Exmark Ultra VAC QDS LAZER Z, Ultra VAC QDS Lazer Z XP, Ultra VAC QDS LASER Z XS, Ultra Vac QDS UVD60C, Ultra Vac QDS UVD72C Operator's Manual

Page 1

For Ultra Vac Serial Nos.

510,000 & Higher

(to fit Units 352,000 & Higher)

Part No. 103-8854

Page 2

POTENTIAL HAZARD

♦ This product is a piece of power equipment.

WHAT CAN HAPPEN

♦ Failure to follow safe operating pr actices can result in serious

operator injury or even death.

HOW TO AVOID THE HAZARD

♦ Keep all shields, guards and safety devices (especially the grass

discharge system) in place and in proper working condition.

♦ Stop engine and wait for all moving parts t o st op. Remove key

before adjusting, servicing, or performing maint enance.

♦ If mower deck or blower becomes clogg ed, st op engine and wait

for all moving parts to stop. Remove spark plug wire(s) or

remove key before cleaning blockage.

♦ Keep hands, feet and clothing away from power driven parts.

♦ Keep off mower unless seat platf orm is provided.

♦ Keep others off mower.

WARNING

Exmark reserves the right to make changes or add improvements to its products at any time

without incurring any obligation to make such chang es t o products manufactured previously.

Exmark, or its distributors and dealer s, accept no responsibility for variations which may be evident

in the actual specifications of it s pr oduct s and t he st atements and descriptions contained in this

publication.

ii

Page 3

EXMARK PARTS PLUS® PROGRAM

EFFECTIVE DATE: September 1, 1995

Program

If your Exmark dealer does not have the Exmark part in stock,

Exmark will get the parts to the dealer the next business day or the

part will be FREE* Guaranteed!!

How the Program Works

1. If dealer does not have part in stock for a "down" unit at

the time of request by customer, the dealer contacts his

distributor by 1:00 p.m., local time, and requests Exmark

Parts Plus

®

shipment of six (6) line items or less.

2. Distributor ships part(s) to dealer or customer, as

requested by dealer, same day, overnight UPS Distributor

3. If distributor does not have the part(s) in stock to satisfy

bills dealer for part and freight charges where applicable.

Exmark Parts Plus

p.m., central time, with an Exmark Parts Plus

®

order, he contacts Exmark by 3:00

®

order of six

(6) line items or less.

4. If order is received by 3:00 p.m. central time, Exmark ships part(s) direct to dealer or customer, as requested by

distributor, same day, overnight UPS Exmark bills the distributor for parts and shipping charges, where

applicable.

5. The customer pays for the part and freight if it is shipped under the Exmark Parts Plus® and if it arrives in

6. Who pays for the part and freight if it fails to arrive overnight in accordance to the program?

A. Under any circumstance the customer does not pay.

accordance to the program.

B. If the part does not arrive overnight due to:

®

1. The dealer not submitting the Exmark Parts Plus

dealer pays for the part and freight.

order to his Exmark distributor by 1:00 p.m., the

2. The Distributor being unable to ship the part the same day or not submitting the Exmark Parts Plus®

order to Exmark by 3:00 p.m., central time, the Distributor pays for the part and freight.

3. Exmark being unable to ship the part and the Exmark parts order is received by 3:00 p.m., central time,

Exmark pays for the part and freight.

4. If the part does not arrive overnight due to the shipper (UPS), the shipper pays for the freight and

Exmark pays for the part.

The following restrictions apply -- The Exmark Parts Plus® Program is available only through participating

Exmark Dealers and applies only to orders submitted on this program Monday through Thursday. Parts Plus service is

available only in the 48 contiguous United States. UPS has initiated a Saturday delivery program to many areas of the

continental United States and can be requested for an overnight shipment on Friday to be delivered Saturday. The next

day air charge, plus the Saturday delivery fee will be the responsibility of the purchaser. Exmark Mfg. will assume no

responsibility for Saturday delivery shipments. To qualify, all Exmark Parts Plus® orders must be received by Exmark by

3:00 p.m., central time. Orders must be six (6) line items or less. Exclusions from the Exmark Parts Plus

®

Program are:

Any wholegood or accessory in its entirety, engines and engine replacement parts, 5-speed Peerless transmissions and

5-speed transaxles, hydraulic or hydrostatic wheel motors, cutter decks and engine decks or any item exceeding United

Parcel Service size and weight restrictions.

Due to UPS restrictions, aerosol spray paint is considered a hazardous material and cannot be shipped via UPS next day

or Second Day Air.

Exmark Manufacturing stocks a limited supply of parts for transaxles, pumps and wheel motors. These parts can be

ordered for Next Day Air shipment but will not be guaranteed per the Parts Plus Program.

iii

Page 4

OPERATOR'S MANUAL

This manual contains assembly, operating, maintenance, adjustment and safety instructions

for your Exmark Ultra Vac Q DS.

BEFORE OPERATING YOUR ULTRA VAC QDS, CAREFULLY READ AND

UNDERSTAND THIS MANUAL AND THE OPERATOR’S MANUAL FOR YOUR MOWER IN

THEIR ENTIRETY.

By following the operating, maintenance and safety instructions, you will prolong the lif e of

your Ultra Vac QDS, maintain its maximum efficiency and promote safe operation.

If additional information is needed, or should you require trained mechanic ser vice, cont act

your authorized Exmark equipment dealer or dist r ibut or .

All Exmark equipment dealers and dist r ibut or s ar e kept informed of t he latest methods of

servicing and are equipped to provide prompt and ef ficient service in the field or at their ser vice

stations. They carry ample stock of ser vice part s or can secure them promptly for you from t he

factory.

All Exmark parts are thoroughly tested and inspected before leaving the factory, however,

attention is required on your part if you are to obtain the fullest measure of satisfaction and

performance.

iv

Page 5

TABLE OF CONTENTS

Description

Page

1. Safety

1.1 Safety Alert Symbol.............................................................................. 1

1.2 Training ................................................................................................ 1

1.3 Preparation........................................................................................... 1

1.4 Operation...........................................................................................2-3

1.5 Safety Signs.........................................................................................4

2. Specifications

2.1 Model Number and Required Accessories............................................ 5

2.2 Dimensions........................................................................................... 5

2.3 Bagging System ................................................................................... 5

3. Assembly Instructions

3.1 Assembly Diagram................................................................................ 6

3.2 Install Hopper Assembly..................................................................7-11

3.3 Install Blower Assembly................................................................. 11-12

3.4 Assemble Tubes............................................................................ 12-13

3.5 Install the Front Weight.................................................................. 13-15

3.6 Install the Caster Weights................................................................... 15

3.7 Adjustments................................................................................... 15-16

4. Operation

4.1 Pre-Start............................................................................................. 16

4.2 Mowing.......................................................................................... 16-17

4.3 Bagger Removal for Side Discharge.............................................. 17-18

4.4 Transporting..................................................................................18-19

5. Maintenance

5.1 Periodic Maintenance.................................................................... 20-21

5.2 Adjustments................................................................................... 21-22

6. Warranty ...............................................................................................

23

v

Page 6

1. SAFETY

1.1 SAFETY ALERT SYMBOL

This SAFETY ALERT SYMBOL is used both in this manual and on the machine to

identify important safet y messages which must be followed to avoid accidents. This

symbol means:

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The safety alert symbol appears above information which alerts you to unsafe actions or

situations and will be followed by the word DANGER, WARNING, or CAUTION.

DANGER: White lett ering/Red background. Indicat es an im minently hazardous situation

which, if not avoided, WILL result in death or serious injur y.

CAUTION: Black lettering/ Yellow backgr ound. Indicates a potentially hazardous situation

1.2 TRAINING

1.2.1 Regar d the Exmark Ultra Vac QDS as a piece of power equipm ent and t each this

1.2.2 Bef or e oper at ing your Ultra Vac QDS, carefully read and understand this manual and

1.2.3 Do not allow operation of this machine by untrained personnel. Never allow

1.2.4 Avoid mowing while people, especially children, or pets, are nearby. Keep in

1.3 PREPARATION

1.3.1 Evaluate the terrain to determine what accessories and attachment s ar e needed

1.3.2 The use of personal protective equipment , such as (but not limited to) protect ion

WARNING: Black lettering/Or ange background. Indicates a potent ially hazardous

situation which, if not avoided, COULD result in deat h or ser ious inj ury.

which, if not avoided, MAY result in minor or moderate injury.

regard to all who operate this unit.

the operator’s manual for your m ower in their entirety. Familiarize yourself with the

controls and the proper use of the eq uipm ent. If the operator(s ) or m echanic( s) can

not read English, it is the owner’s responsibility to explain this ma t er ial t o t hem .

children, teenagers, or people unfamiliar with these instructions to use the mower.

Local regulations may restrict the age of the operator.

mind that the operator or user is responsible for accidents or hazards occurring to

other people or their property.

to properly and safely perform the job. Only use accessories and attachments

approved by Exmark.

for the eyes, ears, feet , and head is r ecom m ended.

POTENTIAL HAZARD

♦ This machine produces sound levels in excess of 85

dBA at the operator’s ear when in operation.

WHAT CAN HAPPEN

♦ Exposure to sound levels of 85 dBA or above for

extended periods of time can cause hearing loss.

HOW TO AVOID THE HAZARD

♦ Wear hearing protection when operating this machine.

1.3.3 While mowing, always wear substantial footwear and long trousers. Do not

operate equipment when barefoot or when wearing open sandals.

1.3.4 Thoroughly inspect the area where the equipment is to be used and remove all

stones, sticks, wires, bones, and other foreign objects which may damage the

equipment or cause personal injury to the operat or or bystander s.

CAUTION

1

Page 7

1.4 OPERATION

Although hazard control and accident prevention are partially dependent upon the

design and configuration of the equipment, t hese factors are also dependent upon

the awareness, concern, prudence, and proper training of t he personnel i nvol ved in

the operation, transport, maintenance, and st orage of t he equi pment . It is essential

that all Operator Safety Mechanisms be connect ed and i n operat i ng condi t ion prior

to use for mowing. Refer to the Operator’s Manual for the mower for additional

hazard control and accident prevention information.

POTENTIAL HAZARD

♦ An uncovered discharge opening will allow objects to

be thrown in operator’s or bystander’s direction.

Also, contact with blade could occur.

WHAT CAN HAPPEN

♦ Thrown objects or blade contact can cause serious

injury or kill you or bystanders.

HOW TO AVOID THE HAZARD

♦ Never operate mower unless discharge chute or

entire grass collection system is installed.

HOW TO AVOID THE HAZARD

1.4.1 Use EXTREME caution when mowing and/or turning on slopes as loss of traction

and/or tip-over could occur. The operator is r esponsible for safe operation on slopes.

POTENTIAL HAZARD

♦ There are rotating blades in the blower and under the

mower deck.

WHAT CAN HAPPEN

♦ Blade contact can cause serious operator or bystander

injury or even death.

♦ Do NOT reach into Blower unless Rotation Indicator

has Stopped. Disengage PTO, stop engine, remove

key, WAIT FOR MOVING PARTS TO STOP

♦

Do NOT operate mower without deflector chute or

entire bag system in place.

WARNING

DANGER

POTENTIAL HAZARD

♦ Mowing on wet grass or steep slopes can cause

sliding and loss of control.

WHAT CAN HAPPEN

♦ Wheels dropping over edges, ditches, steep banks,

or water can cause rollovers, which may result in

serious injury, death or drowning.

HOW TO AVOID THE HAZARD

♦ Do not mow slopes when grass is wet.

♦ Do not mow near drop-offs or near water.

♦ Do not mow slopes greater than 15 degrees.

♦ Reduce speed and use extreme caution on slopes.

♦ Avoid sudden turns or rapid speed changes.

DANGER

2

Page 8

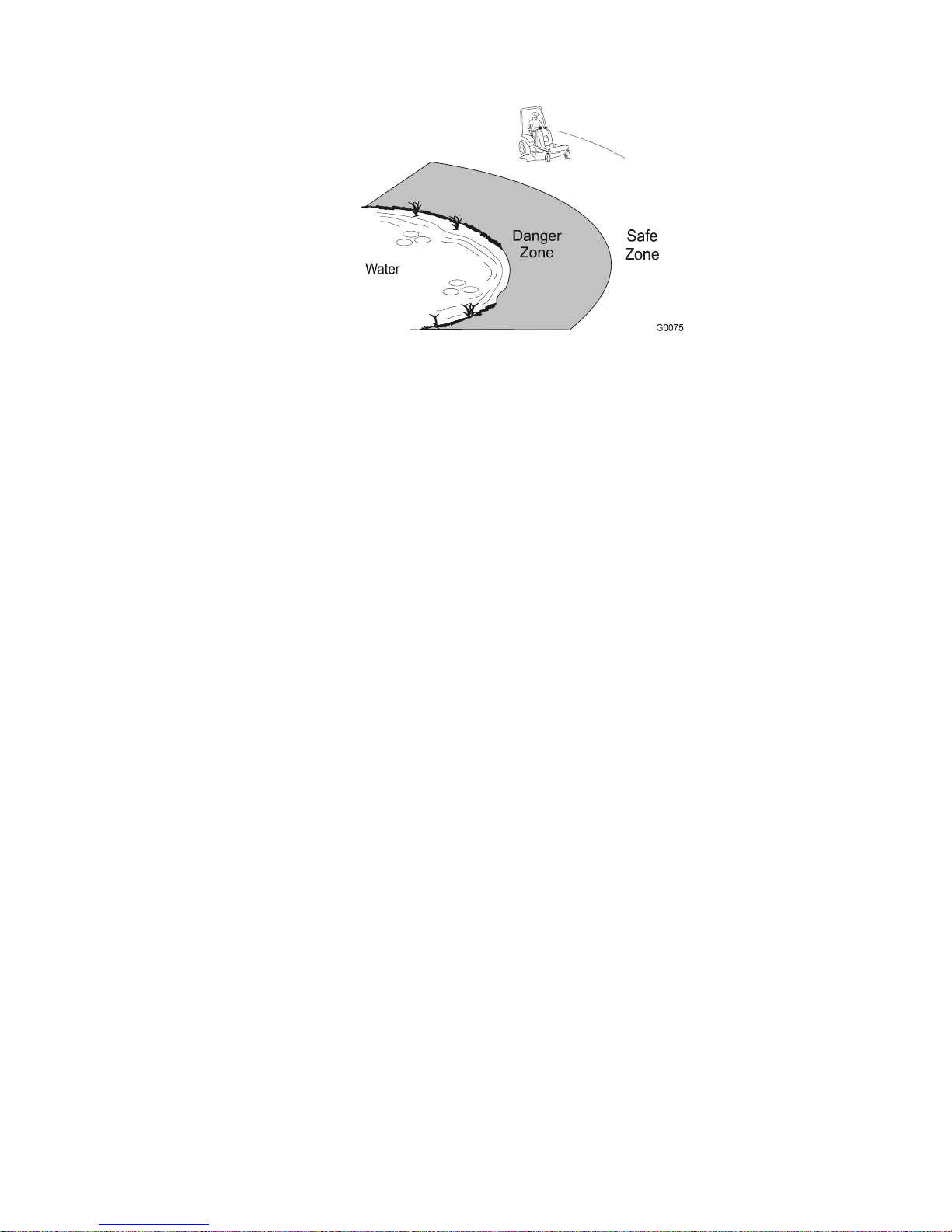

• Use a walk behind mower and/or a hand trimmer near drop-offs, ditches, steep

banks or water. This area can be dangerous, see Figure 1.

Figure 1

SAFE ZONE FOR MOWING

• Progressively greater care is needed as the slope increases.

• Always avoid sudden starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly off the slope.

• Avoid sudden starts when mowing uphill. Mower may tip backwards.

• Be aware that loss of traction may occur going downhill. Weight transfer to

the front wheels may cause drive wheels to slip and cause loss of braking

and steering.

• Watch for ditches, holes, rocks, dips, and r ises t hat change the operating

angle, as rough terrain could overtur n the machine.

• Remove or mark obstacles such as rocks, t r ee lim bs, et c. from the mowing

area. Tall grass can hide obstacles.

• The operating characteristics of the machine will change with the Ultra Vac

QDS installed. The stability and traction of the machine will change as the

Ultra Vac QDS hopper fills with grass clipping s. Use pr ogressively greater

care on slopes as the hopper fills.

• Always install and remove the Ultra Vac QDS, including counterweights, as

instructed. Failure to do so will cause a reduction in stability or tr act ion. Do

not operate the mower with only a portion of the Ultra Vac Q DS inst alled.

1.4 SAFETY SIGNS

1.4.1 Keep all safety signs legible. Rem ove all g r ease, dirt and debris from saf et y

signs and instructional labels.

1.4.2 Safety signs must be replaced if they are missing or illegible.

1.4.3 When new components ar e inst alled, be sur e that current safety signs are

affixed to the replaced components.

1.4.4 Replacement safety signs may be obtained from your authorized Exmark

equipment dealer or distributor or from Exmark Mfg. Co. Inc.

1.4.5 Safety signs may be affixed by peeling off the backing t o expose the adhesive

surface. Apply only to a clean, dry surface. Smooth to remove any air bubbles.

1.4.6 Familiarize yourself with the following safet y signs and instruction labels. They

are critical to the safe operation of your Exmark Ultra Vac QDS.

3

Page 9

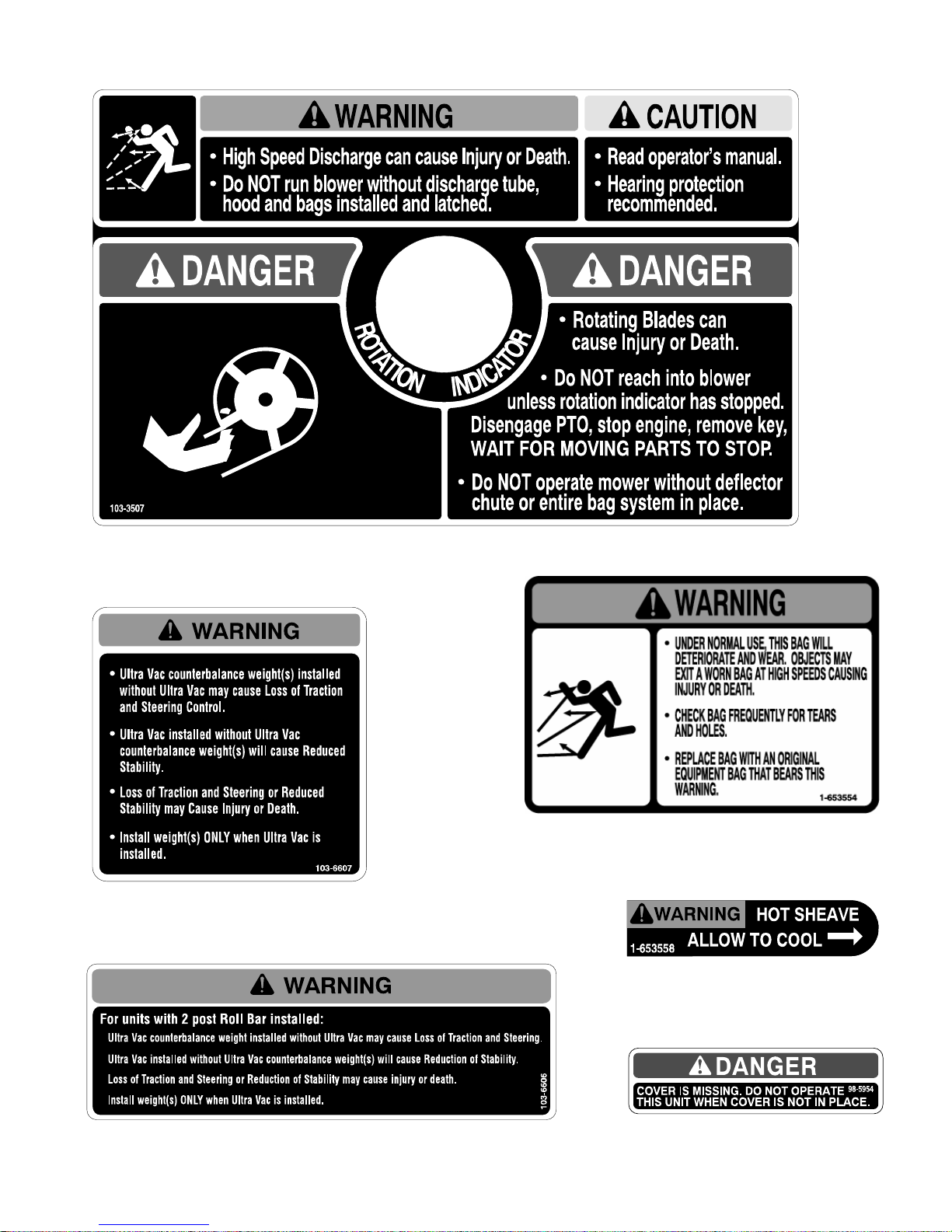

PART NO. 103-3507

LOCATION: Top of Blower

PART NO. 103-6607

LOCATION: Top of Caster Weights &

Top of Blower

PART NO. 1-653554

LOCATION: Rear of Bag

PART NO. 1-653558

LOCATION: Top of Idler Arm

PART NO. 103-6606

LOCATION: Top of Front Weight

4

PART NO. 98-5954

LOCATION: Under Bearing

Cover

Page 10

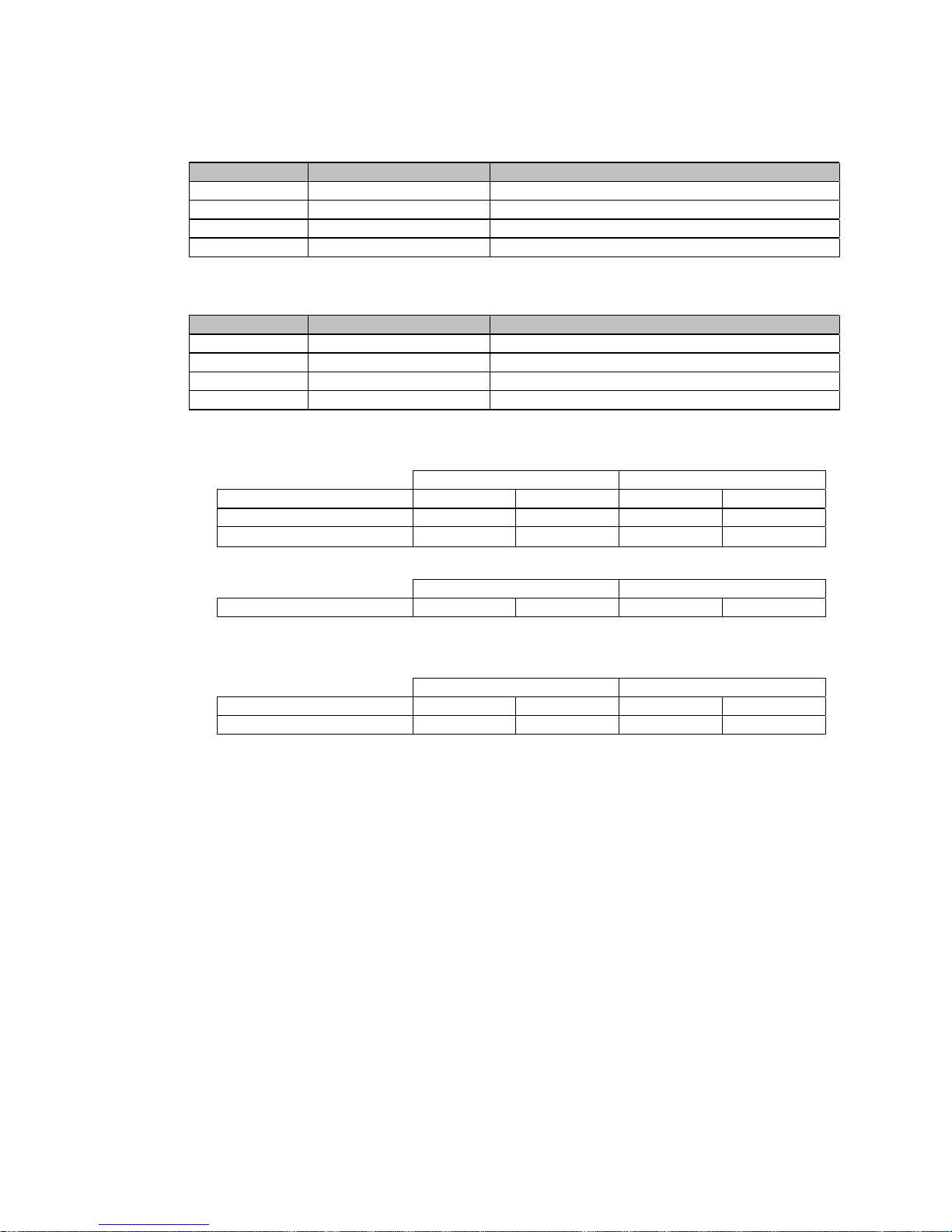

2. SPECIFICATIONS

2.1 MODEL NUMBERS AND REQUIRED ACCESSORIES:

UVD60C

The following accessories are required for installation:

Unit Serial Number Required to Mount Ultra Vac QDS

60” Lazer Z 510,000 and Higher None Required

60” Lazer Z SN 352,000 – 509,999 103-7419- Kit, 05 UV to previous Lazer Z units

60” Lazer Z XP All Serial Numbers None Required

60” Lazer Z XS All Serial Numbers 103-7876 - Kit, UV to XS

UVD72C

The following accessories are required for installation:

Unit Serial Number Required to Mount Ultra Vac QDS

72” Lazer Z 510,000 and Higher None Required

72” Lazer Z SN 352,000 – 509,999 103-7419- Kit, 05 UV to previous Lazer Z units

72” Lazer Z XP All Serial Numbers None Required

72” Lazer Z XS All Serial Numbers None Required

2.2 DIMENSIONS

5.2.1 Overall unit length w/Ultra Vac Q DS:

60" Deck 72" Deck

Lazer Z XP & Lazer Z XS 107.90" (274.1 cm) 112.00" (284.5 cm)

Lazer Z - Air Cooled 106.65" (270.9 cm) 110.75" (281.3 cm)

Lazer Z - Liquid Cooled 106.90" (271.5 cm) 111.00" (281.9 cm)

5.2.2 Overall unit width w/Ultra Vac QDS:

60" Deck 72" Deck

All Units 74.44" (189.1 cm) 86.49" (219.7 cm)

2.3 BAGGING SYSTEM

5.3.1 Weight:

60" Deck 72" Deck

Lazer Z XP 308 lbs. (140 kg) 308 lbs. (140 kg)

Lazer Z & Lazer Z XS 361 lbs. (164 kg) 308 lbs. (140 kg)

5.3.2 Collection Hopper : Steel and Polyethylene hopper. Commercial grade, cloth

mesh door with reinforced bottom.

Capacity: 11.0 bushels

5.3.3 Dump Mechanism: Manual dump from seat

5.3.4 Blower tube: fixed, abrasion resist ant m olded polyethylene

5.3.5 Impeller: 5-bladed, 0. 25” thick abrasion resistant steel, with vertical axis.

Impeller bearings: 1” (2. 54 cm) sealed, non-greaseable bearings.

5

Page 11

g

3. ASSEMBLY INSTRUCTIONS – LAZER Z & LAZER Z XP

(

y)

3.1 ASSEMBLY DIAGRAM

Item Description

1 Hopper Assembly 1 1

2 Upper Tube 1 1

3 Lower Tube 1 1

4 #10-24 X .75 Screw 3 / 6 3 / 6

5 #10-24 Nyloc Nut 3 / 6 3 / 6

6 #10 Flat Washer 3 / 6 3 / 6

7 Handle Assembly 1 1

8 Blower Assembly 1 1

9 Bagger Mount Weldment 1 1

10 Belt Cover 1 1

11 Removable Weight 2 2

12 Jackshaft 1 1

13 Blower Drive Belt 1 1

14 Frame Bracket RH 1

15 Frame Bracket LH 1

16 Frame Bracket 2

17 Mount Spacer 2

18 Mount Pin Weldment 1 1

19 Clevis Pin 4 4

20 Hair Pin (large) 4 4

21 Chute Pivot Pin 1 1

22 Hair Pin (small) 1 1

23 3/8-16 x 1.00 Hex Screw 13 16

* Used only on units below SN 352,000

Items 21, 22, 29, 30, 31, 32 and 44 not shown.

See figure 7 for installation of 29 and 30.

See figure 16 for installation of 21 and 22.

See fi

ure 13 for use of 44.

LZ

(352,000-

(60/72)

509,999)

QTY

LZ XP, XS

(All) & LZ

Higher)

(510,000 &

Item Description

24 3/8 Whizlock Nut 20 23

25 3/8 Spring Disk Washer 13 16

26 Handle Mount 1

27 Belt Shield Stud 1 1

28 3/8-16 x .75 Hex Screw 3 3

29 Belt Cover Spacer

30 7/16 Spring Disk Washer

31 Washer – ¼ thick *

32 3/8-16x3.25 Tap Bolt *

33 Weight Bracket 2 2

34 3/8-16 Square Head Bolt 4 4

35 Weight Plate 5 5

36 5/16-18 Hex Screw 4 4

37 5/16 Flat Washer 4 4

38 5/16-18 Whizlock nut 4 4

39 Plug 1 1

40 Weight Plate Assembly 2 2

41 Weight Mounting Plate 2 2

42 Cotter Hairpin 2 2

43 Spacer 6

44 Drill Template 1 1

45 Nut, Nyloc thin 2 2

LZ

509,999)

(352,000-

LZ XP, XS

QTY

(60/72)

1 - 60 only 1 - 60 only

2 - 60 only 2 - 60 only

2 - 60 only

2 - 60 only

(All) & LZ

Higher)

(510,000 &

LAZER Z SN 352,000 – 509,999

ASSEMBLY DIAGRAM

(Shown w i t hout ROPS for clarity)

LAZER Z XP, LAZER Z XS,

and LAZER Z SN 510,000 & HIGHER

ASSEMBLY DIAGRAM

Shown wi t hout ROPS for clarit

6

Page 12

3.2 INSTALL THE HOPPER ASSEMBLY

Lazer Z XP, Lazer Z XS and Lazer Z SN 510,000 & Higher units only (Lazer Z SN

352,000 – 509,999 units skip to section 3.2. 9)

NOTE: Units with a 2 post folding ROPS installed, the ROPS must be temporarily

removed for installation of the Ultra Vac QDS.

For Lazer Z units SN 510,000 and Higher:

3.2.1 When installing the Ultra Vac QDS onto a liquid cooled Lazer Z, the rear bumper

plate must be removed. Remove rear bumper plate. Reattach the lower side

bumper bars to the vertical “HOT” engine guard shield using two of the original

screws, washers and whizlock nuts removed from the bumper plate.

3.2.2 Remove the lower two screws holding the rear engine guard (“HOT” eng ine guard

on liquid cooled units) to the rear frame of the Lazer Z unit.

3.2.3 Install the m ount weldment (Item 9) loosely to the rear of the machine using the

two screws and nuts removed in section 3.2.2.

For Lazer Z XP and Lazer Z XS units:

3.2.4 Install r ear mount weldment (Item 9) loosely to the rear bum per using the two

holes provided. Use the 3/8-16 x 1.00 screws (Item 23), 3/8 spring disk washers

(Item 25) and 3/8-16 whizlock nuts (Item 24).

For Lazer Z XP, Lazer Z XS and Lazer Z SN 510,000 and Higher units:

3.2.5 Attach t he handle assem bly (I t em 7) onto frame bracket (Item 16) using 3/8-16 x

1.00 screws (Item 23), 3/8 spring disk washers (I t em 25) and 3/8-16 whizlock

nuts (Item 24). Make sure that the raised portion of the spring disk washer f aces

the head of the screw.

3.2.6 Install t he frame brackets (Item 16) and spacers (Item 17) loosely to the mount

weldment (Item 9). Use (2) 3/8-16 x 1 screws (Item 23) , ( 2) 3/8 spring disk

washers (Item 25) and (2) 3/8-16 whizlock nuts (Item 24) . Make sure that the

raised portion of the spring disk washer f aces t he head of the screw.

3.2.7 For units without a ROPS installed: I nstall the frame bracket s ( Item 16) to the

mounting pads on the Lazer frame. Use ( 4) 3/ 8- 16 x 1 screws (Item 23), (4) 3/8

spring disk washers (Item 25) and (4) 3/ 8- 16 whizlock nuts ( I t em 24).

3.2.8 For units with a ROPS installed: I nst all the frame brackets (Item 16), and ROPS

lower roll bar tubes LOOSELY to the mounting pads on the Lazer frame. Use

the ROPS mounting hardware, 3/8-16 x 1 1/2 screws, 3/8 spr ing disk washers

and 3/8-16 whizlock nuts. Make sure that the raised portion of the spring disk

washer faces the head of the screw. See Figure 4.

FIGURE 4

LOWER ROLL BAR INSTALLATION

7

Page 13

Lazer Z units SN 352,000 – 509,999 only (Lazer Z XP, Lazer Z XS, and Lazer Z

510,000 units skip to section 3.2.17) :

3.2.9 When installing the Ultra Vac QDS onto a liquid cooled Lazer Z, the rear bumper

plate must be removed. Remove rear bumper plate. Reattach the lower side

bumper bars to the vertical “HOT” engine guard shield using two of the original

screws, washers and whizlock nuts removed from the bumper plate.

3.2.10 Remove the lower two screws holding the rear engine guard (“HOT” engine g uard

on liquid cooled units) to the rear frame of the Lazer Z unit.

3.2.11 I nstall the mount weldment (Item 9) loosely to the r ear of the machine using the

two screws and nuts removed in section 3.2.7.

POTENTIAL HAZARD

♦ Relying solely on mechanical or hydraulic jacks to

support the mower could be dangerous.

WHAT CAN HAPPEN

♦ The mechanical or hydraulic jacks may not be enough

support or may malfunction allowing the unit to fall,

which could cause injury.

HOW TO AVOID THE HAZARD

♦ DO NOT rely solely on mechanical or hydraulic jacks

for support. Use adequate jack stands or equivalent

support.

3.2.12 Remove the E-clip and handle from the handle assembly (Item 7). Discard the

mount that came with the handle assembly. Install the handle and E- clip onto

the handle mount (Item 26) that came in the completing kit.

3.2.13 Mount the handle assembly (I t em 7) onto left hand frame bracket (Item 15) using

3/8-16 x 1.00 screws (Item 23), 3/8 spring disk washers (Item 25) and 3/8-16

whizlock nuts (Item 24). Make sure that the r aised por t ion of the spring disk

washer faces the head of the bolt.

3.2.14 Jack the rear of the unit up and safely support it on jack stands. Remove the

rear wheels.

CAUTION

3.2.15 I nstall the right and left hand frame brackets (It em s 14 and 15) loosely to the

mount weldment and the wheel channels of the Lazer Z frame. The flanges on

the right and left hand frame brackets should face in towards the unit to provide

the maximum tire clearance.

FIGURE 2

8

Page 14

Secure using (8) 3/8-16 x 1.00 screws (Item 23), ( 8) 3/8 spring disk washers

(Item 25) and (8) 3/8-16 whizlock nuts (I t em 24). Make sure that the raised

portion of the spring disk washer faces the head of the bolt.

NOTE: On units with a ROPS installed, the lower f r ont screw that attaches to the

wheel motor channel must be left uninstalled. Units with Serial Numbers above

440,000 will have a captured bolt in this position. See Figure 2.

NOTE: On 60 inch units, this bolt on the wheel channel is best installed by

positioning the nut behind the hole using a deep sock et and turning the bolt

through the hole into the nut.

For installation (or re-inst allation) of a 2 post foldable ROPS on Lazer Z uni t s w ith

SN 352,000 – 509,999:

3.2.16 Inst all t he two lower roll bar tubes.

a) Align three spacers on each side and tape with masking tape to the rear

frame as shown in Figure 3.

b) Align lower roll bar tubes along wheel motor channels as shown in Figur e 3.

c) LOOSELY install the lower roll bar hardware from the bolt bag to the tubes

in the following order (Refer ence Figure 3 for alignment and inst allation

instructions below):

1) Discard the 3/8-16 regular nyloc nut provided with the Lazer Z unit or

ROPS kit and replace with the 3/8-16 thin nyloc nut (Item 45) provided

with this Ultra Vac.

2) Inst all the 3/8-16 thin nyloc nut and spring disk washer to bolt prot r uding

from the wheel motor channel as shown.

NOTE: Be sure the spring disk washer cone is installed towards the

nyloc nut.

Units with Serial Numbers below 440,000 require use of a Gr ade 5 3/ 8-

16 x 1 1/2 screw, spring disk washer and whizlock nut. These items are

included with ROPS kit number FRPSLZ.

NOTE: On 60 inch units, the lower bolt on the wheel channel is best

installed by positioning the nut behind the hole using a deep sock et and

turning the bolt throug h the hole into the nut.

3) Install one 3/8-16 x 1 1/2 hex capscrew, spring disk washer and 3/8-16

whizlock nut to the top front hole as shown (it will be necessary to push

the capscrew through the masking t ape applied in step a).

4) Install one 3/8-16 x 1 1/2 hex capscrew, spring disk washer and 3/8-16

whizlock nut to the top rear hole as shown (it will be necessary to push

the capscrew through the masking t ape applied in step a).

5) Install one 3/8-16 x 4 1/2 hex capscrew, spring disk washer and 3/8-16

whizlock nut through the top tube as shown (it will be necessary to push

the capscrew through the masking t ape applied in st ep a).

NOTE: Be sure the spring disk washer cone is installed towards the

head of all capscrews.

9

Page 15

FIGURE 3

LOWER ROLL BAR INSTALLATION

3.2.17 All units with a ROPS installed: Inst all t he upper u-shaped section of the roll bar.

(Reference Figure 4 f or alignment and installation instructions below):

a) Locate the latch pin assemblies (pin and hairpin connected with a lanyard).

b) Install a 1/2-13 x 3 1/4 capscrew in the washer on the lanyard of each pin

assembly.

Note: Make sure the bent tab in the washer points toward the head of the

capscrew.

b)

Lightly oil the inside surfaces of t he ear - shaped plates at the upper end of

the lower roll bar tubes.

c) Locate the upper u-shaped section of the roll bar. Install the upper roll bar

section using one 1/2-13 x 3 1/4 capscrew (from step b) and one 1/ 2- 13 hex

flange lock nut on each side. Do not over t ighten. Make sure upper roll bar

can pivot freely.

Notes:

• Make sure the capscrew and nuts are installed with the nut to the inside of

the roll bar.

• Make sure the tab on the lanyard washer is installed as shown and points

toward the front of t he unit .

d) Raise the roll bar into the upright posit ion and secure with the latch pin

assemblies on each side. Install latch pin from outer surface of roll bar

assembly and secure with the hairpin to the inside.

e) Tig hten the front knobs ag ainst t he upper roll bar ends.

10

Page 16

FIGURE 4

UPPER ROLL BAR INSTALLATION

3.2.18 All Units: Tighten all the hardware that attaches the Ultra Vac mount to the

machine frame. Start with the screws that hold t he mount weldment to the rear of

the unit and work forward.

3.2.19 All Units with a ROPS installed: Torque all lower roll bar hardware att ached to

the machine frame to 30-35 ft-lbs. (41-47 N-m).

3.2.20 All Lazer Z units SN 352,000 – 509,999: Reinstall the rear wheels and lower the unit

from the jack stands.

3.2.21 Apply a light coat of grease to the front and rear of the upper tube of the mount

weldment. Install the hopper assembly (Item 1) onto the mount by slipping the

hook portion over the top mounting t ube of the mount weldment. Secure the

assembly to the mount using the clevis pins (Item 19) and hair pins (Item 20).

3.2.22 Attach the handle link to t he act uation arm on the hopper assembly.

3.3 INSTALL BLOWER ASSEMBLY

3.3.1 Lower the deck f ully. Rem ove the r ight hand belt cover. Remove the belt cover

mounting stud that protrudes from the deck.

3.3.2 Remove the deck drive belt from around t he r ight hand spindle sheave.

3.3.3 Support the righ t m ower blade and shaft so that it will not fall out of the deck

when the right sheave nut is removed.

3.3.4 Remove the rig ht sheave nut, spr ing disk washer, and sheave from the spindle shaft .

Block the blade rotation with a block of wood between the blade and baf f les

as indicated in the blade service section of t he Lazer Z operat or’ s manual .

Do not use the blade bolt to prevent rotation.

3.3.5 Apply a light coat of Mobile HTS grease (or food gr ade antisieze) to the top

portion of the spindle shaft where the sheave mounts.

3.3.6 Install t he jackshaft (Item 12) ont o the right spindle shaft. Inst all the spring

disk washer and nut. Torque the sheave nut to 140-145 ft. lbs. Make sure

that the spring disk washer cone is installed towards nut. See Figure 5.

Block the blade rotation with a block of wood between the blade and baf f les

as indicated in the blade service section of t he Lazer Z operat or’ s manual .

Do not use the blade bolt to prevent rotation.

11

Page 17

Check blade bolt torque after compl et i ng t hi s installation:

For units with a 5/8-18x2 3/4 blade bolt, torque to 115-120 ft-lbs (156-163 N-m)

For units with a 1/2-20x2 blade bolt, torque to 55-60 ft-lbs (75-81N-m)

3.3.7 Re-install the deck dr ive belt in t he lower g r oove of the double sheave.

Install the plug (Item 24) into the bore of the double sheave.

3.3.8 Remove the discharge chute from the deck. Discard the m ount ing hardware, but

save the discharge chute for use during side discharge operation. The chute pivot

pin (Item 21) and hairpin (Item 22) may be stored in the pivot holes on the discharge

chute during bagging operation.

3.3.9 Install the belt cover mounting stud (Item 27) included in the Ult ra Vac QDS

completing kit.

FIGURE 5

For 60 inch units only, install the spacer (Item 29), t wo 7/16 spring disk

washers (Item 30) and the pl ast i c knob as shown in Figure 6. The knob

does not need to be tightened against the washers at this time.

FIGURE 6

3.3.10 Install the mounting pin weldment (Item 18) to the blower assembly using the 3/816 x .75 screws (Item 28) and whizlock nuts (Item 24). Maximum deck clearance

will be provided if the bolts are installed from below the mounting pin. The mount

pin can be installed in two positions. For 60 inch decks the pin should be installed

as far away from the bumper end as possible. For 72 inch decks the pin should

be installed close to the bumper end. See Figure 7.

FIGURE 7

12

Page 18

3.3.11 Install the belt (Item 13) onto the blower by working it ar ound t he im peller sheave.

3.3.12 Mount the blower on the deck by sliding the mounting pin into the tube at the rear

right corner of the deck. Swing the blower closed. Adjust the position of the front

pin to engage the slot in the front of the deck. Use t he latch to lock the blower in

this position. Adjust the tension on the lat ch to draw the blower up to the deck,

yet allow for release by hand.

3.3.13 Pull the spring loaded idler back and slip the belt over the top sheave on the deck

spindle.

3.3.14 Install the plastic belt cover (Item 10). On 60” units t he out side end of the cover is

slotted and can slip between the two washers assembled in step 3.3.9. The

plastic knob does not need to be removed. On 72” units t he cover has a hole,

and the plastic knob must be installed after the cover has been positioned.

3.4 ASSEMBLE THE TUBES

3.4.1 Remove the (6) screws, nuts, and washers (Item s 4, 5, and 6) from the lower tube

(Item 3) and slide the lower and upper tube (It em 2) together. The arrow on the

upper tube should align with the dimple on the lower tube. There ar e two sets of

holes on the lower tube. The first set r eached is for use with Lazer XP and Lazer

XS units. The second set reached is f or Lazer Z unit s. Align the arrow on the

upper tube with the dimple on the lower tube and slide them toget her until the

proper set of holes is reached.

3.4.2 Fasten the upper and lower tubes toget her using three of the hardware sets

removed from the lower tube in step 3.4.1. The heads of the screws must be inside

the tube to prevent accumulation of gr ass inside the tube. The washer and the nut

should be installed on the outside of the tube. Use t he remaining three hardware

sets to plug the exposed holes in the lower tube. On 60“ Lazer Z units, discar d the

remaining hardware sets.

3.4.3 Slip the upper end of t he t ube assembly into the hopper opening. Slide the lower

end of the tube assembly over the blower outlet and align the not ch with the t ube

latch. Latch the tube to the blower.

3.5 INSTALL THE FRONT WEIGHTS

3.5.1 A total of five weight plates (Item 35) must be inst alled on t he front panel of the

floor pan. Four of these weight s ar e m ount ed behind the front panel of the floor

pan. The remaining weight plate must be mounted on top of the f r ont panel of

the floor pan. These weights give proper balance to the machine when the mount

and handle are installed and the blower, hopper, and tubes are removed f or side

discharge operation.

Units with the 2 post foldable ROPS installed require additional mounting plates

(Item 44) and front weight (Item 43) to be installed. The front weight is removable

and retained by using hairpins (Item 45).

Lazer Z units prior to SN 440,000:

3.5.2 Locate the position of t he mounting holes by clamping a weight plate to the front

of the floor pan (See Figur e 8). The ears on the weight plate should be towards

the bottom (upside down from the act ual m ounted position). Align the bottom

edge of the weight plate with the bottom edge of the floor pan front panel. Center

the weight plate side to side. Mark the position of all four holes using a center

punch.

13

Page 19

FIGURE 8

3.5.4 Drill 3/8” holes at the points marked.

3.5.5 For Lazer Z units without a ROPS: Open the floor pan and install four weight

plates (Item 35) behind the f ront panel and one weight plate (Item 35) in front of

the panel using the 5/16-18 x 1.75 screws, 5/16 washers and5/16-18 whizlock

nuts (Items 36, 37, and 38). The weight plates will only fit with the ears located

near the bend in the floor pan (See Figur e 9) . Apply the decal included in the

literature pack to the center of the weight plate that was mounted to the t op of the

floor pan.

FIGURE 9

3.5.6 For Lazer Z units prior to SN 440,000 with a ROPS: Open the floor pan and install (4)

weight plates behind the front panel, ( 1) weight plate in front of t he front panel, and

(2) weight mounting plates (I t em s 35, and 41) as shown in Figur e 12 using (4) 5/1618 x 2.0 screws, (4) 5/16 flat washers, and (4) 5/16-18 whizlock nuts (Items, 36, 37,

and 38).

3.5.7 Hook weight plate assembly (Item 40) over the top of the weight mounting plates and

secure with two hairpins (Item 42) as shown in Figure 10.

Note: The removable weight i s heavy. Use care when lifting. Make sure

that you can hold the weight securely before lifti ng. Use caut ion when

positioning your hands so that you do not set the weight down on your

hands or fingers.

14

Page 20

FIGURE 10

Lazer Z units SN 440,000 and higher:

3.5.8 Locate the position of the mounting holes by aligning the template (P/N 103-5865)

on the front face of the floor pan as shown in Figure 11. Clamp the t emplate in

place. Using a center punch, mark t he positions of the holes on the floor pan. Flip

the template over and repeat on the other end of the floor pan face.

Align template along

these 3 edges.

FIGURE 11

3.5.9 Drill 3/8” holes at the points marked.

3.5.10 Follow steps 3.5.6 through 3.5.7 for weight installation ( See Fig ure10).

3.6 INSTALL THE CASTER WEIGHTS

Note: The caster weights are heavy. Use care when lif t i ng them. Make sure that

you can hold them securely before lifting them. Use caution w hen posi t ioning

your hands so that you do not set them down on your hands or fingers.

3.6.1 Assemble the weight brackets (Item 33) to the caster weight s ( I tem 11) using the

3/8-16 square head bolts (Item 34) and 3/ 8 whizlock nuts ( I t em 25) .

Unit 1.5” Bracket 2.0” Bracket

Lazer Z 60” Units 1 1

Lazer Z 72” Units 2

Lazer Z XP 60” Units 2 1

Lazer Z XP 72” Units 2

Lazer Z XS 60” Units 2 2

Lazer Z XP 72” Units 2

1 Second 2.0” bracket is included in Ultra Vac XS completion kit 103-7876.

3.6.2 Install the caster weight assemblies over the

3.6.3 Inst all a clevis pin (I t em 19) and hairpin (Item

3.6.4 Tighten knob on weight assembly until the

2

Second 2.0” bracket is included in Ultra Vac XP completion kit 103-7420.

caster arms. On 60 inch Lazer Z machines one

weight has a wide mounting bracket and one has

a narrow bracket. They will only fit the machine

one way. Weights for the 60 Lazer XP, 60” Lazer

XS, and all 72’s are interchangeable left and right.

20) on each caster weight to retain them.

weight is clamped securely to the caster arm.

FIGURE 12

15

Page 21

3.7 ADJUSTMENTS:

Your Ultra Vac QDS was adjusted at the factory to operate properly. However, there are

three basic adjustments that can be made, should your unit r equire them:

3.7.1 Door closi ng: The closing of the door is controlled by the two hinge links (Figure

13 – A) and the two stop screws (Figure 13 – B). The stop screws should be

adjusted so that both will be contacted when the contacting arm is straight up and

down. With the stop scr ews adjusted, t he length of the hinge links can be

changed to provide complete closing of t he door , and reasonable force on the

handle to latch or unlatch the door. Lengthen the links to reduce the for c e.

Shorten the links to increase the force. With the door closed, both links should be

slightly tight to minimize rattling.

3.7.2 Door openi ng: After adjusting the hinge links for door closing, the handle link

(Figure 13 – C) can be adjusted to obtain m aximum door opening. Lengthen the

link to open the door fart her . Shorten the link to open the door less. The

maximum door opening is limited by the contacting ar m hitting the stop (Figure 13

– D). This stop is non adjustable, and prevents over opening dam age from

occurring to the linkage.

3.7.3 Latches: Once the open and closed positions have been set, the latches (Figur e 13

– E) can be adjusted. With the door closed, the latch link should be set so that the

latch plate completely engages and contacts the latch rod welded to the door. The

latch plates should not be tight against the latch rod. They should easily “wiggle”.

FIGURE 13

16

Page 22

4. OPERATION:

4.1 PRE-START

4.1.1 Read the operator’s manual for your mower and fam iliar ize yourself with all

controls before operating t he machine. Make sure that you understand the

controls, their locations, their functions, and their safety requirements.

4.1.2 Ensure the blower, belt cover, door m esh, tube and hopper are in good condition,

properly attached, and latched.

Note: When mowing in areas with sandy soil, use low lift blades on the cutting

deck and higher cutting heights to minimize wear on the blower component s.

4.2 MOWING

4.2.1 The Ult r a Vac QDS blower operates when deck drive is engaged. Be sure that all

persons are clear of the mower deck bef ore engagi ng t he cutting blades. Set

the throttle to “midway” position. Pull out ward on the PTO switch to the

“ROTATE” position. Accelerate to full throttle to begin mowing.

4.2.2 To disengage the PTO and blower, set the throttle to “midway” position. Push in

on the PTO switch to the “STOP” position to stop the cutting blades and blower.

The cutting blades will require a slightly longer amount of time t o com e to a

complete stop when the blower is installed on the deck. Verify that all rotation

indicators have stopped before clearing blower assembly or mower deck

4.2.3 To em pt y the hopper , first shut off deck drive. Lift up on the handle to open the

door and empty the hopper. If the unit i s t o be dri ven onto a truck or t r ai ler

with the hopper full, always back the unit up the ramp. This will reduce the

chance of rearward tip up. See secti on 4. 1 Transporti ng f or addi t ional

information regarding loading a unit on a truck or t r ai l er.

4.2.4 Close and latch t he door before continuing mowing. Do not engage the cutt ing

blades while the door is in the open position.

4.3 BAGGER REMOVAL FOR SIDE DISCHARGE:

4.3.1 Disengage the PTO, stop engine and wait f or all moving parts to stop. Remove

spark plug wire(s) or remove key.

4.3.2 Remove the discharge tube by releasing the latch at the blower. Slide the tube

off the blower outlet and remove the upper end from the hopper.

4.3.3 Remove the Belt cover by loosening t he knobs. For 60” units the outboard knob

does not need to be removed completely to remove the belt cover.

CAUTION

POTENTIAL HAZARD

♦ The deck sheave will become very hot

WHAT CAN HAPPEN

♦ Touching a hot deck sheave can cause severe burns.

HOW TO AVOID THE HAZARD

♦ Allow the deck sheave to cool completely before

removing the belt.

4.3.4 Pull the idler release handle and remove the belt from the upper groove of the

deck sheave.

4.3.5 Unlatch t he front end of the blower. Pivot the blower back and lift it off t he deck.

4.3.6 Install the discharge chute using the chute pivot pin and hairpin (See Figure 14).

17

Page 23

21

22

FIGURE 14

DISCHARGE CHUTE INSTALLATION

4.3.7 Re-install the plastic belt cover and tig hten the knobs.

4.3.8 Disconnect the handle link from the actuation arm on the hopper. Connect the

link to the arm on the handle mount for storage during side dischar ge operation.

4.3.9 Remove the hair pins and clevis pins holding the hopper assembly to t he m ount

weldment.

4.3.10 Lift the hopper assembly off the mount.

4.3.11 The removable weights must be removed from above the caster wheels (and front

of floor pan for unit s with a 2 post foldable ROPS). To remove the caster weight s.

Loosen the clamping knobs until the weight can be m oved relative to t he cast er

arm. Remove the hairpins and clevis pins that hold the weights to the cast er

arms. Carefully lift the weights off of the caster arms.

For units with 2 post foldable ROPS: To remove the front weight , r emove the 2

hairpins that retain it and then lift it from the m ount plates.

The weights and brackets bolted to t he floor pan remain on the unit.

Note: The removable weights are heavy. Use care when lifti ng t hem. M ake sure t hat

you can hold them securely before lifting them. Use caution w hen posi t i oning

your hands so that you do not set them down on your hands or fingers.

Note: The portions of the Ultra Vac QDS bagger that are not bol t ed t o t he mower

are designed to be installed or removed in their entirety. Failure to do so

will cause a reduction in stability or traction. Do not operate the mower

with only a portion of the Ultra Vac QDS installed.

CAUTION

POTENTIAL HAZARD

♦ Caster or front floor pan weights installed without

bagger may cause Loss of Tract ion and St eer ing

control.

WHAT CAN HAPPEN

♦ Loss of control can result in an accident, which may

cause Death, Injury, or property damag e.

HOW TO AVOID THE HAZARD

♦ Install caster and front floor pan weights ONLY when

bagger is installed.

4.3.12 The machine can now be used for side discharge mowing.

18

Page 24

4.4 TRANSPORTING

4.4.1 Transporting a Unit: Use a heavy-duty trailer or truck to tr anspor t t he machine. Lock

brake and block wheels. Securely fasten the machine to the trailer or truck with

straps, chains, cable, or ropes. Be sure t hat t he trailer or truck has all necessary

lighting and marking as required by law. Secure a trailer with a safety chain.

POTENTIAL HAZARD

♦ This unit does not have proper turn signals, lights, reflective

markings, or a slow moving vehicle emblem. These items

are required to drive on a public street or roadway.

WHAT CAN HAPPEN

♦ Driving on a street or roadway without such equipment is

dangerous and can lead to accidents causing personal injury.

♦ Driving on a street or roadway without such equipment may

also be a violation of State laws and the operator may be

subject to traff ic tickets and/or fines.

HOW TO AVOID THE HAZARD

♦ Do not drive a unit on a public street or roadway.

POTENTIAL HAZARD

♦ Loading a unit on a trailer or truck increases the possibility of

backward tip-over.

WHAT CAN HAPPEN

♦ Backward tip-over of the unit could cause serious injury or

death.

HOW TO AVOID THE HAZARD

♦ Use extreme caution when operating a unit on a ramp.

♦ Use only a single, full width ramp; DO NO T use individual

ramps for each side of the unit .

♦ If individual ramps must be used, use enough ram ps t o

create an unbroken ramp surf ace wider than t he unit .

♦ DO NOT exceed a 15° angle between ramp and ground or

between ramp and trailer or truck.

♦ Avoid sudden acceleration while driving unit up a ramp to

avoid tipping backward.

♦ Avoid sudden deceleration while backing unit down a ramp to

avoid tipping backward.

CAUTION

WARNING

4.4.2 Loading a Unit: If the unit is to be driven onto a truck or trailer with the

hopper full, always back the unit up the ramp. This will reduce the chance

of rearward tip up. Use extrem e caut ion when loading unit s on trailers or trucks.

One full width ramp that is wide enough to extend beyond the rear tires is

required instead of individual ramps for each side of the unit. The lower rear

section of the tractor frame extends back between the rear wheels and serves as

a stop for tipping backward. Having a full width ramp provides a surface for the

frame members to contact if the unit starts to tip backward. If it is not possible to

use one full width ramp, you must use enough individual ramps to simu lat e a full

width continuous ramp.

19

Page 25

Ramp should be long enough so that t he angles between the ramp and the

ground and the ramp and the trailer or truck do not exceed 15°. A steeper angle

may cause mower deck components to get caught as the unit moves from ramp

to trailer or truck. St eeper angles may also cause the unit to tip backward. If

loading on or near a slope, position the trailer or truck so it is on the down side of

the slope and the ramp extends up the slope. This will minimize the ramp angle.

The trailer or truck should be as level as possible.

DO NOT attempt to turn the unit while on the ramp, you may lose control and

drive off the side.

Avoid sudden acceleration when driving up a ramp and sudden deceleration when

backing down a ramp. Both maneuvers can cause the unit to tip back ward.

Dump contents of hopper before transport. Do not transport the unit with the

hopper full.

5. MAINTENANCE

POTENTIAL HAZARD

♦ While maintenance or adjustments are being made,

someone could start the engine.

WHAT CAN HAPPEN

♦ Accidental starting of the engine could seriously injure

you or other bystanders.

HOW TO AVOID THE HAZARD

♦ Remove the key from the ig nit ion switch and pull the

wire(s) off the spark plug(s) before you do any

maintenance. Also push the wire(s) aside so it does

not accidentally contact the spark plug(s ) .

POTENTIAL HAZARD

♦ The engine can become very hot.

WHAT CAN HAPPEN

♦ Touching a hot engine can cause severe burns.

HOW TO AVOID THE HAZARD

♦ Allow the engine to cool completely before service or

making repairs around the eng ine area.

WARNING

WARNING

5.1 PERIODIC MAINTENANCE

5.1.1 Blower Housing/Impeller Service Interval: Daily.

Inspect for wear or damage daily. Replace or repair worn parts as needed.

Note: When mowing in areas with sandy soil, use low lift blades on the

5.1.2 Idler Bushings: Service Interval: 25 Hours.

Lubricate with 1-2 pumps of SAE No. 2 m ulti-purpose grease.

5.1.3 Door Handle: Service Interval: 25 Hours.

Lubricate with 1-2 pumps of SAE No. 2 multi-purpose grease.

IMPORTANT: Before conducting any maintenance, Disengage the PTO, stop engine

and wait for all moving parts to st op. Remove spark plug wire(s) or remove key.

cutting deck and higher cutting heights to mi ni mi ze wear on the blower

components.

20

Page 26

5.1.4 Door cloth m esh: Service Interval: Daily.

Inspect the cloth mesh for wear, tear s, or dam age.

POTENTIAL HAZARD

♦ Under normal use the cloth mesh will deteriorate and

wear. Objects could exit through worn cloth mesh at

high speeds.

WHAT CAN HAPPEN

♦ Thrown objects can cause serious injury or kill you or

bystanders.

HOW TO AVOID THE HAZARD

♦ Check cloth mesh frequently for tears and holes.

Replace worn cloth mesh.

5.1.5 Belts. Service Interval: 50 Hours.

Inspect the belt for damage or wear. Replace belt with one of the following.

60” deck – PN 103-0866

72” deck – PN 103-0867

5.1.6 Clean muffler and r ear frame area: Service Interval: Daily

POTENTIAL HAZARD

♦ Operating engine parts, especially the m uffler, become

extremely hot.

WHAT CAN HAPPEN

♦ Severe burns can occur on contact.

♦ Debris, such as leaves, grass, brush, etc. can catc h fire.

HOW TO AVOID THE HAZARD

♦ Allow engine parts, especially the muff ler, to cool before

touching.

♦ Remove accumulated debris from muffler and engine area.

♦ Install and maintain in working order a spar k arrester before

using equipment on forest - covered, grass-covered, brushcovered unimproved land.

WARNING

WARNING

5.2 ADJUSTMENTS

Your Ultra Vac QDS was adjusted at the fact or y to oper at e pr operly. However, there are

three basic adjustments that can be made, should your unit r equire them:

5.2.1 Door closing: The closing of the door is controlled by the two hinge links (Figur e

15 – A) and the two stop screws (Figure 15 – B). The stop screws should be

adjusted so that both will be contacted when the contacting arm is straight up and

down. With the stop scr ews adjusted, t he length of the hinge links can be

changed to provide complete closing of t he door , and reasonable force on the

handle to latch or unlatch the door. Lengthen the links to reduce the for c e.

Shorten the links to increase the force. With the door closed, both links should be

slightly tight to minimize rattling.

21

Page 27

5.2.2 Door opening: After adjusting the hinge links for door closing, the handle link

(Figure 15 – C) can be adjusted to obtain m aximum door opening. Lengthen the

link to open the door fart her . Shorten the link to open the door less. The

maximum door opening is limited by the contacting ar m hitting the stop (Figure 15

– D). This stop is non adjustable, and prevents over opening dam age from

occurring to the linkage.

5.2.3 Latches: Once the open and closed positions have been set, the latches (Figur e 15

– E) can be adjusted. With the door closed, the latch link should be set so that the

latch plate completely engages and contacts the latch rod welded to the door. The

latch plates should not be tight against the latch rod. They should easily “wiggle”.

6. Tips and Troubleshooting

Your Exmark Ultra Vac has been designed to be the m ost pr oductive bagging system on the

market. The following tips have been collected to help you get the most out of your Ultra Vac

right from the star t .

6.1 When mowing in areas with sandy soil, use low lift blades on the cutting deck and

higher cutting heights t o minimize wear on the blower components.

6.2 When mowing in wet conditions, such as just after a rain or in heavy dew, use low

lift blades on the cutting deck to minimize plugging of t he blower.

6.3 When the bags get full, the sound of the blower will change and there will be slight

blowout from the front right corner of the deck . Emptying the bags at this point will

minimize the potential for the tube to plug.

6.4 If there is excessive blowout from the deck, check to make sure that the rear

screen in the hood is clear of grass build up. I t is recommended that the screen

and mesh portions of the bags be cleaned regularly to maintain proper air flow.

This is especially important in wet conditions.

6.5 During dry conditions check engine air cleaners and clean cooling fins more

frequently. The Ultr a Vac has been designed to minimize the impact of dust and

debris on the mower, but bagging can be a dir t y environment.

6.6 During dry conditions, switching to a lower lift blade may reduce blowout without

hurting quality of cut.

6.7 Maintaining a ground speed that does not pull down the engine RPM will allow for

the highest productivity and best quality of cut . Bogging the engine RPM down by

going too fast will cause plugg ing and quality of cut issues.

6.8 When stor ing the Ultra Vac, it is recommended that any build up in the blower be

cleaned out. Dry grass build up may cause problems with the impeller when the

unit is put back into operation.

6.9 The condition of the belt drive is critical t o proper operation. A sticking idler ar m or

worn belt may cause plugging or blowout. Replace the belt when the idler arm is

riding on or near the stop.

22

Page 28

6.

2-Year Limited Warranty

Exmark Turf Equipment

Conditions and Products Covered

Exmark Mfg. Co. Inc. and its affiliate, Exmark Warranty

Company, pursuant to an agreement between them, jointly

warrant on the terms and conditions herein, that we will repair,

replace or adjust any part manufactured by Exmark and found

by us (in the exercise of our reasonable discretion) to be

defective in factory materials or workmanship for a period of

two years.

This warranty applies to Exmark turf equipment purchased on

or after October 1, 2004 sold in the US or Canada. This

warranty may only be assigned or transferred to a second (or

third) owner by an authorized Exmark dealer. The warranty

period commences upon the date of the original retail

purchase.

Products

• All Products (except as noted below) 2 years

• All Attachments and Accessories 1 year

• Metro 21 Series 1 year

• Belts and Tires 90 days

• Battery 1 Year Prorated

• Engine* Warranty is covered by engine manufacturer

*Please refer to the engine manufacturer’s warranty statement

that is included in the literature packet. We are not authorized

to handle warranty adjustments on engines.

This warranty only includes the cost of parts and labor.

This warranty does not cover the following:

• Pickup and delivery charges to and from any authorized

• Any damage or deterioration due to normal use, wear

• Cost of regular maintenance service or parts, such as

• Any product or part which has been altered or misused

• Any repairs necessary due to use of parts, accessories

All warranty work must be performed by an authorized Exmark

Service Dealer using Exmark approved replacement parts.

1. Contact any Exmark Service Dealer to arrange service at

their dealership. To locate a dealer convenient to you,

access our website at www.exmark.com. U.S. Customers

may also call 402-223-6375.

2. Bring the product and your proof of purchase (sales

receipt) to the Exmark Service Dealer.

If for any reason you are dissatisfied with the Service Dealer’s

analysis or with the assistance provided, contact us at:

Exmark Customer Service Department

The Exmark Warranty Company

2101 Ashland Avenue

Beatrice, NE 68310

402-223-6375 or

service@exmark.com

Warranty Period

Items and Conditions Not Covered

Exmark Service Dealer.

and tear, or exposure.

filters, fuel, lubricants, tune-up parts, and adjustments.

or required replacement or repair due to normal wear,

accidents, or lack of proper maintenance.

or supplies, including gasoline, oil or lubricants,

incompatible with the turf equipment or other than as

recommended in the operator's manual or other

operational instructions provided by Exmark.

Instructions for Obtaining Warranty Service

(For units purchased on or after October 1, 2004)

Owner’s Responsibilities

The Exmark turf equipment, including any defective part,

must be returned to an authorized Exmark service dealer

within the warranty period. This warranty extends only to

turf equipment operated under normal conditions. You

must properly service and maintain your Exmark product

as described in the operator’s manual. Such routine

maintenance, whether performed by a dealer or by you, is

at your expense.

As a condition to this warranty, customer shall have read

the operator's manual and shall have completed and

submitted to Exmark Warranty Company, within the

prescribed time, the Exmark warranty registration.

General Conditions

The sole liability of Exmark and Exmark Warranty Company

with respect to this warranty shall be repair and replacement

as set forth herein. Neither Exmark nor Exmark Warran ty

Company shall have any liability for any other cost, loss

or damage, including but not limited to, any incidental

or consequential loss or damage.

In particular, we shall have no liability or responsibility for:

• Expenses related to gasoline, oil or lubricants.

• Travel time, overtime, after hours time or other

extraordinary repair charges or charge relating to

repairs or replacements outside of normal business

hours at the place of business of the authorized

Exmark service dealer.

• Rental of like or similar replacement equipment

during the period of any warranty, repair or

replacement work.

• Any telephone or telegram charges or travel charges.

• Loss or damage to person or property other than that

covered by the terms of this warranty.

• Any claims for lost revenue, lost profit or additional

cost as a result of a claim of breach of warranty.

• Attorney's fees.

No Claim of breach of warranty shall be cause for

cancellation or rescission of the contract of sale of any

Exmark mower.

There are no understandings, agreements, representations,

or warranties, express or implied, including but not limited to

any regarding the merchantability (that product is fit for

ordinary use) or fitness for use (that product is fit for a

particular purpose), not specified herein, respecting the

equipment which is the subject of this warranty.

Some states do not allow exclusions of incidental or

consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions and

limitations may not apply to you.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

23

Page 29

NOTES

24

Page 30

NOTES

25

Page 31

SERVICE RECORD

Date Descri pt i on of Work Done Service Done By

26

Page 32

M

M

SEE EXMARK’S COMPLETE

LINE OF ACCESSORIES

RIDING ACCESSORIES

CUSTOM RIDE SEAT SUSPENSION SYSTEM

DECK LIFT ASSIST KIT

HITCH KIT

LIGHT KIT

MICRO-MULCH SYSTEM

ROLL OVER PROTECTION SYSTEM (ROPS)

SNOW BLADE

SUN SHADE

TRASH CONTAINER

TURF STRIPER

ULTRA VAC COLLECTION SYSTEM

ULTRA VAC QUICK DISPOSAL SYSTEM

WALK BEHIND ACCESSORIES

GRASS CATCHER

MICRO-MULCH SYSTEM

STEERABLE SULKY

SULKY HITCH KIT

TURF STRIPER

Check us out on the Web:

www.exmark.com

©2000-2004 EXMARK MFG. CO. INC. PART NO. 103-8854

INDUSTRIAL PARK BOX 808 (402) 223-6300

BEATRICE, NE 68310 FAX (402) 223-5489

ALL RIGHTS RESERVED PRINTED IN U.S.A.

FG. CO. INC.

FG. CO. INC.

®

®

Loading...

Loading...