Page 1

VIKING

ForSerialNos.

920,000&Higher

PartNo.4500-693Rev.A

™

HYDRO

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

(CPRC)Section4442touseoroperatethis

engineonanyforest-covered,brush-covered,or

grass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilar

laws.

Toacquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

Thissparkignitionsystemcomplieswiththe

CanadianstandardICES-002.Cesystèmed’allumage

parètincelledevèhiculeestconformeàlanorme

NMB-002duCanada.

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2010ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency ,andpromotesafe

operation.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

Exmarkpartsmanualsareavailableonlineat

http://www.exmark.com/manuals.htm

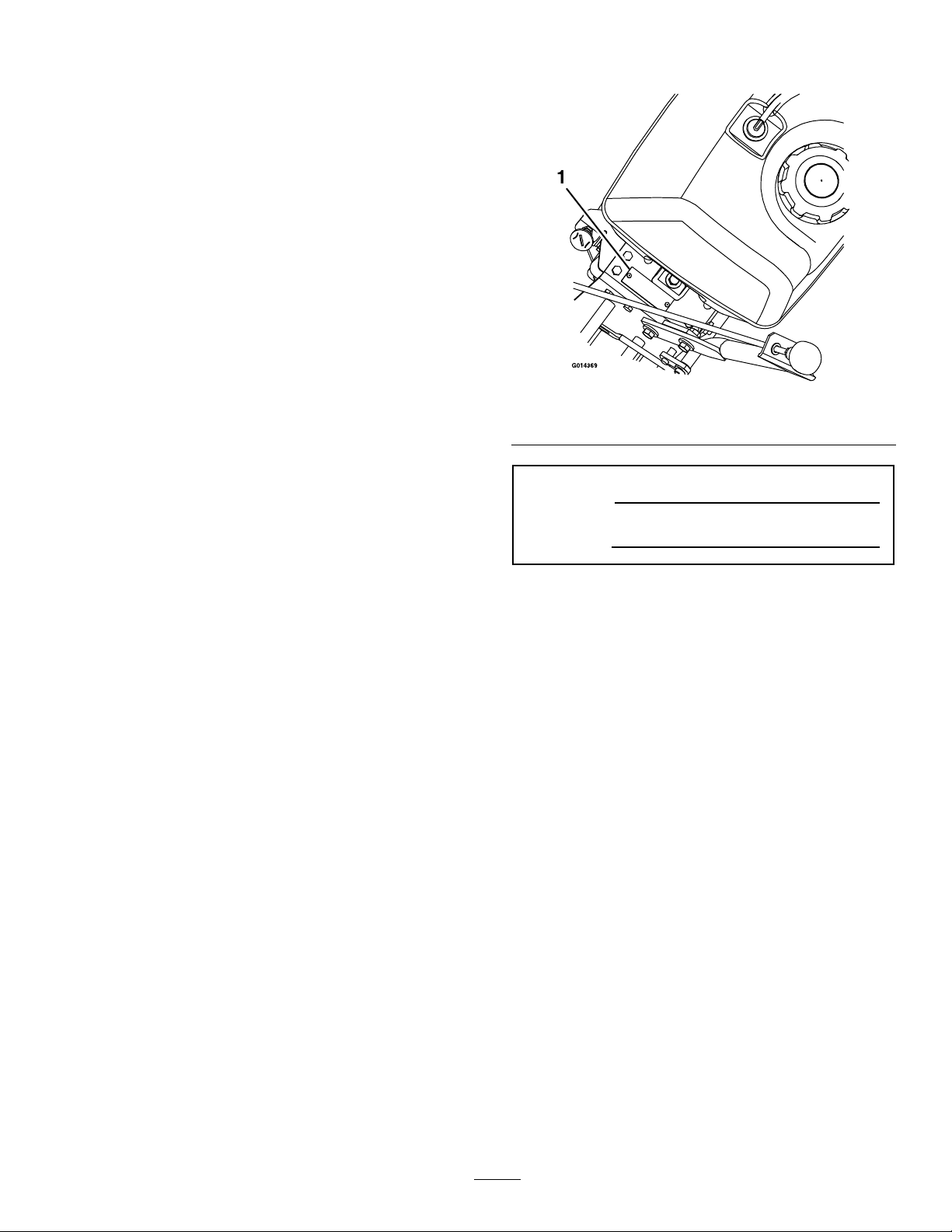

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.....................10

Specications.......................................................13

ModelNumbers............................................13

Systems.........................................................13

Dimensions...................................................14

TorqueRequirements....................................14

ProductOverview................................................15

Operation.............................................................15

Controls........................................................15

Pre-Start........................................................17

OperatingInstructions..................................17

Transporting.................................................19

Maintenance.........................................................20

RecommendedMaintenanceSchedule(s)...........20

PeriodicMaintenance.......................................21

CheckEngineOilLevel.................................21

CheckMowerBlades.....................................21

CheckSafetyInterlockSystem.......................22

CheckforLooseHardware............................22

ServiceAirCleaner........................................23

ChangeEngineOil........................................23

CheckHydraulicOilLevel.............................23

CheckTirePressures.....................................23

CheckConditionOfBelts..............................23

LubricateGreaseFittings...............................24

CheckSparkPlugs.........................................24

ChangeHydraulicSystemFilter.....................24

ReplaceEmissionsAirIntakeFilter................26

WheelHub-SlottedNutTorque

Specication..............................................26

ThreadLockingAdhesives.............................27

MobilHTSGrease(OrFood-Grade

Anti-seize).................................................27

Copper-BasedAnti-seize..............................27

DielectricGrease...........................................27

Adjustments.....................................................28

AdjustingtheCuttingHeight.........................28

AdjustingtheAxlePosition............................29

AdjustingtheNumberofSpacersbelow

CasterSupportHub...................................30

AdjustingtheCuttingHeightwithBlade

Spacers......................................................30

PTOEngagementLinkage

Adjustment...............................................31

PTOSafetySwitchAdjustment......................31

EnginetoMowerDeckBelt

Adjustment...............................................31

BladeBrakeAdjustment................................32

BeltGuideAdjustment..................................33

PumpDriveBeltTension...............................33

HydroDriveLinkageAdjustment..................33

TrackingAdjustment.....................................36

HydroPumpSpringTensionSetting..............36

ParkBrakeAdjustment..................................36

Cleaning...........................................................37

CleanEngineAirCoolingSystem...................37

RemoveEngineShroudsandCleanCooling

Fins...........................................................37

CleanGrassBuild-UpUnderDeck................37

WasteDisposal..............................................37

Troubleshooting...................................................38

Schematics...........................................................40

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThislawnmowermeetsorexceedstheB71.4

specicationsoftheAmericanNationalStandards

Instituteineffectatthetimeofproduction.

Exmarkdesignedandtestedthislawnmowertooffer

reasonablysafeservice;however,failuretocomply

withthefollowinginstructionsmayresultinpersonal

injury.

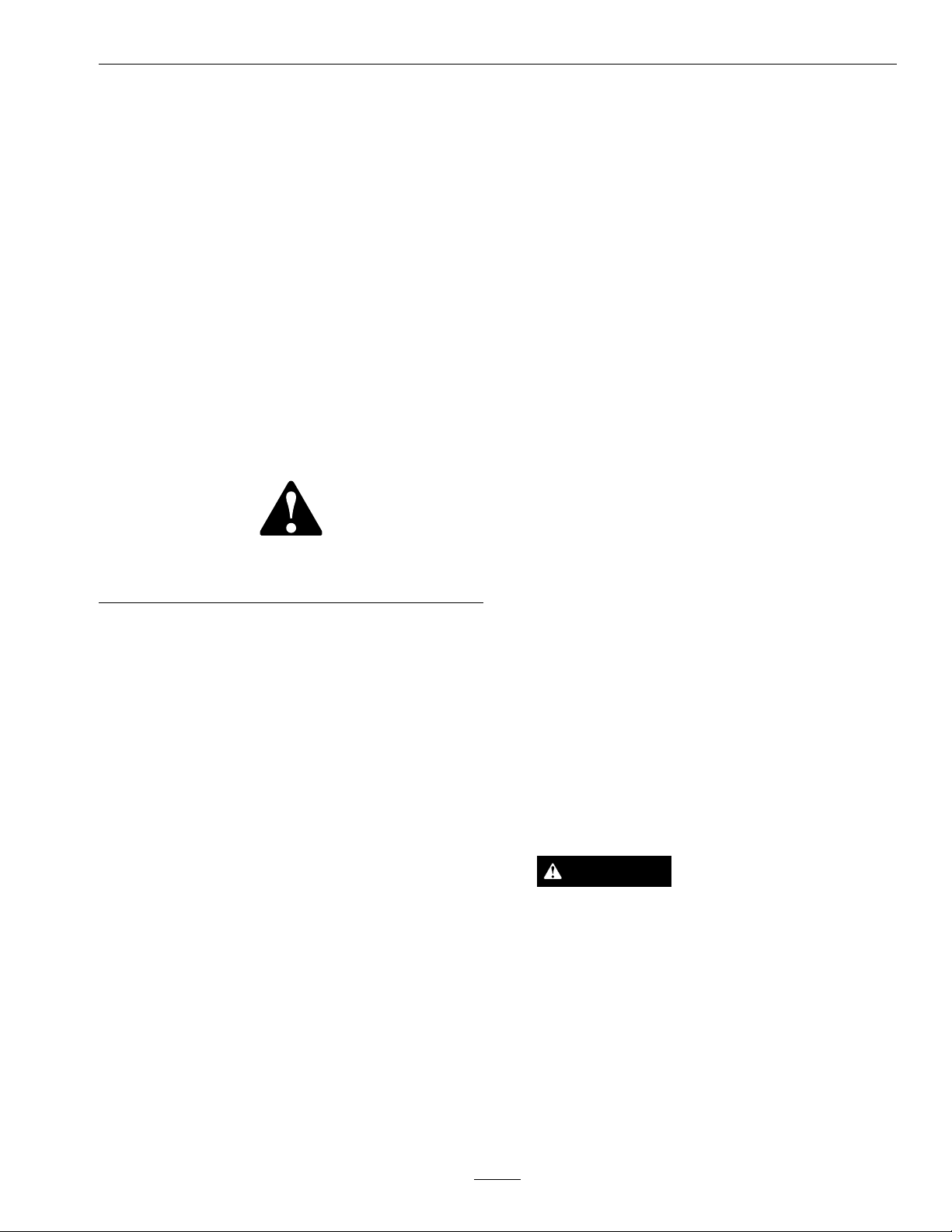

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

1.Safetyalertsymbol

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

amower,andevenmatureteenagersshouldhave

adultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator’s

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

mowerwithouttakingrisks.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

5

Page 6

Safety

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengine

oremissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoradd

fuelwhenengineisrunningorwhenthe

engineishot.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperator’spresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

6

Page 7

Safety

Operation

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscanoccur

oncontactanddebris,suchasleaves,grass,

brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,to

coolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcankill

you.

DoNotrunengineindoorsorinasmallconned

areawheredangerouscarbonmonoxidefumes

cancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Neverraisedeckwithbladesrunning.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkmachineonlevelground.Stopengine,wait

forallmovingpartstostop,removekeyand

engageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

–Beforemakingheightadjustments.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•DONOToperatethemowerwhenpeople,

especiallychildren,orpetsareinthearea.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

7

Page 8

Safety

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Lossofcontrol

and/orlossofoperator’sfootingcouldresultina

fallwithanarmorleggettingunderthemower

orenginedeckwhichmayresultinserious

injury,deathordrowning .

•Mowacrossslopes,neverupanddown.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan20degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatoperatingonwetgrass,acrosssteep

slopesordownhillmaycausethemowertolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•Letenginecoolbeforestoringanddonotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththe

enginerunning.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

MaintenanceandStorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

WARNING

Removingstandardoriginalequipmentparts,

orusingnon-Exmarkreplacementpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.Failuretouseoriginal

Exmarkpartscouldcauseseriousinjuryor

death.

Replaceallpartsincluding,butnotlimitedto,

tires,belts,andbladeswithoriginalExmark

parts.

8

Page 9

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemay

result.

•Ifequipped,makesureallhydraulicuid

hosesandlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretohydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,to

ndhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembyplacingthemotioncontrollevers

inneutralandshuttingofftheenginebefore

performinganyworkonthehydraulicsystem.

Safety

9

Page 10

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

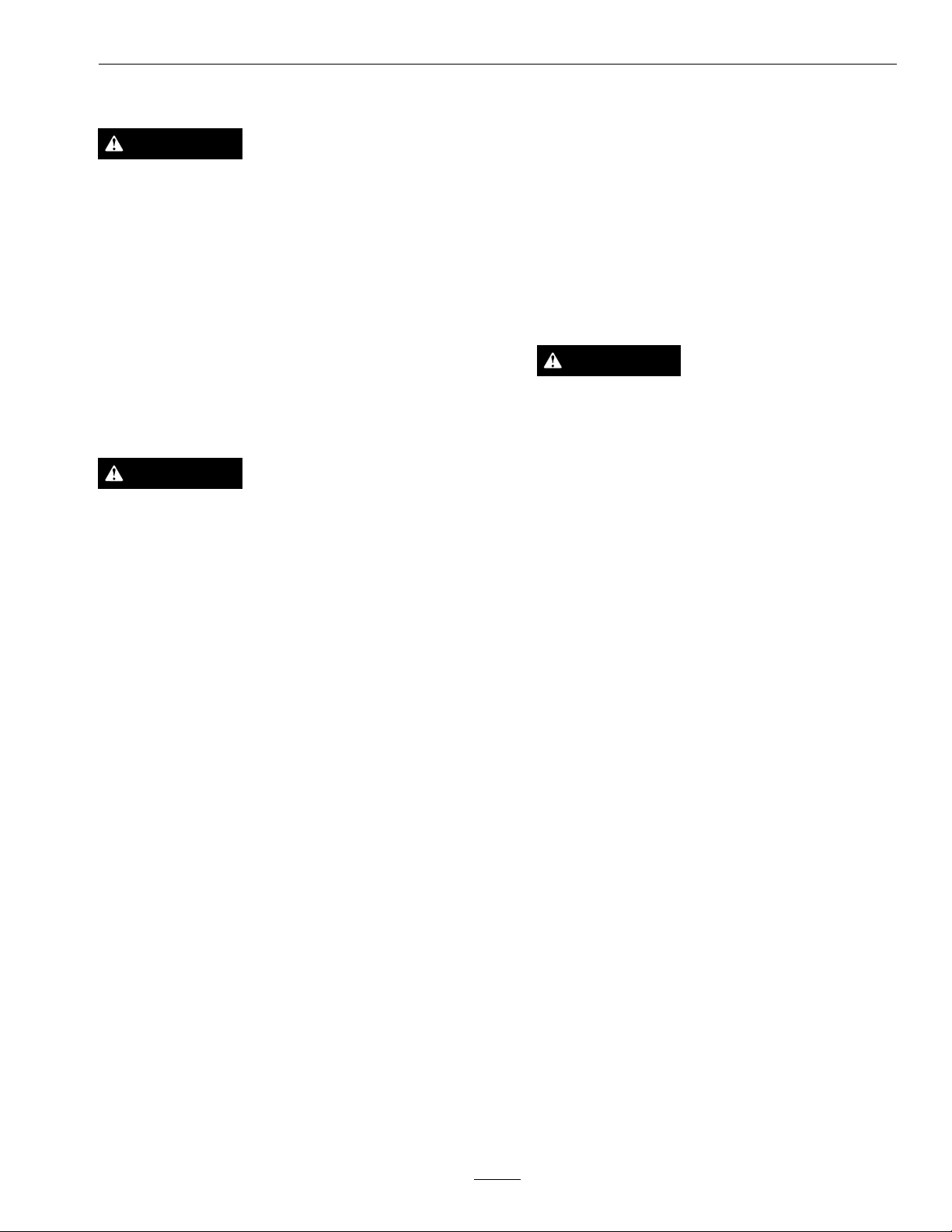

1-303508

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

1-403005

1-303517

1-323427

36inchDeckUnitsOnly

1-403143

1-413214

98-5954

10

Page 11

Safety

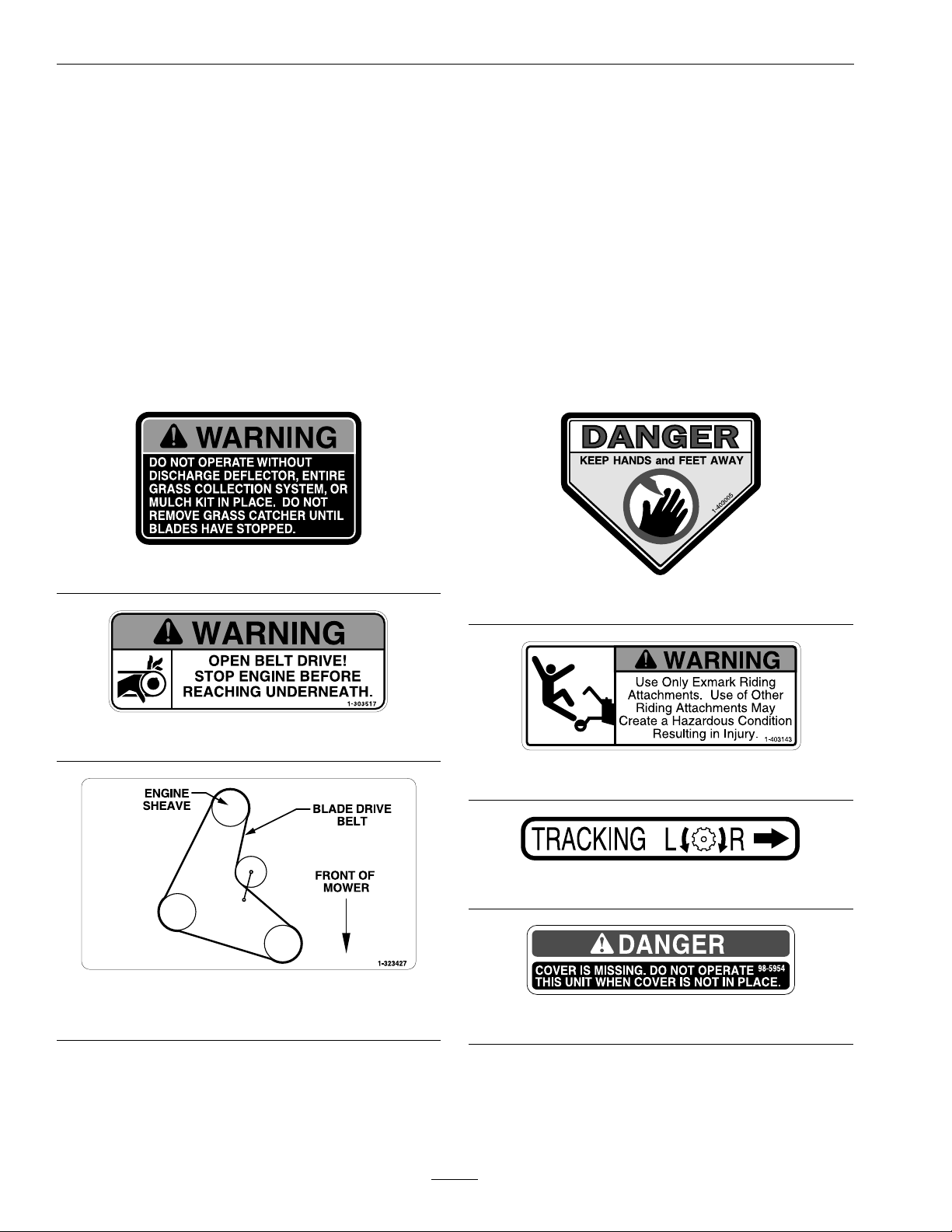

103-1798

103-2076

103-2103

103-2196

103–2242

11

Page 12

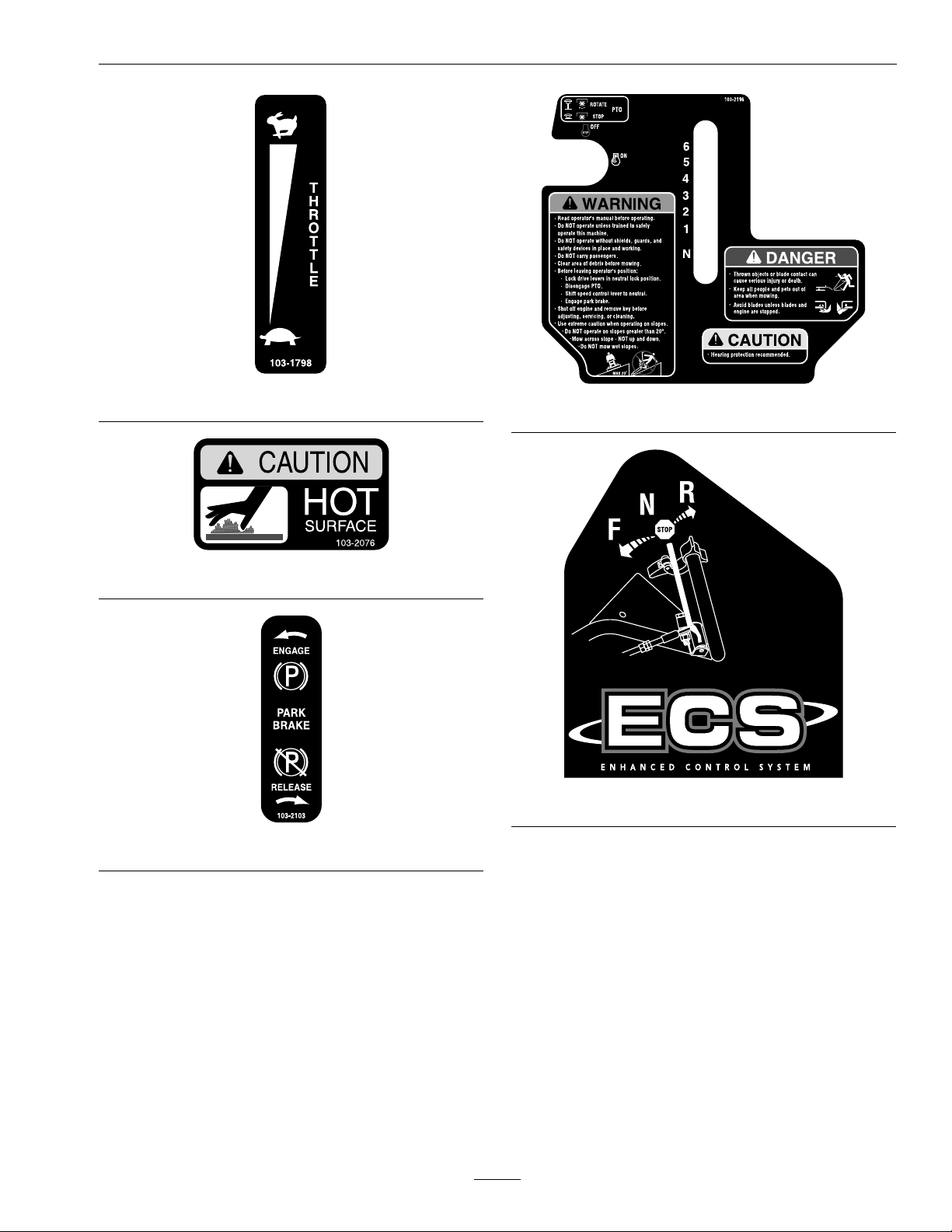

Safety

116-0404

103–2243

103-4935

103-5626

48inchDeckUnitsOnly

117–2718

12

Page 13

Specications

ModelNumbers

SerialNos:920,000andHigher

VH16KA362;VH16KA483;VH16KA362CA;VH16KA483CA

Specications

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•EngineOilType:Exmark4–CyclePremium

EngineOil

•RPM:FullSpeed:3600(NoLoad)

Idle:1550RPM

FuelSystem

•Capacity:5.0gal.(18.9L)

•TypeofFuel:Regularunleadedgasoline,87

octaneorhigher;containingnomorethan10%

methanolorethanol.

•FuelFilter:ReplaceableIn-line

•FuelShut-OffValve:1/4turnincrements

SafetyInterlockSystem:

Transmission

•TwoHydroGearvariabledisplacementpiston

pumpsindependentlycoupledtotwohigh

efciencyParkerwheeldrivemotors.

•HydraulicOil:UseExmarkPremiumHydroOil.

•HydraulicOilCapacity:2.4qt.(2.2L)

•HydraulicFilterisreplaceablecartridgetype.

P/N109–4180:25microns,10psibypass

(Summeruseabove32°F(0°C))

P/N1–523541:40microns,18psibypass(Winter

usebelow32°F(0°C))

•Speeds:

–0-6.2mph(10.0km/hr)forward.

–0-2.2mph(3.5km/hr)reverse.

WheelDriveSystem

DrivewheelsaredirectcoupledtoParkerwheeldrive

motorswith1inch(25.4mm)taperedshaft.

•OperatormusthaveOPC(OperatorPresence

Control)leversheldincontactwithhandle

grips,speedcontrolleverinneutral,andPTO

disengagedtostartengine.ReleaseofOPClevers

willcausetheenginetostopifspeedcontrollever

isnotinneutraland/orPTOisengaged.

•Parkbrakemustbedisengagedtomovespeed

controloutofneutralorenginewillkill.

Steering/BrakeControls

Fingertipdrivecontrolleversprovideindependent

speedcontrol,brakingandneutraltoeachdrive

wheelformovingforwardorreverse,stoppingand

powerturning.

Tires&Wheels

DriveFrontCaster

Pneumatic

(Air-Filled)

Quantity

Tread

Size16x6.50–89x3.50-4

PlyRating

Pressure

13

22

TurfMasterSmooth

4

14psi

(97kPa)

SemiPneumatic

Page 14

Specications

CuttingDeck

•CuttingWidth:

–36inchDeck:35.38inches(89.9cm)

–48inchDeck:47.25inches(120.0cm)

•Discharge:Side

•BladeSize:

–36inchDeck:18.00inches(45.7cm)—

Quantity:2

–48inchDeck:16.25inches(41.3cm)—

Quantity:3

•DeckDrive:Manualengagementofbeltwith

over-centerlock.Bladebelttensionisadjustable

viaturnbuckle.

•BladeBrake:WhenthePTOengagementcontrol

ismovedtothedisengagedpositionafriction

brakepadstopstherotationoftheblades.

•DeckMounting:Bolteddirectlytoenginedeck.

•DeckDepth:

–36inchDeck:5.0inches(12.7cm)

–48inchDeck:5.0inches(12.7cm)

•CuttingHeightAdjustment:

Adjustsfrom1inch(2.5cm)to41/4inches(10.8

cm)in1/4inch(6.4mm)incrementsbyvarious

adjustmentsofcasterspacers,bladespacers,and

axleheight.

Dimensions

TreadWidth:(OutsidetoOutsideof

Tires,Widthwise)

36inchDeck48inchDeck

35.6inches

(90.4cm)

40.4inches

(102.6cm)

CurbWeight:

36inchDeck48inchDeck

573lb(260kg)633lb(287kg)

TorqueRequirements

BoltLocation

Blade/CutterHousing

SpindleBolt

CasterBracketMounts

MowerDeck/Engine

DeckMount

EngineMountingBolts

WheelLugNuts

WheelHubSlottedNut

(StyleA)

WheelHubSlottedNut

(StyleB)

WheelMotorMounting

Bolts

Torque

75-80ft-lb(102-109N-m)

30-35ft-lb(41-48N-m)

30-35ft-lb(41-48N-m)

17-23ft-lb(23-31N-m)

90-95ft-lb(122-129N-m)

140-155ft-lb

(190-210N-m)

minimum100ft-lb

(136N-m)

30-35ft-lb(41-48N-m)

OverallWidth:

36inchDeck48inchDeck

DeectorUp36.4inches

(92.5cm)

DeectorDown47.0inches

(119.4cm)

48.1inches

(122.2cm)

57.9inches

(147.1cm)

OverallLength:

36inchDeck48inchDeck

77.3inches(196.3cm)72.3inches(183.6cm)

OverallHeight:

36inchDeck48inchDeck

43.2inches(109.7cm)43.2inches(109.7cm)

14

Page 15

Operation

ProductOverview

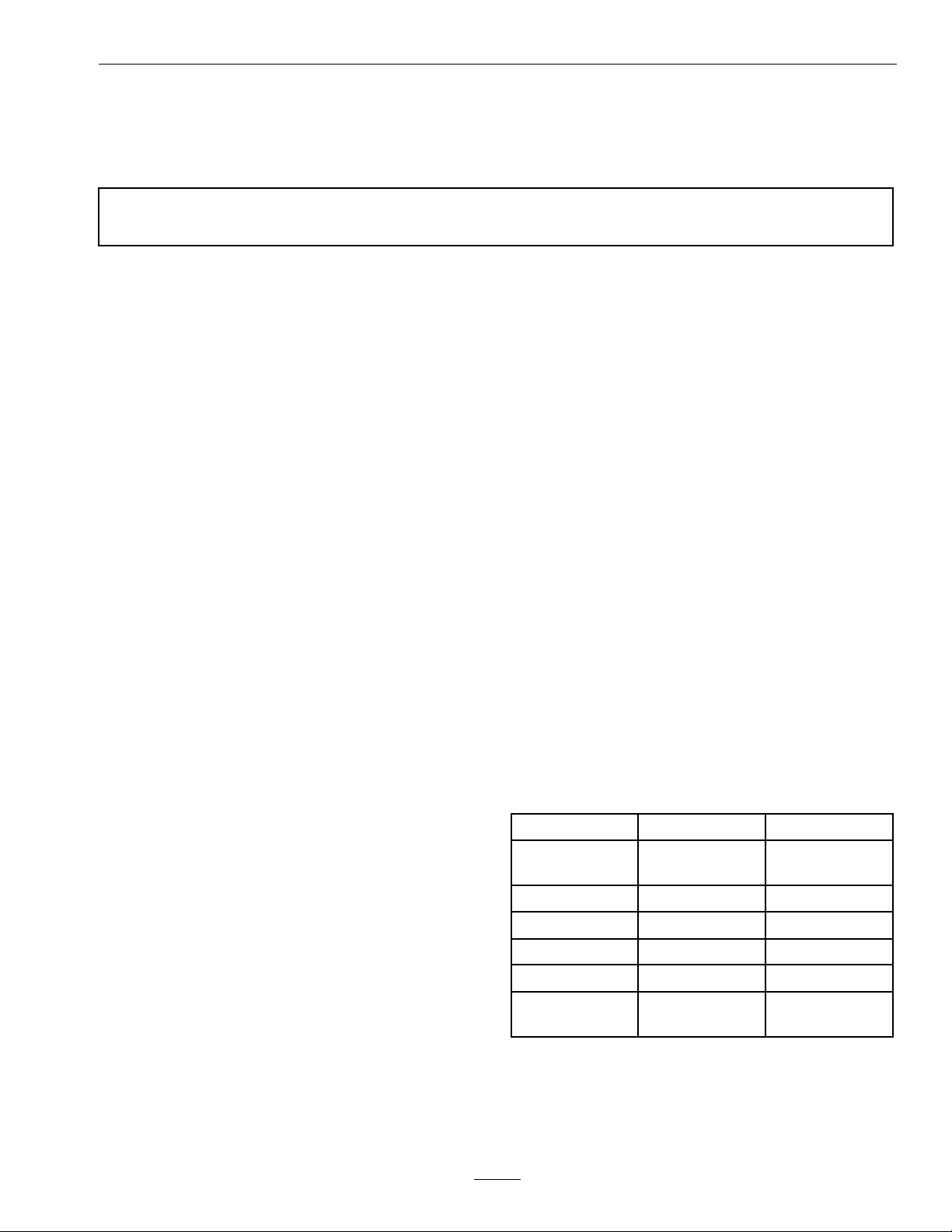

Figure3

1.ECSHandles3.FuelCap

2.Controls4.BladeSpacers

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

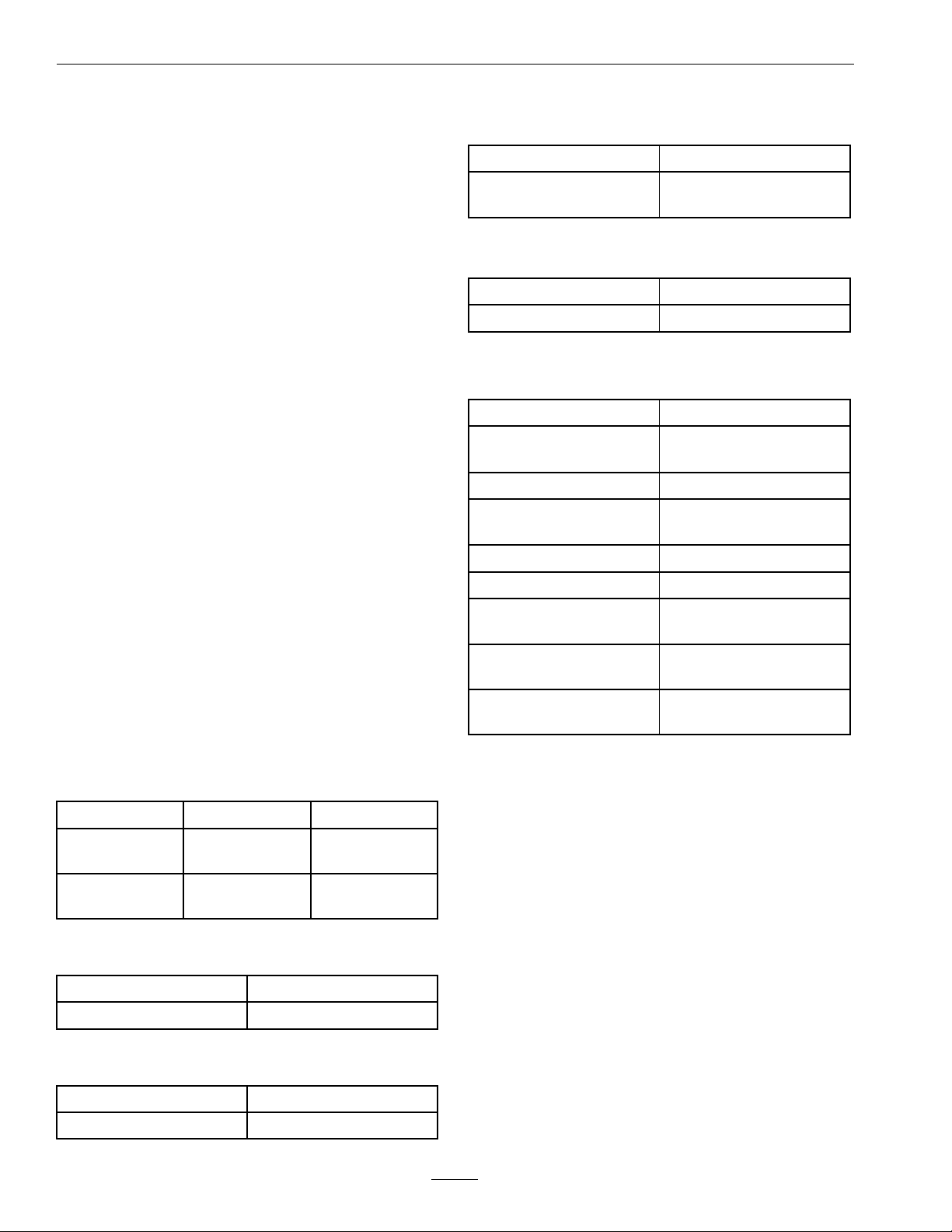

OperatorPresenceControl(OPC)

Levers

Locatedontheupperhandleassemblydirectlyabove

thehandlegrips.

Whentheseleversaredepressed,theOPCsystem

sensesthattheoperatorisinthenormaloperator’s

position.Whentheleversarereleased,theOPC

systemsensesthattheoperatorhasmovedfromthe

normaloperatingpositionandwillkilltheengineif

eitherthespeedcontrolleverisnotintheneutral

positionorthePTOisengaged(see

Figure4).

Figure4

1.OPCLever

2.Rotateneutrallocklatch

downwardforneutral

lockposition

3.NeutralLockLatch

4.DriveLeverinneutral

position

DriveLevers

Locatedoneachsideoftheupperhandleassembly

aheadofandbelowthehandlegrips.

Theseleversindividuallycontrolthespeedand

directionofeachdrivewheel.Whenthespeedcontrol

leverismovedoutoftheneutralpositionandthe

neutrallocklatchesaremovedintothedriveposition,

15

Page 16

Operation

asshowninFigure4,andthedriveleversarereleased,

thedrivewheelsareengagedintheforwarddirection.

Squeezingthelefthandand/orrighthandlever

causesthelefthandand/orrighthanddrivewheel

respectivelytoslowdown,stop,orreverse,depending

onhowfareachdriveleveris“squeezed”.Squeezing

thedriveleversbeyondtheneutralpositioncauses

thedrivewheelstoengageinthereversedirection

regardlessofthepositionoftheneutrallocklatches

andthespeedcontrollever.

NeutralLockLatch

Locatedattheendofthehandles.

Thepurposeoftheselatchesistoallowtheoperator

tolockthedriveleversina"neutral"positionwhere

neitherofthedrivewheelsareengagedineithera

forwardorreversedirection(see

Figure4).

ParkBrakeLever

Locatedontherightsideoftheunitabovethe

hydraulictank.

Thebrakeleverengagestheparkbrakeonthedrive

wheels.

Pulltheleverupandrearwardtoengagethebrake.

Pushtheleverforwardanddowntodisengagethe

brake.

Whenparkingonasteepslope,thewheelsmustbe

chockedorblockedinadditiontothebrakebeing

engaged.Theunitmustbetieddownandbrake

engagedwhentransporting.

speedandmovingittotherearwilldecreaseengine

speed.Movingthethrottleforwardintothedetent

isfullposition.

SpeedControlLever

Locatedinmiddleofcontrolconsole.

Thespeedcontrollevercontrolsthemaximum

forwardspeedandisinnitelyvariablefromneutral

0–6.2mph(10.0km/hr).

Parkbrakemustbedisengagedtomovespeedcontrol

outofneutralorenginewillkill.

“Off-Run”Switch

Locatedonthecontrolconsole.

Turnthekeytothe“Run”positiontoallowthe

enginetobestarted.Turnthekeytothe“Off”

positiontoshutengineoff.

FuelShut-OffValve

Locatedinthefuellinemidwaybetweenthetank

andengine.

Thefuelshut-offvalveisusedtoshutoffthe

owoffuelwhenparkinginsideabuilding,during

transportationtoandfromthejobsites,andwhen

themachinewillnotbeusedforafewdays.

Rotatevalve1/4turnclockwisetoshutfueloff.

Rotatevalve1/4turncounterclockwisetoturnfuel

on.

Parkbrakemustbedisengagedtomovespeedcontrol

outofneutralorenginewillkill.

ChokeControl

Locatedonthefrontleftcornerofthefueltank

support.

Chokeisusedtoaidinstartingacoldengine.The

chokecontrolispulledouttobeinthe“ON”position

andpushedintobeinthe“OFF”position.DoNot

runawarmenginewithchokeinthe“ON”position.

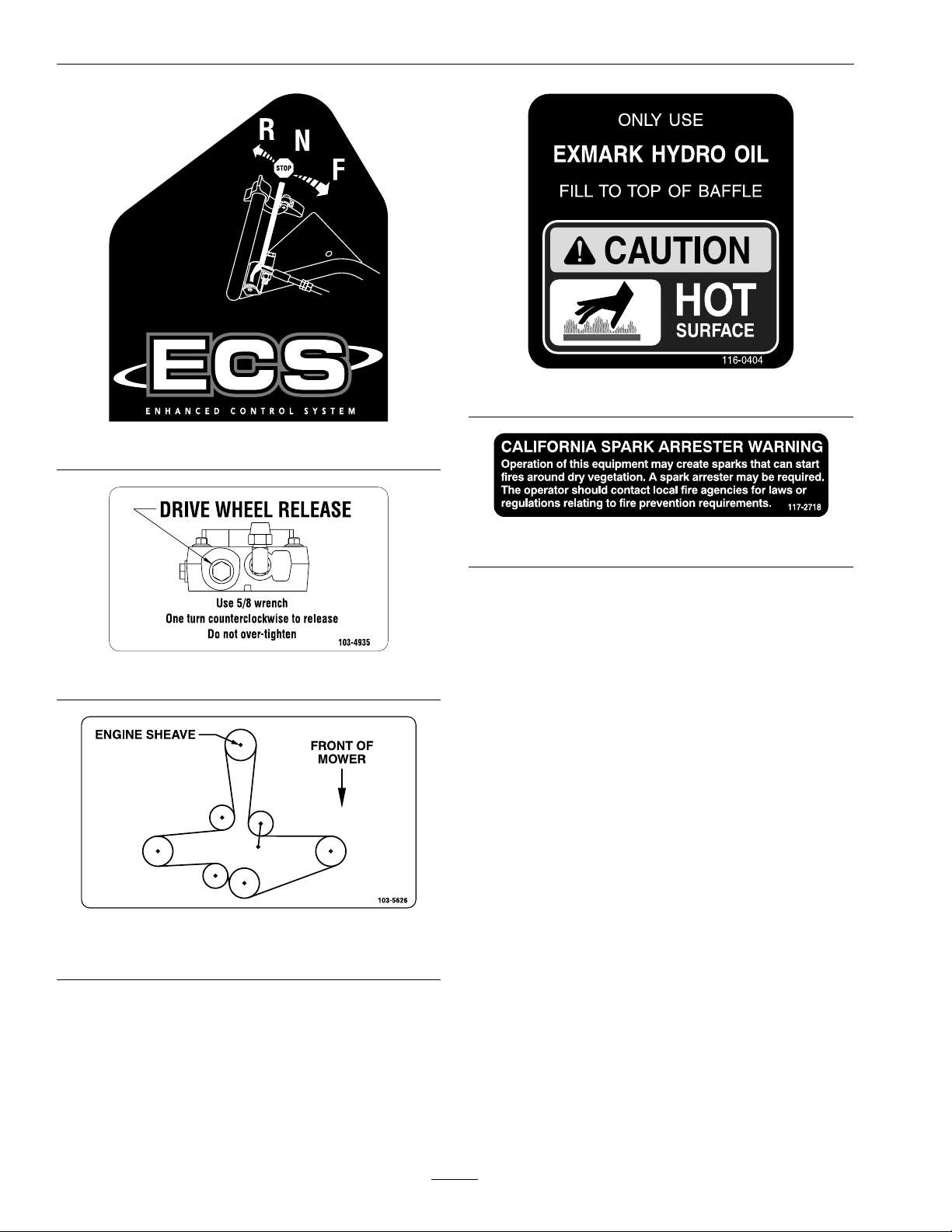

ThrottleControl

Locatedontheonthecontrolconsolerightside.

Thethrottleisusedtocontrolenginespeed.Moving

thethrottlecontrolforwardwillincreaseengine

DriveWheelReleaseValves

Locatedonthetoprearcornerofthehydrostatic

pumps.

Drivewheelreleasevalvesareusedtoreleasethe

hydro-staticdrivesystemtoallowthemachinetobe

movedbyhandwithouttheenginerunning.

Witha5/8wrench,turnbothvalvesoneturn

counterclockwisetoreleasethedrivesystem.

Turnclockwisetoresetthedrivesystem.DoNot

overtighten.

TrackingAdjustmentKnob

Locatedontheright-handsideoftherearofthefuel

tanksupport.

16

Page 17

Operation

Theknobcanbeadjustedsothatmachinewill

“track”straightaheadwiththedriveleversreleased.

PTOEngagementControl

Locatedonleftsideofcontrolconsole.

Toengagetheblades,theknobmustbepulled

towardtheoperatoruntiltheturnbuckle(attached

tothebladeengagementidler)locksover-center.T o

disengagetheblades,pushtheknobdownuntilthe

assistarmcontactsthepinonthedeck.

ParkbrakemustbedisengagedbeforePTOis

engagedorenginewillkill.

ColdStartKit

Locatedontherighthandsideofenginedeck,below

andslightlyaheadofthehydrocontrolshield.

Thecoldstartkitisusedtoeasethestartingofthe

unitincoldweatherorwhentheunithasnotbeen

operatedforaperiodoftime.Thecoldstartkit

movestheidlerpulleyawayfromthepumpbelt,

releasingthetensiononthebeltwhichallowsthe

enginetoturnoverwithlessresistance(seeStarting

theEnginesectioninOperation).

Pre-Start

Fillfueltankonlevelground.Forbestresultsuse

onlyclean,freshregulargradeunleadedgasolinewith

anoctaneratingof87orhigher.

Important:Neverusemethanol,gasoline

containingmethanol,gasoholcontainingmore

than10%ethanol,premiumgasoline,orwhite

gasbecausethefuelsystemcouldbedamaged.

DoNotaddoiltogasoline.

DoNotoverllfueltank.Fillthefueltanktothe

bottomofthellerneck.Theemptyspaceinthe

tankallowsgasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineoremission

system.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

OperatingInstructions

OpentheFuelShut-OffValve

Rotatethevalve1/4turncounterclockwisetoturn

fuelon.

StartingtheEngine

Note:OperatormusthavePTOdisengagedand

speedcontrolleverinneutralpositionwhenstarting

theengine.

Lockdriveleversinneutralandengageparkbrake

Note:Acoldweatherstartingkithasbeenaddedfor

easeofstartingineithercoldweatherorwhenthe

unithasnotbeenrunforaperiodoftime.

•Tousecoldstartkit:

1.Pullsplitringstraightoutthesideoftheunit,

andhooktheringoverthelowerfronthydro

controlshieldbolt.

2.Startengine.Refertothefollowingguidelines

forfurtherstartingsuggestions.

•Toengagepumpdrive(disengagecoldstartkit):

1.Pullchainstraightoutfromthesideofthe

unituntilthesplitringcanberemovedfrom

thebolt.

2.Slowlyreleasetensiononchain.

1.Pulloutthechokecontrol.Placethethrottle

controlmidwaybetweenthe“Slow”and“Fast”

positions.Turnthekeyswitchtothe“Run”

position.

2.Pullrecoilropetostartengine.Afterengine

warmsup,graduallypushinthechokecontrol.

DoNotrunwarmenginewiththechokeinthe

“ON”position.

Note:Kawasakienginesgenerallyneedtobe

“choked”evenwhenwarm.

EngagingthePTO

DANGER

Therotatingbladesunderthemowerdeckare

dangerous.Bladecontactcancauseserious

injuryorkillyou.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

DoNotputhandsorfeetunderthemoweror

mowerdeckwhenthebladesareengaged.

17

Page 18

Operation

DANGER

Anuncovereddischargeopeningwillallow

objectstobethrowninanoperator’sor

bystander’sdirection.Also,contactwiththe

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryordeath.

Neveroperatethemowerwiththedischarge

deectorraised,removed,oralteredunlessthere

isagrasscollectionsystemormulchkitinplace

andworkingproperly.

ThePTOswitchengagesthecuttingblades.Besure

thatallpersonsareclearofmowerdeckanddischarge

areabeforeengagingthePTO.

1.Setthrottleto“MIDW AY”position.

2.PullthePTOengagementknobuptoengage

blades.

3.Placethethrottleinthe“FAST”positiontobegin

mowing.

Note:ParkbrakemustbedisengagedbeforePTOis

engagedorenginewillkill.

DisengagingthePTO

1.Setthrottleto“MIDW AY”position.

2.PushdownonthePTOengagementknobto

disengagetheblades.

StoppingtheEngine

transporting,orwhentheunitisparkedinside

abuilding.

DrivingtheMachine

DriveLever/NeutralLockLatchOperation

Tolockthedriveleversin“neutrallock”,squeezethe

driveleverstothe“neutral”position(DoNotsqueeze

thedriveleversallthewaybackasthiswillcausethe

drivewheelstogointofullreversedirection).See

Figure5position1.Placethumbsontheinnerlobe

oftheneutrallocklatchesandrotatethemunder

thedriveleversintothe“neutrallock”position.See

Figure5position2.Releasethedrivelevers.

CAUTION

Iftheneutrallocklatchesarenotcompletely

engagedthedriveleverscouldunexpectedlyslip

intotheforwarddriveposition.Ifthedrivelevers

slipintothedrivepositiontheunitcouldlurch

forwardandcauseinjuryorpropertydamage.

Besurethedriveleversarepasttherollerand

securelyseatedatthebottomoftheneutrallock

latches.

Toplacethedriveleversinthe“forward”position,

slightlysqueezethedriveleverswhileplacingthumbs

ontheouterthumblobeoftheneutrallocklatches

(ortheindexngeronthefrontlobe)androtatethem

fromunderthedrivelevers.Slowlyandcarefully

releasethedrivelevers.See

Figure5position3.

1.Bringtheunittoafullstop.

2.Lockdriveleversinneutral.

3.DisengagethePTO.

4.Movespeedcontrollevertoneutral.

5.Engagetheparkingbrake.

6.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

7.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

8.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

9.Closethefuelshut-offvalvewhenthemachine

willnotbeinuseforafewdays,when

Toplacethedriveleversinthe“reverse”position,

squeezethedriveleverspasttheneutralposition.See

Figure5position4.

18

Page 19

1.DriveLeverinneutral

position

2.DriveLeverlockedin

neutralposition

DrivingForward

Figure5

3.DriveLeverinforward

position

4.DriveLeverinreverse

position

Operation

DrivinginReverse

Tomoverearwardinastraightline,squeezedrive

leversintothereverseposition.

Toturnleftorright,squeezetherighthanddrivelever

toturnleftandthelefthanddrivelevertoturnright.

Tomakea“zeroturn”,squeezeeitherthelefthand

ortherighthanddriveleverbackintothereverse

positionwhiletheoppositedriveleverisinaforward

positionatanequalbutoppositespeed.

Note:Forsmoothoperationofthismachine,avoid

quick,jerkymovementsofthedrivelevers.Movethe

driveleverssmoothlyanddeliberately.

Tostop,squeezedriveleversbacktothe“neutral”

position.Movetheneutrallocklatchesintothe

“neutrallock”positionandreleasedrivelevers.Move

thespeedcontrollevertotheneutralposition.

1.Releasetheparkingbrake.

2.Withdriveleverslockedin“neutral”,shiftspeed

controllevertodesiredforwardspeed.

3.Slowlysqueezeandholdbothdriveleversin

theneutralpositionandrotatebothneutrallock

latchesfromtheneutrallockpositiontothe

forwardposition.

Note:DoNotsqueezebothdriveleversallthe

wayback.Thiswillcausethedrivewheelsto

engageinthereversedirection.

4.Tomoveforwardinastraightline,smoothly

releasebothdriveleverstoengagedrivewheels.

Toturnleftorright,squeezetherighthanddrive

levertoturnrightandthelefthanddrivelever

toturnleft.

Tomakea“zeroturn”,squeezeeithertheleft

handortherighthanddriveleverbackintothe

reversepositionwhiletheoppositedriveleverisin

aforwardpositionatanequalbutoppositespeed.

Note:Forsmoothoperationofthismachine,

avoidquick,jerkymovementsofthedrivelevers.

Movethedriveleverssmoothlyanddeliberately .

Tostop,squeezedriveleversbacktothe“neutral”

position.Movetheneutrallocklatchesintothe

“neutrallock”positionandreleasedrivelevers.

Movethespeedcontrollevertotheneutral

position.

Transporting

TransportingaUnit

WARNING

Loadingthemowerontoatrailerwithoutstrong

enoughorproperlysupportedrampscouldbe

dangerous.Therampscouldcollapsecausing

theunittofall,whichcouldcauseinjury.

•Useproperrampsthataresecuredtothe

truckortrailer.

•Keepfeetandlegsoutfromundertheunit

whenloadingandunloading.

•Ifnecessary,useassistancewhenloading.

Besurethefuelshut-offvalveisclosed.

Useaheavydutytrailertotransportthemachine.

Engageneutrallocklatchesandparkbrake,then

blockwheels.

Securelyfastenthemachinetothetrailerwithstraps,

chains,cables,orropes.

DoNotrelysolelyontheparkingbraketoholdthe

machineonthetrailer.

Besurethatthetrailerhasallnecessarylightingand

markingasrequiredbylawanduseasafetychain.

19

Page 20

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecouldseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitch,engage

parkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenance.Also

pushthewire(s)asidesoitdoesnotaccidentally

contactthesparkplug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst100hours

Aftertherst250hours

Beforeeachuseordaily

MaintenanceProcedure

•Changetheengineoil.

•Checkwheelhub-slottedtorquespecication.

•Changethehydrauliclter.

•Checktheengineoillevel.

•Checkthemowerblades.

•Checkthesafetyinterlocksystem.

•Checkforloosehardware.

•Greasethecasterwheelbearings.

•Greasecasterpivots.

•Cleanengineaircoolingsystem(SeeEngineOwner’ sManual)

•Cleanthegrassbuild-upfromunderthedeck.

WARNING

Theenginecanbecomeveryhot.Touchingahot

enginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheenginearea.

Every25hours

Every40hours

Every100hours

Every160hours

Every200hours

Every500hours

•Servicethefoamelement.(Mayneedmoreoftenundersevereconditions.SeetheEngine

Owner’smanualforadditionalinformation.)

•Checkthehydraulicoillevel.

•Checkthetirepressures.

•Checktheconditionofthebelts.

•Greasethepumpdriveidlerpivot.

•Greasethepumpcontrolbearings.

•Greasethemowerdeckidlerpivot

•Servicethepaperelement.(Mayneedmoreoftenundersevereconditions.SeetheEngine

Owner’smanualforadditionalinformation.)

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Removeengineshroudsandcleancoolingns.

•Checkthesparkplugs.

•Replacethepaperelement.

•Changethehydrauliclter(Every250hours/yearlyifusingMobil115W50)

•Replacetheemissionsairintakelter.

•Checkwheelhub-slottedtorquespecication.

Monthly

•GreasethePTOengagementbellcrank.

20

Page 21

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Cleanareaarounddipstick.Removedipstickand

wipeoiloff.Reinsertthedipstickandpushitall

thewaydownintothetube.DoNotscrewinto

place.Removethedipstickandreadtheoillevel.

4.Iftheoillevelislow ,wipeofftheareaaroundthe

oilllcap,removecapandlltothe“FULL”

markonthedipstick.Exmark4-CyclePremium

EngineOilisrecommended;refertotheEngine

Owner’smanualforanacceptablealternative.Do

Notoverll.

Maintenance

Figure6

1.Springdiscwasher(conetowardsbolthead)

2.Bladebolttorqueto75-80ft-lb(102-109N-m).

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

CheckMowerBlades

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Liftdeckandsecureinraisedpositionasstated

intheCleanGrassBuild-UpUnderDeck

procedure.

3.Inspectbladesandsharpenorreplaceasrequired.

4.Re-installtheblades(iftheywereremoved)and

torquebladeboltsto75-80ft-lb(102-109N-m).

Besurethespringdiscwasherconeisinstalled

towardthebolthead(see

Figure6).

ReplacingtheDischarge

Deector

ServiceInterval:Asrequired

DANGER

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperator’sor

bystander’sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

Neveroperatethelawnmowerunlessyouinstall

amulchplate,dischargedeector,orgrass

collectionsystem.

1.Toremoveadamagedorworndischarge

deector,liftthelegofthespringwiththeloop

outofthenotchinthedischargedeectorand

slidetherodoutofthedischargedeector

brackets,anddischargedeector.

2.Toinstallnewdischargedeector,orientthe

springontherodasshowninFigure7.Slidethe

rodthroughthefrontdischargedeectorbracket,

dischargedeector,andreardeectorbracket.

21

Page 22

Maintenance

Figure7

1.Rod4.Mowerdeck

2.Spring5.Dischargedeector

3.Dischargedeector

3.Hookthebentendoftherodaroundthefront

dischargedeectorbrackettoretainitfrom

slidingout.Placethelegofthespringwiththe

loopinthenotchinthedischargedeectorto

holdthedischargedeectorinthedownposition

Figure7).

(see

Important:Thedischargedeectormustbe

springloadedinthedownposition.Liftthe

deectoruptotestthatitsnapstothefull

downposition.

bracket

6.Assembledview

CheckSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

1.Foryoursafety,yourExmarkmowerisequipped

withOperatorPresenceControls,referredtoas

(OPC).WheneitherthePTOisengaged,or

thespeedcontrolleverisnotinneutralandthe

operatorremovesbothhandsfromthehandles,

themowerenginemuststop.

2.TodetermineiftheOPCisinoperatingcondition,

clearareaofbystanders.Runtheengineat

one-thirdthrottle,thenwiththedriveleversand

neutrallocklatchesinthe“neutrallock”position,

movethespeedcontrolleveroutofneutraland

releasetheOPClevers–theenginemuststop.

3.Again,runtheengineatone-thirdthrottle,move

thespeedcontrollevertoneutral,engagethe

PTOandreleasetheOPClevers–theengine

muststop.

Note:Parkbrakemustbedisengagedbeforethe

speedcontrolleverismovedoutofneutralor

PTOisengagedorenginewillkill.

Note:Ifmachinedoesnotpassanyofthesetests,

donotoperate.ContactyourauthorizedEXMARK

SERVICEDEALER.

Important:Itisessentialthatoperatorsafety

mechanismsbeconnectedandinproper

operatingconditionpriortouseformowing.

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

22

Page 23

Maintenance

ServiceAirCleaner

ServiceInterval:Every25hours—Service

thefoamelement.(May

needmoreoftenunder

severeconditions.See

theEngineOwner’s

manualforadditional

information.)

Every100hours—Service

thepaperelement.(May

needmoreoftenunder

severeconditions.Seethe

EngineOwner’smanual

foradditionalinformation.)

Every200hours/Yearly

(whichevercomes

rst)—Replacethepaper

element.

1.Stopengine,waitforallmovingpartstostop,and

removekeyorsparkplugwire(s).Engageparking

brake.

2.SeetheEngineOwner’sManualformaintenance

instructions.

ChangeEngineOil

ServiceInterval:Aftertherst5hours

Every100hours(May

needmoreoftenunder

severeconditions.)

5.Cleanaroundoilllcapandremovecap.Fillto

speciedcapacityandreplacecap.

6.UseoilrecommendedintheCheckEngineOil

Levelsection.DoNotoverll.Starttheengine

andcheckforleaks.Stopengineandrecheckoil

level.

CheckHydraulicOilLevel

ServiceInterval:Every40hours

1.Stopengineandwaitforallmovingpartstostop,

andremovekey.Engageparkingbrake.

2.Cleanareaaroundhydraulicreservoircapand

removecap.Oillevelshouldbetothetopofthe

bafeinsidethetank.Ifnot,addoil.UseExmark

PremiumHydroOil.Replacehydraulicreservoir

capandtightenuntilsnug.DoNotovertighten.

Note:Thebafeislabeled“HOT”and

“COLD”.Theoillevelvarieswiththe

temperatureoftheoil.The“HOT”levelshows

thelevelofoilwhenitisat225°F(107°C).The

“COLD”levelshowstheleveloftheoilwhen

itisat75°F(24°C).Filltotheappropriatelevel

dependinguponthetemperatureoftheoil.For

example:Iftheoilisabout150°F(65°C),llto

halfwaybetweenthe“HOT”and“COLD”levels.

Iftheoilisatroomtemperature(about75°F

(24°C)),llonlytothe“COLD”level.

CheckTirePressures

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Drainoilwhileengineiswarmfromoperation.

3.Theoildrainhoseassemblyislocatedontheleft

sideoftheengine.

Placepanundermachinetocatchoil.Removeoil

drainplug.Allowoiltodrainandreplaceoildrain

plug.Torqueplugto20-24ft-lb(27-33N-m).

4.ReplacetheoillterpertheEngineOwner’s

Manual.Cleanaroundoillterandunscrewlter

toremove.Beforethenewlterisinstalled,

applyathincoatingofExmark4–CyclePremium

EngineOilonthesurfaceoftherubberseal.

Turnlterclockwiseuntilrubbersealcontacts

thelteradapter,thentightenlteranadditional

2/3to3/4turn.

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto12–14psi(83–97kPa).

4.Inatetirestopressuresstatedabove.Measure

thecircumferenceofeachdrivetire.Adjusttire

pressureswithintheaboverangetotrytomake

tirecircumferencesmatchascloselyaspossible.

5.Semi-pneumaticcastertiresDoNotneedtobe

inated.

CheckConditionOfBelts

ServiceInterval:Every40hours

23

Page 24

Maintenance

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Removethemowerdeckbeltshieldtocheck

mowerbladedrivebeltcondition.

3.Lookunderenginedecktocheckthepumpdrive

beltcondition.

4.Checkallidlerarmstobesuretheypivotfreely .

Disassemble,cleanandgreasepivotbushingsif

necessary.

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.LubricatettingswithNGLIgrade#2

multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.CasterWheel

Bearings

2.CasterPivots

3.PTO

Engagement

Bellcrank

4.PumpDrive

IdlerPivot

5.Pump

Control

Bearings

6.MowerDeck

IdlerPivots

Initial

Pumps

122

22

11

21

22

21

Numberof

Places

Service

Interval

Daily

Daily

Monthly

40hours

40hours

40hours

Number4IdlerPivot(PumpDrive)Located

underenginedeck

Number4and6(IdlerPivots)Disassembleandgrease

onceamonthundera“NoLoad”condition.

3.Lubricatepivotpointswithaspraypenetrating

lubricantasshownintheSprayLubricantChart.

SprayLubricantChart

PivotPoint

1.PTOEngagement

UpperBellcrank

NumberofPlaces

1

ServiceInterval

40hours

CheckSparkPlugs

ServiceInterval:Every160hours

Removesparkplugs,checkconditionandresetgaps,

orreplacewithnewplugs.SeeEngineOwner’ s

Manual.

ChangeFuelFilter

ServiceInterval:Asrequired

Afuellterisinstalledinthefuellinebetweenthe

fueltankandtheengine.Replacewhennecessary.

ChangeHydraulicSystem

Filter

ServiceInterval:Aftertherst250hours

Every500hours/Yearly

(whichevercomes

rst)thereafter

(Every250hours/Yearlyif

usingMobil115W50)

24

Page 25

Maintenance

Note:UseonlyExmarkPartNo.109-4180for

Summeruseabove32°F(0°C)orP/N1-523541for

Winterusebelow32°F(0°C)(RefertoTransmission

sectioninSpecicationsforlterspecications).

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Carefullycleanareaaroundlter.Itisimportant

thatnodirtorcontaminationenterhydraulic

system.

3.Unscrewltertoremoveandallowoiltodrain

fromreservoir.

Important:Beforereinstallingnewlter,

llitwithExmarkPremiumHydroOiland

applyathincoatofoilonthesurfaceofthe

rubberseal.

Turnlterclockwiseuntilrubbersealcontactsthe

lteradapter,thentightenthelteranadditional

2/3to3/4turn.

4.FillreservoirasstatedinCheckHydraulicOil

Level.

ExmarkPremiumHydroOilisrecommended.

Refertothechartforanacceptablealternative:

CAUTION

Raisingthemowerforserviceormaintenance

relyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalor

hydraulicjacksmaynotbeenoughsupport

ormaymalfunctionallowingtheunittofall,

whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

7.Ifeitherdrivewheeldoesnotrotate,oneorboth

ofthechargepumps(locatedonthetopofthe

mainpumpasshownin

their“prime”.RefertoHydraulicSystemAir

Purgesection.

Note:DoNotchangehydraulicsystemoil(except

forwhatcanbedrainedwhenchanginglter),unless

itisfelttheoilhasbeencontaminatedorbeen

extremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

Figure8)mayhavelost

HydroOil

ExmarkPremiumHydro

Oil(Preferred)

Mobil115W50

5.Loosenlter1/2turnandallowasmallamount

ofoiltoleakfromtheoillter(thisallowsairto

bepurgedfromtheoillterandsupplyhosefrom

thehydraulicreservoir).Turnlterclockwise

untilrubbersealcontactsthelteradapter.Then

tightenthelteranadditional2/3to3/4turn.

6.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely .

ChangeInterval

500Hours

250Hours

HydraulicSystemAirPurge

ServiceInterval:Asrequired

Airmustbepurgedfromthehydraulicsystem

whenanyhydrauliccomponents,includingoil

lter,areremovedoranyofthehydrauliclinesare

disconnected.

Thecriticalareaforpurgingairfromthehydraulic

systemisbetweentheoilreservoirandeach

chargepumplocatedonthetopofeachvariable

displacementpump(

thehydraulicsystemwillbepurgedthroughnormal

operationoncethechargepumpis“primed”.

Figure8).Airinotherpartsof

25

Page 26

Maintenance

Figure8

1.Chargepumpcap2.Loosen11/2turnsonly

asteadyowofoiltoowoutfromunderthe

housing.Retightenthecapscrews.Dothisfor

bothpumps.

Note:Hydraulicreservoircanbepressurizedup

to5psitospeedthisprocess.

6.Ifeitherdrivewheelstilldoesnotrotate,stop

andrepeatsteps

pump.Ifwheelsrotateslowly,thesystemmay

primeafteradditionalrunning.Checkoillevel

asstatedinChecktheHydraulicOilLevel

section.

7.Allowunittorunseveralminutesafterthecharge

pumpsare“primed”withdrivesysteminthefull

speedposition.CheckoillevelasstatedinCheck

theHydraulicOilLevelsection.

8.Checkhydrodrivelinkageadjustmentasstatedin

HydroDriveLinkageAdjustmentsectionin

Adjustments.

4and5abovefortherespective

ReplaceEmissionsAirIntake

1.Stopengineandwaitforallmovingpartstostop.

Raisetherearofthemachineupontojackstands

highenoughtoraisethedrivewheelsoffthe

ground.

2.CheckoillevelasstatedinCheckHydraulicOil

Levelsection.

3.Startengineandmovethrottlecontrolaheadto

fullthrottleposition.Movethespeedcontrol

levertothemiddlespeedpositionandplacethe

driveleversinthe“drive”position.

Ifeitherdrivewheeldoesnotrotate,itispossible

toassistthepurgingofthechargepumpby

carefullyrotatingthetireintheforwardposition.

Note:Itisnecessarytolightlytouchthecharge

pumpcapwithyourhandtocheckthepump

temperature.Ifthecapistoohottotouch,turn

offengine.Thepumpsmaybedamagedifthe

pumpbecomestoohot.

Ifeitherdrivewheelstilldoesnotrotatecontinue

withstep

4.

Filter

ServiceInterval:Every500hours

1.Stopengine,waitforallmovingpartstostop,and

removekeyorsparkplugwire(s).Engageparking

brake.

2.Removethelterfromtheventhose.

3.Insertanewlterintotheendoftheventhose.

WheelHub-SlottedNut

TorqueSpecication

ServiceInterval:Aftertherst100hours

Every500hoursthereafter

Figure9todeterminewhichslottednuthasbeen

See

installedontheunit.

4.Thoroughlycleantheareaaroundeachofthe

chargepumphousings.

5.To“prime”chargepump,loosentwohexsocket

headcapscrews(showninFigure8)11/2turns

only.Makesureengineisnotrunning.Lift

thechargepumphousingupwardandwaitfor

Figure9

1.StyleA(blacknish)3.StyleB(yellowzinc)

2..03inch(.76mm)4..24inch(6mm)

•StyleA(blacknish):

26

Page 27

Maintenance

Torquetheslottednutto140-155ft-lb(190-210

N-m).

Note:DoNotuseanti-seizeonwheelhub.

•StyleB(yellowzinc):

1.Removeanddiscardthecotterpin.

2.Torquetheslottednutto100ft-lb(136N-m).

3.Checkdistancefrombottomofslotinnutto

insideedgeofhole.Twothreads(0.1inch)or

lessshouldbeshowing.

Figure10

1.0.1inchmax2.Nomorethantwo

threads(0.1inchmax)

shouldbeshowinghere.

•Sheaveretainingboltinendofenginecrankshaft.

•Fueltankbulkheadttingthreads

Adhesivessuchas“LoctiteRC/609orRC/680”or

“Fel-ProPro-LockRetainingIorRetainingII”are

usedonthefollowing:

•OPCleverhubsandcross-shaft.

Note:Caremustbeusednottobondthe

bearing,nexttoeachOPChub,tothecross-shaft

whichcouldcausebindingoftheOPCleversand

erraticoperation.

•Fueltankstuds,wherestudsareinsertedintotank.

MobilHTSGrease(Or

Food-GradeAnti-seize)

MobilHTSgrease(orfood-gradeanti-seize)isused

inthefollowinglocations:

•Betweenthecutterhousingspindleandbearings.

•Betweenthecutterhousingspindleandsheave.

•Undertopcutterhousingbearingguard.

4.Ifmorethantwothreads(0.1inch)are

showingremovenutandinstallwasher(P/N

1-523157)betweenhubandnut.

5.Torquetheslottednutto100ft-lb(136N-m).

6.Thentightennutuntilthenextsetofslotsline

upwiththecrossholeinshaft.DoNotloosen

nuttoaligntheslot.Ifrequired,tightento

thenextsetofslots.

7.Installnewcotterpin(P/N1-806800).

Note:DoNotuseanti-seizeonwheelhub.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

•Pumpsheavesetscrews.

•Squareheadsetscrewsonhydropumpcontrol

arms.

Copper-BasedAnti-seize

Copper-basedanti-seizeisusedinthefollowing

locations:

Betweenthebladedriveandpumpdrivesheavesand

enginecrankshaft.

DielectricGrease

Dielectricgreaseisusedonallbladetypeelectrical

connectionstopreventcorrosionandlossofcontact.

•OPCleversetscrews.

•Shoulderboltsinendsofspeedcontrolcrank.

27

Page 28

Maintenance

Adjustments

Note:DisengagePTO,shutoffengine,waitfor

allmovingpartstostop,engageparkingbrake,and

removekeybeforeservicing,cleaning,ormakingany

adjustmentstotheunit.

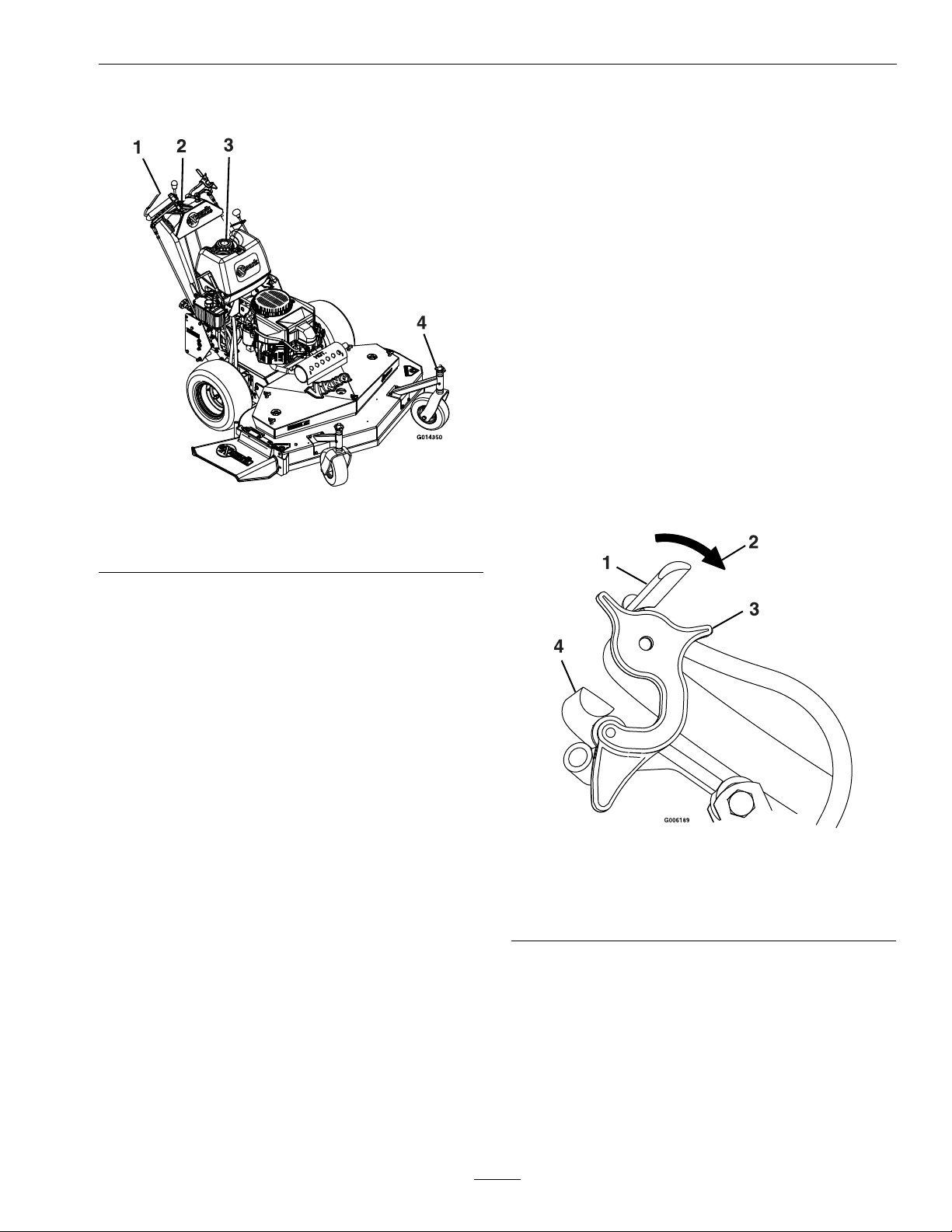

AdjustingtheCuttingHeight

Thecuttingheightofthemowerdeckisadjusted

from1inchto41/4inches(2.54cmto11.4cm)in

1/4inch(.64cm)incrementsbyadjustingtheaxle

position,numberofspacersbelowthecasterhub,

andnumberofspacersbetweenbladeandspindle.

RefertotheCuttingHeightAdjustmenttableand

selectacuttingheightrangeinthelefthandcolumn

whichcorrespondstotherangeofcuttingheights

youwillmostoftenbeusing.Adjustmentswithinthis

rangecanthenbemadebyadjustingthenumberof

bladespacersbetweenthebladeandthebottomof

thespindle(thisisamucheasieradjustmenttomake

thanadjustingaxlepositionandnumberofspacers

belowcastersupporthub).

Notethat:

•Forthebestcutanddischarge,placeaminimum

oftwospacersbetweenthebladeandthespindle.

•Forhighestqualitycut,placeallfourspacers

betweenthebladeandthespindle.

•Ifmulchingkitisinstalled,thehighestqualitycut

canbeobtainedwith3spacersbetweentheblade

andthespindle(minimumis1foragoodcut).

•Whenmulchingleavesitisbesttohavefewer

spacersbetweenbladeandspindle.

Refertothetableandselectdesiredcuttingheight

range.RefertoAdjustingtheAxlePosition,

AdjustingtheNumberofSpacersbelowCaster

SupportHub,andAdjustingtheCutting

HeightwithBladeSpacersandsectionstomake

adjustmentsmakeadjustmenttoobtainspecic

cuttingheight.

CuttingHeightAdjustmentT able(1inchto41/4inches(2.5cm-10.8cm))

Cutting

Height

Range

1–2inches

(2.5–5.0cm)A00

11/8–

21/8inches

(2.9–5.4cm)A01

13/8–

23/8inches

(3.5–6.0cm)A10

13/8–

23/8inches

(3.5–6.0cm)B01

15/8–

25/8inches

(4.1–6.7cm)B10

13/4–

23/4inches

(4.4–7.0cm)B11

2–3inches

(5.0–7.6cm)B20

17/8–

27/8inches

(4.8–7.3cm)C11

Axle

Position

(Figure11)

NumberOfSpacers

BelowCaster

SupportHub

1/2

inch

(1.2cm)

3/16

(.48cm)

Numberof1/4inch(.64cm)BladeSpacersBelowSpindle

4

inch

1inch

(2.5cm)

11/8inch

(2.9cm)

13/8inch

(3.5cm)

13/8inch

(3.5cm)

15/8inch

(4.1cm)

13/4inch

(4.4cm)

2inch

(5.0cm)

17/8inch

(4.8cm)

11/4inch

(3.2cm)

13/8inch

(3.5cm)

15/8inch

(4.1cm)

15/8inch

(4.1cm)

17/8inch

(4.8cm)

2inch

(5.0cm)

21/4inch

(5.7cm)

21/8inch

(5.4cm)

32

11/2inch

(3.5cm)

15/8inch

(4.1cm)

17/8inch

(4.8cm)

17/8inch

(4.8cm)

21/8inch

(5.4cm)

21/4inch

(5.7cm)

21/2inch

(6.4cm)

23/8inch

(6.0cm)

10

13/4inch

(4.4cm)

17/8inch

(4.8cm)

21/8inch

(5.4cm)

21/8inch

(5.4cm)

23/8inch

(6.0cm)

21/2inch

(6.4cm)

23/4inch

(7.0cm)

25/8inch

(6.7cm)

2inch

(5.0cm)

21/8inch

(5.4cm)

23/8inch

(6.0cm)

23/8inch

(6.0cm)

25/8inch

(6.7cm)

23/4inch

(7.0cm)

3inch

(7.6cm)

27/8inch

(7.3cm)

28

Page 29

CuttingHeightAdjustmentTable(1inchto41/4inches(2.5cm-10.8cm))(cont'd.)

Maintenance

Cutting

Height

Range

21/8–

31/8inches

(5.4–7.9cm)C20

21/4–

31/4inches

(5.7–8.3cm)C21

21/2–

31/2inches

(6.4–8.9cm)C30

23/8–

33/8inches

(6.0–8.6cm)D21

21/2–

31/2inches

(6.4–8.9cm)D30

23/4–

33/4inches

(7.0–9.5cm)D31

3–4inches

(7.6–10.1cm)D40

27/8–

37/8inches

(7.3–9.8cm)E31

31/8–

41/8inches

(7.9–10.5cm)E40

31/4–

41/4inches

(8.3–10.8cm)E41

Axle

Position

(Figure11)

NumberOfSpacers

BelowCaster

SupportHub

1/2

inch

(1.2cm)

(.48cm)

Numberof1/4inch(.64cm)BladeSpacersBelowSpindle

3/16

inch

4

21/8inch

(5.4cm)

21/4inch

(5.7cm)

21/2inch

(6.4cm)

23/8inch

(6.0cm)

21/2inch

(6.4cm)

23/4inch

(7.0cm)

3inch

(7.6cm)

27/8inch

(7.3cm)

31/8inch

(7.9cm)

31/4inch

(8.3cm)

32

23/8inch

(6.0cm)

21/2inch

(6.4cm)

23/4inch

(7.0cm)

25/8inch

(6.7cm)

23/4inch

(7.0cm)

3inch

(7.6cm)

31/4inch

(8.3cm)

31/8inch

(7.9cm)

33/8inch

(8.6cm)

31/2inch

(8.9cm)

25/8inch

(6.7cm)

23/4inch

(7.0cm)

3inch

(7.6cm)

27/8inch

(7.3cm)

3inch

(7.6cm)

31/4inch

(8.3cm)

31/2inch

(8.9cm)

33/8inch

(8.6cm)

35/8inch

(9.2cm)

33/4inch

(9.5cm)

10

27/8inch

(7.3cm)

3inch

(7.6cm)

31/4inch

(8.3cm)

31/8inch

(7.9cm)

31/4inch

(8.3cm)

31/2inch

(8.9cm)

33/4inch

(9.5cm)

35/8inch

(9.2cm)

37/8inch

(9.8cm)

4inch

(10.1cm)

31/8inch

(7.9cm)

31/4inch

(8.3cm)

31/2inch

(8.9cm)

33/8inch

(8.6cm)

31/2inch

(8.9cm)

33/4inch

(9.5cm)

4inch

(10.1cm)

37/8inch

(9.8cm)

41/8inch

(10.5cm)

41/4inch

(10.8cm)

Important:AlwaysadjusttheNumberofSpacersbelowCasterHubtocorrespondtotheAxle

Positionasshownintabletoobtainproper“rake”(bladesshouldalwaysbeleveltotheground

ortippedslightlydownatthefront).

AdjustingtheAxlePosition

Desiredcuttingheightrangecanbeobtainedby

adjustingtherearaxleandplacingcasterspacers

aboveorbelowthecasterarm(seeFigure11and

Figure12alongwiththeCuttingHeightAdjustment

Chart).

Toadjustrearaxle:

1.Stopthemachineandmovethedriveleversto

theneutrallockposition.

2.DisengagethePTO.

3.Raisetherearofthemachineupontojackstands

andremovethedrivewheels.

4.Loosenbutdonotremovethetoptwobolts

oneachhydraulicmotormountingbracket(see

Figure11).

5.Removethebottomsetsofhardwareforeach

bracket.

6.Repositionthemountingbrackettothedesired

heightandreinstallthebottomhardware.

7.Tightenallhardwareandremountdrivewheels.

29

Page 30

Maintenance

8.Removejack.

9.Adjustwheeldriveandbrakelinkagesas

required(seeBrakeandWheelDriveLinkage

Adjustmentsection).

Figure11

1.PositionA4.PositionD

2.PositionB5.PositionE

3.PositionC

6.AxlePivotBolt-loosen

butDoNotremove

Figure12

1.Four1/2inch(127mm)

spacers

2.QuickPin4.Castersupport

3.3/16inch(4.8mm)

spacer

7.Adjustthenumberof1/2inchspacersbetween

bottomofhubandcasteryoketoobtainthe

desiredcuttingheightfromtheCuttingHeight

AdjustmentTableintheAdjustingtheCutting

Heightsection.

8.Installremainingspacersontopofhub.

9.Install“quickpin”.

10.Repeatforothercaster.

Note:Theaxlepositionsarein1/2inch(1.3cm)

incrementsandthelargecasterspacersare1/2

inch(1.3cm)thick.Therefore,byadjustingthe

samenumberof1/2inch(1.3cm)casterspacersas

axleholepositionsthebladeswillretainthesame

front-to-backtip(rake).

AdjustingtheNumber

ofSpacersbelowCaster

SupportHub

1.Stopthemachineandmovethedriveleversto

theneutrallockposition.

2.DisengagethePTO.

3.Placethedriveleversinthe“parkbrake”position.

4.Pushdownonhandlestoliftfrontcastersoffthe

ground.

5.Supportwithjackstands.

6.Remove“quickpin”fromonecasterandremove

casterfromhub(seeFigure12).

AdjustingtheCuttingHeight

withBladeSpacers

1.Stopthemachineandmovethedriveleverstothe

neutrallockedposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Bladesmaybeadjustedforcuttingheightbyusing

thefour1/4inch(.64cm)spacersfoundonthe

bladespindlebolts(factorysettingistwoabove

andtwobelow).Thisallowsa1inch(2.5cm)

rangein1/4inch(.64cm)incrementsofcutting

heightinanyaxleposition.Thesamenumber

ofbladespacersmustbeusedonallbladesto

achievealevelcut(twoaboveandtwobelow,one

aboveandthreebelow,etc.).

6.Raisefrontofdeckandsupportwithjackstands.

7.Holdbladeboltonbottomandloosenspindle

nutontop.

8.Adjustnumberofspacersbetweenbottomof

spindleandbladeasindicatedintheCutting

30

Page 31

HeightAdjustmentTableandnotesinthe

AdjustingtheCuttingHeightsection.

9.Installunusedspacersbetweentopofspindleand

spindlenut.

10.Torqueboltto75–80ft-lb(102–109N-m)(see

Figure13).

Maintenance

Figure14

1.ThebellcrankjustclearsthegussetwiththePTO

engaged

2.PTOSafetySwitch(locatedbeneaththeenginedeck)

3.Bellcrank

Figure13

1.Springdiscwasher

(conetowardsbolthead)

2.Bladebolttorqueto

75–80ft-lb(102–109

N-m)

PTOEngagementLinkage

Adjustment

LocatedbetweenthePTOengagementbellcrankand

PTOengagementassistarmbeneaththefront,left

handcorneroftheenginedeck.

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.Removekeyorsparkplug

wire(s).

2.WithPTOengaged(leverpulledup,adjustthe

linkagelengthtowherethelowerendofthe

bellcrankjustclearstheaxlesupportgusset(see

Figure14).Makesuretheassistarmisagainstthe

rearassistarmstoponthedeck(seeFigure15).

Pushtheleverdowntothedisengagedposition.

Theassistarmshouldcontactthefrontassistarm

stoponthedeck.Ifitdoesnotcontact,readjust

sothatthebellcrankisclosertothegusset.

PTOSafetySwitch

Adjustment

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.Removekeyorsparkplug

wire(s).

2.WithPTOdisengagedandassistarmagainstthe

frontassistarmstop,adjustthebladesafetyswitch

mountingbracket(ifneeded)untilthebellcrank

depressestheplungerby1/4inch(.64cm).

3.BesurethebellcrankDoesNottouchtheswitch

bodyordamagetotheswitchcouldoccur.

4.Retightenswitchmountingbracket.

EnginetoMowerDeckBelt

Adjustment

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.Removekeyorsparkplug

wire(s).

2.EngagePTO.

3.Checkbeltguidesunderrearengineandfront

mowerdecktoseethattheyareproperlyset(see

BeltGuideAdjustmentsectionforinstructions).

4.Beltmustbetightenoughsoitdoesnot

slipduringheavyloadswhilecuttinggrass.

Over-tensioningwillreducebeltandspindle

bearinglife.Toadjustbelttension,loosenthe

5/16inchwhizlocknutonturnbuckleandrotate

theturnbuckle;rotateturnbuckletowardrearof

31

Page 32

Maintenance

mowertotighten,andtowardfrontofmowerto

loosenbelttension(seeFigure15).

For48inchDecks:Ifthereisnoadjustmentleft

intheturnbuckleandthebeltisstillloose,therear

idlerpulleycanberepositionedinthefronthole

Figure15).Thebeltguidelocatednexttothe

(see

pulleymustalsoberepositionedinthefronthole

whenthepulleyismoved.Theturnbucklewill

needtobereadjusted.

Checkbelttensionafterthersthourofoperation

andatleasttwiceduringtherst24hoursof

operation.Adjustasnecessary.

Note:Afterreadjustingthebelttensioncheck

thebeltguideadjustmentasstatedinthe

BeltGuideAdjustmentandBladeBrake

Adjustmentsections.

Figure16

36inchMowerDeck

Figure15

48inchDeckShownforReferenceOnly

1.PulleylocationforVikingHydro

2.Beltguidemustbemovedtothefrontpositionifthe

pulleyismoved(48inchdeckonly)

3.Pulleycanbemovedtothefrontpositiontotightenthe

beltwhenthereisnoadjustmentleftintheturnbuckle

(48inchdeckonly)

4.Turnbuckle

5.5/16inch(.79cm)minimumengagement

6.5/16inchwhizlocknut

7.RearAssistArmStop

8.AssistArm

9.FrontAssistArmStop

10.Point“A”

5.Properbelttensionwillrequireabout10lb(4.5

kg)sidepullonbelt,halfwaybetweenpulleys(see

Figure15,item10–PointA)todeectbelt1/2

inch(1.3cm).

MowerDeckBeltRoutings:

Figure17

48inchMowerDeck

BladeBrakeAdjustment

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.Removekeyorsparkplug

wire(s).

2.DisengagePTO.

3.Makesurethebladebrakepadrestsagainst

thesheave.Adjustthespringmountingbolts

toproperlyalignthepadonthesheave(see

Figure18).

32

Page 33

Figure18

ShownwithBladesDisengaged

1.BladeBrakeRod

2.SpringMountingBolts

3.1/8inchto3/16inch

(.32–.47cm)

4.Checkthedistancebetweenthespacerandthe

nutattheendofthebladebrakerod.The

distanceshouldbebetween1/8inch(.32cm)and

3/16inch(.47cm)(see

Figure18).

5.EngagethePTOandchecktomakesurethe

bladebrakepadclearsthesheave.

Maintenance

Figure20

48inchBeltGuideLocation

(Viewedfromunderneaththeenginedeck)

1.13/8inch(3.5cm)3.Endofslot

2.1/4inch(.64cm)

clearance

PumpDriveBeltTension

Self-tensioning-Noadjustmentnecessary.

BeltGuideAdjustment

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.Removekeyorsparkplug

wire(s).

2.EngagethePTO.

3.Checkbeltguideundertheenginedeckforproper

adjustment(seeFigure19andFigure20).Adjust

asnecessary.

Figure19

36inchBeltGuideLocation

(Viewedfromunderneaththeenginedeck)

HydroDriveLinkage

Adjustment

•AdjustSpeedControlLinkageandNeutral

SafetySwitch:

1.Stopengineandwaitforallmovingpartsto

stop.Engageparkingbrake.Removekeyor

sparkplugwire(s).

2.Movethespeedcontrollever(locatedon

theconsole)tothefullforwardpositionand

checktheorientationofthetabsontheends

ofthespeedcontrolcrank(see

Thesetabsshouldbepointingstraightdown

atthe6o’clockpositionorslightlyforward.

Adjustthethreadedyokeatthebottomofthe

speedcontrollinkage(see

tabsarepositionedcorrectly.

Figure21)untilthe

Figure21).

1.11/4inch(3.1cm)3.Endofslot

2.1/4inch(.64cm)

clearance

33

Page 34

Maintenance

Figure21

ViewedfromLeftSideofUnit

1.NeutralSafetySwitch3.5/16inch(7.9mm)

2.ActuatingTabinneutral

position

3.Pullthespeedcontrolleverbacktoneutral.

Checkthattheneutralsafetyswitchactuating

tabhasdepressedtheplungeroftheswitch

sothatthereisabout5/16inch(7.9mm)

betweenthetabandtheswitch(see

Ifnecessary,movetheswitchforeandaft.

•AdjustNeutralControlLinkages:

1.Raisetherearofthemachineupontojack

standshighenoughtoraisethedrivewheels

offoftheground.

2.Starttheengineandmovethethrottleahead

tothefullthrottleposition.Placetheneutral

locklatchesinthe“forward”positionas

shownin

Figure4.Releasetheparkbrake

andmovethespeedcontrollevertothe

“mid-speed”position.

Note:TheOPCleversmustbehelddown

andtheparkbrakemustbedisengaged

wheneverthespeedcontrolleverismoved

outofneutralortheenginewillkill.

3.Squeezetherespectivedriveleveruntilan

increasedresistanceisfelt,thisiswhere

neutralshouldbe.

Ifthewheelturnswhileholdingthedrive

leverinneutral,theneutralcontrollinkages

needtobeadjusted.Ifthewheelstopsthen

gotostep

7.

Figure21).

Figure22

ViewedfromLeftSideofUnit

1.NeutralControlLinkage5.SpeedControlLinkage

2.HydroControlLinkage

3.DriveLeverLinkage7.Loosennut

4.SpeedControlCrank

6.Adjusthere-rotateat

approximately1/4

turnincrementsand

re-check.

8.Yoke

4.Loosenthenutagainsttheneutralcontrol

linkageyokeasshowninFigure22.

5.Adjusttheneutralcontrollinkageuntil

therespectivedrivewheelstopswhenthe

leverispulledagainsttheneutralspring

(neutralposition).Turntheadjustingbolt

approximately1/4turnclockwiseifthe

wheelisturninginreverseorturnthebolt

approximately1/4turncounterclockwiseif

thewheelisturningforward.Releasethe

drivelevertotheforwarddrivepositionand

squeezebackintotheneutralposition.Check

toseeifthewheelstops.Ifnot,repeatthe

aboveadjustmentprocedure.

6.Makethisadjustmentonbothsides.

7.Afteradjustmentsaremadeandthewheels

stopwhenthedriveleversareintheneutral

position,tightenthenutsagainsttheyokes.

•AdjustHydroControlLinkages:

1.Placethespeedcontrolleverinthe“neutral”

position.Thisadjustmentisagainmadewith

rearofmachineonjackstandsandengine

runningatfullthrottle.OPCleverswillhave

tobehelddownandtheparkbrakemustbe

34

Page 35

Maintenance

disengagedwheneverspeedcontrolleversare

movedoutoftheneutralposition.

Note:Theneutrallocklatchesshouldbe

“unlocked”andintheforwardposition.

2.Loosenthefrontnutonlefthydrocontrol

linkageasshownin

Figure22.Turntherear

controllinkageadjustingnutcounterclockwise

untilwheelrotatesforward.Turntherearnut

ofleftcontrollinkageclockwise1/4ofaturn

atatime,stoppingtomovethespeedcontrol

forwardandbacktoneutral,untilleftwheel

stopsrotatingforward.

Turntherearnutanadditional1/2turnand

tightenthefrontnutmakingsurenottoput

abindonthelinkage.Makesureatpartof

linkageisperpendiculartopinpartofswivel

Figure23).

(see

toneutral.Recheckthedrivewheelrotation

toseeiffurtheradjustmentisnecessary.

4.Thespringthatkeepstensionontheknob

shouldnormallynotneedadjustment.

However,ifadjustmentisneeded,adjustto

wherelengthofspringisabout1inch(2.5cm)

betweenthewashers.Adjustspringlengthby

turningnutatfrontofspring.

•DriveLeverLinkageAdjustment:

1.Withrearofmachinestillonjackstandsand

enginerunningatfullthrottle,disengage

theparkbrakeandmovethespeedcontrol

levertothemidwayposition.Movethe

respectivedriveleverupwarduntilitreaches

theneutralpositionandengageneutrallock

latches(

Figure24).Ifthetirerotatesineither

direction,thelengthofthedriveleverlinkwill

needtobeadjusted.

Figure23

1.LeftHydroControlLink

(leftsideshown)

2.Frontnut5.Linkageinincorrect

3.Rearnut

4.Linkageisperpendicular

topin(correctposition)

position

6.Endviewofswivel

Afteradjustingthelefthydrocontrollinkage,

movethespeedcontrollevertothemid-speed

positionandthenbacktotheneutralposition.