Page 1

RADIUS®

ForSerialNos.

400,000,000&Higher

PartNo.4502-907Rev.B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442or4443touse

oroperatetheengineonanyforest-covered,

brush-covered,orgrass-coveredlandunlessthe

engineisequippedwithasparkarrester,as

denedinSection4442,maintainedineffective

workingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionof

re.

Toacquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

Thissparkignitionsystemcomplieswiththe

CanadianstandardICES-002.Cesystèmed’allumage

parètincelledevèhiculeestconformeàlanorme

NMB-002duCanada.

ForallmodelsthatdonothaveExmarkengines,

pleaserefertotheenginemanufacturer’s

informationincludedwiththemachine.

Labeledpowerratingsaresuppliedbytheengine

manufacturerinaccordancewithSAEtesting

andgross/netpowerratingstandards(J1940,

J1995,J1349).

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2016ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

2

Contactusatwww.Exmark.com.

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency,andpromotesafe

operation.

Important:Tomaximizesafety,performance,

andproperoperationofthismachine,itis

essentialthatalloperatorscarefullyreadand

fullyunderstandthecontentsoftheOperator’s

manualprovidedwiththeproduct.Safe

operationofExmarkequipmentisessential.

Failuretocomplywiththeoperatinginstructions

orreceivepropertrainingmayresultininjury.

Gotohttp://www.Exmark.comforadditional

safeoperationinformation,suchassafetytips,

trainingmaterials,andOperator’smanuals.

Ifadditionalinformationisneeded,orshould

yourequiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

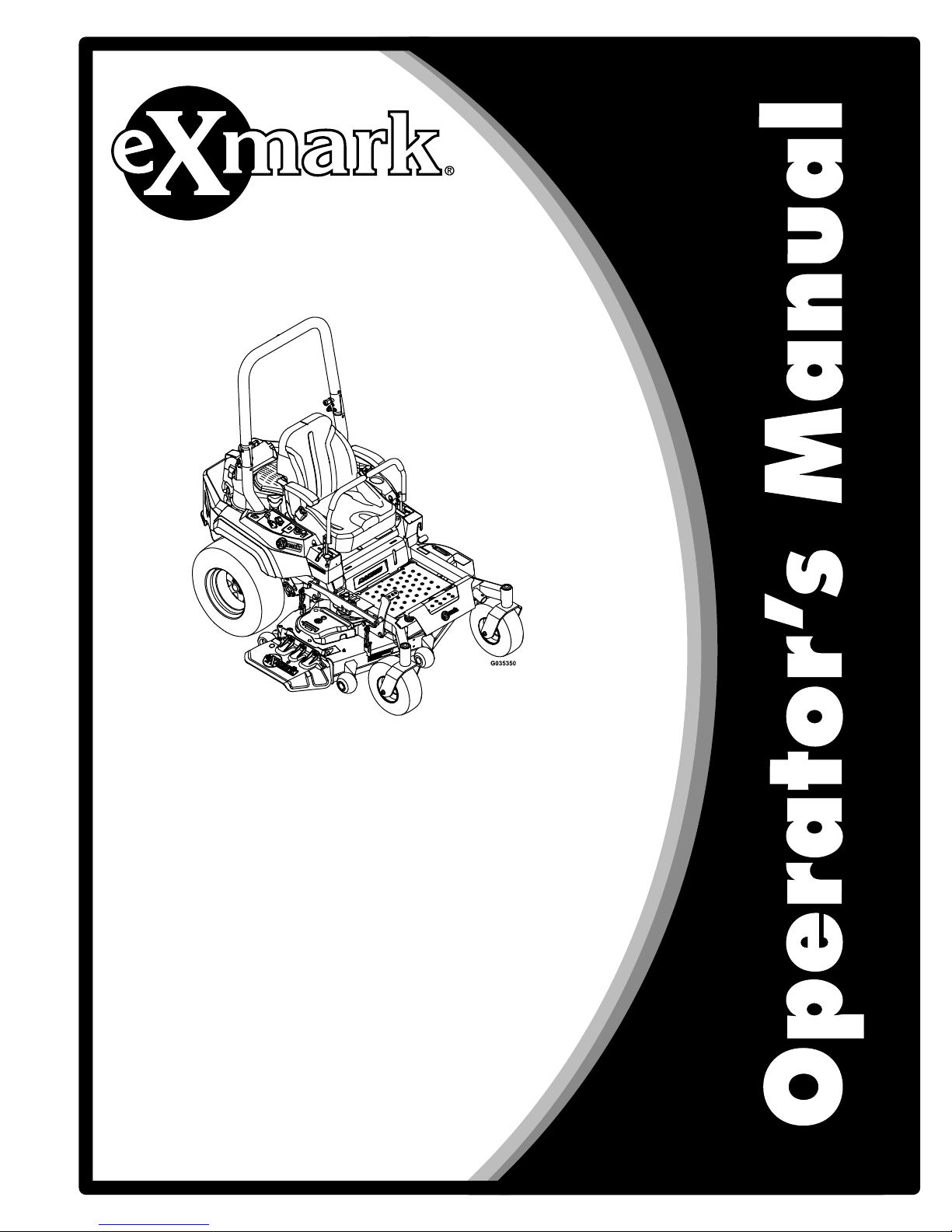

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals......................11

Specications........................................................18

Systems..........................................................18

Dimensions....................................................21

TorqueRequirements.....................................23

ProductOverview.................................................23

Operation..............................................................24

Controls.........................................................24

Pre-Start.........................................................26

OperatingInstructions...................................27

Transporting..................................................32

Maintenance..........................................................35

RecommendedMaintenanceSchedule(s)............35

PeriodicMaintenance........................................36

EngineMaintenance.......................................36

ServicingtheEngineOil.................................40

ServicingtheSparkPlug-Exmark708cc

Engine.......................................................48

ServicingtheSparkPlug-Kohler

Engine.......................................................50

ServicingtheSparkPlug-Kawasaki

Engine.......................................................51

CheckBatteryCharge.....................................52

CheckMowerBlades......................................53

CheckSafetyInterlockSystem........................55

CheckRolloverProtectionsSystems(Roll

Bar)Knobs.................................................58

CheckSeatBelt...............................................58

CheckforLooseHardware.............................58

CheckHydraulicOilLevel..............................58

CheckTirePressures......................................58

CheckConditionOfBelts...............................58

LubricateGreaseFittings................................59

ReplaceEmissionsAirIntakeFilter(If

Applicable).................................................60

ChangeHydraulicSystemFilterand

Fluid..........................................................61

CheckSparkArrester(ifequipped)..................62

ThreadLockingAdhesives..............................62

Copper-BasedAnti-seize...............................62

DielectricGrease............................................62

Adjustments......................................................63

DeckLeveling................................................63

AdjustingtheBladeSlope...............................64

PumpDriveBeltTension................................65

DeckBeltTension..........................................65

AdjustingtheParkingBrake............................65

MotionControlHandleAdjustment...............66

FullForwardTrackingAdjustment..................66

MotionControlLinkageAdjustment..............67

AdjustingtheSeatRideSuspensionS-Series

Only...........................................................68

ElectricClutchAdjustment.............................68

Cleaning............................................................69

CleanEngineandExhaustSystem

Area...........................................................69

RemoveEngineShroudsandClean

CoolingFins...............................................69

CleanDebrisFromMachine...........................69

CleanGrassBuild-UpUnderDeck.................69

WasteDisposal...............................................69

Troubleshooting....................................................71

Schematics............................................................73

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThislawnmowermeetsorexceedstheB71.4

specicationsoftheAmericanNationalStandards

Instituteineffectatthetimeofproduction.

Exmarkdesignedandtestedthislawnmowertooffer

reasonablysafeservice;however,failuretocomply

withthefollowinginstructionsmayresultinpersonal

injury.

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

SafetyAlertSymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Indicatesanimminentlyhazardous

situationwhich,ifnotavoided,Willresultindeathor

seriousinjury.

WARNING:Indicatesapotentiallyhazardous

situationwhich,ifnotavoided,Couldresultindeath

orseriousinjury.

CAUTION:Indicatesapotentiallyhazardous

situationwhich,ifnotavoided,Mayresultinminor

ormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readthismanual,itistheowner’sresponsibilityto

explainthismaterialtothem;otherlanguagesmay

beavailableonourwebsite.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

amower,andevenmatureteenagersshouldhave

adultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator's

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

mowerwithouttakingrisks.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialslip-resistantfootwear,andhearing

protection.Longhair,looseclothingorjewelry

maygettangledinmovingparts.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

5

Page 6

Safety

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengine

oremissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoradd

fuelwhenengineisrunningorwhenthe

engineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Do

Notuseanozzlelockopendevice.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperatorpresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

6

Page 7

Safety

Operation

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscanoccur

oncontactanddebris,suchasleaves,grass,

brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,to

coolbeforetouching.

•Removeaccumulateddebrisfrommuferand

enginearea.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcankill

you.

DoNotrunengineindoorsorinasmallconned

areawheredangerouscarbonmonoxidefumes

cancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

DoNotoperatethemachine;seekshelter.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.Useseatbelts

withtherollbarintheraisedandlockedposition.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly .

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkmachineonlevelground.Stopengine,wait

forallmovingpartstostop,removekeyand

engageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesinplace

andworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•NEVERcarrypassengers.DONOToperate

themowerwhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecaution

whencrossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

7

Page 8

Safety

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.Wheelsdroppingover

edges,ditches,steepbanks,orwatercancause

rollovers,whichmayresultinseriousinjury,

deathordrowning.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

•Keeptherollbarintheraisedandlocked

positionanduseseatbelt.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

(Figure3).

Figure3

1.SafeZone-Usethemowerhereonslopeslessthan15

degrees

2.DangerZone-Useawalkbehindmowerand/orhand

trimmeronslopesgreaterthan15degrees,near

drop-offsandwater.

3.Water

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatoperatingonwetgrass,acrosssteep

slopesordownhillmaycausethemowertolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

UsingtheRolloverProtectionSystem

(ROPS)

ARolloverProtectionSystem(rollbar)isinstalled

ontheunit.

WARNING

Thereisnorolloverprotectionwhentherollbar

isdown.Wheelsdroppingoveredges,ditches,

steepbanks,orwatercancauserollovers,which

mayresultinseriousinjury,deathordrowning.

•DoNotremovetheROPS.

•Keeptherollbarintheraisedandlocked

positionanduseseatbelt.

•Lowertherollbaronlywhenabsolutely

necessary.

•DoNotwearseatbeltwhentherollbaris

down.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Becertainthattheseatbeltcanbereleasedquickly

intheeventofanemergency.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,andelectricalwires)before

drivingunderanyobjectsandDoNotcontact

them.

•Intheeventofarollover,taketheunittoan

AuthorizedServiceDealertohavetheROPS

inspected.

8

Page 9

Safety

•ReplaceadamagedROPS.DoNotrepairor

revise.

•Anyaccessories,alterations,orattachmentsadded

totheROPSmustbeapprovedbyExmark.

MaintenanceandStorage

•Disengagedrives,setparkingbrake,stopengine

andremovekeyordisconnectsparkplugwire.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•LetenginecoolbeforestoringandDoNotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

DANGER

Chargingorjumpstartingthebatterymay

produceexplosivegases.Batterygasescan

explodecausingseriousinjury.

•Keepsparks,ames,orcigarettesaway

frombattery.

•Ventilatewhenchargingorusingbattery

inanenclosedspace.

•Makesureventingpathofbatteryis

alwaysopenoncebatteryislledwith

acid.

•Alwaysshieldeyesandfacefrombattery.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldeyes,and

rubberglovestoprotectskinandclothing

whenhandlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwith

waterandcalladoctorimmediately.

CAUTION

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagementof

components.Sparkscouldcauseanexplosion

ormovingpartscouldaccidentallyengage

causingpersonalinjury.

Besureignitionswitchisinthe“OFF”

positionbeforechargingthebattery.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

9

Page 10

Safety

WARNING

Removalormodicationoforiginalequipment,

partsand/oraccessoriesmayalterthewarranty,

controllability,andsafetyofthemachine.

Unauthorizedmodicationstotheoriginal

equipmentorfailuretouseoriginalExmark

partscouldleadtoseriousinjuryordeath.

Unauthorizedchangestothemachine,engine,

fuelorventingsystem,mayviolateapplicable

safetystandardssuchas:ANSI,OSHAand

NFPAand/orgovernmentregulationssuchas

EPAandCARB.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemay

result.

•Ifequipped,makesureallhydraulicuid

hosesandlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretohydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,to

ndhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembyplacingthemotioncontrollevers

inneutralandshuttingofftheenginebefore

performinganyworkonthehydraulicsystem.

TowingSafety

•Donotattachtowedequipmentexceptatthe

hitchpoint.

•Followtheattachmentmanufacturer's

recommendationforweightlimitsfortowed

equipmentandtowingonslopes.Towed

weightmustnotexceedtheweightofthe

machine,operator,andballast;otherwise

hydrostatictransmissionfailuremayoccur.Use

counterweightsorwheelweightsasdescribedin

theattachmentmanufacturer'smanual.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipment

maycauselossoftraction,increasedriskof

rollover,andlossofcontrol.Reducethetowed

weightandslowdown.

•Stoppingdistanceincreaseswiththeweightofthe

towedload.Travelslowlyandallowextradistance

tostop.

•Makewideturnstokeeptheattachmentclearof

themachine.

10

Page 11

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

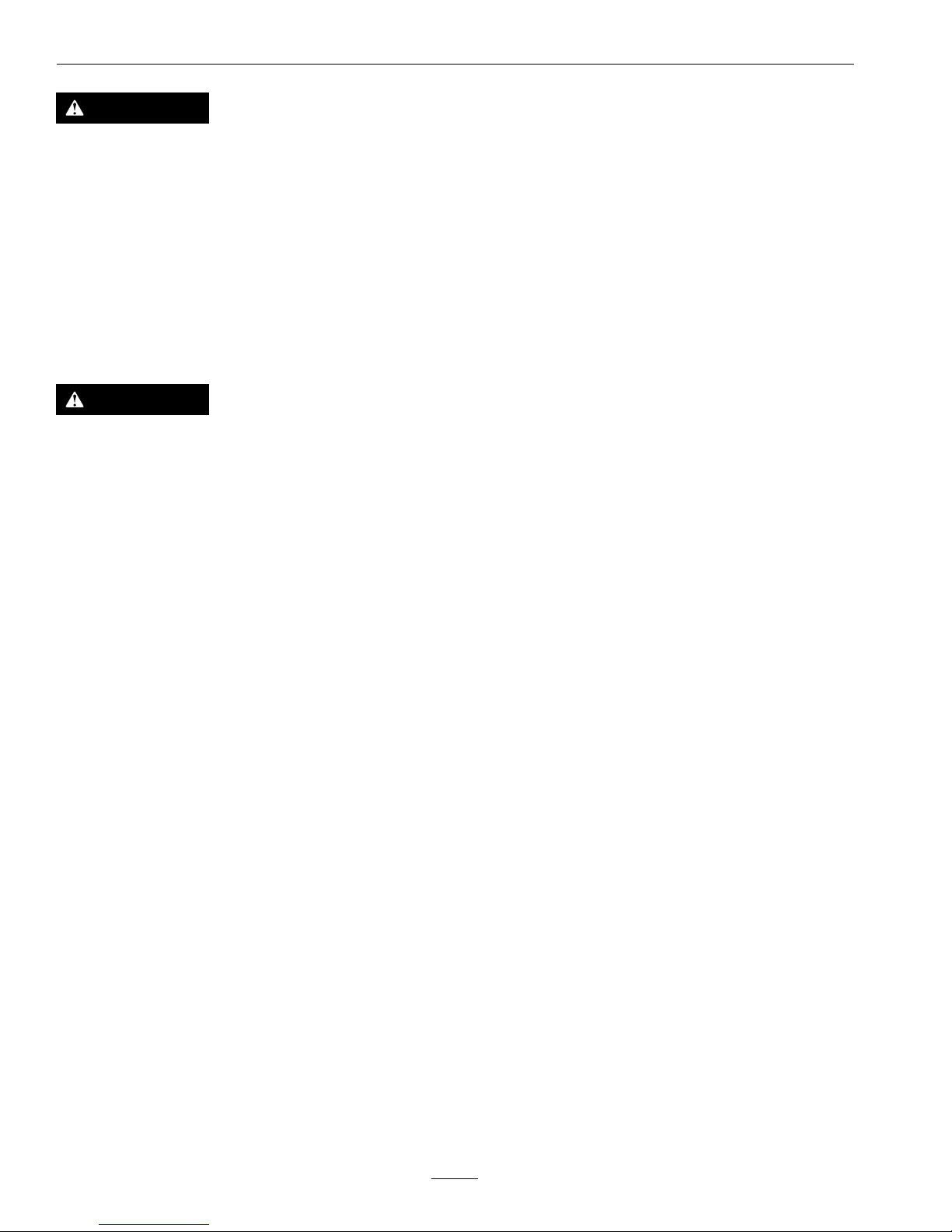

106-5517

1.Warning—donottouchthehotsurface.

107-3069

1.Warning-thereisnorolloverprotectionwhentherollbar

isdown.

2.Toavoidinjuryordeathfromarolloveraccident,keep

therollbarinthefullyraisedandlockedposition

andweartheseatbelt.Lowertherollbaronlywhen

absolutelynecessary;donotweartheseatbeltwhen

therollbarisdown.

3.ReadtheOperator’smanual;driveslowlyandcarefully.

11

Page 12

Safety

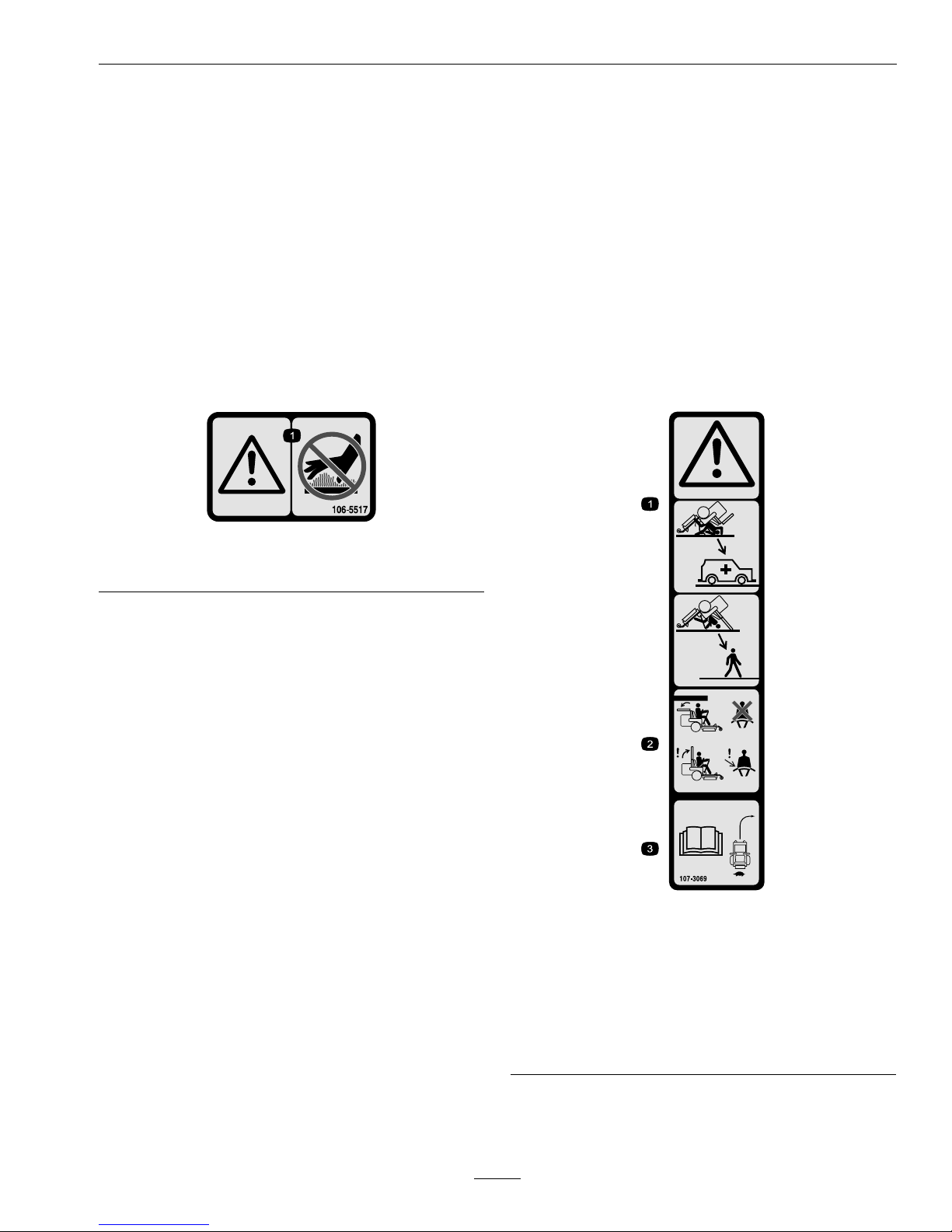

109-6014

109-6035

SideDischargeUnitsOnly

109-6036

1.ReadtheOperator’smanual

2.Removetheignitionkeyandreadtheinstructionsbefore

servicingorperformingmaintenance.

3.Heightofcut

112-9028

1.Warning—stayawayfrommovingparts;keepallguards

inplace.

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

116-8283

1.Warning—readtheOperator'sManualforinstructions

ontorquingthebladebolt/nutto55-60ft-lb(75-81N-m).

12

Page 13

Safety

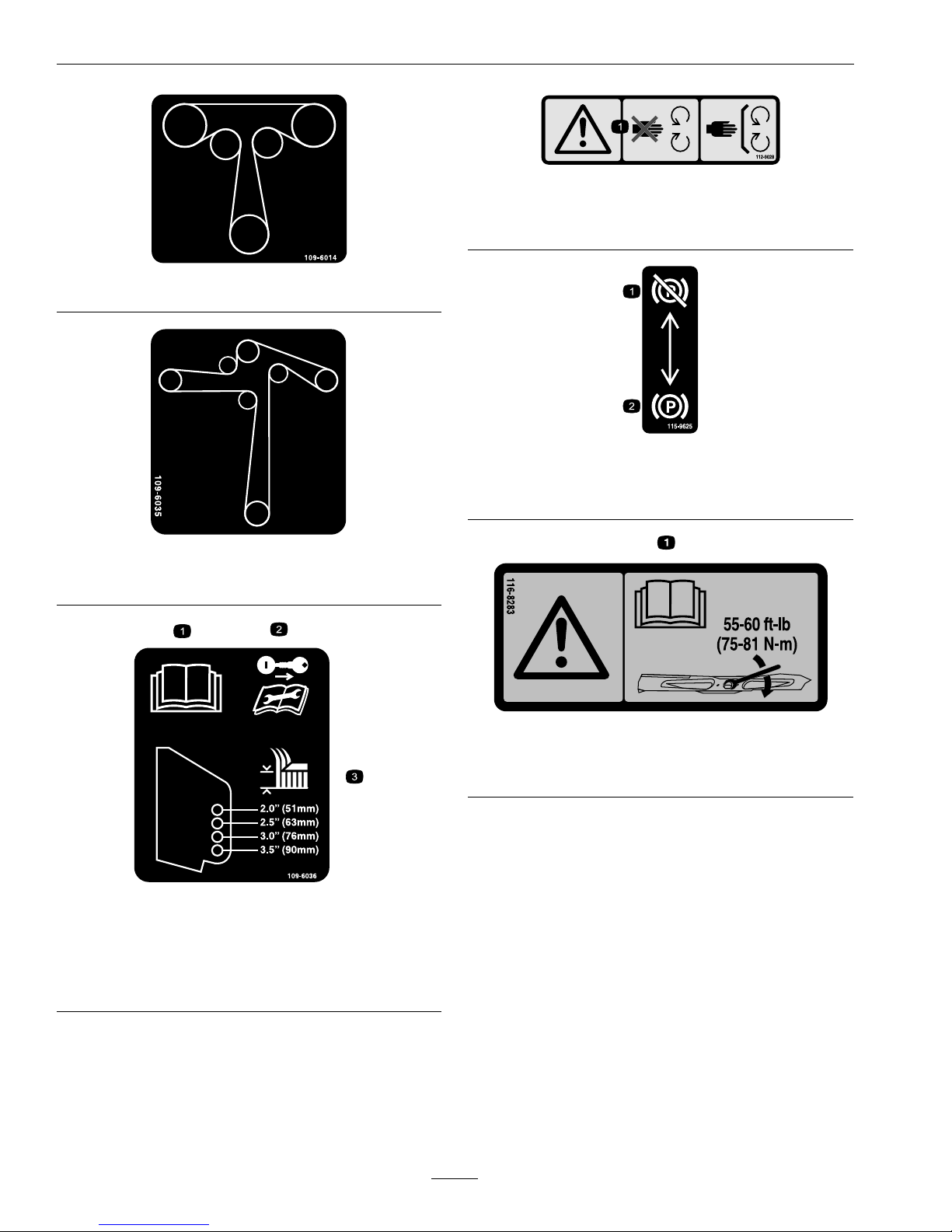

116-8588

1.ReadtheOperator’smanual.

2.Rotatethedrivereleaseknobtoloosen,slidetheknob,

andtighten.

3.Pushthemachine.

117-2718

126-0768

RearDischargeUnitsOnly

126-4363

1.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—Stopengineandremovekeybefore

adjusting,servicingorcleaning.

126-4784

1.Heightofcut

13

Page 14

Safety

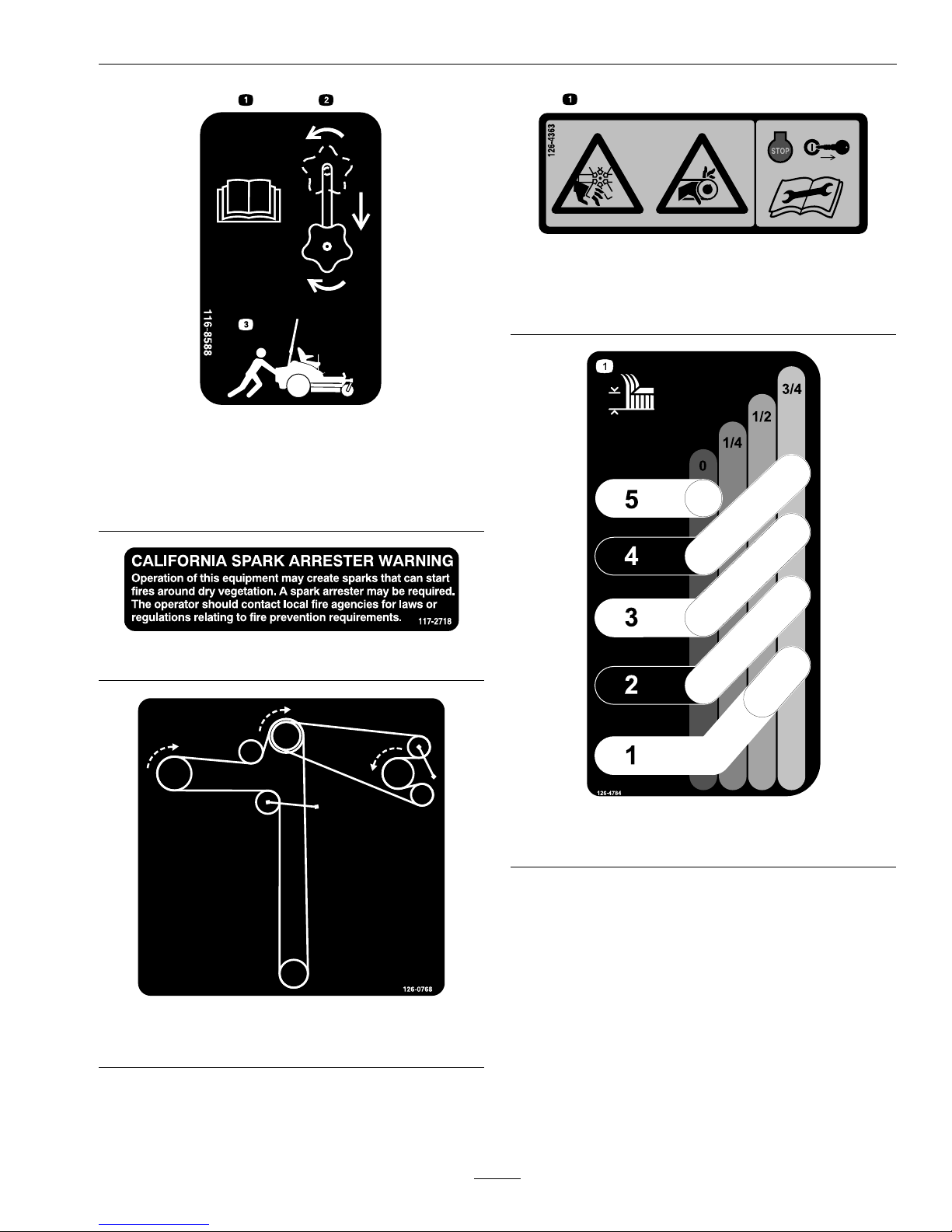

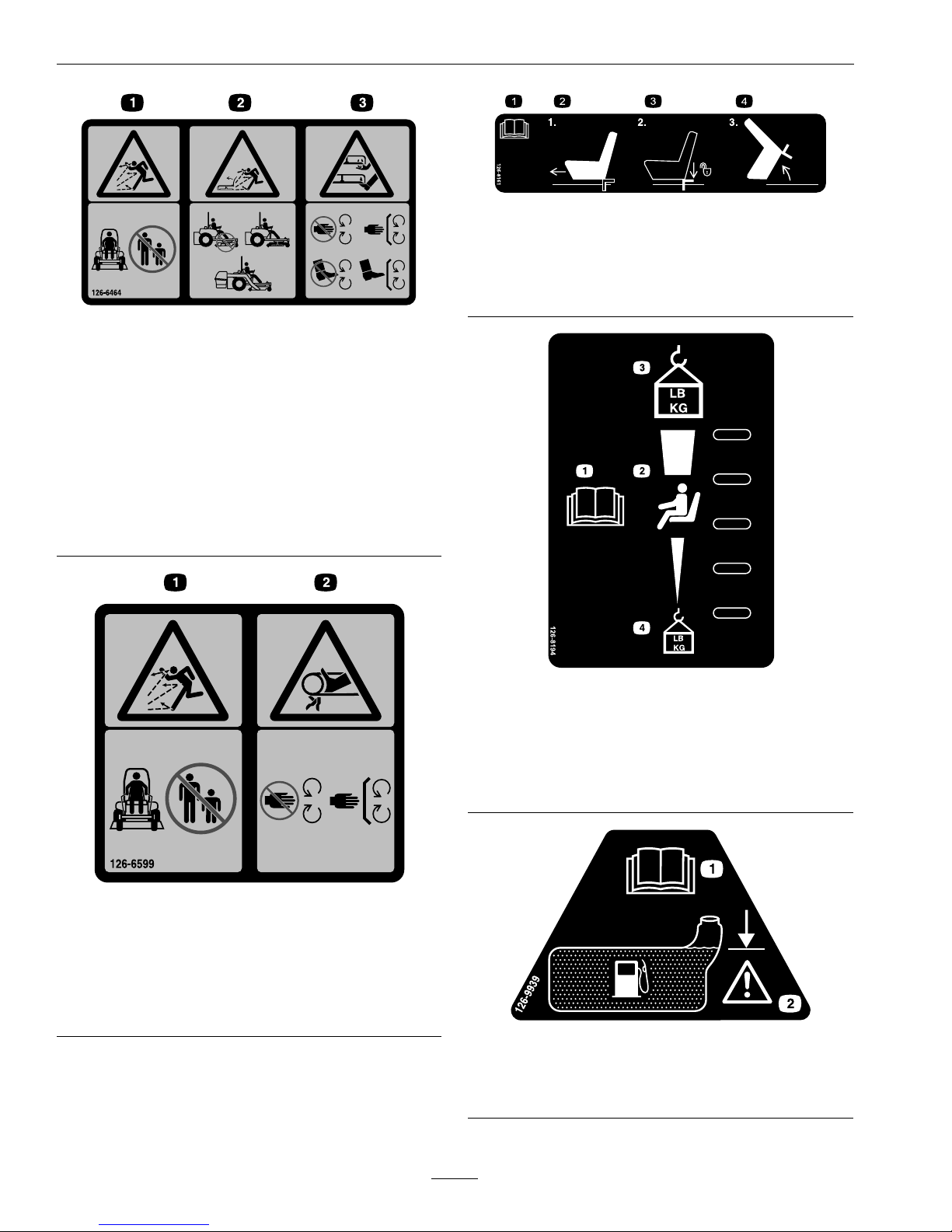

126-6464

SideDischargeUnits

1.Thrownobjectshazard

-keepbystandersa

safedistancefromthe

machine

3.Cutting/dismemberment

ofhandorfoot-stay

awayfrommovingparts;

keepallguardsand

shieldsinplace.

2.Thrownobjectshazard,

mower-donotoperate

withoutthedeector,

dischargecoverorgrass

collectionsystemin

place.

126-6599

RearDischargeUnits

1.Thrownobjectshazard

-keepbystandersa

safedistancefromthe

machine.

2.Cutting/dismemberment

ofhand-stayawayfrom

movingparts;keepall

guardsandshieldsin

place.

126-8161

X-SeriesUnits

1.ReadOperator’smanual

3.Pressdownonlatchto

unlockseat

2.Slideseatforward

4.Rotateseat

126-8194

S-SeriesUnits

1.ReadtheOperator’s

manual

3.Firmestposition/operator

200lb(91kg)andover

2.Seatadjustment4.Softestposition/operator

lessthan200lb(91kg)

126-9939

1.ReadtheOperator’s

Manual

2.Filltobottomofller

neck;warning–donot

overllthetank

14

Page 15

Safety

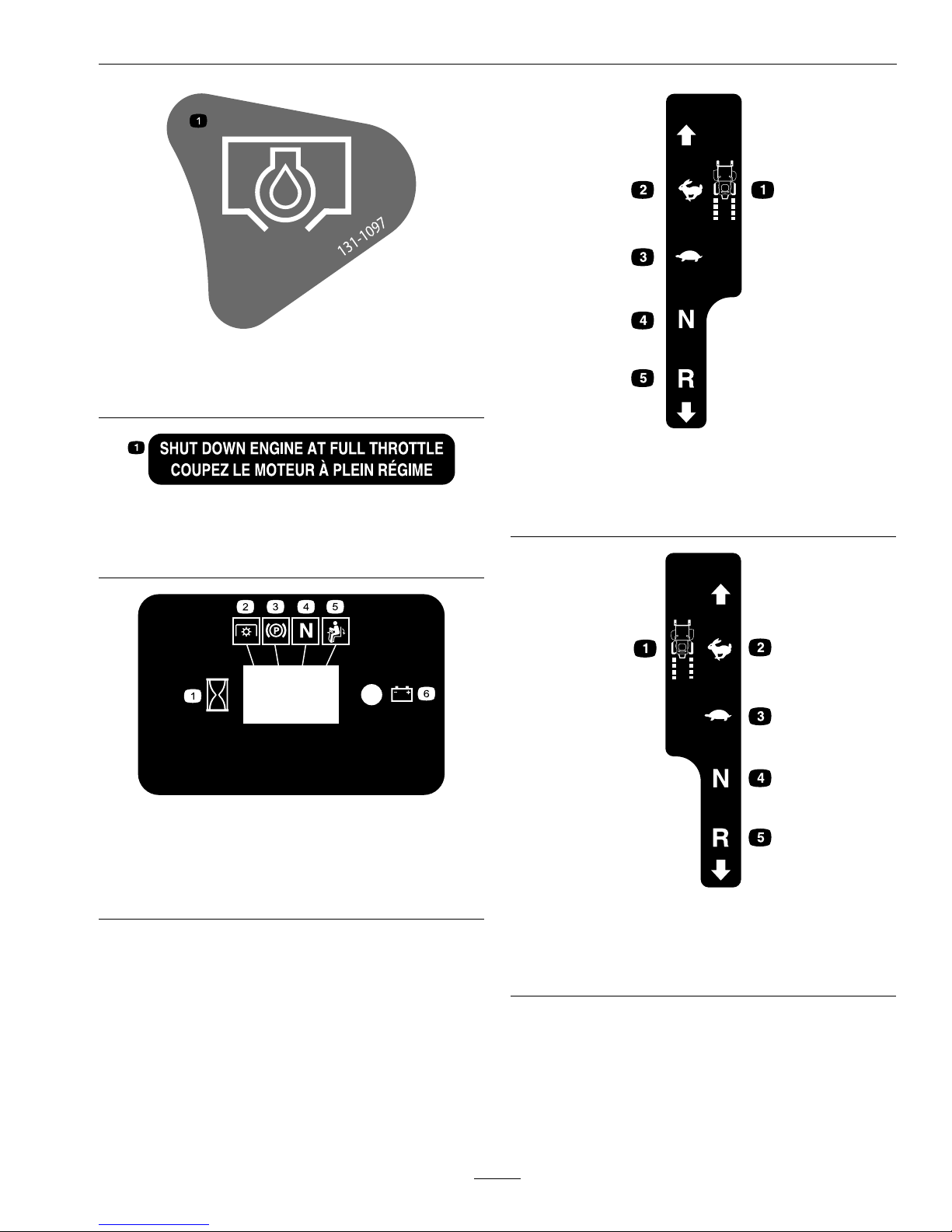

131-1097

Exmark708ccEngineOnly

1.Oildrain

Exmark708ccEngineOnly

1.Shutdownengineatfullthrottle

MessageDisplay

1.Hour4.Neutral

2.PTO5.Operatorpresence

switch

3.Parkingbrake6.Battery

LHMotionControl

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

RHMotionControl

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

15

Page 16

Safety

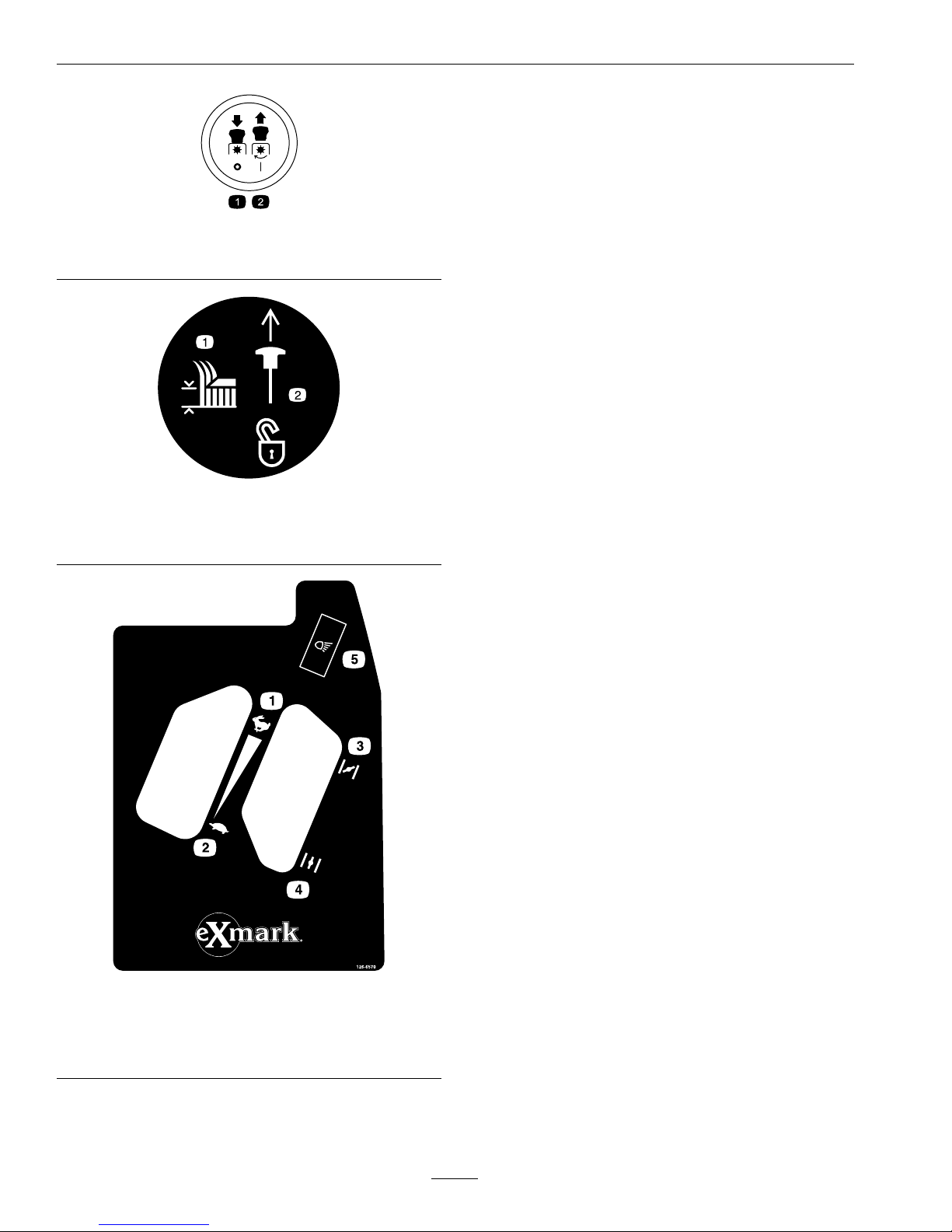

PTOSwitchSymbols

1.PTO–disengage2.PTO–engage

TransportLock

1.Heightofcut

2.Pulluptounlockthe

transportlock

126-6570

1.Throttle-fast4.Choke-off

2.Throttle-slow

5.Optionallightaccessory

3.Choke-on

16

Page 17

Safety

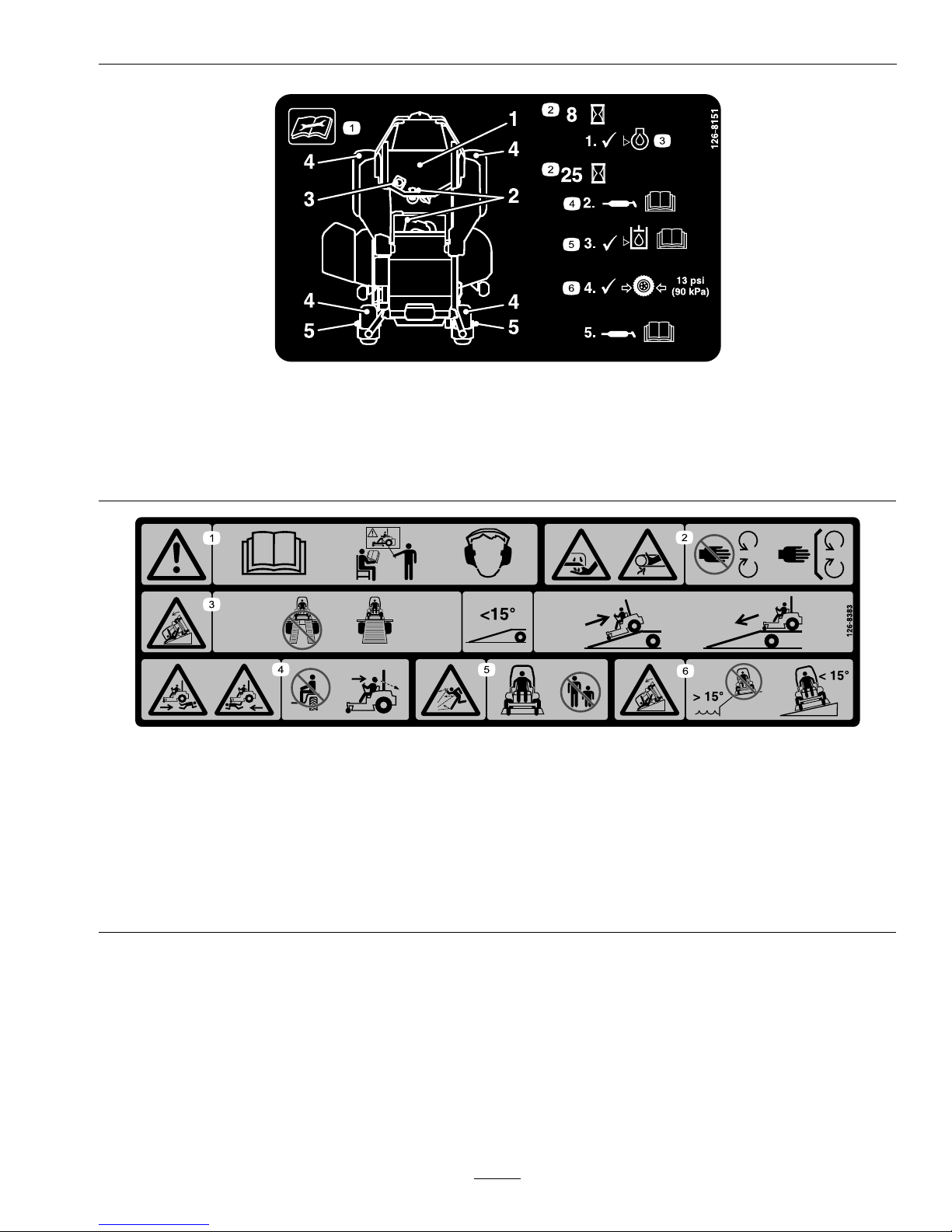

126-8151

1.Readtheinstructionsbeforeservicingorperforming

maintenance

4.RefertotheOperator'smanualforgreaseinstructions

2.Timeinterval

5.CheckhydraulicoillevelandrefertotheOperator's

manualorfurtherinstructions

3.Checkoillevel6.Checktirepressure

126-8383

1.Warning-ReadtheOperator’sManual.DoNotoperatethis

machineunlessyouaretrained.Wearhearingprotection.

4.Bodilyharmhazard-lookbehindyouwhenmowingin

reverse.

2.Cuttingandpinchinghazard-keephandsandfeetaway

frommovingparts;keepallguardsandshieldsinplace.

5.Thrownobjecthazard-keepbystandersaway.

3.Ramphazard-whenloadingontoatrailer,donotuse

dualramps;onlyuseasingularrampwideenoughforthe

machineandthathasaninclinelessthan15degrees;

backuptheramp(inreverse)anddriveforwardoffthe

ramp.

6.Tippinghazardonslopes-donotuseonslopesnearopen

water;donotuseonslopesgreaterthan15degrees.

17

Page 18

Specications

Specications

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•EngineOilType:Exmark4–CyclePremium

EngineOil

•RPM:

–X-andS-Series:FullSpeed:3750±50RPM

(PTOnotengaged)Idle:1500±100RPM

–E-Series:FullSpeed:3600±50RPM(PTO

notengaged)Idle:1500±100RPM

FuelSystem

•Capacity:7.0gal.(26.5L)

•FuelRecommendations:

–Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

–Oxygenatedfuelwithupto10%ethanolor

15%MTBEbyvolumeisacceptable.

–DoNotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanol

byvolume.Performanceproblemsand/or

enginedamagemayresultwhichmaynotbe

coveredunderwarranty.

–DoNotusegasolinecontainingmethanol.

–DoNotstorefueleitherinthefueltankor

fuelcontainersoverthewinterunlessafuel

stabilizerisused.

–DoNotaddoiltogasoline.

•FuelFilter:

Kohler:KohlerP/N2405013

Kawasaki:KawasakiP/N49019-0014

ExmarkEngine:ExmarkP/N133-1563

•FuelShut-OffValve:

AllUnits:1/4turn(“ON”,“OFF”).

ElectricalSystem

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:15amps

•BatteryType:BCIGroupU1

•RecommendedMinimumBatteryCCA:260CCA

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuses:

Allunits:

–20ampchargingsystemfuse

(notusedonKohlerengines)

–15ampmainfuse

SafetyInterlockSystem

•LCDindicatorsappearforthePTO ,parkbrake,

drivelevers,andoperatorpresenceinthemessage

displayontheRHcontrolpanel.

•PTOmustbedisengaged,brakeengaged,and

motioncontrolleversout(neutrallock)tostart

engine.(Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.)

•OperatormustbeinseatwhenPTOisengaged,

brakeisdisengaged,ormotioncontrolleversare

movedinorenginewillstop.

•Enginewillstopifeithertheleft,theright,or

bothleversaremovedfromneutrallockposition

whilebrakeisengaged.

OperatorControls

•SteeringandMotionControl:

Note:Motioncontrolleversareadjustableto

threeheights.

–Separatelevers,oneachsideoftheconsole,

controlspeedanddirectionoftravelofthe

respectivedrivewheels.

–Steeringiscontrolledbyvaryingtheposition

oftheleversrelativetoeachother.

–Movingmotioncontrolleversoutward(in

slots)locksthedrivesysteminneutral.

•PTOEngagementSwitch:Engageselectricclutch

(todrivebelt)whichengagesmowerblades.

•ParkingBrakeLever:Engagesparkingbrake.

•DeckHeightAdjustmentLever:Setscutting

heighttodesiredposition.

•DeckLiftPedal:Footpedalthatliftsdeck.

•TransportLock:Latchingposition:Automatically

latchesatthetransportposition.

18

Page 19

Specications

Seat

•SeatType:

–X-Series:

Deluxesuspension(adjustablespring

suspension)seatwithhighback,moldedfoam

ip-uparmrests,andintegralsafetyswitch.

–S-Series:

Standardseatwithfoampaddedseatcushion

witharmrests,integralsafetyswitch,and

adjustableSeatIsolationSystemsuspension

forreducedvibrationandenhancedride.

–E-Series:

Standardseatwithfoampaddedseatcushion

witharmrestsandintegralsafetyswitch.

•Mounting:

–X-andS-Series:Hingedseatframetotiltup

seat.Adjustableforeandaftonseattracks.

–E-Series:Adjustableforeandaftonseat

tracks.

•Armrests:Moldedip-uparmrests.

•SeatSafetySwitch:Integratedseatswitch.

Timedelayseatswitcheliminatesroughground

cut-outs.

HydrostaticGroundDriveSystem

•Twounitizedhydrostatictransmissions:

–X-Series:

HydroGearZT3400

–S-Series:

◊Unitswithsidedischargedecks:

HydroGearZT3100

◊Unitswithreardischargedeck:

HydroGearZT3400

–E-Series:

◊Unitswith48or52inchdecks:

HydroGearZT2800

◊Unitswith60inchdeck:

HydroGearZT3100

•HydraulicOilType:ExmarkPremiumHydroOil.

•HydraulicOilCapaczity:77oz(2.3L)perside

•HydraulicFilter:P/N109-3321

•Speeds:

–X-Series:

◊Forward:0-10mph(16.1km/hr)forward.

◊Reverse:0-7mph(11.3km/hr)reverse.

–S-Series:

◊Forward:0-9mph(14.5km/hr)forward.

◊Reverse:0-6mph(9.7km/hr)reverse.

–E-Series:

◊Forward:0-8mph(12.9km/hr)

◊Reverse:0-5mph(8.0km/hr)reverse.

•Drivewheelreleasevalvesallowmachinetobe

movedwhenengineisnotrunning.

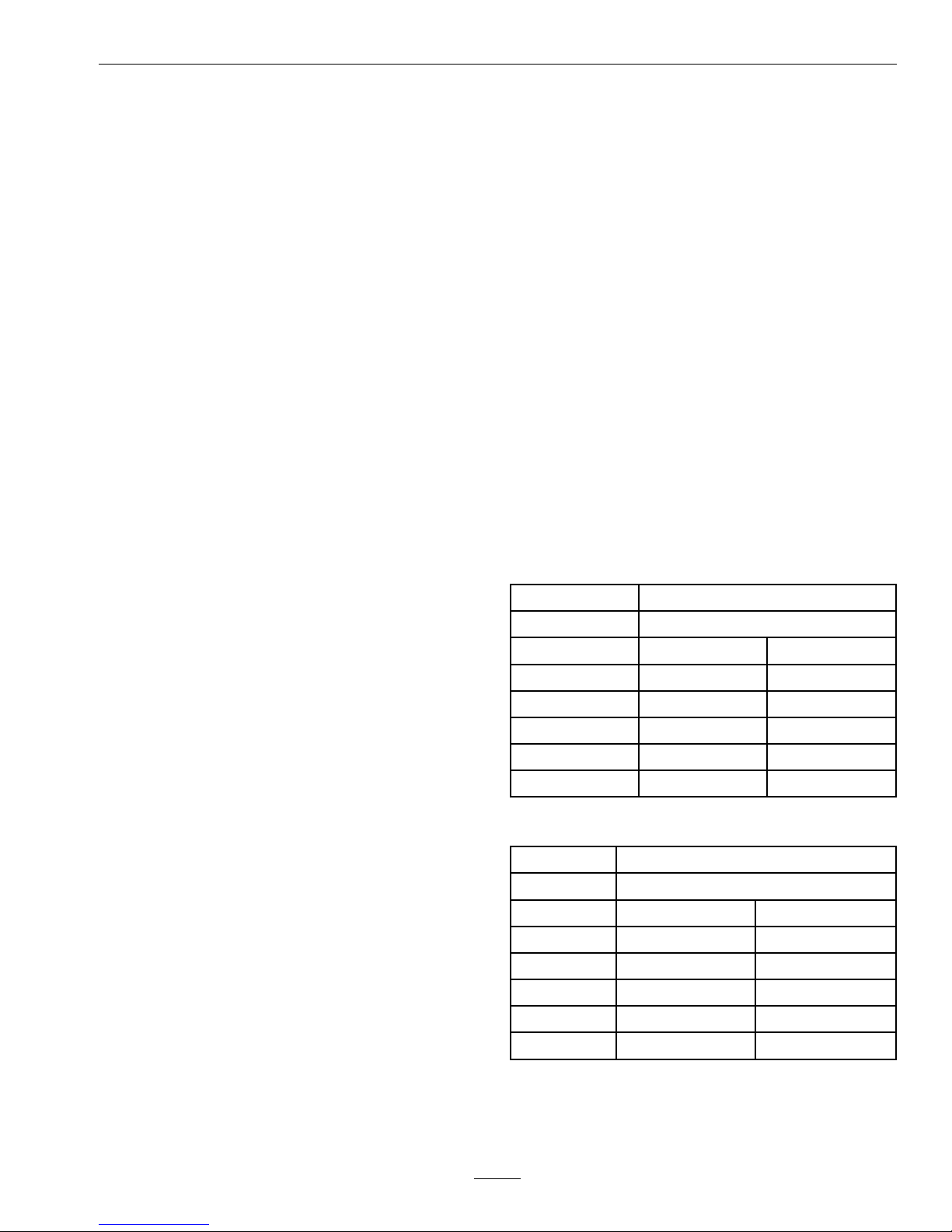

Tires&Wheels

X-Series:

Drive

Pneumatic(Airlled)

DeckSize

48&5260

Quantity

22

Tread

K500K500

Size24x9.50-1224x10.5-12

PlyRating

44

Pressure

13psi(90kPa)13psi(90kPa)

S-Series:

Drive

Pneumatic(Airlled)

DeckSize

48&5260

Quantity

22

Tread

K500K500

Size23x9.50-1223x10.50-12

PlyRating

44

Pressure

13psi(90kPa)13psi(90kPa)

19

Page 20

Specications

E-Series:

Drive

Pneumatic(Airlled)

DeckSize

48&5260

Quantity

22

Tread

K500K500

Size22x9.50-1222x10.50-12

PlyRating

44

Pressure

13psi(90kPa)13psi(90kPa)

FrontCaster—AllModels

Pneumatic(Airlled)

DeckSize

AllModels

Quantity

2

Tread

Smooth

Size13x6.50-6

PlyRating

4

Pressure

13psi(90kPa)

CuttingDeck

•CuttingWidth:

–48inchDeck:(121.9cm)

–52inchDeck:(132.1cm)

–60inchDeck:(152.4cm)

•Discharge:

–SideDischarge:Non“R”models

–RearDischarge:“R”models

•BladeSize:

–48inchDeck:16.25inches(41.3cm)–(3ea.)

–52inchDeck:18.00inches(45.7cm)–(3ea.)

–60inchDeck:20.50inches(52.1cm)–(3ea.)

•BladeSpindles:

–X-Series:Solidsteelspindleswith.98inch(25

mm)I.D .bearings.

–S-andE-Series:Solidsteelspindleswith.67

inch(17mm)I.D.bearings.

•DeckDrive:“B”Sectionbeltwithself-tensioning

idler.

•Electricclutch:

–48&52InchDecks:125ft-lbMagStop

–60InchDeck:125ft-lbNeo-MagStop

•Deck:Fulloatingdeckisattachedtoout-front

supportframe.Anti-scalprollersprovide

maximumturfprotection.Deckdesignallowsfor

bagging,mulchingorsidedischarge.

–48inchDeck:3anti-scalprollers

–52inchDeck:5anti-scalprollers

–60inchDeck:5anti-scalprollers

–60inchDeck-RearDischarge:

4anti-scalprollers

–SideDischarge:Fulloatingdeckisattached

toout-frontsupportframe.Anti-scalprollers

providemaximumturfprotection.Deck

designallowsforbagging,mulchingorside

discharge.

–RearDischarge:Fulloatingdeckisattached

toout-frontsupportframe.Anti-scalprollers

andsidebumpersprovidemaximumturf

protection.Deckdesignallowsforrear

dischargeornishcut(reduceddischarge).

•DeckDepth:

–S-andE-Series:

◊SideDischarge:5.0inches(12.7cm)

◊RearDischarge:5.5inches(14.0cm)

–X-Series:

AllDecks:5.5inches(14.0cm)

•CuttingHeightAdjustment:

Footactivatedleverisusedtoadjustthecutting

heightfrom11/2inch(3.8cm)to5inches(12.7

cm)in1/4inch(6.4mm)increments.

•MulchingKit:Optional.

20

Page 21

Specications

Dimensions

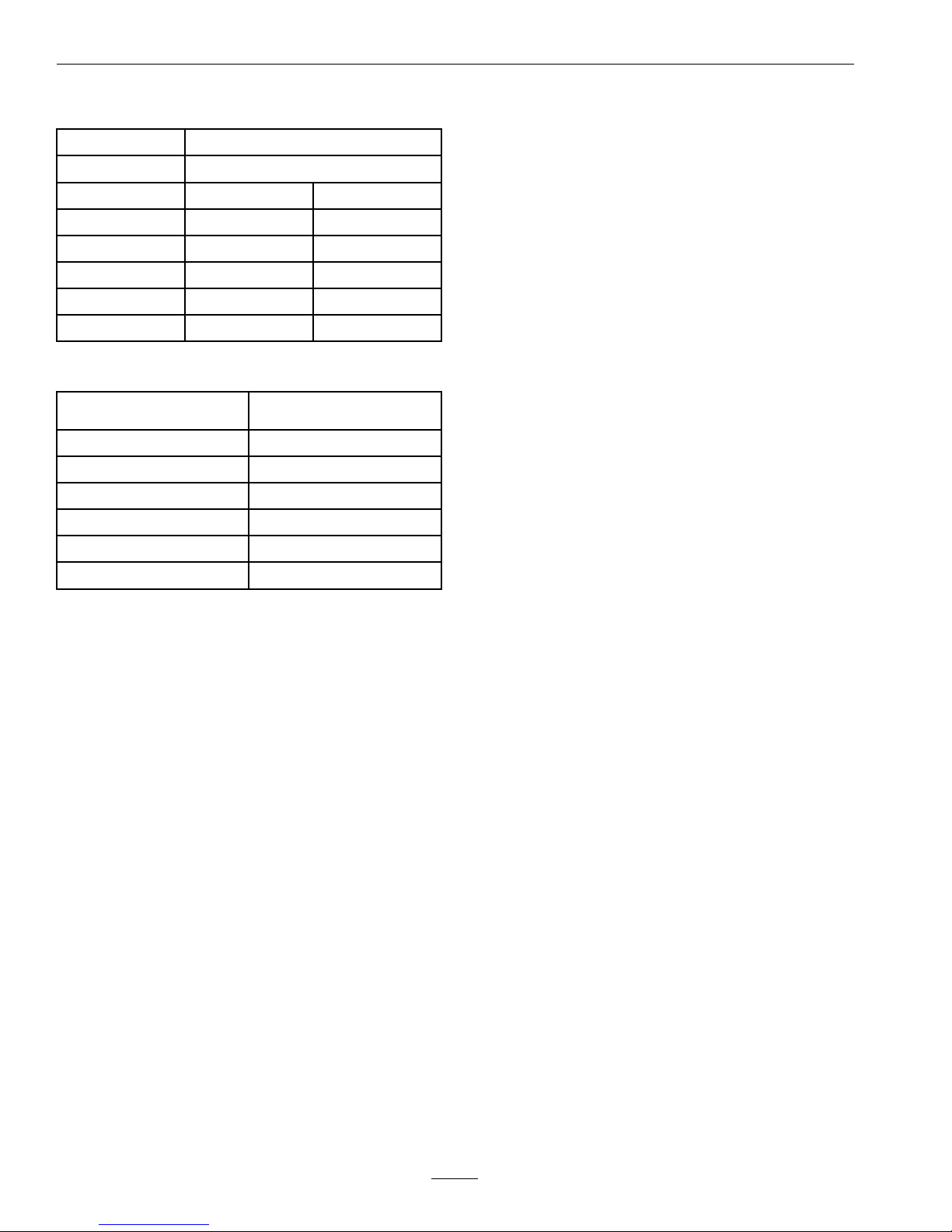

OverallWidth:

X-Series—SideDischargeUnits:

48inch

Deck

52inch

Deck

60inch

Deck

Without

Deck

47.4inches

(120.4cm)

48.7inches

(123.7cm)

52.1inches

(132.3cm)

Deector

Up

52.6inches

(133.6cm)

57.3inches

(145.5cm)

61.7inches

(156.7cm)

Deector

Down

59.5inches

(151.1cm)

64.6inches

(164.1cm)

72.7inches

(184.7cm)

S-Series—SideDischargeUnits:

48inch

Deck

52inch

Deck

60inch

Deck

Without

Deck

47.2inches

(119.9cm)

48.5inches

(123.2cm)

51.4inches

(130.6cm)

Deector

Up

52.6inches

(133.6cm)

57.3inches

(145.5cm)

61.7inches

(156.7cm)

Deector

Down

59.5inches

(151.1cm)

64.3inches

(163.3cm)

72.3inches

(183.6cm)

E-Series—SideDischargeUnits:

48inch

Deck

52inch

Deck

60inch

Deck

Without

Deck

46.7inches

(118.6cm)

48.0inches

(121.9cm)

51.2inches

(130.0cm)

Deector

Up

52.6inches

(133.6cm)

57.3inches

(145.5cm)

61.7inches

(156.7cm)

Deector

Down

59.5inches

(151.1cm)

64.3inches

(163.3cm)

72.3inches

(183.6cm)

RearDischargeUnits:

60inchDeck

WithoutDeck51.4inches

(130.6cm)

WithDeck66.0inches

(167.6cm)

OverallLength:

SideDischargeUnits:

48inchDeck52inchDeck60inchDeck

81.7inches

(207.5cm)

81.7inches

(207.5cm)

82.2inches

(208.8cm)

RearDischargeUnits:

60inchDeck

84.3inches

(214.1cm)

OverallHeight:

X-Series—SideDischargeUnits

RollBar-UpRollBar-Down

70.4inches(178.8cm)48.4inches(122.9cm)

S-Series—SideDischargeUnits

RollBar-UpRollBar-Down

70.2inches(178.3cm)48.9inches(124.2cm)

E-Series—SideDischargeUnits

RollBar-UpRollBar-Down

69.7inches(177.0cm)47.0inches(119.4cm)

RearDischargeUnits

RollBar-UpRollBar-Down

70.2inches(178.3cm)48.9inches(124.2cm)

21

Page 22

Specications

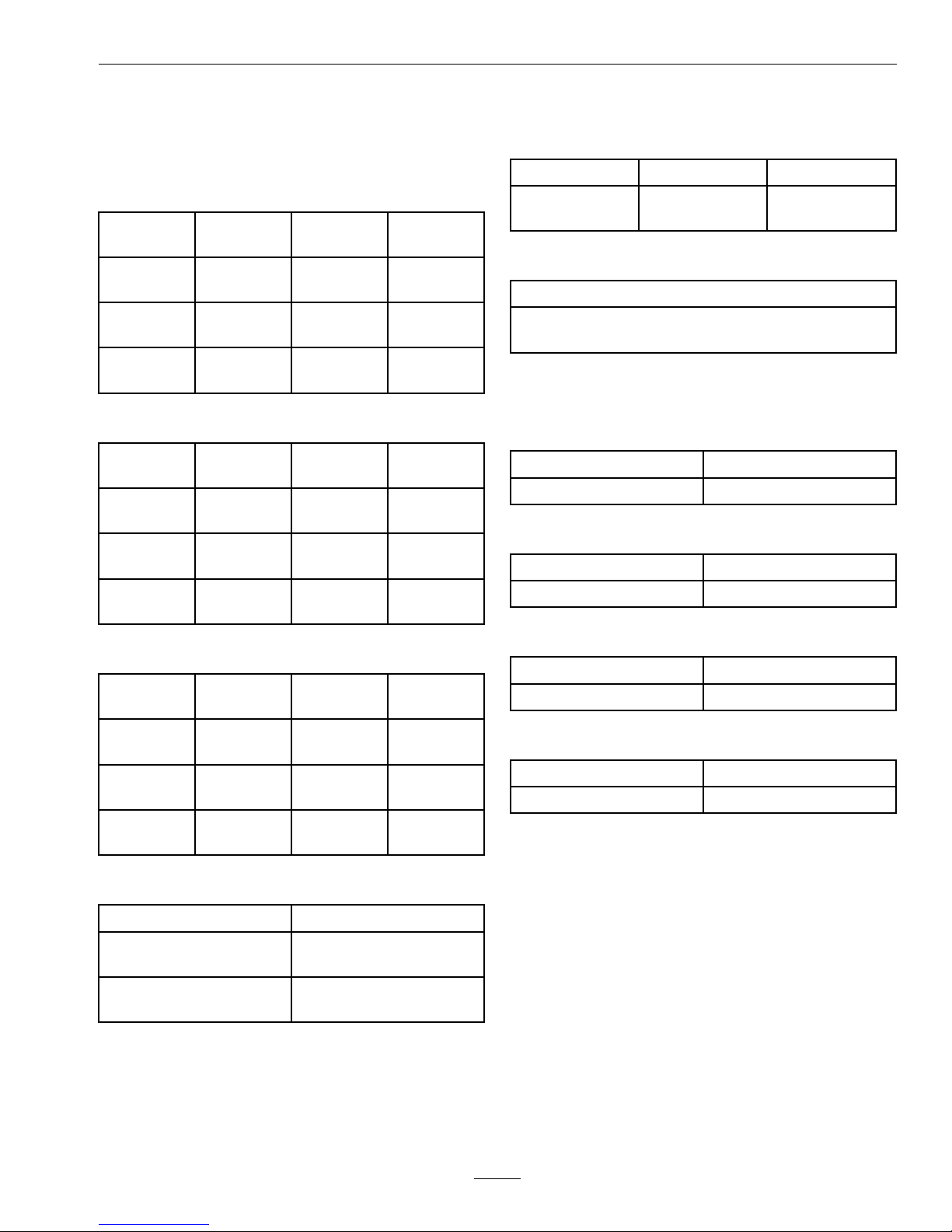

TreadWidth:(CentertoCenterof

Tires,Widthwise)

X-Series—SideDischargeUnits

48inch

Deck

52inch

Deck

60inch

Deck

Drive

Wheels

37.7inches

(95.8cm)

39.0inches

(99.1cm)

40.7inches

(103.4cm)

Caster

Wheels

33.1inches

(84.1cm)

33.1inches

(84.1cm)

38.2inches

(97.0cm)

S-Series—SideDischargeUnits

48inch

Deck

52inch

Deck

60inch

Deck

Drive

Wheels

37.7inches

(95.8cm)

39.0inches

(99.1cm)

40.7inches

(103.4cm)

Caster

Wheels

33.1inches

(84.1cm)

33.1inches

(84.1cm)

38.2inches

(97.0cm)

E-Series—SideDischargeUnits

48inch

Deck

52inch

Deck

60inch

Deck

Drive

Wheels

37.7inches

(95.8cm)

39.0inches

(99.1cm)

40.7inches

(103.4cm)

Caster

Wheels

33.1inches

(84.1cm)

33.1inches

(84.1cm)

38.2inches

(97.0cm)

RearDischargeUnits:

60inchDeck

DriveWheels40.7inches

(103.4cm)

CasterWheels31.0inches

(78.7cm)

WheelBase:(CenterofCasterTireto

CenterofDriveTire)

SideDischargeUnits:

48inchDeck52inchDeck60inchDeck

49.7inches

(126.2cm)

49.7inches

(126.2cm)

50.2inches

(127.5cm)

RearDischargeUnits:

60inchDeck

52.3inches

(132.8cm)

CurbWeight:

Unitswith48InchSide

DischargeDecks

849-937lb

(385-425kg)

Unitswith52InchSide

DischargeDecks

862-957lb

(391–434kg)

Unitswith60InchSide

DischargeDecks

901-1006lb

(409-456kg)

Unitswith60InchRear

DischargeDecks

1012lb(459kg)

22

Page 23

ProductOverview

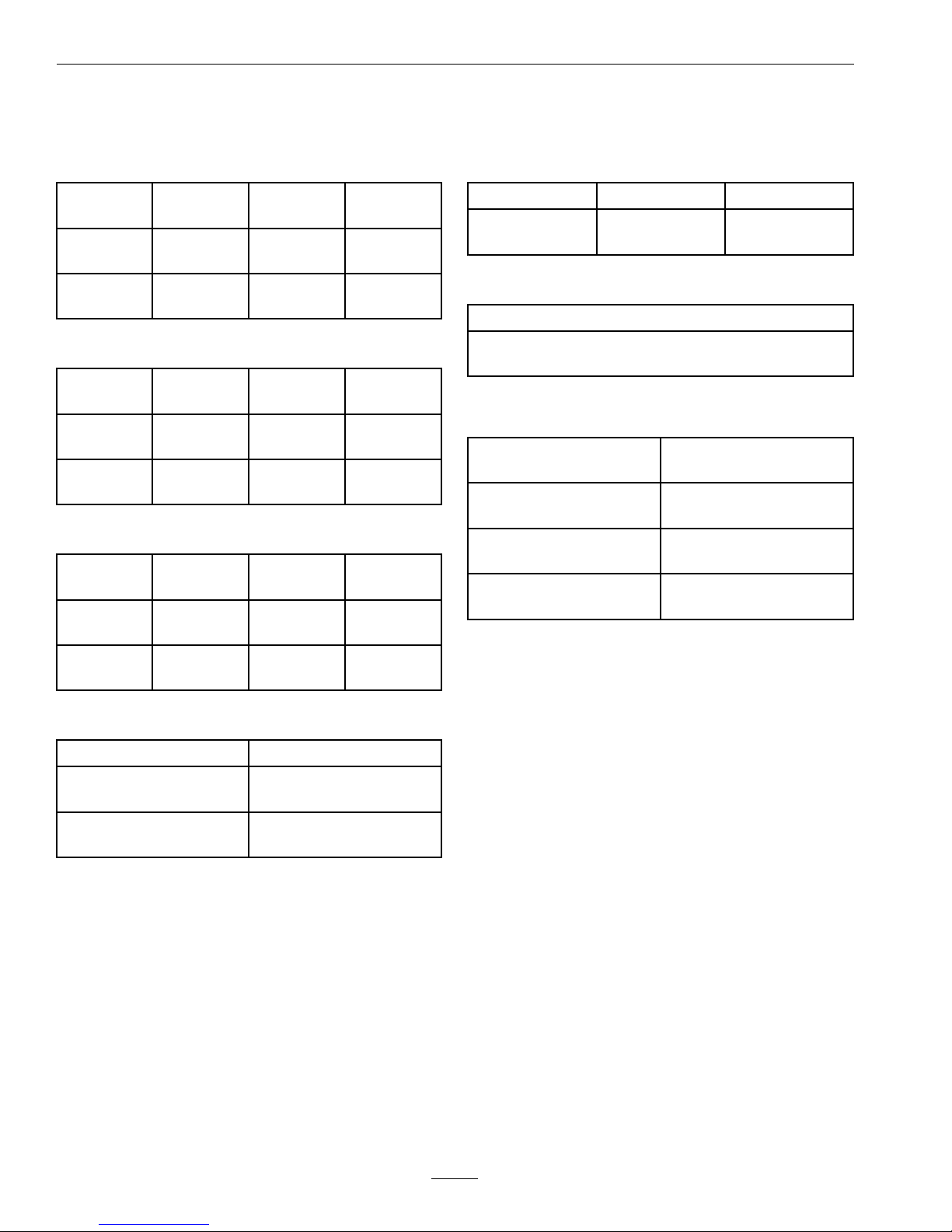

TorqueRequirements

BoltLocation

Torque

X-Series:

BladeDriveSheave

MountingNut

130-160ft-lb(176-217N-m)

S-andE-Series:

BladeDriveSheave

MountingNut

75-85ft-lb(102-115N-m)

BladeMounting

Bolt(lubricatewith

anti-seize)

50-60ft-lb(68-81N-m)

Anti-ScalpRoller

NylocNut—Side

DischargeUnitsOnly

(SeeFigure18)

50-55ft-lb(68-75N-m)

Anti-ScalpRoller

NylocNut—Rear

DischargeUnitsOnly

(SeeFigure19)

30-35ft-lb(41-47N-m)

EngineMountingBolts

27-33ft-lb(37-45N-m)

WheelLugNuts

90-100ft-lb(122-136N-m)

RolloverProtection

System(RollBar)1/2

inchMountingBolts

90-100ft-lb(122-136N-m)

ClutchRetaining

Bolt(securedwith

threadlocker)

49-61ft-lb(66-83N-m)

RearDischargeSide

Bumpers

10-12ft-lb(14-16N-m)

ProductOverview

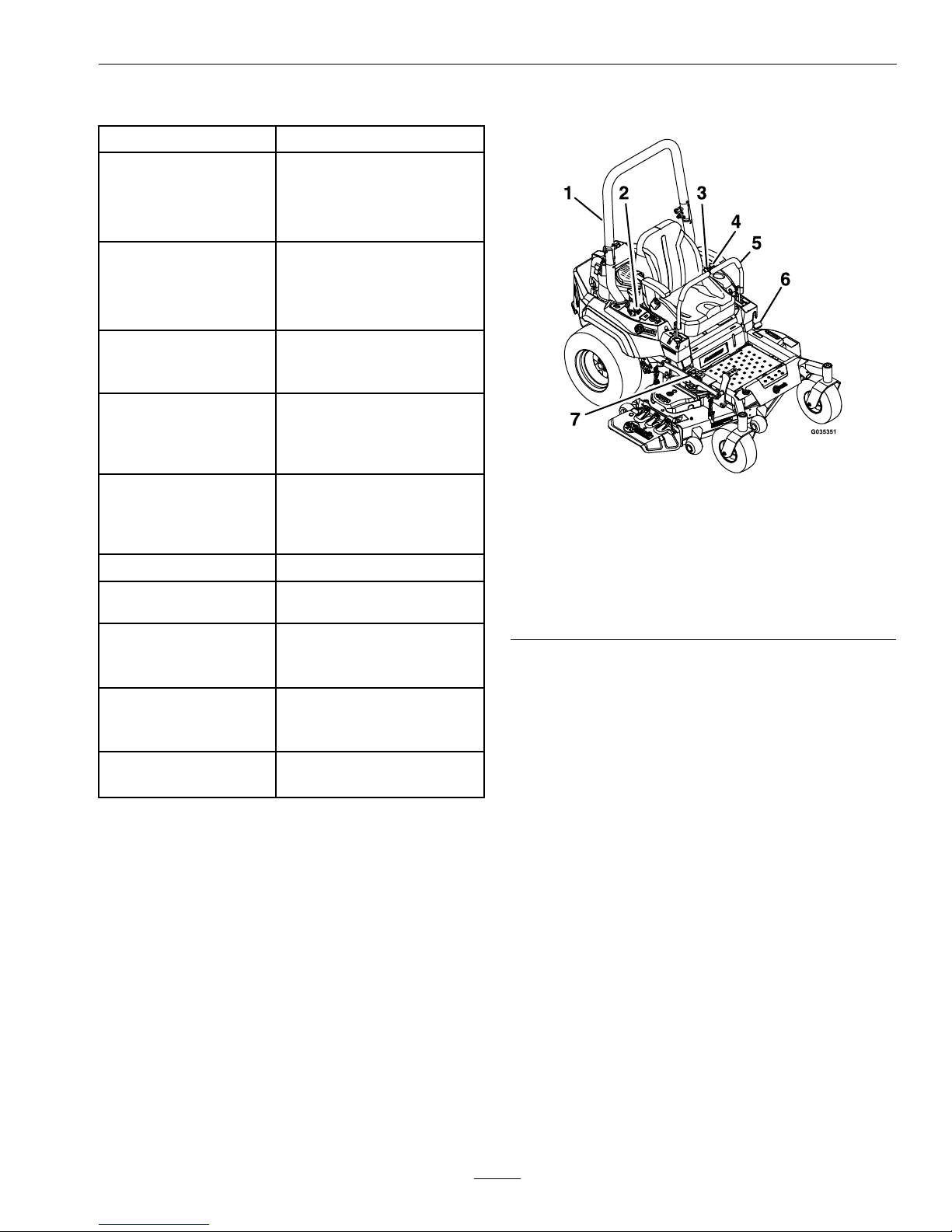

Figure4

1.RolloverProtection

System(ROPS)

5.Motioncontrollevers

2.EngineControls(right

console)

6.Parkingbrake

3.Seatbelt7.Heightofcutadjustment

4.Fuelcap

23

Page 24

Operation

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

MotionControlLevers

Themotioncontrolleversarelocatedoneachside

oftheconsoleandcontroltheforwardandreverse

motionofthemachine.

Movingtheleversforwardorbackwardturns

thewheelonthesamesideforwardorreverse

respectively.Wheelspeedisproportionaltothe

amounttheleverismoved.

Movingtheleversoutwardfromthecenterposition

intotheT-slotlocksthemintheneutralposition

(Figure5).

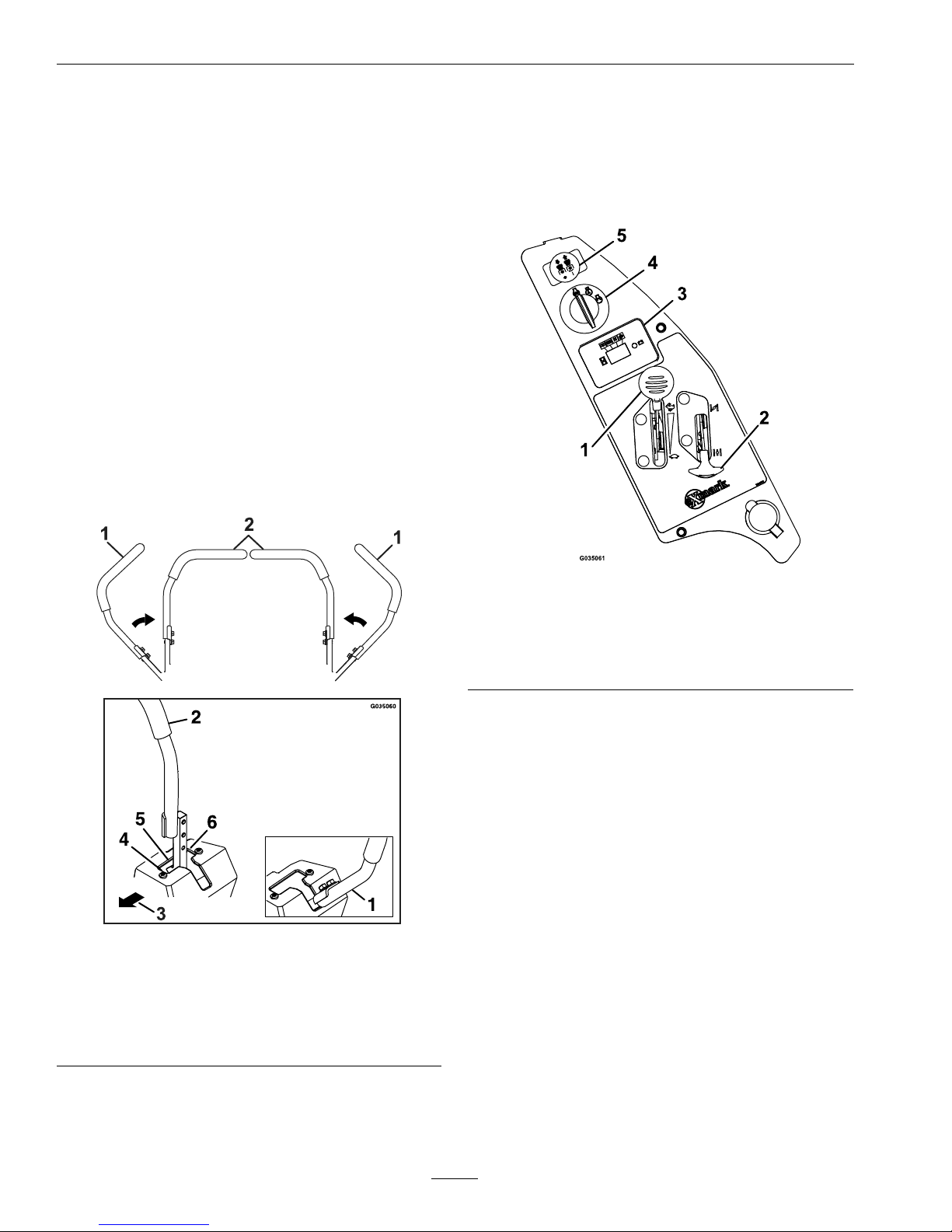

Figure5

1.Neutrallockposition

(handlesout)

4.Forward

2.Neutraloperateposition

(handlesin)

5.Neutral(operate)

3.Frontofunit

6.Reverse

ChokeControl

Locatedonrightconsole(blacklever)(seeFigure6).

Thechokeisusedtoaidinstartingacoldengine.

Movingthechokeleverforwardwillputthechokein

the“ON”positionandmovingthechokelevertothe

rear,tothedetent,willputthechokeinthe“OFF”

position.DoNotrunawarmenginewithchokein

the“ON”position.

Figure6

1.Throttlelever4.Ignitionswitch

2.Chokelever

5.Bladecontrolswitch

(powertake-off)

3.Hourmeter

ThrottleControl

Locatedonrightconsole(redlever)(seeFigure6).

Thethrottleisusedtocontrolenginespeed.Moving

thethrottleleverforwardwillincreaseenginespeed

andmovingthethrottlelevertotherearwilldecrease

enginespeed.Movingthethrottleforwardintothe

detentisfullthrottle.

BrakeLever

Locatedonleftsideofunit,justtothefrontofthe

LHmotioncontrollever.

Thebrakeleverengagesaparkingbrakeonthedrive

wheels.

Pulltheleverupandrearwardtoengagethebrake.

Pushtheleverforwardanddowntodisengagethe

brake.

24

Page 25

Operation

Theunitmustbetieddownandbrakeengagedwhen

transporting.

IgnitionSwitch

Locatedonrightconsole(seeFigure6).

Theignitionswitchisusedtostartandstopthe

engine.Theswitchhasthreepositions“OFF”,“ON”

and“START”.Insertkeyintoswitchandrotate

clockwisetothe“ON”position.Rotateclockwiseto

thenextpositiontoengagethestarter(keymustbe

heldagainstspringpressureinthisposition).Allow

thekeytoreturntothe“ON”positionimmediately

aftertheenginestarts.

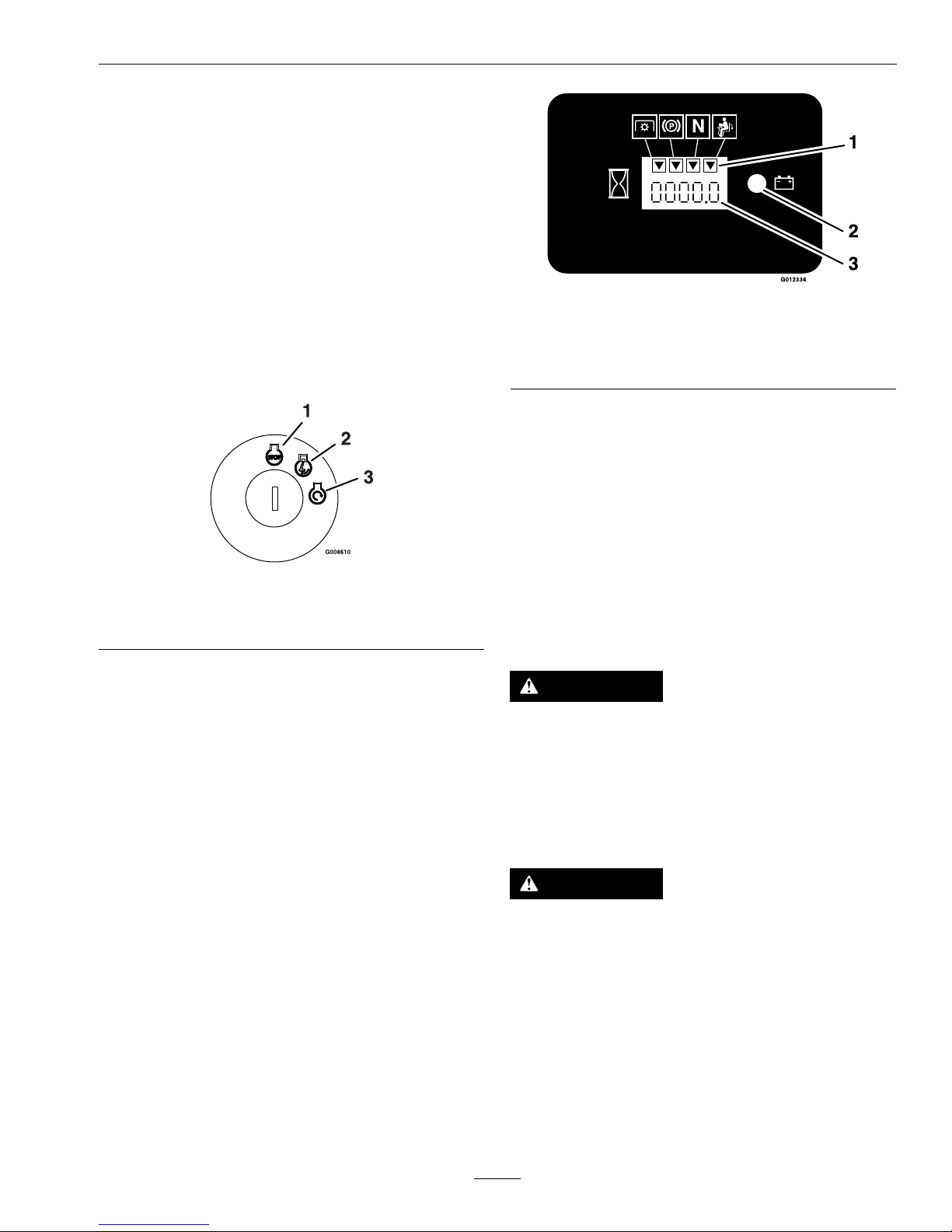

Figure7

1.Off3.Start

2.On

Note:Brakemustbeengaged,motioncontrol

leversout(neutrallockposition)andPTOswitch

disengagedtostartengine.(Itisnotnecessaryforthe

operatortobeintheseattostarttheengine.)

HourMeter

Locatedonthecontrolpanel(seeFigure6and

Figure8).

Thehourmeterrecordsthenumberofhoursthat

theenginehasrun.

Figure8

1.LCDindicators3.Hour/Voltagedisplay

2.Lowvoltageindicator

light

FuelShut-OffValve

LocatedbythelowerLHROPStubemounting.

Thefuelshut-offvalveisusedtoshutoffthefuel

whenthemachinewillnotbeusedforafewdays,

duringtransporttoandfromthejobsite,andwhen

parkedinsideabuilding.

Alignvalvehandlewiththefuellinetoopen.Rotate

90°toclose.

DriveWheelReleaseValves

WARNING

Handsmaybecomeentangledintherotating

drivecomponentsbelowtheenginedeck,which

couldresultinseriousinjuryordeath.

Stopengine,removekey,allowallthemoving

partstostopbeforeaccessingthedrivewheel

releasevalves.

WARNING

Theengineandhydraulicdriveunitscanbecome

veryhot.T ouchingahotengineorhydraulic

driveunitscancausesevereburns.

Allowtheengineandhydraulicdriveunitsto

coolcompletelybeforeaccessingthedrivewheel

releasevalves.

Locatedontheleftandrightsidesunderneaththe

enginedeck.

Duringnormaloperatingconditions,thedrivewheel

releasevalvesarepositionedinfrontoftheslots.If

25

Page 26

Operation

themachinehastobepushedbyhand,thevalves

mustbeinthe“released”position(seeFigure9).

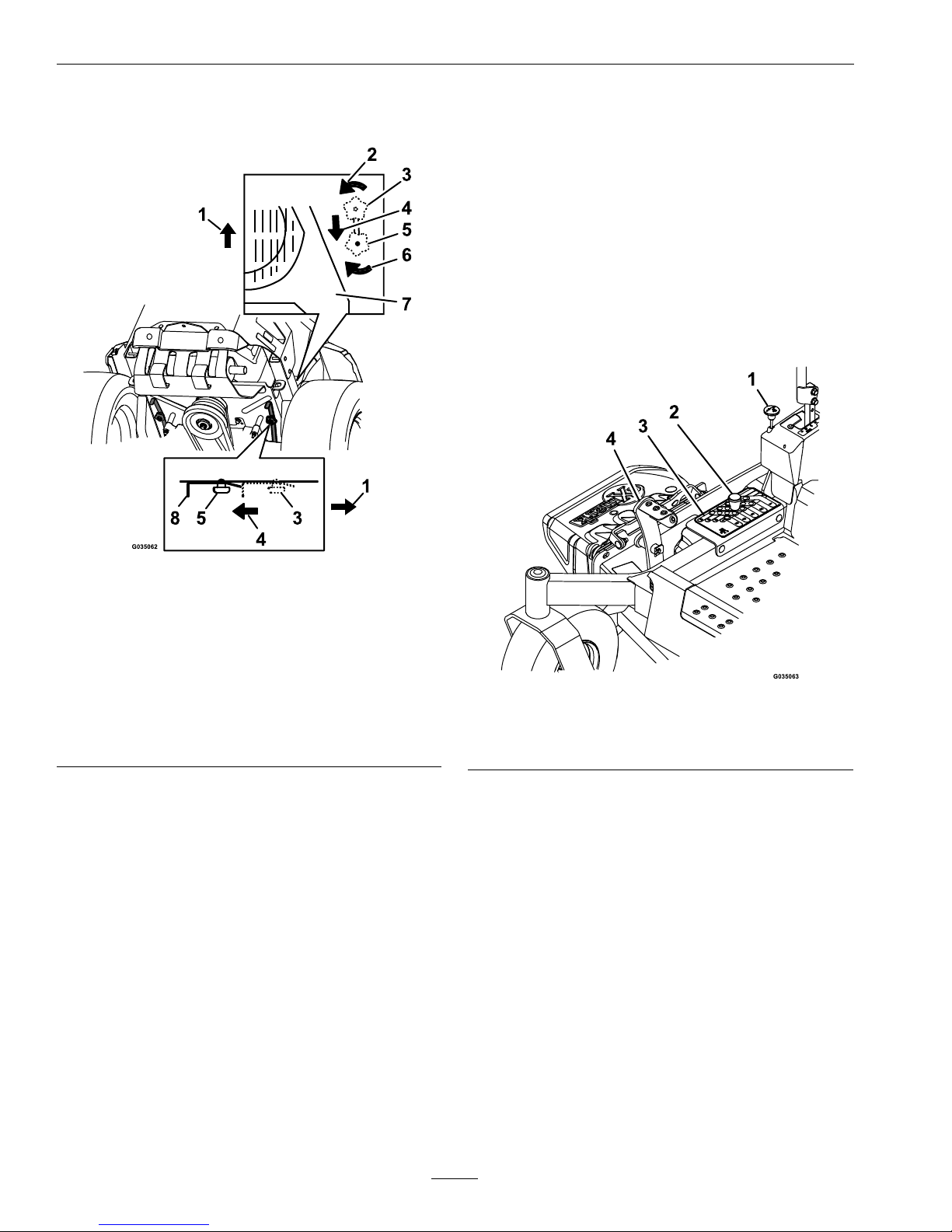

Figure9

1.Frontofthemachine

2.Rotatebypassreleaseknobcounterclockwisetoloosen

3.Leverpositionforoperatingthemachine

4.Pullleverinthisdirectiontopushthemachine

5.Leverpositionforpushingthemachine

6.Rotatebypassreleaseknobclockwisetotighten

7.Engine

8.Releaselever

Toreleasethedrivesystem(seeitem1inFigure9),

loosentheknobbyturningcounterclockwise.Then

pullthereleaseleverontheundersideofmachine

towardsthebackofthemachineandretightenthe

knobtoholdthereleaseleverbackinthereleased

state.Repeatthisoneachsideofthemachine.

Releasetheparkingbrake.Themachineisnowable

tobepushedbyhand.

Toresetthedrivesystem(seeitem2inFigure9),

loosentheknobbyturningcounterclockwise.Then

pushthereleaseleverontheundersideofmachine

towardsthefrontofthemachineandretightenthe

knobtoholdthereleaseleverintheoperatingstate.

Repeatthisoneachsideofthemachine.

DoNottowmachine.

PTOEngagementSwitch

Locatedonrightconsole(seeFigure6).

Switchmustbepulledout(up)toengagetheblades.

Switchispushedintodisengagetheblades.

DeckLiftPedal

Locatedattherightfrontcorneroftheoorpan.

Pushthepedalforwardwithyourfoottoraisethe

cuttingdeck.Allowthepedaltomoverearwardto

lowerthecuttingdecktothecutheightthathasbeen

set.

Figure10

1.Transportlockknob

3.Heightofcutdecal

2.Heightadjustmentpin

4.Deckfootpedal

TransportLock

LocatedonRHconsoleinfrontofthemotion

controllever(seeFigure10).

Thetransportlatchingmechanismwillautomatically

engagewhenthedeckisraisedtothetransport

position.Toreleasethedeckfromthetransport

position:pushthefootpedaltoremovetheload

fromthetransportlatchingmechanism,pullupon

thetransportlockknob,andletthepedalcomeback

tolowerthedeckdowntothedesiredcutheight.

Pre-Start

Fillfueltankonlevelground.SeeFuel

RecommendationsintheSpecicationssectionfor

additionalgasolineinformation.

26

Page 27

Operation

DoNotaddoiltogasoline.

DoNotoverllfueltank.Fillthefueltanktothe

bottomofthellerneck.Theemptyspaceinthe

tankallowsgasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineoremission

system.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

RaisetheRolloverProtectionSystem

(ROPS)

Important:Therollbarisanintegraland

effectivesafetydevice.Keeptherollbarinthe

raisedandlockedpositionwhenoperatingthe

mower.Lowertherollbartemporarilyonlywhen

absolutelynecessary.

1.Theknobmustbecompletelylatchedwiththe

tabsinterlockingasshowninFigure11tolock

therollbarintheraised,operateposition.

2.Applyforwardpressuretotheupperhoopofthe

rollbar.

3.Pulltheknobandrotate90°toholdinthe

unlatchedpositiontolowertherollbar.

4.Toreturntotheoperateposition,raisetheroll

bar,andthenrotateknobs90°sothatthetabs

interlockpartially.Applyforwardpressuretothe

rollbarupperhoopandobservethattheknobs

returntothecompletelylatchedposition.

Figure11

1.Rollbarupperhoop

2.Knobin“latched”position

3.Pullknobtounlatch

4.Rotate90°toholdunlatched

5.Knobin“unlatched”position

5.Makesuretheknobsarefullyengagedwiththe

rollbarintheraisedposition.Theupperhoopof

therollbarmayneedtobepushedforwardor

pulledrearwardtogetbothknobsfullyengaged

(seeFigure12).

27

Page 28

Operation

Figure12

1.Engaged2.Partiallyengaged—Do

NotoperatewithROPS

inthiscondition.

Important:Alwaysusetheseatbeltwiththe

rollbarintheoperate(raised)position.Ensure

thattherearpartoftheseatissecuredwiththe

seatlatch.

OpentheFuelShut-OffValve

Rotatethevalveandalignwiththefuellinetoopen.

StartingtheEngine

1.Movethemotioncontrolleversouttotheneutral

lockposition.

2.Pullupandbackontheparkingbrakeleverto

engagetheparkingbrake.

3.PushdownonthePTOswitchtothe“disengage”

position.

Note:Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.

4.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

5.Onacoldengine,pushthechokeleverforward

intothe“ON”position.

Onawarmengine,leavethechokeinthe“OFF”

position.

6.Turnignitionswitchtothe“START”position.

Releasetheswitchassoonastheenginestarts.

Important:DoNotcranktheengine

continuouslyformorethantensecondsata

time.Iftheenginedoesnotstart,allowa60

secondcool-downperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor.

7.Ifthechokeisinthe“ON”position,gradually

returnchoketothe“OFF”positionastheengine

warmsup.

EngagingthePTO

DANGER

Therotatingbladesunderthemowerdeckare

dangerous.Bladecontactcancauseserious

injuryorkillyou.

DoNotputhandsorfeetunderthemoweror

mowerdeckwhenthebladesareengaged.

DANGER

Anuncovereddischargeopeningwillallow

objectstobethrowninanoperator’sor

bystander’sdirection.Also,contactwiththe

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryordeath.

Neveroperatethemowerwiththedischarge

deectorraised,removed,oralteredunlessthere

isagrasscollectionsystemormulchkitinplace

andworkingproperly.

ThePTOpush-pullswitchengagesthecuttingblades.

Besurethatallpersonsareclearofthemowerdeck

anddischargeareabeforeengagingPTO.

Important:Operatormustbeinseatbeforethe

PTOcanbeengaged.

1.Setthethrottlemidwaybetweenthe“SLOW”and

“FAST”positions.

2.PullthePTOswitchoutwardtoengagetheblades.

3.Placethethrottleinthe“FAST”positiontobegin

mowing.

DisengagingthePTO

1.Setthethrottlemidwaybetweenthe“SLOW”and

“FAST”positions.

2.PushthePTOswitchintodisengagetheblades.

StoppingtheEngine

1.Bringtheunittoafullstop.

28

Page 29

Operation

2.Movethemotioncontrolleversouttotheneutral

lockposition.

3.Engagetheparkingbrake.

4.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

5.DisengagethePTO .

6.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

7.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

8.Closethefuelshut-offvalvewhenthemachine

willnotbeinuseforafewdays,when

transporting,orwhentheunitisparkedinside

abuilding.

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioningone

levertoomuchaheadoftheother.Operatormay

losecontrolofthemachine,whichmaycause

damagetothemachineorinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Important:Tobeginmovement(forwardor

backward)theoperatormustbeintheseat,the

brakelevermustbedisengaged(pusheddown)

beforethemotioncontrolleverscanbemovedin

ortheenginewillstop.

Whenthemotioncontrolleversarepositionedfully

outward(apart)intheT-slot,thedrivesystemisin

theneutrallockposition(Figure12).

Whenthemotioncontrolleversaremoveddirectly

inward(together)thedrivesystemisintheneutral

operateposition.

Figure13

1.Neutrallockposition

(handlesout)

4.Forward

2.Neutraloperateposition

(handlesin)

5.Neutral(operate)

3.FrontofUnit

6.Reverse

DrivingForward

1.Releasetheparkingbrake.

2.Movethemotioncontrolleversinwardtothe

centertotheneutralposition.

3.Tomoveforwardinastraightline,moveboth

leversforwardwithequalpressure.

29

Page 30

Operation

Figure14

Toturnleftorright,pullthemotioncontrollever

backtowardneutralinthedesiredturndirection.

Themachinewillmovefasterthefartherthe

motioncontrolleversaremovedfromtheneutral

position.

4.Tostop,positionbothmotioncontrolleversin

theneutraloperateposition.

DrivinginReverse

1.Movethemotioncontrolleversinwardtothe

neutraloperateposition.

2.Tomoverearwardinastraightline,moveboth

leversrearwardwithequalpressure.

Figure15

Toturnright,releasepressureontheRHmotion

controlleverandtherearofthemachinewill

movetowardstherearandtotheright.

Toturnleft,releasepressureontheLHmotion

controlleverandtherearofthemachinewill

movetowardstherearandtotheleft.

3.Tostop,positionbothmotioncontrolleversin

theneutraloperateposition.

AdjustingtheCuttingHeight

Thecuttingheightofthemowerdeckisadjusted

from11/2to5inches(3.8cmto12.7cm)in1/4

inch(6.4mm)increments.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO .

3.Raiseandlockthedecktothetransportposition

(Figure16).

Thedeckisraisedbypushingthefootoperated

deckliftpedalforward.Thepedalislocatedatthe

frontrightcorneroftheoorpan.

Note:Whenchangingthecuttingheight

positions,alwayscometoacompletestop

anddisengagethePTO.

Figure16

1.Transportlockknob

3.Heightofcutdecal

2.Heightadjustmentpin

4.Deckfootpedal

4.Inserttheheightadjustmentpinintothehole

correspondingtothedesiredcuttingheight.

30

Page 31

Operation

Seethedecalonthetopofthedeckliftplatefor

cutheights.

5.Pushthefootleverforward,pulluponthe

transportlockknobandletthedecklower

downtothepredeterminedcutheightbyslowly

decreasingfootpressureallowingthefootlever

totravelrearward.

AdjustingtheAnti-ScalpRollers

Itisrecommendedtochangetheanti-scalproller

position,whentheheightofcuthaschanged.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO .

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthemounting

hardware.

6.Placetherollersinoneofthepositionsshown

(Figure17).Rollerswillmaintain3/4inch(19

mm)clearancetothegroundtominimizegouging

androllerwearordamage.

Figure17

Forcuttingheightsabove3.5inches(90mm)usethe

bottomhole.Therollerswillstillbeeffectiveagainst

scalping.

1.Anti-scalproller

mountingbracket

2.Cuttingheight

ForMaximumDeckFlotation,placetherollers

oneholepositionlower.Rollersshouldmaintain

1/4inch(6.4mm)clearancetotheground.Do

Notadjusttherollerstosupportthedeck.

7.Reinstallthemountinghardware.

•SideDischargeUnits:

A.Besuretherollerboltsareinstalledwith

thespringdiscwasherbetweenthehead

oftheboltandthemountingbracket(see

Figure18).

B.Torquethe3/8nylocnutto50–55ft-lb

(68-75N-m).

Figure18

1.3/8-16X33/4inch

Grade8bolt

3.Frontrightanti-scalp

bracketshown

2.Springdiscwasher

(conetowardsbolthead)

4.3/8inchnyloc-torqueto

50-55ft-lb(68-75N-m)

31

Page 32

Operation

•RearDischargeUnits:

Torquethe3/8nylocnutto30-35ft-lb(41-47

N-m)(seeFigure19).

Figure19

1.3/8inchnyloc-torqueto

50-55ft-lb(68-75N-m)

3.Wheelspacer

2.Anti-scalprollers

4.3/8-16X73/8inchbolt

Note:Thefootoperateddeckliftassistlevercanbe

usedtomomentarilyliftthedecktoclearobjects.Be

surethatPTOisdisengaged.

AdjustingtheSideBumpers

(RearDischargeUnitsOnly)

Mountthesidebumpersinthetopholeswhen

operatinginheightofcutshigherthan21/2inches

(64mm)andinthecenterholeswhenoperatingin

heightofcutslowerthan21/2inches(64mm).

Note:Whenbumpersbecomeworn,switchthe

bumperstotheoppositesidesofthemower,ipping

themover.Thisallowsthebumperstobeusedlonger

beforereplacingthem.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO .

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Positionthetransportlockinthelatching

position.

6.Removetheboltsandnutsfromeachbumper.

Figure20

1.Bolt3.Nut

2.Bumper

7.Moveeachbumpertothedesiredpositionand

securethemwiththeboltsandnuts.

Note:Onlyusethetoporcentersetsofholesto

adjustthebumpers.Thebottomholesareused

whenswitchingsides,atwhichtimetheybecome

thetopholesontheothersideofthemower.

Transporting

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarylightingandmarkingasrequiredbylaw .

Thoroughlyreadallofthesafetyinstructions.

Knowingthisinformationcouldhelpyou,your

family,pets,orbystandersavoidinjury.

Totransportthemachine:

•Lockthebrakeandblockthewheels.

•Besurethefuelshut-offvalveisclosed.

•Securelyfastenthemachinetothetraileror

truckwithstraps,chains,cable,orropes.Only

usethefourdesignatedtie-downlocationson

themower–twoontheleftsideandtwoonthe

right(seeFigure21).Usetheselocationseven

whentransportingthemowerwithanattached

accessory.Usingnon-designatedlocationsmay

causedamagetothemowerand/orattachment.

32

Page 33

Operation

Figure21

Rightsideshown

1.Tie-downlocation

•Secureatrailertothetowingvehiclewithsafety

chains.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcan

leadtoaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetor

roadway.

LoadingtheMachine

Useextremecautionwhenloadingorunloading

machinesontoatraileroratruck.Useafull-width

rampthatiswiderthanthemachineforthis

procedure.Backuprampsanddriveforwarddown

ramps(Figure22).

g028043

Figure22

1.Backupramps

2.Driveforwarddown

ramps

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

Ensuretherampislongenoughsothattheanglewith

thegrounddoesnotexceed15degrees(Figure23).

Onatground,thisrequiresaramptobeatleastfour

times(4X)aslongastheheightofthetrailerortruck

bedtotheground.Asteeperanglemaycausemower

componentstogetcaughtastheunitmovesfromthe

ramptothetrailerortruck.Steeperanglesmayalso

causethemachinetotiporlosecontrol.Ifloadingon

ornearaslope,positionthetrailerortrucksothatit

isonthedownsideoftheslopeandtherampextends

uptheslope.Thiswillminimizetherampangle.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•EnsurethattheROPSisintheupposition

andusetheseatbeltwhenloadingor

unloadingthemachine.Ensurethatthe

ROPSwillclearthetopofanenclosedtrailer.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentheramp

andthetrailerortruck.

•Ensurethelengthoframpisatleastfour

times(4X)aslongastheheightofthetrailer

ortruckbedtotheground.Thiswillensure

thatrampangledoesnotexceed15degrees

onatground.

•Backuprampsanddriveforwarddown

ramps.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampasthis

couldcausealossofcontroloratip-over

situation.

33

Page 34

Operation

g027996

5

1

2

6

Figure23

1.Full-widthrampin

stowedposition

4.Rampisatleastfour

times(4X)aslongasthe

heightofthetraileror

truckbedtotheground

2.Sideviewoffull-width

rampinloadingposition

5.H=heightofthetraileror

truckbedtotheground

3.Notgreaterthan

15degrees

6.Trailer

34

Page 35

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecouldseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitch,engage

parkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenance.Also

pushthewire(s)asidesoitdoesnotaccidentally

contactthesparkplug(s).

WARNING

Theenginecanbecomeveryhot.Touchingahot

enginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheenginearea.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst5hours

•Changetheengineoil(Exmark708ccEngine).

•Changetheengineoil(KohlerEngine).

•Changetheengineoil(KawasakiEngine).

Aftertherst75hours

•Changethehydrauliclteranduid.

Beforeeachuseordaily

•Checktheaircleanerfordirty,looseordamagedparts.

•Checktheengineoil(Exmark708ccEngine).

•Checktheengineoil(KohlerEngine).

•Checktheengineoil(KawasakiEngine).

•Checkthemowerblades.

•Checkthesafetyinterlocksystem.

•Checktherolloverprotectionssystems(rollbar)knobs.

•Checktheseatbelt.

•Checkforloosehardware.

•Checkthehydraulicoillevelintheexpansiontank.

•Cleantheengineandexhaustsystemarea.

•Cleanthegrassanddebrisbuild-upfromthemachineandcuttingdeck.

•Cleanthegrassbuild-upfromunderthecuttingdeck.

Every25hours

•Cleantheaircleanerfoamelement(moreoftenindusty ,dirtyconditions)(Exmark708cc

engine).

•Serviceorreplacetheaircleanerprecleaner(moreoftenunderextremelydusty,dirty

conditions)(Kohlerengine).

•Greasethefrontcasteraxles(S-andE-SeriesOnly).

Every50hours

•Servicetheaircleanerpaperelement(moreoftenunderextremelydusty ,dirty

conditions)(Kohlerengine).

•Checkthetirepressures.

•Checktheconditionofthebelts.

•Greasethedeckandpumpidlerpivot.

•Checksparkarrester(ifequipped).

35

Page 36

Maintenance

MaintenanceService

Interval

MaintenanceProcedure

Every100hours

•Servicetheaircleanerpaperelement(moreoftenindusty ,dirtyconditions)(Exmark

708ccengine).

•Replacetheaircleanerfoamelement(moreoftenindusty,dirtyconditions)(Exmark

708ccengine).

•Replacetheaircleanerpaperelement(moreoftenunderextremelydusty ,dirty

conditions)(Kohlerengine).

•Changetheengineoil(changeitmoreoftenunderaheavyloadorinhigh

temperatures)(Exmark708ccEngine).

•Changetheengineoil(changeitmoreoftenunderaheavyloadorinhightemperatures)

(KohlerEngine).

•Changetheengineoil(changeitmoreoftenunderaheavyloadorinhightemperatures)

(KawasakiEngine).

•Checkthesparkplug(Exmark708ccengine).

•Checkthesparkplug(Kawasakiengine).

•Removetheengineshroudsandcleanthecoolingns.

Every200hours

•Replacetheaircleanerpaperelement(moreoftenindusty,dirtyconditions)(Exmark

708ccengine).

•Replacethesparkplug(Exmark708ccengine).

•Checkthesparkplug(Kohlerengine).

•Replacethesparkplug(Kawasakiengine).

Every250hours

•Replacetheprimaryairlter(moreoftenunderextremelydusty ,dirtyconditions)(Kawasaki

engine).

•Checkthesafetyairlter(moreoftenunderextremelydusty ,dirtyconditions)(Kawasaki

engine).

Every500hours

•Replacethesafetyairlter(moreoftenunderextremelydusty,dirtyconditions)(Kawasaki

engine).

•Replacethesparkplug(Kohlerengine).

•Replacetheemissionsairintakelter(ifapplicable).

•Changethehydrauliclteranduid(Every250hoursifusingMobil115W50)Mayneed

moreoftenundersevereconditions.

•Checktheparkbrakeadjustment.

Monthly

•Checkthebatterycharge.

Yearly

•Greasethefrontcasteraxles(X-SeriesOnly).

Important:ForKawasakiandKohlerEngines,refertotheEngineOwner’sManualforadditional

maintenanceprocedures.

PeriodicMaintenance

EngineMaintenance

Important:Ifyouareusingamachinewith

anExmarkengineabove5,000ft(1500m)fora

continuousperiod,ensurethattheHighAltitude

Kithasbeeninstalledsothattheenginemeets

CARB/EPAemissionregulations.TheHigh

AltitudeKitincreasesengineperformancewhile

preventingsparkfouling,hardstarting,and

increasedemissions.Onceyouhaveinstalled

thekit,attachthehigh-altitudelabelnextto

theserialdecalonthemachine(reference

Figure1).ContactanAuthorizedServiceDealer

toobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocatea

dealerconvenienttoyou,accessourwebsiteat

http://www.Exmark.comorcontactourExmark

CustomerCareDepartmentatthenumber(s)

listedinyourEmissionControlWarranty

Statement.Removethekitfromtheengine

andrestoretheenginetoitsoriginalfactory

congurationwhenrunningtheengineunder

5,000ft(1500m).DoNotoperateanengine

thathasbeenconvertedforhigh-altitudeuseat

aloweraltitudes;otherwise,youcouldoverheat

anddamagetheengine.Ifyouareunsure

36

Page 37

Maintenance

whetherornotyourmachinehasbeenconverted

forhighaltitudeuse,lookforthefollowinglabel:

Figure24

HighAltitudeLabel

1.Note:Theengineonthisproducthasbeenmodiedfor

useatabove5,000feetelevation.Ifusingbelow5,000

feet,itmustberevisedbacktooriginalspecications.

ServicingtheAirCleaner–Exmark

708ccEngine

ServiceInterval:Every100hours/Yearly

(whichevercomes

rst)—Servicetheair

cleanerpaperelement

(moreoftenindusty,dirty

conditions)(Exmark708cc

engine).

Every200hours/Every2

years(whichevercomes

rst)—Replacetheair

cleanerpaperelement

(moreoftenindusty,dirty

conditions)(Exmark708cc

engine).

Every25hours/Monthly

(whichevercomes

rst)—Cleantheair

cleanerfoamelement

(moreoftenindusty,dirty

conditions)(Exmark708cc

engine).

Every100hours/Yearly

(whichevercomes

rst)—Replacetheair

cleanerfoamelement

(moreoftenindusty,dirty

conditions)(Exmark708cc

engine).

Checktheaircleanerdailyorbeforestartingthe

engine.Checkforabuildupofdirtanddebrisaround

theaircleanersystem.Keepthisareaclean.Also

checkforlooseordamagedcomponents.Replaceall

bentordamagedaircleanercomponents.

Note:Operatingtheenginewithlooseordamaged

aircleanercomponentscouldallowunlteredairinto

theenginecausingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty ,dirtyconditions.

RemovingtheElements:

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,movethemotioncontrol

leverstothebrakeposition,stoptheengine,

removethekey ,andwaituntilallmovingparts

stopbeforeleavingtheoperatingposition.

2.Cleanaroundtheaircleanercovertopreventdirt

fromgettingintotheengineandcausingdamage.

3.Liftthecoverandrotatetheair-cleanerassembly

outoftheengine(seeFigure25andFigure26).

g027800

Figure25

g027801

Figure26

4.Separatethefoamandpaperelements.

37

Page 38

Maintenance

g027802

Figure27

CleaningtheFoamandPaperElements:

FoamElement:

Washthefoamelementwithwater.

Important:Replacethefoamelementifitis

tornorworn.

PaperElement:

1.Lightlytaptheelementonaatsurfacetoremove

dustanddirt.

2.Inspecttheelementfortears,anoilylm,and

damagetotheseal.

Important:Donotcleanthepaperelement

withpressurizedairorliquids,suchas

solvent,gas,orkerosene.Replacethepaper

elementifitisdamagedorcannotbecleaned

thoroughly.

TolearnmoreabouttheExmarktwin-cylinderengine

gotohttp://exmark.com/enginesorscantheQR

code.

Figure28

708ccEngine

ServicingtheAirCleaner–Kohler

Engine

ServiceInterval:Beforeeachuseor

daily—Checktheair

cleanerfordirty,looseor

damagedparts.

Every25hours—Service

orreplacetheaircleaner

precleaner(moreoften

underextremelydusty,

dirtyconditions)(Kohler

engine).

Every50hours—Service

theaircleanerpaper

element(moreoften

underextremelydusty,

dirtyconditions)(Kohler

engine).

Every100hours—Replace

theaircleanerpaper

element(moreoften

underextremelydusty,

dirtyconditions)(Kohler

engine).

Thisengineisequippedwithareplaceable,high

densitypaperaircleanerelement.Checktheair

cleanerdailyorbeforestartingtheengine.Checkfor

abuildupofdirtanddebrisaroundtheaircleaner

system.Keepthisareaclean.Also,checkforlooseor

damagedcomponents.Replaceallbentordamaged

aircleanercomponents.

Note:Operatingtheenginewithlooseordamaged

aircleanercomponentscouldallowunlteredairinto

theengine,causingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty ,dirtyconditions.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,movethemotioncontrol

leverstothebrakeposition,stoptheengine,

removethekey ,andwaituntilallmovingparts

stopbeforeleavingtheoperatingposition.

2.Removethecovertoaccesstheaircleaner

element(seeFigure29).

38

Page 39

Maintenance

Figure29

1.Cover

3.Paperelement

2.Aircleanerbase4.Precleaner

3.Removetheprecleanerandpaperelement.

4.Removetheelement,andgentlytaptheelement

todislodgedirt.

Note:DoNotwashthepaperelementoruse

pressurizedair,asthiswilldamagetheelement.

Note:Replaceadirty,bent,ordamagedelement.

Handlethenewelementcarefully;donotuseif

thesealingsurfacesarebentordamaged.

5.Washtheprecleanerinwarmwaterwithdetergent,

rinse,andairdry.

6.Lightlyoiltheprecleanerwithnewengineoiland

squeezeoutexcessoil.

7.Cleantheaircleanerbaseasrequired,andcheck

thecondition.

8.Installtheprecleaneroverthepaperelement.

9.Installtheprecleanerandpaperelementontothe

aircleanerbase.

10.Installthecover,andsecureitwiththelatches.

ServicingtheAirCleaner–Kawasaki

Engine

ServiceInterval:Every250hours—Replace

theprimaryairlter

(moreoftenunder

extremelydusty,dirty

conditions)(Kawasaki

engine).

Every250hours—Check

thesafetyairlter

(moreoftenunder

extremelydusty ,dirty

conditions)(Kawasaki

engine).

Every500hours—Replace

thesafetyairlter

(moreoftenunder

extremelydusty ,dirty

conditions)(Kawasaki

engine).

Note:Servicetheaircleanermoreoftenunder

extremelydusty ,dirtyconditions.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,movethemotioncontrol

leverstothebrakeposition,stoptheengine,

removethekey ,andwaituntilallmovingparts

stopbeforeleavingtheoperatingposition.

2.Releasethelatchesontheaircleanerandpull

theaircleanercoverofftheair-cleanerbody(see

Figure30).

Figure30

1.Aircleanerbody4.Aircleanercover

2.Primarylter5.Safetylter

3.Latch

3.Cleantheinsideoftheaircleanercoverwith

compressedair.

4.Gentlyslidetheprimarylteroutofthe

air-cleanerbody .

Note:Avoidknockingthelterintothesideof

thebody.

39

Page 40

Maintenance

5.Removethesafetylteronlyifyouintendto

replaceit.

Important:Donotattempttocleanthe

safetylter.Ifthesafetylterisdirty,then

theprimarylterisdamaged.Replaceboth

lters.

6.Inspecttheprimarylterfordamagebylooking

intothelterwhileshiningabrightlightonthe

outsideofthelter.

Note:Holesinthelterappearasbrightspots.

Ifthelterisdamaged,discardit.

ServicingthePrimary

Filter–KawasakiEngine

•Iftheprimarylterisdirty,bent,ordamaged,

replaceit.

•Donotcleantheprimarylter.

ServicingtheSafetyFilter–Kawasaki

Engine

Replacethesafetylter,nevercleanit.

Important:Donotattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamaged.Replacebothlters.

InstallingtheFilters–Kawasaki

Engine

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandthe

coverinstalled.

1.Ifinstallingnewlters,checkeachlterfor

shippingdamage.

Note:Donotuseadamagedlter.

2.Ifyouarereplacingthesafetylter,carefullyslide

itintothelterbody(seeFigure30).

3.Carefullyslidetheprimarylteroverthesafety

lter.

Note:Ensurethattheprimarylterisfully

seatedbypushingonitsouterrimwhileinstalling

it.

Important:Donotpressonthesoftinside

areaofthelter.

4.Installtheaircleanercoverwiththesideindicated

asupfacingupwardandsecurethelatches.

ServicingtheEngineOil

CheckingtheEngineOil

Level–Exmark708ccEngine

ServiceInterval:Beforeeachuseordaily

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagemayresult.

1.Parkthemachineonalevelsurface,disengage

thebladecontrolswitch,stoptheengine,engage

parkingbrake,andremovethekey.

2.Makesuretheengineisstopped,level,andiscool

sotheoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outof

theengine,cleantheareaaroundtheoilll

cap/dipstickbeforeremovingit.

4.Checktheengineoillevel.

40

Page 41

Maintenance

B

A

C

D

E

G029368

F

G H

I J K

Figure31

5.Ifthelevelislow ,wipeofftheareaaroundtheoil

llcap,removecap/dipstickandaddoiltothe

“FULL”markonthedipstick.Exmark4-Cycle

PremiumEngineOilisrecommended;referto

thefollowinginformationforanappropriateAPI

ratingandviscosity.Alwayscheckthelevelwith

thedipstickbeforeaddingmoreoil.DoNot

overll.

•CrankcaseCapacity:2.4L(2.5qt)

•RecommendedOilType:Exmark4-Cycle

PremiumEngineOil

–APIserviceSF ,SG,SH,SJ,orSL

SAE 5W -30, 10W -30

SAE 30

SYNTHETIC 5W -20, 5W -30, 10W -30

g029683

Figure32

Viscositytable