Page 1

TURFTRACER®

ForSerialNos.

790,000&Higher

PartNo.4500-361Rev.A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,or

otherreproductiveharm.

Important:Whenthemowerisusedoroperated

onanyCaliforniaforest,brushorgrasscovered

land,aworkingsparkarrestermustbeattached

tothemufer.Ifnot,theoperatorisviolating

statelaw,Section4442PublicResourceCode.To

acquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

ThissparkignitionsystemcomplieswithCanadian

ICES-002Cesystèmed’allumageparètincellede

vèhiculeestconformeàlanormeNMB-002du

Canada

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2008—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency,andpromotesafe

operation.

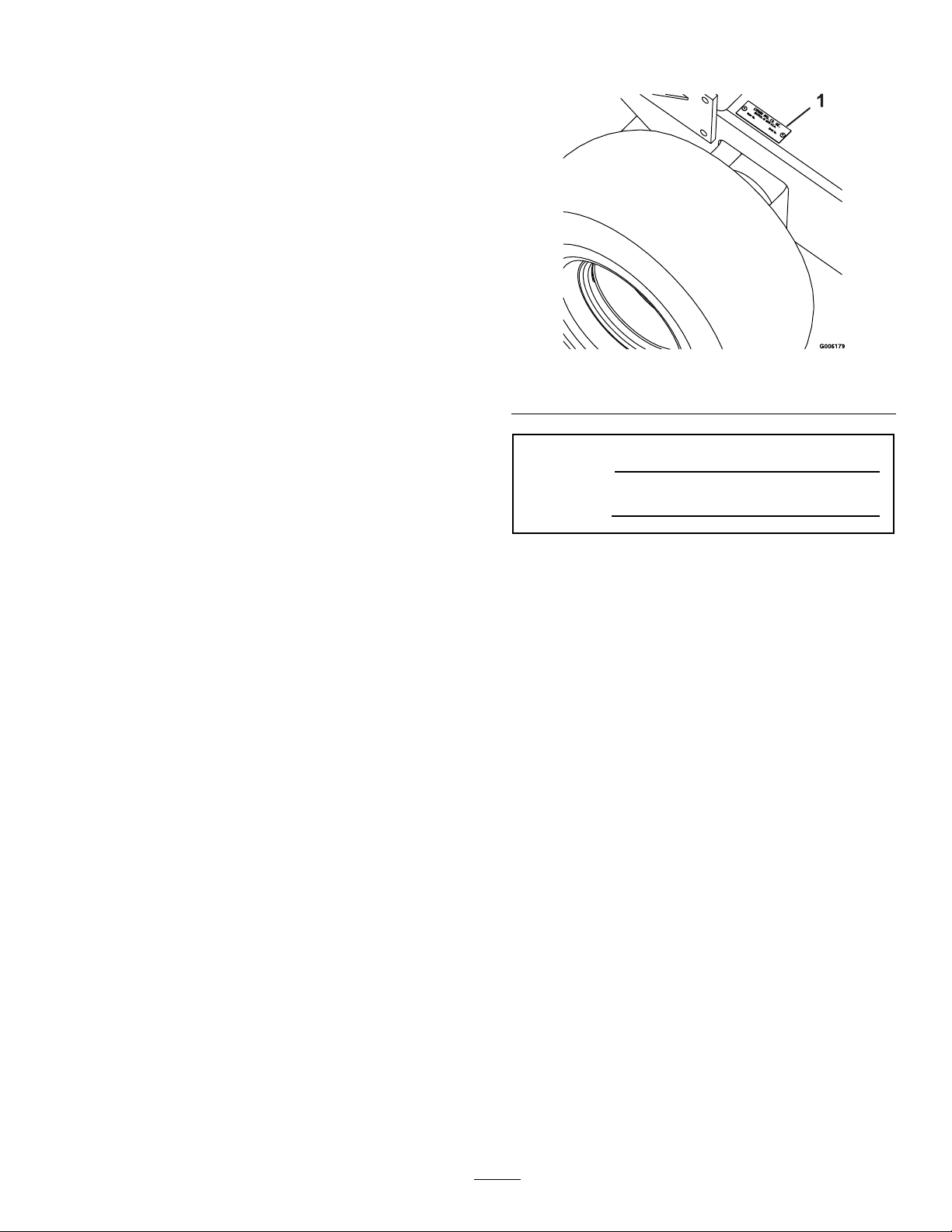

Figure1

1.Modelandserialnumberlocation

ModelNo.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

SerialNo.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.....................10

Specications.......................................................12

ModelNumbers............................................12

Systems.........................................................12

Dimensions...................................................13

TorqueRequirements....................................14

ProductOverview................................................14

Operation.............................................................15

Controls........................................................15

Pre-Start........................................................16

OperatingInstructions..................................17

Transporting.................................................21

Maintenance.........................................................22

RecommendedMaintenanceSchedule(s)...........22

PeriodicMaintenance.......................................23

CheckEngineOilLevel.................................23

CheckBatteryCharge....................................23

CheckMowerBlades.....................................23

CheckSafetyInterlockSystem.......................24

CheckforLooseHardware............................25

ServiceAirCleaner........................................25

ChangeEngineOil........................................25

CheckHydraulicOilLevel.............................25

CheckTirePressures.....................................25

CheckConditionOfBelts..............................26

LubricateGreaseFittings...............................26

LubricateCasterWheelHubs........................26

RemoveEngineShroudsandCleanCooling

Fins...........................................................27

CheckSparkPlugs.........................................27

ChangeHydraulicSystemFilter.....................28

ThreadLockingAdhesives.............................29

MobilHTSGrease(OrFood-Grade

Anti-seize).................................................30

Copper-BasedAnti-seize..............................30

DielectricGrease...........................................30

Adjustments.....................................................30

DeckLeveling...............................................30

PumpDriveBeltTension...............................30

DeckBeltTension.........................................30

BladeDriveBeltTension..............................30

BrakeAdjustment..........................................30

SpeedControlLinkageandNeutralSafety

SwitchAdjustment....................................30

NeutralControlLinkagesAdjustment............31

HydroControlLinkageAdjustment...............31

DriveLeverLinkageAdjustment...................32

TrackingAdjustment.....................................32

HydroPumpSpringTensionSetting..............33

ElectricClutchAdjustment............................33

Cleaning...........................................................33

CleanGrassBuild-UpUnderDeck................33

WasteDisposal..............................................33

Troubleshooting...................................................35

Schematics...........................................................37

4

Page 5

Safety

Safety

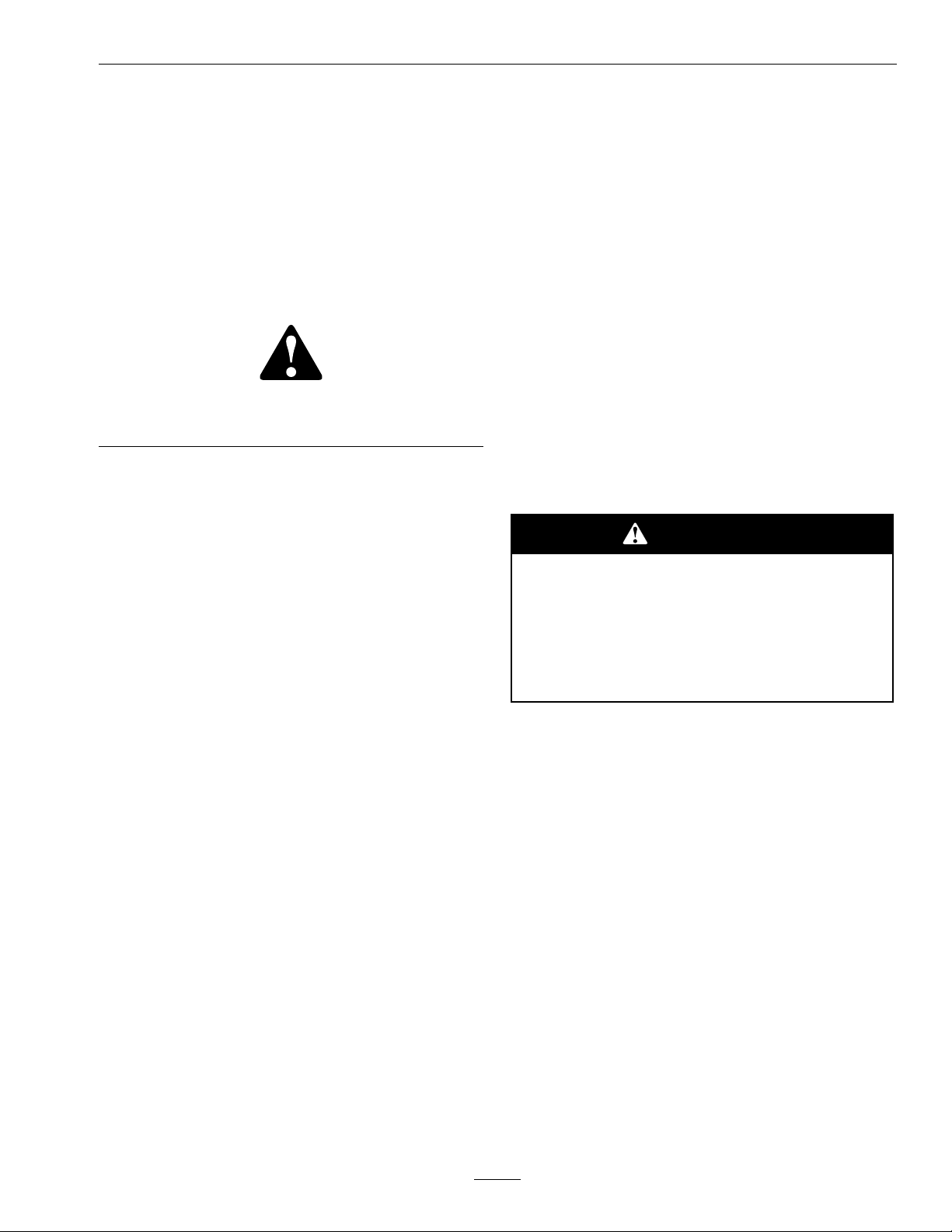

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

1.Safetyalertsymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

CAUTION

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Y ellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

5

Page 6

Safety

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsinanopen

area,whentheengineiscold.Wipeup

anygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletely

full.Addgasolinetothefueltankuntil

thelevelis1/4to1/2inch(6–13mm)

belowthebottomofthellerneck.This

emptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,

andstayawayfromanopenameor

wheregasolinefumesmaybeignitedby

spark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.

Neverremovethecapofthefueltankor

addfuelwhenengineisrunningorwhen

theengineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperator’spresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly .DoNotoperateunlessthey

arefunctioningproperly.

6

Page 7

Safety

Operation

WARNING

Operatingengineparts,especiallythe

mufer,becomeextremelyhot.Severeburns

canoccuroncontactanddebris,suchas

leaves,grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Neverraisedeckwithbladesrunning.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly .

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Stopengine,waitforallmovingpartstostop,

removekeyandengageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

–Beforemakingheightadjustments.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•DONOToperatethemowerwhenpeople,

especiallychildren,orpetsareinthearea.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

7

Page 8

Safety

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Lossof

controland/orlossofoperator’sfooting

couldresultinafallwithanarmorleg

gettingunderthemowerorenginedeck

whichmayresultinseriousinjury,deathor

drowning.

•Mowacrossslopes,neverupanddown.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan20

degrees.

•Reducespeedanduseextremecaution

onslopes.

•Avoidsuddenturnsorrapidspeed

changes.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatoperatingonwetgrass,acrosssteep

slopesordownhillmaycausethemowertolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

MaintenanceandStorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•Letenginecoolbeforestoringanddonotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Allreplacementpartsmustbethesameas

orequivalenttothepartssuppliedasoriginal

equipment.

8

Page 9

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbya

doctorfamiliarwiththisformofinjuryor

gangrenemayresult.

•Makesureallhydraulicuidhoses

andlinesareingoodconditionand

allhydraulicconnectionsandttings

aretightbeforeapplyingpressureto

hydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,

tondhydraulicleaks.

Safety

•Safelyrelieveallpressureinthehydraulic

systembyplacingthemotioncontrol

leversinneutralandshuttingoffthe

enginebeforeperforminganyworkon

thehydraulicsystem.

9

Page 10

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

1-303517

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

1-403143

103–1541

1-413214

1-513747

103–2076

10

Page 11

Safety

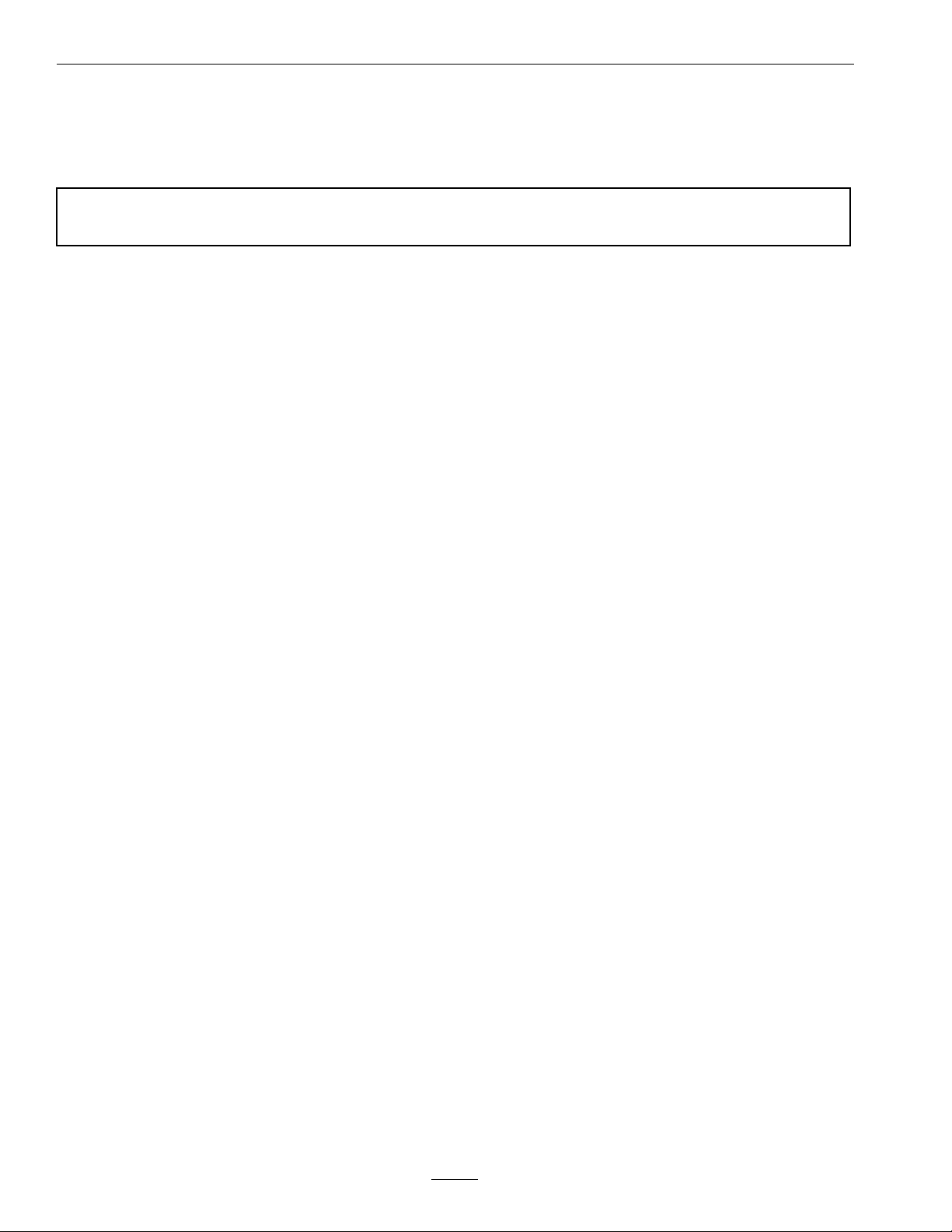

103–2242

103–2243

103-2432

103-4935

116-0404

11

Page 12

Specications

Specications

ModelNumbers

SerialNos:790,000andHigher

TT20KCE,TT23KAE

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•RPM:FullSpeed:3600(NoLoad)

FuelSystem

•Capacity:5.0gal.(18.9L)

•TypeofFuel:Regularunleadedgasoline,87

octaneorhigher.

•FuelFilter:ReplaceableIn-line

•FuelShut-OffValve:1/4turnincrements

ElectricalSystem

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:15amps

•BatteryType:BCIGroupU1235amps0°F

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuses:Twobladetype,20amptochargingcircuit;

20amptoelectricclutch

OperatorControls

SteeringControl:Fingertipdrivecontrollevers

provideindependentspeedcontrol,brakingand

neutraltoeachdrivewheelformovingforwardor

reverse,stopping,andpowerturning.

Transmission

•TwoHydroGearvariabledisplacementpiston

pumpsindependentlycoupledtotwohigh

efciencyParkerwheeldrivemotors.

•HydraulicOil:UseExmarkPremiumHydroOil.

•HydraulicOilCapacity:2.4qt.(2.2L)

•HydraulicFilterisreplaceablecartridgetype.

P/N109–4180:25microns,10psibypass

(Summeruseabove32°F(0°C))

P/N1–523541:40microns,18psibypass(Winter

usebelow32°F(0°C))

•Speeds:

–0-6.75mph(10.9km/hr)forward.

–0-2.25mph(3.6km/hr)reverse.

•Drivewheelreleasevalvesallowmachinetobe

movedwhenengineisnotrunning.

SafetyInterlockSystem:

•OperatormusthaveOPC(OperatorPresence

Control)leversheldincontactwithhandle

grips,speedcontrolleverinneutral,andPTO

disengagedtostartengine.ReleaseofOPClevers

willcausetheenginetostopifspeedcontrollever

isnotinneutraland/orPTOisengaged.

•Parkbrakemustbeengagedtomovespeed

controloutofneutralorenginewillkill.

WheelDriveSystem

DrivewheelsaredirectcoupledtoParkerwheeldrive

motorswith1inch(25.4mm)taperedshaft.

12

Page 13

Specications

Tires&Wheels

DriveFrontCaster

Pneumatic

(Air-Filled)

AllSerial

Nos.

Quantity

Tread

Size18x8.50-811x4.00-511x4.00-5

PlyRating

Pressure

222

TurfMasterSmoothSmooth

44

14psi(96

kPa)

Pneumatic

(Air-Filled)

SN599,999

&Lower

16psi(110

kPa)

CuttingDeck

•ModelNumbers:

–FMD524

–FMD604

•CuttingWidth:

•CuttingHeightAdjustment:

Adjustsfrom11/2inches(3.8cm)to41/2

inches(11.4cm)in1/2inch(1.3cm)increments.

SemiPneumatic

SN600,000

&Higher

•MulchingKit:Optional

•Bagger:Optional

Dimensions

OverallWidth:

52inchDeck60inchDeck

DeectorUp53.4inches

(135.6cm)

DeectorDown64.8inches

(164.6cm)

OverallLength:

52inchDeck60inchDeck

83.4inches(211.8cm)83.4inches(211.8cm)

61.4inches

(156.0cm)

73.0inches

(185.4cm)

–52inch(132.1cm)

–60inch(152.4cm)

•Discharge:Side

•BladeSize:(3ea.)

–52inchDeck:18.00inches(45.7cm)

–60inchDeck:20.50inches(52.1cm)

•BladeSpindles:Solidsteelspindleswith13/4

inch(4.45cm)I.D .bearings.

•DeckDrive:

–Electricclutchmountedonengineshaft.

–Bladesdrivenbytwobelts(w/self-tensioning

idlers).

•Deck:

Fulloatingdeckisattachedtoout-frontsupport

frame,removableforservice.Sixanti-scalprollers

providemaximumturfprotection.Deckdesign

allowsforbagging,mulchingorsidedischarge.

•DeckDepth:

–52inchDeck:5.5inches(14.0cm)

OverallHeight:

52inchDeck60inchDeck

45inches(114.3cm)45inches(114.3cm)

TreadWidth:(OutsidetoOutsideof

Tires,Widthwise)

52inchDeck60inchDeck

45.8inches(116.3cm)45.8inches(116.3cm)

WheelBase:(CenterofCasterTireto

CenterofDriveTire)

52inchDeck60inchDeck

43.3inches(110.0cm)43.3inches(110.0cm)

CurbWeight:

52inchDeck60inchDeck

720lb(327kg)760lb(345kg)

–60inchDeck:5.5inches(14.0cm)

13

Page 14

ProductOverview

TorqueRequirements

BoltLocation

CutterHousingSpindle

Nut

BladeMountingBolt

(lubricatewithanti-seize)

EngineDeck/Mower

DeckSupportMount

Bolts

Type1Hardware

–Anti-ScalpRoller

WhizlockNutSeeFigure9

Type2

Hardware–Anti-Scalp

RollerNylocNutSee

Figure9

Type2&3Hardware

–Anti-ScalpRollerHex

CapscrewSeeFigure9

Type3

Hardware–Anti-Scalp

RollerFlangedNylocNut

SeeFigure9

Torque

140–145ft-lb(190–197

N-m)

55-60ft-lb(75-81N-m)

30-35ft-lb(41-47N-m)

40-45ft-lb(54-61N-m)

30-35ft-lb(41-47N-m)

50-55ft-lb(68-75N-m)

30-35ft-lb(41-47N-m)

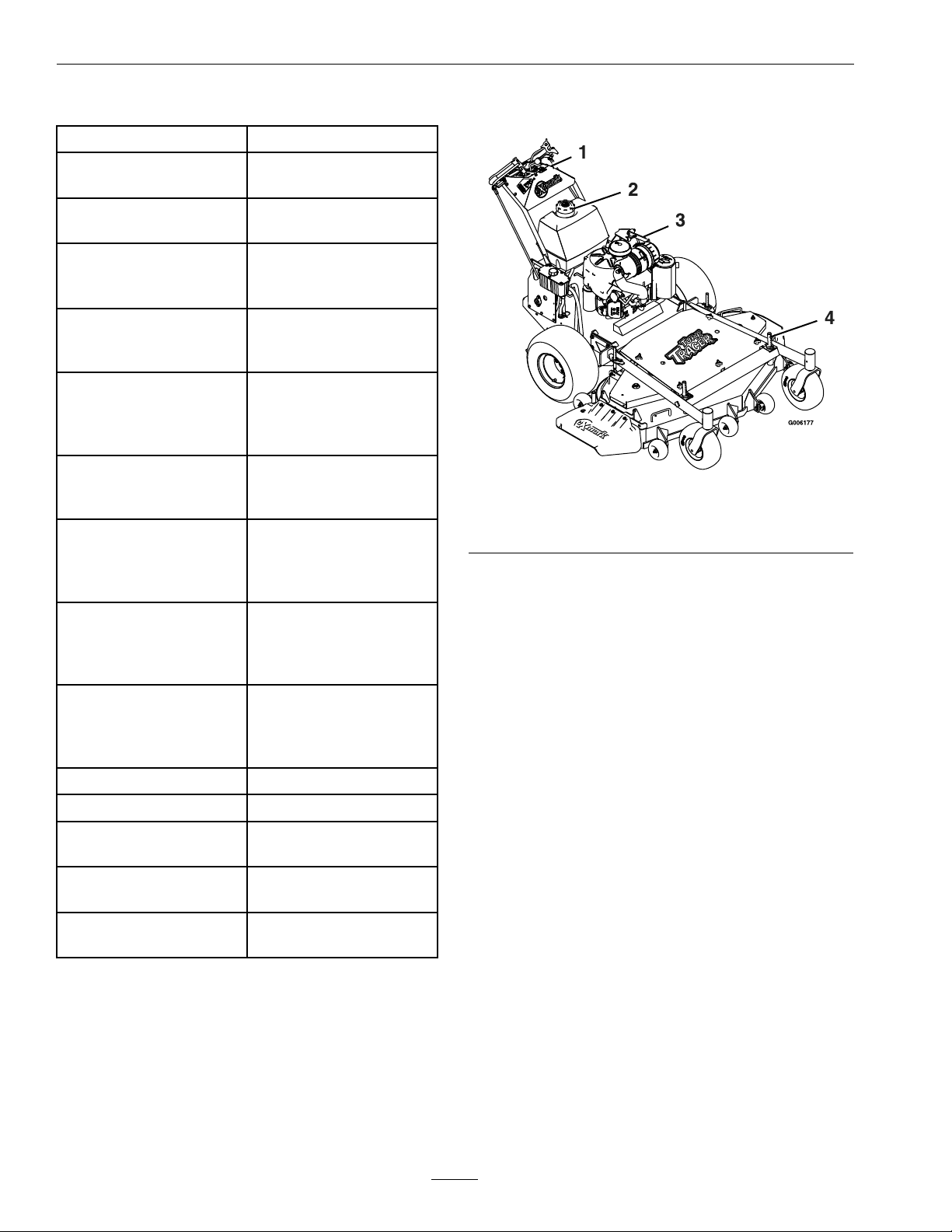

ProductOverview

Figure3

1.Controls

2.FuelCap4.Height-of-CutPins

3.ParkBrakeLever

Type4

Hardware–Anti-Scalp

RollerWhizlockNutSee

Figure9

Type4

Hardware–Anti-Scalp

RollerNylocNutSee

Figure9

EngineMountingBolts

WheelLugNuts

WheelHubSlottedNutsminimum100ft-lb(136

ClutchRetainingBolt

(securedwiththreadlocker)

WheelMotorMounting

Bolts

30-35ft-lb(41-47N-m)

30-35ft-lb(41-47N-m)

15-20ft-lb(20-27N-m)

90-95ft-lb(122-129N-m)

N-m)

55-60ft-lb(75-81N-m)

30-35ft-lb(41-47N-m)

14

Page 15

Operation

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

OperatorPresenceControl(OPC)

Levers

Locatedontheupperhandleassemblydirectlyabove

thehandlegrips.

Whentheseleversaredepressed,theOPCsystem

sensesthattheoperatorisinthenormaloperator’s

position.Whentheleversarereleased,theOPC

systemsensesthattheoperatorhasmovedfromthe

normaloperatingpositionandwillkilltheengineif

eitherthespeedcontrolleverisnotintheneutral

positionorthePTOisengaged.

asshowninFigure4,andthedriveleversarereleased,

thedrivewheelsareengagedintheforwarddirection.

Squeezingthelefthandand/orrighthandlever

causesthelefthandand/orrighthanddrivewheel

respectivelytoslowdown,stop,orreverse,depending

onhowfareachdriveleveris“squeezed”.Squeezing

thedriveleversbeyondtheneutralpositioncauses

thedrivewheelstoengageinthereversedirection

regardlessofthepositionoftheneutrallocklatches

andthespeedcontrollever.

NeutralLockLatches

Locatedontheupperhandleassemblyontheends

ofthehandlegrips.

Theselatchesallowtheoperatortolockthedrive

leversina“neutral”positionwherethedrivewheels

arenotengagedineitheraforwardorreverse

direction.

ChokeControl

1.OPCLever

2.Rotateneutrallocklatch

downwardforneutral

lockposition

DriveLevers

Figure4

3.NeutralLockLatch

4.DriveLeverinneutral

position

Locatedonthecontrolconsolefrontrighthandside.

Chokeisusedtoaidinstartingacoldengine.The

chokecontrolispulledouttobeinthe“ON”position

andpushedintobeinthe“OFF”position.DoNot

runawarmenginewithchokeinthe“ON”position.

ThrottleControl

Locatedonthecontrolconsole’srightside.

Thethrottleisusedtocontrolenginespeed.Moving

thethrottlecontrolforwardwillincreaseengine

speedandmovingittotherearwilldecreaseengine

speed.Movingthethrottleforwardintothedetent

isfullposition.

SpeedControlLever

Locatedinmiddleofcontrolconsole.

Thespeedcontrollevercontrolsthemaximum

forwardspeedandisinnitelyvariablefromneutral

0–6.75mph(10.9km/hr).

Locatedoneachsideoftheupperhandleassembly

aheadofandbelowthehandlegrips.

Theseleversindividuallycontrolthespeedand

directionofeachdrivewheel.Whenthespeedcontrol

leverismovedoutoftheneutralpositionandthe

neutrallocklatchesaremovedintothedriveposition,

Parkbrakemustbedisengagedtomovespeedcontrol

outofneutralorenginewillkill.

BrakeLever

Locatedontheleftsideoftheunitabovethe

hydraulictank.

15

Page 16

Operation

Thebrakeleverengagestheparkbrakeonthedrive

wheels.

Pulltheleverupandrearwardtoengagethebrake.

Pushtheleverforwardanddowntodisengagethe

brake.

Whenparkingonasteepslope,thewheelsmustbe

chockedorblockedinadditiontothebrakebeing

engaged.Theunitmustbetieddownandbrake

engagedwhentransporting.

Parkbrakemustbedisengagedtomovespeedcontrol

outofneutralorenginewillkill.

IgnitionSwitch

Locatedontheleftsideofthecontrolconsole.

Theignitionswitchisusedtostartandstopthe

engine.Theignitionswitchhasthreepositions,

“Off”,“On”and“Start”.Insertkeyintoswitch

androtateclockwisetothe“On”position.Rotate

clockwisetothenextpositiontoengagethestarter

(keymustbeheldagainstspringpressureinthis

position).Operatormusthavespeedcontrolleverin

neutral,OPCleversdepressedandPTOdisengaged

tostartengine.Whenenginestarts,releasekey.

HourMeter

Locatedonthefrontlefthandsideofconsolejust

abovethePTOswitch.

DriveWheelReleaseValves

Locatedontheleftrearcornerofthehydrostatic

pumps.

Drivewheelreleasevalvesareusedtoreleasethe

hydro-staticdrivesystemtoallowthemachinetobe

movedbyhandwithouttheenginerunning.

Witha5/8wrench,turnbothvalvesoneturn

counterclockwisetoreleasethedrivesystem.

Turnclockwisetoresetthedrivesystem.DoNot

overtighten.

TrackingAdjustmentKnob

Locatedontheright-handsideoftherearofthefuel

tanksupport.

Theknobcanbeadjustedsothatmachinewill

“track”straightaheadwiththedriveleversreleased.

PTOEngagementSwitch

Switchislocatedonleftsideofcontrolconsole.

Theswitchmustbepulledouttothe“Rotate”

positiontoengagetheblades.Theswitchispushed

intothe“Stop”positiontostoptheblades.Operator

musthaveoperatorpresencecontrolleversdepressed

whenPTOisengagedorenginewillstop.

Thehourmeterisconnectedtoapressureswitch

installedintheengineblockanditrecordsthe

numberofhoursthattheenginehasrun.Ifignition

switchisleftonwithoutenginerunning,hourmeter

willnotrun.

Note:Thisswitchisnotalowoilsensorandwillnot

alerttheoperatoriftheengineoilislow .

FuelShut-OffValve

Locatedinthefuellinemidwaybetweenthetank

andengine.

Thefuelshut-offvalveisusedtoshutoffthe

owoffuelwhenparkinginsideabuilding,during

transportationtoandfromthejobsites,andwhen

themachinewillnotbeusedforafewdays.

Rotatevalve1/4turnclockwisetoshutfueloff.

Rotatevalve1/4turncounterclockwisetoturnfuel

on.

Pre-Start

Fillfueltanks.Forbestresultsuseonlyclean,fresh

regulargradeunleadedgasolinewithanoctanerating

of87orhigher.Regulargradeleadedgasolinemay

alsobeused;however,combustionchamberand

cylinderheadwillrequiremorefrequentservice.See

EngineOwner’sManual.

DoNotaddoiltogasoline.

DoNotoverllfueltank.Neverllthefueltankso

thatthefuellevelrisesabovealevelthatis1/2inch

belowthebottomofthellernecktoallowforfuel

expansionandpreventfuelspillage.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

16

Page 17

Operation

OperatingInstructions

OpentheFuelShut-OffValve

Rotatethevalve1/4turncounterclockwisetoturn

fuelon.

StartingtheEngine

1.Onacoldengine,placethethrottlemidway

betweenthe“Slow”and“Fast”positionsand

placethechokeinthe“On”position.Onawarm

engine,placethethrottlelevermidwaybetween

“Slow”and“Fast”positionsandleavethechoke

inthe“Off”position.

2.Turnignitionswitchto“Start”position.Release

theswitchassoonastheenginestarts.

3.Onacoldengine,graduallyreturnchoketothe

“Off”positionafterenginestartsandwarmsup.

Important:Donotcranktheengine

continuouslyformorethantensecondsat

atime.Iftheenginedoesnotstart,allowa

60secondstartercool-downperiodbetween

startingattempts.Failuretofollowthese

guidelinescanburnoutthestartermotor.

DANGER

Anuncovereddischargeopeningwillallow

objectstobethrowninanoperator’sor

bystander’sdirection.Also,contactwiththe

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryordeath.

Neveroperatethemowerwiththedischarge

deectorraised,removed,oralteredunless

thereisagrasscollectionsystemormulch

kitinplaceandworkingproperly.

ThePTOswitchengagesthecuttingblades.Besure

thatallpersonsareclearofmowerdeckanddischarge

areabeforeengagingthePTO .

1.Setthrottleto“MIDW AY”position.

2.PullthePTOswitchoutwardtothe“ROTATE”

positiontoengagetheblades.

3.Placethethrottleinthe“FAST”positiontobegin

mowing.

DisengagingthePTO

1.Setthrottleto“MIDW AY”position.

Note:Itishelpfultohavetheleftandright

neutrallocklatcheslockedinneutralwhen

startingtheengine.RefertoNeutralLock

LatchessectioninControls.

PTOEngagement

DANGER

Therotatingbladesunderthemowerdeck

aredangerous.Bladecontactcancause

seriousinjuryorkillyou.

DoNotputhandsorfeetunderthemower

ormowerdeckwhenthebladesareengaged.

2.Pushinontheswitchtothe“STOP”position

todisengagetheblades.

StoppingtheEngine

1.Bringtheunittoafullstop.

2.Lockdriveleversinneutral.

3.DisengagethePTO.

4.Movespeedcontrollevertoneutral.

5.Engagetheparkingbrake.

6.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

7.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

8.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

9.Closethefuelshut-offvalvewhenthemachine

willnotbeinuseforafewdays,when

transporting,orwhentheunitisparkedinside

abuilding.

17

Page 18

Operation

DrivingtheMachine

DriveLever/NeutralLockLatchOperation

Tolockthedriveleversin“neutrallock”,squeezethe

driveleverstothe“neutral”position(DoNotsqueeze

thedriveleversallthewaybackasthiswillcausethe

drivewheelstogointofullreversedirection).See

Figure5position1.Placethumbsontheinnerlobe

oftheneutrallocklatchesandrotatethemunder

thedriveleversintothe“neutrallock”position.See

Figure5position2.Releasethedrivelevers.

CAUTION

Iftheneutrallocklatchesarenotcompletely

engagedthedriveleverscouldunexpectedly

slipintotheforwarddriveposition.Ifthe

driveleversslipintothedrivepositionthe

unitcouldlurchforwardandcauseinjuryor

propertydamage.

Besurethedriveleversarepasttherollerand

securelyseatedatthebottomoftheneutral

locklatches.

Toplacethedriveleversinthe“forward”position,

slightlysqueezethedriveleverswhileplacingthumbs

ontheouterthumblobeoftheneutrallocklatches

(ortheindexngeronthefrontlobe)androtatethem

fromunderthedrivelevers.Slowlyandcarefully

releasethedrivelevers.SeeFigure5position3.

Toplacethedriveleversinthe“reverse”position,

squeezethedriveleverspasttheneutralposition.See

Figure5position4.

Figure5

1.DriveLeverinneutral

position

2.DriveLeverlockedin

neutralposition

3.DriveLeverinforward

position

4.DriveLeverinreverse

position

DrivingForward

1.Releasetheparkingbrake.

2.Withdriveleverslockedin“neutral”,shiftspeed

controllevertodesiredforwardspeed.

3.Slowlysqueezeandholdbothdriveleversin

theneutralpositionandrotatebothneutrallock

latchesfromtheneutrallockpositiontothe

forwardposition.

Note:DoNotsqueezebothdriveleversallthe

wayback.Thiswillcausethedrivewheelsto

engageinthereversedirection.

4.Tomoveforwardinastraightline,smoothly

releasebothdriveleverstoengagedrivewheels.

Toturnleftorright,squeezetherighthanddrive

levertoturnrightandthelefthanddrivelever

toturnleft.

Tomakea“zeroturn”,squeezeeithertheleft

handortherighthanddriveleverbackintothe

reversepositionwhiletheoppositedriveleverisin

aforwardpositionatanequalbutoppositespeed.

Note:Forsmoothoperationofthismachine,

avoidquick,jerkymovementsofthedrivelevers.

Movethedriveleverssmoothlyanddeliberately.

Tostop,squeezedriveleversbacktothe“neutral”

position.Movetheneutrallocklatchesintothe

“neutrallock”positionandreleasedrivelevers.

Movethespeedcontrollevertotheneutral

position.

18

Page 19

DrivinginReverse

Tomoverearwardinastraightline,squeezedrive

leversintothereverseposition.

Toturnleftorright,squeezetherighthanddrivelever

toturnleftandthelefthanddrivelevertoturnright.

Tomakea“zeroturn”,squeezeeitherthelefthand

ortherighthanddriveleverbackintothereverse

positionwhiletheoppositedriveleverisinaforward

positionatanequalbutoppositespeed.

Note:Forsmoothoperationofthismachine,avoid

quick,jerkymovementsofthedrivelevers.Movethe

driveleverssmoothlyanddeliberately.

Tostop,squeezedriveleversbacktothe“neutral”

position.Movetheneutrallocklatchesintothe

“neutrallock”positionandreleasedrivelevers.Move

thespeedcontrollevertotheneutralposition.

AdjustingtheCuttingHeight

WARNING

Whenthetwofrontsupportrodhairpinsare

removedfromthemowerdeck,theweightof

thetractorsectionmaycausethefrontframe

oftheunittorisesuddenly.Iftheunitrises

suddenly,injurymayoccur.

Securelyholddownthefrontoftheunitwhen

thefrontsupportrodhairpinsareremoved.

Operation

Figure6

1.Decksupportpin

B.ThetirepressuresaresetasdirectedinCheck

TirePressuresintheMaintenancesection.

C.Thelengthofthereardecksupportlink

assembliesaverage6.89inches(approximately

67/8inches)(175.01mm)fromthecenterof

theballjointtothecenterofthefarthesthole.

SeeFigure7.

Note:Allfourpinsmustequallysupportthe

weightofthedeck.Adjustmentinthelength

ofthereardecksupportassembliesmaybe

necessary.Ifonesideislongerthan6.89

inches(approximately67/8inches)(175.01

mm),thantheoppositesidemustbeshorter

bythesameamount.

2.CuttingHeight

Thecuttingheightofthemowerdeckisadjusted

from11/2to41/2inches(3.81cmto11.4cm)in

1/2inchincrements.

1.Stopthemachineandmovethedriveleverstothe

neutrallockedposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Installhairpinclipsintheholesforthedesired

cuttingheight.SeeFigure6.

Important:T omaintaincorrectcutting

heightandrake,checkthefollowingfor

properadjustment.

A.Thefrontandrearhairpinsareinthesame

holeswiththeproperspacersunderthehair

pins.SeeFigure6.

19

Page 20

Operation

Figure8

Forcuttingheightsabove3.5inches(38mm)usethe

bottomhole.Therollerswillstillbeeffectiveagainst

scalping.

Figure7

LeftHandSideShown

AdjustingtheAnti-ScalpRollers

Itisrecommendedtochangetheanti-scalproller

position,whentheheightofcuthaschanged.

1.Stopthemachineandmovethedriveleversto

theneutrallockposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthespringdisc

washerandbolt(seestep7).

6.Adjustanti-scalprollersforNormalOperating

Conditions.Placerollersinoneofthepositions

showninFigure8.Rollerswillmaintain3/4

inches(19mm)clearancetothegroundto

minimizegougingandrollerwearordamage.

Note:ForMaximumDeckFlotation,place

rollersoneholepositionlower.Rollersshould

maintain1/4inch(6.35mm)clearancetoground.

DoNotadjustrollerstosupportthedeck.Be

surerollerboltsareinstalledwiththespringdisc

washerbetweenheadoftheboltandmounting

bracket.

1.Anti-scalproller

mountingbracket

2.Cuttingheight

7.Fourtypesofanti-scalprollerassembliesare

available.SeeFigure9todeterminewhich

assemblyhasbeeninstalledontheunit.Torque

hardwareasspecied,orlossofrollermayresult.

SeeFigure9.

Figure9

Frontleftanti-scalpbracketshown

1.Type1hardware

2.Type2hardware

3.Type3hardware

4.Type4hardware

5.(Type1)3/8–16x4hexscrew

6.(Type2&3)3/8–24x2hexscrew—T orqueto50–55

ft-lb(68–75N-m)

7.(Type4)3/8whizlocknut—T orqueto30–35ft-lb

(41–47N-m)

8.Springdiscwasher(conetowardsbolthead)

9.(Type1)3/8whizlocknutandheavyatwasher—

Torqueto40–45ft-lb(54–61N-m)

10.(Type2)3/8nylocnutandheavyatwasher—T orque

to30–35ft-lb(41–47N-m)

11.(T ype3)3/8angednylocnutwithoutwasher—T orque

to30–35ft-lb(41–47N-m)

12.(Type4)3/8nylocnut—T orqueto30–35ft-lb

(41–47N-m).

20

Page 21

Transporting

TransportingaUnit

WARNING

Loadingthemowerontoatrailerwithout

strongenoughorproperlysupportedramps

couldbedangerous.Therampscould

collapsecausingtheunittofall,whichcould

causeinjury.

•Useproperrampsthataresecuredtothe

truckortrailer.

•Keepfeetandlegsoutfromunderthe

unitwhenloadingandunloading.

•Ifnecessary,useassistancewhenloading .

Besurethefuelshut-offvalveisclosed.

Operation

Useaheavydutytrailertotransportthemachine.

Engageneutrallocklatchesandparkbrake,then

blockwheels.

Securelyfastenthemachinetothetrailerwithstraps,

chains,cables,orropes.

DoNotrelysolelyontheparkingbraketoholdthe

machineonthetrailer.

Besurethatthetrailerhasallnecessarylightingand

markingasrequiredbylawanduseasafetychain.

21

Page 22

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)aside

soitdoesnotaccidentallycontactthespark

plug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst250hours

Beforeeachuseordaily

MaintenanceProcedure

•Changetheengineoil.

•Changethehydrauliclter.

•Checktheengineoillevel.

•Checkthemowerblades.

•Checkthesafetyinterlocksystem.

•Checkforloosehardware.

•Cleanthegrassbuild-upfromunderthedeck.

WARNING

Theenginecanbecomeveryhot.Touching

ahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

Every40hours

Every50hours

Every80hours

Every100hours

Every160hours

Every500hours

Every600hours

•Checkthehydraulicoillevel.

•Checkthetirepressures.

•Checktheconditionofthebelts.

•Greasethehydrocontrolarmsupportbushings.

•Servicetheaircleaner.(Mayneedmoreoftenundersevereconditions.SeetheEngine

manualforadditionalinformation.)

•Removeengineshroudsandcleancoolingns.

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Checkthesparkplugs.

•Changethehydrauliclter(Every250hours/yearlyifusingMobil115W50)

•Replacetheaircleanerelements.(Mayneedmoreoftenundersevereconditions.Seethe

Enginemanualforadditionalinformation.)

Monthly

Yearly

•Checkthebatterycharge.

•Greasethefrontcasterwheelhubs.

•Greasefrontcasterpivots.

•Greasetheidlerpivots(MowerDeck).

•Greasetheidlerpivot(PumpDrive).

•Lubricatethecasterwheelhubs.

22

Page 23

Maintenance

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Cleanareaarounddipstick.Removedipstickand

wipeoiloff.Reinsertthedipstickandpushitall

thewaydownintothetube.DoNotscrewinto

place.Removethedipstickandreadtheoillevel.

4.Iftheoillevelislow ,wipeofftheareaaroundthe

oilllcap,removecapandlltothe“FULL”

markonthedipstick.Useoilasspeciedin

EngineOwner’ sManual.DoNotoverll.

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

CheckBatteryCharge

ServiceInterval:Monthly

timeintervaltobringthechargeuptoafullcharge

of12.6voltsorgreater.

Important:Makesurethenegativebattery

cablesaredisconnectedandthebatterycharger

usedforchargingthebatteryhasanoutputof

16voltsand7ampsorlesstoavoiddamaging

thebattery(seechartforrecommendedcharger

settings).

Voltage

Reading

12.6or

greater

12.4–12.675–100%

12.2–12.450–75%

12.0–12.225–50%

11.7–12.00–25%

11.7orless

Percent

Charge

100%

0%

Maximum

Charger

Settings

16volts/7

amps

16volts/7

amps

16volts/7

amps

14.4volts/4

amps

14.4volts/4

amps

14.4volts/2

amps

Charging

Interval

No

Charging

Required

30Minutes

1Hour

2Hours

3Hours

6Hoursor

More

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

Allowingbatteriestostandforanextendedperiodof

timewithoutrechargingthemwillresultinreduced

performanceandservicelife.Topreserveoptimum

batteryperformanceandlife,rechargebatteriesin

storagewhentheopencircuitvoltagedropsto12.4

volts.

Note:Topreventdamageduetofreezing,battery

shouldbefullychargedbeforeputtingawayfor

winterstorage.

Checkthevoltageofthebatterywithadigital

voltmeter.Locatethevoltagereadingofthebatteryin

thetableandchargethebatteryfortherecommended

CheckMowerBlades

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Liftdeckandsecureinraisedpositionasstated

intheCleanGrassBuild-UpUnderDeck

procedure.

3.Inspectbladesandsharpenorreplaceasrequired.

4.Reinstallblades(iftheywereremoved)inthe

followingorder:

A.Installbushingthroughbladewithbushing

angeonbottom(grass)sideofblade.

23

Page 24

Maintenance

Figure10

1.Installbushinginbladepriortoinstallingbushingin

spindle.

B.Installbushing/bladecombointospindle.

WARNING

Incorrectinstallationofthebladeor

componentsusedtoretainthebladecan

bedangerous.Failuretousealloriginal

componentsandassembledasshowncould

allowabladeorbladecomponenttobe

thrownoutfromunderthedeckresultingin

seriouspersonalinjuryordeath.

AlwaysinstalltheoriginalExmarkblades,

bladebushings,andbladeboltsasshown.

CheckSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

1.Checkstartingcircuit.Startershouldcrankwith:

OperatorPresenceControlleversdepressed,

speedcontrolleverinneutral,andPTO

disengaged.

Figure11

1.Usewrenchherefor

bladeinstallation.This

nuthasbeentorquedto

90–110ft-lb(122–149

N-m)

2.Torqueto55-60ft-lb

(75-81N-m)Apply

lubricanttothreads

asneededtoprevent

seizing.Copper-based

anti-seizepreferable.

Greaseacceptable

substitute.

C.Applylubricanttothreadsofbladeboltas

neededtopreventseizing.Copper-based

anti-seizepreferable.Greaseacceptable

substitute.Installbladeboltngertight.Place

wrenchonthetopspindlenutthentorquethe

bladeboltsto55-60ft-lb(75-81N-m).

TrytostarttheenginewithOPClevers

disengaged,speedcontrolleverinneutraland

PTOdisengaged-startermustnotcrank.

Trytostartwith,OPCleversdepressed,speed

controlleverinanyspeedbutneutralandPTO

disengaged-startermustnotcrank.

TrytostartwithOPCleversdepressed,

speedcontrolleverinneutralandPTO

engaged-startermustnotcrank..

2.CheckOPCcircuits.Clearthearea.Runengine

atone-thirdthrottle,then,withdriveleversand

neutrallocklatchesinneutrallockposition,

movethespeedcontrolleveroutofneutraland

releaseOPCleversenginemuststop.Again,

runengineatone-thirdthrottle,movethespeed

controllevertoneutral,engagePTOandrelease

OPClevers-enginemuststop.

Note:Parkbrakemustbedisengagedbeforethe

speedcontrolleverismovedoutofneutralorengine

willkill.

Note:Ifmachinedoesnotpassanyofthesetests,

donotoperate.ContactyourauthorizedEXMARK

SERVICEDEALER.

Important:Itisessentialthatoperatorsafety

mechanismsbeconnectedandinproper

operatingconditionpriortouseformowing.

24

Page 25

Maintenance

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

ServiceAirCleaner

ServiceInterval:Every50hours—Service

theaircleaner.(May

needmoreoftenunder

severeconditions.See

theEnginemanualfor

additionalinformation.)

Every600hours—Replace

theaircleanerelements.

(Mayneedmoreoften

undersevereconditions.

SeetheEnginemanualfor

additionalinformation.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Loosenretainingclipsandremoveaircleaner

compartmentcover.

3.Removepaperelement.Checkthecondition

ofthepaperelement.Replaceifdirty,bentor

damaged.

4.Checktheconditionoftheinnerelement.Replace

wheneveritappearsdirty,typicallyeveryother

timethepaperelementisreplaced.Cleanthebase

aroundtheinnerelementbeforeremoving,so

dirtdoesnotgetintotheengine.

5.DoNotwashorusepressurizedairtoclean

paperelementorinnerelement.

6.Reinstallelements.Positionthecoversothatthe

rubberdustejectorispointingdownwardand

securewithretainingclips.

2.Drainoilwhileengineiswarmfromoperation.

3.Theoildrainhoseislocatedonrighthandside

ofengine.Placepanundermachinetocatchoil.

Removeplugfromendofdrainhose.Allowoil

todrainandreplaceoildrainplug.Torqueplug

to20-24ft-lb.

4.Replacetheoilltereveryotheroilchange.Clean

aroundoillterandunscrewltertoremove.

Beforereinstallingnewlter,applyathincoating

ofoilonthesurfaceoftherubberseal.Turn

lterclockwiseuntilrubbersealcontactsthelter

adapterthentightenlteranadditional1/2to

3/4turn.

5.Cleanaroundoilllcapandremovecap.Fillto

speciedcapacityandreplacecap.

6.Useoilrecommendedinengineowner’smanual.

DoNotoverll.Starttheengineandcheckfor

leaks.Stopengineandrecheckoillevel.

CheckHydraulicOilLevel

ServiceInterval:Every40hours

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.

2.Cleanareaaroundhydraulicreservoircapand

removecap.Oillevelshouldbetothetopofthe

bafeinsidethetank.Ifnot,addoil.UseExmark

PremiumHydrooil.Replacehydraulicreservoir

capandtightenuntilsnug.DoNotovertighten.

Note:Thebafeislabeled“HOT”and

“COLD”.Theoillevelvarieswiththe

temperatureoftheoil.The“HOT”levelshows

thelevelofoilwhenitisat225°F(107°C).The

“COLD”levelshowstheleveloftheoilwhen

itisat75°F(24°C).Filltotheappropriatelevel

dependinguponthetemperatureoftheoil.For

example:Iftheoilisabout150°F(65°C),llto

halfwaybetweenthe“HOT”and“COLD”levels.

Iftheoilisatroomtemperature(about75°F

(24°C)),llonlytothe“COLD”level.

ChangeEngineOil

ServiceInterval:Aftertherst5hours

Every100hours(May

needmoreoftenunder

severeconditions.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

CheckTirePressures

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto12–14psi(83–97kPa).

25

Page 26

Maintenance

4.Inatetirestopressuresstatedabove.Measure

thecircumferenceofeachdrivetire.Adjusttire

pressureswithintheaboverangetotrytomake

tirecircumferencesmatchascloselyaspossible.

5.ForSerialNos.599,999andLower:Checkthe

tirepressureinthepneumaticfrontcastertires.

Adjustthetirepressureto16psi(110kPa).

Note:Frontcastertireshavepermanenttire

sealantinstalled.

ForSerialNos.600,000andHigher:

Semi-pneumaticcastertiresdonotneedtobe

inated.

Note:DoNotaddanytypeoftirelinerorfoam

llmaterialtothetires.Excessiveloadscreatedby

foamlledtiresmaycausefailurestothehydrodrive

system,frame,andothercomponents.Foamlling

tireswillvoidthewarranty.

CheckConditionOfBelts

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

LubricationChart

Fitting

Locations

2.Front

Caster

Pivots

3.Idler

Pivots

(Mower

Deck)

4.Idler

Pivot(Pump

Drive)

5.Hydro

Control

Arm

Support

Bushings

Initial

Pumps

*0

12

21

22

Numberof

Places

2

*Seestep3forspeciallubricationinstructionson

thefrontcasterpivotsandtheLubricateCaster

WheelHubssectionforspeciallubrication

instructionsonthefrontcasterswheelhubs.

Service

Interval

*Yearly

Yearly

Yearly

40Hours

2.Removethethreemowerdeckbeltshields

tocheckmowerprimaryandsecondarybelt

condition.

3.Lookunderenginedecktocheckthepumpdrive

beltcondition.

4.Checkallidlerarmstobesuretheypivotfreely.

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lubricatettingswithonetotwopumpsof

NGLIgrade#2multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.Front

Caster

WheelHubs

Initial

Pumps

*0

Numberof

Places

2

Service

Interval

*Yearly

Number4(IdlerPivot(PumpDrive)Located

UnderEngineDeck

3.Lubricatefrontcasterpivotsonceayear.Remove

hexplugandcap.Threadgreasezerkinholeand

pumpwithgreaseuntilitoozesoutaroundtop

bearing.Removegreasezerkandthreadplugback

in.Placecapbackon.

LubricateCasterWheelHubs

ServiceInterval:Yearly

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

26

Page 27

Figure12

1.Sealguard2.Spacernutwithwrench

ats

2.Removecasterwheelfromcasterforks.

3.Removesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethatthread

lockingadhesivehasbeenappliedtolockthe

spacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)from

thewheelassembly .

5.Pryoutseals,andinspectbearingsforwearor

damageandreplaceifnecessary.

6.PackthebearingswithaNGLIgrade#1

multi-purposegrease.

7.Insertonebearing,onenewsealintothewheel.

Note:Seals(ExmarkPN103-0063)mustbe

replaced.

8.Iftheaxleassemblyhashadbothspacernuts

removed(orbrokenloose),applyathreadlocking

adhesivetoonespacernutandthreadontothe

axlewiththewrenchatsfacingoutward.Do

Notthreadspacernutallofthewayontotheend

oftheaxle.Leaveapproximately1/8inch(3mm)

fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

NGLIgrade#1multi-purposegrease.

11.Insertthesecondbearingandnewsealintothe

wheel.

12.Applyathreadlockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrenchats

facingoutward.

Maintenance

13.T orquethenutto75-80in-lb(8-9N-m),loosen,

thenre-torqueto20-25in-lb(2-3N-m).Make

sureaxledoesnotextendbeyondeithernut.

14.Reinstallthesealguardsoverthewheelhuband

insertwheelintocasterfork.Reinstallcasterbolt

andtightennutfully .

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjusttorqueon

spacernutuntilthereisaslightamountofdrag.

Reapplythreadlockingadhesive.

RemoveEngineShroudsand

CleanCoolingFins

ServiceInterval:Every80hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Removecoolingshroudsfromengineandclean

coolingns.Alsocleandust,dirt,andoilfrom

externalsurfacesofenginewhichcancause

impropercooling.

3.Makesurecoolingshroudsareproperly

reinstalled.Operatingtheenginewithout

coolingshroudswillcauseenginedamagedueto

overheating.

CheckSparkPlugs

ServiceInterval:Every160hours

Removesparkplugs,checkconditionandresetgaps,

orreplacewithnewplugs.SeeEngineOwners

Manual.

ChangeFuelFilter

ServiceInterval:Asrequired

Afuellterisinstalledinthefuellinebetweenthe

fueltankandtheengine.Replacewhennecessary.

ReplacementFilters

Kawasaki

KawasakiP/N

49019–7001

27

Page 28

Maintenance

ChangeHydraulicSystem

Filter

ServiceInterval:Aftertherst250hours

Every500hours/Yearly

(whichevercomes

rst)thereafter

(Every250hours/Yearlyif

usingMobil115W50)

Note:UseonlyExmarkPartNo.109-4180for

Summeruseabove32°F(0°C)orP/N1-523541for

Winterusebelow32°F(0°C)(RefertoTransmission

sectioninSpecicationsforlterspecications).

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Carefullycleanareaaroundlter.Itisimportant

thatnodirtorcontaminationenterhydraulic

system.

3.Unscrewltertoremoveandallowoiltodrain

fromreservoir.

Important:Beforereinstallingnewlter,ll

itwithExmarkPremiumHydrooilandapply

athincoatofoilonthesurfaceoftherubber

seal.

mainpumpasshowninFigure13)mayhavelost

their“prime”.RefertoHydraulicSystemAir

Purgesection.

Note:DoNotchangehydraulicsystemoil(except

forwhatcanbedrainedwhenchanginglter),unless

itisfelttheoilhasbeencontaminatedorbeen

extremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

HydraulicSystemAirPurge

ServiceInterval:Asrequired

Airmustbepurgedfromthehydraulicsystem

whenanyhydrauliccomponents,includingoil

lter,areremovedoranyofthehydrauliclinesare

disconnected.

Thecriticalareaforpurgingairfromthehydraulic

systemisbetweentheoilreservoirandeach

chargepumplocatedonthetopofeachvariable

displacementpump(Figure13).Airinotherpartsof

thehydraulicsystemwillbepurgedthroughnormal

operationoncethechargepumpis“primed”.

Turnlterclockwiseuntilrubbersealcontactsthe

lteradapter,thentightenthelteranadditional

2/3to3/4turn.

4.FillreservoirasstatedinCheckHydraulicOil

Level.

ExmarkPremiumHydroOilisrecommended.

Refertothechartforanacceptablealternative:

HydroOil

ExmarkPremiumHydro

Oil(Preferred)

Mobil115W50

5.Loosenlter1/2turnandallowasmallamount

ofoiltoleakfromtheoillter(thisallowsairto

bepurgedfromtheoillterandsupplyhosefrom

thehydraulicreservoir).Turnlterclockwise

untilrubbersealcontactsthelteradapter.Then

tightenthelteranadditional2/3to3/4turn.

6.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

7.Ifeitherdrivewheeldoesnotrotate,oneorboth

ofthechargepumps(locatedonthetopofthe

ChangeInterval

500Hours

250Hours

28

Page 29

Figure13

1.Chargepumpcap2.Loosen11/2turnsonly

Maintenance

asteadyowofoiltoowoutfromunderthe

housing.Retightenthecapscrews.Dothisfor

bothpumps.

Note:Hydraulicreservoircanbepressurizedup

to5psitospeedthisprocess.

6.Ifeitherdrivewheelstilldoesnotrotate,stop

andrepeatsteps4and5abovefortherespective

pump.Ifwheelsrotateslowly,thesystemmay

primeafteradditionalrunning.Checkoillevel

asstatedinChecktheHydraulicOilLevel

section.

7.Allowunittorunseveralminutesafterthecharge

pumpsare“primed”withdrivesysteminthefull

speedposition.CheckoillevelasstatedinCheck

theHydraulicOilLevelsection.

8.Checkhydrodrivelinkageadjustmentasstatedin

HydroDriveLinkageAdjustmentsectionin

Adjustments.

FuelTank—Mounting

1.Stopengineandwaitforallmovingpartstostop.

Raisetherearofthemachineupontojackstands

highenoughtoraisethedrivewheelsoffthe

ground.

2.CheckoillevelasstatedinCheckHydraulicOil

Levelsection.

3.Startengineandmovethrottlecontrolaheadto

fullthrottleposition.Movethespeedcontrol

levertothemiddlespeedpositionandplacethe

driveleversinthe“drive”position.

Ifeitherdrivewheeldoesnotrotate,itispossible

toassistthepurgingofthechargepumpby

carefullyrotatingthetireintheforwardposition.

Note:Itisnecessarytolightlytouchthecharge

pumpcapwithyourhandtocheckthepump

temperature.Ifthecapistoohottotouch,turn

offengine.Thepumpsmaybedamagedifthe

pumpbecomestoohot.

Ifeitherdrivewheelstilldoesnotrotatecontinue

withstep4.

4.Thoroughlycleantheareaaroundeachofthe

chargepumphousings.

5.To“prime”chargepump,loosentwohexsocket

headcapscrews(showninFigure13)11/2turns

only.Makesureengineisnotrunning.Lift

thechargepumphousingupwardandwaitfor

HardwareSpecications

ServiceInterval:Asrequired

Wheninstallingthenutsonthefueltankstuds,fully

tightenthenylocnutandbackoff1/2turn.This

allowsfornormalfueltankexpansionandcontraction

withchangesintemperatureandfuellevels.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

•Pumpdrivesheavesetscrews.

•SquareheadsetscrewsonHydropumpcontrol

arms.

•Shoulderboltsinendsofspeedcontrolcrank.

•OPCleversetscrews.

•Electricclutchretainingbolt.

•Pumpdriveidlerpivotbolt.

•Thumblatchscrewthreadsonhandles.

•Casterwheelspacernuts.

•Fueltankbulkheadttingnuts.

Adhesivessuchas“LoctiteRC/609orRC/680”or

“Fel-ProPro-LockRetainingIorRetainingII”are

usedonthefollowing:

29

Page 30

Maintenance

•OPCleverhubsandcross-shaft

Note:Caremustbeusednottobondthe

bearing,nexttoeachOPChub,tothecross-shaft

whichcouldcausebindingoftheOPCleversand

erraticoperation.

•Fueltankstuds,wherestudsareinsertedintotank.

MobilHTSGrease(Or

Food-GradeAnti-seize)

MobilHTSgrease(orfood-gradeanti-seize)isused

inthefollowinglocations:

•Betweenthecutterhousingspindleandbearings.

•Betweenthecutterhousingspindleandsheave.

•Undertopcutterhousingbearingguard.

Copper-BasedAnti-seize

Copper-basedanti-seizeisusedinthefollowing

locations:

OnthreadsofBladeBoltsSerialNos.540,000and

Higher.SeeCheckMowerBladessectionfor

instructions.

Adjustments

Note:DisengagePTO,shutoffengine,waitfor

allmovingpartstostop,engageparkingbrake,and

removekeybeforeservicing,cleaning,ormakingany

adjustmentstotheunit.

DeckLeveling

SeeAdjustingtheCuttingHeightsectionin

Operation.

PumpDriveBeltTension

Self-tensioning-Noadjustmentnecessary.

DeckBeltTension

Self-tensioning-Noadjustmentnecessary.

BladeDriveBeltTension

Self-tensioning-Noadjustmentnecessary.

BrakeAdjustment

DielectricGrease

Dielectricgreaseisusedonallbladetypeelectrical

connectionstopreventcorrosionandlossofcontact.

1.Shutoffengineandwaitforallmovingpartsto

stop.

2.Disengagetheparkbrake.

3.Removethehairpinintheparkbrakelinkage.

Turnthelinkageintheyokeuntilthereis3/16

inch(4.8mm)to1/4inch(6.4mm)clearance

betweentheparkbraketirebarsandthetireswith

theparkbrakedisengaged.Re-installthehairpin.

SpeedControlLinkage

andNeutralSafetySwitch

Adjustment

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Movespeedcontrollever(locatedonconsole)to

thefullforwardpositionandcheckorientationof

tabsontheendsofthespeedcontrolcrank,see

Figure14.Thesetabsshouldbepointingstraight

downatthe6o’clockpositionorslightlyforward.

Adjustthreadedyokeatthebottomofspeed

30

Page 31

Maintenance

controllinkageuntiltabsarepositionedcorrectly.

SeeFigure14.

3.Pullspeedcontrolleverbacktoneutral.Check

thattheneutralsafetyswitchactuatingtabhas

depressedtheplungeroftheswitchsothatthere

isabout5/16inch(7.9mm)betweenthetaband

theswitchasshowninFigure14.Ifnecessary,

movetheswitchforeandaft.

Figure14

Viewedfromleftsideofunit

1.NeutralSafetySwitch3.5/16inch(7.9mm)

2.ActuatingT abinneutral

position

5.Adjusttheneutralcontrollinkageuntilthe

respectivedrivewheelstopswhentheleveris

pulledagainsttheneutralspring(neutralposition).

Turntheadjustingboltapproximately1/4turn

clockwiseifthewheelisturninginreverseorturn

theboltapproximately1/4turncounterclockwise

ifthewheelisturningforward.Releasethedrive

levertotheforwarddrivepositionandsqueeze

backintotheneutralposition.Checktoseeifthe

wheelstops.Ifnot,repeattheaboveadjustment

procedure.

6.Makethisadjustmentonbothsides.

7.Afteradjustmentsaremadeandthewheelsstop

whenthedriveleverisintheneutralposition,

tightenthenutagainsttheyokes.

NeutralControlLinkages

Adjustment

1.Raisetherearofthemachineupontojackstands

highenoughtoraisethedrivewheelsoffofthe

ground.

2.Starttheengineandmovethethrottleaheadto

thefullthrottleposition.Placetheneutrallock

latchesinthe“forward”positionasshownin

Figure4andmovethespeedcontrollevertothe

“mid-speed”position.

Note:Theparkbrakemustbedisengagedand

theOPCleversmustbehelddownwheneverthe

speedcontrolleverisoutoftheneutralposition

ortheenginewillkill.

3.Squeezetherespectivedriveleveruntilan

increasedresistanceisfelt;thisiswhereneutral

shouldbe.

Ifthewheelturnswhileholdingthedriveleverin

neutral,theneutralcontrollinkagesneedtobe

adjusted.Ifwheelsstopthengotostep7.

Figure15

1.NeutralControlLinkage

2.HydroControlLinkage

3.DriveLeverLinkage7.Y oke

4.SpeedControlLinkage

5.Adjusthere;rotateat

approximately1/4turn

increments

6.Loosennut

HydroControlLinkage

Adjustment

1.Placethespeedcontrolleverinthe“neutral”

position.Thisadjustmentisagainmadewithrear

ofmachineonjackstandsandenginerunning

atfullthrottle.OPCleverswillhavetobeheld

downwheneverspeedcontrolleverismovedout

ofneutralposition.

4.Loosenthenutagainsttheneutralcontrollinkage

yokeasshowninFigure15

Note:Theneutrallocklatchesshouldstillbe

“unlocked”andinthe“forward”position.

31

Page 32

Maintenance

2.Loosenthefrontnutonlefthydrocontrollink

asshowninFigure16.Turntherearcontrol

linkageadjustingnutcounterclockwiseuntilwheel

rotatesforward.Turntherearnutofleftcontrol

linkclockwise1/4ofaturnatatime,stopping

tomovethespeedcontrolforwardandbackto

neutral,untilleftwheelstopsrotatingforward.

Turnthenutanadditional1/2turnandtighten

thefrontjamnutmakingsurenottoputabind

onthelinkage.Makesureatpartoflinkageis

perpendiculartopinpartofswivel.SeeFigure16.

Figure16

1.LeftHydroControlLink

(leftsideshown)

2.Frontnut5.Linkageinincorrect

3.Rearnut

4.Linkageisperpendicular

topin(correctposition)

position

6.Endviewofswivel

DriveLeverLinkage

Adjustment

1.Withrearofmachinestillonjackstandsand

enginerunningatfullthrottle,movethespeed

controllevertothemidwayposition.Movethe

respectivedriveleverupwarduntilitreachesthe

neutralpositionandengageneutrallocklatches

seeFigure17.Ifthetirerotatesineitherdirection,

thelengthofthedriveleverlinkagewillneedto

beadjusted.

Figure17

Afteradjustingthelefthydrocontrollinkage,

movethespeedcontrollevertothemid-speed

positionandthenbacktotheneutralposition.

Rechecktheleftdrivewheelrotationtoseeif

furtheradjustmentisnecessary-besurethespeed

controlleverisintheneutralposition.

Important:Ifinconsistentneutraloccurs,

checktobesurebothspringsareproperly

tightenedonthespeedcontrolleverunderthe

console–especiallytherearpivotspring.

3.Placethespeedcontrolleverinneutral.Adjust

therightsidelinkagebyturningthequicktrack

knobcounterclockwiseuntilthetirebeginsto

rotateforward.Begintoretightentheknob

clockwiseabout1/4turnatatime,stoppingto

movethespeedcontrolforwardandbackto

neutral.Recheckthedrivewheelrotationtoseeif

furtheradjustmentisnecessary.

4.Thespringthatkeepstensionontheknobshould

normallynotneedadjustment.However,if

adjustmentisneeded,adjusttowherelengthof

springisabout1inch(2.5cm)betweenwashers.

Adjustspringlengthbyturningnutatfrontof

spring.

2.Adjustthelinkagelengthbylooseningthejam

nutsatbothendsofthelinkageandrotatingthe

linkageintheballjoints.Lengthenthelinkage

ifthetireisturninginreverseandshortenthe

linkageifthetireiscreepingforward.Tightenthe

jamnutsatbothends.Releaseandre-engagethe

neutrallockcheckingthatthetirestops.Continue

thisprocessuntilthetireisatadeadstop.

3.Makethisadjustmentforbothsides.

TrackingAdjustment

1.Stopengineandwaitforallmovingpartstostop.

Raiserearofmachine,removejackstands,and

carefullylowermachinetotheground.

2.Checkthedrivetirepressuresandtire

circumferencesasstatedinChecktheTire

PressuressectioninMaintenance.

3.Runtheunitandobservethetrackingonalevel,

smooth,hardsurfacesuchasconcreteorasphalt.

4.Iftheunittrackstoonesideortheother,turnthe

quicktrackknob.Turntheknobrightto“steer”

right,turntheknobleftto“steer”left.

32

Page 33

Maintenance

HydroPumpSpringTension

Setting

1.Formediumorheavydutydriveconditionssuch

asoperationwithasulkyonsteepslopes,ahigher

springforcemayberequiredonthehydropump

controlarmstopreventthedrivesystemfrom

stalling.

2.Foraheavierdrivesetting,relocatethespring

anchorlinkasshowninFigure13.Thespring

anchorlinksarelocatedundertheenginedeckon

theleftandrighthandsides.

Note:In“medium”or“heavyduty”positions,

thedriveleverforcesattheupperhandlewillalso

beincreased.

Cleaning

CleanGrassBuild-UpUnder

Deck

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Raisedecktothetransport(maximumcutting

height)position.Liftthefrontofunitandsupport

unitusingjackstandsorequivalentsupport.

CAUTION

Raisingthemowerdeckforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

theunittofall,whichcouldcauseinjury.

Figure18

1.Heavyduty

2.Mediumduty4.Retainingbolt

3.Standard

ElectricClutchAdjustment

Noadjustmentnecessary.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

3.Cleanoutanygrassbuild-upfromundersideof

deckandindischargechute.

WasteDisposal

MotorOilDisposal

Engineoilandhydraulicoilarebothpollutantsto

theenvironment.Disposeofusedoilatacertied

recyclingcenteroraccordingtoyourstateandlocal

regulations.

33

Page 34

Maintenance

BatteryDisposal

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldeyes,and

rubberglovestoprotectskinandclothing

whenhandlingelectrolyte.

•DoNotswallowelectrolyte.

Federallawstatesthatbatteriesshouldnotbeplaced

inthegarbage.Managementanddisposalpractices

mustbewithinrelevantfederal,state,orlocallaws.

Ifabatteryisbeingreplacedoriftheunitcontaining

thebatteryisnolongeroperatingandisbeing

scrapped,takethebatterytoalocalcertiedrecycling

center.Ifnolocalrecyclingisavailablereturnthe

batterytoanycertiedbatteryreseller.

34

Page 35

Troubleshooting

Troubleshooting

Important:Itisessentialthatalloperatorsafetymechanismsbeconnectedandinproperoperating

conditionpriortomoweruse.

Whenaproblemoccurs,donotoverlookthesimplecauses.Forexample:startingproblemscouldbecaused

byanemptyfueltank.

Thefollowingtablelistssomeofthecommoncausesoftrouble.DoNotattempttoserviceorreplacemajor

itemsoranyitemsthatcallforspecialtimingofadjustmentsprocedures(suchasvalves,governor,etc.).Have

thisworkdonebyyourEngineServiceDealer.

Note:WhendisconnectingelectricalconnectorsDoNotpullonthewirestoseparatetheconnectors.

ProblemPossibleCauseCorrectiveAction

Starterdoesnotcrank.

Enginewillnotstart,startshard,orfailsto

keeprunning.

1.PTOisengaged.

2.Speedcontrolleverisarenotinneutral

lockposition.

3.OPCleversarereleased.

4.Batterydoesnothaveafullcharge.4.Chargethebattery.

5.Electricalconnectionsarecorroded,loose

orfaulty.

6.Fuseisblown.6.Replacetheblownfuse.

7.Relayorswitchisdefective.7.ContactanAuthorizedServiceDealer.

1.Fueltankisempty.1.Fillthefueltank.

2.Fuelshutoffvalveisclosed.

3.Thethrottleandchokearenotinthe

correctposition.

4.Dirtinfuellter.4.Replacethefuellter.

5.Dirt,water,orstalefuelisinthefuel

system.

6.Aircleanerisdirty.

7.Electricalconnectionsarecorroded,loose

orfaulty.

8.Relayorswitchisdefective.8.ContactanAuthorizedServiceDealer.

9.Faultysparkplug.

10.Sparkplugwireisnotconnected.

1.DisengagethePTO.

2.Ensurethespeedcontrolleverisinthe

neutrallockposition.

3.DepressOPClevers.

5.Checktheelectricalconnectionsfor

goodcontact.Cleanconnectorterminals

thoroughlywithelectricalcontactcleaner,

applydielectricgreaseandreconnect.

2.Openthefuelshutoffvalve.

3.Besurethethrottlecontrolismidway

betweenthe“SLOW”and“F AST”

positions,andthechokeisinthe“ON”

positionforacoldengineorthe“OFF”

positionforawarmengine.

5.ContactanAuthorizedServiceDealer.

6.Cleanorreplacetheaircleanerelement.

7.Checktheelectricalconnectionsfor

goodcontact.Cleanconnectorterminals

thoroughlywithelectricalcontactcleaner,

applydielectricgreaseandreconnect.

9.Clean,adjustorreplacesparkplug.

10.Checkthesparkplugwireconnection.

Enginelosespower.

Engineoverheats.

1.Engineloadisexcessive.1.Reducethegroundspeed.

2.Aircleanerisdirty.

3.Oillevelinthecrankcaseislow .

4.Coolingnsandairpassagesforthe

engineareplugged.