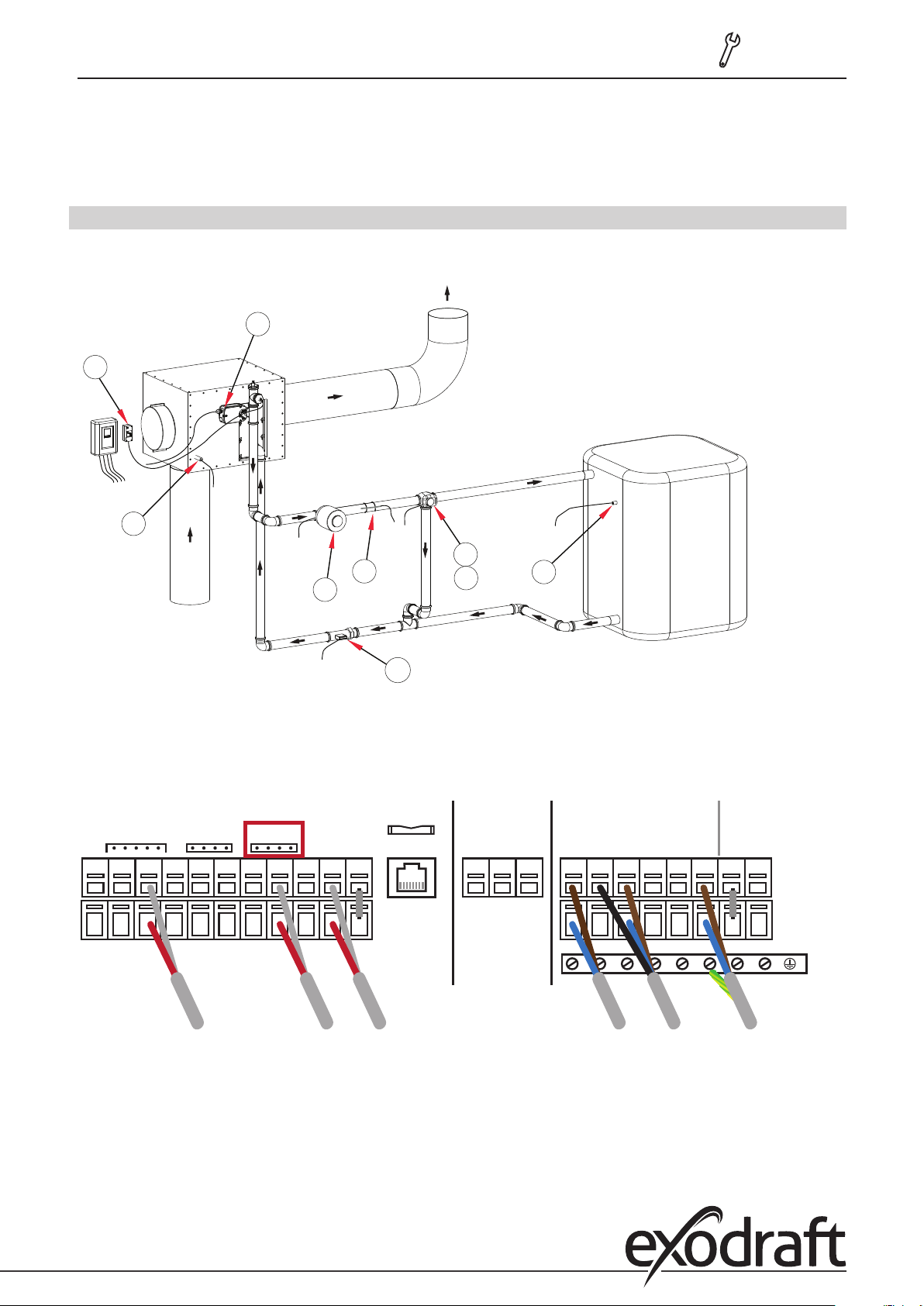

D. Pin-out diagram

D.1 Program 6.1.7 Heat exchanger with bypass damper, one buer memory and mixer.

This diagram shows the following system:

Heat exchanger with bypass damper. A buer memory, a mixer and a circulating pump.

Place the S8 temperature sensor in the entry of the heat exchanger.

Mount the S3 temperature sensor on the supply pipe immediately behind the circulating pump.

Mount the S1 temperature sensor in the lower part of the buer memory.

VFS is the sensor for heat quantity measurement – optionally available.

A1 is the STB safety temperature limiter. Warning: only use with external sensors!

A2 Passage adjustment valve (provided).

The mixer should be mounted on R4 (brown/black) and R5 (black/brown). See SM230 with MV20/25/32 on page 9 of the

installation guide.

Mount the circulating pump on the R1 terminal.

Mount the bypass engine on the R6 terminal.

The lower terminal strip is the minus pole and/or the neutral point.

An STB safety temperature limiter must be mounted in the supply and must close the bypass damper at

a temperature of 100°C!

3110086 EHC20 UK 110515

Connection diagrams • 9

N

L1

PE

1 111 12 2222 3 3 34 44 5

1 111 12 2222 3 3 34 44 5

CAN

RC stecker

VFS2 Sensor

VFS1 Sensor

CAN

exodraft EHC10/EHC20 Regler

PF-Relais

0-10V Ausgang

0-10V Ausgang

Temperaturfühlereingang 8

Temperaturfühlereingang 7

Temperaturfühlereingang 6

Temperaturfühlereingang 5

Temperaturfühlereingang 4

Temperaturfühlereingang 3

Temperaturfühlereingang 2

Temperaturfühlereingang 1

Relaisausgang 6

Relaisausgang 5

Relaisausgang 4

Relaisausgang 3

CGND GNDGND GNDGND GND GNDGNDGND GND

CGND GNDGND GNDGND GND GNDGNDGND GND

N NN

N NN

Schwartz/Braun

Blau

Braun/Schwartz

L

N

PE

L

N

PE

Netz / Mains

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

Relaisausgang 1

Relaisausgang 2

NNNNC NO

R1R2R3R4R5R6S1S2S3S4S5S6S7S8V1V2

NNNNC NO

R1R2R3R4R5R6S1S2S3S4S5S6S7S8V1V2

t°

STB Thermostat

N

N

L

L

PE

PE

CCWCW N CCWCW N

N

N

L

L

PE

PE

-S8

U

U

-S3

U

-S1

Rauchgastemperatur Vorlauftemperatur Pufferspeicher-

temperatur

MischerBypass Pumpe

10 • Installation

3110086 EHC20 UK 110515

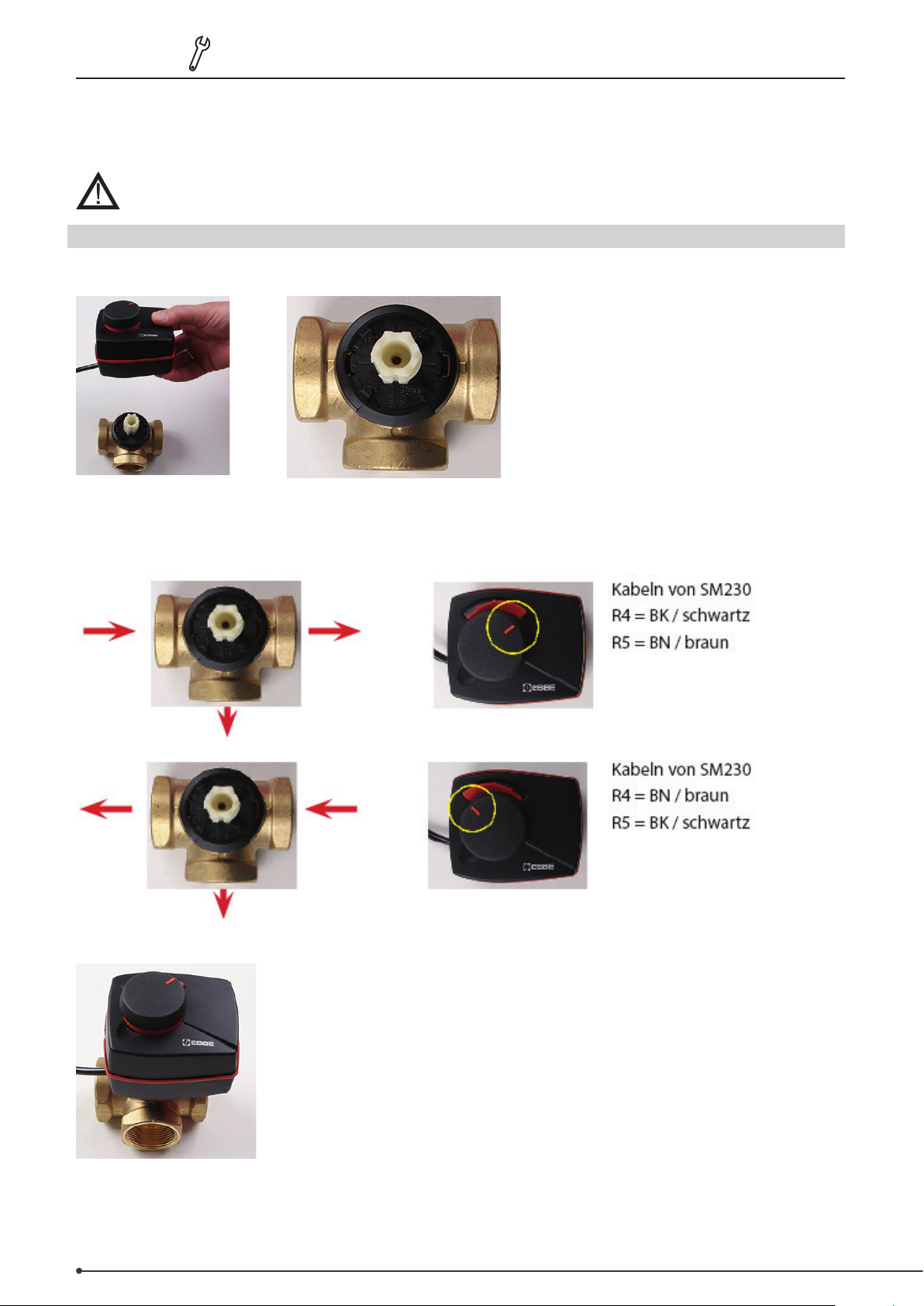

E. Installation note for 3-way mixing valve

Please pay attention to the installation note during use of the Exodraft SM230 with MV20 three-way mixing valve.

When using a dierent three-way mixing valve, please pay attention to the ow direction during

installation!

E.1 SM230 with MV20/25/32 installation note

Pay attention to the basic setting of the mixing valve and ow direction before installing the MV20/25/32!

The drive axle notch must be in the centre of the valve exit.

Please pay attention to the mixer setting in case of a change in ow direction:

Connect the motor to the valve and screw together. The motor is xed in place by removing the front cover.

3110086 EHC20 UK 110515

F. Service and start-up

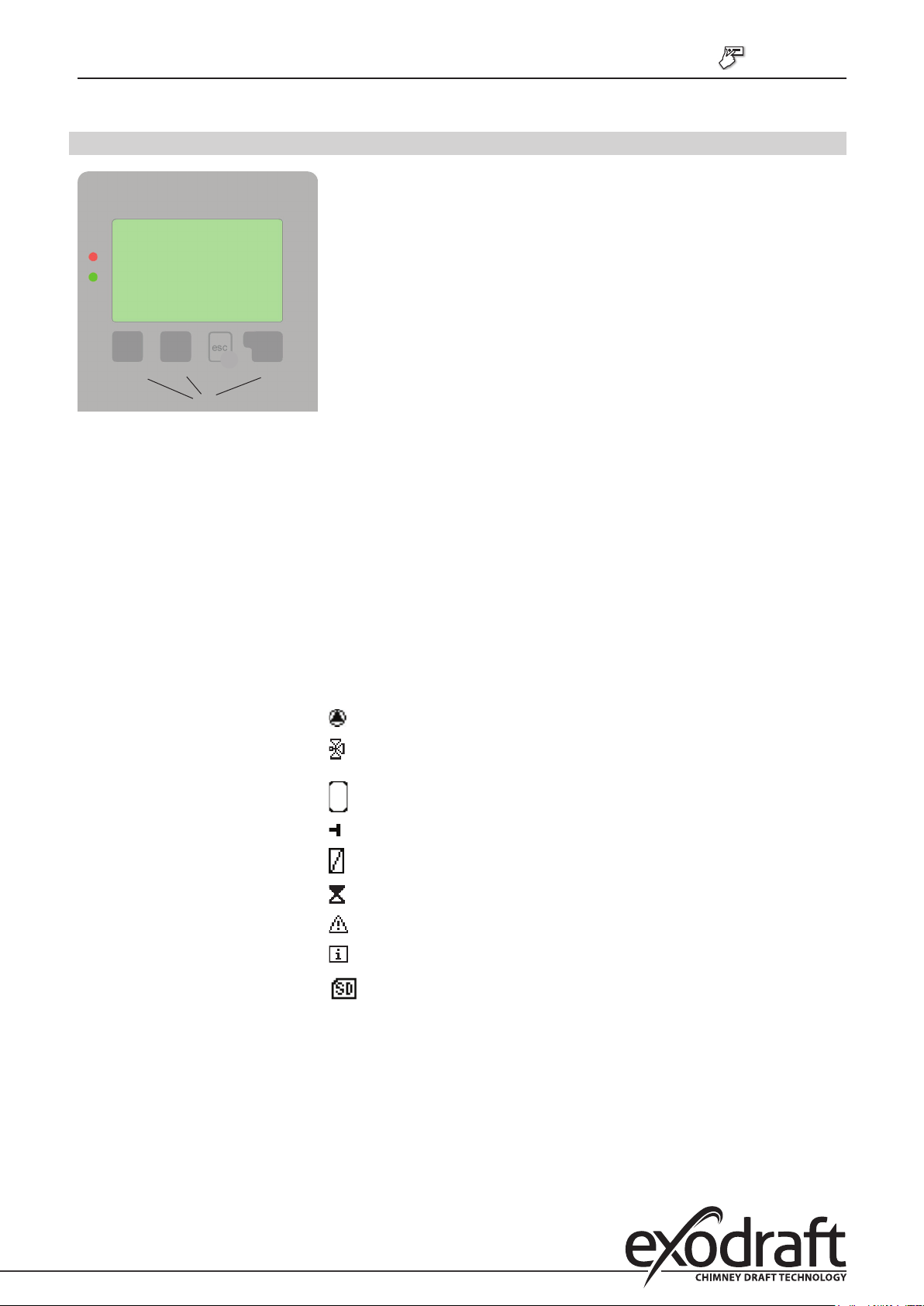

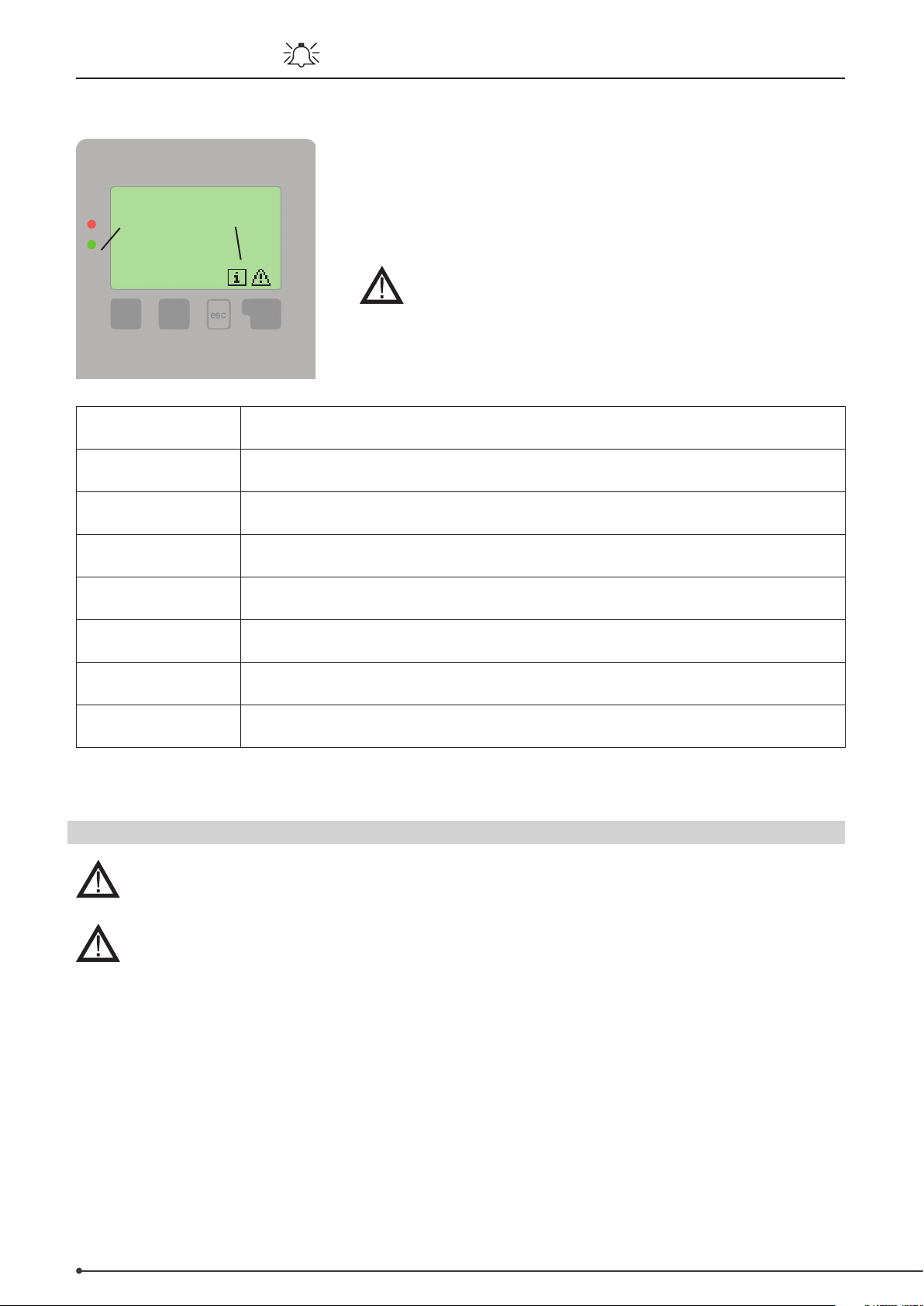

F.1 Display and entry

Operation • 11

The display (1), which has extensive text and graphics modes, makes servicing

the automatic controller both simple and almost self-explanatory.

Please press the ESC key to return to the main menu.

(1)

(2)

(3)

(4)

Examples of key functions +/-

▼/▲

YES/NO

Information

Back

OK

Conrm

The green LED status light (2) illuminates when a relay is switched on, the red

LED light blinks in the event of an error message or when saving information.

Entries are made with 4 keys (3+4) that have various functions, depending on

the situation. The ESC key (3) is used to interrupt an entry or leave a menu.

If necessary, a security question will be displayed which asks if you wish to save

the completed changes.

The function of the other 3 keys (4) is explained in the display that is directly

above the keys; the key on the right is normally used to conrm and select.

Increase/Reduce values

Menu scroll up/down

Accept/Decline

Further information

about the previous display

Conrm selection

Conrm setting

Examples of display symbols

You can nd other symbols explained in the special functions menu.

Pump (swivels when in operation)

Valve (black indicates the direction of

ow)

Storage

Temperature sensor

Heat exchanger

Charging pause (see charging time)

Warning /Error message

New information available

Logging switched on

12 • Operation

3110086 EHC20 UK 110515

F.2 Initial start-up with the start-up assistant

The start-up assistant will appear when you switch on the device for the rst time

and will guide you through the following menu:

1. Choose language –> press OK to conrm

2. Time and date –> adjust with the arrow keys and press OK to conrm each

selection. Press ESC to return to the previous menu.

3. Run start-up assistant –> press OK to conrm

The start-up assistant can also be terminated at any time and later restarted

from the special function menu.

4. Would you like to launch the start-up assistant? –> Press YES and follow the menu

5. Select 6.1.7 for mixer with bypass and one buer memory by using the arrow keys –> Press OK to conrm.

6. Follow the menu and set the following values, then press OK to conrm:

Designation/Description

6.20 Temperature unit

4.1 Tmin S8 – Heat exchanger

temperature sensors

4.4 ΔT S8, S1 - temperature

dierential

4.5 Tmax S1 –

Desired buer memory temperature

6.2.1 Rotation speed R1

Factory

settings

°C

60°C

10/3°C

60°C

From

Should be set

Yes: √/No: 0 /Conrm

Ø/Conrm

Ø/Conrm

Ø/Conrm x 2

Conrm/Use arrow

keys to change and

conrm

Ø /Conrm

Start-up values

90°C

7. To move to the next point, display CLOSE AND SAVE and conrm

8. Close and save –> Press YES to conrm

Congratulations! You have completed the start-up!

If the start-up assistant does not launch automatically, then it can be launched manually. Press ESC to

go to the main menu and select ”6. Special functions”. Select ”12. Start-up” on the menu and press OK.

After a successful start-up, the menu will automatically close

(deactivation: see chapter H)

G. Lock menu

The lock menu is used to prevent any unintentional changes to the entered values.

The following menu items remain fully accessible when the lock menu has been activated and can be adapted as

needed:

1. Measured values, 2. Evaluation, 6.23. Time & date, 8. Lock menu, 9. Service values

G.1 Activate/deactivate the lock menu

To activate/deactivate the lock menu, press ESC to return to the main menu and use the arrow keys to select menu

point ”7. Lock menu.”

It will indicate whether the lock menu is activated or not.

Press INFO to change the status of the lock menu.

1. Use the arrow keys to activate/deactivate the lock menu and press OK to conrm.

2. Leave the menu by pressing ESC.

3. ”Save changes?” –> press YES to conrm

You can press ESC now to leave the main menu.

3110086 EHC20 UK 110515

Installation• 13

H. Option for heat quantity counter SE 20/SE 25/SE 32

The integrated VFS heat quantity counter and ow quantity meter (optional equipment) can be used to measure the

amount of recovered heat.

Warning! Not calibrated!

H.1 Assembly and connection

When installing the heat quantity counter (WPS), it is vital to pay attention to the ow direction, because otherwise

correct functioning cannot be ensured.

R6

A1

S8

R4

S3

R1

VFS

R5

Connect the EHC 20 by inserting the plug in the VFS1 connection socket.

Anschlussbuchse

V2 V1 S8 S7

Wärmemengezähler

VFS2RC VFS1

S6 S5 S4 S3 S2 S1

SD Card

GND

Ethernet

S1

R6NC C NO R5 R4 R3 R2 R1 N L

S8 S3 S1

R4/R5 R1R6

14 • Operation

3110086 EHC20 UK 110515

H.2 Start-up and set-up

Select ”6. Special functions” in the main menu to start up the heat quantity counter, and then ”9. Heat quantity”.

Conrm each selection by pressing OK. Then follow the steps shown below:

1. ”1. Constant ow”

This will display whether the heat quantity counter is switched on or o.

To change this, press INFO and use the +/- key to select ON, then conrm.

2. ”2. Flow sensor”

This will display the threshold temperature for activating measurement of the ow temperature.

Press INFO to open the menu and use the +/- key to select ”S3 ow” and conrm.

3. ”4. Return ow sensor”:

This will show which temperature sensor is activated for measurement of the return ow temperature.

Press INFO to open the menu and use the +/- key to select ”VFS 1T” and conrm.

4. ”5. Glycol type”

If you use glycol in your system, enter the exact type of liquid used here.

If you do not use antifreeze, then enter the following:

Press INFO to open the menu and conrm ”propylene”.

5. ”6. Glycol percentage”

Press INFO to open the menu and use the +/- keys to set the value to ”0%”.

6. ”7. Supply ow”

Press INFO to open the menu and select the nominal ow rate for the VFS quantity counter. Conrm

7. ”9. ΔT oset

Press INFO to open the menu and set the correction factor for the temperature dierence as needed.

Otherwise, set and conrm ”0%”

8. Press ESC to leave the menu

9. ”Save changes?” –> Press YES to conrm

3110086 EHC20 UK 110515

Product information • 15

I. SD card

You can store the current conguration, measurement results, etc. on the included SD card or overwrite a software

update on the automatic controller.

To do this, press ESC to go to the main menu and select ”6. Special functions” and then select menu item ”14. SD card”

I.1 SD card

Setting the logging function with data storage on the SD card

I.2 Logging

In this menu, the sensor and relay data recording is activated or deactivated.

The display shows whether logging is activated or deactivated.

To change this, press INFO and use the +/- key to select ”ON” or ”OFF” and conrm.

It must be set to ”ON” to activate the sensor and relay data recording.

I.3 Free storage

This displays the available storage space on the SD card.

I.4 Load conguration

This function allows you to load all the automatic controller settings on the SD card.

All previous settings in the automatic controller will be overwritten.

I.5 Save conguration

This function allows you to save all the settings in the automatic controller, including the service values, onto the SD

card.

To do this, press the ESC key to go to the main menu.

I.6 Firmware update

This function copies rmware that has been saved on the SD card to the automatic controller.

Never switch o or disconnect the automatic controller during a rmware update – this can

cause irreparable damage.

Settings may be changed and/or overwritten. Reset the automatic controller back to the

factory settings after any rmware update and perform a new start-up.

I.7 Ejection

To prevent any damage or loss of data, you must safely log-out before ejecting the SD card.

16 • Faults with error messages

J. Error messages

(LED ashes + warning

symbol)

3110086 EHC20 UK 110515

If the automatic controller recognises a malfunction, the warning symbol

will appear in the display. When the error is corrected, then the warning

symbol changes to an information symbol.

Further information about the error may be obtained by pressing the key

under the warning or information symbol.

Do not act on your own accord.

Ask a specialist for advice in the event of problems!

Possible error

messages

Sensor error Either the sensor, sensor entry on the automatic controller or the connection cable is/was

Restart Means that the automatic controller was restarted, e.g., because of a loss of power.

Time and date This display appears automatically after a lengthy loss of power because the time and date

Strong clocking This is displayed if the pump switches on and o more than 5 times in 5 minutes (that is, in

No ow Displayed if the steam turbine is >=50°C for more than 5minutes while the pump is on.

Excessive/Insucient

system pressure

SD card error Displayed when an SD card is recognised but the automatic controller cannot read it or

Notes for the specialist

defective.

Check the date and time!

must be checked and, if necessary, reset.

the event of 11 starts and stops).

Displayed if Pmin and/or Pmax is less or more than allowed when the pressure monitor is

switched on.

write to it.

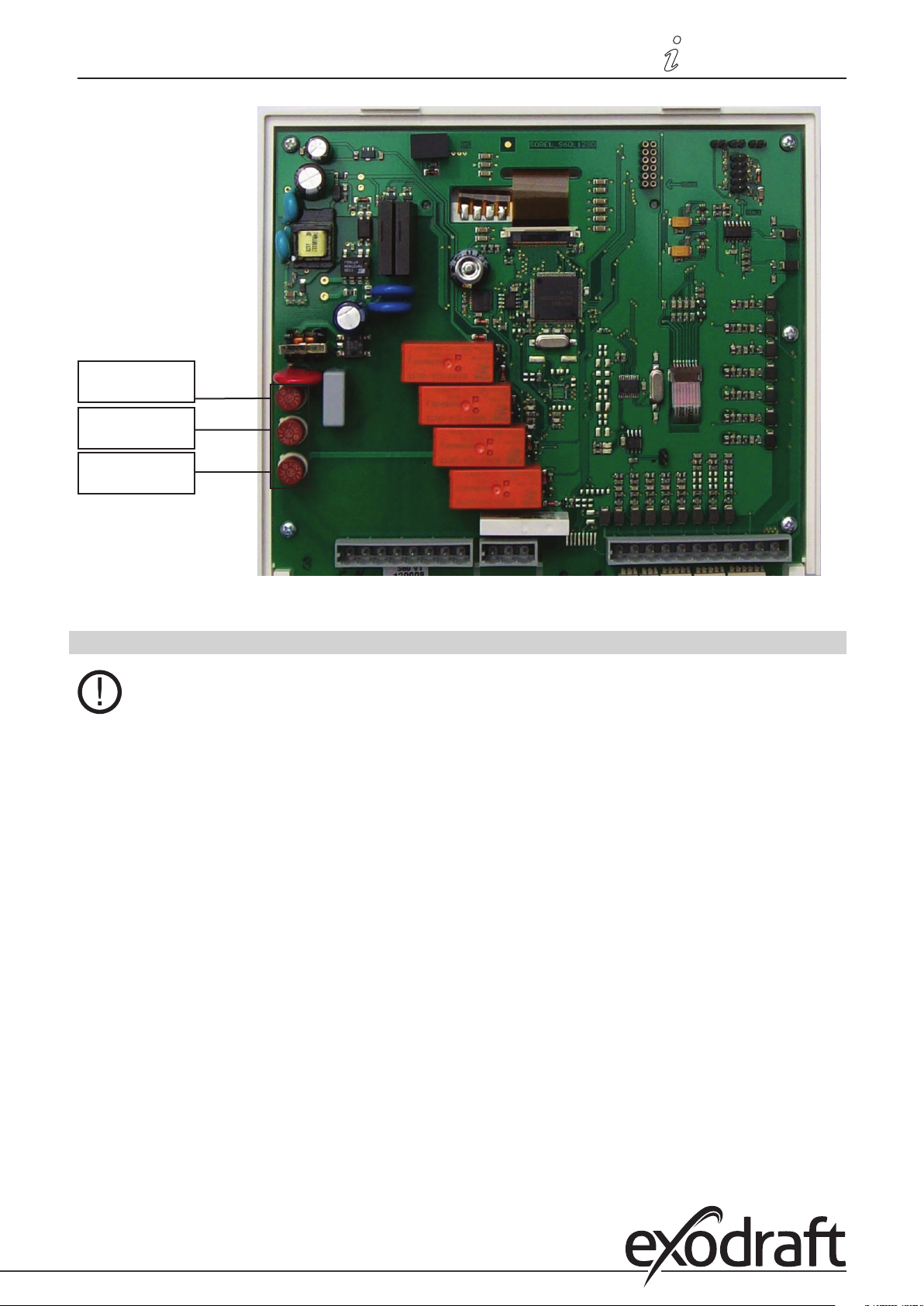

J.1 Replacing a fuse

Repair and maintenance may only be carried out by a specialist. Disconnect the power supply

before working on the device and secure against reconnection! Make sure the power is o!

Only use the spare fuse included, or a fuse that is constructed in an identical manner and has

the following characteristics: T2 A / 250 V.

Three fuses have been installed in the automatic controller that protect the dierent relays as well as the controller

electronics. If the automatic controller has no function or display when it is connected to power, or no mechanical or

electronic relays are functioning, then open the device as described under C, below, then remove and check all fuses.

Change the defective fuse, and nd and exchange any external defective parts (e.g. pump).

Finally, restart the automatic controller.

3110086 EHC20 UK 110515

Fuses

T2 A/250 V

Circuit board

Electronic relays

Mechanical relays

Product information • 17

J.2 Maintenance

In the course of the annual general servicing of your heater, you should also have the specialist

check the functions of the automatic controller and, if necessary, optimise its settings.

Carrying out maintenance

• Checking the date and time

• Assessment/Plausibility check of the evaluations

• Managing the error log memory

• Check/Plausibility check of the current measured values

• Managing the switch outputs/loads in manual operation

• Possible optimisation of the set parameters

18 • Product information

3110086 EHC20 UK 110515

K. Product information

K.1 Description

The controller was produced and tested in accordance with strict quality and safety requirements. The legal warranty

period of two years from the date of sale applies to the device.

However, the manufacturer shall accept no liability or warranty claims for personal injuries and damage to property

resulting from one or more of the following:

• Failure to observe these mounting and operating instructions

• Incorrect mounting, setup, maintenance and operation

• Improper repairs

• Unauthorized modications to the device

• Installation of additional components that were not tested together with the device

• All damages resulting from continued use of the device in spite of an obvious defect

• Failure to use original spare parts and accessories

• Use of the device in an unintended manner

• Failure to observe the limit values set out in the technical data

• Force majeure

K.2 About the controller

The EHC temperature dierential controller helps you to use your heating system and control its functions eciently.

The device has an impressive range of functions and is virtually self-explanatory in use. The individual entry buttons

have specic functions and are explained in the context of each step. In the controller menu, you will nd not only

keywords but also help texts and clear graphics relating to the measurements and settings.

The EHC can be used as a temperature dierential controller for various types of systems . These are illustrated and

explained from page 24 onwards.

Key features of the EHC:

• Illuminated display showing graphics and texts

• Straightforward querying of current measurements

• Various options for evaluating and monitoring the system, e.g. graphical statistics

• Extensive settings menus with explanations

• Menu lock function to prevent accidental changes

• Reset option for restoring previous values or factory settings

• Various additional functions are optionally available

K.3 Items supplied

• EHC temperature dierential controller

• 3 screws (3.5 x 35 mm) and 3 plugs (6 mm) for wall mounting

• 12 strain relief clamps with 24 screws, replacement fuses 1x T2 A / 250 V

• Micro SD card

• EHC mounting and operating manual

Optionally supplied depending on model/order:

• Pt1000 temperature sensors and thermowells

• Ethernet connection

Also available:

• Pt1000 temperature sensors, thermowells, overvoltage protection

• CAN bus data logger

3110086 EHC20 UK 110515

L. Controller description

L.1 Technical data

Electrical data:

Mains voltage 100 - 240 VAC

Mains frequency 50 - 60 Hz

Power consumption 0.5 - 3 W

Switching power

Total electronic relay switching power: 460 VA for AC1 / 240 W for AC3

Electronic relay R1 Min. 5 W...max. 120 W for AC3

Electronic relay R2 Min. 5 W...max. 120 W for AC3

Total mechanical relay switching power: 460 VA for AC1 / 460 W for AC3

Mechanical relay R3 460 VA for AC1 / 460 W for AC3

Mechanical relay R4 460 VA for AC1 / 460 W for AC3

Mechanical relay R5 460 VA for AC1 / 460 W for AC3

Mechanical relay R6 460 VA for AC1 / 460 W for AC3

Potential-free relay R7 460 VA for AC1 / 185 W for AC3

0..10V output Designed for 10 kΩ load resistance

PWM output Freq. 1 kHz, level 10 V

Internal fuse 2A slow-blow 250 V (3x)

Protection type IP40

Protection class II

Overvoltage category II

Pollution level II

Sensor inputs 8 x Pt1000

2 x Grundfos direct sensors

1 x RC21

Measuring range

PT1000 -40°C to 300°C

Grundfos direct sensor: 0°C - 100°C (-25°C / 120°C briey)

Controller description • 19

VFS 1 l/min - 12 l/min (VFS1-12) RPS 0 - 0.6 bar

2 l/min - 40 l/min (VFS2-40) 0 - 1 bar

5 l/min - 100 l/min (VFS5-100) 0 - 1.6 bar

10 l/min - 200 l/min (VFS10-200) 0 - 2.5 bar

0 - 4 bar

0 - 6 bar

0 - 10 bar

Permitted total cable lengths:

Sensors S7 and S8 <30 m

Other Pt1000 sensors <10 m

VFS/RPS sensors <3 m

CAN <3 m

PWM/ 0...10 V <3 m

Electronic relay <3 m

Mechanical relay <10 m

Network connections

Ethernet (optional)

CAN bus

Storage medium Micro SD card slot

Real time clock RTC with 24-hour power backup

Permitted ambient conditions:

Ambient temperature

during controller operation 0°C...40°C

during transport/storage 0°C...60°C

Air humidity

during controller operation Max. 85% rel. humidity at 25°C

during transport/storage No condensation allowed

Other data and dimensions

Housing design Three-part, ABS plastic

Installation options Wall mounting, switch panel mounting (optional)

Overall dimensions 228 x 180 x 53 mm

Display Fully graphical display, 128 x 128 dots

LEDs 2:, 1 x red, 1 x green

Operation 4 entry buttons

20 • Installation

161

11,8

195,4

9

R4.5

4.4

3333

139,3

n

3.5

169.3

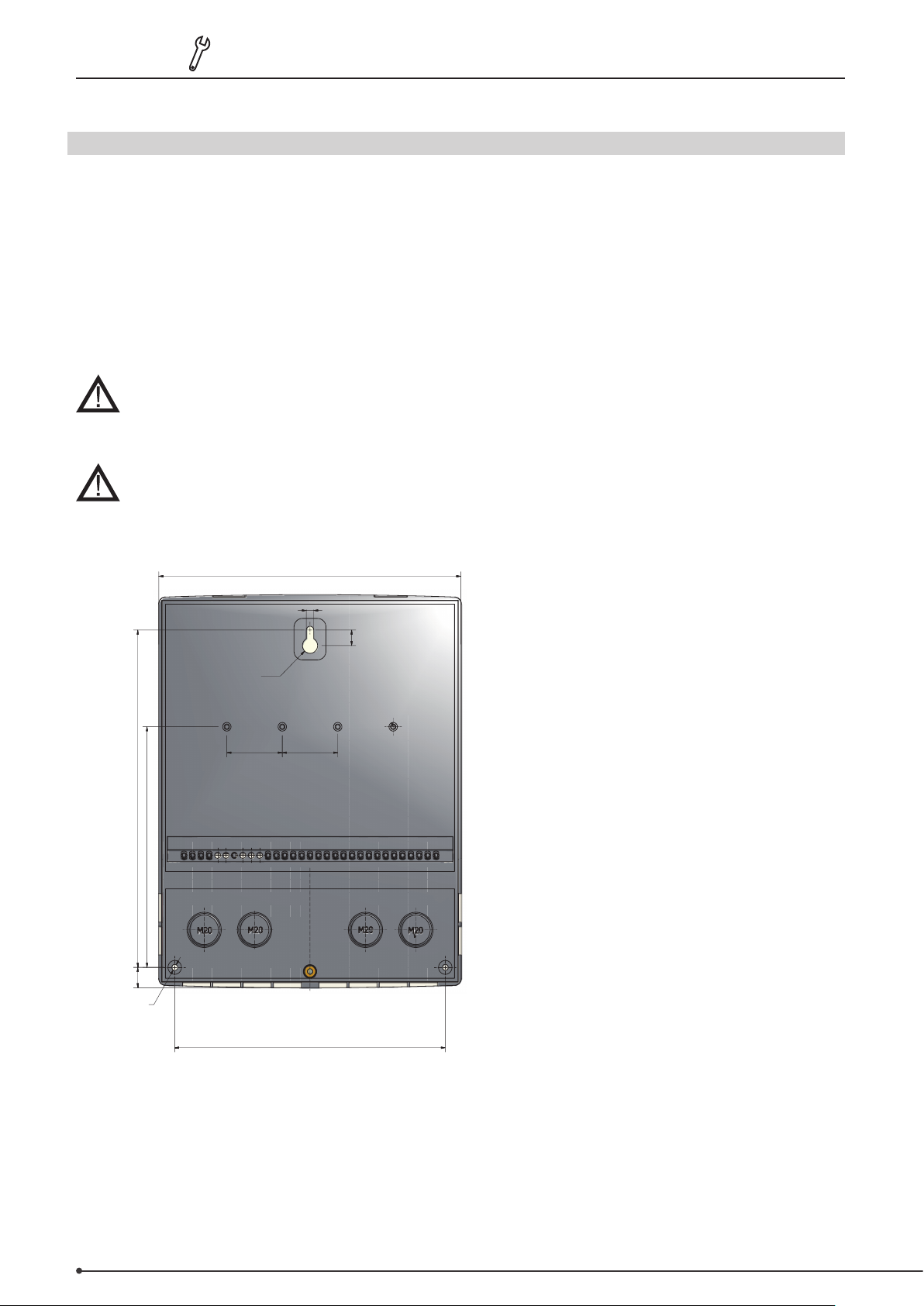

M. Installation

M.1 Wall mounting

1. Completely loosen the cover screw

2. Carefully remove the terminal box cover from the bottom section. Loosen the two screws in the top

section and remove the top section from the base.

3. Mark the three xing holes (see ”C.1.1 Housing base”). Make sure that the wall surface is as at as

possible to prevent the housing distorting when the screws are tightened.

4. Using a drill and a size 6 mm bit, drill three holes in the wall at the points marked and insert the plugs.

5. Mount the controller from the top screw.

6. Insert the two bottom screws and tighten them.

Install the controller only in rooms that are dry and meet the environmental requirements set

out in “B.1 Technical data”.

The controller must not be accessible from behind.

3110086 EHC20 UK 110515

M.1.1 Housing base

3110086 EHC20 UK 110515

M.1.2 Housing top

Terminal box cover

Cover screw

M.2 Electrical connection

Before working on the device, disconnect the power supply and ensure that the device cannot

be switched on again! Check that the power is switched o.

The electrical connection work should only be carried out by a specialist in accordance with the

regulations in place. The controller must not be used if there is visible damage to the housing,

e.g. cracks.

Installation• 21

Extra low voltage leads such as temperature sensor leads should be kept away from the mains

cables. Temperature sensor leads should only be inserted into the left-hand side and mains

cables only into the right-hand side of the device.

An omnipolar cut-o device, e.g. an emergency heating switch, should be tted to the power

supply system for the controller by the customer.

No more than 55 mm of the sheath on the leads that are to be connected to the device should

be stripped, and the sheath should reach just beyond the strain relief clamp where the cable

enters the housing.

The controller and VFS sensor must have the same ground potential. The VFS sensor has a

functional earthing system (PELV). The controller’s PE terminal must be connected to the pipe

system close to the sensor.

22 • Installation

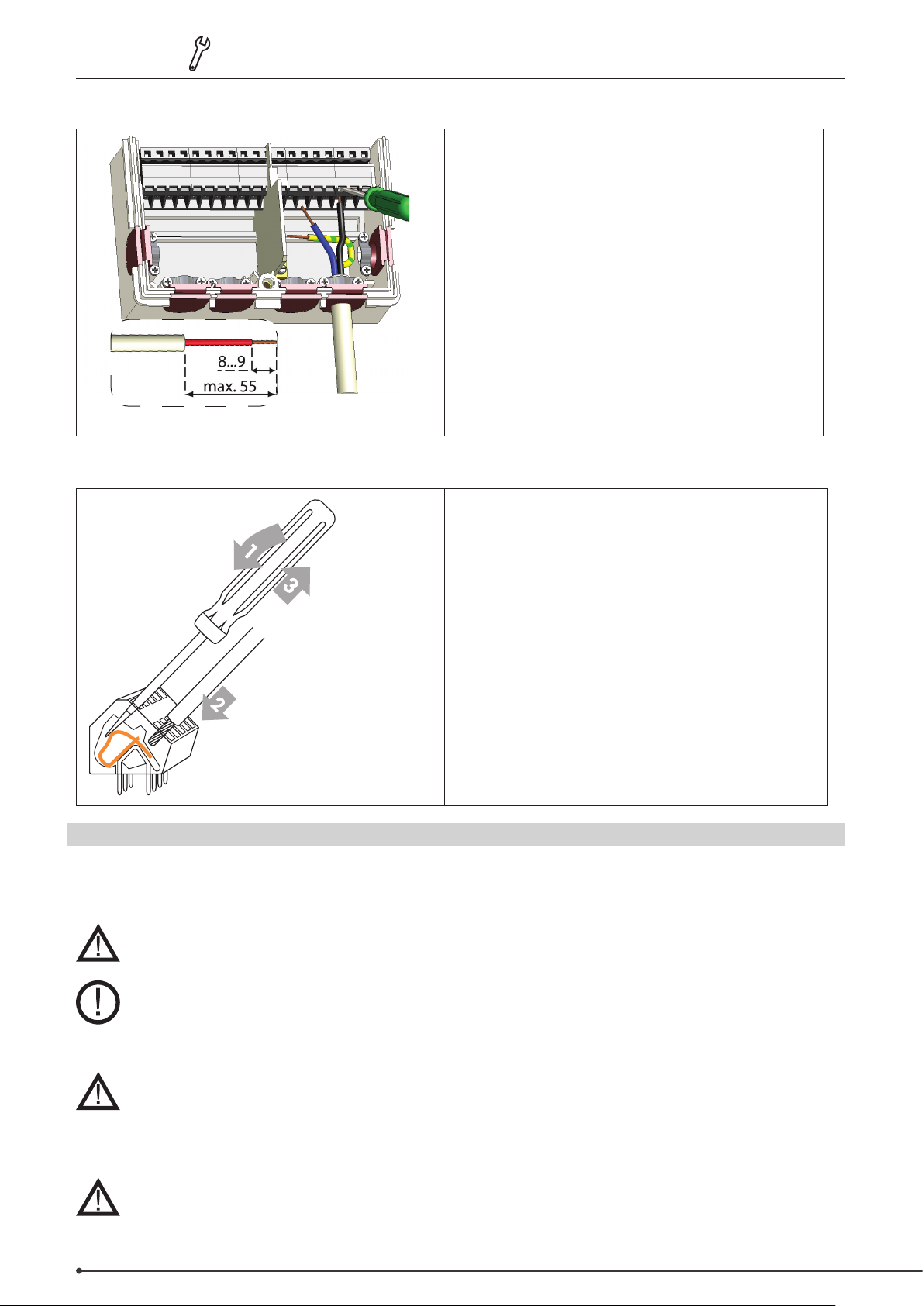

M.2.1

M.2.2

3110086 EHC20 UK 110515

1. Select the required program/hydraulic system (see

"N.3 Hydraulic variants / overview / systems", page

24)

2.

Open the terminal box cover ("N.1 Terminal box", page

23)

3. Strip no more than 55 mm of the cable sheath, insert

cables, attach the strain relief clamps, strip 8-9 mm of

the insulation o the ends of the wires (Fig. ”M.2.1”)

4. Open the terminals using a suitable screwdriver

(Fig. ”M.2.2”) and connect the power supply to

thecontroller

5. Replace the terminal box cover and secure it with

thescrew

6. Switch on the mains power and begin using the

controller

Instructions for terminals:

1. Insert a suitable screwdriver into the top opening

and push the locking bar downwards. Keep the

screwdriver in this position.

2. Insert the cable into the bottom opening.

3. Remove the screwdriver.

M.3 Installing the temperature sensors:

The controller works with Pt1000 temperature sensors. These measure the temperature extremely accurately and thus

ensure that the system functions optimally from a control point of view.

The temperature sensor leads should be kept separate from the mains power cables and must

for example not be routed through the same cable channel.

Position the sensors exactly in the area to be measured! Use only the immersion pipe or atmounted sensor with the appropriate permitted temperature range for the particular

application.

If necessary, the sensor lead connected to S7/S8 can be extended to a maximum length of 30 m

using a cable at least 0.75 mm² in size. The sensor leads connected to S1 to S6 can be extended

to a maximum length of 10 m using a cable at least 0.75 mm² in size.

When connecting the cables, ensure that no transition resistances occur.

The VFS direct sensors should be connected using the appropriate plugs.

To avoid damaging the direct sensors, it is recommended that you position them only in the

return ow.

When mounting the direct sensor (VFS), the correct ow direction must be observed.

Loading...

Loading...