Page 1

QUEST®

ForSerialNos.

720,000&Higher

PartNo.4500-338Rev.A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,or

otherreproductiveharm.

Important:Thisengineisnotequippedwith

asparkarrestermufer.Itisaviolationof

CaliforniaPublicResourceCodeSection4442to

useoroperatetheengineonanyforest-covered,

brush-covered,orgrass-coveredland.Other

statesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002,ISO14982,EN55012.

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingtheUS

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenance,andwarranty.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1940.

Asconguredtomeetsafety ,emission,andoperating

requirements,theactualenginehorsepoweronthis

classoflawnmowerwillbesignicantlylower.

©2007–2008—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Introduction

Readthisinformationcarefullytolearnhowto

operateandmaintainyourproductproperlyandto

avoidinjuryandproductdamage.Youareresponsible

foroperatingtheproductproperlyandsafely .

YoumaycontactExmarkdirectlyat

www.Exmark.comforproductandaccessory

informationorhelpndingadealer.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Figure1

Behindtheseat

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.......................8

Specications.......................................................13

ModelNumbers............................................13

Systems.........................................................13

Dimensions...................................................14

TorqueRequirements....................................15

ProductOverview................................................15

Operation.............................................................16

Controls........................................................16

OperatingInstructions..................................17

RecommendedGasoline................................18

CheckingtheEngineOilLevel.......................19

StartingtheEngine........................................19

OperatingtheBlades.....................................20

StoppingtheEngine......................................21

TheSafetyInterlockSystem...........................21

DrivingForwardorBackward........................22

StoppingtheMachine....................................23

TrackingAdjustment.....................................23

AdjustingtheHeightofCut...........................23

AdjustingtheAnti-ScalpRollers.....................24

PositioningtheSeat.......................................24

ChangingtheSeatRideSuspension................24

AdjustingtheMotionControlLevers.............25

PushingtheMachinebyHand........................25

SideDischarge...............................................26

Transporting.................................................26

OperatingTips.............................................27

Maintenance.........................................................29

RecommendedMaintenanceSchedule(s)...........29

PremaintenanceProcedures..............................30

RaisingtheSeat.............................................30

AccessingtheBattery....................................30

PeriodicMaintenance.......................................30

Lubrication....................................................30

EngineMaintenance......................................31

ServicingtheEngineOil................................32

CheckingtheHydraulicOilLevel...................34

ChangetheHydraulicSystemFilter................34

ServicingtheSparkPlug................................35

CleaningtheBlowerHousing.........................35

FuelSystemMaintenance..............................36

ElectricalSystemMaintenance.......................36

ChargingtheBattery......................................37

ServicingtheFusesandRelay.........................38

DriveSystemMaintenance............................39

CheckingtheTirePressure............................39

MowerMaintenance......................................39

ServicingtheCuttingBlades..........................39

MowerBeltMaintenance...............................41

LevelingtheMowerDeck..............................42

AdjustingtheBladeSlope..............................42

RemovingtheMowerDeck...........................44

InstallingtheMowerDeck.............................44

ReplacingtheDischargeDeector.................45

Cleaning...........................................................46

WashingtheUndersideoftheMower.............46

Storage.................................................................47

CleaningandStorage.....................................47

Troubleshooting...................................................48

Schematics...........................................................50

4

Page 5

Safety

Safety

SafetyAlertSymbol

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

Thismachinemeetsorexceedsthesafety

specicationsoftheAmericanNational

StandardsInstituteB71.1-2003ineffectatthe

timeofproduction.However,improperuse

ormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialfor

injury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,

orDANGER-"personalsafetyinstruction."

Failuretocomplywiththeinstructionmayresult

inpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.1-2003.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

•Allowonlyresponsibleadultswhoarefamiliar

withtheinstructionstooperatethemachine.

•Cleartheareaofobjectssuchasrocks,toys,wire,

etc.,whichcouldbepickedupandthrownbythe

blade.

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthe

area.

•Nevercarrypassengers.

•DoNotmowinreverseunlessabsolutely

necessary.Alwayslookdownandbehindbefore

andwhilebackingup.

•Beawareofthemowerdischargedirectionand

DoNotpointitatanyone.Avoiddischarging

materialagainstawallorobstruction.Material

mayricochetbacktowardtheoperator.Stopthe

bladeswhencrossinggravelsurfaces.

•DoNotoperatethemowerwithouteitherthe

entiregrasscollectionsystemorthedischarge

deectorinplace.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

•Neverleavearunningmachineunattended.

Alwaysturnoffblades,engageparkingbrake,

stopengine,andremovekeybeforedismounting.

•Turnoffbladeswhennotmowing.Stopthe

engine,waitforallpartstocometoacomplete

stop,engageparkingbrake,andremovekey

beforecleaningthemachine,removingthegrass

oruncloggingthedeector.

•Operatethemachineonlyindaylightorgood

articiallight.

•DoNotoperatethemachinewhileunderthe

inuenceofalcoholordrugs.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

GeneralOperation

•Read,understand,andfollowallinstructionsin

theoperator’ smanualandonthemachinebefore

starting.

•DoNotplacehandsorfeetnearrotatingpartsor

underthemachine.Keepclearofthedischarge

openingatalltimes.

•Useextracarewhenloadingorunloadingthe

machineintoatrailerortruck

•Alwaysweareyeprotectionwhenoperatingthe

mower.

•Dataindicatesthatoperators,age60yearsand

above,areinvolvedinalargepercentageofriding

mower-relatedinjuries.Theseoperatorsshould

evaluatetheirabilitytooperatetheridingmower

5

Page 6

Safety

safelyenoughtoprotectthemselvesandothers

fromseriousinjury.

•Alwaysfollowtherecommendationsforwheel

weightsorcounterweights.

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operationonallslopesrequiresextra

caution.Ifyoucannotbackuptheslopeorifyou

feeluneasyonit,DoNotmowit.

•DoNotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Choosealowgroundspeedsoyouwillnothave

tostopwhileoperatingonaslope.

•DoNotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Reducespeedanduseextremecautiononslopes.

•DoNotmakesuddenturnsorrapidspeed

changes.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheels

maycausedrivewheelstoslipandcauselossof

brakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Useextremecarewithgrasscollectionsystemsor

otherattachments.Thesecanchangethestability

ofthemachineandcauselossofcontrol.

•DoNottrytostabilizethemachinebyputting

yourfootontheground.

Children

Tragicaccidentscanoccuriftheoperatorisnot

alerttothepresenceofchildren.Childrenareoften

attractedtothemachineandthemowingactivity.

Neverassumethatchildrenwillremainwhereyou

lastsawthem.

•Keepchildrenoutofthemowingareaandunder

thewatchfulcareofanotherresponsibleadult,

nottheoperator.

•Bealertandturnthemachineoffifchildrenenter

thearea.

•Beforeandwhilebackingorchangingdirection,

lookbehind,down,andside-to-sideforsmall

children.

•Nevercarrychildren,evenwiththebladesoff.

Theymayfalloffandbeseriouslyinjuredor

interferewithsafemachineoperation.

•Childrenwhohavebeengivenridesinthepast

maysuddenlyappearinthemowingareafor

anotherrideandberunoverorbackedoverby

themower.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,

shrubs,trees,theendofafenceorotherobjects

thatmayobscurevision.

Towing

•UsefortowingonlyifequippedwithanExmark

hitchkit.DoNotattachtowedequipmentexcept

atthehitchpoint.

•FollowExmark’srecommendationforweight

limitsfortowedequipmentandtowingonslopes.

Thisinformationcanbefoundinthehitchkit

instructionsheetandonthedecal.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipment

maycauselossoftractionandlossofcontrol.

•Travelslowlyandallowextradistancetostop.

•DoNotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

Service

SafeHandlingofGasoline

Toavoidpersonalinjuryorpropertydamage,use

extracarewhenhandlinggasolineandotherfuels.

Theyareammableandthevaporsareexplosive.

6

Page 7

Safety

•Extinguishallcigarettes,cigars,pipesandother

sourcesofignition.

•Useonlyanapprovedcontainer.

•Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Neverllcontainersinsideavehicleorona

truckortrailerwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removegas-poweredequipmentfromthetruck

ortrailerandrefuelitontheground.Ifthisis

notpossible,thenrefuelsuchequipmentwitha

portablecontainer,ratherthanfromagasoline

dispensernozzle.

•Keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

thefuelingiscomplete.DoNotuseanozzle

lock-opendevice.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Neveroverllthefueltank.Replacegascapand

tightensecurely.

GeneralService:

•Neverrunamachineinsideaclosedarea.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Keepthemachinefreeofgrass,leaves,orother

debrisbuild-up.Cleanupoilorfuelspillageand

fuelsoakeddebris.Allowthemachinetocool

beforestoring.

•Stopandinspecttheequipmentifyoustrikean

object.Repair,ifnecessary,beforerestarting.

•Nevermakeanyadjustmentsorrepairswiththe

enginerunning.

•Grasscollectionsystemcomponentsaresubject

towear,damageanddeterioration,whichcould

exposemovingpartsorallowobjectstobe

thrown.Frequentlycheckcomponentsand

replacewithmanufacturers’recommendedparts,

whennecessary.

•Mowerbladesaresharpandcancut.Wrapthe

bladesorweargloves,anduseextracautionwhen

servicingthem.

•Checkforproperbrakeoperationfrequently .

Adjustandserviceasrequired.

•Maintainorreplacesafetyandinstructiondecals

asnecessary.

•UseonlygenuineExmarkreplacementpartsto

ensurethatoriginalstandardsaremaintained.

ExmarkRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toExmarkproductsorothersafetyinformationthat

youmustknowthatisnotincludedintheANSI

standards.

•Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.Do

Notrunengineindoorsorinanenclosedarea.

•Stoptheengine,waitforallmovingpartstostop,

engageparkingbrake,disconnectsparkplug

wire(s)andremovekeybeforeperformingany

service,repairs,maintenanceoradjustments.

•Keephands,feet,hair,andlooseclothingaway

fromattachmentdischargearea,undersideof

mowerandanymovingpartswhileengineis

running.

•DoNottouchequipmentorattachmentparts

whichmaybehotfromoperation.Allowtocool

beforeattemptingtomaintain,adjustorservice.

•Batteryacidispoisonousandcancauseburns.

Avoidcontactwithskin,eyes,andclothing.

Protectyourface,eyes,andclothingwhen

workingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfrombattery.

•UseonlyExmarkapprovedattachments.

Warrantymaybevoidedifusedwithunapproved

attachments.

•Ifloadingthemachineontoatrailerortruck,use

asingle,full-widthramponly .Therampangle

shouldnotexceed15degrees.

Note:Theleftandrightsidesofthemachineare

determinedwhilesittingintheseatinthenormal

operatingposition

7

Page 8

Safety

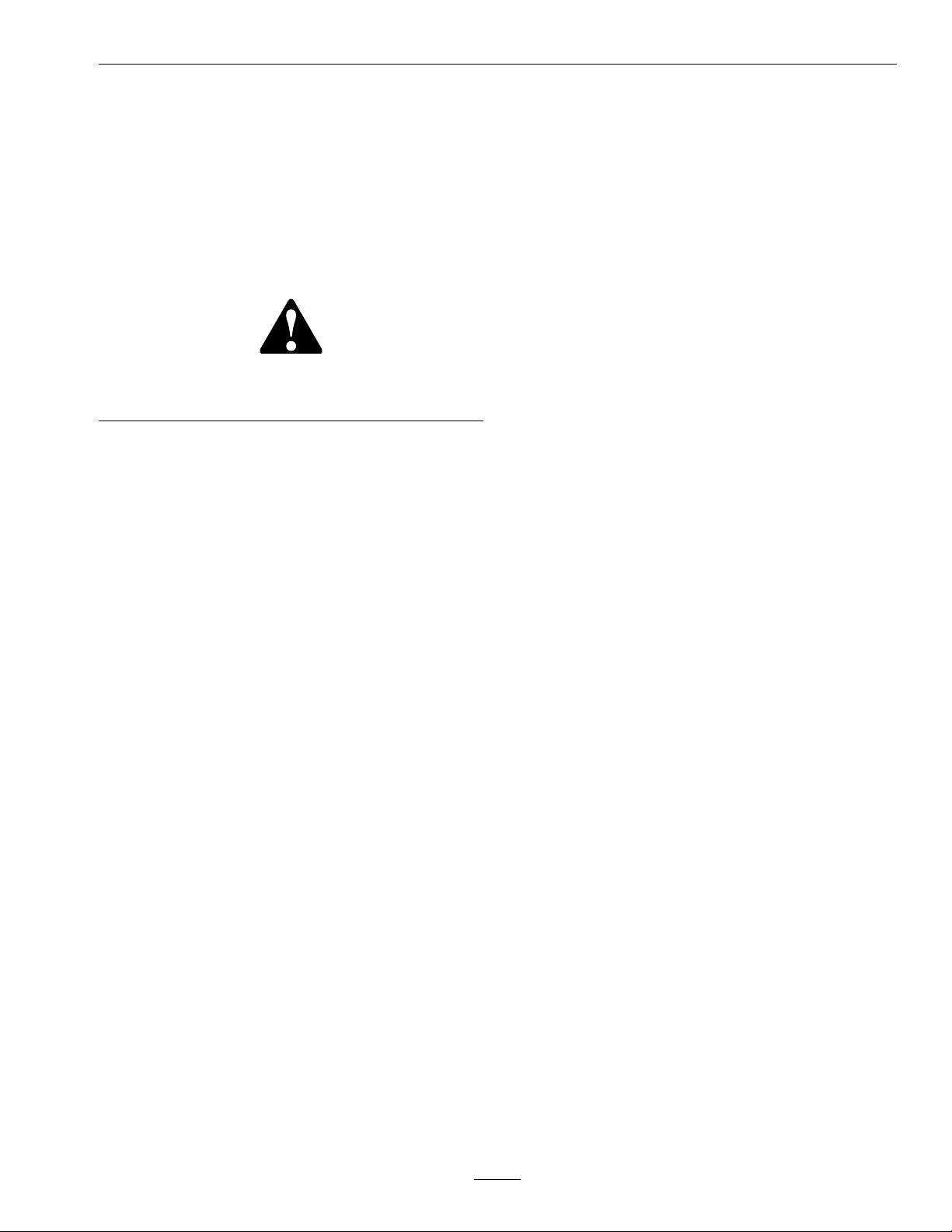

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

93-7009

1.Warning–DoNotoperate

themowerwiththe

dischargedeectorup

orremoved;keepthe

dischargedeectorin

place.

2.Cutting/dismemberment

hazardofhandorfoot,

mowerblade–stayaway

frommovingparts.

109-6014

TractionDriveBeltRouting

106-5517

1.Warning–DoNottouchthehotsurface.

109-6008

1.ReadtheOperator’s

Manual.

2.Rotatethedriverelease

knobtoloosen,slidethe

knob,andtighten.

3.Pushthemachine.

1.Engine–stop

2.Engine–run

3.Engine–start8.Throttle–slow

4.Powertake-off(PTO),

Bladecontrolswitch

5.ReadtheOperator’s

Manual.

109-6029

6.Throttle–fast

7.Choke–on

9.Choke–off

8

Page 9

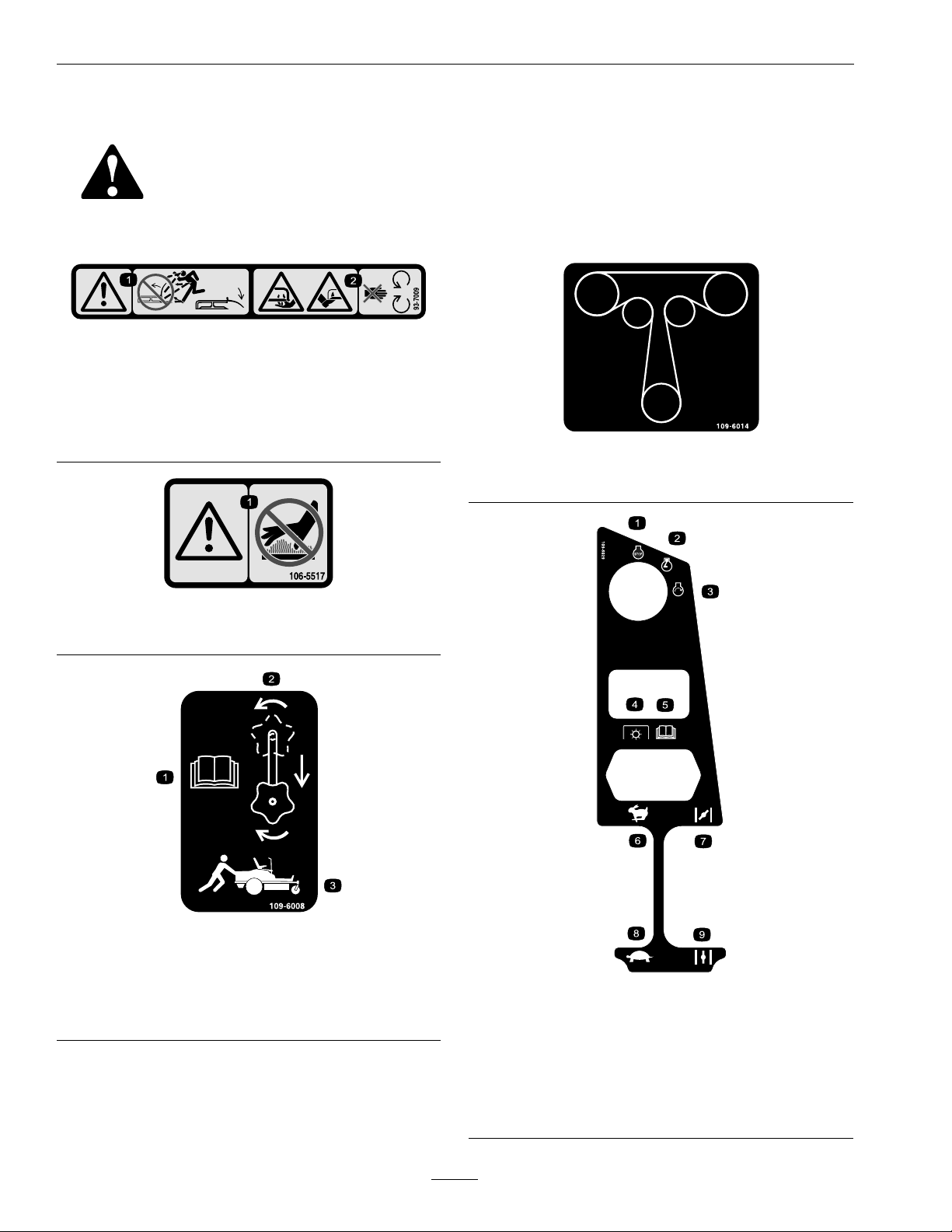

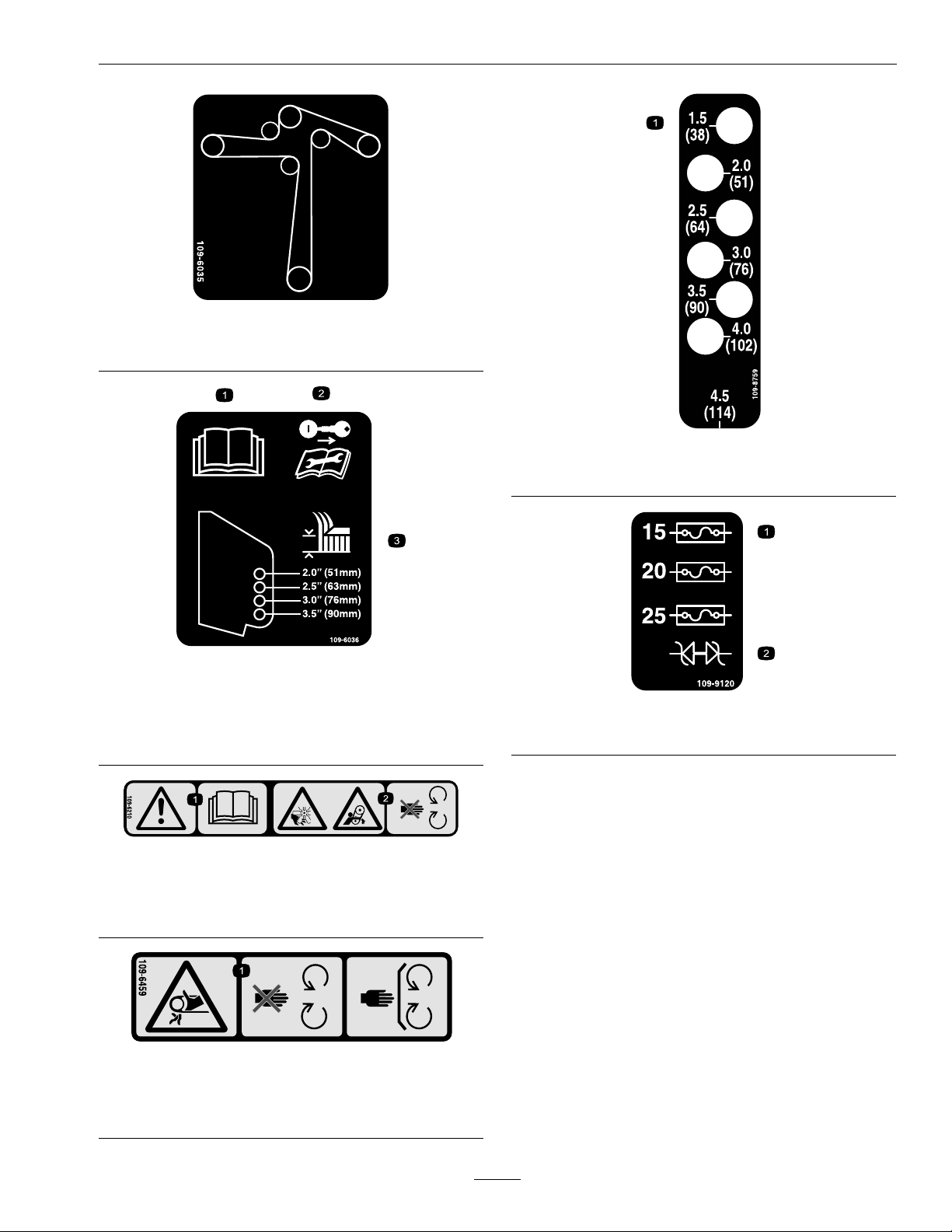

DeckDriveBeltRouting

Safety

109-6035

109-8759

1.Heightofcut

109-6036

1.ReadtheOperator’sManual.

2.Removetheignitionkeyandreadtheinstructionsbefore

servicingorperformingmaintenance.

3.Heightofcut.

109-6210

1.ReadtheOperator’sManual.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt–stayawayfrommovingparts.

109-6459

1.Entanglementhazard,belt—DoNotopenorremove

safetyshieldswhileengineisrunning,keepshieldsin

place.

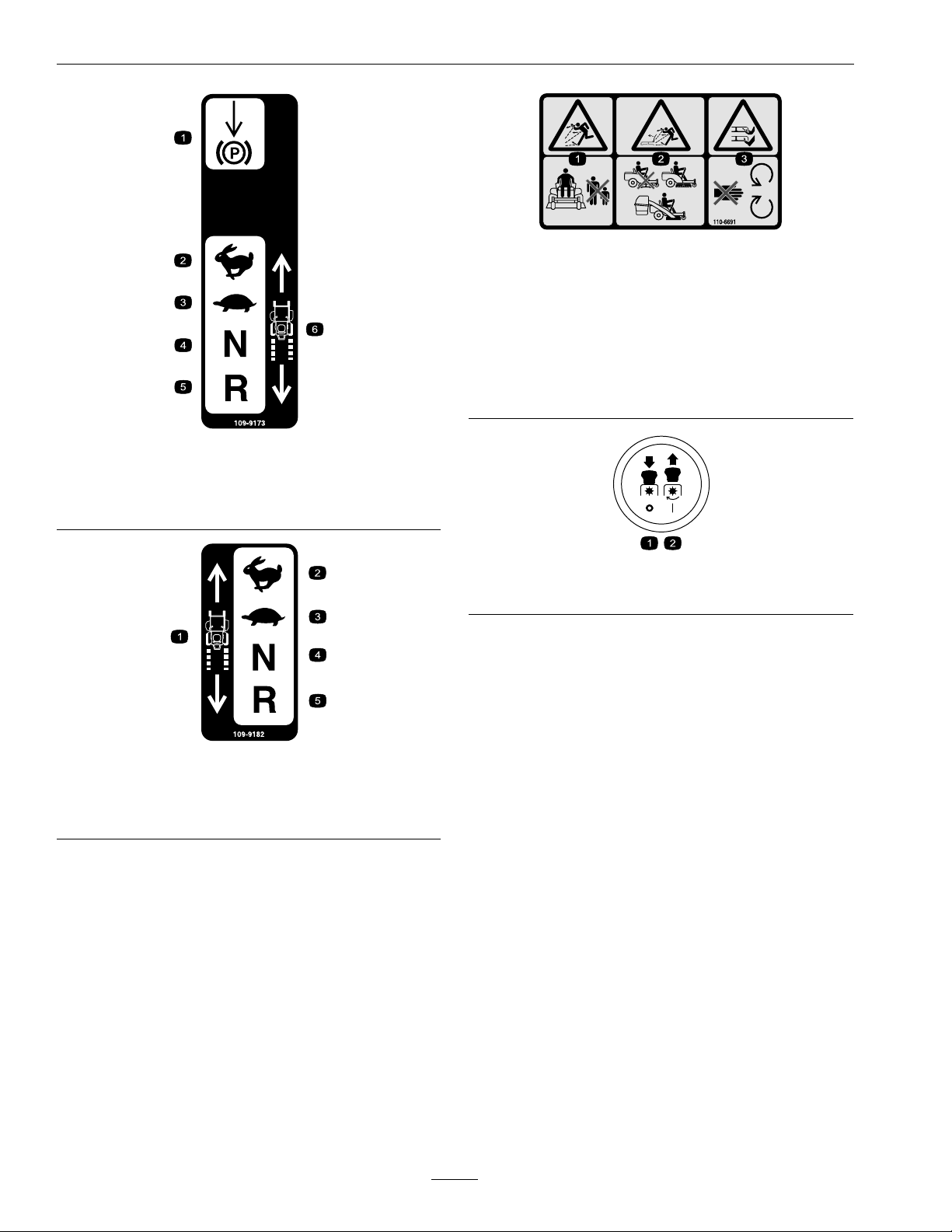

109-9120

1.Fuse2.Diode

9

Page 10

Safety

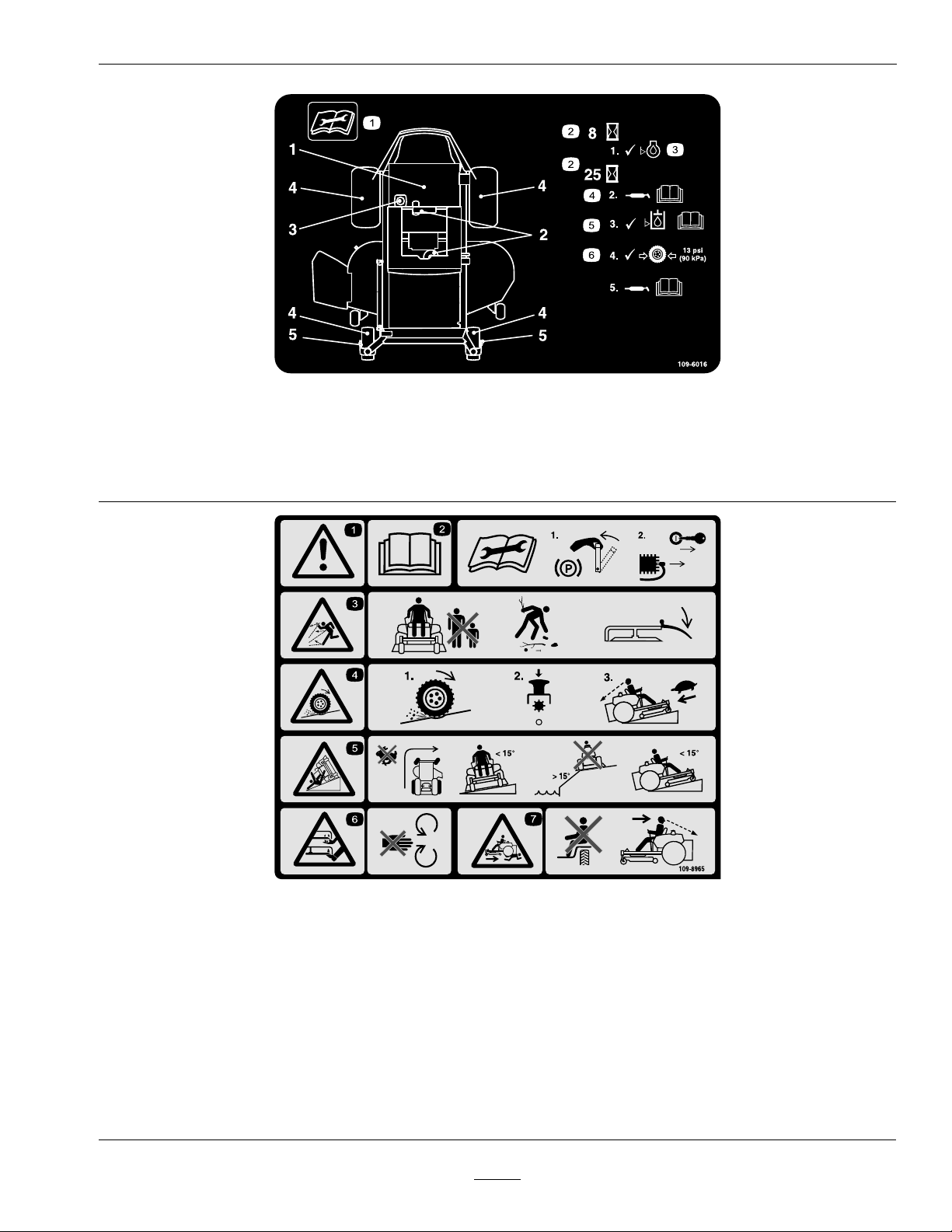

109-9173

1.Parkingbrake4.Neutral

2.Fast5.Reverse

3.Slow6.MachineSpeed

1.Thrownobjects

hazard–keepbystanders

asafedistancefromthe

machine.

2.Thrownobjectshazard,

mower–keepthe

dischargedeector

orcollectionsystemin

place.

110-6691

3.Cutting/dismemberment

ofhandorfoot–stay

awayfrommovingparts.

109-9182

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

PTOSymbols

1.PTO—Off2.PTO—On

10

Page 11

109-6016

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Timeinterval

3.Checkoillevel.6.Checktirepressure.

4.RefertotheOperator’smanualforgreaseinstructions.

5.CheckhydraulicoillevelandrefertotheOperator’s

Safety

Manualforfurtherinstructions.

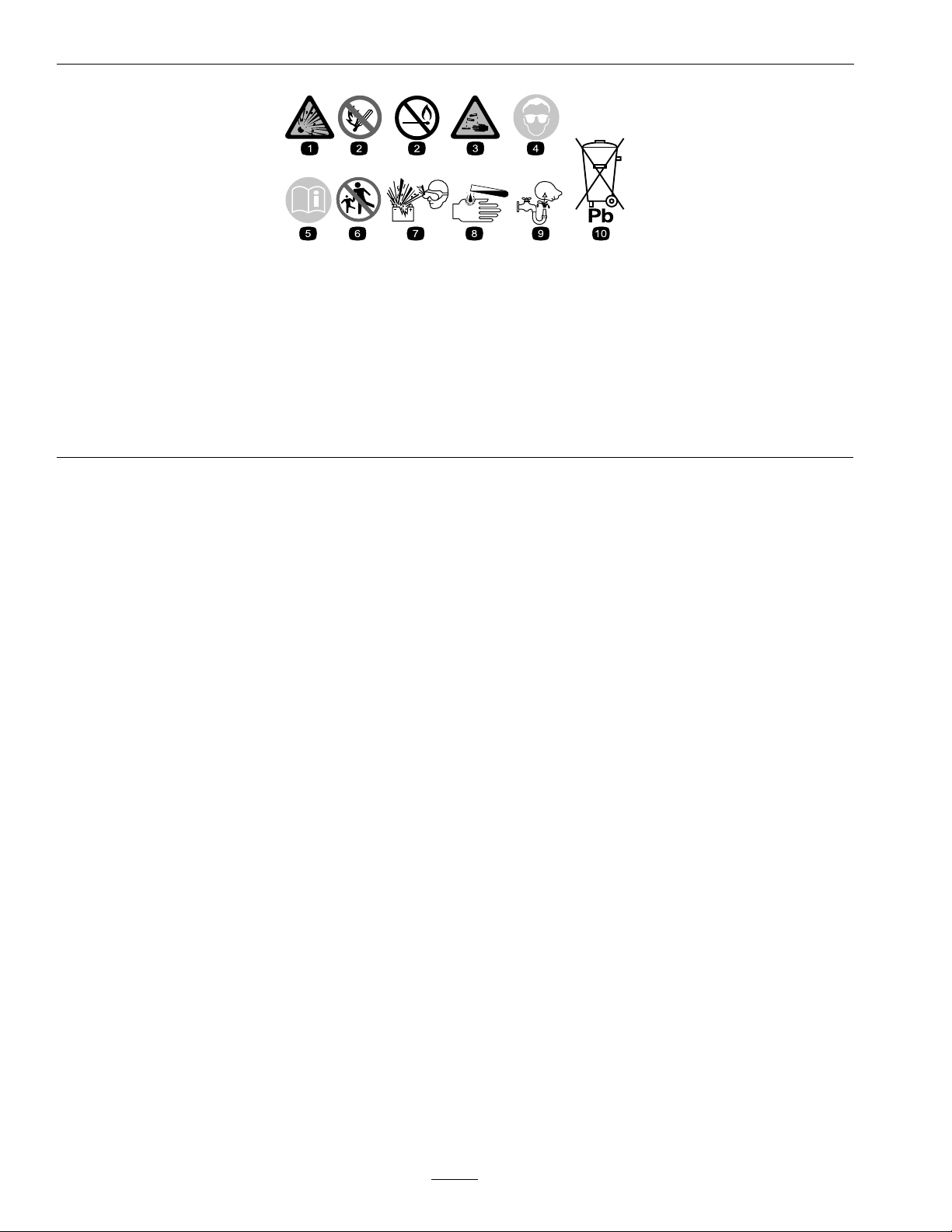

1.Warning–readtheOperator’sManual.

2.Readtheinstructionsbeforeservicingorperforming

maintenance;applyparkingbrake,removetheignitionkey

anddisconnectthesparkplugwire.

3.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine,pickupdebrisbeforeoperating,keep

thedischargedeectorinplace.

4.Lossoftraction/controlhazard,slopes–lossof

traction/controlonslope,disengagethebladecontrol

switch(PTO),proceedofftheslopeslowly.

109-8965

5.Tippinghazard–avoidsuddenandsharpturnswhileon

slopes,onlymowacrossslopeslessthan15degrees,

keepasafedistancefromwater ,andonlymowupand

downslopeslessthan15degrees.

6.Cutting/dismembermenthazardofhandorfoot,mower

blade–stayawayfrommovingparts.

7.Crushing/dismembermenthazardofbystanders,

reversing–DoNotcarrypassengers,lookbehindand

downwhenreversing.

11

Page 12

Safety

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

1.Explosionhazard

2.Nore,openames,orsmoking6.Keepbystandersasafedistance

3.Causticliquid/chemicalburnhazard

4.Weareyeprotection8.Batteryacidcancauseblindnessor

5.ReadtheOperator’sManual.

fromthebattery.

7.Weareyeprotection;explosive

gasescancauseblindnessand

otherinjuries.

severeburns.

9.Flusheyesimmediatelywithwater

andgetmedicalhelpfast.

10.Containslead;donotdiscard.

12

Page 13

Specications

ModelNumbers

SerialNos:720,000andHigher

QST22BE482;QST23KC482;QST23KC522;QST24BE522

Specications

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•RPM:

Briggs&Stratton:FullSpeed:3650±100(max)

RPM(NoLoad)Idle:1650(min)RPM

KohlerCommand:FullSpeed:3600±75(max)

RPM(NoLoad)Idle:1750(min)RPM

FuelSystem

•Capacity:4.0gal.(15.1L)

•TypeofFuel:Regularunleadedgasoline,87

octaneorhigher.

•FuelFilter:

Briggs&Stratton:Briggs&StrattonP/N695666

KohlerCommand:KohlerP/N2405010

•FuelShut-OffValve:1/4turnincrements(“ON”,

“OFF”)

engine.(Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.)

•OperatormustbeinseatwhenPTOisengaged,

brakeisdisengaged,ormotioncontrolleversare

movedinorenginewillstop.

•Enginewillstopifeithertheleft,theright,or

bothleversaremovedfromneutrallockposition

whilebrakeisengaged.

OperatorControls

•SteeringandMotionControl:

Note:Motioncontrolleversareadjustableto

twoheights.

–Separatelevers,oneachsideoftheconsole,

controlspeedanddirectionoftravelofthe

respectivedrivewheels.

–Steeringiscontrolledbyvaryingtheposition

oftheleversrelativetoeachother.

–Movingmotioncontrolleversoutward(in

slots)locksthedrivesysteminneutral.

ElectricalSystem

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:

Briggs&Stratton:16amps

KohlerCommand:15amps

•BatteryType:BCIGroupU1

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuses:One25amp,one20amp;one15amp

bladetype

•Diode:TVS

SafetyInterlockSystem

•PTOmustbedisengaged,brakeengaged,and

motioncontrolleversout(neutrallock)tostart

•PTOEngagementSwitch:Engageselectricclutch

(todrivebelt)whichengagesmowerblades.

•ParkingBrakeLever:Engagesparkingbrake.

•DeckHeightAdjustmentPin:Setscuttingheight

todesiredposition.

•DeckLiftAssistLever:Footpedalthatassists

inraisingthedeck.

Seat

•Type:Standardseatwithhighback,foampadded

withspringsuspensionandarmrests.

•Mounting:Hingedtotiltupforaccessto

hydraulicpumps,batteryandothercomponents.

Heldintiltedpositionwithlanyard.Adjustable

foreandaftseattrack.

13

Page 14

Specications

•Armrests:Standard–foampaddedip-up

adjustableheightarmrests.

•SeatSafetySwitch:IncorporatedintotheSafety

InterlockSystem.

HydrostaticGroundDriveSystem

•HydrostaticPumps:TwoHydroGearZT2800

Integrateddrivesystems.

•HydraulicOilType:UseMobil115W-50

Syntheticmotoroil.

•Speeds:

–0-7.0mph(11.3km/hr)forward.

–0-5.0mph(8.0km/hr)reverse.

•Drivewheelreleases,locatedonleftandright

sidesofenginedeck,allowmachinetobemoved

whentheengineisnotrunningandbrakeisoff.

Tires&Wheels

Drive

Pneumatic(Air-Filled)

DeckSize

Quantity

Tread

Size20x8.00-820x10.00-810x4

PlyRating

Pressure

4852

222

TurfTecTurfTecSmooth

44

13psi

(90kPa)

13psi

(90kPa)

Front

Caster

Pneumatic

(Air-Filled)

AllDecks

13psi

(90kPa)

•Deck:Fulloatingdeckisattachedtoout-front

supportframe.Maximumturfprotectionis

providedwiththreeanti-scalprollers(bothdeck

sizes).

Deckdesignallowsforbagging,mulchingorside

discharge.

•DeckDepth:

–48inchDeck:5.0inches(12.7cm)

–52inchDeck:5.0inches(12.7cm)

•CuttingHeightAdjustment:Afootdeckliftlever

isusedtoadjustthecuttingheightfrom11/2

inch(3.8cm)to41/2inches(11.4cm)in1/2

inch(1.3cm)increments.

•MulchingKit:Optional.

Dimensions

OverallWidth:

48inchDeck52inchDeck

WithoutDeck45.5inches

(116cm)

DeectorUp48.3inches

(122cm)

DeectorDown59.4inches

(151cm)

OverallLength:

48inchDeck52inchDeck

47.0inches

(119cm)

53.0inches

(135cm)

64.2inches

(163cm)

CuttingDeck

•CuttingWidth:

–48inchDeck:48inches(122cm)

–52inchDeck:52inches(132cm)

•Discharge:Side

•BladeSize:(3ea.)

–48inchDeck:16.25inches(41.3cm)

–52inchDeck:18.00inches(45.7cm)

•BladeSpindles:Solidsteelspindleswithno

maintenancebearings.

•DeckDrive:Electricclutchmountedonvertical

engineshaft.Bladesaredrivenbyonebelt

(w/self-tensioningidler)directfromtheengine.

73.4inches(186cm)73.4inches(186cm)

OverallHeight:

48inchDeck52inchDeck

41.8inches(106cm)41.8inches(106cm)

14

Page 15

ProductOverview

TreadWidth:(CentertoCenterof

Tires,Widthwise)

48inchDeck52inchDeck

DriveWheels36.0inches

(91cm)

CasterWheels33.5inches

(85cm)

36.8inches

(93cm)

33.5inches

(85cm)

WheelBase:(CenterofCasterTireto

CenterofDriveTire)

48inchDeck52inchDeck

48.9inches(124cm)48.9inches(124cm)

CurbWeight:

48inchDeck52inchDeck

645lb(293kg)660lb(299kg)

TorqueRequirements

BoltLocation

SpindlePulleyNut95-105ft-lb(129-142N-m)

Torque

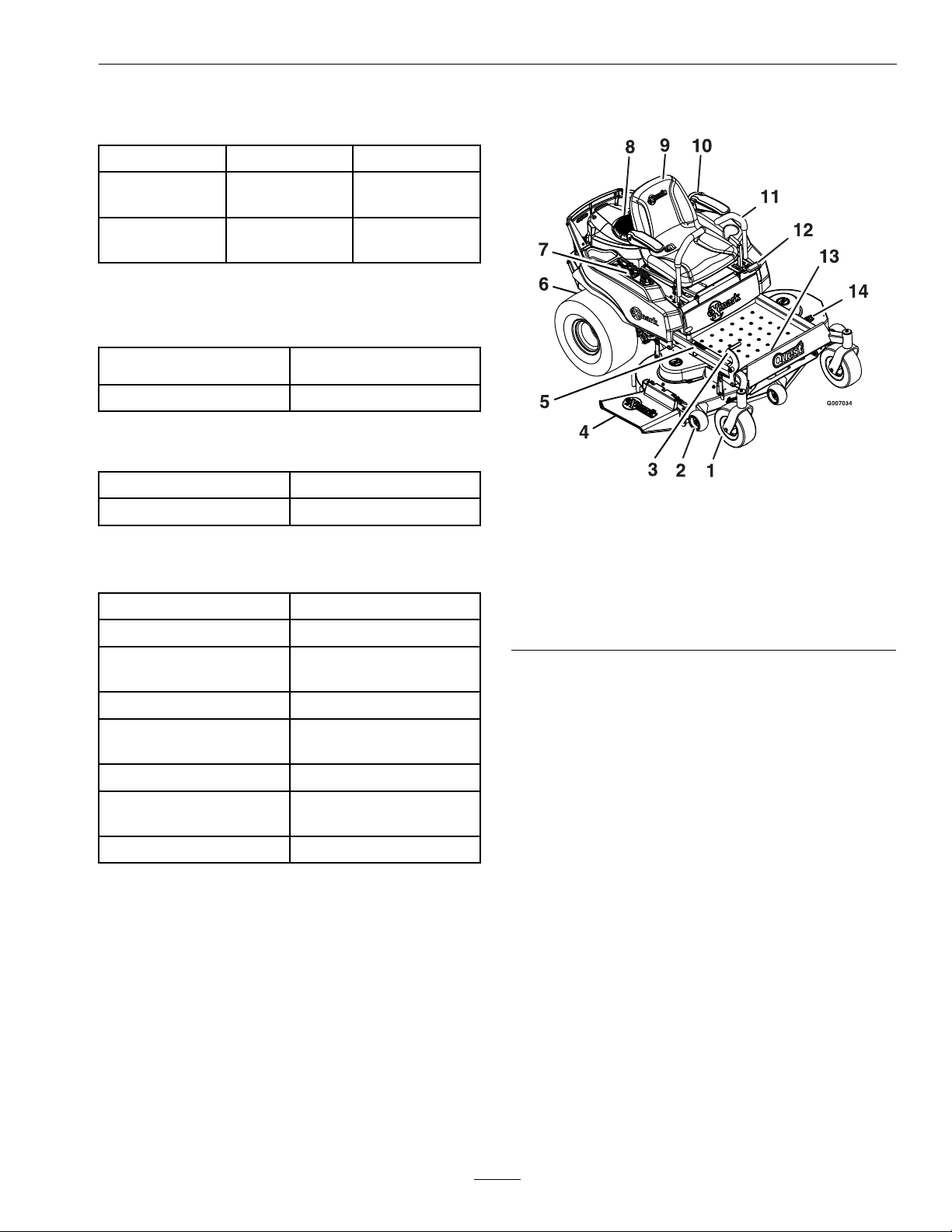

ProductOverview

Figure3

1.Frontcasterwheel8.Engine

2.Anti-scalproller

3.Heightofcutfootlever

4.Dischargedeector

5.Heightofcutadjustment

6.Reardrivewheel13.Footrest

7.Controlpanel14.Washouttting

9.Seat

10.Armrest

11.Motioncontrollevers

12.Parkbrake

BladeMountingBolt

(lubricatewithanti-seize)

EngineMountingBolts

Anti-ScalpRollerNyloc

Nut

WheelLugNuts

ClutchMountingBolt

(securedwiththreadlocker)

SparkPlug

32-42ft-lb(43-57N-m)

27-33ft-lb(37-45N-m)

27-33ft-lb(37-45N-m)

70-90ft-lb(95-122N-m)

50-55ft-lb(68-75N-m)

15ft-lb(20N-m)

15

Page 16

Operation

Operation

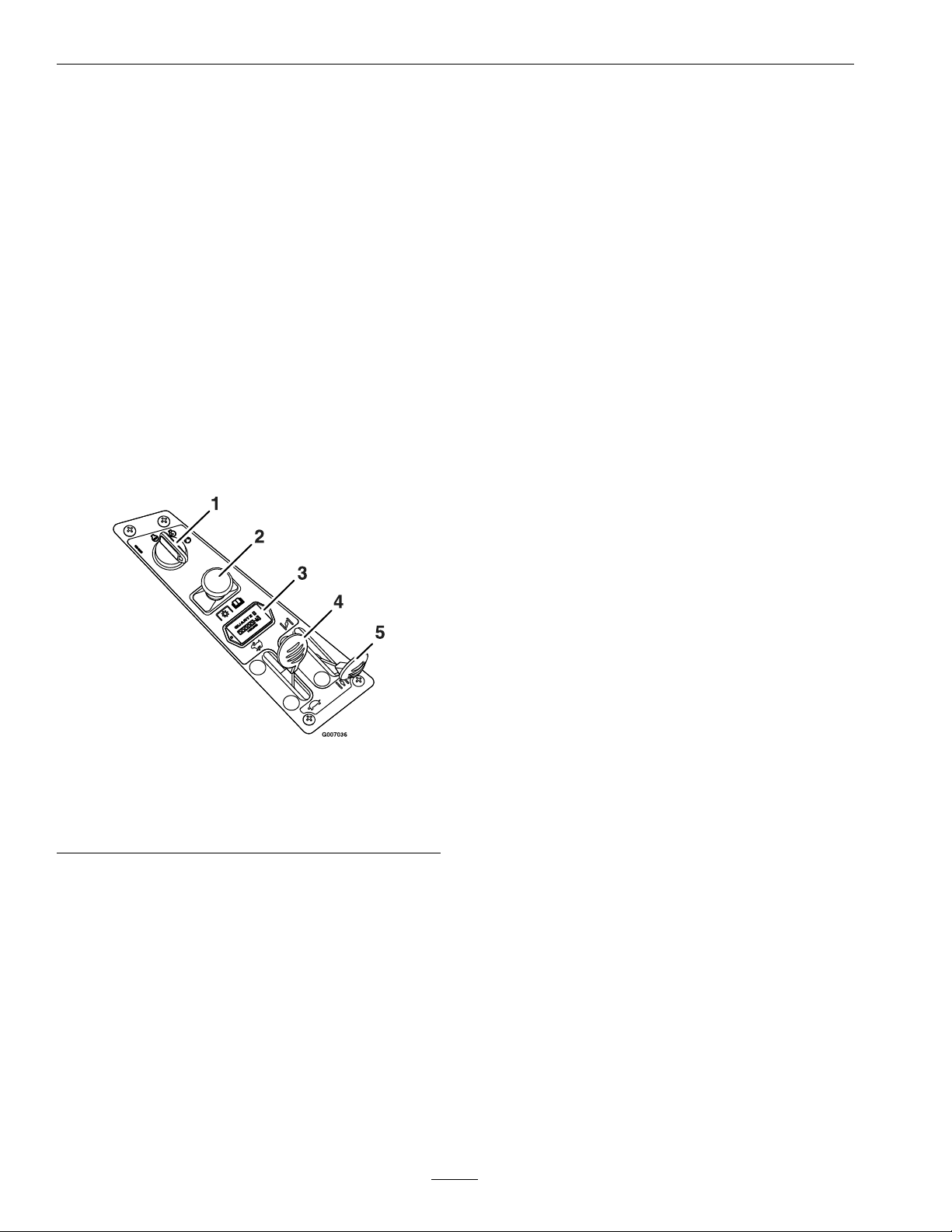

Controls

Note:Becomefamiliarwithallofthecontrolsin

Figure3andFigure4beforeyoustarttheengineand

operatethemachine.

IgnitionSwitch

Locatedoncontrolpanel.

Theignitionswitchisusedtostartandstopthe

engine.Theswitchhasthreepositions“OFF”,

“RUN”and“START”(Figure4).Insertkeyinto

switchandrotateclockwisetothe“ON”position.

Rotateclockwisetothenextpositiontoengagethe

starter(keymustbeheldagainstspringpressurein

thisposition).

BladeControlSwitch(Power

Take-Off)

Locatedonthecontrolpanel.

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengages

powertothemowerblades.

Pulloutonthebladecontrolswitchto“On”to

engagetheblades

Pushthebladecontrolswitchto“Off”todisengage

theblades

ChokeControl

Locatedoncontrolpanel.

Thechokeisusedtoaidinstartingacoldengine.Do

Notrunawarmenginewiththechokeinthe“ON”

position.Movingthechokeleverforwardwillputthe

chokeinthe“ON”positionandmovingthechoke

levertotherearwillputthechokeinthe“OFF”

position(Figure4).

Figure4

1.Ignitionswitch4.Throttle

2.Bladecontrolswitch

(powertake-off)

3.Hourmeter

Note:Brakemustbeengaged,motioncontrollevers

out(neutrallockposition)andPTOswitch“OFF”to

startengine.(Itisnotnecessaryfortheoperatorto

beintheseattostarttheengine.)

TurningthekeytotheOffpositionwillstopthe

engine;however,alwaysremovethekeywhenleaving

themachinetopreventsomeonefromaccidentally

startingtheengine

5.Choke

ThrottleControl

Locatedoncontrolpanel.

Thethrottleisusedtocontrolenginespeed.Moving

throttleleverforwardwillincreaseenginespeedand

movingthrottlelevertotherearwilldecreaseengine

speed.Movingthethrottleforwardintothedetentis

fullthrottle(seeFigure4).

MotionControlLevers

Themotioncontrolleverslocatedoneachsideof

theseat(Figure3).

Themotioncontrolleversarespeedsensitivecontrols

ofindependentwheelmotors.Movingalever

forwardorbackwardturnsthewheelonthesameside

forwardorinreverse;wheelspeedisproportionalto

theamounttheleverismoved.Movingthecontrol

leversoutwardfromthecenterpositionlocksthem

intheneutralposition.Alwayspositionthemotion

controlleversintotheneutralpositionandengage

theparkbrakeleverwhenyoustopthemachineor

leaveitunattended.Theunitmustbetieddownand

brakeengagedwhentransporting.

16

Page 17

Operation

ParkingBrakeLever

Locatedonleftsideoftheconsole(Figure3).

Thebrakeleverengagesaparkingbrakeonthedrive

wheels.

Pulltheleverupandrearwardtoengagethebrake.

Pushtheleverforwardanddowntodisengagethe

brake.

Height-of-CutFootLever

Theheightofcutleverallowstheoperatortolower

andraisethedeckfromtheseatedposition(Figure3).

Whentheleverismovedforward,awayfromthe

operatorthedeckisraisedfromthegroundand

whenmovedback,towardstheoperatoritislowered

towardtheground.Onlyadjusttheheightofcut

whilemachineisnotmoving.

HourMeter

Locatedonthecontrolpanel.

Thehourmeterisconnectedtoapressureswitch

installedintheengineblockanditrecordsthenumber

ofhoursthattheenginehasrun(Figure4).Ifthe

ignitionswitchisleftonwithoutenginerunning,

hourmeterwillnotrun.

Note:Thisswitchisnotalowoilsensorandwillnot

alerttheoperatoriftheengineoilislow .

DANGER

Mowingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Wheels

droppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death

ordrowning.Alossoftractionisalossof

steeringcontrol.

Toavoidlossofcontrolandpossibilityof

rollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15

degrees.

•Reducespeedanduseextremecaution

onslopes.

•Whenmowingslopes,graduallywork

fromlowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeed

changes.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdownthe

slopereducestraction.

•Attachmentschangethehandling

characteristicsofthemachine.Useextra

cautionwhenusingattachmentswiththe

machine.

OperatingInstructions

ThinkSafetyFirst

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Pleasecarefullyreadallofthesafetyinstructions

anddecalsinthesafetysection.Knowingthis

informationcouldhelpyou,yourfamily,petsor

bystandersavoidinjury.

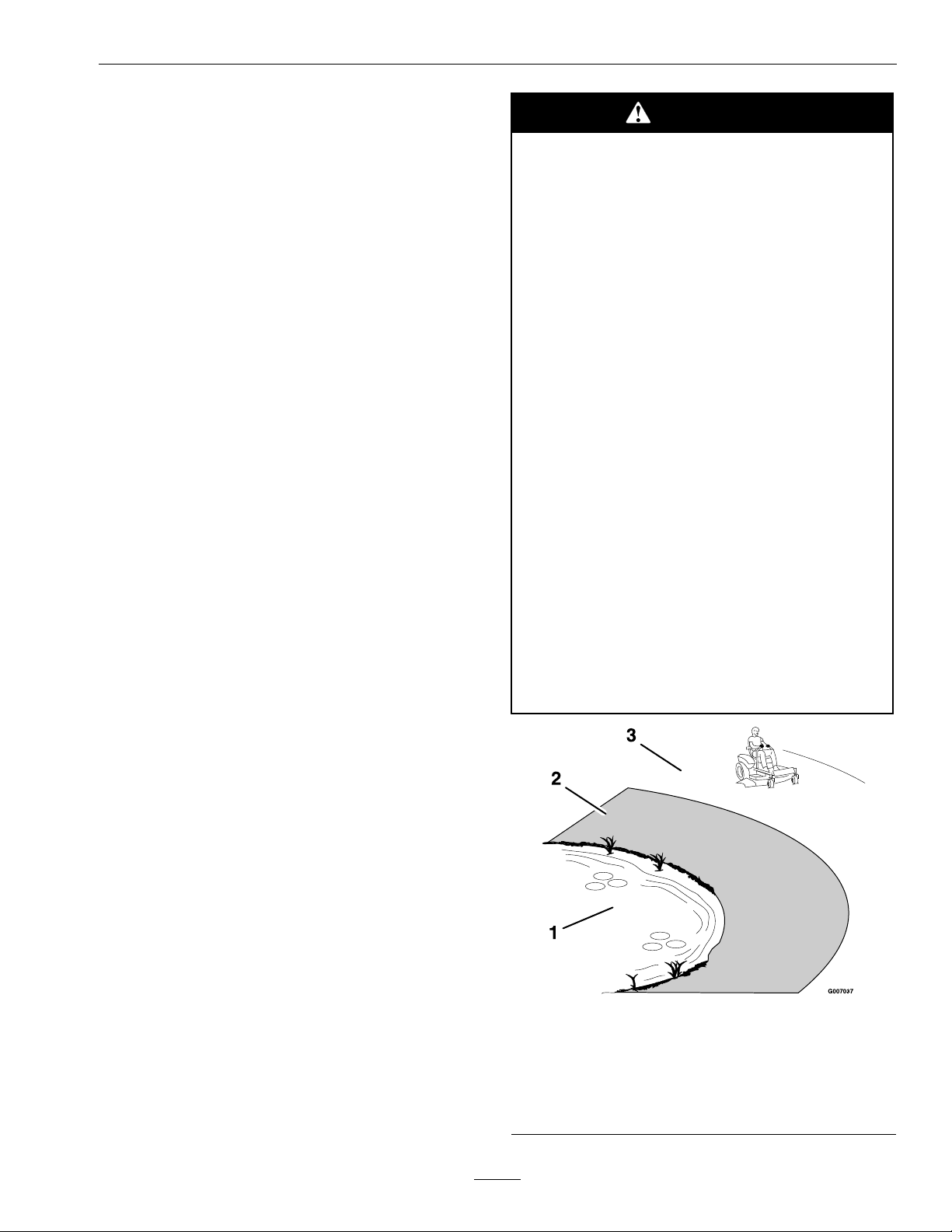

1.Water

2.Usewalkbehindmower

17

Figure5

3.SafeZone-usetheQuest

here.

and/orhandtrimmer

neardrop-offsand

water.

Page 18

Operation

Seeinsidebackcovertodeterminetheapproximate

slopeangletobemowed.

RecommendedGasoline

UseUNLEADEDRegularGasolinesuitablefor

automotiveuse(87pumpoctaneminimum).

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontaining

morethan10%ethanolbecausethefuelsystem

couldbedamaged.DoNotmixoilwithgasoline.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsinanopen

area,whentheengineiscold.Wipeup

anygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Addgasolinetothefueltankuntilthe

bodyofthetankisfullbutfueldoesnot

lltheneckofthetank.Thisemptyspace

inthetankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,

andstayawayfromanopenameor

wheregasolinefumesmaybeignitedby

spark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Neverbuymorethana30-daysupplyof

gasoline.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

18

Page 19

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof30daysor

less.Forlongerstorageitisrecommendedthat

thefueltankbedrained.

•Cleanstheenginewhileitruns.

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstartingAddthe

correctamountofgasstabilizer/conditionerto

thegas.

Operation

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

Gasoline/Alcoholblends

Gasohol(upto10percentethylalcohol,90percent

unleadedgasolinebyvolume)isapprovedforfueluse

bytheenginemanufacturer.Othergasoline/alcohol

blendsarenotapproved.

FillingtheFuelTank

1.Shuttheengineoffandsetthemotioncontrols

totheneutralpositionandengageparkingbrake.

2.Cleanaroundthefueltankcapandremovethe

cap.

3.Addunleadedregulargasolineuntilthebodyof

thetankisfullbutfueldoesnotlltheneckof

thetank(Figure6).Thisspaceintheneckofthe

tankallowsgasolinetoexpand.Donotllthe

fueltankcompletelyfull.

Figure6

1.Gastankopening3.Gastankbody

2.Filltohere,

approximately

4.Installthefueltankcapsecurely.Wipeupany

gasolinethatmayhavespilled.

CheckingtheEngineOil

Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheOilLevelinEngineMaintenance.

StartingtheEngine

1.Sitdownontheseatandmovethemotion

controlsoutwardtotheneutralpositionand

engagetheparkingbrake.

2.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure7).

19

Page 20

Operation

Figure7

1.Controlpanel

3.Movethethrottlelevertomidwayandthechoke

leverforwardbeforestartingacoldengine

(Figure8).

Note:Awarmorhotenginemaynotrequire

choking.

2.Bladecontrol

switch—Offposition

Figure9

1.Ignitionkey—start

position

2.Controlpanel

3.Choke6.Off

4.Start

5.Run

5.Iftheenginestallsorhesitates,movethe

chokeleverpartiallyforwardforafewseconds

(Figure9).

Figure8

1.Controlpanel

2.Choke—on5.Throttle—fast

3.Choke–off

4.Throttle—slow

4.TurntheignitionkeytoStarttoenergizethe

starter.Whentheenginestarts,releasethekey

(Figure9).

Important:Donotengagethestarterfor

morethan5secondsatatime.Iftheengine

failstostart,allowa60secondcool-down

periodbetweenattempts.Failuretofollow

theseinstructionscanburnoutthestarter

motor.

OperatingtheBlades

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengages

powertothemowerblades.Thisswitchcontrols

powertoanyattachmentsthatdrawpowerfromthe

engine,includingthemowerdeckandcuttingblades.

EngagingtheBlades

1.Releasepressureonthemotioncontrolleversand

placethemachineinneutral.

2.MovethethrottlemidwaytotheFastposition.

Note:Alwaysengagethebladeswiththethrottle

inthemidwayposition.

3.PulloutonthebladecontrolswitchtoOnto

engagetheblades(Figure10).

20

Page 21

1.Controlpanel

Figure10

2.Bladecontrol

Operation

TheSafetyInterlockSystem

CAUTION

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•DoNottamperwiththeinterlock

switches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

switch—Onposition

4.Movethrottletofullforwardpositionbefore

mowing.

DisengagingtheBlades

Setthrottletomidwayposition.Pushtheblade

controlswitchtoOfftodisengagetheblades

(Figure11).

Figure11

1.Controlpanel

2.Bladecontrol

switch—Offposition

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Thebladesaredisengaged.

•Themotioncontrolleversareintheneutral

position.

•Theparkingbrakeisengaged.

Thesafetyinterlocksystemisdesignedtoinitiate

engineshutdownwhen:

•Theparkingbrakeisdisengagedandtheoperator

getsoffmachine.

•ThePTOisengagedandtheoperatorgetsoff

machine.

•Theparkingbrakeisdisengagedandleversarein

andtheoperatorgetsoffmachine.

•Theparkingbrakeisengagedandmotioncontrol

leversarein.

TestingtheSafetyInterlockSystem

StoppingtheEngine

1.MovethethrottlelevertobetweenFastandhalf

throttle(Figure9).

2.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure11).

3.TurntheignitionkeytoOff(Figure9).

4.Pullthewireoffofthesparkplug(s)toprevent

thepossibilityofsomeoneaccidentallystarting

themachinebeforetransportingorstoringthe

machine.

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime

1.Checkstartingcircuit.Startershouldcrankwith

parkingbrakeengaged,PTOdisengagedand

motioncontrolleversmovedoutintheneutral

lockposition.Theoperatordoesnotneedtobe

intheseattostarttheengine.

Trytostartwithoperatorinseat,parkingbrake

disengaged,PTOdisengagedandmotioncontrol

leversintheneutrallockposition-startermust

notcrank.

21

Page 22

Operation

Trytostartwithoperatorinseat,parkingbrake

engaged,PTOengagedandmotioncontrol

leversintheneutrallockposition-startermust

notcrank.

Trytostartwithoperatorinseat,parkingbrake

engaged,PTOdisengaged,andtheleftmotion

controlleverin,startermustnotcrank,repeat

againwiththerightleverin,thenwithboth

leversin-startermustnotcrank.

2.Checkkillcircuits.Runengineatone-third

throttle,disengageparkingbrakeandraiseoff

ofseat(butdonotgetoffofmachine)engine

mustinitiateshutdown.

Runengineatone-thirdthrottle,engagePTO

andraiseoffofseat(butdonotgetoffof

machine)enginemustinitiateshutdown.

Runengineatone-thirdthrottle,withbrake

disengaged,moveleversinandraiseoffseat(but

donotgetoffofmachine)enginemustinitiate

shutdown.

CAUTION

Machinecanspinveryrapidlybypositioning

onelevertoomuchaheadoftheother.

Operatormaylosecontrolofthemachine,

whichmaycausedamagetothemachine

orinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Forward

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotioncontrol

leversforward(Figure12).

Again,runengineatone-thirdthrottle,brake

engaged,andmoveleftmotioncontrolleverin

-enginemustinitiateshutdown.

Repeatagainmovingtherightleverin,then

movingbothleversin-enginemustinitiate

shutdownwhetheroperatorisonseatornot.

Note:Ifmachinedoesnotpassanyofthesetests,

donotoperate.ContactyourauthorizedEXMARK

SERVICEDEALER.

Important:Itisessentialthatoperatorsafety

mechanismsbeconnectedandinproper

operatingconditionpriortouseformowing.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFastpositionforbest

performance.AlwaysoperateintheFast(fullthrottle)

position.

Figure12

1.Neutralposition3.Backward

2.Centerunlockposition

Togostraight,applyequalpressuretoboth

motioncontrollevers(Figure12).

4.Forward

Toturn,pullbackonthemotioncontrollever

towardthedirectionyouwanttoturn(Figure12).

Thefartheryoumovethemotioncontrollevers

ineitherdirection,thefasterthemachinewill

moveinthatdirection.

Tostop,pullthemotioncontrolleverstoneutral.

22

Page 23

Operation

Backward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(Figure12).

Togostraight,applyequalpressuretoboth

motioncontrollevers(Figure12).

Toturn,releasethepressureonthemotion

controllevertowardthedirectionyouwantto

turn(Figure12).

Tostop,pushthemotioncontrolleverstoneutral.

StoppingtheMachine

Tostopthemachine,movethemotioncontrol

leverstoneutralandoutwardtotheneutralposition,

disengagethebladecontrolswitch,movethethrottle

levertobetweenFastandhalfthrottle,andturnthe

ignitionkeytooff.Remembertoremovethekey

fromtheignitionswitch.

TrackingAdjustment

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhile

itisunattended.

Alwaysremovetheignitionkeyandmovethe

motioncontrolleversoutwardtotheneutral

positionandapplytheparkingbrakewhen

leavingthemachineunattended,evenifjust

forafewminutes.

AdjustingtheHeightofCut

1.Raisethedecktothetransportposition(4.5inch

(114mm)cutheight)bypushingthefootactuated

leverforward(Figure14).Thespringloaded

transportpinwillautomaticallyengageandwill

clickintoplace.

Ifthemachineturnsrightorleftwhenhandlesare

pushedforwardtogether,adjustthestopontheside

oppositethedirectionofturn(seeFigure13).Loosen

thescrewsthatholdthemotioncontrollimiterstop.

Movethestopbackuntiltheunitdrivesstraight.

Tightenthescrewstolockthestopinplace.Readjust

handlesifnecessary.

1.Pushforward

2.Footactuated

height-of-cutlever

3.Height-of-cutpositions

Figure14

4.Heightadjusterpin

5.Transportreleasehandle

1.Controlarmshaft

2.Limiterstopscrews

Figure13

3.Adjuststop

2.Movethedeckheightadjusterpintothedesired

cutheight.

3.Pushthefootleverforward,pullthetransport

releasehandleupandletthedecklowerdownto

23

Page 24

Operation

thepredeterminedcutheightbyslowlydecreasing

footpressureallowingthefootlevertotravel

rearward.

AdjustingtheAnti-Scalp

Rollers

Itisrecommendedtochangetheanti-scalproller

positionwhentheheightofcuthaschanged.

1.Stopthemachineandmovethedriveleversto

theneutrallockposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthenylocnut.

6.Adjusttheanti-scalprollersforthenormal

operatingconditions.Placerollersinoneof

thepositionsshowninFigure15.Rollerswill

maintain3/4inches(19mm)clearancetothe

groundtominimizegougingandrollerwearor

damage.

Note:ForMaximumDeckFlotation,place

therollersoneholepositionlower.Rollersshould

maintain1/4inch(6.35mm)clearancetothe

ground.DoNotadjustrollerstosupportthe

deck.

PositioningtheSeat

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable.

1.Pushtheadjustmentlevertowardsthecenterof

themachinetoreleasetheseatadjustertrack

(Figure16).

Figure16

1.Adjustmentlever

2.Movetheseattothedesiredpositionandrelease

thelevertolockinthatposition.

ChangingtheSeatRide

Suspension

Thenumberofseatspringscanbechangedto

maximizeridercomfort.Morespringsshouldbeused

withheavieroperatorsandonroughterrain.Fewer

springsshouldbeusedwithlighteroperatorsand

whenmowingsmooth,wellestablishedlawns.Always

keepthenumberofspringsontheleftandrightside

thesamewhenaddingandremovingsprings.

Figure15

Forcuttingheightsabove31/2inches(38mm)usethe

bottomhole.Therollerswillstillbeeffectiveagainst

scalping.

1.Anti-scalproller

mountingbracket

7.Torquehardwareto27-33ft-lb(37-45N-m)or

lossofrollermayresult.

2.Cuttingheight

24

Page 25

Operation

2.Movethecontrollevertothenextsetofholes.

Securetheleverwiththetwobolts.

3.Repeattheadjustmentfortheoppositecontrol

lever.

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollever

tothecontrolarmshaft.

Figure17

1.Bolt3.Nut

2.Spring

Uptovespringscanbesecuredtotheseatboxwith

anutandbolt,seeFigure17.

RefertoyourPartsManualforspringandhardware

partnumbers.

4.Additionalmounting

holes

AdjustingtheMotionControl

Levers

AdjustingtheHeight

Themotioncontrolleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort.

1.Removethetwoboltsholdingthecontrolleverto

thecontrolarmshaft(Figure18).

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforeoraft(Figure18).Tightenboth

boltstosecurethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrol

lever.

PushingtheMachineby

Hand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausedamagemay

occur.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardto

neutralposition,engageparkingbrake,stopthe

engine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

Figure18

1.Controlarmshaft

2.Controllever5.Slottedholes

3.Washer

4.Bolt

3.Locatethebypassreleaseknobsoneithersideof

theenginedeck(Figure19).

25

Page 26

Operation

Figure19

1.Frontofthemachine.5.Leverpositionfor

2.Rotatebypassrelease

knobcounterclockwise

3.Leverpositionfor

operatingthemachine.

4.Pullleverinthisdirection

pushingthemachine

6.Rotatebypassrelease

knobclockwise

7.Releaselever

DANGER

Withoutthedischargedeector,mulchkit,

orentiregrasscollectionsystemmountedin

place,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethedischargedeector

fromthemowerbecausethedischarge

deectorroutesmaterialdowntoward

theturf.Ifthedischargedeectorisever

damaged,replaceitimmediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytocleardischargeareaor

mowerbladesunlessyoumovethemove

thebladecontrolswitchtoOffandrotate

theignitionkeytoOff.Alsoremovethe

keyandpullthewireoffthesparkplug(s).

Transporting

4.Loosentheknobbyturningcounterclockwise.

Thenpullthereleaseleverontheundersideof

machine(Figure19)towardsthebackofthe

machineandretightentheknobtoholdthe

releaseleverbackinthereleasedstate.Repeatthis

oneachsideofthemachine.

5.Releasetheparkingbrake.Themachineisnow

abletobepushedbyhand.

ToOperatetheMachine

Loosenthebypassknob,pushthereleaselevers

forward,andretightentheknobtoengagethedrive

system(Figure19).

SideDischarge

Themowerhasahingeddischargedeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Securely

fastenthemachinetothetrailerortruckwithstraps,

chains,cable,orropes.Besurethatthetrailerortruck

hasallnecessarylightingandmarkingasrequiredby

law .Secureatrailerwithasafetychain.

CAUTION

Thisunitdoesnothaveproperturn

signals,lights,reectivemarkings,ora

slowmovingvehicleemblem.Drivingona

streetorroadwaywithoutsuchequipment

isdangerousandcanleadtoaccidents

causingpersonalinjury.Drivingonastreet

orroadwaywithoutsuchequipmentmayalso

beaviolationofStatelawsandtheoperator

maybesubjecttotrafcticketsand/ornes.

DoNotdriveaunitonapublicstreetor

roadway.

26

Page 27

Operation

WARNING

Loadingaunitonatrailerortruckincreases

thepossibilityofbackwardtip-over.

Backwardtip-overcouldcauseseriousinjury

ordeath.

•Useextremecautionwhenoperatinga

unitonaramp.

•Useonlyasingle,fullwidthramp;Do

Notuseindividualrampsforeachside

oftheunit.

•Ifindividualrampsmustbeused,use

enoughrampstocreateanunbroken

rampsurfacewiderthantheunit.

•DoNotexceeda15°anglebetweenramp

andgroundorbetweenrampandtrailer

ortruck.

•Avoidsuddenaccelerationwhiledriving

unituparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

unitdownaramptoavoidtipping

backward.

LoadingaUnit

Important:DoNotattempttoturntheunit

whileontheramp,youmaylosecontroland

driveofftheside.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdownaramp.

Bothmaneuverscancausetheunittotipbackward.

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,

operatetheengineattheFastposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdoesnotscalpany

unevenground.However,thecuttingheightusedin

thepastisgenerallythebestonetouse.Whencutting

grasslongerthansixinchestall,youmaywanttocut

thelawntwicetoensureanacceptablequalityofcut.

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinstead

ofindividualrampsforeachsideoftheunit.The

lowerrearsectionofthetractorframeextendsback

betweentherearwheelsandservesasastopfor

tippingbackward.Havingafullwidthrampprovides

asurfacefortheframememberstocontactifthe

unitstartstotipbackward.Ifitisnotpossibletouse

onefullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Rampshouldbelongenoughsothattheangles

betweentherampandthegroundandtherampand

thetrailerortruckdonotexceed15°.Asteeperangle

maycausemowerdeckcomponentstogetcaughtas

theunitmovesfromramptotrailerortruck.Steeper

anglesmayalsocausetheunittotipbackward.If

loadingonornearaslope,positionthetraileror

trucksoitisonthedownsideoftheslopeandthe

rampextendsuptheslope.Thiswillminimizethe

rampangle.Thetrailerortruckshouldbeaslevel

aspossible.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrowsmore

slowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.Soto

maintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthe

grassgrowthrateslowsinmidsummer,mowless

frequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmow

againtwodayslateratalowerheightsetting.

27

Page 28

Operation

CuttingSpeed

Toimprovecutquality,useaslowergroundspeed.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheight

toensurethatuneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylonger

thannormal,orifitcontainsahighdegreeof

moisture,raisethecuttingheighthigherthanusual

andcutthegrassatthissetting.Thencutthegrass

againusingthelower,normalsetting.

WhenStopping

Ifthemachine’sforwardmotionmustbestopped

whilemowing,aclumpofgrassclippingsmaydrop

ontoyourlawn.Toavoidthis,moveontoapreviously

cutareawiththebladesengaged.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

cutterbladesdailyforsharpness,andforanywearor

damage.Filedownanynicksandsharpentheblades

asnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineExmarkreplacement

blade.OnlyExmarkbladesaretobeusedwiththis

unit.Nootherbladesareapproved.

28

Page 29

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeingmade,someonecouldstarttheengine.Accidental

startingoftheenginecouldseriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,engageparkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenance.Alsopushthewire(s)asidesoitdoesnotaccidentally

contactthesparkplug(s).

WARNING

Theenginecanbecomeveryhot.T ouchingahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybeforeserviceormakingrepairsaroundtheenginearea.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst200hours

Beforeeachuseordaily

Every25hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Changethehydraulicsystemlter.

•Checkthesafetyinterlocksystem.

•Checktheaircleanerfordirty,loose,ordamage.

•Checktheairintakeandcoolingareas,cleanasnecessary.

•Checktheoillevelbeforestartingorafterevery8hours.

•Checkthehydraulicoillevelintheexpansiontank.

•Checkthemowerblades.

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Servicetheaircleaner.(Mayneedmoreoftenunderextremelydustyordirtyconditions.)

•Checkthetirepressure.

•Checkthebelts.

•Replacethepaperelement.(Moreoftenunderextremelydusty,dirtyconditions.)

•Replacetheaircleanerelement.

•Changetheengineoilandlter.

•Cleantheblowerhousing.Moreoftenunderdirtyconditions.

•Replacethefuellter.

•Servicethesparkplug.

Every500hours

Beforestorage

Monthly

•Replacethesparkplug.

•Chargethebatteryanddisconnectthebatterycables.

•Performallmaintenanceproceduresbeforestorage.

•Paintanychippedsurfaces.

•Checkthebatterycharge.

29

Page 30

Maintenance

1

G007184

Important:RefertoyourEngineOperator’sManualforadditionalmaintenanceprocedures.

Premaintenance

Procedures

RaisingtheSeat

Makesurethemotioncontrolleversarelockedin

theneutralposition.Lifttheseatforwarduntilthe

lanyardistight.Thefollowingcomponentscanbe

accessedbyraisingtheseat:

•Auxiliary12VPlug(12Vaccessoryupto15amp)

•Fuses

•Batterycables

AccessingtheBattery

Thebatteryislocatedundertheseat.Toaccess,raise

theseat(Figure20).

PeriodicMaintenance

Lubrication

GreasingtheBearings

GreaseType:NGLIgrade#2multi-purposegun

grease.

Greasethefrontcasterpivotsandwheels(Figure21).

Figure21

1.Frontcastertire

1.Auxiliary12VPlug

2.Battery

Figure20

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutralposition,engageparkingbrake,stopthe

engine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettings(Figure21andFigure22)

3.Seat

witharag.Makesuretoscrapeanypaintoffof

thefrontofthetting(s).

30

Page 31

Maintenance

cleanerdailyorbeforestartingtheengine.Checkfor

abuildupofdirtanddebrisaroundtheaircleaner

system.Keepthisareaclean.Alsocheckforlooseor

damagedcomponents.Replaceallbentordamaged

aircleanercomponents.

Note:Operatingtheenginewithlooseordamaged

aircleanercomponentscouldallowunlteredairinto

theenginecausingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

Figure22

Locatedonthebackoftheseat.

1.Readtheinstructions

beforeservicingor

performingmaintenance

2.Greaseidlerpivots.5.Checkhydraulicoillevel

3.Timeinterval.

4.Checkoillevel.

andrefertoOperator’s

manualforfurther

instructions.

6.Checktirepressure.

4.Connectagreaseguntoeachtting(Figure21

andFigure22).Pumpgreaseintothettingsuntil

greasebeginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Every100hours—Replace

thepaperelement.(More

oftenunderextremely

dusty,dirtyconditions.)

Figure23

Briggs&Strattonengine

1.Aircleaner3.Aircleanercover

2.Knobs

Figure24

KohlerCommandengine

1.Aircleanercover3.Aircleaner

2.Knob

Thisengineisequippedwithareplaceable,high

densitypaperaircleanerelement.Checktheair

31

Page 32

Maintenance

ServicingPaperElement

ServiceInterval:Every25hours(May

needmoreoftenunder

extremelydustyordirty

conditions.)

Every100hours/Yearly

(whichevercomes

rst)—Replacetheair

cleanerelement.

1.Removetheaircleanercover(Figure23).

2.Removetheaircleanerelementwiththeintegral

rubberseal.

3.Gentlytapthepleatedsideofthepaperelement

todislodgedirt.DoNotwashthepaperelement

orusepressurizedair,asthiswilldamagethe

element.Replaceadirty,bent,ordamaged

element.Handlenewelementscarefully;DoNot

useiftherubbersealorfoamsleeveisdamaged.

4.Cleanallaircleanercomponentsofany

accumulateddirtorforeignmaterial.Preventany

dirtfromenteringthecarburetor.

5.Installtheaircleanerelementwiththepleated

side“out”andseattherubbersealontotheedges

oftheaircleanerbase.

6.Reinstalltheaircleanercoverandsecurewith

theknobs.

ServicingtheEngineOil

Figure25

1.Oildipstick3.Oillevel

2.Fillertube

5.Removethedipstickandchecktheoillevel.

Theoillevelshouldbeupto,butnotover,the

“F”markonthedipstick.

6.Ifthelevelislow,addoilofthepropertype,upto

the“F”markonthedipstick.Alwayscheckthe

levelwiththedipstickbeforeaddingmoreoil.

Note:Topreventextensiveenginewearor

damage,alwaysmaintaintheproperoillevelin

thecrankcase.Neveroperatetheenginewiththe

oillevelbelowthe“L”markoroverthe“F”mark

onthedipstick.

CheckingtheOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,disengage

thebladecontrolswitch,stoptheengine,engage

parkingbrake,andremovethekey.

2.Makesuretheengineisstopped,level,andiscool

sotheoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outof

theengine,cleantheareaaroundtheoilll

cap/dipstickbeforeremovingit.

4.Pullandremovetheoilllcap/dipstick;wipeoil

off.Reinsertthedipstickandpushrmlyinto

place(Figure25).

ChangingtheOilandFilter

ServiceInterval:Aftertherst5hours

Every100hours/Yearly

(whichevercomesrst)

thereafter.

Changetheoilandlterwhiletheengineisstill

warm.Theoilwillowmorefreelyandcarryaway

moreimpurities.Makesuretheengineislevelwhen

lling,checking,orchangingtheoil.

1.Starttheengineandletitrununtilwarm.This

warmstheoilsoitdrainsbetter.

2.Disengagethebladecontrolswitchandmovethe

motioncontrolsoutwardtotheneutralposition

andengageparkingbrake.

32

Page 33

Maintenance

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleantheareaaroundthedrainplugandonthe

machineframe.Placeapanunderneathmachine

directlybelowthedrainholeintheframeas

showninFigure26andFigure27.

Figure26

Briggs&Strattonengine

1.Oildrain

2.Oildrainplug

3.Pan

5.Removetheoildrainplug(Figure26and

Figure27).Removetheoilllcap/dipstick

(Figure25).

Figure28

1.Oillter2.Gasket

6.Besuretoallowampletimeforcomplete

drainage.

7.Removetheoldlterandwipeoffthemounting

pad(Figure28).

8.Whentheoilhasdrainedcompletely,installthe

oildrainplug.Tightentheplugto14N-m(125

in-lb)torque.Wipeupanyexcessoilontheframe

(Figure26andFigure27).

Note:Disposeoftheusedoilatarecycling

center.

9.Applyathinlmofcleanoiltotherubbergasket

onthenewlter.

1.Oildrainhose

2.Oildrainplug

Figure27

KohlerCommandengine

10.Installthereplacementoilltertothemounting

pad.Turntheoillterclockwiseuntiltherubber

gasketcontactsthepad,thentightenthelteran

additional1/2to3/4turn(Figure28).

11.Slowlypourapproximately80%ofthespecied

oilintothellertube—useoilrecommendedin

theEngineOwner’sManual.

12.Installtheoilllcap/dipstickandpushrmly

intoplace.

13.Checktheoillevel(Figure25);refertoChecking

theOilLevel.

14.Slowlyaddadditionaloiltobringittothefull

mark.DoNotoverll.

15.Installtheoilllcap/dipstickandpushrmly

3.Pan

intoplace.

16.Starttheengineandcheckforleaks.

33

Page 34

Maintenance

CheckingtheHydraulicOil

Level

ServiceInterval:Beforeeachuseordaily

CheckexpansiontankandifnecessaryaddMOBIL1

15W-50syntheticmotoroiltotheFULLCOLDline

Figure29

1.Engine2.Expansiontank

5.Removetheventplugoneachtransmissionand

llthroughexpansionreservoir,whenoilcomes

outofventreinstallplug.Torqueplugsto180

in-lb(244N-m).Continuetoaddoiluntilit

reachestheFULLCOLDlineontheexpansion

reservoir.

Figure30

1.Oillter3.Leftreartire

2.Ventplug

ChangetheHydraulic

SystemFilter

ServiceInterval:Aftertherst200hours

Note:UseonlyMOBIL115W -50Syntheticmotor

oil.

1.Stopengine,waitforallmovingpartstostop,and

allowenginetocool.Removekeyandengage

parkingbrake.

2.Locatethetwoltersunderthetransmissions.

Removelterguards.

3.Carefullycleanareaaroundlters.Itisimportant

thatnodirtorcontaminationenterhydraulic

system.

4.Unscrewlterstoremoveandallowoiltodrain

fromdrivesystem.

Important:Beforereinstallingnewlters,

applyathincoatofoilonthesurfaceofthe

ltersrubberseal.

Turntheltersclockwiseuntilrubberseal

contactsthelteradapterthentightenthelter

anadditional3/4to1fullturn.

6.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

7.Startengineandmovethrottlecontrolaheadto

1/2throttleposition.Disengageparkingbrake.

A.Withthebypassvalveopenandtheengine

running,slowlymovethedirectionalcontrol

inbothforwardandreverse(5or6times).

B.Withthebypassvalveclosedandtheengine

running,slowlymovethedirectionalcontrol

inbothforwardandreversedirections(5to

6times).Checktheoillevel,andaddoilas

requiredafterstoppingtheengine.

C.ItmaybenecessarytorepeatstepsAand

Buntilalltheairiscompletelypurgedfrom

thesystem.Whenthetransaxleoperatesat

normalnoiselevelsandmovessmoothly

forwardandreverseatnormalspeeds,then

thetransaxleisconsideredpurged.

DoNotchangehydraulicsystemoil(exceptforwhat

canbedrainedwhenchanginglter),unlessitisfelt

theoilhasbeencontaminatedorbeenextremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

34

Page 35

Maintenance

ServicingtheSparkPlug

ServiceInterval:Every200hours/Every2

years(whichevercomes

rst)

Every500hours—Replace

thesparkplug.

Asstatedinthemaintenanceintervals,removethe

sparkplug,checkcondition,andresetthegapor

replacewithanewplugasnecessary.

ThesparkplugisRFIcompliant.Equivalentalternate

brandplugscanalsobeused.

Type:ChampionXC92YC(forBriggs&Stratton)

ChampionRC12YCorQC12Cmaybeusedifyour

areadoesnotrequirecompliancewithCanadian

ICES-002,ISO14982,orEN55012.

Type:ChampionRC12YC(forKohlerCommand)

AirGap:0.030inch(0.76mm)

RemovingtheSparkPlug

1.Disengagethebladecontrolswitch,movethe

motioncontrolsoutwardtotheparkposition,

stoptheengine,andremovethekey.

2.Pullthewireoffofthesparkplug(Figure31).

Cleanaroundthesparkplugtopreventdirtfrom

fallingintotheengineandpotentiallycausing

damage.

Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isusuallythemosteffectivemethodforcleaning.

Thesparkplugismostaccessiblewhenthe

blowerhousingisremovedforcleaning.

3.Removethesparkplugandmetalwasher.

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure32).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingon

theinsulatorusuallymeanstheaircleanerisdirty.

Important:Nevercleanthesparkplug.

Alwaysreplacethesparkplugwhenithasa

blackcoating,wornelectrodes,anoilylm,

orcracks.

2.Checkthegapbetweenthecenterandside

electrodes(Figure32).Bendthesideelectrodeif

thegapisnotcorrect.

Figure32

1.Sideelectrode3.Airgap(nottoscale)

2.Centerelectrode

insulator

InstallingtheSparkPlug

1.Installthesparkplug.Makesurethattheairgap

issetcorrectly.

2.Tightenthesparkplugto15ft-lb(20N-m).

3.Pushthewireontothesparkplug(Figure31).

CleaningtheBlowerHousing

1.Sparkplugandwirelocation

Figure31

ServiceInterval:Every100hours/Yearly

(whichevercomesrst)

Moreoftenunderdirty

conditions.

Toensurepropercooling,makesurethegrassscreen,

coolingns,andotherexternalsurfacesoftheengine

arekeptcleanatalltimes.

1.Removetheblowerhousingandanyothercooling

shrouds.

2.Cleanthecoolingnsandexternalsurfacesas

necessary.

3.Makesurethecoolingshroudsarereinstalled

35

Page 36

Maintenance

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,

and/orcoolingshroudsremoved,willcause

enginedamageduetooverheating .

FuelSystemMaintenance

ReplacingtheFuelFilter

ServiceInterval:Every100hours/Yearly

(whichevercomesrst)

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Performanyfuelrelatedmaintenance

whentheengineiscold.Dothisoutdoors

inanopenarea.Wipeupanygasoline

thatspills.

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

Neverinstalladirtylterifitisremovedfromthe

fuelline.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutralposition,engageparkingbrake,stopthe

engine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Thefuellterisinthefuellinebetweenthetank

andengine.

Figure33

1.Fueltank6.Hoseclamps

2.Fuelshutoffvalve—off

3.Fuelshutoffvalve

4.Fuelshutoffvalve—on

5.Fuellinefromtank

4.Turnfuelshutoffvalve90°to“off”position.

5.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure33).

6.Removethelterfromthefuellines.

7.Installanewlterwiththeowdirectionarrow

comingfromthefueltankandpointingtothe

engine.Movethehoseclampsclosetothelter

(Figure33)tosecureitinplace.

8.Turnfuelshutoffvalvebackto“on”position.

7.Fuellinetoengine

8.Filter

9.Flowdirectionarrow

ElectricalSystem

Maintenance

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

36

Page 37

Maintenance

ChargingtheBattery

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

DoNotallowthebatteryterminalsto

touchanymetalpartsofthemachine.

•DoNotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

themachine.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutralposition,engageparkingbrakestopthe

engine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Raisetheseat.

4.Disconnectthenegative(black)groundcable

fromthebatterypost(Figure34).Retainall

fasteners.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

5.Slidetherubbercoverupthepositive(red)cable.

Disconnectthepositive(red)cablefromthe

batterypost.Retainallfasteners.

6.Removethebatteryhold-down(Figure34)and

liftthebatteryfromthebatterytray.

ChargingtheBattery

1.Removethebatteryfromthechassis;referto

RemovingtheBattery.

2.Allowingbatteriestostandforanextendedperiod

withoutrechargingthemwillresultinreduced

performanceandservicelife.Topreserve

optimumbatteryperformanceandlife,recharge

batteriesinstoragewhentheopencircuitvoltage

dropsto12.4volts.

Figure34

1.Batteryhold-down5.Terminalboot

2.Wingnut6.Positivebatterypost

3.Negativebatterypost7.Battery

4.Bolt,washer,andnut

Note:Topreventdamageduetofreezing,

batteryshouldbefullychargedbeforeputting

awayforwinterstorage.

3.Checkthevoltageofthebatterywithadigital

voltmeter.Locatethevoltagereadingofthe

batteryinthetablebelowandchargethebattery

fortherecommendedtimeintervaltobringthe

chargeuptoafullchargeof12.6voltsorgreater.

Important:Makesurethenegativebattery

cablesaredisconnectedandthebattery

chargerusedforchargingthebatteryhasan

outputof16voltsand7ampsorlesstoavoid

damagingthebattery(seechartbelowfor

recommendedchargersettings).

37

Page 38

Maintenance

Voltage

Reading

12.6or

greater

12.4–12.675–100%

12.2–12.450–75%

12.0–12.225–50%

11.7–12.00–25%

11.7orless

Percent

Charge

100%

0%

Maximum

Charger

Settings

16volts/7

amps

16volts/7

amps

16volts/7

amps

14.4volts/4

amps

14.4volts/4

amps

14.4volts/2

amps

4.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure35).

Charging

Interval

No

Charging

Required

30Minutes

1Hour

2Hours

3Hours

6Hoursor

More

3.Installthenegativebatterycabletothenegative

(-)batteryterminalusingthefastenersremoved

previously.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure34).

ServicingtheFusesand

Relay

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,check

thecomponent/circuitforamalfunctionorshort.

Thereisalsoareplaceablerelay/snexttothefuse.

RefertoyourPartsmanualforcorrectreplacement

components.

FuseBlock:

•Mainfuse:25ampfuse,blade-type

•ChargeCircuit:20ampfuse,blade-type

•Auxiliarycircuit:15ampfuse,blade-type

Figure35

1.Negativebatterypost

2.Black(-)chargerlead

3.Red(+)chargerlead

4.Positivebatterypost

Note:DoNotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

InstallingtheBattery

1.Positionthebatteryinthetraywiththeterminal

poststowardtheoperatingposition(Figure34).

2.Installthepositive(red)batterycabletothe

positive(+)batteryterminalusingthefasteners

removedpreviously

•Diode:TVS

1.Raisetheseattogainaccesstothefuseholder

(Figure36).

Figure36

1.Cover

2.Relay6.Diode

3.Auxilliary–15amp

4.Charge–20amp8.KohlerCommandunit

5.Main–25amp

7.Briggs&Strattonunit

38

Page 39

Maintenance

2.RemovecoverasshowninFigure36.

3.Toreplaceafuse,pulloutonthefusetoremoveit

DriveSystemMaintenance

CheckingtheTirePressure

ServiceInterval:Every25hours/Monthly

(whichevercomesrst)

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.

Checkthepressureatthevalvestem(Figure37).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

RearTires:13psi(90kPa)

FrontTires(casterwheels):13psi(90kPa)

WARNING

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,andmovethemotioncontrol

leversoutwardtotheneutralpositionandengage

parkingbrake.Stoptheengine,removethekey,and

disconnectthesparkplugwire(s)fromthespark

plug(s).

Figure37

1.Valvestem

MowerMaintenance

ServicingtheCuttingBlades

ServiceInterval:Beforeeachuseordaily

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedor

worn,replaceitimmediatelywithagenuineExmark

replacementblade.Forconvenientsharpeningand

replacement,youmaywanttokeepextrabladeson

hand.

InspectingtheBlades

1.Inspectthecuttingedges(Figure38).Iftheedges

arenotsharporhavenicks,removeandsharpen

theblades;refertoSharpeningtheBlades.

2.Inspecttheblades,especiallythecurvedarea.If

younoticeanydamage,wear,oraslotformingin

thisarea(item3inFigure38),immediatelyinstall

anewblade.

Figure38