Page 1

V ANTAGE

ForSerialNos.

312,000,000&Higher

PartNo.4501-211Rev.A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

(CPRC)Section4442touseoroperatethis

engineonanyforest-covered,brush-covered,

orgrass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilar

laws.

Toacquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

Thissparkignitionsystemcomplieswiththe

CanadianstandardICES-002.Cesystèmed’allumage

parètincelledevèhiculeestconformeàlanorme

NMB-002duCanada.

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2011ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

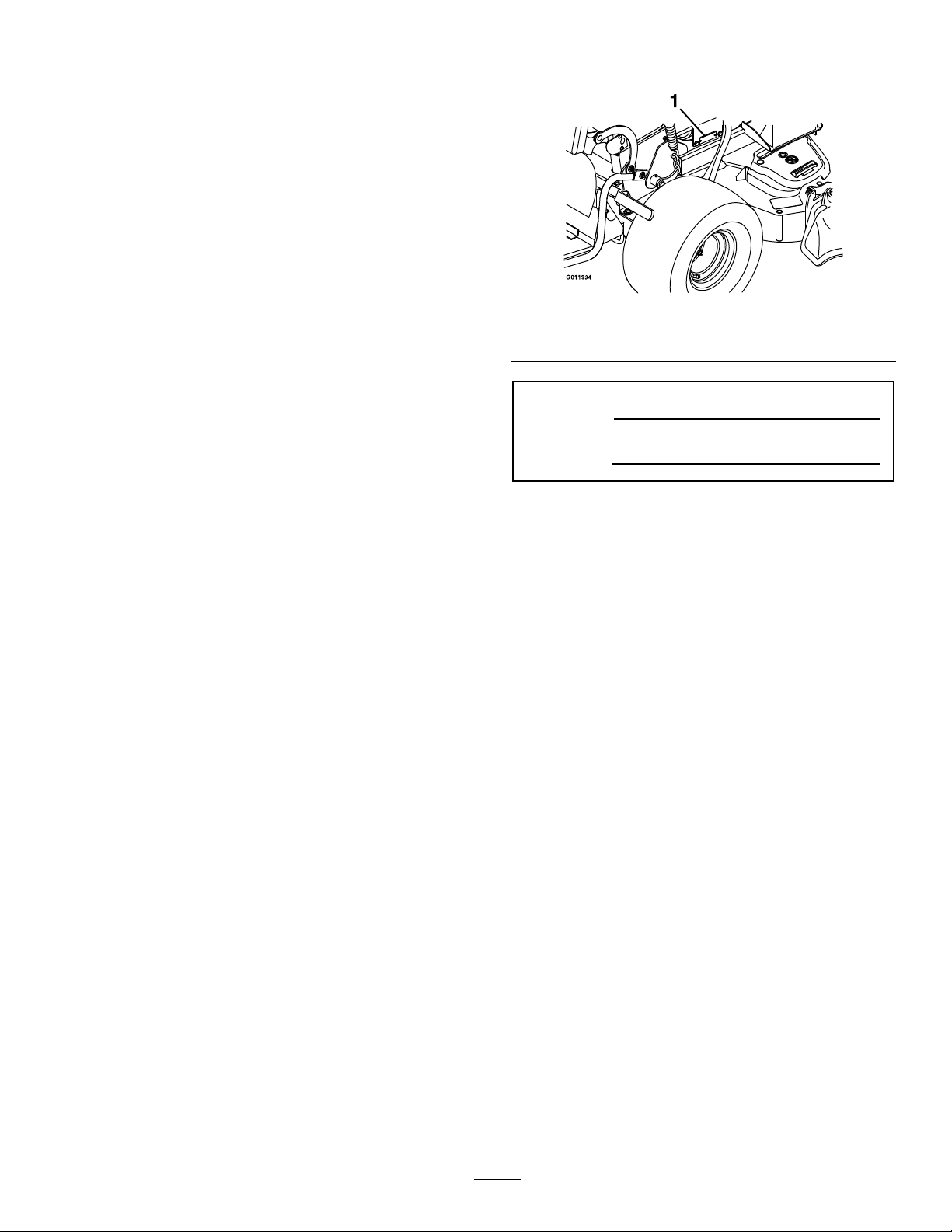

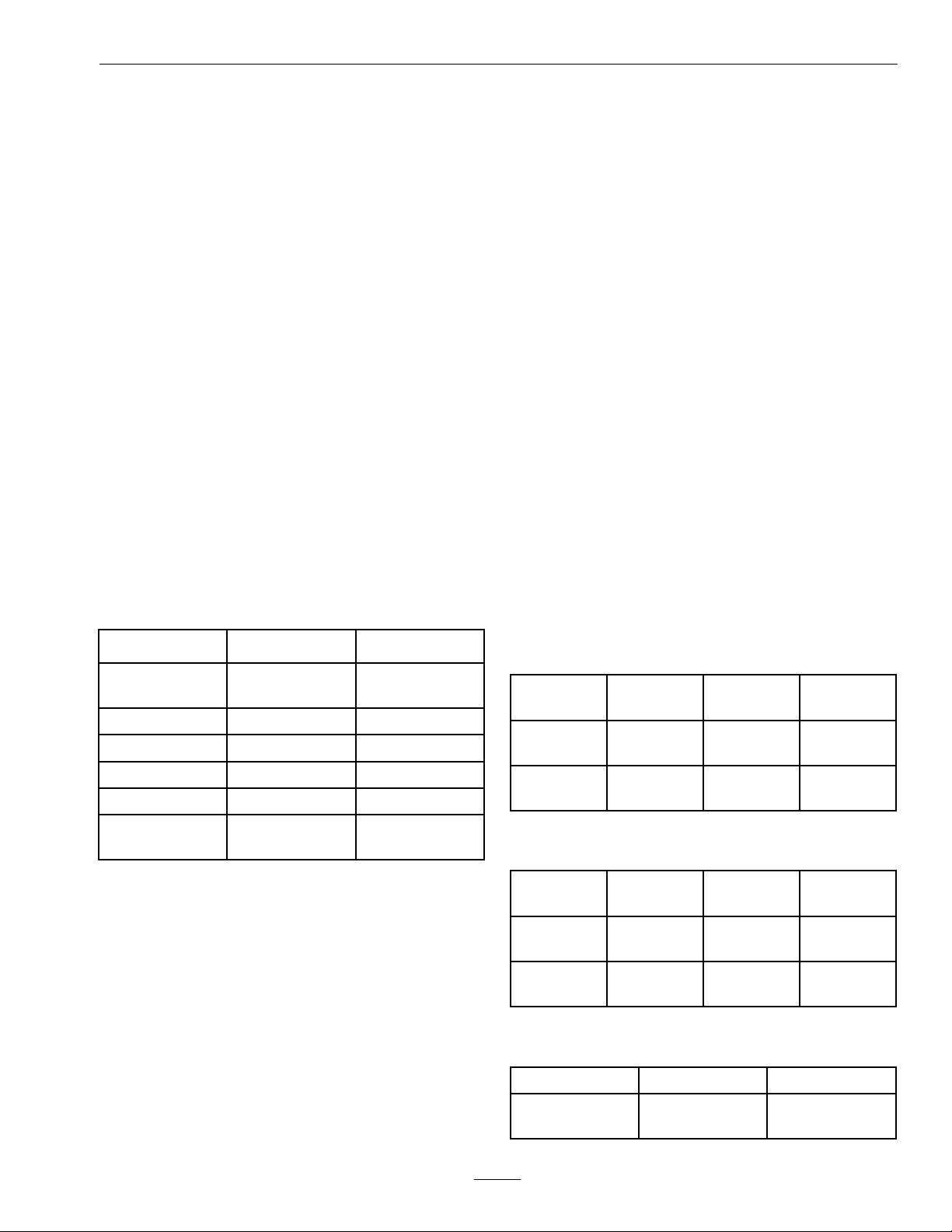

Figure1

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency,andpromotesafe

operation.

Ifadditionalinformationisneeded,orshould

yourequiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

Exmarkpartsmanualsareavailableonlineat

http://www.exmark.com

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals......................10

Specications........................................................14

ModelNumbers.............................................14

Systems..........................................................14

Dimensions....................................................15

TorqueRequirements.....................................16

ProductOverview.................................................16

Operation..............................................................17

Controls.........................................................17

Pre-Start.........................................................19

OperatingInstructions...................................19

Transporting..................................................24

Maintenance..........................................................26

RecommendedMaintenanceSchedule(s)............26

PeriodicMaintenance........................................27

CheckEngineOilLevel..................................27

CheckMowerBlades......................................29

CheckSafetyInterlockSystem........................30

CheckforLooseHardware.............................31

ServiceAirCleaner.........................................31

ChangeEngineOil.........................................31

CheckHydraulicOilLevel..............................31

CheckTirePressures......................................32

CheckConditionOfBelts...............................32

LubricateGreaseFittings................................32

LubricateCasterWheelHubs.........................32

CheckSparkPlugs..........................................33

ChangeHydraulicSystemFilterand

Fluid..........................................................33

WheelHubNutTorqueSpecication..............35

CheckSparkArrester(ifequipped)..................35

ThreadLockingAdhesives..............................36

MobilHTSGrease(OrFood-Grade

Anti-seize)..................................................36

Copper-BasedAnti-seize................................36

DielectricGrease............................................36

Adjustments......................................................36

DeckLeveling................................................36

AdjustingtheCuttingDeckRake....................37

AdjustingtheRearoftheDeck........................38

PumpDriveBeltTension................................38

MowerDeckDriveBeltTension.....................38

ChecktheParkBrake......................................38

ParkBrakeAdjustment...................................38

ElectricClutchAdjustment.............................40

MotionControlNeutralAdjustment...............41

MotionControlTrackingAdjustment.............42

ChecktheNeutralSwitchAlignment

..................................................................42

AdjustRHMotionControlHandle

Position......................................................43

CasterPivotBearingsPre-Load

Adjustment................................................44

Cleaning............................................................45

CleanEngineandExhaustSystem

Area...........................................................45

RemoveEngineShroudsandClean

CoolingFins...............................................45

CleanDebrisFromMachine...........................45

CleanGrassBuild-UpUnderDeck.................45

WasteDisposal...............................................45

Troubleshooting....................................................47

Schematics............................................................50

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThislawnmowermeetsorexceedstheB71.4

specicationsoftheAmericanNationalStandards

Instituteineffectatthetimeofproduction.

Exmarkdesignedandtestedthislawnmowertooffer

reasonablysafeservice;however,failuretocomply

withthefollowinginstructionsmayresultinpersonal

injury.

ThisSafetyAlertSymbol(

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

SafetyAlertSymbol

Figure2)isusedbothin

Figure2

SafeOperatingPractices

Training

•ReadtheOperator’ sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

amower,andevenmatureteenagersshouldhave

adultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator's

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

mowerwithouttakingrisks.

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

5

Page 6

Safety

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengine

oremissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoradd

fuelwhenengineisrunningorwhenthe

engineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperator'spresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly .DoNotoperateunlessthey

arefunctioningproperly.

6

Page 7

Safety

Operation

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscanoccur

oncontactanddebris,suchasleaves,grass,

brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,to

coolbeforetouching.

•Removeaccumulateddebrisfrommuferand

enginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcankill

you.

DoNotrunengineindoorsorinasmallconned

areawheredangerouscarbonmonoxidefumes

cancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Neverraisedeckwithbladesrunning.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkmachineonlevelground.Stopengine,wait

forallmovingpartstostop,removekeyand

engageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

–Beforemakingheightadjustments.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesinplace

andworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•NEVERcarrypassengers.DONOToperate

themowerwhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecaution

whencrossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

7

Page 8

Safety

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Lossofcontrol

and/orlossofoperator'sfootingcouldresultina

fallwithanarmorleggettingunderthemower

orenginedeckwhichmayresultinseriousinjury,

deathordrowning.

•Mowacrossslopes,neverupanddown.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan20degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•Letenginecoolbeforestoringanddonotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatoperatingonwetgrass,acrosssteep

slopesordownhillmaycausethemowertolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

MaintenanceandStorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

DANGER

Chargingorjumpstartingthebatterymay

produceexplosivegases.Batterygasescan

explodecausingseriousinjury.

•Keepsparks,ames,orcigarettesaway

frombattery.

•Ventilatewhenchargingorusingbattery

inanenclosedspace.

•Makesureventingpathofbatteryis

alwaysopenoncebatteryislledwith

acid.

•Alwaysshieldeyesandfacefrombattery.

8

Page 9

Safety

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldeyes,and

rubberglovestoprotectskinandclothing

whenhandlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwith

waterandcalladoctorimmediately.

CAUTION

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagementof

components.Sparkscouldcauseanexplosion

ormovingpartscouldaccidentallyengage

causingpersonalinjury.

Besureignitionswitchisinthe“OFF”

positionbeforechargingthebattery.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemay

result.

•Ifequipped,makesureallhydraulicuid

hosesandlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretohydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,to

ndhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembyplacingthemotioncontrollevers

inneutralandshuttingofftheenginebefore

performinganyworkonthehydraulicsystem.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,traction,

andsafetyofthemachine.Failuretouseoriginal

Exmarkpartscouldcauseseriousinjuryor

death.Makingunauthorizedchangestothe

engine,fuelorventingsystem,mayviolateEPA

andCARBregulations.

Replaceallpartsincluding,butnotlimitedto,

tires,belts,blades,andfuelsystemcomponents

withoriginalExmarkparts.

WARNING

Fuelsystemcomponentsareunderhigh

pressure.Theuseofimpropercomponentscan

resultinsystemfailure,gasolineleakageand

possibleexplosion.

Useonlyapprovedfuellinesandfuelltersfor

highpressuresystems.

9

Page 10

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

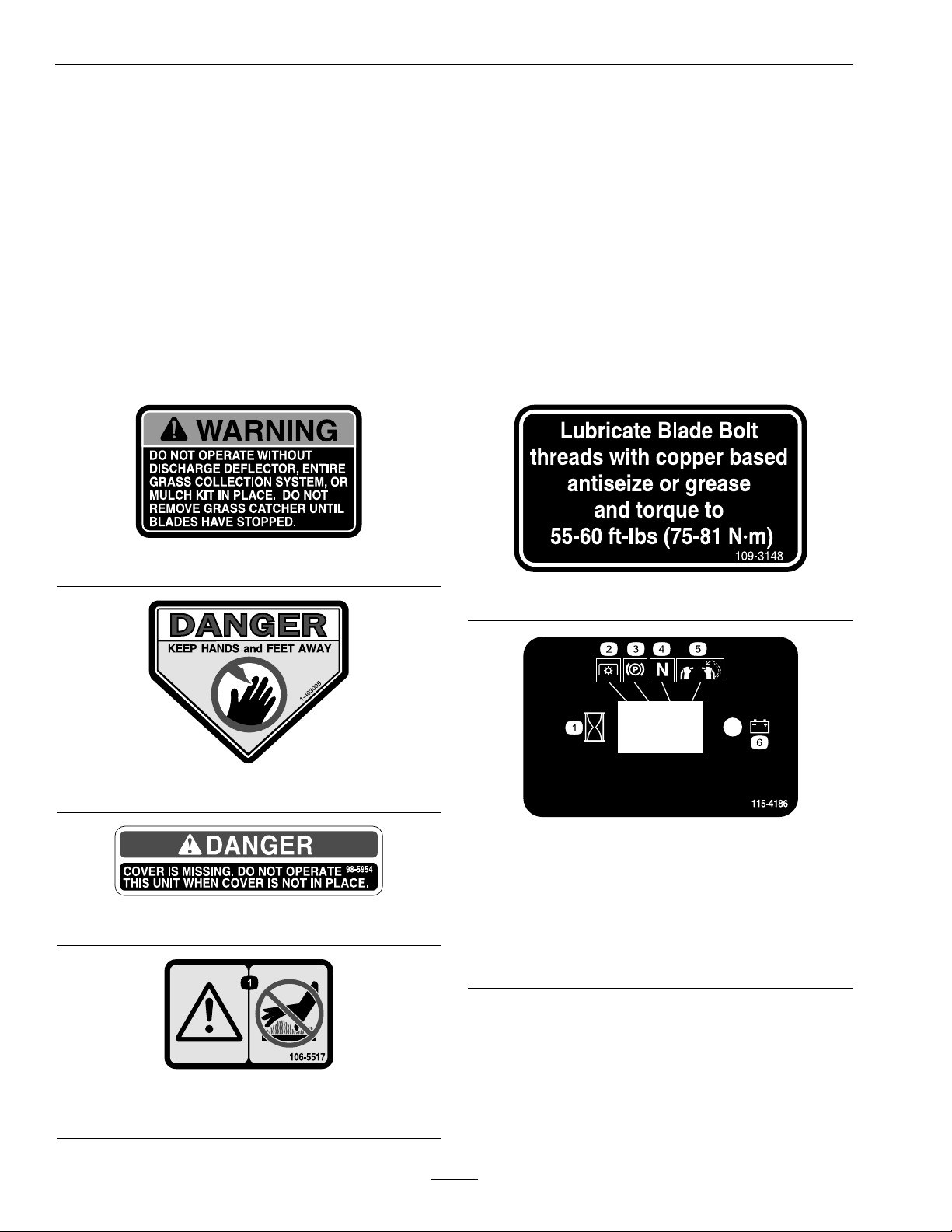

1-303508

109-3148

1-403005

115-4186

1.Interval

2.PowerT ake-off(PTO)

98-5954

3.Parkingbrake

4.Neutral

5.Operatorpresenceswitch

6.Battery

106-5517

1.Warning—donottouchthehotsurface.

10

Page 11

Safety

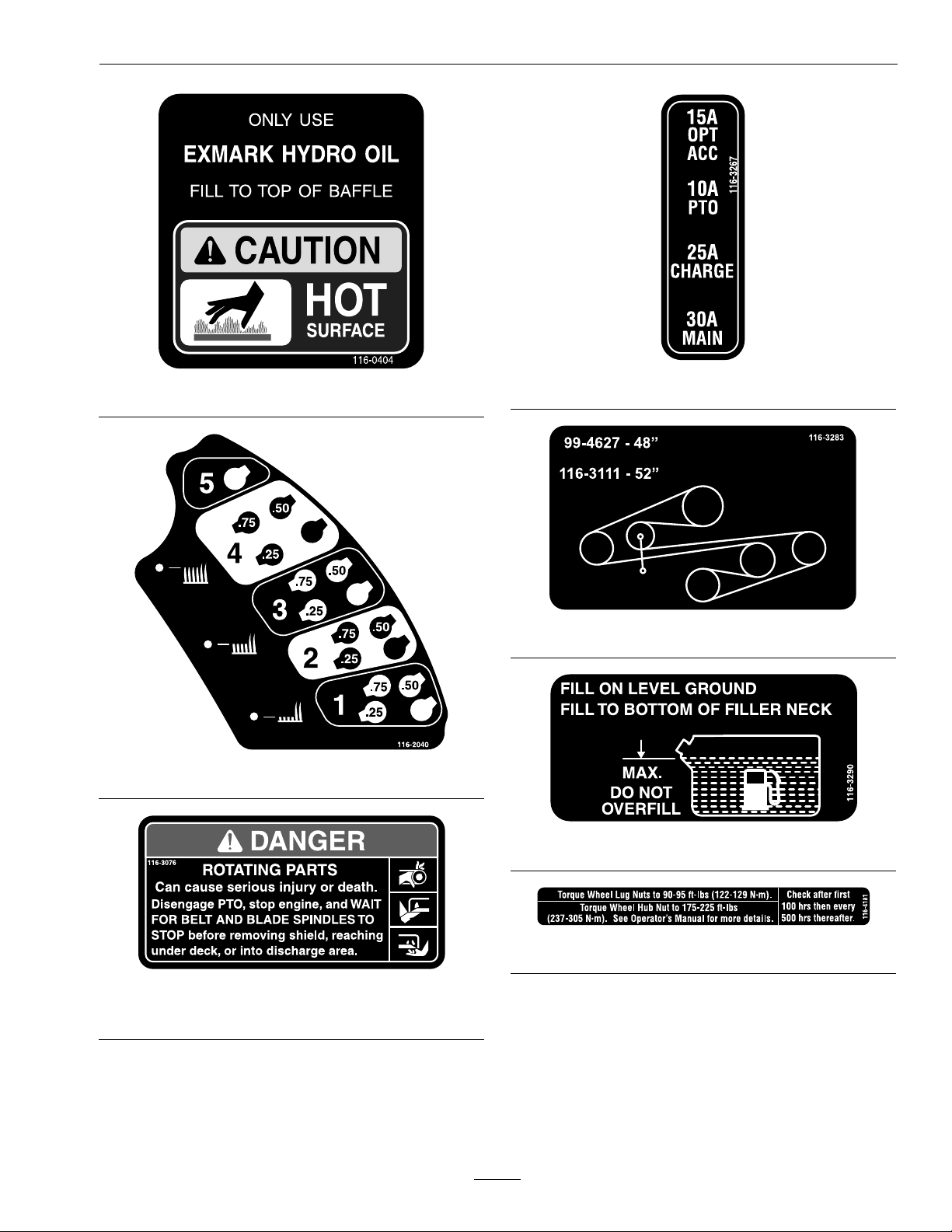

116-0404

116-2040

116-3267

116-3283

60InchModel

116-3290

116-4181

116-3076

11

Page 12

Safety

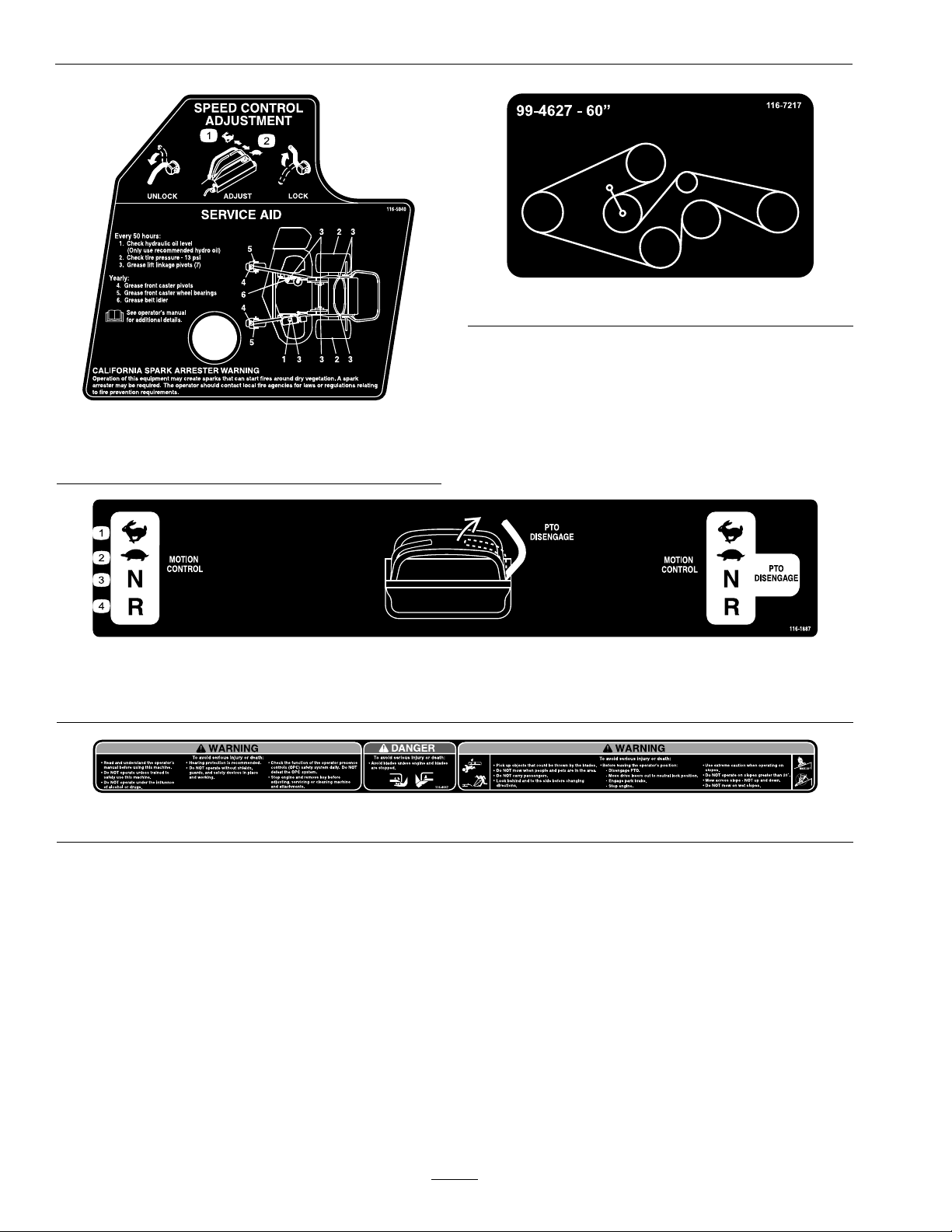

116-7217

116-5040

1.Forwardposition–faster

1.Fast3.Neutral

2.Slow

2.Backwardposition–

slower

116-1887

116-4647

4.Reverse

12

Page 13

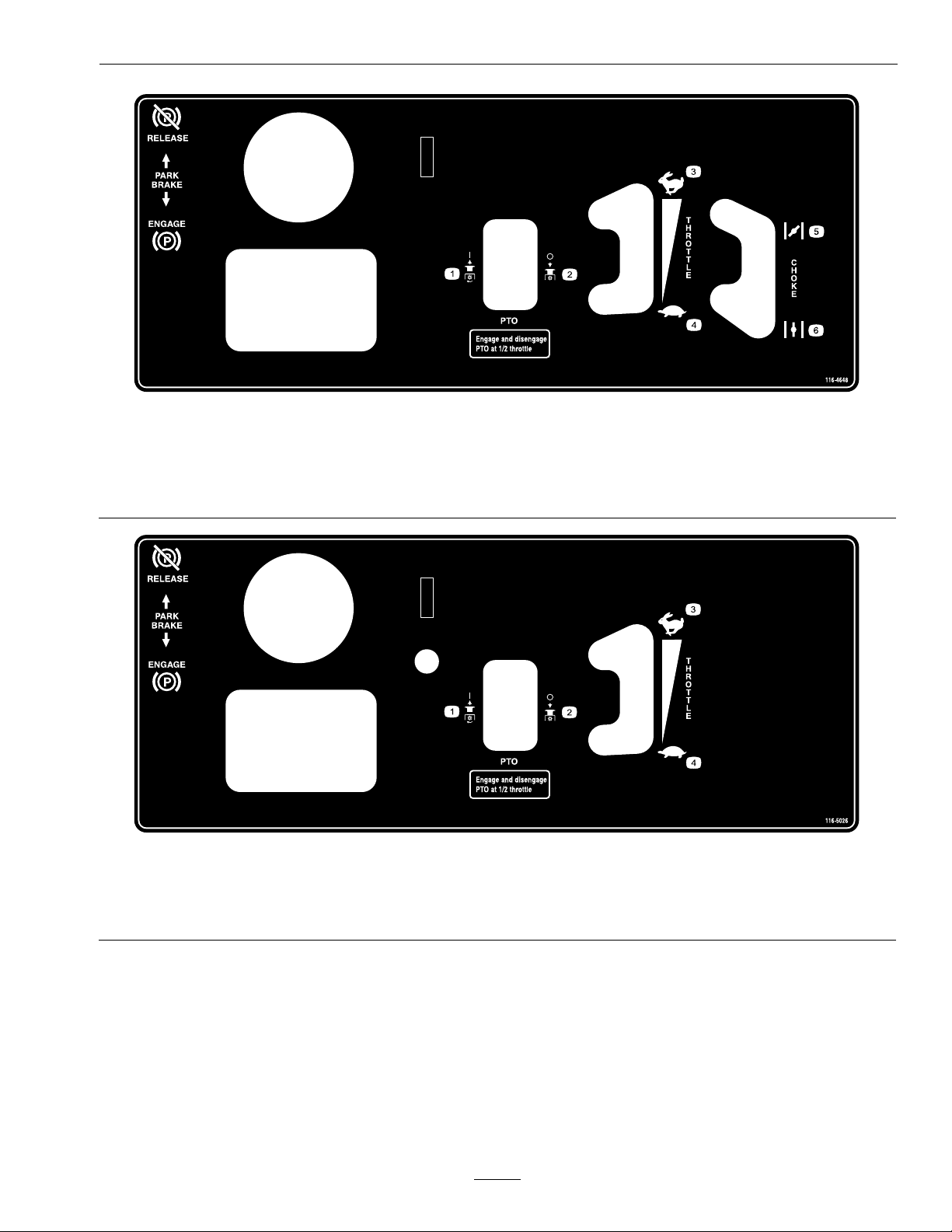

116-4648

AllUnitsExceptEFI

1.PTO-on4.Slow

2.PTO-off5.Choke-on

3.Fast

Safety

6.Choke-off

116-5026

EFIOnly

1.PTO-on

2.PTO-off4.Slow

13

3.Fast

Page 14

Specications

Specications

ModelNumbers

SerialNos:312,000,000andHigher

VT651KA484;VT691KA484CA;VT691KA524;VT691KA524CA;VT730EKC524;VT740EKC604;

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’ s

Manual

•EngineOilType:Exmark4–CyclePremium

EngineOil

•RPM:FullSpeed:3600±100RPM(NoLoad)

FuelSystem

•Capacity:8.0gal.(30.2L)

•FuelRecommendations:

–Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

–Oxygenatedfuelwithupto10%ethanolor

15%MTBEbyvolumeisacceptable.

–DoNotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanol

byvolume.Performanceproblemsand/or

enginedamagemayresultwhichmaynotbe

coveredunderwarranty.

–DoNotusegasolinecontainingmethanol.

–DoNotstorefueleitherinthefueltankor

fuelcontainersoverthewinterunlessafuel

stabilizerisused.

–DoNotaddoiltogasoline.

•FuelFilter:

–Kawasaki:

KawasakiP/N49019-7005

–KohlerEFI:

Kawasaki:15amps

KohlerEFI:20amps

•BatteryType:BCIGroupU1

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuses:

–30ampmainfuse

–25ampchargingsystemfuse

–10ampPTOfuse

–15ampaccessoryfuse

SafetyInterlockSystem

•LCDindicatorsappearfortheparkbrake,drive

levers,andoperatorpresenceinthemessage

displayonthefrontcontrolpanel.

Note:BecausethePTOmustbedisengaged

tostarttheengine,theLCDindicatorwillnot

illuminateatthistime.

•PTOmustbedisengagedandmotioncontrol

leversinneutraltostartengine.(Itisnot

necessaryfortheoperatortobeontheplatform

tostarttheengine.)

•Mowerbladeswillstopiftherightsidemotion

controlleverismovedorreleasedintothePTO

disengageposition.

•Enginewillstopifthemotioncontrolleversare

movedfromtheneutralpositionwiththepark

brakeengaged.

KohlerP/N2505042

•FuelShut-OffValve:1/4turnincrements

ElectricalSystem(ElectricStart)

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:

OperatorControls

SteeringControl:Fingertipdrivecontrollevers

provideindependentspeedcontrol,brakingand

neutraltoeachdrivewheelformovingforwardor

reverse,stopping,andpowerturning.

14

Page 15

Specications

Transmission

•TwoHydroGearvariabledisplacementhigh

efciencypumpsindependentlycoupledtotwo

highefciencyParker/Rosswheeldrivemotors.

•HydraulicOil:UseExmarkPremiumHydroOil.

•HydraulicOilCapacity:2.4qt.(2.2L)

•HydraulicFilterisreplaceablecartridgetype.

P/N109-4180:25microns,10psibypass

(Summeruseabove32°F(0°C))

P/N1-523541:40microns,18psibypass(Winter

usebelow32°F(0°C))

•Speeds:

–0-8.0mph(13km/hr)forward.

–0-4.0mph(6km/hr)reverse.

•Drivewheelreleasevalvesallowmachinetobe

movedwhenengineisnotrunning.

WheelDriveSystem

DrivewheelsaredirectcoupledtoParkerwheeldrive

motorswith1inch(25.4mm)taperedshaft.

•BladeSpindles:Solidsteelspindleswith1.00inch

(25.4mm)I.D.bearings.

•DeckDrive:

–Electricclutchmountedonengineshaft.

–Bladesdrivenbyonebelt(w/self-tensioning

idlers).

•Deck:Fulloatingdeckisattachedtosupport

frame,removableforservice.Deckdesignallows

forbagging,mulchingorsidedischarge.

•DeckDepth:

–48inchDeck:5.5inches(14.0cm)

–52inchDeck:5.5inches(14.0cm)

–60inchDeck:5.5inches(14.0cm)

•CuttingHeightAdjustment:

Adjustsfrom1inch(2.5cm)to5inches(12.7cm)

in1/4inch(6.4mm)increments

•MulchingKit:Optional

•Bagger:Optional

Tires&Wheels

DriveFrontCaster

Pneumatic

(Air-Filled)

Quantity

Tread

Size20x10.50–811x4.00-5

PlyRating

Pressure

22

K500

4

13psi

(90kPa)

CuttingDeck

•CuttingWidth:

–48inchDeck:48inches(121.9cm)

–52inchDeck:52inches(132.1cm)

–60inchDeck:60inches(152.4cm)

•Discharge:Side

•BladeSize:(3ea.)

–48inchDeck:16.25inches(41.3cm)

–52inchDeck:18.00inches(45.7cm)

–60inchDeck:20.50inches(52.1cm)

Dimensions

OverallWidth:

SemiPneumatic

Smooth

Deector

Up

Deector

Down

OverallLength:

PlatformUp60.5inches

Platform

Down

OverallHeight:

48inchDeck52inchDeck60inchDeck

50.0inches

(127.0cm)

48inch

Deck

51.8inches

(131.6cm)

59.6inches

(151.4cm)

48inch

Deck

(153.7cm)

74.0inches

(188.0cm)

50.0inches

(127.0cm)

52inch

Deck

56.3inches

(143.0cm)

64.8inches

(164.6cm)

52inch

Deck

60.5inches

(153.7cm)

74.0inches

(188.0cm)

60inch

Deck

63.9inches

(162.3cm)

72.8inches

(184.9cm)

60inch

Deck

62.4inches

(158.5cm)

75.9inches

(192.8cm)

50.0inches

(127.0cm)

15

Page 16

ProductOverview

TreadWidth:(OutsidetoOutsideof

Tires,Widthwise)

48inchDeck52inchDeck60inchDeck

46.5inches

(118.1cm)

46.5inches

(118.1cm)

50.5inches

(128.3cm)

CurbWeight:

48inchDeck52inchDeck60inchDeck

855lb

(388kg)

875lb

(397kg)

883lb

(401kg)

Note:Weightswillvaryslightlydependingonengine.

TorqueRequirements

BoltLocation

CutterHousingSpindle

Nut

BladeMountingBolt

(lubricatewithanti-seize)

Torque

130-160ft-lb

(176-217N-m)

50-60ft-lb(68-81N-m)

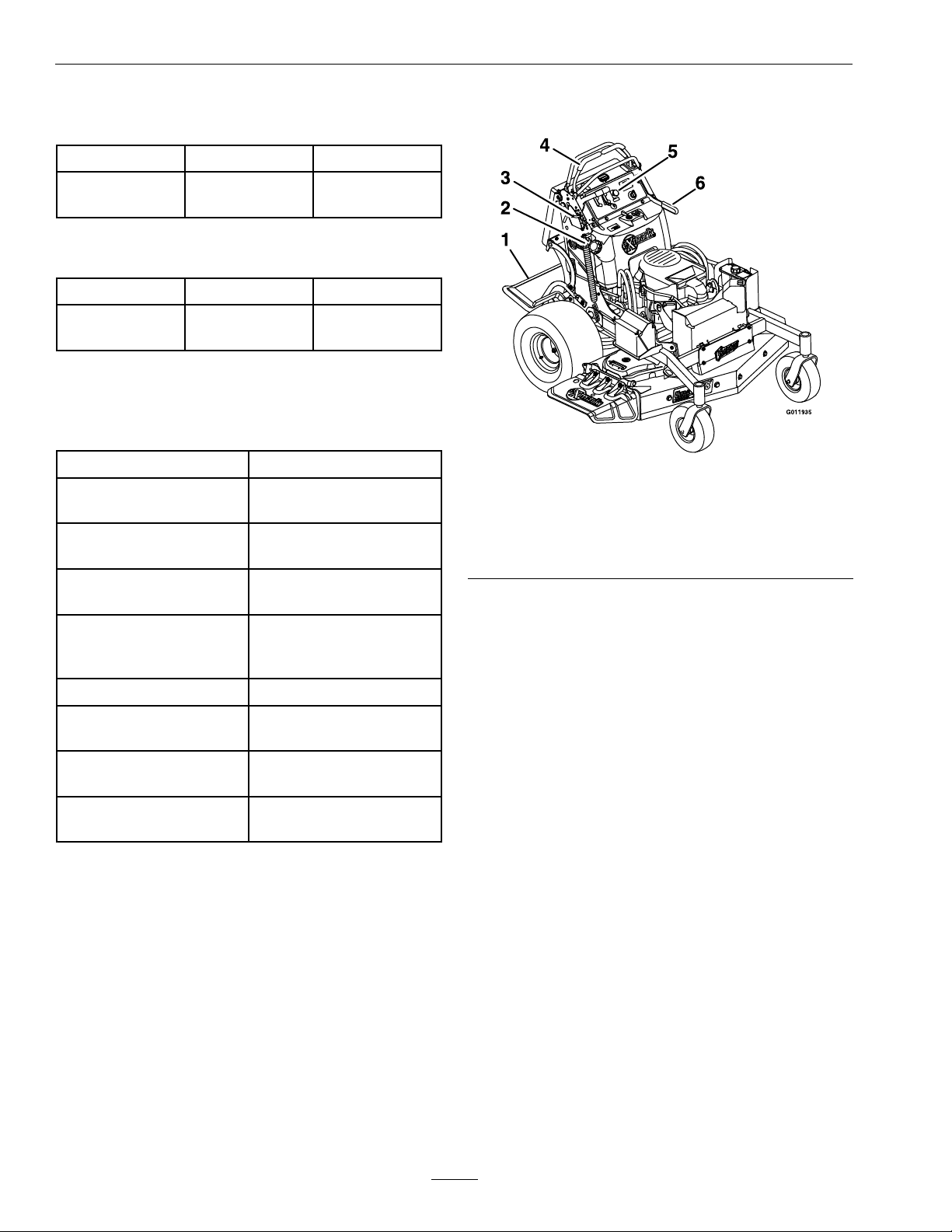

ProductOverview

Figure3

1.Platform

2.FuelCap5.EngineControls

3.Height-of-Cut

Adjustment

4.Motioncontrollevers

6.ParkBrakeLever

EngineDeck/MowerDeck

SupportMountBolts

EngineMountingBolts

Kawasaki

Kohler

WheelLugNuts

WheelHubNuts175-225ft-lb

WheelMotorMounting

Bolts

HydroPumpRelease

Valves

30-35ft-lb(41-47N-m)

17-23ft-lb(23-31N-m)

27-33ft-lb(37-45N-m)

90-95ft-lb(122-129N-m)

(237-305N-m)

67-83ft-lb(91-113N-m)

110-130in-lb(12-15N-m)

16

Page 17

Operation

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

MotionControlLevers

Themotioncontrollevers,locatedoneachsideofthe

topconsole,controltheforwardandreversemotion

ofthemachine.

Movingtheleversforwardorbackwardturns

thewheelonthesamesideforwardorreverse

respectively.Wheelspeedisproportionaltothe

amounttheleverismoved.

Thechokeisusedtoaidinstartingacoldengine.

Movingthechokeleverforwardwillputthechokein

the“ON”positionandmovingthechokelevertothe

rear,tothedetent,willputthechokeinthe“OFF”

position.DoNotrunawarmenginewithchokein

the“ON”position.

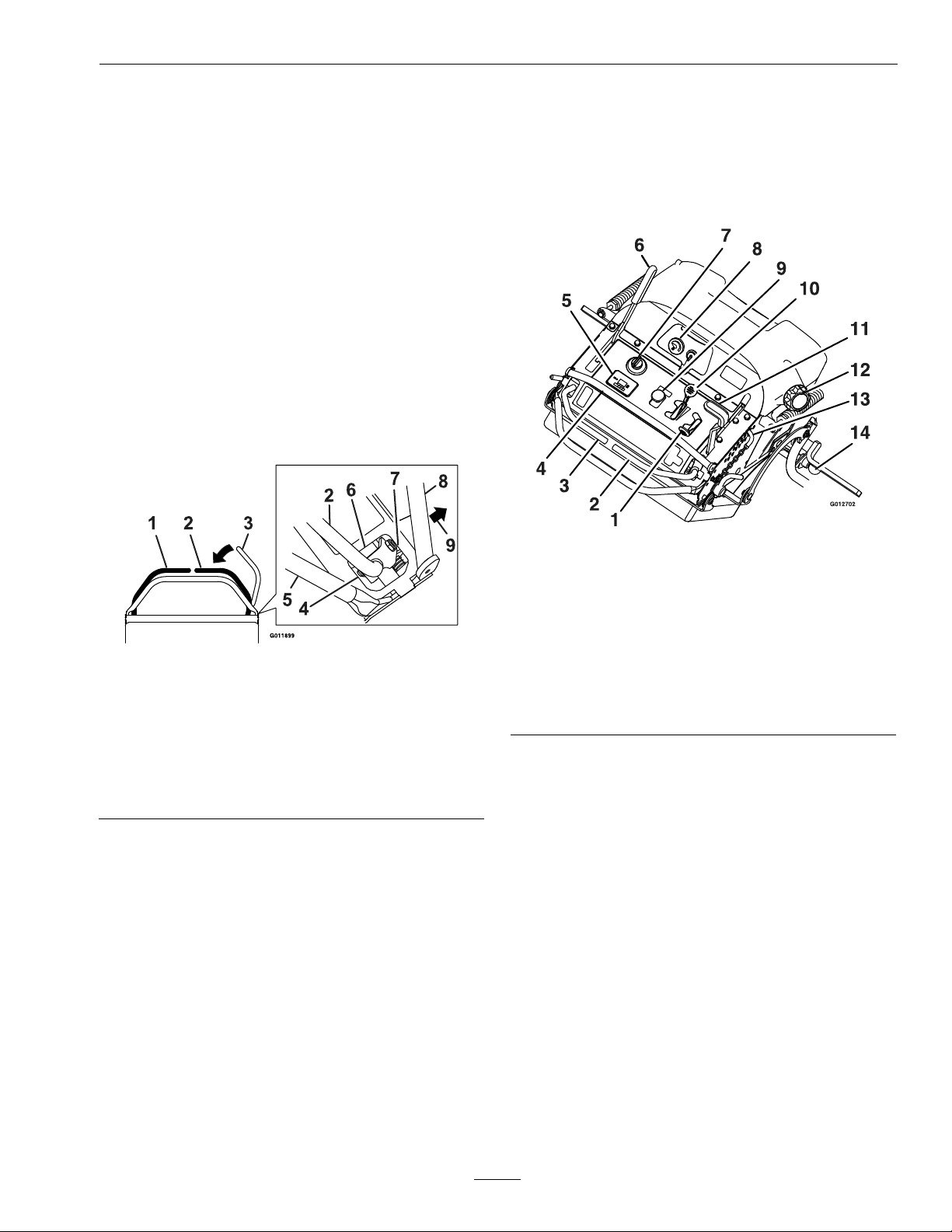

Figure5

Figure4

1.LHMotioncontrollever6.Neutral

2.RHMotioncontrollever7.Forward

3.RHMotioncontrol

leverinPTOdisengage

position

4.Reverse

5.Rearreferencebar

8.Frontreference/Speed

controlbar

9.Frontofunit

Whenthemotioncontrolleversareintheneutral

position,theLCDindicatorappearsinthemessage

displayonthefrontcontrolconsole(seeFigure5and

Figure7).

Whenthemotioncontrolleversareintheneutral

positionandtheRHmotioncontrolleverismoved

intothePTOdisengageposition,themowerblades

willdisengage.

ChokeControl(AllUnitsExcept

KohlerEFI)

Locatedonthefrontcontrolconsolerightofthe

PTOengagementswitch.

1.Throttle8.Fuelgauge

2.RHMotioncontrollever

3.LHMotioncontrollever

4.FrontReference/Speed

ControlBar

5.Messagedisplay12.Fuelcap

6.Parkbrakelever

7.Ignitionswitch

9.PTOengagementswitch

10.Choke

11.Decklifthandle

13.Height-of-cutpin

14.Platformlatch

ThrottleControl

LocatedontheRHsideofthefrontcontrolconsole

(redlever)(seeFigure5).

Thethrottleisusedtocontrolenginespeed.Moving

thethrottleleverforwardwillincreaseenginespeed

andmovingthethrottlelevertotherearwilldecrease

enginespeed.Movingthethrottleforwardintothe

detentisfullthrottle.

FrontReference/SpeedControlBar

Locatedinfrontofthemotioncontrollevers(see

Figure5).

Thefrontreference/speedcontrolbarcontrolsthe

maximumforwardspeedandisinnitelyvariable

fromapproximately4–8mph(6–13km/hr).

17

Page 18

Operation

ParkBrakeLever

Locatedonleftsideofunit,justtothefrontofthe

LHmotioncontrollever(seeFigure5).

Thebrakeleverengagesaparkingbrakeonthedrive

wheels.

Note:TheLCDindicatorappearsinthemessage

displayonthefrontconsolewhentheparkbrakeis

engaged(see

Figure5andFigure7).

Toengagethebrake,pulltheleverrearwardandto

therighttopositionintotheengagedposition.

Torelease,pullthebrakeleverbackandovertothe

left,positionintotheslotandpushtheleverforward.

Whenparkingonasteepslope,thewheelsmustbe

chockedorblockedinadditiontothebrakebeing

engaged.Theunitmustbetieddownandbrake

engagedwhentransporting.

Parkbrakemustbedisengagedbeforemovingmotion

controloutofneutralorenginewillkill.

IgnitionSwitch

disengaged.(Itisnotnecessaryfortheoperatorto

beontheplatform.)

HourMeter

LocatedontheLHsideofthefrontcontrolconsole

inthemessagedisplay(see

Thehourmeterrecordsthenumberofhoursthat

theenginehasrun.

1.LCDIndicators

2.Lowvoltageindicatorlight

3.Hour/Voltagedisplay

Figure5andFigure7).

Figure7

LocatedontheLHsideofthefrontcontrolconsole

Figure5).

(see

Theignitionswitchisusedtostartandstopthe

engine.Theswitchhasthreepositions“OFF”,“ON”

and“START”.Insertkeyintoswitchandrotate

clockwisetothe“ON”position.Rotateclockwiseto

thenextpositiontoengagethestarter(keymustbe

heldagainstspringpressureinthisposition).Allow

thekeytoreturntothe“ON”positionimmediately

aftertheenginestarts.

Figure6

1.Off3.Start

2.On

Note:Tostarttheengine,placetheLHmotion

controlleverinneutral,theRHmotioncontrol

inPTOdisengageposition,andthePTOswitch

Thehourmeterisrecordingwhenthedecimalpoint

isashinginHour/Voltagedisplay.

Hoursaredisplayedwhenthekeyisofforwhenthe

machineisrunning.

Note:Iftheignitionkeyisturnedtothe“ON”

positionforafewsecondsbeforecrankingtheengine,

thebatteryvoltagewilldisplayintheareawherethe

hoursarenormallydisplayed.

Note:TheLCDindicatorsappearwheneach

controlmeetsthe“safetostart”mode.Becausethe

PTOmustbedisengagedtostarttheengine,the

LCDindicatorwillnotilluminateatthistime.

FuelShut-OffValve

LocatedontheRHsideofthecontroltowerbehind

thekneecushionforKawasakiunits.Locatedon

theLHsideofthemachine,towardstherearofthe

engine,onKohlerunits.

Thefuelshut-offvalveisusedtoshutoffthefuel

whenthemachinewillnotbeusedforafewdays,

duringtransporttoandfromthejobsite,andwhen

parkedinsideabuilding.

Alignvalvehandlewiththefuellinetoopen.Rotate

90°toclose.

18

Page 19

Operation

FuelGauge

Locatedonthetopleftsideofthetank(seeFigure5).

Thefuelgaugemonitorstheamountoffuelinthe

tank.

DriveWheelReleaseValves

Locatedontherightfrontcornerofthehydrostatic

pumps.

Drivewheelreleasevalvesareusedtoreleasethe

hydrostaticdrivesystemtoallowthemachinetobe

movedbyhandwithouttheenginerunning.

Witha5/8wrench,turnbothvalvesoneturn

counterclockwisetoreleasethedrivesystem.

Turnclockwisetoresetthedrivesystem.Torqueto

110-130in-lb(12-15N-m).DoNotovertighten.

DoNottowmachine.

PTOEngagementSwitch

Locatedonfrontcontrolpanel(seeFigure5).

Pullthehandlerearwardandtotherighttolatch

thecuttingdeckintotheraisedtransportposition

(

Figure6).

ElectronicControlUnitMalfunction

Indicator

KohlerEFIUnitsOnly:

Theelectroniccontrolunit(ECU)continuously

monitorsoperationoftheEFIsystem.Ifaproblem

orfaultwithinthesystemisdetected,themalfunction

indicatorlight(MIL)isilluminated.TheMILis

thelightlocatedintheconsolepaneltotheleftof

thePTOswitch.Followthetroubleshootingsteps

outlinedintheKohlerengineoperator’smanualifthe

MILisilluminated.

Pre-Start

Fillfueltankonlevelground.SeeFuel

RecommendationsintheSpecicationssectionfor

additionalgasolineinformation.

Switchmustbepulledout(up)toengagetheblades.

Switchispushedintodisengagetheblades.

TheLCDindicatorwillappearwhenthePTOswitch

isengaged(see

Figure7).

LowVoltageIndicator

Locatedonthefrontcontrolpanelinthemessage

display(seeFigure5andFigure7).

Alowvoltagecondition(lessthan12.3volts)exists

whenthelowvoltageindicatorlightappearsonthe

messagedisplaywhiletheengineisrunning.

Iftheignitionkeyisturnedtothe“ON”positionfor

afewsecondsbeforecrankingtheengine,thebattery

voltagewilldisplayintheareawherethehoursare

normallydisplayed.

Note:Theindicatornormallyappearswhenthe

engineisoffandthekeyswitchisturnedtothe

“ON”position.

DeckLiftHandle

LocatedontheRHofthefrontcontrolpanel.

Pullthehandlerearwardtoraisethecuttingdeck.

Allowthehandletomoveforwardtolowerthe

cuttingdecktothecutheightthathasbeenset.

DoNotaddoiltogasoline.

DoNotoverllfueltank.Fillthefueltanktothe

bottomofthellerneck.Theemptyspaceinthe

tankallowsgasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineoremission

system.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

OpentheFuelShut-OffValve

Rotatethevalveandalignwiththefuellinetoopen.

StartingtheEngine

1.LeavetheLHmotioncontrolleverinneutraland

theRHleverinthePTOdisengageposition(see

Figure4).

2.Pulltheparkingbrakerearwardandovertothe

righttoengagetheparkingbrake.

19

Page 20

Operation

3.Pushin(down)onthePTOswitchtothe

“disengage”position.

4.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

5.Onacoldengine,pushthechokeleverforward

intothe“ON”position(exceptKohlerEFIunits).

Onawarmengine,leavethechokeinthe“OFF”

position.

6.Turnignitionswitchtothe“START”position.

Releasetheswitchassoonastheenginestarts.

Important:DoNotcranktheengine

continuouslyformorethantensecondsata

time.Iftheenginedoesnotstart,allowa60

secondcool-downperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor.

7.Ifthechokeisinthe“ON”position,gradually

returnchoketothe“OFF”positionastheengine

warmsup.

PTOEngagement

DANGER

3.Movetherightsidemotioncontrollevertothe

center,operateposition.

4.Continueholdingtherightsidemotioncontrol

leverinthecenter,operatepositionandpullup

onthebladecontrolswitch(PTO)andrelease.

Theclutchshouldengageandthemowerblades

beginrotating.

5.Placethethrottleinthe“FAST”positiontobegin

mowing.

DisengagingthePTO

1.Setthethrottlemidwaybetweenthe“SLOW”and

“FAST”positions.

2.PushdownonthePTOswitchtodisengagethe

blades.

Note:ThePTOwillbedisengagedbyreleasing

therightsidemotioncontrolleverandallowingit

tospringoutwardtothePTOdisengageposition.

ThePTOwillnotre-engagewhentheRHmotion

controlleverismovedoutofthePTOdisengage

positionwithoutpullinguponthePTOswitch.

TofullydisengagethePTO,continuetopushthe

switchdownward.

Therotatingbladesunderthemowerdeckare

dangerous.Bladecontactcancauseserious

injuryorkillyou.

DoNotputhandsorfeetunderthemoweror

mowerdeckwhenthebladesareengaged.

DANGER

Anuncovereddischargeopeningwillallow

objectstobethrowninanoperator’sor

bystander’sdirection.Also,contactwiththe

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryordeath.

Neveroperatethemowerwiththedischarge

deectorraised,removed,oralteredunlessthere

isagrasscollectionsystemormulchkitinplace

andworkingproperly.

ThePTOswitchengagesthecuttingblades.Besure

allpersonsareclearofmowerdeckanddischarge

areabeforeengagingthePTO .

1.Setthrottleto“MIDW AY”position.

StoppingtheEngine

1.Bringtheunittoafullstop.

2.Movethemotioncontrolleverstotheneutral

position;movetheRHcontrolleverouttothe

PTOdisengageposition.

3.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

4.PushdownonthePTOswitchtodisengagethe

blades.

5.Engagetheparkingbrake.

6.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

7.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

8.Closethefuelshut-offvalvewhenthemachine

willnotbeinuseforafewdays,when

transporting,orwhentheunitisparkedinside

abuilding.

2.Releasetheparkingbrake.

20

Page 21

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioningone

levertoomuchaheadoftheother.Operatormay

losecontrolofthemachine,whichmaycause

damagetothemachineorinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Important:Tobeginmovement(forwardor

backward),thebrakelevermustbedisengaged

(pushedforward)beforethemotioncontrol

leverscanbemovedortheenginewillstop.

WhentheRHmotioncontrolleverispositioned

fullyoutward(apart),thedrivesystemisinthePTO

disengageposition(

Note:The“N”LCDindicatorappearswhenthe

RHleverisinthePTOdisengageposition.

WhentheRHmotioncontrolleverismoveddirectly

inward(together)thedrivesystemisintheneutral

operateposition.

Figure8).

Operation

Figure9

Toturnleftorright,pullthemotioncontrollever

backtowardneutralinthedesiredturndirection.

Themachinewillmovefasterthefartherthe

motioncontrolleversaremovedfromtheneutral

position.

Figure8

1.LHMotioncontrollever6.Neutral

2.RHMotioncontrollever7.Forward

3.RHMotioncontrol

leverinPTOdisengage

position

4.Reverse

5.Rearreferencebar

8.Frontreference/Speed

controlbar

9.Frontofunit

DrivingForward

1.Makesurethemotioncontrolleversareinthe

neutralposition.

2.Releasetheparkingbrake.

3.Tomoveforwardinastraightline,moveboth

leversforwardwithequalpressure.

4.Tostop,positionbothmotioncontrolleversin

theneutraloperateposition.

DrivinginReverse

1.Movethemotioncontrolleverstotheneutral

operateposition.

2.Tomoverearwardinastraightline,slowlymove

bothleversrearwardwithequalpressure.

21

Page 22

Operation

Figure10

Toturnleftorright,releasepressureonthe

motioncontrollevertowardthedesiredturn

direction.

3.Tostop,positionbothmotioncontrolleversin

theneutraloperateposition.

AdjustingtheFrontReference/Speed

ControlBar

Adjustthefrontreference/speedcontrolbarfor

desiredmaximumforwardspeed.

1.Stopthemachineandmovethemotioncontrol

leverstotheneutralposition.

2.DisengagethePTO.

3.Unlockthehandlesonbothsidesofthecontrol

towerbypullingoutward(see

Figure11).

Figure11

1.Frontofthemachine

2.Controltower

3.Unlock6.Lock

4.Forwardposition—

faster

5.Backwardposition—

slower

4.Movethebarforwardtoobtainthefastestspeed.

Movethebarbackwardtoobtaintheslowest

speed.

5.Onbothsides,rotateandpushthehandlesinward

tolockthehandlesagainstthecontroltower.

Important:Makesurethehandlesarelocked

inplacesothefrontreference/speedcontrol

bardoesnotmoveduringoperation.

OperatingthePlatform

Themachinecanbeusedwiththeplatforminthe

upordownposition.Itistheoperator'spreference

onwhichpositiontouse.

22

Page 23

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenloweringandraisingtheoperator

platform.Theplatformmaysuddenlydropifnot

supportedwhenthelatchpinispulledout.

•DoNotputyourhandsorngersinthe

platformpivotareawhenloweringorraising

theoperatorplatform.

•Makesuretheplatformissupportedwhen

thelatchpinispulledout.

•Makesurethelatchsecurestheplatform

whenfoldingitintheupposition.Pushit

tightagainstthecushionforthelatchpinto

lockintoplace.

OperatingtheMachinewiththe

PlatformUp

Operatingthemachinewiththeplatformupis

recommendedwhen:

•Mowingneardrop-off's

•Mowingsmallareaswherethemachineistoolong

•Areaswithlowoverhangingbranchesorobstacles

•Loadingthemachinefortransport

•Unloadingthemachineaftertransport

•Drivinguporbackingdownslopesorramps.

Operation

Figure12

1.Platform

2.Raiseupward

3.Latchpinknobsnapsinward

OperatingtheMachinewiththe

PlatformDown

Operatingthemachinewiththeplatformdownis

recommendedwhen:

•Mowingmostareas

•Drivingdownslopes

Tolowertheplatform,pushtheplatformforward

againstthecushiontoreleasepressureonthelatch

pin,pulltheknoboutward,andlowertheplatform

Figure13).

(see

•Turningintightareaswhereplatformmaycontact

obstacles.

Toraisetheplatform,pullthebottomupwardand

pushittightagainstthecushion.Thelatchpinknob

willsnapinwardtolocktheplatformintoplace(see

Figure12).

Figure13

1.Pulllatchpinknoboutward

2.Platform

3.Lower

23

Page 24

Operation

AdjustingtheCuttingHeight

Thecuttingheightofthemowerdeckisadjusted

from1to5inches(2.5cmto12.7cm)in1/4inch

(6.4mm)increments.

1.Stopthemachineandmovethemotioncontrol

leverstotheneutralposition.

2.DisengagethePTO.

3.Raiseandlockthedecktothe5inch(12.7cm)

transportposition.

Thedeckisraisedbypullingthedecklifthandle

rearwardandtotherighttoplaceitintothe

transportlockposition.

1.Heightadjustmentpin

2.Heightofcutholes

Transporting

Figure15

3.Decklifthandle

Figure14

1.Transportlockposition

2.RHMotioncontrollever

3.Frontreference/speed

controlbar

4.Decklifthandle

Note:Whenchangingthecuttingheight

positions,alwayscometoacompletestop

anddisengagethePTO.

4.Inserttheheightadjustmentpinintothehole

correspondingtothedesiredcuttingheight.

Seethedecalonthesideofthedeckliftplatefor

cutheights(reference

Figure15).

5.Pullthedecklifthandlerearwardandtotheleft

andslowlyallowthedecktolowertothecutting

height.

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Securely

fastenthemachinetothetrailerortruckwithstraps,

chains,cable,orropes.Besurethatthetrailerortruck

hasallnecessarylightingandmarkingasrequiredby

law .Secureatrailerwithasafetychain.

CAUTION

Thisunitdoesnothaveproperturnsignals,

lights,reectivemarkings,oraslowmoving

vehicleemblem.Drivingonastreetorroadway

withoutsuchequipmentisdangerousand

canleadtoaccidentscausingpersonalinjury.

Drivingonastreetorroadwaywithoutsuch

equipmentmayalsobeaviolationofStatelaws

andtheoperatormaybesubjecttotrafctickets

and/ornes.

DoNotdriveaunitonapublicstreetorroadway.

24

Page 25

WARNING

Loadingaunitonatrailerortruckincreases

thepossibilityofbackwardtip-over.Backward

tip-overcouldcauseseriousinjuryordeath.

•Useextremecautionwhenoperatingaunit

onaramp.

•Useonlyasingle,fullwidthramp;DoNot

useindividualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurface

widerthantheunit.

•DoNotexceeda20degreeanglebetween

rampandgroundorbetweenrampandtrailer

ortruck.

•Avoidsuddenaccelerationwhiledrivingunit

uparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

Operation

LoadingaUnit

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinstead

ofindividualrampsforeachsideoftheunit.With

theplatformup,afullwidthrampprovidesasurface

towalkonbehindtheunit.Ifitisnotpossibletouse

onefullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Rampshouldbelongenoughsothattheangles

betweentherampandthegroundandtheramp

andthetrailerortruckdonotexceed20degrees.A

steeperanglemaycausemowerdeckcomponentsto

getcaughtastheunitmovesfromramptotrailer

ortruck.Steeperanglesmayalsocausetheunitto

tipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideofthe

slopeandtherampextendsuptheslope.Thiswill

minimizetherampangle.Thetrailerortruckshould

beaslevelaspossible.

Important:DoNotattempttoturntheunit

whileontheramp,youmaylosecontroland

driveofftheside.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdownaramp.

Bothmaneuverscancausetheunittotipbackward.

25

Page 26

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecouldseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitch,engage

parkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenance.Also

pushthewire(s)asidesoitdoesnotaccidentally

contactthesparkplug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst100hours

Aftertherst250hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthewheelhubtorquespecication.

•Checkthewheellugnuts.

•Changethehydrauliclteranduid.

WARNING

Theenginecanbecomeveryhot.T ouchingahot

enginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheenginearea.

Beforeeachuseordaily

Every50hours

Every80hours

Every100hours

Every160hours

Every250hours

•Checktheengineoillevel.

•Checkthemowerblades.

•Checkthesafetyinterlocksystem.

•Checkforloosehardware.

•Cleantheengineandexhaustsystemarea.

•Cleanthegrassanddebrisbuild-upfromthemachineandcuttingdeck.

•Cleanthegrassbuild-upfromunderthedeck.

•Checkthehydraulicoillevel.

•Checkthetirepressures.

•Checktheconditionofthebelts.

•Greasetheliftlinkagepivots.

•Checksparkarrester(ifequipped).

•Removeengineshroudsandcleancoolingns.

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Checkthesparkplugs.

•Replacetheprimaryaircleanerelement—checksecondaryaircleanerelement;replaceif

dirty.(Mayneedmoreoftenundersevereconditions.SeetheEnginemanualforadditional

information.)

26

Page 27

Maintenance

MaintenanceService

Interval

Every500hours

Yearly

MaintenanceProcedure

•Replacethesecondaryaircleanerelement.(Mayneedmoreoftenundersevereconditions.

SeetheEnginemanualforadditionalinformation.)

•Changethehydrauliclteranduid(Every250hours/yearlyifusingMobil115W50)

•Checkthewheelhubtorquespecication.

•Checkthewheellugnuts.

•Greasethefrontcasterpivots.

•Greasethedeckbeltidlerpivot.

•Lubricatethecasterwheelhubs.

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Cleanareaarounddipstick.Removedipstickand

wipeoiloff.Reinsertthedipstickandpushitall

thewaydownintothetube.DoNotscrewinto

place.Removethedipstickandreadtheoillevel.

4.Iftheoillevelislow,wipeofftheareaaroundthe

oilllcap,removecapandaddoiltothe“FULL”

markonthedipstick.Exmark4-CyclePremium

EngineOilisrecommended;refertotheEngine

Owner'smanualforanacceptablealternative.Do

Notoverll.

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

CheckBatteryCharge

ServiceInterval:Asrequired

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

Allowingbatteriestostandforanextendedperiodof

timewithoutrechargingthemwillresultinreduced

performanceandservicelife.Topreserveoptimum

batteryperformanceandlife,rechargebatteriesin

storagewhentheopencircuitvoltagedropsto12.4

volts.

Note:Topreventdamageduetofreezing,battery

shouldbefullychargedbeforeputtingawayfor

winterstorage.

Checkthevoltageofthebatterywithadigital

voltmeterorwiththemessagedisplay.Iftheignition

keyisturnedtothe“on”positionforafewseconds,

thebatteryvoltagewillbedisplayedintheareawhere

thehoursarenormallydisplayed.Locatethevoltage

readingofthebatteryinthetableandchargethe

batteryfortherecommendedtimeintervaltobring

thechargeuptoafullchargeof12.6voltsorgreater.

Important:Makesurethenegativebatterycable

isdisconnectedandthebatterychargerusedfor

chargingthebatteryshouldhaveanoutputof

16voltsand7ampsorlesstoavoiddamaging

thebattery(seechartforrecommendedcharger

settings).ThisisespeciallyimportantonKohler

EFI(ElectronicFuelInjection)units.Failureto

dosomaydamagetheECU(ElectronicControl

Unit).

Voltage

Reading

12.6or

greater

12.4–12.675–100%

12.2–12.450–75%

Percent

Charge

100%

Maximum

Charger

Settings

16volts/7

amps

16volts/7

amps

16volts/7

amps

Charging

Interval

No

Charging

Required

30Minutes

1Hour

27

Page 28

Maintenance

Voltage

Reading

12.0–12.225–50%

11.7–12.00–25%

11.7orless

Percent

Charge

0%

Maximum

Charger

Settings

14.4volts/4

amps

14.4volts/4

amps

14.4volts/2

amps

Charging

Interval

2Hours

3Hours

6Hoursor

More

Important:ForKohlerEFIunits:Unplugthe

harnessfromtheECUbeforeperformingany

weldingontheequipment.

RecommendedJump

StartingProcedure

ServiceInterval:Asrequired

1.Checktheweakbatteryforterminalcorrosion

(white,green,orblue“snow”),itmustbecleaned

offpriortojumpstarting.Cleanandtighten

connectionsasnecessary.

CAUTION

Corrosionorlooseconnectionscancause

unwantedelectricalvoltagespikesatanytime

duringthejumpstartingprocedure.

CAUTION

Connectingthejumpercablesincorrectly

(wrongpolarity)canimmediatelydamagethe

electricaland/orEFIsystem.

Becertainofbatteryterminalpolarityand

jumpercablepolaritywhenhookingup

batteries.

Note:Thefollowinginstructionsareadapted

fromtheSAEJ1494Rev.Dec.2001–Battery

BoosterCables–SurfaceV ehicleRecommended

Practice(SAE–SocietyofAutomotive

Engineers).

WARNING

Batteriescontainacidandproduceexplosive

gases.

•Shieldtheeyesandfacefromthebatteries

atalltimes.

•DoNotleanoverthebatteries.

Note:Besuretheventcapsaretightandlevel.

Placeadampcloth,ifavailable,overanyvent

capsonbothbatteries.Besurethevehiclesdo

nottouchandthatbothelectricalsystemsare

offandatthesameratedsystemvoltage.These

instructionsarefornegativegroundsystemsonly .

DoNotattempttojumpstartwithlooseor

corrodedbatteryterminalsordamagetothe

engineorEFImayoccur.

DANGER

Jumpstartingaweakbatterythatiscracked,

frozen,haslowelectrolytelevel,oran

open/shortedbatterycell,cancausean

explosionresultinginseriouspersonalinjury.

DoNotjumpstartaweakbatteryifthese

conditionsexist.

2.Makesuretheboosterisagoodandfullycharged

leadacidbatteryat12.6voltsorgreater.Use

properlysizedjumpercables(4to6AWG)with

shortlengthstoreducevoltagedropbetween

systems.Makesurethecablesarecolorcodedor

labeledforthecorrectpolarity .

3.Connectthepositive(+)cabletothepositive(+)

terminalofthedischargedbatterythatiswiredto

thestarterorsolenoidasshownin

Figure16.

28

Page 29

Figure16

1.Positive(+)cableondischargedbattery

2.Positive(+)cableonboosterbattery

3.Negative(–)cableontheboosterbattery

4.Negative(–)cableontheengineblock

5.Boosterbattery

6.Dischargedbattery

7.Engineblock

Maintenance

6.Raisethecushionandslideitontothepinson

bothsidesofthemachine(

7.Pushtheplasticslidesintothecushionbracket

andsecurethemwithahairpin.

Figure17).

4.Connecttheotherendofthepositivecabletothe

positiveterminaloftheboosterbattery.

5.Connecttheblacknegative(–)cabletotheother

terminal(negative)oftheboosterbattery.

6.MAKETHEFINALCONNECTIONON

THEENGINEBLOCKOFTHESTALLED

VEHICLE(NOTTOTHENEGATIVEPOST)

AWAYFROMTHEBATTERY .STANDBACK.

7.Startthevehicleandremovethecablesinthe

reverseorderofconnection(theengineblock

(black)connectionisthersttodisconnect).

ReleasetheCushionforRear

Access

ServiceInterval:Asrequired

Thecushioncanbereleasedforrearaccesstothe

machineformaintenanceoradjustment.

1.Lowertheplatform.

2.Removethehairpinsoneachsideofthecushion.

3.Pushtheplasticslidestotheinside.

4.Removethecushionandlowerittotheplatform.

5.Performanymaintenanceoradjustmentonthe

machine.

Figure17

1.Plasticslide

2.Cushionbracketwithkeyhole

3.Hairpin

CheckMowerBlades

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Liftdeckandsecureinraisedpositionasstatedin

theCleanGrassBuild-UpUnderDecksection.

3.Inspectbladesandsharpenorreplaceasrequired.

4.Reinstalltheblades(iftheywereremoved)inthe

followingorder:

29

Page 30

Maintenance

A.Installbushingthroughbladewithbushing

angeonbottom(grass)sideofblade.

Figure18

1.Installbushinginbladepriortoinstallingbushingin

spindle.

B.Installbushing/bladeassemblyintospindle.

WARNING

Incorrectinstallationofthebladeor

componentsusedtoretainthebladecan

bedangerous.Failuretousealloriginal

componentsandassembledasshowncould

allowabladeorbladecomponenttobe

thrownoutfromunderthedeckresultingin

seriouspersonalinjuryordeath.

AlwaysinstalltheoriginalExmarkblades,

bladebushings,andbladeboltsasshown.

CheckSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitches

beforeoperatingthemachine.

Figure19

1.Usewrenchherefor

bladeinstallation.This

nuthasbeentorquedto

130-160ft-lb(176–217

N-m)

2.Torqueto50-60ft-lb

(68-81N-m)Apply

lubricanttothreads

asneededtoprevent

seizing.Copper-based

anti-seizepreferable.

Greaseacceptable

substitute.

C.Applylubricanttothreadsofbladeboltas

neededtopreventseizing.Copper-based

anti-seizepreferable.Greaseacceptable

substitute.Installbladeboltngertight.Place

wrenchonthetopspindlenutthentorquethe

bladeboltsto50-60ft-lb(68-81N-m).

UnderstandingtheSafetyInterlockSystem

Thesafetyinterlocksystemisdesignedtopreventthe

mowerbladesfromrotatingunless:

•Therightsidemotioncontrolleverismovedto

thecenter,operatingposition.

•Thebladecontrolswitch(PTO)ispulledon.

Thesafetyinterlocksystemisdesignedtostop

themowerbladesifyoumoveorreleasetheright

sidemotioncontrolleverintothePTOdisengage

position.

•Therightsidemotioncontrolleverismovedto

thecenter,operatingposition,theparkingbrake

isengaged,andthebladecontrolswitch(PTO)is

pulledon.

CheckingtheSafetyInterlockSystem

1.Starttheengine.

2.Settheparkingbrake.

3.Movethemotioncontrolleversforward.

Theengineshouldinitiateshutdownafter

momentarypause.

4.Starttheengineandreleasetheparkingbrake.

30

Page 31

Maintenance

5.Movetherightsidemotioncontrollevertothe

center,operatingposition.

6.Continueholdingtherightsidemotioncontrol

leverinthecenter,operatingpositionandpullup

onthebladecontrolswitch(PTO)andrelease.

Theclutchshouldengageandthemowerblades

beginrotating.

7.Moveorreleasetherightsidemotioncontrol

leverintotheneutralposition.Theblades

shouldstoprotatingandtheengineshould

continuerunning.

8.Pushthebladecontrolswitchdownandmove

therightsidemotioncontrollevertothecenter,

operatingposition.

9.Continueholdingtherightsidemotioncontrol

leverinthecenter,operatingpositionandpullup

onthebladecontrolswitch(PTO)andrelease.

Theclutchshouldengageandthemowerblades

beginrotating.

10.Pushthebladecontrolswitch(PTO)downtothe

offposition.Thebladesshouldstoprotating.

11.Withtheenginerunning,pullupthebladecontrol

switch(PTO)andreleasewithoutholdingright

sidemotioncontrollevertothecenter,operating

position.Thebladesshouldnotrotate.

aircleanerelement.(May

needmoreoftenunder

severeconditions.See

theEnginemanualfor

additionalinformation.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.SeetheEngineOwner'sManualformaintenance

instructions.

ChangeEngineOil

ServiceInterval:Aftertherst5hours

Every100hours(May

needmoreoftenunder

severeconditions.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Drainoilwhileengineiswarmfromoperation.

3.Theoildrainhoseassemblyislocatedontheleft

sideoftheengine.

Placepanundermachinetocatchoil.Removeoil

drainplug.Allowoiltodrainandreplaceoildrain

plug.Torqueplugto20-24ft-lb(27-33N-m).

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

ServiceAirCleaner

ServiceInterval:Every250hours—Replace

theprimaryaircleaner

element—check

secondaryaircleaner

element;replaceifdirty.

(Mayneedmoreoften

undersevereconditions.

SeetheEnginemanualfor

additionalinformation.)

Every500hours—

Replacethesecondary

4.ReplacetheoillterpertheEngineOwner's

Manual.Cleanaroundtheoillterandcarefully

removethelterbyunscrewingit.Makesureno

oildrainsontothebeltdriveorclutchthrough

theholesintheenginedeck.Beforethenew

lterisinstalled,applyathincoatingofExmark

4–CyclePremiumEngineOilonthesurfaceof

therubberseal.Turnlterclockwiseuntilrubber

sealcontactsthelteradapter,thentightenlter

anadditional2/3to3/4turn.

5.Cleanaroundoilllcapandremovecap.Fillto

speciedcapacityandreplacecap.

6.UseoilrecommendedintheCheckEngineOil

Levelsection.DoNotoverll.Starttheengine

andcheckforleaks.Stopengineandrecheckoil

level.

7.Wipeupanyspilledoilfromenginedeck

mountingsurfaces.

CheckHydraulicOilLevel

ServiceInterval:Every50hours

31

Page 32

Maintenance

1.Stopengineandwaitforallmovingpartstostop,

andremovekey.Engageparkingbrake.

2.Cleanareaaroundhydraulicreservoircapand

removecap.Oillevelshouldbetothetopofthe

bafeinsidethetank.Ifnot,addoil.UseExmark

PremiumHydroOil.Replacehydraulicreservoir

capandtightenuntilsnug.DoNotovertighten.

Note:Thebafeislabeled“HOT”and

“COLD”.Theoillevelvarieswiththe

temperatureoftheoil.The“HOT”levelshows

thelevelofoilwhenitisat225°F(107°C).The

“COLD”levelshowstheleveloftheoilwhen

itisat75°F(24°C).Filltotheappropriatelevel

dependinguponthetemperatureoftheoil.For

example:Iftheoilisabout150°F(65°C),llto

halfwaybetweenthe“HOT”and“COLD”levels.

Iftheoilisatroomtemperature(about75°F

(24°C)),llonlytothe“COLD”level.

CheckTirePressures

2.LubricatettingswithNGLIgrade#2

multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.LiftLinkage

Pivots

2.DeckBeltIdler

Pivot

3.FrontCaster

WheelHubs

4.FrontCaster

Pivots

InitialPumpsNumberof

1–2

11

*0

*0

Places

7

2

2

Service

Interval

Every50

hours

Yearly

*Yearly

*Yearly

ServiceInterval:Every50hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto13psi(90kPa).

4.Semi-pneumaticcastertiresdonotneedtobe

inated.

CheckConditionOfBelts

ServiceInterval:Every50hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lookonthetopsideofthecuttingdecktocheck

themowerbladedrivebeltcondition.

3.Lookundertheenginedecktocheckthepump

drivebeltcondition.

4.Checkallidlerarmstobesuretheypivotfreely.

*Seestep3forspeciallubricationinstructionson

thefrontcasterpivots.

3.Lubricatefrontcasterpivotsonceayear.Remove

hexplugandcap.Threadgreasezerkinholeand

pumpwithgreaseuntilitoozesoutaroundtop

bearing.Removegreasezerkandthreadplugback

in.Placecapbackon.

LubricateCasterWheelHubs

ServiceInterval:Yearly

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

32

Page 33

Figure20

1.Sealguard2.Spacernutwithwrench

ats

2.Removecasterwheelfromcasterforks.

3.Removesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethatthread

lockingadhesivehasbeenappliedtolockthe

spacernutstotheaxle.Removetheaxle(withthe

otherspacernutstillassembledtoit)fromthe

wheelassembly.

5.Pryoutseals,andinspectbearingsforwearor

damageandreplaceifnecessary.

6.PackthebearingswithaNGLIgrade#1

multi-purposegrease.

7.Insertonebearing,onenewsealintothewheel.

Maintenance

13.Torquethenutto75-80in-lb(8-9N-m),loosen,

thenre-torqueto20-25in-lb(2-3N-m).Make

sureaxledoesnotextendbeyondeithernut.

14.Reinstallthesealguardsoverthewheelhuband

insertwheelintocasterfork.Reinstallcasterbolt

andtightennutfully .

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjusttorqueon

spacernutuntilthereisaslightamountofdrag.

Reapplythreadlockingadhesive.

CheckSparkPlugs

ServiceInterval:Every160hours

Removesparkplugs,checkconditionandresetgaps,

orreplacewithnewplugs.SeeEngineOwner's

Manual.

ChangeFuelFilter

ServiceInterval:Asrequired

Afuellterisinstalledinthefuellinebetweenthe

fueltankandtheengine.Replacewhennecessary.

Note:Seals(ExmarkP/N103-0063)mustbe

replaced.

8.Iftheaxleassemblyhashadbothspacernuts

removed(orbrokenloose),applyathreadlocking

adhesivetoonespacernutandthreadontothe

axlewiththewrenchatsfacingoutward.Do

Notthreadspacernutallofthewayontotheend

oftheaxle.Leaveapproximately1/8inch(3mm)

fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

NGLIgrade#1multi-purposegrease.

11.Insertthesecondbearingandnewsealintothe

wheel.

12.Applyathreadlockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrenchats

facingoutward.

ForKohlerEFIUnits:

WARNING

Fuelsystemcomponentsareunderhigh

pressure.Theuseofimpropercomponentscan

resultinsystemfailure,gasolineleakageand

possibleexplosion.

Useonlyapprovedfuellinesandfuelltersfor

highpressuresystems.

ReplacementFilters

KawasakiKawasaki

P/N49019-7005

KohlerEFIKohler

P/N2405003

ChangeHydraulicSystem

FilterandFluid

ServiceInterval:Aftertherst250hours

33

Page 34

Maintenance

Every500hours/Yearly

(whichevercomes

rst)thereafter

(Every250hours/Yearlyif

usingMobil115W50)

Note:UseonlyExmarkPartNo.109–4180for

Summeruseabove32°F(0°C)orP/N1-523541for

Winterusebelow32°F(0°C)(RefertoTransmission

sectioninSpecicationsforlterspecications).

1.Stopengine,waitforallmovingpartstostop,and

removekeyorsparkplugwire(s).Engageparking

brake.

2.Carefullycleanareaaroundlter.Itisimportant

thatnodirtorcontaminationenterhydraulic

system.

3.Unscrewltertoremoveandallowoiltodrain

fromreservoir.

Important:Beforereinstallingnewlter,ll

itwithExmarkPremiumHydrooilandapply

athincoatofoilonthesurfaceoftherubber

seal.

Turnlterclockwiseuntilrubbersealcontactsthe

lteradapter,thentightenthelteranadditional

2/3to3/4turn.

CAUTION

Raisingthemowerforserviceormaintenance

relyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalor

hydraulicjacksmaynotbeenoughsupport

ormaymalfunctionallowingtheunittofall,

whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

7.Ifeitherdrivewheeldoesnotrotate,oneorboth

ofthechargepumps(locatedonthetopofthe

mainpumpasshowninFigure21)mayhavelost

their“prime”.RefertoHydraulicSystemAir

Purgesection.

Note:DoNotchangehydraulicsystemoil(except

forwhatcanbedrainedwhenchanginglter),unless

itisfelttheoilhasbeencontaminatedorbeen

extremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

HydraulicSystemAirPurge

4.FillreservoirasstatedinCheckHydraulicOil

Level.

ExmarkPremiumHydroOilisrecommended.

Refertothechartforanacceptablealternative:

HydroOil

ExmarkPremiumHydro

Oil(Preferred)

Mobil115W50

5.Loosenlter1/2turnandallowasmallamount

ofoiltoleakfromtheoillter(thisallowsairto

bepurgedfromtheoillterandsupplyhosefrom

thehydraulicreservoir).Turnlterclockwise

untilrubbersealcontactsthelteradapter.Then

tightenthelteranadditional2/3to3/4turn.

6.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

ChangeInterval

500Hours

250Hours

ServiceInterval:Asrequired

Airmustbepurgedfromthehydraulicsystem

whenanyhydrauliccomponents,includingoil

lter,areremovedoranyofthehydrauliclinesare

disconnected.

Thecriticalareaforpurgingairfromthehydraulic

systemisbetweentheoilreservoirandeach

chargepumplocatedonthetopofeachvariable

displacementpump(

thehydraulicsystemwillbepurgedthroughnormal

operationoncethechargepumpis“primed”.

Figure21).Airinotherpartsof

34

Page 35

Figure21

Maintenance

pump.Ifwheelsrotateslowly,thesystemmay

primeafteradditionalrunning.Checkoillevel

asstatedinChecktheHydraulicOilLevel

section.

7.Allowunittorunseveralminutesafterthecharge

pumpsare“primed”withdrivesysteminthefull

speedposition.CheckoillevelasstatedinCheck

theHydraulicOilLevelsection.

8.Checkhydrodrivelinkageadjustmentasstatedin

HydroDriveLinkageAdjustmentsectionin

Adjustments.

1.Chargepumpcap2.Loosen11/2turnsonly

1.Stopengineandwaitforallmovingpartstostop.

Raisetherearofthemachineupontojackstands

highenoughtoraisethedrivewheelsoffthe

ground.

2.CheckoillevelasstatedinCheckHydraulicOil

Levelsection.

3.Startengineandmovethrottlecontrolaheadto

fullthrottleposition.MoveRHmotioncontrol

leverinward(together)andmovebothlevers

forwardwithequalpressure.

Ifeitherdrivewheeldoesnotrotate,itispossible

toassistthepurgingofthechargepumpby

carefullyrotatingthetireintheforwardposition.

Note:Itisnecessarytolightlytouchthecharge

pumpcapwithyourhandtocheckthepump

temperature.Ifthecapistoohottotouch,turn

offengine.Thepumpsmaybedamagedifthe

pumpbecomestoohot.

Ifeitherdrivewheelstilldoesnotrotatecontinue

withstep

4.

WheelHubNutTorque

Specication

ServiceInterval:Aftertherst100hours

Every500hoursthereafter

Torquethenutonthewheelmotortaperedshaftto

175-225ft-lb(237-305N-m).

Note:DoNotuseanti-seizecompoundonthe

wheelhub.

CheckSparkArrester

(ifequipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresult

inpersonalinjuryorpropertydamage.

4.Thoroughlycleantheareaaroundeachofthe

chargepumphousings.

5.To“prime”chargepump,loosentwohexsocket

headcapscrews(showninFigure21)11/2turns

only.Makesureengineisnotrunning.Lift

thechargepumphousingupwardandwaitfor

asteadyowofoiltoowoutfromunderthe

housing.Retightenthecapscrews.Dothisfor

bothpumps.

Note:Hydraulicreservoircanbepressurizedup

to5psitospeedthisprocess.

6.Ifeitherdrivewheelstilldoesnotrotate,stop

andrepeatsteps4and5abovefortherespective

DoNotrefuelorrunengineunlesssparkarrester

isinstalled.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Waitformufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacearrester.

4.Ifpluggingofthescreenisobserved,remove

arresterandshakelooseparticlesoutofthe

arresterandcleanscreenwithawirebrush(soak

insolventifnecessary).Reinstallarresteron

exhaustoutlet.

35

Page 36

Maintenance

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

•Pumpsheavesetscrews.

•Sheaveretainingboltinendofenginecrankshaft.

•Casterwheelspacernuts.

•Platformspringpin.

MobilHTSGrease(Or

Food-GradeAnti-seize)

MobilHTSgrease(orfood-gradeanti-seize)isused

inthefollowinglocations:

Betweensplinesofthecutterhousingspindleand

sheave.

Copper-BasedAnti-seize

Copper-basedanti-seizeisusedinthefollowing

locations:

Adjustments

Note:DisengagePTO,shutoffengine,waitfor

allmovingpartstostop,engageparkingbrake,and

removekeybeforeservicing,cleaning,ormakingany

adjustmentstotheunit.

CAUTION

Raisingthemowerforserviceormaintenance

relyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalor

hydraulicjacksmaynotbeenoughsupportor

maymalfunctionallowingtheunittofall,which

couldcauseinjury.