Page 1

Z-PLUG™

ForSerialNos.

404,314,159andHigher

PartNo.4504-453Rev.B

Page 2

Introduction

TotheOwner

Introduction

ReadthismanualentirelyBEFOREoperatingthe

Z-Plug.

Theinformationpresentedhereinwillprepareyou

tooperatetheZ-Pluginasafeandknowledgeable

manner.OperatingtheZ-Pluginapropermanner

willprovideasaferworkingenvironment,create

moreefcientresultsandpromotehigherquality.

Keepthismanualonhandatalltimesforready

reference.Thetestedsafetyanddesign(s)ofthe

Z-Plugisdependentuponitsoperationwithinthe

guidelinesandlimitationsoutlinedinthismanual.

OperatingtheZ-Plugoutsideofthestatedsafety

guidelinespresentedinthismanualruntheriskof

injuryandavoidinthewarranty.

ProductRegistration

Immediatelyrecordthemodelandserialnumberof

yourZ-Pluginthespacesbelow.Thesenumbers

canbefoundontheleftsideoftheengineplate.

Providingthisinformationwillhelpassurethatyou

getthecorrectparts,informedaboutanyupdatesor

productreviews.

ModelNumber:

____________________________________

SerialNumber:

____________________________________

©2019ExmarkMfg.Co.,Inc.

2101AshlandAve

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Introduction...........................................................2

TotheOwner..................................................2

Safety.....................................................................4

SafetyAlertSymbol.........................................4

SafeOperatingPractices..................................4

Transporting..................................................10

SafetyandInstructionalDecals......................12

Operation..............................................................15

SpreaderOperations.......................................15

SpreaderSystem.............................................16

AeratorOperations........................................16

Maintenance..........................................................19

PeriodicMaintenance........................................19

EngineMaintenance.......................................19

HydraulicSystemMaintenance.......................20

TractionUnitMaintenance.............................20

SpreaderMaintenance....................................20

AeratorHead/TineMaintenance....................20

Troubleshooting....................................................23

Engine:...........................................................23

Hydraulics:.....................................................23

Tracking:........................................................23

Granular:........................................................23

ChargingIssues:.............................................24

Schematics............................................................27

3

Page 4

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure1)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure1

SafetyAlertSymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Indicatesanimminentlyhazardous

situationwhich,ifnotavoided,Willresultindeathor

seriousinjury.

WARNING:Indicatesapotentiallyhazardous

situationwhich,ifnotavoided,Couldresultindeath

orseriousinjury.

CAUTION:Indicatesapotentiallyhazardous

situationwhich,ifnotavoided,Mayresultinminor

ormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

WARNING

Chemicalsubstancesusedinthemachine’s

chemicalsystemmaybehazardousandtoxicto

you,bystanders,animals,plants,soilsorother

property.

•Carefullyreadandfollowthechemical

warninglabelsandSafetyDataSheets(SDS)

forallchemicalsusedandprotectyourself

accordingtothechemicalmanufacturer's

recommendations.Ensurethataslittle

skinaspossibleisexposedwhileusing

chemicals.UseappropriatePersonal

ProtectiveEquipment(PPE)toguardagainst

g000502

personalcontactwithchemicals,suchas:

–safetyglasses,goggles,and/orfaceshield

–chemicalresistantgloves

–rubberbootsorothersubstantialfootwear

–hearingprotection

–respiratororltermask

–cleanchangeofclothes,soap,and

disposabletowels,tobekepton-hand,inthe

eventofachemicalspill.

•Keepinmindthattheremaybemorethan

onechemicalused,andinformationoneach

chemicalshouldbeassessed.

•Refusetooperateorworkonthemachineif

thisinformationisnotavailable!

•Beforeworkingonthemachine’schemical

system,makesurethatthesystemhas

beentriplerinsedandneutralizedaccording

totherecommendationsofthechemical

manufacturer(s).

•Verifythereisanadequatesupplyofclean

waterandsoapnearby,andimmediatelywash

offanychemicalsthatcontactyou.

SafeOperatingPractices

Alwaysshutofftheengine,andremovethekey.Wait

forallmovementtostopandallowthemachineto

coolbeforeadjusting,cleaning,storing,orrepairingit.

ChemicalSafety

TheintendeduseoftheZ-Plugmachineisforlawn

care.

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer'sinstructions

forthesafeapplicationofthechemical.

•Handlechemicalsinawellventilatedarea.

•Havecleanwateravailable.

•DoNoteat,drink,orsmokewhileworkingwith

chemicals.

4

Page 5

Safety

•Alwayswashyourhandsandotherexposedareas

assoonaspossibleafternishingthework.

•Keepchemicalsintheiroriginalpackagesandina

safelocation.

•Properlydisposeofunusedchemicalsand

chemicalcontainersasinstructedbythechemical

manufacturerandyourlocalcodes.

•Chemicalsandfumesaredangerous;neverenter

hopperorplaceyourheadoverorintheopening.

•Followalllocal/state/federalrequirementsforthe

spreadingofchemicals.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readthismanual,itistheowner’ sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

themachine,andevenmatureteenagersshould

haveadultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator's

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

machinewithouttakingrisks.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyandsafely

performthejob.Onlyuseapprovedaccessories

andattachments.

•Wearappropriateclothingincludingsafetyglasses,

substantialslip-resistantfootwear,andhearing

protection.Tiebacklonghairandavoidloose

clothingorloosejewelrywhichmaygettangledin

movingparts.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichmaybe

contaminatedbychemicalsand/oraffectthe

stabilityofthemachine.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengine

oremissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoradd

fuelwhenengineisrunningorwhenthe

engineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

5

Page 6

Safety

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Do

Notuseanozzlelockopendevice.

Operation

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscanoccur

oncontactanddebris,suchasleaves,grass,

brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,to

coolbeforetouching.

•Removeaccumulateddebrisfrommuferand

enginearea.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcankill

you.

DoNotrunengineindoorsorinasmallconned

areawheredangerouscarbonmonoxidefumes

cancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

DoNotoperatethemachine;seekshelter.

•Beawareofweatherconditionsandcheckthat

spreaderpatternsandvolumearesuitable.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperatorpresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

•DoNotll,calibrate,orcleanthemachinewhen

people,especiallychildren,orpetsareinthearea.

•Makesuretheoperatorplatformiscleanandfree

fromchemicalresidueanddebrisbuildup.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkmachineonlevelground.Stopengine,wait

forallmovingpartstostop,removekeyand

engageparkingbrake:

–Beforechecking,cleaningorworkingonthe

machine.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemachinefor

damageandmakerepairsbeforerestarting

andoperatingthemachine).

–Beforeclearingblockages.

–Wheneveryouleavethemachine.

6

Page 7

Safety

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesinplace

andworkingproperly.

•Keephands,feet,hair,loosejewelry,or

clothingawayfromrotatingparts.

•NEVERcarrypassengers.DONOToperate

themachinewhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.

•Stopspreadingwhenmakingtightturnsto

minimizeunevendistributionpattern,application

rate,andchemicaldrift.

•Raisethetines,slowdownandusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemachinetoandfromthework

area.DoNotmakeazeroturnwhenthetinesare

downasturftearingwillresult.

•Chemicalsmaydriftandcauseinjurytopeople

andanimals;itmayalsodamageplants,soil,or

otherproperty.

•DoNotoperatethemachineundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningofthemachine.

•Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientstoppingdistance.

Useextracautiononslopes.

•Reducespeedandloadwhenoperatingonrough

terrain,unevenground,andnearcurbs,holes,and

othersuddenchangesinterrain.Loadsmayshift,

causingthemachinetobecomeunstable.

WARNING

Suddenchangesinterrainmaycauseabrupt

steeringcontrolmovement,possiblyresulting

inhandandarminjuries.

Reducespeedwhenoperatingonrough

terrainornearcurbs.

SlopeOperation

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,theoperatormust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachine

onaslope.

•Operateacrossslopes,neverupanddown.Avoid

operationonexcessivelysteeporwetslopes.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardropoffs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalkbehind

machineorahandheldtooltooperateinthese

areas.

•Granularmaterialscanshift.Thisshifting

happensmostoftenwhileturning,goingupor

downhills,suddenlychangingspeeds,orwhile

drivingoverroughsurfaces.Shiftingloadscan

causetheunittotipover.

7

Page 8

Safety

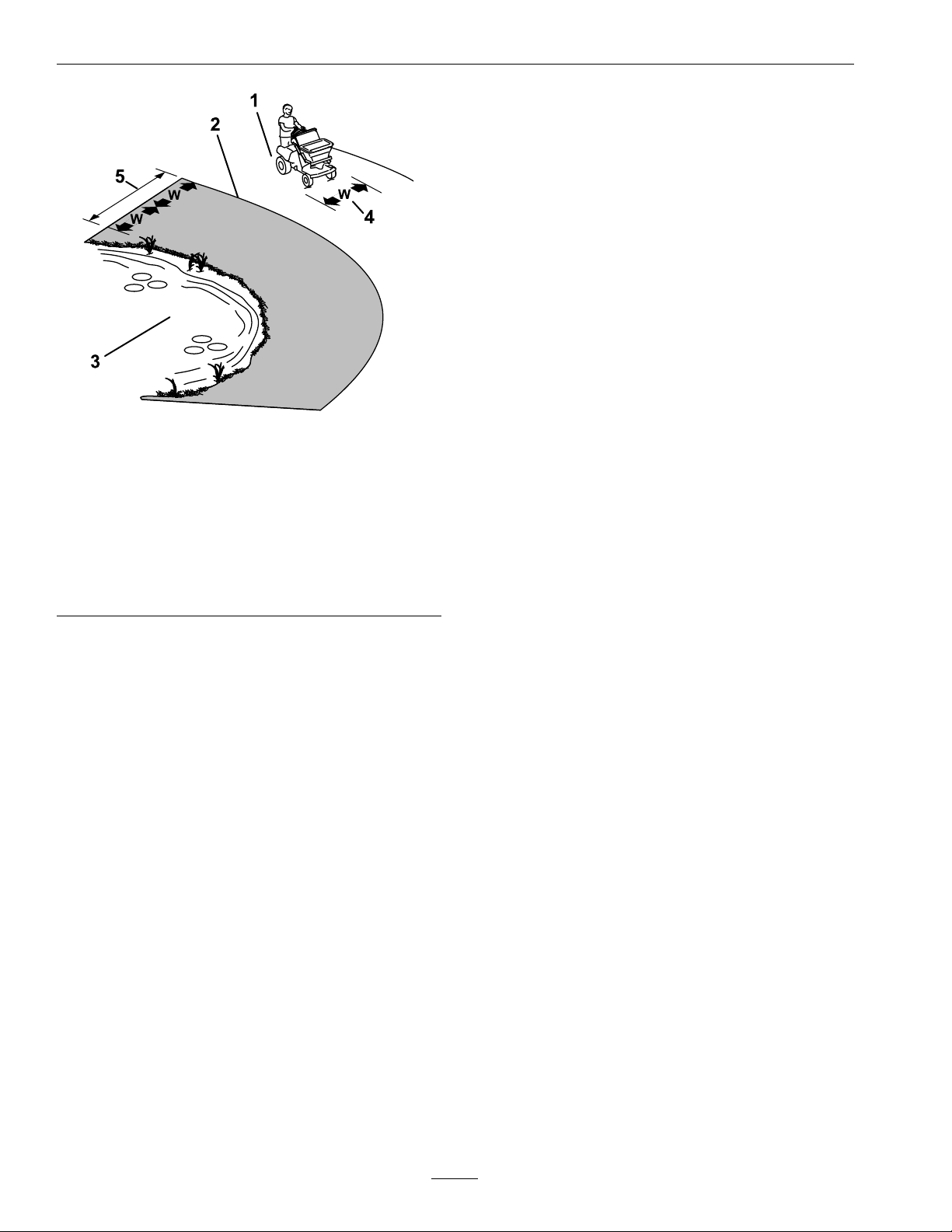

1.SafeZone—Usethe

machinehere

2.DangerZone-Usea

walkbehindmachine

orahandheldtool

neardropoffs,ditches,

embankments,wateror

otherhazards.

3.Water

Figure2

4.W=widthofthemachine

5.Keepasafedistance

(twicethewidthofthe

machine)betweenthe

machineandanyhazard.

MaintenanceandStorage

•Raisethetines,closethespreadergate,setthe

parkingbrake,stopengineandremovekeyor

disconnectsparkplugwire.Waitforallmovement

tostopbeforeadjusting,cleaningorrepairing.

•Keepengineandengineareafreefromexcessive

greaseoroilandotherdebriswhichcan

accumulateintheseareas.Thesematerialscan

becomecombustibleandmayresultinare.

•Letenginecoolbeforestoringanddonotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

g222400

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevel,hardground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Emptythehopperbeforetiltingthemachinefor

maintenanceandbeforestoring.

•Avoidstarting,stoppingorturningthemachine

onslopes.Avoidmakingsuddenchangesinspeed

ordirection;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwetgrass,

acrossslopesordownhillmaycausethemachine

tolosetraction.Lossoftractiontothedrive

wheelsmayresultinslidingandalossofbraking

andsteering.Themachinecanslideevenifthe

drivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.Tall

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Useextracarewhileoperatingwithaccessories

orattachments.Thesecanchangethestabilityof

themachineandcausealossofcontrol.Follow

directionsforcounterweights.

•Ifyoulosecontrolofthemachine,stepoffand

awayfromthedirectionoftravelofthemachine.

•Usecarewhencheckingandservicingtines.Wrap

thetine(s)orweargloves,andusecautionwhen

servicingthem.Onlyreplacedamagedtines.

Neverstraightenorweldthem.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

8

Page 9

Safety

DANGER

Chargingorjumpstartingthebatterymay

produceexplosivegases.Batterygasescan

explodecausingseriousinjury.

•Keepsparks,ames,orcigarettesaway

frombattery.

•Ventilatewhenchargingorusingbattery

inanenclosedspace.

•Makesureventingpathofbatteryis

alwaysopenoncebatteryislledwith

acid.

•Alwaysshieldeyesandfacefrombattery.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldeyes,and

rubberglovestoprotectskinandclothing

whenhandlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwith

waterandcalladoctorimmediately.

CAUTION

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagementof

components.Sparkscouldcauseanexplosion

ormovingpartscouldaccidentallyengage

causingpersonalinjury.

Besureignitionswitchisinthe“OFF”

positionbeforechargingthebattery.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

WARNING

Removalormodicationoforiginal

equipment,partsand/oraccessoriesmay

alterthewarranty,controllability,andsafety

ofthemachine.Unauthorizedmodications

totheoriginalequipmentorfailuretouse

originalmanufacturerpartscouldlead

toseriousinjuryordeath.Unauthorized

changestothemachine,engine,fuelor

ventingsystem,mayviolateapplicablesafety

standardssuchas:ANSI,OSHAandNFPA

and/orgovernmentregulationssuchasEPA

andCARB.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbya

doctorfamiliarwiththisformofinjuryor

gangrenemayresult.

•Ifequipped,makesureallhydraulicuid

hosesandlinesareingoodconditionand

allhydraulicconnectionsandttingsare

tightbeforeapplyingpressuretohydraulic

system.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,

tondhydraulicleaks.

•Beforeperforminganyworkonthe

hydraulicsystem:

–Safelyrelieveallpressureintheground

drivehydraulicsystembyplacingthe

motioncontrolleversinneutraland

shuttingofftheengine.

–Safelyrelieveallpressureintheauxiliary

hydraulicsystembyshuttingoffthe

engine,turningtheignitionswitchto

the“ON”position,andpressingthetine

groundengagementswitch.Oncethe

tineshaveloweredtotheground,release

thetinegroundengagementswitchand

turntheignitionswitchtothe“OFF”

position.

9

Page 10

Safety

Transporting

Note:Refertothechemicalwarningproduct

label(s)beforetransportingtheunitandfollowall

local/state/federalrequirementsfortransporting

chemicals.

Note:Makesurethespreaderhoppercoverissecure

beforetransporting.

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Besurethe

fuelshut-offvalveisclosedduringtransport.Securely

fastenthemachinetothetrailerortruckwithstraps,

chains,cable,orropes.Whensecuringthefrontof

theunit,onlyusethetiedownlocations.Ifpossible,

bothfrontandrearstrapsshouldbedirecteddown

andoutwardfromthemachine.Besurethatthe

trailerortruckhasallnecessarylightingandmarking

asrequiredbylaw .Secureatrailerwithasafetychain.

WARNING

Securingthemachineonanyupperframe

locationwillcausetheparkingbraketonot

functionproperly,whichcouldcauseserious

injuryordeath.

Onlyusethefronttiedownlocationsonthe

lowerframetosecurethemachine.

CAUTION

Thismachinedoesnothaveproperturnsignals,

lights,reectivemarkings,oraslowmoving

vehicleemblem.Drivingonastreetorroadway

withoutsuchequipmentisdangerousand

canleadtoaccidentscausingpersonalinjury.

Drivingonastreetorroadwaywithoutsuch

equipmentmayalsobeaviolationofStatelaws

andtheoperatormaybesubjecttotrafctickets

and/ornes.

DoNotdriveamachineonapublicstreetor

roadway.

WARNING

Loadingamachineonatrailerortruckincreases

thepossibilityofbackwardtip-over.Backward

tip-overcouldcauseseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyasingle,fullwidthramp;DoNotuse

individualrampsforeachsideofthemachine.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurface

widerthanthemachine.

•Avoidsuddenaccelerationwhiledriving

machineuparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

machinedownaramptoavoidtipping

backward.

LoadingaMachine

Useextremecautionwhenloadingmachineson

trailersortrucks.Onefullwidthrampthatis

wideenoughtoextendbeyondthereartiresis

recommendedinsteadofindividualrampsforeach

sideofthemachine.Ifitisnotpossibletouseone

fullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Asteeprampanglemaycausecomponentstoget

caughtasthemachinemovesfromramptotraileror

truck.Steeperanglesmayalsocausethemachineto

tipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideofthe

slopeandtherampsextendsuptheslope.Thiswill

minimizetherampangle.Thetrailerortruckshould

beaslevelaspossible.

Important:DoNotattempttoturnthemachine

whileontheramp,youmaylosecontroland

driveofftheside.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdowna

ramp.Bothmaneuverscancausethemachinetotip

backward.

WasteDisposal

ChemicalDisposal:Improperchemicaldisposal

canpollutetheenvironmentandcausehealthissues.

Followthedisposaldirectionsonthechemical

manufacturer’slabel.Disposeofchemicalsand

containersinaccordancetolocal/state/federallaws.

10

Page 11

MotorOilDisposal:Engineoilandhydraulicoilare

bothpollutantstotheenvironment.Disposeofused

oilatacertiedrecyclingcenteroraccordingtoyour

stateandlocalregulations.

BatteryDisposal

DANGER

Batteryelectrolytecontainssulfuricacid,which

ispoisonousandcancausesevereburns.

Swallowingelectrolytecanbefatalorifittouches

skincancausesevereburns.

•Wearsafetyglassestoshieldeyes,andrubber

glovestoprotectskinandclothingwhen

handlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwithwater

andcalladoctorimmediately.

Safety

Federallawstatesthatbatteriesshouldnotbeplaced

inthegarbage.Managementanddisposalpractices

mustbewithinrelevantfederal,state,orlocallaws.

Ifabatteryisbeingreplacedoriftheunitcontaining

thebatteryisnolongeroperatingandisbeing

scrapped,takethebatterytoalocalcertiedrecycling

center.Ifnolocalrecyclingisavailablereturnthe

batterytoanycertiedbatteryreseller.

11

Page 12

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

decal126-2055

126-2055

1.Wheellugnut—torqueto129N∙m(95ft-lb).

2.Wheelhubnut—torqueto319N∙m(235ft-lb).

3.ReadtheOperator’sManualbeforeperforming

maintenance;checkthetorqueaftertherst100hours

andevery500hoursafter.

•Newsafetysignsmaybeobtainedfromyour

authorizedequipmentdealerordistributor.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourmachine.

decal135-6725

135-6725

1.Cutting/dismembermenthazardofhand,spinner—stay

awayfrommovingparts.

1.Pressandholdthefoot

pedaltolockthecaster

wheelsinthestraight

position.

decal135-6430

135-6430

2.Releasethefootpedalto

unlockthecasterwheels

toallowturning.

12

Page 13

Safety

decal135-7771

135-7771

1.Fast

2.Slow17.Spreaderspeed—decrease

3.Neutral

4.Reverse

5.Warning—readtheOperator’sManual;donotoperatethis

machineunlessyouaretrained;wearhearingprotection.

6.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace;shutofftheengineandremovethe

keybeforeperformingmaintenance.

7.Warning—disengagethesprayercontrols,movethedrive

levertotheneutralposition,engagetheparkingbrake,

andshutofftheenginebeforeleavingthemachine.

8.Crushing/dismembermenthazardofbystanders,forward

andreverse—donotcarrypassengers;lookbehindand

downwhenreversing.

9.Thrownobjecthazard—keepbystandersaway .24.Hourmeter

10.Warning—onlyoperateacrossslopes;donotoperateup

anddownslopes.

11.Causticliquid/chemicalburnhazard;asphyxiationhazard,

poisonousfumesortoxicgases—wearhandandskin

protection;weareyeandrespiratoryprotection.

12.Warning—usefresh,cleanwaterforrst-aidwashingand

rinsingthetank.

13.Parkbrake—engaged28.PressLHmotioncontrolbuttontolowertines.

14.Parkbrake—disengaged29.PressRHmotioncontrolbuttontoraisetines.

15.Spreaderspeed

16.Spreaderspeed—increase

18.Spraypump—on;optionalsprayeraccessory

19.Spraypump—off;optionalsprayeraccessory

20.Operatorpresencecontrol

21.Throttle—fast

22.Continuousvariablesetting

23.Throttle—slow

25.Engine—off

26.Engine—on

27.Engine—start

13

Page 14

Safety

decal135-6281c

135-6281

14

Page 15

Operation

Operation

SpreaderOperations

Overview

TheSpreaderMotorControldeterminesthespeedof

theimpellerinthefrontonthemachine.Themachine

iscapableofvaryingitsspreadpatternfrom3–25

feetwiththiscontrol.Beinghydraulicallydriven,the

spreadpatternisindependentofthegroundspeed.

Thehoppercontrolcableopensandclosesthedoor

insidethebaseofthehopper.Themaximumsizeof

theopeningwillbedeterminedbytherateadjustment

ontheknobdial.Thiswillsetyourrategatelinkage

bartolimitandstoptheratethedoorcanopen.

TheDiffuseradjustmentallowstheusertoadjustthe

intensityofthespreadpattern.Asmallturnshifts

theproductplacementontheimpeller.Thisinturn

balancesthespreadpatternheaviertotheleft(back

sideramp)orheaviertotheright(frontsideramp).

Adjustmentisverysensitive,somultipleadjustments

mayberequired.

Themachineisequippedwiththe120lbmodel

spreader.Thehydraulicspreadermotorwiththe

spreadermotorcontrolhastheabilitytovary

spreadwidthsfrom3to25feet.Thisdependson

volume/density,particlesizeandrateoftravel,and

weatherconditions.Thepatterncanbeincreasedor

decreasedwhilespreadingdependingonneeds.A

typicalpatternistooverlapfertilizerpatternbackto

thetiretracks.

Thespreadthinsandfeathersattheouteredges,

eliminatingsharp“edgetoedge”lineswhichcause

stripesandstreaks.

Determineadialsettingonthelowside.Ifsetting

istoolow,covertheareamorethanonetime.A

highersettingcanbeusedwhenaprovendialsetting

isestablished.Travelataconstantspeed.

Remember-Publisheddialsettingsareapproximate

only.Openthehopperdoorafterthespreaderis

turnedonatoperatingspeed.

Operations

andthenthebrake.PushJoySticksforwardequally

tomoveunitforward.Shouldyouwanttheunitto

backupinthereversedirection,pullbackontheJoy

Sticks.Ifaturnisdesired,pushoppositeJoyStickof

thedirectionyouwanttheunittoheadforward(if

wantingtoturnleft,pushtherightJoyStickforward

whilekeepingtheleftJoyStickslightlybackofthe

rightthusallowingtherighttiretoturnmorethanthe

left.PushmoreontheleftJoyStickifyoudesireto

turntheunittotheright).Becautiousasturnradius

changeswiththespeedyouaregoingandtheamount

eachJoyStickispositionedforwardorbackward.

Usingthespreadersystem,therearetwocablesto

operatethehopperdoor(topcable),thediffuser

(rightcable).Bypullingonthetophopperdoor

cable,thiswillopenthedoorandallowproductto

fallonthespinner.Adjustmentsastohowwidethe

dooropensaremadeonthefrontonthehopper

withtheHopperRateDial.Thislimitshowwide

thedoorwillopenandhowmuchgranularproduct

willbecomingout.Thediffusercable(rightcable)

controlsthespreadpattern.Turningthecableknob

counter-clockwisewillloosenthecablelockandallow

youtoadjust(pullfurtheroutorpushfurtherin)this

cable.Doingthiswillallowyoutospreadgranular

productheaviertotheleft,consistentinthemiddle

orheaviertotheright.Onceyouhaveadjustedto

yourdesiredpattern,turntheknobclockwisetolock

inposition.

Duringnormalspreadingapplications,thedeector

shieldwouldstayintheupposition.Whenwanting

tocloseofftheleftsideandusethedeectorshield,

engagetheparkingbrakeandshutoffthemachine.

Waitforallmovingpartstostopbeforeleavingthe

operator’sposition.Gotothefrontofthemachine

andpushthedeectortothedownposition.

TheLockingCasterSystem(Figure3)allowsthe

operatortolockthefrontcasterwheelsinthe

forwardpositiontocreatemoresidehillstability.The

LockingCasterSystemisappliedwhentheoperator

compressestheLockingCasterSystemfootpedal

locatedontherightsideofthefootplate.When

compressingthefootpedal,lockingmechanism

slidesoverthecasterpinlockingthewheelinthe

forward/straightposition.Thissystemisspring

loaded,sobyreleasingthispedalitwillreleasethe

lockonthefrontcasterwheels.

Uponturningthekeyontostarttheunit,applyfull

choke.Onceunithasstarted,releaserstthechoke

15

Page 16

Operation

Figure3

1.Casterpinlockingmechanism

SpreaderSystem

SpreaderCalibration/Layout

TheSpreaderMotorControldeterminesthespeed

oftheimpellerinthefrontonthemachine.Your

machineiscapableofvaryingitsspreadpatternfrom

3–25feetwiththiscontrol.Beinghydraulically

driven,thespreadpatternisindependentofthe

groundspeed.

heaviertotheright(placingproducttothemiddle

oftheimpeller).

Yourmachineisequippedwitha120lb.Spyker

modelspreader.Thehydraulicspreadermotorwith

thespreadermotorcontrolhastheabilitytovary

spreadwidthsfrom3to25feet.Thisdependson

volume/density,particlesizeandrateoftravel,and

g271157

weatherconditions.Thepatterncanbeincreasedor

decreasedwhilespreadingdependingonneeds.A

typicalpatternistooverlapfertilizerpatternbackto

thetiretracksandthespraypatternboomtoboom.

Thisfeathersmaterialattheouteredges,eliminating

sharp“edgetospread”lineswhichcausestripesand

streaks.

Determineadialsettingonthelowside.Ifsetting

istoolow,covertheareamorethanonetime.A

highersettingcanbeusedwhenaprovendialsetting

isestablished.Travelataconstantspeed.

Thehoppercontrolcableopensandclosesthedoor

insidethebaseofthehopper.Themaximumsizeof

theopeningwillbedeterminedbytherateadjustment

ontheHopperRateDial.Thiswillsetyourrategate

linkagebartolimitandstoptheratethedoorcan

open.

Figure4

1.Hopper

2.Diffuser

TheDiffuseradjustmentallowstheusertoadjustthe

intensityofthespreadpattern.Asmallpullshifts

theproductplacementontheimpellereithertothe

edgeoftheimpellerorthemiddleoftheimpeller.

Thisinturnshiftsthespreadpatternheaviertothe

left(placingproducttotheedgeoftheimpeller)or

g271240

Figure5

1.Dial

2.Diffuser

Remember-Publisheddialsettingsareapproximate

only.Openthehopperdoorafterthespreaderis

g286783

turnedonatoperatingspeed.

*Spray/SpreadCalibrationDecalChartsareavailable

fromthepartsdepartment.

AeratorOperations

Overview

TheZ-Plugcancover100,000squarefeetperhour

andproduceupto31/2inchcores.Thefulloating

16

Page 17

Operation

tineheadcanmaneuveraroundtreesandbedswhile

engaged.The2,000lbhydrauliccylinderpicksup

theheadinlessthan2.5secondsforturningaround

orgettingheadupinthetransportposition.Forced

intheoppositedirection,thehydrauliccylinderputs

downforceontheheadaddingweighttothetine

headfordeepersoilpenetration.BallSwivelandpin

attachpointsallow30degreesofpivotlefttoright

forbettersteeringinthedownposition.TheBall

Swivelandpinattachpointsalsoallowforeasyattach

anddisassembleoftheAeratorhead(oranyother

attachmentdesignedfortheZ-Plug).

Operations

Uponturningthekeyontostarttheunit,applyfull

choke.Onceunithasstarted,release(pushdownor

pulldown)rstthechokeandthenthebrakelever.

BringunituptoacomfortablespeedwiththeControl

Lever.Whenyouarrivetodesiredaeratingarea,use

theThumbSwitchtoloweraeratortinesintotheturf

(aeratorheadcanoatupto30degreesandmake

gradualturnsaroundbedsandtrees).

Onceyouhavecometoadesignatedturnaround

location,usethehydraulicThumbSwitchtolifttine

headtotransportposition.Makedesignatedturnand

repeatprocessofloweringtineheadintoturfand

resumeaeration.

wheelintheforward/straightposition.Thissystemis

springloaded,sobyreleasingthispedalitwillrelease

thelockonthefrontcasterwheels..

AeratorTineHeadRemoval

Theaeratortineheadisremovableforservice,

cleaningandremovingfromtractionunittoinstall

otherattachments.T oremovethetineheadfromthe

tractionunit,rstadjustthehydrauliccylindersothat

thetineheadstartstomakecontactwiththeground

(takingweightoffofthehead).Pullpindisconnecting

theballswivellinkagetotheaeratorhead.Lower

cylinderreleasingtensiononthechainsandremove

the2ballswivelchainsconnectedtotheouterframe

section(weldedtochainandspringsupports).

Pullthepinfromtheaeratorfrontframeneck(itwill

beattachedtothefrontframeofthetractionunit)

anddismounttheballswivelfromthepin(pullneck

downward).Lowerfrontneckoftheaeratorhead

andpositionyourselfbackonthetractionunit.Drive

awayfromtheaeratorheadbyturningeitherleftor

right(turningtotherightofthehead—reference

Figure7)byturningthefrontofthetractionunitin

eitherdirection.Toinstallheadbackontheunit,

reversetheunitalongthebackofthetines.Oncethe

rearinsidetirelinesuptothecenteroftheaerator

head,slowlystartturningunitovertheaeratorhead

(makesurethatyoulineuptheballswivelintheneck

oftheaeratorandthepullpinbeneaththenoseof

thetractionunittomakeiteasyformounting).

Figure6

1.RHmotioncontrolthumb

switchraisestines

2.LHmotioncontrolthumb

switchlowerstines

Ifaeratingonhillsides,theLockingCasterSystem

allowstheoperatortolockthefrontcasterwheels

intheforwardpositiontocreatemoresidehill

stability.TheLockingCasterSystemisappliedwhen

theoperatorcompressestheLockingCasterSystem

footpedallocatedontherightsideofthefoot

plate.Whencompressingthefootpedal,locking

mechanismslidesoverthecasterpinlockingthe

g286617

17

Page 18

Operation

g286624

Figure7

1.Turningrightofaeratortinehead

Note:Theremovableweightsareheavy.Usecare

whenliftingthem.Makesurethatyoucanhold

themsecurelybeforeliftingthem.Usecautionwhen

positioningyourhandssothatyouDoNotsetthem

onyourhands,ngers,orfeet.Itisrecommendedto

usetwopeoplewhenremovingweights.

18

Page 19

Maintenance

Maintenance

PeriodicMaintenance

Alwaysshutofftheengine,andremovethekey.Wait

forallmovementtostopandallowthemachineto

coolbeforeadjusting,cleaning,storing,orrepairingit.

EngineMaintenance

**USECOMPRESSEDAIR(NOTWATER)

WHENCLEANINGENGINE**

Useonlyoriginalequipmentreplacementparts.

Otherpartsmaynotperformaswell,maydamage

unit,andmayresultininjury.

OilRecommendations:ExmarkPremium4-Cycle

Oilisrecommendedforbestperformance.Other

high-qualitydetergentoilareacceptableifclassied

forserviceSF,SG,SH,SJorhigher.Donotuse

specialadditives.Changeengineoilafterrst5hours

andthenevery50hoursthereafter.

IftheoillevelisbelowtheADDmark,addoiluntil

itreachestheFULLmark.Starttheengineandrun

forafewseconds.Turnengineoffandcheckdipstick

forproperlllevel.

Figure8

1.Engineoildrainhosebehindengine

FuelRecommendations:Fuelmustmeetthese

requirements

•Clean,fresh,unleadedgasoline.

•Aminimumof87octane/87AKI(91RON).

•Gasolinewithupto10%ethanol(gasohol)or

upto15%MTBE(methyltertiarybutylether)

isacceptable.

Fullmaintenanceinformationcanbelocatedinthe

enginemanualprovided.

19

g286804

Page 20

Maintenance

HydraulicSystem

Maintenance

**USECOMPRESSEDAIR(NOTWATER)

WHENCLEANINGHYDRAULICSYSTEM**

Hydro-Gearrecommendsthattheuidandlter(s)

bechangedaftertherst100hoursandevery500

hoursthereafter.UseExmarkPremiumHydroOil

whenreplacingtheoilinyoursystem.Thehydraulic

reservoirshouldbelledsotheoillevelishalfway

upthesightwindow .

Hydraulicsystemrequires25micronoilltersor

equivalenttobeused.

Checkforhydraulicleaksdailytoensureproperuid

levels.

TractionUnitMaintenance

Themachinehas11greasettingsthatrequire

periodicgreasing.Theselocationscanbefound

onthewheelassembly(1oneachfrontwheel

assembly),onthecasterassembly(1oneachfront

casterassembly),andthedrivebeltidler(1onidler

arm),PillowBlockBearings(4each)and2onthe

LiftCylinder..

Inspectwheelandcasterassemblyevery25hoursfor

bearingwear,damage,debris,andproperinstallation.

Inspectidlerarmbushingevery50hoursforwear.

Thesebushingsareawearitemandwillhavetobe

replacedperiodically.

Inspectallbolts,washers,nuts,pinsandother

mountinghardwareofZ-Plugonceaweektoensure

thathardwarepiecesareproperlytightened.

SpreaderMaintenance

TheZ-Plugcomesequippedwitha120lbspreader

andrequiresthesameamountofattentionand

maintenance.

**USECOMPRESSEDAIR(NOTWATER)

WHENCLEANINGHOPPER**

Lubricate(SiliconeSpray)Hopper,Deectorand

Diffusercablesweekly.

CleandebrisandproductfromHopperdailyto

eliminatebuildup.

Keephydraulichosettingstightandfreeofleaks.

BesurethattheRateGate&DiffuserGuidesarenot

damagedtoallowthehopperdoortoslidefreely.

Checkagitatorwireonadailybasis.Ifwireisnot

present,productwillruntheriskofbuildingupprior

toreachinghopperdoorandnotspreadingevenly.

AeratorHead/Tine

Maintenance

Checkalltinestoensurethatthereisnobends,

cracksand/ordamagestothetines(replaceanybent,

crackedand/ordamagedtines).

Checktomakesurethatallnutsontinehead

assemblyaretightandsecure.

Checktoensurethatpillowblockbearingassemblyis

securedandbearingsaremovingfreely.

MaintenanceChart

ServiceInterval:Asrequired

Service

Actions(s)

FrontCaster

Wheels

(grease)

FrontCaster

Yokes(grease)

FrontTire

Pressure(22

PSI)

DailyWeeklyBi-WeeklyMonthlyYearly

X

X

X

20

Hours

Page 21

Maintenance

Service

Actions(s)

RearTire

Pressure(18

PSI)

RearRimNut

Torque(95lbs)

RearHub

CastleNut

(235ft-lb)

IdlerPulley

Arm(grease)

BeltTension

(1/2inch

deectionat

15lbs)

BeltWear

(cracks,tears

ormissing

material)

Hopper

Cables

(lubricatew/

SiliconeSpray)

Accuway

Cable

(lubricatew/

SiliconeSpray)

Deector

ShieldCable

(ifapplicable)

(lubricatew/

SiliconeSpray)

Bottomof

HopperTub

(wirebrush

cleaning)

Hopper

Bottom

Bushing

(changeif

needed)

Impeller

(changeif

needed)

EngineOil

(check)

DailyWeeklyBi-WeeklyMonthlyYearly

X

X

X

X

X

X

X

X

X

X

X

X

X

Replace

Hours

21

Page 22

Maintenance

Service

Actions(s)

EngineAir

FilterCheck

(changeif

needed)

EngineAir

Pre-Filter

Check(change

ifneeded)

EngineFuel

FilterCheck

(changeif

needed)

EngineSpark

Plugs

Hydraulic

Oilandlter

(change)

HydraulicOil

Level(check)

HydroSystem

Fittings(check

forleaks)

In-LineFilter

(check)

In-LineFilter

Gasket(check)

PillowBlock

Bearings

AeratorTine

Inspection

AeratorTine

Hardware

(NutandBolt)

BallSwivel

Inspection

*Blowoff

debrisdaily*

DailyWeeklyBi-WeeklyMonthlyYearly

X

X

X

X

X

X

X

X

X

X

X

Replace

Replace

Hours

50hrs

25hrs

Afterrst

100hrsand

every500hrs

thereafter

22

Page 23

Troubleshooting

Troubleshooting

Engine:

•Notstarting.Thereareafewreasonsastowhyyourenginefailstostart.Iftheenginedoesnotturnover,

thenthebatterycouldbedead,badconnectiontothebatterywires,keyswhichmaybebad,30AMPfuse

onthewiringharness(orangewire)maybeblownorthestartersolenoidmaybebad(youwillhearthe

startersolenoidtryingtoclickon,butnothingishappening).Anothercommonreasonforaunitnot

startingisafterunithasbeenwashed.W atergetsintothesparkplugbootandgetsthesparkplugwet.Pull

sparkplugbootanddry(sprayWD-40).

•Engineturnsoverbutdoesn’tstart.Thereareafewreasonsastowhyyourenginewillturnoverbutnot

start:looseorbadsparkplug,waterinfuel,chokepartiallyclosedorwetand/orfoulplugs.Checkforfuel..

•Enginewon’tstayrunning.Fewthingstolookforifyourenginedoesnotstayrunningarecloggedfuel

lter,cloggedand/ordirtyairlter,waterinfuelorlowfuel.

Hydraulics:

•Hydraulicsystemmakingloudnoisewhenrunning.Thiscouldbecausedbyacoupleofthings.Themost

commonisifthereisairinthesystem.Thiscanbecausedwhenchangingoutahydropump,replacinga

hydraulichoseorhavingaloosettingontheintakelines.Ifairisnotpresent,checkforlowlevelsinthe

system.Thishappenswhenthereisaleakinthehydraulicsystemsomewhereorhydraulicuidswerejust

changedanddidnotgetbacktotheproperlllevel.

•Needtotowmyunit;whatdoIneedtodoinordertonotruinmyhydropumps?ThereareTowValves

oneachofthehydropumps(hexheadwithholerunningthroughitontheleftsiderearofthehydraulic

pump)thatneedstobeturnatleast1½revolutionscounterclockwisetoopenthehydraulicsystem

(butNEVERremove).Oncetheunitisbroughttoadesiredlocation,remembertotightenthetow

valvesbacktight(clockwise).

Tracking:

Unitnottrackingstraightwhenpushingbothcontrolarmstothespeedbar.Thisiscausedwhenthelinkage

tothehydraulicpumpisnotevenorahydraulicpumpisgoingbad.Traditionallythelinkageneedstobe

adjustedsothattheybothhavethesameamountofpull.Ifitispullingtotheleft,thelefthydraulicpump

linkageislongerthantheright;youcaneitheradjusttherighttoalongerlength,oradjustthelefttoashorter

lengthtomatchtheright.

Granular:

•Therearenumerouspotentialchallengesthatcanoccuronthegranularsideduetotheamountofusethis

portionoftheunitsees.Ifproductisnotspreadingevenlyorconsistently,thenlookforafewthingswith

yourhopperimpellerorhopperdiffuser.IfthereisbuildupattheendoftheImpellertipsorthetipsare

worn,thiswillcauseanunevenand/orinconsistentspreadpattern.Anotherpotentialchallengeisifthe

patternisnotevenwhentheAccuwayisnotpartofthepicture.Thisissometimescausedwhengranular

productismoistandholdingonlongerthannormal.

•Ifgranularproductisleakingoutfromthehopper,determinewhereitiscomingfromandlookattherepair

options.Ifthegranularproductisleakingthroughthehoppershaftarea,thenyourhopperbushingisworn.

Thiswillallowproducttogetinbetweentheshaftandthehopperbushing.Ifgranularproductisleaking

23

Page 24

Troubleshooting

throughthehopperdoorarea,thenDiffuserGuidesarelooseorwornallowingagapbetweenthedoorand

thehopperbase.Alsoapotentialfactorisifthehoppercableisnotcompletelyclosingthehopperdoor.

•Whenyourhopperdoorcannotopen,therearetypically3thingstolookat.Oneisthatyourhoppercable

maybefrozenandlockedup,theballjointendmayhavebrokenoffortheremaybeproductjammed

betweenthehopperdoorandthebase(duetoloosedoorguides).

ChargingIssues:

16AmpRegulatedAlternator

The16ampregulatedalternatorsystemprovidesACcurrentthroughtwooutputleadstotheregulator-rectier.

Theregulator-rectierconvertstheACcurrenttoDC,andregulatescurrenttothebattery.Thecharging

ratewillvarywithengineRPMandtemperature.

1.BLACKtestleadfrommeter(1)(Figure9)

2.REDtestleadfrommeter(2)

3.Connector(3)

4.TwoYELLOWACinputleads(4)

5.REDDCOUTPUTWIRE(5)

6.ACOutputterminals(6)

7.REDDCoutputlead(7)toconnector

Note:Stator,regulator-rectierandy-wheelareNOTINTERCHANGEABLEwithanyothercharging

system.

Figure9

OutputTest

g268055

WHENCHECKINGTHEALTERNATORCOMPONENTS,PERFORMTHETESTINTHE

FOLLOWINGSEQUENCE:

Temporarilydisconnectstatorwireharnessfromregulator-rectier.

1.InsertREDtestleadintoVΩreceptacleinmeter.

2.InsertBLACKtestleadintoCOMreceptacle.

3.RotateselectortoV~(ACVOLTS)position.

24

Page 25

Troubleshooting

CAUTION

AttachmetertestleadstotheACoutputterminals(YELLOWwires)intheconnectorBEFORE

startingtheengine.Ifthestatorisgrounded(defective)andthemetertestleadscontactthecenter

DCoutputpin(REDwire)intheconnector,arcingcouldoccur,damagingthewiring.

4.AttachRED(2)andBLACK(1)testleadprobestotheYELLOWwire(4)ACoutputterminals(6),ofthe

connector(3),asshowninFigure10.(MetertestclipleadsmaybeattachedtoeitherACoutputterminal).

Figure10

5.IfNOorLOWoutputisfoundcheckforbarewiresorotherdefects.Ifshortedleadsarenotvisible,

replacethestator.

6.Withtheenginerunningat3600RPMoutputshouldbenolessthan26Volts.

DCOutputChargingWireTest

AsimpletestcanbeusedtotesttheDCoutputchargingwirecircuit.Ifawiringproblemexistsitcanbe

correctedbeforetestingregulator-rectier.

Leavestatorwireharnessdisconnectedfromregulator-rectier.EquipmentkeyswitchmustbeinOFF

position.

1.1.InsertREDtestleadintoVΩreceptacleinmeter.

2.InsertBLACKtestleadintoCOMreceptacle.

3.RotateselectortoV==(DCvolts)position.

4.AttachREDtestleadprobe(2)totheREDwire(5)DCoutputterminal(7),oftheconnector(Figure10).

5.AttachBLACKtestleadprobe(1)tonegativebatteryterminal.

6.TurnequipmentkeyswitchtoONposition.MetershoulddisplayBATTERYVOLTAGE.

g268086

7.Ifmeterdoesnotdisplayvoltage,checkforblownfuseorbrokenorshortedwire.

Regulator-RectierT est

25

Page 26

Troubleshooting

TheDCShuntMUSTbeinstalledontheNEGATIVE(-)terminalofthebattery,(Figure11)toavoid

blowingthefuseinthemeterwhentestingtheoutputofthe16ampsystem.Allconnectionsmustbeclean

andtightforcorrectreadings.

1.Connectstatorwireharnesstoregulator-rectier.

2.InstallDCShunt(4)onNEGATIVEbatteryterminal.

3.InsertREDtestleadintoVΩreceptacleinmeterandconnecttoREDpostterminalonshunt(5),Figure11.

g268088

Figure11

4.InsertBLACKtestleadinCOMreceptacleinmeter.ConnecttoBLACKpostterminalonshunt(3).

5.Rotateselectorto300mVposition.

6.Withtheenginerunningat3600RPM,theoutputshouldbe3-20Amps.

Note:Dependingonbatteryvoltageand/orcurrentdrawonsystem

IfNOorLOWoutputisfound,besurethatregulator-rectierisgroundedproperlyandallequipment

connectionsarecleanandsecure.IfthereisstillNOorLOWoutput,replacetheregulator-rectier.

26

Page 27

Schematics

GREEN

YELLOW

IGNITION SWITCH

P1601

P1601

BLACK

4

G

B

5

START

RUN

L

3

SW1601

OFF

S

A

1

2

J1601

M

YELLOW

YELLOW

YELLOW

SP1602

J1603 J1604

BLACK

BLACK

RED

RED

OPC SWITCH

SW1604

FRAME GROUND

FRAME GROUND

J1605

START

FRAME GROUND

J1619

J1623

YELLOW

P1606

ENGINE

ENG13

IGNITION

MODULES

FLYWHEEL

ALT

GND-S/D

REG

RED

RED

BLACK

BLACK

BLACK

BLACK

SOLENOIDS &

CYLINDER

RAISE

LOWER

J1626

J1628

RIGHT

THUMB SWITCH

LEFT

THUMB SWITCH

BLACK

BLACK

ORANGEORANGEORANGE

BLACK

J1627

RED

SP1608

SP1609

ATC-ATO FUSE HOLDER

MAIN

F27 20A

SPEEDOMETER

+12VDC

GND

SENSOR +

SENSOR -

P1609

SP1607

P1611

RED

BLACK

RED

BLACK

YELLOWYELLOW

SPEED SENSOR

& CABLE

FRAME GROUND

FRAME GROUND

FRAME GROUND

J1622

ATC-ATO FUSE HOLDER

SPEEDOMETER

WHITE

J1616 J1617

J1613

J1614

K1601

START SOLENOID

RED

RED

RED

ORANGE

ORANGEORANGERED

BLACK

SP1603

MAIN

ATC-ATO FUSE HOLDER

J1605

J1606

J1607

J1611

BT1601

J1612

J1608

J1609

J1610

BATTERY

TERMINAL -

TERMINAL +

F26 10A

HR

HOUR METER

DIS 1601

1

1

J1602

DC

REG

Schematics

ElectricalSchematic

g287990

27

Page 28

PlaceModelNo.andSerialNo.

LabelHere(IncludedintheLiterature

Pack)orFillinBelow

ModelNo.EngineSerialNo.(E/No)

SerialNo.

DatePurchased

EngineModelNo.andSpec.No.

©2019ExmarkMfg.Co.,Inc.

2101AshlandAve

Beatrice,NE68310

AllRightsReserved

PartNo.4504-453Rev.B

(402)223-6375

Fax(402)223-5489

PrintedintheUSA

*4504-453*B

www.exmark.com

Loading...

Loading...