Page 1

ULTRAV AC®QDS

LAZERZ®HPMODELS

ForUltraVacSerialNos.

790,000&Higher

PartNo.4500-420Rev.A

Page 2

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2008—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkUltraVacQDS.Thisproducthasbeen

carefullydesignedandmanufacturedtogiveyou

amaximumamountofdependabilityandyearsof

trouble-freeoperation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

UltraVacQDS.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourUltra

VacQDS,maintainitsmaximumefciency,and

promotesafeoperation.

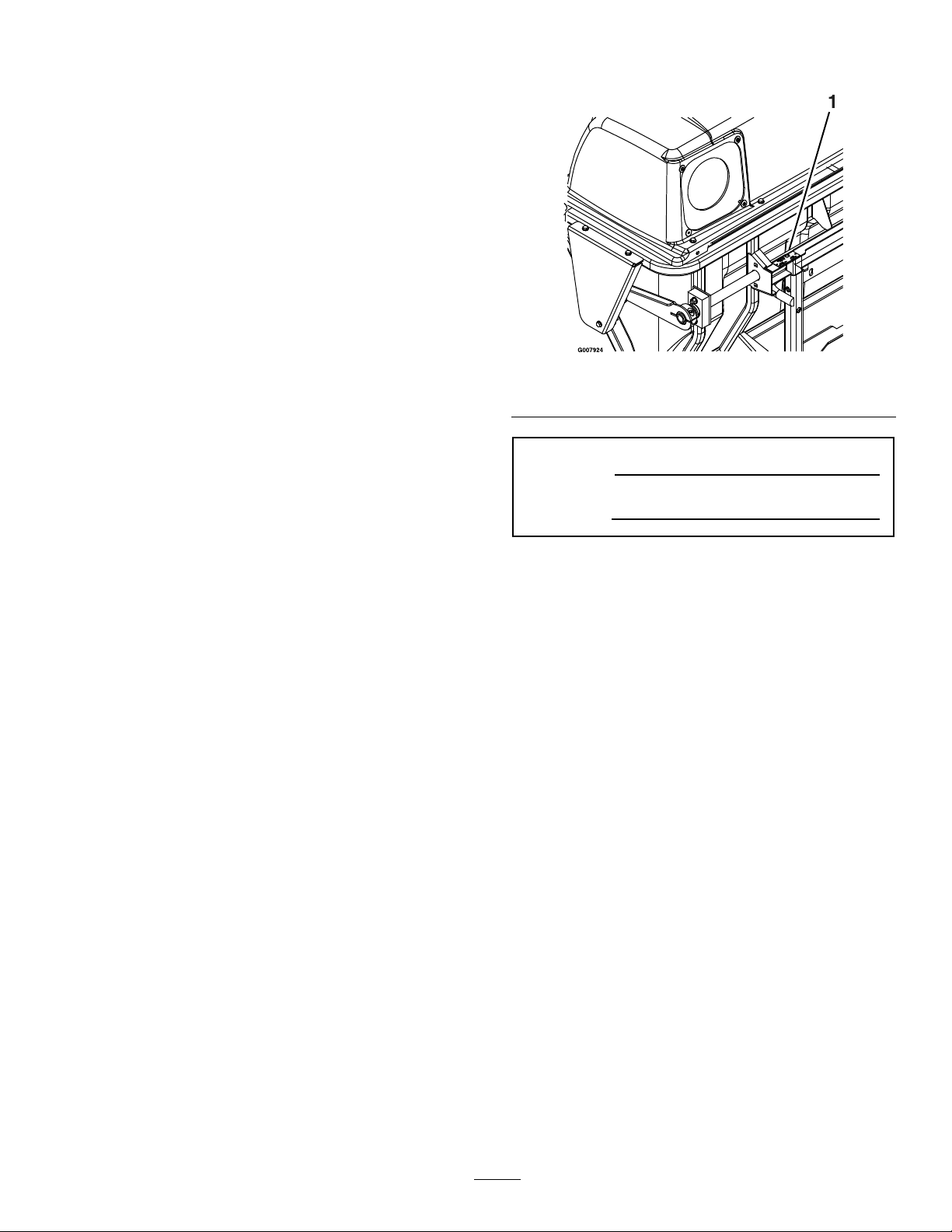

Figure1

1.Modelandserialnumberlocation

ModelNo.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

SerialNo.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.......................8

Specications.......................................................10

ModelNumbers............................................10

Systems.........................................................10

Dimensions...................................................10

TorqueRequirements....................................10

ProductOverview................................................11

Operation.............................................................11

Pre-Start........................................................11

OperatingInstructions..................................11

Transporting.................................................14

Maintenance.........................................................16

RecommendedMaintenanceSchedule(s)...........16

PeriodicMaintenance.......................................16

CheckBlowerHousing/Impeller...................16

CheckDoorClothMesh................................16

LubricateGreaseFittings...............................17

CheckConditionofBelt................................17

Adjustments.....................................................18

Cleaning...........................................................19

CleanMuferandRearFrameArea................19

CleanRearScreenInHood............................19

CleanBlower.................................................19

Troubleshooting...................................................20

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

1.Safetyalertsymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadthetractorandUltraVacQDSOperator’s

Manualsandothertrainingmaterial.Ifthe

operator(s)ormechanic(s)cannotreadEnglish

itistheowner’sresponsibilitytoexplainthis

materialtothem.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyandsafely

performthejob.Onlyuseonmachinesapproved

byExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

Operation

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

5

Page 6

Safety

DANGER

Therearerotatingbladesintheblowerand

underthemowerdeck.Bladecontactcan

causeseriousoperatororbystanderinjury

orevendeath.

•DoNotreachintoblowerunlessrotation

indicatorhasstopped.DisengagePTO,

stopengine,removekey ,waitforall

movingpartstostop.Engageparking

brake.

•Neveroperatemowerunlessdischarge

deector,entiregrasscollectionsystem,

ormulchkitisinstalled.

•Stopengine,waitforallmovingpartstostop,

removekeyandengageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

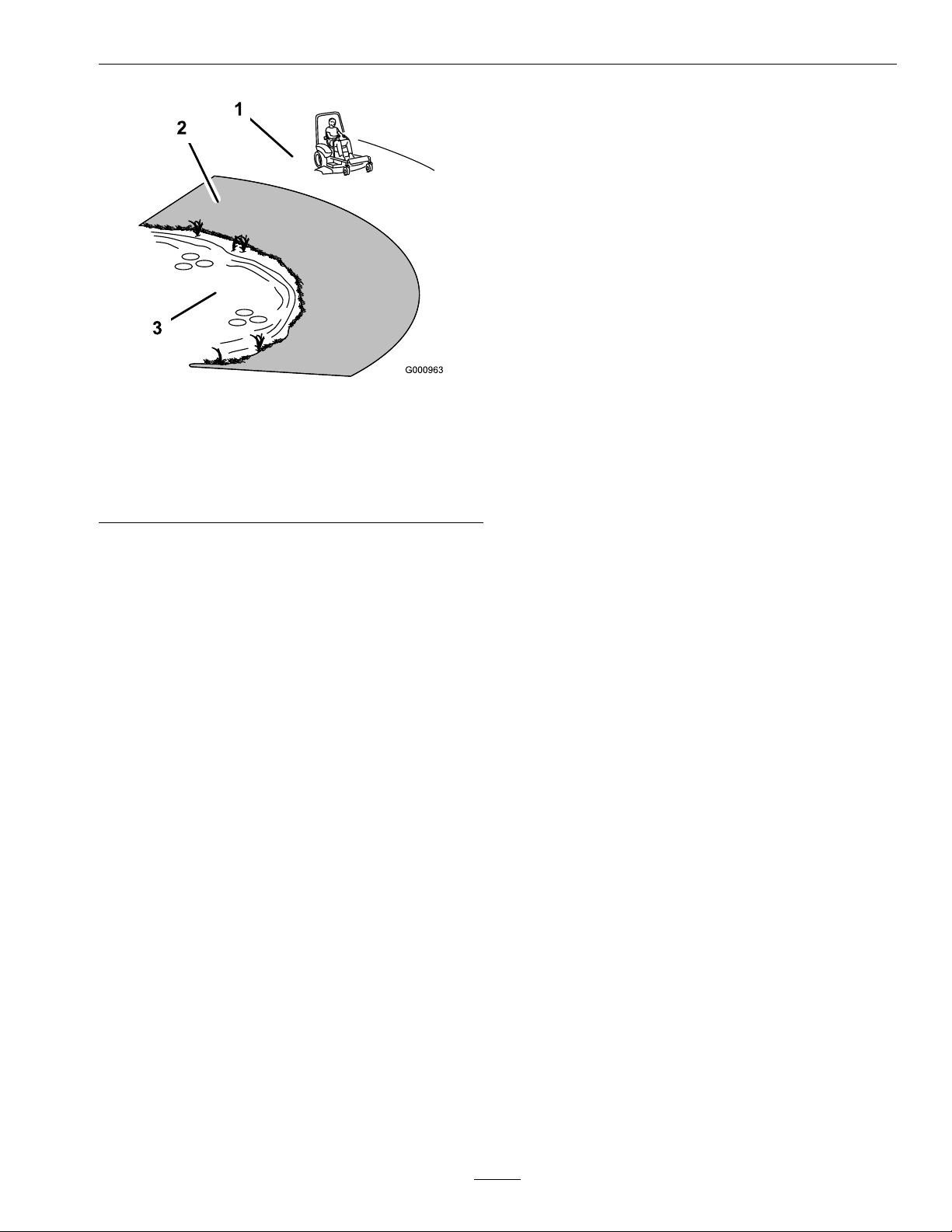

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Wheels

droppingoveredges,ditches,steepbanks,or

watercancauserollovers,whichmayresult

inseriousinjury,deathordrowning.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan15

degrees.

•Reducespeedanduseextremecaution

onslopes.

•Avoidsuddenturnsorrapidspeed

changes.

•Keeptherollbarintheraisedandlocked

positionanduseseatbelt.

–Wheneveryouleavethemower.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

(Figure3).

6

Page 7

Useprogressivelygreatercareonslopesasthe

hopperlls.

MaintenanceandStorage

•Disengagedrives,setparkingbrake,stopengine

andremovekeyordisconnectsparkplugwire.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

Safety

Figure3

1.SafeZone-Usethemowerhereonslopeslessthan15

degrees

2.DangerZone-Useawalkbehindmowerand/orhand

trimmeronslopesgreaterthan15degrees,near

drop-offsandwater.

3.Water

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatoperatingonwetgrass,acrosssteep

slopesordownhillmaycausethemowertolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Allreplacementpartsmustbethesameas

orequivalenttothepartssuppliedasoriginal

equipment.

•Followthemanufacturer’srecommendationsfor

counterweightstoimprovestability .Always

installandremovetheUltraVacQDS,including

counterweights,asinstructed.Failuretodoso

willcauseareductioninstabilityortraction.Do

Notoperatethemowerwithonlyaportionofthe

UltraVacQDSinstalled.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.Thestability

andtractionofthemachinewillchangeasthe

UltraVacQDShopperllswithgrassclippings.

7

Page 8

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

103-6605

ForUnitswithaTwo-PostROPSOnly

1-653554

1-653558

98-5954

103-6604

ForUnitswithaTwo-PostROPSOnly

8

Page 9

Safety

103-3508

9

Page 10

Specications

Specications

ModelNumbers

SerialNos:790,000andHigher

LHPUVD4448;LHPUVD4650;LHPUVD5256

Systems

BaggingSystem

•CollectionHopper:

–Commercialgrade,steelandpolyethylene

hopperwithreardischargedoor,commercial

gradeclothmeshdoorpanel.

–Capacity:6.7bushels

•DumpMechanism:Singlemotionactuationfrom

operator’sseat.

•BlowerTube:Fixed,abrasionresistantmolded

polyethylene.

•Impeller:5–bladed,1/4inch(6.4mm)thick

abrasionresistantsteel,withverticalaxis.

•Impellerbearings:1inch(2.5cm)sealed

non-greaseablebearings.

Dimensions

w/UltraV acQDS

52inchDeck95.00inches(241.3cm)

56inchDeck99.86inches(253.6cm)

CurbWeight:

LazerZHP-220lb(100kg),includingthefront

weight.

TorqueRequirements

BoltLocation

ImpellerSpindleBottom

Nut

ImpellerSpindleT opNut75-80ft-lb(102-108N-m)

Torque

55-60ft-lb(75-81N-m)

OverallWidth:

w/UltraV acQDS

44inchDeck58.47inches(148.5cm)

46inchDeck60.67inches(154.1cm)

48inchDeck61.73inches(159.8cm)

50inchDeck64.66inches(164.2cm)

52inchDeck66.47inches(168.8cm)

56inchDeck70.85inches(180.0cm)

OverallLength:

w/UltraV acQDS

44inchDeck93.76inches(283.2cm)

46inchDeck96.69inches(245.6cm)

48inchDeck93.76inches(283.2cm)

50inchDeck97.12inches(246.7cm)

10

Page 11

Operation

ProductOverview

Figure4

1.Hood4.Tube

2.Weight5.Door

3.Blower

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Pre-Start

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

Ensuretheblower,doormesh,tubeandhopperare

ingoodcondition,properlyattached,andlatched.

ForunitsaboveSerialNumber600,000withTriton

decks:Makesurethattheadjustabledoglegbafeis

closedtomatchtheintakeintotheUltraVacBlower.

WARNING

Ifthedeckdischargeopeningandtheblower

intakeopeningdonotmatchcorrectly,it

willallowobjectstobethrowninoperator’s

orbystander’sdirection.Also,contactwith

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryorkillyou

orbystanders.

Adjustdoglegbafetomatchintake

opening.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

Mowing

1.TheUltraVacQDSbloweroperateswhendeck

driveisengaged.Besurethatallpersonsareclear

ofthemowerdeckbeforeengagingthecutting

blades.Setthethrottleto“midway”position.Pull

outwardonthePTOswitchtothe“ROTATE”

position.Acceleratetofullthrottletobegin

mowing.

2.TodisengagethePTOandblower,setthe

throttleto“midway”position.Pushinonthe

PTOswitchtothe“STOP”positiontostopthe

cuttingbladesandblower.Thecuttingbladeswill

requireaslightlylongeramountoftimetocome

toacompletestopwhentheblowerisinstalled

onthedeck.Verifythatallrotationindicators

11

Page 12

Operation

havestoppedbeforeclearingblowerassemblyor

mowerdeck

3.Toemptythehopper,rstshutoffdeckdrive.

Liftuponthehandletoopenthedoorand

emptythehopper.Iftheunitistobedriven

ontoatruckortrailerwiththehopperfull,

alwaysbacktheunituptheramp.Thiswill

reducethechanceofrearwardtipup.Seethe

Transportingsectionforadditionalinformation

regardingloadingaunitonatruckortrailer.

4.Closeandlatchthedoorbeforecontinuing

mowing.DoNotengagethecuttingbladeswhile

thedoorisintheopenposition.

Tipsformowingconditions:

•Whenmowinginareaswithsandysoil,use

lowliftbladesonthecuttingdeckandhigher

cuttingheightstominimizewearontheblower

components.

•Whenmowinginwetconditions,suchasjustafter

arainorinheavydew ,uselowliftbladesonthe

cuttingdecktominimizepluggingoftheblower.

•Maintainingagroundspeedthatdoesnotpull

downtheengineRPMwillallowforthehighest

productivityandbestqualityofcut.Boggingthe

engineRPMdownbygoingtoofastwillcause

pluggingandqualityofcutissues.

•Whenthehoppergetsfull,thesoundofthe

blowerwillchangeandtherewillbeslight

blowoutfromthefrontrightcornerofthedeck.

Emptyingthehopperatthispointwillminimize

thepotentialforthetubetoplug.

•ForunitsbelowSerialNumber600,000:

Anti-blowoutkitsareavailableforleafcollection.

Theyhelptoprevent“chasing”theleaves.To

reduce“plowing”leaves,raisethedeckslightly.

Figure5

1.HopperAssembly4.Hairpin

2.Tube

3.Blower

5.ClevisPin

3.Removethebeltcoverbylooseningtheknobs.

CAUTION

Thedecksheavewillbecomeveryhot.

Touchingahotdecksheavecancausesevere

burns.

Allowthedecksheavetocoolcompletely

beforeremovingthebelt.

•OnTriton:Raisefrontadjustablebafeto

reduceplowing.Loweringfrontadjustablebafe

mayprevent“chasing”.Matchdischargeopening

toUltraVacintakeforbestperformance.

BaggerRemovalforSideDischarge

1.Shutoffthedeckdrive,stopengineandwaitfor

allmovingpartstostop.Removekey.

2.Removethedischargetubebyreleasingthelatch

attheblower.Slidethetubeoffthebloweroutlet

andremovetheupperendfromthehopper.

Figure6

1.Hairpin4.Beltshield

2.Chutepivotpin

3.Dischargechute6.Knob

5.Weight

4.Pulltheidlerreleasehandleandremovethebelt

fromtheuppergrooveofthedecksheave.

5.Unlatchthefrontendoftheblower.Pivotthe

blowerbackandliftitoffthedeck.

12

Page 13

Operation

6.Installthedischargechuteusingthechutepivot

pinandhairpin(seeFigure7).

Figure7

Viewedfromtherightside

1.Hairpin3.Dischargechute

2.Chutepivotpin

Note:Installchutewiththetabstotherearof

thedecktabsasshown.

WARNING

Anuncovereddischargeopeningwill

allowobjectstobethrowninoperator’sor

bystander’sdirection.Also,contactwith

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryorkillyou

orbystanders.

Neveroperatemowerunlessdischarge

deector,orentiregrasscollectionsystem,or

mulchkitisinstalled.

7.Re-installtheplasticbeltcoverandtightenthe

knobs.

8.Removethehairpinsandclevispinsholdingthe

hopperassemblytothemountweldment.

9.Liftthehopperassemblyoffthemount.

10.Removethehairpinsandliftthefrontweightsoff

ofthemountplate.

Note:Theremovableweightsareheavy.Use

carewhenliftingthem.Makesurethatyoucan

holdthemsecurelybeforeliftingthem.Use

cautionwhenpositioningyourhandssothatyou

DoNotsetthemdownonyourhandsorngers.

Note:TheportionsoftheUltraVacbaggerthat

arenotboltedtothemoweraredesignedtobe

installedorremovedintheirentirety .DoNot

operatethemowerwithonlyaportionofthe

UltraVacinstalled.

WARNING

Casterorfrontoorpanweightsinstalled

withoutbaggermaycauselossoftraction

andsteeringcontrol.Lossofcontrolcan

resultinanaccident,whichmaycausedeath,

injury,orpropertydamage.

Installcasterorfrontoorpanweights

ONLYwhenbaggerisinstalled.

11.Themachinecannowbeusedforsidedischarge

mowing.

BaggerInstallationforBagging

1.Stopengine,removekey,andwaitforallmoving

partstostop.

2.Removehairpinandchutepivotpin.Remove

dischargechute.Pivotpinandhairpinmaybe

storedinthepivotholesofthedischargechute

duringbaggingoperation.

3.Slidetubeendsofhopperassemblyintothetubes

ofthemountweldment(seeFigure5).Installtwo

clevispinsthroughholesintubes.Retainwith

twohairpins.

4.Removethebeltcoverontherightsideofthe

deck(seeFigure6).Installtheblowerbyinserting

themountingpinintothetubeweldedtotherear

cornerofthedeck.Pivotthebloweruntilthe

frontpinengagestheslotinthedeck.Adjustthe

positionofthefrontpinifnecessarytoengage

theslot.Usethelatchtolocktheblowerinthis

position.

5.Pulltheidlerreleasehandleandinstallthebeltin

theuppergrooveofthedecksheave.

6.Installthebeltcoverusingthetwoknobs.

7.Installthedischargetubeassemblybyslippingthe

upperendintothehood,thenslidingthelower

endovertheblowerdischargeopening.Usethe

latchestoretainthelowerendtotheblower.

8.ForUnitsSerialNumber600,000andHigher

withTritonDecks:Adjustpositionofdogleg

bafetomatchtheintakeoftheUltraVacblower

bafeadjustedtoowidemayallowobjectstobe

thrownfromunderdeck.Bafeadjustedtoo

narrowmaycausepluggingissues.

13

Page 14

Operation

Transporting

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Securely

fastenthemachinetothetrailerortruckwithstraps,

chains,cable,orropes.Besurethatthetrailerortruck

hasallnecessarylightingandmarkingasrequiredby

law .Secureatrailerwithasafetychain.

CAUTION

Thisunitdoesnothaveproperturn

signals,lights,reectivemarkings,ora

slowmovingvehicleemblem.Drivingona

streetorroadwaywithoutsuchequipment

isdangerousandcanleadtoaccidents

causingpersonalinjury.Drivingonastreet

orroadwaywithoutsuchequipmentmayalso

beaviolationofStatelawsandtheoperator

maybesubjecttotrafcticketsand/ornes.

DoNotdriveaunitonapublicstreetor

roadway.

WARNING

Loadingaunitonatrailerortruckincreases

thepossibilityofbackwardtip-over.

Backwardtip-overcouldcauseseriousinjury

ordeath.

•Useextremecautionwhenoperatinga

unitonaramp.

•Useonlyasingle,fullwidthramp;Do

Notuseindividualrampsforeachside

oftheunit.

•Ifindividualrampsmustbeused,use

enoughrampstocreateanunbroken

rampsurfacewiderthantheunit.

•DoNotexceeda15°anglebetweenramp

andgroundorbetweenrampandtrailer

ortruck.

•Avoidsuddenaccelerationwhiledriving

unituparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

unitdownaramptoavoidtipping

backward.

LoadingaUnit

Iftheunitistobedrivenontoatruckortrailer

withthehopperfull,alwaysbacktheunitupthe

ramp.Thiswillreducethechanceofrearward

tipup.

DumpcontentsofhopperbeforetransportDoNot

transporttheunitwiththehopperfull.

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinstead

ofindividualrampsforeachsideoftheunit.The

lowerrearsectionofthetractorframeextendsback

betweentherearwheelsandservesasastopfor

tippingbackward.Havingafullwidthrampprovides

asurfacefortheframememberstocontactifthe

unitstartstotipbackward.Ifitisnotpossibletouse

onefullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Rampshouldbelongenoughsothattheangles

betweentherampandthegroundandtherampand

thetrailerortruckDoNotexceed15°.Asteeper

anglemaycausemowerdeckcomponentstoget

14

Page 15

caughtastheunitmovesfromramptotraileror

truck.Steeperanglesmayalsocausetheunittotip

backward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideofthe

slopeandtherampextendsuptheslope.Thiswill

minimizetherampangle.Thetrailerortruckshould

beaslevelaspossible.

Important:DoNotattempttoturntheunit

whileontheramp,youmaylosecontroland

driveofftheside.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdownaramp.

Bothmaneuverscancausetheunittotipbackward.

Operation

15

Page 16

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)aside

soitdoesnotaccidentallycontactthespark

plug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

MaintenanceProcedure

•Checktheblowerhousing/impeller.

•Checkdoorclothmesh.

•Cleanmuferandrearframearea.

•Cleanrearscreeninthehood.

WARNING

Theenginecanbecomeveryhot.Touching

ahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

Every25hours

Every50hours

Yearlyorbeforestorage

•Lubricategreasettings.

•Checkconditionofbelt.

•Cleanblower.

PeriodicMaintenance

CheckBlower

Housing/Impeller

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Inspectforwearordamagedaily.Replaceor

repairwornpartsasneeded

Note:Whenmowinginareaswithsandysoil,

uselowliftbladesonthecuttingdeckandhigher

cuttingheightstominimizewearontheblower

components.

CheckDoorClothMesh

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Inspectthebagsforwear,tears,ordamage.

WARNING

Undernormalusetheclothmeshwill

deteriorateandwear.Objectscouldexit

throughwornclothmeshathighspeeds.

Thrownobjectscancauseseriousinjuryor

killyouorbystanders.

Checkclothmeshfrequentlyfortearsand

holes.Replacewornclothmesh.

16

Page 17

Maintenance

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.LubricatettingswithNGLIgrade#2

multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.Idler

Bushings

Initial

Pumps

1–21

Numberof

Places

Service

Interval

25Hours

CheckConditionofBelt

ServiceInterval:Every50hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Inspectthebeltpositionontheidlerarm.

Theidlerarmmaybecomebentduringuseor

transport.Abentidlerarmcouldcausethebelt

tojumpoffoftheidlerandbedamaged.

3.Inspectthebeltfordamageorwear.Replacebelt

withoneofthefollowing:

Deck

44inchDeck

46inchDeck

48inchDeck

50inchDeck

52inchDeck

56inchDeck

PartNo.

1-653332

1-653438

1-653333

103-0866

1-653438

109-9249

A.Toreplacebelt,removethebeltguideonthe

blower(Figure8)

Figure8

1.Springloadedidler

2.Impellersheave5.Decksheave

3.Fixedidler

4.Beltguide

A.Makesurethebeltcoverisinstalledandrun

theblowerforonetotwominutes.

B.Shutoffthedeckdrive,stopengineandwait

forallmovingpartstostop.Removekey.

Removethebeltcoverandchecktomakesure

thatthebeltisridingnearthecenterofthe

atidlerontheidlerarm.

C.Ifthebeltisnotridingnearthecenterofthe

idler,removetheblower,andbendtheidler

armslightly.

D.Reinstalltheblowerandbeltcoverandrepeat

stepsAthroughCuntilthebeltispositioned

nearthecenteroftheidler.

B.Installthebeltontotheblowerassemblyas

shown.

C.Reinstallthebeltguideremovedpreviously.

17

Page 18

Maintenance

Adjustments

Note:TheUltraVacQDSwasadjustedatthe

factorytooperateproperly.However,therearethree

basicadjustmentsthatcanbemade,shouldyourunit

requirethem:

Figure9

1.Bellcrankarm

2.Upperframetube

3.Maintainsamedistanceonbothsides

3.Dooropening:Afteradjustingthehingelinks

fordoorclosing,thehingestops(Figure10B)can

beadjustedtoobtainmaximumdooropening.

Thestopplatesshouldbeadjustedsothatthe

doorlinkcontactsthemwhentheuppertubeof

thedoorframeiswithin1/4inch(6.4mm)±1/8

inch(3.2mm)fromthelowerlipofthemolded

hood.Bothleftandrightstopsmustmake

contactwhenthedoorlinkarmisatthisposition.

Figure10

1.1/4inch(6.4mm)±1/8inch(3.2mm)

1.ArmPosition:Theleftandrightbellcrankarms

controlthetimingoftheleftandrightdoor

openingmechanisms.Theendsofthesearms

mustbepositionedequallyfromtheupperframe

tubeforproperactuation.Checkthisdistance

withthedoorclosed.Ifadjustmentisnecessary,

loosentheallenheadclampingscrewonthehub

oftherighthandarm.Positionthearmssothat

theirendsarethesamedistancefromtheupper

frametube.Tightentheclampingbolttohold

theminthisposition(seeFigure9).

2.Doorclosing:Theclosingofthedooris

controlledbythetwohingelinks(Figure10A).

Thelengthofthehingelinkscanbechanged

toprovidecompleteclosingofthedoorand

reasonableforceonthehandletolatchorunlatch

thedoor.Lengthenthelinkstoreducetheforce.

Shortenthelinkstoincreasetheforce.Theleft

andrightsidesmustbeapproximatelyequal.With

thedoorclosed,bothlinksshouldbeslightlytight

tominimizerattling.

18

Page 19

Cleaning

CleanMuferandRear

FrameArea

ServiceInterval:Beforeeachuseordaily

Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

WARNING

Operatingengineparts,especiallythe

mufer,becomeextremelyhot.Severeburns

canoccuroncontactanddebris,suchas

leaves,grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

Maintenance

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,

brush-coveredunimprovedland.

CleanRearScreenInHood

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Opendoorandremoveclippingsthatarestuck

tothescreen.

CleanBlower

ServiceInterval:Yearlyorbeforestorage

Grassbuildupmaycauseproblemswiththeimpeller

whentheunitisputbackintooperation.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Removegrassbuildupfromaroundtheimpeller

beforeplacingitinstorage.

19

Page 20

Troubleshooting

Troubleshooting

Important:Itisessentialthatalloperatorsafetymechanismsbeconnectedandinproperoperating

conditionpriortomoweruse.

Whenaproblemoccurs,DoNotoverlookthesimplecauses.Forexample:startingproblemscouldbe

causedbyanemptyfueltank.

Thefollowingtablelistssomeofthecommoncausesoftrouble.DoNotattempttoserviceorreplacemajor

itemsoranyitemsthatcallforspecialtimingoradjustmentprocedures(suchasvalves,governor,etc.).Have

thisworkdonebyyourEngineServiceDealer.

Note:WhendisconnectingelectricalconnectorsDoNotpullonthewirestoseparatetheconnectors.

ProblemPossibleCauseCorrectiveAction

Abnormalvibration.

Blowerdrivebeltsnapsorbreaksfrequently.

Excessivegrassblowoutfromthedeck.

Blowerandtubesplugtoofrequently.

Blowerimpellerdoesnotspinfreely.

1.Cuttingblade(s)is/arebentorunbalanced.

2.Blademountingboltisloose.2.Tightentheblademountingbolt.

3.Looseblowerpulleyorpulleyassembly.

4.Blowerimpellerbladesarebent.4.ContactanAuthorizedServiceDealer.

1.Idlerarmisoutofalignment.1.Correctthealignmentoftheidlerarm.

1.Hopperisfull.1.Dumpmorefrequently.

2.Pluggedscreeninbaggerhood.2.Removedebris,leavesorgrassclippings

3.Groundspeedistoofast.

4.Blowerbeltisworn,loose,orbroken.4.Installnewblowerbelt.

5.Pluggedtubeorblower.5.Locateandremovepluggeddebris.

6.Conditionsaredry.6.Uselowerliftblade.

1.Hopperistoofull.1.Dumpmorefrequently

2.Groundspeedistoofast.

3.Grassistoowet.

4.Grassistoolong.4.Cutgrassmorefrequentlyorathighercut

5.Pluggedscreeninbaggerhood.5.Removedebris,leaves,orgrassclippings

6.Blowerdrivebeltisworn,loose,or

broken.

7.Blowerisplugged.7.Uselowliftbladesinwetconditions.

1.Pluggedblower.1.Removedebris,leaves,orgrassclippings

2.Impellernotaligned.2.ContactanAuthorizedServiceDealer.

1.Installnewcuttingblade(s).

3.Tightentheappropriatepulley .

fromthescreen.

3.Drivesloweratfullthrottle.

2.Drivesloweratfullthrottle.

3.Cutgrasswhenitisdry.

height.

fromthescreen.

6.Installnewbelt.

fromtheblowerimpeller.

Plowingleaves.

Chasingleaves.

Blowercomponentsshowsignsofwear

and/oraircleanersandcoolingnsaredirty.

1.Deckistoolow.

1.Blowoutfromdeck.

1.Sandordryconditions.1.Uselowliftbladesonthecutting

1.

UnitsbelowSerialNumber

600,000:Raisethedeckslightly.

Triton:Raisethefrontadjustablebafe.

1.

UnitsbelowSerialNumber600,000:

Installananti-blowoutkit–contact

anAuthorizedServiceDealer.

Triton:Lowerthefrontadjustable

bafe.MatchdischargeopeningtoUltra

Vacintake.

deckandhighercuttingheights.

Cleanaircleanersandcoolingns

frequently.

20

Page 21

Conditions and Products Covered

Exmark Mfg. Co. Inc. and its affiliate, Exmark Warranty

Company, pursuant to an agreement between them, jointly

warrant on the terms and conditions herein, that we will repair,

replace or adjust any part on these products and found by us

(in the exercise of our reasonable discretion) to be defective in

factory materials or workmanship for a period of one year.

This warranty applies to Exmark commercial attachments and

accessories sold in the U.S. or Canada. This warranty may

only be assigned or transferred to a second (or third) owner by

an authorized Exmark dealer. The warranty period commences

upon the date of the original retail purchase.

Warranty Exceptions Warranty Period

• Bags, Belts and Tires 90 days

This warranty only includes the cost of parts and labor.

Items and Conditions Not Covered

This warranty does not cover the following:

• Pickup and delivery charges to and from any authorized

Exmark Service Dealer.

• Any damage or deterioration due to normal use, wear and

tear, or exposure.

• Cost of regular maintenance service or parts, such as filters,

fuel, lubricants, tune-up parts, and adjustments.

• Any product or part which has been altered or misused or

required replacement or repair due to normal wear,

accidents, or lack of proper maintenance.

• Any repairs necessary due to use of parts, accessories or

supplies, including gasoline, oil or lubricants, incompatible

with the attachment or accessory or other than as

recommended in the operator's manual or other operational

instructions provided by Exmark.

All warranty work must be performed by an authorized

Exmark Service Dealer using Exmark approved replacement

parts.

Instructions for Obtaining Warranty Service

The product must be registered with original proof of purchase

by an Exmark Service Dealer before obtaining any warranty

service.

Contact any Exmark Service Dealer to arrange service at their

dealership. To locate a dealer convenient to you, access our

website at www.exmark.com. U.S. or Canada customers may

also call 402-223-6375.

If for any reason you are dissatisfied with the Service Dealer’s

analysis or with the assistance provided, contact us at:

Exmark Customer Service Department

The Exmark Warranty Company

2101 Ashland Avenue

Beatrice, NE 68310

402-223-6375 or

service@exmark.com

Owner’s Responsibilities

The Exmark attachment or accessory, including any defective

part, must be returned to an authorized Exmark service dealer

within the warranty period. This warranty extends only to

commercial attachments and accessories operated under

normal conditions. You must read the operator’s manual. You

must also properly service and maintain your Exmark product

as described in the operator’s manual or other operational

instructions provided by Exmark. Such routine maintenance,

whether performed by a dealer or by you, is at your expense.

General Conditions

The sole liability of Exmark and Exmark Warranty Company

with respect to this warranty shall be repair or replacement of

defective components as set forth herein. Neither Exmark

nor Exmark Warranty Company shall be liable for any

incidental or consequential loss or damage.

Such damages include but are not limited to:

• Expenses related to gasoline, oil or lubricants.

• Travel time, overtime, after hours time or other

extraordinary repair charges or charges relating to repairs or

replacements outside of normal business hours at the place

of business of the authorized Exmark Service Dealer.

• Rental of like or similar replacement equipment during the

period of any warranty, repair or replacement work.

• Any telephone or telegram charges or travel charges.

• Loss or damage to person or property other than that

covered by the terms of this warranty.

• Any claims for lost revenue, lost profit or additional cost as

a result of a claim of breach of warranty.

• Attorney's fees.

No Claim of breach of warranty shall be cause for cancellation

or rescission of the contract of sale of any Exmark attachment

or accessory.

All implied warranties of merchantability (that the

product is fit for ordinary use) and fitness for use (that the

product is fit for a particular purpose) are limited to the

duration of the express warranty.

Some states do not allow exclusions of incidental or

consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions and

limitations may not apply to you.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Exmark Commercial

Attachments and Accessories

1 Year Limited Warranty

G4500-433

21

Page 22

ServiceRecord

Date:

DescriptionofWorkDone:ServiceDoneBy:

22

Page 23

23

Page 24

MI D-MO UNT RIDI NG ACCESSORIES AND OPTION S

SEE EXMARK’S COMPLETE LINE OF ACCESSORIES AND OPTIONS

WALK-BEHIND ACCESSORIES AND OPTIONS

GRASS CATCHER

MICRO-MULCH SYSTEM

TURF STRIPER

STANDON

CUSTOM RIDE SEAT SUSPENSION SYSTEM

FULL SUSPENSION SEAT

DECK LIFT ASSIST KIT

HITCH KIT

LIGHT KIT

12

V POWER PORT

MICRO-MULCH SYSTEM

OPERATOR CONTROLLED DISCHARGE

ROLL OVER PROTECTION SYSTEM (ROPS)

SUN SHADE

TRASH CONTAINER

TURF STRIPER

ULTRA VAC COLLECTION SYSTEM

ULTRA VAC QUICK DISPOSAL SYSTEM

OU T-FRONT RIDING AC CESS ORIE S AN D OP TION S

CUSTOM RIDE SEAT SUSPENSION SYSTEM

DUAL-TAIL WHEEL

FLOOR PAN EXTENDER

HITCH KIT

LIGHT KIT

MICRO-MULCH SYSTEM

ROLL OVER PROTECTION SYSTEM (ROPS)

SNOW BLADE

SNOWBLOWER

SUN SHADE

TRASH CONTAINER

ULTRA VAC COLLECTION SYSTEM

ULTRA VAC QUICK DISPOSAL SYSTEM

WEATHER CAB

PlaceModelNo.andSerialNo.

LabelHere(IncludedintheLiterature

Pack)orFillinBelow

ModelNo.

SerialNo.

©2008ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

AllRightsReserved

DatePurchased

PartNo.4500-420Rev.A

(402)223-6300

Fax(402)223-5489

PrintedintheUSA

www.exmark.com

Loading...

Loading...