Page 1

MFG. CO. INC.

®

Part No. 109-4823 Rev. B

Page 2

®

EXMARK PARTS PLUS

EFFECTIVE DATE: September 1, 1995

Program

If your Exmark dealer does not have the Exmark part in stock,

Exmark will get the parts to the dealer the next business day or

the part will be FREE* Guaranteed!!

How the Program Works

1. If dealer does not have part in stock for a "down" unit at

2. Distributor ships part(s) to dealer or customer, as

3. If distributor does not have the part(s) in stock to satisfy Exmark Parts Plus

4. If order is received by 3:00 p.m. central time, Exmark ships part(s) direct to dealer or customer, as requested by

5. The customer pays for the part and freight if it is shipped under the Exmark Parts Plus® and if it arrives in

6. Who pays for the part and freight if it fails to arrive overnight in accordance to the program?

A. Under any circumstance the customer does not pay.

B. If the part does not arrive overnight due to:

2. The Distributor being unable to ship the part the same day or not submitting the Exmark Parts Plus® order

3. Exmark being unable to ship the part and the Exmark parts order is received by 3:00 p.m., central time,

4. If the part does not arrive overnight due to the shipper (UPS), the shipper pays for the freight and Exmark

the time of request by customer, the dealer contacts his

distributor by 1:00 p.m., local time, and requests Exmark

Parts Plus

®

shipment of six (6) line items or less.

requested by dealer, same day, overnight UPS

Distributor bills dealer for part and freight charges where

applicable.

central time, with an Exmark Parts Plus

distributor, same day, overnight UPS, Exmark bills the distributor for parts and shipping charges, where applicable.

accordance to the program.

1. The dealer not submitting the Exmark Parts Plus

pays for the part and freight.

to Exmark by 3:00 p.m., central time, the Distributor pays for the part and freight.

Exmark pays for the part and freight.

pays for the part.

The following restrictions apply

Dealers and applies only to orders submitted on this program Monday through Thursday. Parts Plus service is available

only in the 48 contiguous United States. UPS has initiated a Saturday delivery program to many areas of the continental

United States and can be requested for an overnight shipment on Friday to be delivered Saturday. The next day air

charge, plus the Saturday delivery fee will be the responsibility of the purchaser. Exmark Mfg. will assume no

responsibility for Saturday delivery shipments. To qualify, all Exmark Parts Plus® orders must be received by Exmark by

3:00 p.m., central time. Orders must be six (6) line items or less. Exclusions from the Exmark Parts Plus

Any wholegood or accessory in its entirety, engines and engine replacement parts, 5-speed Peerless transmissions and

5-speed transaxles, hydraulic or hydrostatic wheel motors, cutter decks and engine decks or any item exceeding United

Parcel Service size and weight restrictions.

Due to UPS restrictions, aerosol spray paint is considered a hazardous material and cannot be shipped via UPS next day

or Second Day Air.

Exmark Manufacturing stocks a limited supply of parts for transaxles, pumps and wheel motors. These parts can be

ordered for Next Day Air shipment but will not be guaranteed per the Parts Plus Program.

PROGRAM

®

®

order of six (6) line items or less.

®

order to his Exmark distributor by 1:00 p.m., the dealer

-- The Exmark Parts Plus® Program is available only through participating Exmark

order, he contacts Exmark by 3:00 p.m.,

®

Program are:

i

Page 3

OPERATOR'S MANUAL

This manual contains assembly, operating, m aint enance, adjustment, and safety

instructions for your Exmark OCD01.

BEFORE OPERATING YOUR MOWER,

CAREFULLY READ THIS MANUAL IN ITS ENTIRETY.

By following the operating, maintenance, and safety instructions, you will prolong the

life of your mower, maintain it s m aximum efficiency, and promote saf e oper at ion.

If additional information is needed, or should you require trained mechanic ser vice, cont act

your authorized Exmark equipment dealer or dist r ibut or .

All Exmark equipment dealers and distr ibut or s are kept informed of the latest methods of

servicing and are equipped to provide prompt and efficient service in the field or at their service

stations. They carry ample stock of service parts or can secure them promptly for you from the

factory.

All Exmark parts are thoroughly tested and inspected before leaving the f actory; however,

attention is required on your part if you are to obtain the fullest measure of satisfaction and

performance.

ii

Page 4

TABLE OF CONTENTS

1. SAFETY PAGE

1.1 Safety Alert Symbol....................................................................................... 1

1.2 Training.........................................................................................................1

1.3 Preparation.................................................................................................1-2

1.4 Operation......................................................................................................2

1.5 Safety Signs...............................................................................................2-3

2. SPECIFICATIONS

2.1 Model Number............................................................................................... 3

3. ASSEMBLY INSTRUCTIONS

3.1 Assembly Diagram........................................................................................ 4

3.2 Installation................................................................................................5-13

4. OPERATION

4.1 Opening the Discharge Gate ...................................................................14-15

4.2 Closing the Discharge Gate.......................................................................... 15

5. ADJUSTMENTS................................................................................................... 16

6. TROUBLESHOOTING ........................................................................................ 16

7. PARTS LIST

7.1 OCD01 Assembly......................................................................................... 17

7.2 Gate Linkage Assembly................................................................................ 18

7.3 Foot Pedal Assembly.................................................................................... 19

8. WARRANTY......................................................................................................... 20

iii

Page 5

1. SAFETY

1.1 SAFETY ALERT SYMBOL

This SAFETY ALERT SYMBOL is used both in this manual and on the machine to

identify important safety messages which must be followed to avoid accidents. This

symbol means:

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The safety alert symbol appears above information which alerts you to unsafe actions or

situations and will be followed by the word DANGER, WARNING, or CAUTION.

DANGER: White lettering / Red background. Indicates an imminently hazardous

situation which, if not avoided, WILL result in death or serious injury.

WARNING: Black lettering / Or ange background. Indicates a potent ially hazardous

situation which, if not avoided, COULD result in deat h or serious injury.

CAUTION: Black lettering / Yellow background. Indicates a potentially hazardous

situation which, if not avoided, MAY result in minor or moderate injury.

1.2 TRAINING

1.2.1 Regard the Exmark mower as a piece of power equipment and teach this regard

to all who operate this unit.

1.2.2 Read the instructions carefully. Familiarize yourself with the cont r ols and the

proper use of the equipment. If the operator(s) or mechanic(s) can not read

English, it is the owner’s responsibility to explain this mater ial t o t hem .

1.2.3 Do not allow operation of this machine by untrained personnel. Never allow

children, teenagers, or people unfamiliar with these instructions to use the

mower. Local regulations may restrict the age of the operator.

1.2.4 Avoid mowing while people, especially children, or pets, are nearby. Keep in

mind that the operator or user is responsible for accidents or hazards occurring

to other people or their property.

1.3 PREPARATION

1.3.1 Evaluate the terrain to determine what accessories and attachments are needed

to properly and safely perform the job. Only use accessories and attachments

approved by Exmark.

1

Page 6

1.3.2 The use of personal protective equipment, such as ( but not limited to) protection

for the eyes, ears, feet , and head is r ecom m ended.

CAUTION

POTENTIAL HAZARD

♦ The mower that the OCD01 attaches to

produces sound levels in excess of 85

dBA at the operator’s ear when in

operation.

WHAT CAN HAPPEN

♦ Exposure to sound levels of 85 dBA or

above for extended periods of time can

cause hearing loss.

HOW TO AVOID THE HAZARD

♦ Wear hearing protection when operating

this machine.

1.3.3 While mowing, always wear substantial footwear and long t rousers. Do not

operate equipment when barefoot or when wearing open sandals.

1.3.4 Thoroughly inspect the area where the equipment is to be used and remove all

stones, sticks, wires, bones, and other foreign objects which may damage the

1.4 OPERATION

Although hazard control and accident prevention are partially dependent upon the

design and configuration of the equipment, these factors are also dependent

upon the awareness, concern, prudence, and proper training of t he personnel

involved in the operation, transport, mai nt enance, and storage of the equipment.

It is essential that all Operator Safety Mechanisms be connected and in operating

condition prior to use for mowing.

equipment or cause personal injury to the operat or or bystander s.

1.4.1 Give complete, undivided attention to the job at hand.

1.4.2 Mow only in daylight or good artificial light, keeping away from holes and hidden

hazards. NEVER carry passengers.

DO NOT operate the mower when children or others are in the area.

1.4.3 When feasible, avoid operat ing the equipment in wet grass.

1.5 SAFETY SIGNS

1.5.1 Keep all safety signs legible. Remove all grease, dir t and debris from safety

signs and instructional labels.

1.5.2 Safety signs must be replaced if t hey are m issing or illegible.

1.5.3 When new components are installed, be sur e t hat cur rent safety signs are

affixed to the replaced components.

1.5.4 New safety signs may be obtained from your authorized Exmark equipment

dealer or distributor or fr om Exmar k Mfg. Co. Inc.

2

Page 7

1.5.5 Safety signs may be affixed by peeling off the backing to expose the adhesive

surface. Apply only to a clean, dry surface. Smooth to remove any air bubbles.

1.5.6 Familiarize yourself with the following safety signs and instruction labels. They

are critical to the safe operat ion of your Exmark commercial mower.

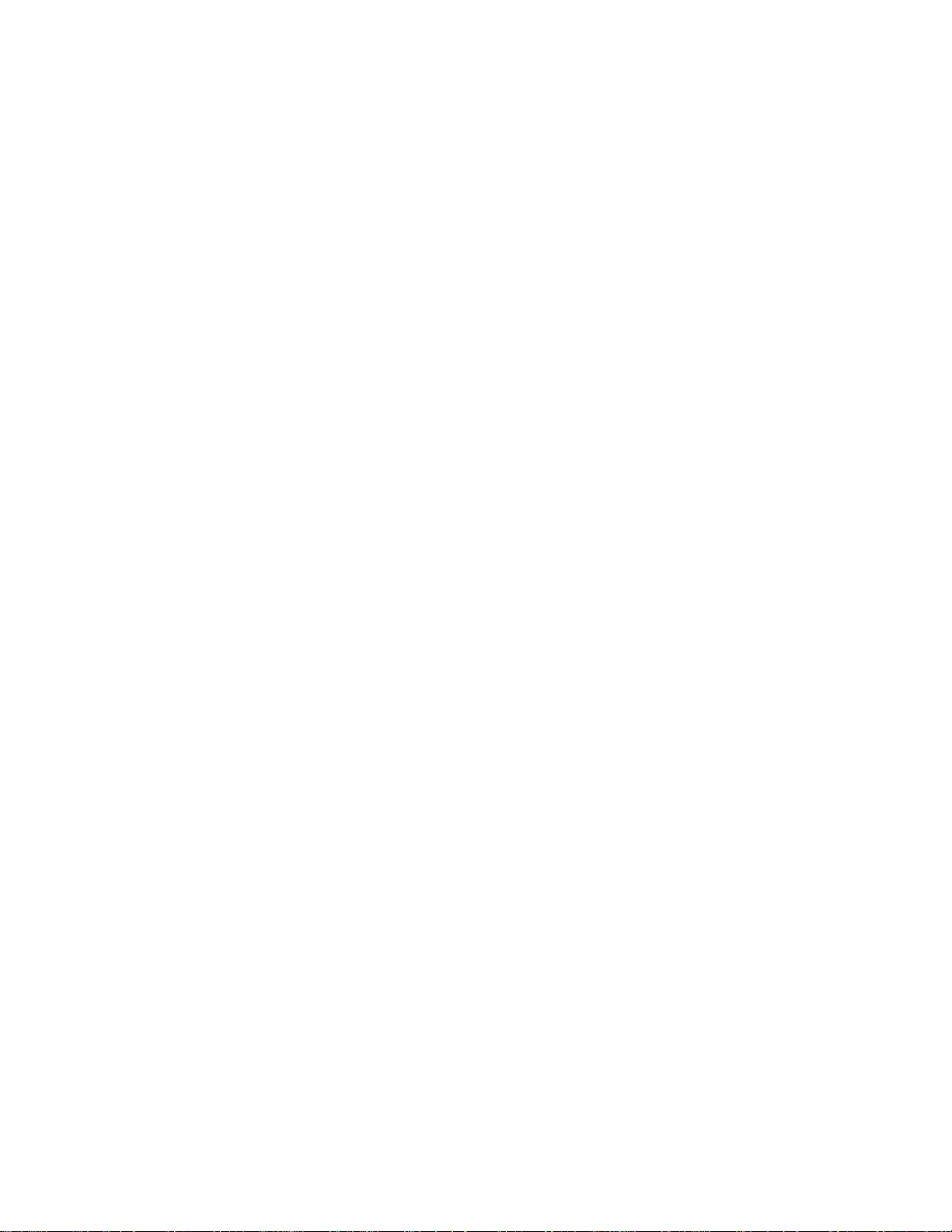

PART NO. 109-3595

LOCATION: On Top of the Cable

Bracket Assembly

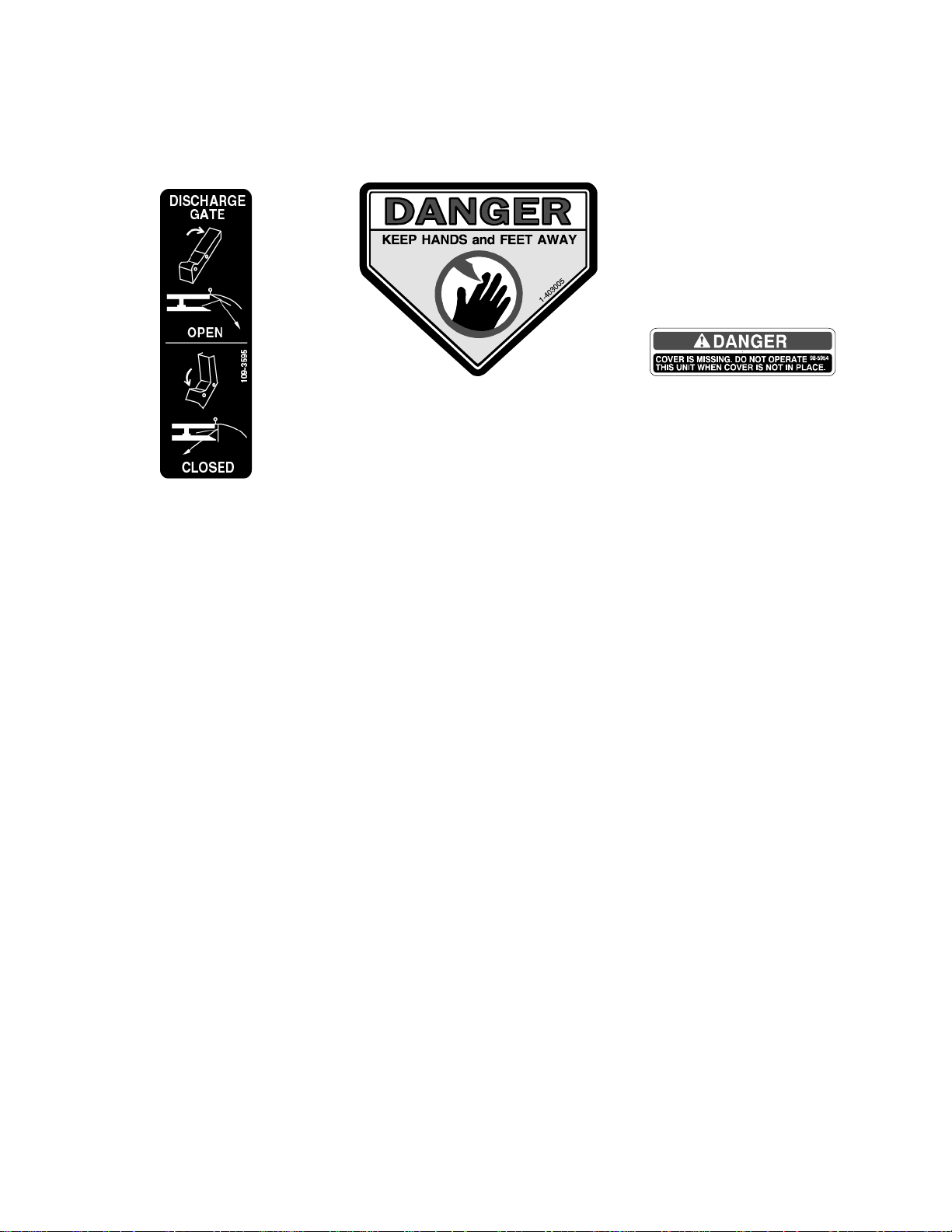

PART NO. 1-403005

LOCATION: On Top of the Gate

Linkage Assembly

PART NO. 98-5954

LOCATION: On the Side of the

Gate Linkage

Assembly

2. SPECIFICATIONS

2.1 MODEL NUMBER: OCD01

3

Page 8

3. ASSEMBLY INSTRUCTIONS

IMPORTANT: Disengage blade, shut off engine, wait f or al l moving parts to stop,

engage parking brake, remove key, and disconnect the wire from the spark plug

before servicing, cleaning, or making any adjustments to the unit.

3.1 ASSEMBLY DIAGRAM

Item Part No. Description

1 109-3880 Asm, Cable Bracket w/Decal ................... 1

2 3296-29 Nut, Nyloc 5/16-18................................... 4

3 3230-9 Bolt, Carriage 5/16-18 x 2 3/4 (Triton)...... 1

3230-9 Bolt, Carriage 5/16-18 x 2 3/4 (UltraCut) .. 2

4 322-3 Screw, HH 5/16-18 x 3/4.......................... 2

5 109-3884 Pedal, Foot .............................................. 1

6 3256-3 Washer, 5/16 Std (Triton)......................... 3

3256-3 Washer, 5/16 Std (UltraCut)..................... 7

7 32128-20 Nut, Whizlock 5/16-18....... ....................... 3

8 109-3606 Asm, Cable 60”-72”.................................. 1

109-3882 Asm, Cable 46”-56”.................................. 1

9 109-4101 Strap, Cable Hanger ................................ 1

10 109-4097-01 Cover, Gate Linkage................................ 1

11 9266714 Screw, HWH 1/4-20 x .50 TF (UltraCut)... 3

Used for Triton (series 5) decks 60”, 66”, & 72” (long cable).

Used for Triton (series 5) decks 46”, 50”, & 56” and UltraCut (series 4) decks 52” & 60” (short cable).

For serial numbers 669,999 and lower. Not incl uded – needs to be purchased separately.

Qty.

Item Part No. Description

12 109-3603 Asm, Gate Linkage w/Decals...................1

13 3230-2 Bolt, Carriage 5/16-18 x 1 (Triton)............ 3

3230-2 Bolt, Carriage 5/16-18 x 1 (UltraCut) ........ 2

14 1-806003 Pin, Hair................................................... 1

15 3256-23 Washer, 5/16 SAE (Triton)....................... 2

3256-23 Washer, 5/16 SAE (UltraCut)................... 1

16 109-3605 Asm, Gate................................................ 1

17 109-4089-01 Plate, Blocker (Triton).............................. 1

18 3230-1 Bolt, Carriage 5/16-18 x 3/4 ..................... 1

19 109-3881-01 Brack et, Chute Pivot (UltraCut)................ 1

20 322-6 Screw, HH 5/16-18 x 1 1/4 (UltraCut)... . ... 1

21 109-3860 Kit, Flexible Discharge Chute (Ultra Cut).. 1

22 9266934 Screw, HWH 5/16 x 1/2 TF ...................... 2

FIGURE 1

Qty.

4

Page 9

3.2 INSTALLING OCD01 TO THE MOWER DECK

3.2.1 Remove discharge chute from deck.

For UltraCut Decks: Remove and discard discharge chut e and har dware. Decks with

serial numbers 669,999 and lower require a flexible discharg e chut e, kit # 109-3860.

The kit is not supplied with the OCD01 accessory and needs to be purchased

separately.

For Triton Decks: Remove and retain the discharge chute and har dware.

3.2.2 Use Figure 2 to locate the correct mount ing holes on the pedal pivot bracket.

FIGURE 2

3.2.3 Install the foot pedal on the pedal pivot bracket. The upper screw, 5/16-18 x 3/4 (item 4)

installs from the bottom of the pedal pivot bracket as shown in Figure 3. Fasten with

whizlock nut (item 7).

FIGURE 3

3.2.4 The lower screw installs from the top down as shown in Figure 4. Fasten with whizlock

nut (item 7).

FIGURE 4

5

Page 10

3.2.5 Install the cable bracket (item 1) by the foot pedal and leave the hardware loose. Use

FIGURE 5A FIGURE 5B

3.2.6 Install cable. Make sure the nuts are centered as shown in Figure 6.

the correct mounting holes as shown in Figure 5A.

FIGURE 6

3.2.7 Remove the belt cover near the discharge opening.

3.2.8 Route the cable over the left side of the cr oss- shaft. Remove the seal and run the nuts

off the cable. Feed the par t s loosely thr ough one hole of the cable hanger strap. Hang

the cable under the right side of t he cr oss- shaft and fasten with cable hanger strap as

shown in Figure 7. Reinstall nuts and seal.

6

Page 11

FIGURE 7

3.2.9 If there are protruding welds on the discharge opening, grind them flush.

NOTE: Any welds left protruding from the face of the discharge opening could

interfere with fr ee operat i on of t he discharge gate.

For Triton decks only: Install the blocker plate (it em 17) as shown in Figur e 8.

3.2.10 For Triton (series 5) decks 46”, 50”, & 56” and UltraCut (series 4) decks

52” & 60”, cut the discharge gate as shown in Figure 9.

FIGURE 8

FIGURE 9

7

Page 12

3.2.11 Hook the gate assembly (item16) to t he gate linkage assembly (item 12). Install the

washer (item15) and fasten with the hairpin (item 14) as shown in Figur e 10.

FIGURE 10

3.2.12 Mount the gate linkage assembly to the deck.

NOTE: The gate is easier t o retain on the link assembly if rotated to the “open” position

when installing on the deck.

For UltraCut deck:

a) Install three 1/4-20 self-tapping scr ews (item 11) into the chute pivot bracket

(item 19) as shown in Figure 11A.

FIGURE 11A

b) Locate the correct mounting hole as shown in Figure 11B. Drill holes in deck as

shown in Figure 11C. Install the two 5/16-18 x 1 bolts (item 13) and fasten to the

deck with washer (item 6) and nyloc nut (item 2). Install 5/ 16- 18 x 3/4 bolt

(item 18) from the bot tom of the deck, and draw up into hole using t he whizlock

nut (item 7).

8

Page 13

FIGURE 11B

FIGURE 11C

For 46”-60” Triton decks:

a) Locate the correct mounting hole as shown in Figure 11D. Install t wo 5/16-18 x

1 bolts (item 13) and fasten to t he deck with washer (item 6) and nyloc nut

(item 2). Install 5/16-18 x 3/4 bolt ( it em 18) from the bottom of the deck, and

draw up into hole using the whizlock nut (item 7), see Figur e 11E for correct

mounting hole location.

FIGURE 11D

9

Page 14

FIGURE 11E

For 66” & 72” Triton decks:

a) Install two 5/16-18 x 1 bolts (item 13) and fasten to the deck with washer (item 6)

and nyloc nut (item 2) as shown in Figure 11E. Drill Ø.375 hole in t he deck to

mate up with the gate linkage assem bly (ite m 12) where shown in Figure 11F.

The drilled hole location will avoid under deck baffles on the deck. Install 5/1618 x 3/4 bolt (item 18) from t he bot tom of the deck, and draw up into hole using

the whizlock nut (item 7).

FIGURE 11F

3.2.13 With foot pedal in unlocked position (see Figure 12), attach the cable onto the blocker

pivot plate assembly. Attach cable and adjust mounting nuts to the center of the

threaded portion of the cable as shown in Figure 13.

FIGURE 12 FIGURE 13

10

Page 15

3.2.14 Slide the bracket that is shown in Figure 6, back and forth to adjust the cable tension.

Take up the slack in the cable, but it should not be taut. Tighten hardware to r etain the

bracket.

3.2.15 When pushing on the spring, there should be a 1/16” gap between the spring and the

blocker pivot plate assembly. Fine adjustments can be made by adjusting the cable

mounting nuts as shown in Figure 13. Press the foot pedal in the forward lock position,

the spring should stretch slight ly when it locks over center .

FIGURE 14

3.2.16 Install the gate linkage cover to the gate linkage assembly as shown in Figure 15.

FIGURE 15

3.2.17 To make sure the OCD01 assembly is installed correct ly:

a) Place the foot pedal in the locked posit ion. Gate should be raised to nearly

horizontal position.

b) Place foot pedal in the unlocked position. Gate should move to vertical position,

closing off the discharge opening. If you try to open the gate with your hands,

the gate should be locked into place. If t he gat e opens, the cable is tensioned

too tightly. Readjust the bracket and nut as st ated in 3.2.14.

11

Page 16

3.2.18 Remove the discharge chute bracket fr om t he discharge chute and retain hardware.

Use the appropriate template provided as a guide t o cut off the lip. Follow steps a)

through d).

For UltraCut 52”-60” use template 109-4091.

For Triton 46”-56” use tem plat e 109- 4091.

For Trition 60”-72” use tem plat e 109-3592.

a) Place the template onto the chute lip.

FIGURE 16A

b) Cut ends as shown on template. Cut around backside of first rib as shown in

Figure 16B

FIGURE 16B

12

G0972

Page 17

c) Remove remaining lip as shown in Figure 16C.

G0945

G0938

FIGURE 16C FIGURE 16D

CHUTE WITH LIP CHUTE WITH LIP REMOVED

d) Using the existing hardware, reinstall the dischar ge chute bracket into the flexible

discharge chute as shown in Figure 17.

For UltraCut Only: Install 5/16-18 x 1-1/4 screw (item 20) and 3 or 4 washers

(item 6) in the center hole of t he bracket as shown in Figure 17, so that the edge

of the chute will be parallel with the deck in the down position.

FIGURE 17

e) When installation is completed, r otate gate assembly (item 16) thr ough its full

travel range and check clearance with discharge chute. Trim additional material

from discharge chute if necessary.

3.2.19 Reinstall the belt cover.

13

Page 18

4. OPERATION

IMPORTANT: Always mow with the flexible discharge chute installed and in the down position.

DANGER

POTENTIAL HAZARD

♦ An uncovered discharge opening will

allow objects to be thrown in an

operator’s or bystander’s direction. Also,

contact with the blade could occur.

WHAT CAN HAPPEN

♦ Thrown objects or blade contact can

cause serious injury or death.

HOW TO AVOID THE HAZARD

♦ Never operate the mower with the

discharge deflector raised, r emoved, or

altered unless there is a grass collection

system or mulch kit in place and working

properly.

DANGER

POTENTIAL HAZARD

♦ The rotating blades under the mower

deck are dangerous.

WHAT CAN HAPPEN

♦ Blade contact can cause serious injury or

kill you.

HOW TO AVOID THE HAZARD

♦ DO NOT put hands or feet under t he

mower or mower deck when the blades

are engaged.

14

Page 19

4.1 OPENING THE DISCHARGE GATE

4.1.1 Press the pedal into the forward lock position and the discharge gate will be open.

4.2 CLOSING THE DISCHARGE GATE

FIGURE 18

4.2.1 Depress the lower tab to unlock the pedal. Then the discharge gate will then close off

the discharge opening.

FIGURE 19

15

Page 20

5. ADJUSTMENTS

IMPORTANT: Disengage blade, shut off engine, wait f or al l moving parts to stop, engage

parking brake, remove key, and disconnect the wire from the spark plug before servici ng,

cleaning, or making any adjustments to the unit.

5.1. Refer back to installation instructions.

6. TROUBLESHOOTING

6.1 GATE DOES NOT LOCK WHEN CLOSED

If you try to open the gate with your hands, the g at e should be locked into place. If the

gate opens, the cable is tensioned too tightly. Fine tune the mounting nuts on the cable by

following steps 3.2.13 through 3. 2. 15.

6.2 GATE DOES NOT OPEN

If the gate does not open when the foot pedal is in the locked position, the cable is not

tensioned properly. Adjust the bracket and m ount ing nuts in step 3.2.13 through 3.2.15.

6.3 GATE DOES NOT ROTATE FREELY AND STICKS IN THE UP POSITION

Check the discharge opening on the deck for protruding welds. Any welds left prot r uding

from the face of the discharge opening could interfere with free operation of the dischar ge

gate. Remove the discharge chute and g ate linkage assembly from the deck and grind

welds flush as shown in Figure 8. Reinstall gate linkag e assem bly and discharge chute.

6.4 GATE INTERFERES WITH THE DISCHARGE CHUTE

When installat ion is comp let ed, rotate gate assembly through it s full travel range and

check clearance with discharge chute. Trim addit ional m aterial from discharge chute if

necessary.

16

Page 21

7. PARTS LIST

7.1 OCD01 ASSEMBLY

Item Part No. Description

1 109-3603 Asm, Gate Linkage W/Decals.......... .....1

2 109-3605 Asm, Gate............................................1

3 109-3880 Asm, Cable Bracket W/Dec al .. . ............1

4 109-3881-01 Bracket, Chute Pivot (Ultra Cut) .......... .1

5 109-3884 Pedal, Foot...........................................1

6 109-4089-01 Plate, Blocker (Triton)...........................1

7 109-4097-01 Cover, Linkage .....................................1

8 109-4101 Strap, Cable Hanger.... . ................... .....1

9 322-3 Screw, HH 5/16-18 x 3/4....... . ...............2

10 3230-1 Bolt, Carriage 5/16-18 x 3/4... .......... .....1

11 3230-2 Bolt, Carriage 5/16-18 x 1 (Ultra Cut) ....2

3230-2 Bolt, Carriage 5/16-18 x 1 (Triton)....... ..3

12 3230-9

3230-9 Bolt, Carriage 5/16-18 x 2 3/4 (Triton)...1

Used for Triton (series 5) decks 60”, 66”, & 72” (long cable)

V Used for Triton (series 5) decks 46”, 50”, & 56” and Ultra Cut (series 4) decks 52” & 60” (short cable)

Q Not shown.

Bolt, Carriage 5/16-18 x 2 3/4 (Ultra Cut).

Qty.

2

Item Part No. Description

13 3256-23 Washer, 5/16 SAE (Ultra Cut)..............1

3256-23 Washer, 5/16 SAE (Triton)...................2

14 3256-3 Washer, 5/16 Std (UltraCut).................7

3256-3 Washer, 5/16 Std (Triton).....................3

15 3296-29 Nut, Nyloc 5/16-18 (Triton)...................4

16 32128-20 Nut, Whizlock 5/16-18..........................3

17 9266714 Screw, HWH 1/4-20 x .50 (Ultra Cut)....6

18 1-806003 Pin, Hair............................................... 1

19 109-3606 Asm, Cable 60” –72” ............................ 1

109-3882 Asm, Cable 46”–56” .............................1

V

20 109-4091 Templat e, Small Chute Cut Patt ern.. . ...1

109-3592 Templat e, Large Chute Cut Pattern...... 1

21 322-6 S crew, HH 5/16-18 x 1 1/4 (UltraCut) ... 1

22 109-3595 Decal, OCD01 Operation...................... 1

Qty.

17

Page 22

7.2 COMPONENTS FOR 109-3603 ASSEMBLY

Item Part No. Description

1 1-403005 Decal, Danger ......................................1

2 98-5954 Decal, Danger ......................................1

3 109-3600 Link, Gate ............................................1

4 109-3604 Spring, Extension .................................1

5 109-4093-01 Bracket, Link Pivot .......... .......... .......... ..1

Qty.

Item Part No. Description

6 109-4096 Wld, Gate Crank .................................. 1

7 3256-23 Washer, 5/16 SAE ............................... 1

8 3272-5 Pin, Cotter 3/32 x 1/2........................... 1

9 9266714 Screw, HWH 1/4-20 x .50..................... 2

10 9266934 Screw, HWH 5/16 x 1/2 TF .................. 2

Qty.

18

Page 23

7.3 COMPONENTS FOR 109-3884 ASSEMBLY

Item Part No. Description

1 109-3608-01 Bracket, Pedal Pivot ...... ................... ....1

2 109-3609-01 Pedal, Gate ..........................................1

3 109-3610 Rod, Pedal Link ......... .......... ................1

4 109-3877-01 Channel, Pedal Link .............................1

Qty.

Item Part No. Description

5 109-3878 Rod, Pedal Pivot.................................. 2

6 109-3879-01 Latch, Gate Pedal................................ 1

7 3256-23 Washer, 5/16 SAE ............................... 1

8 32112-11 Pushnut, Washer Cap.......................... 6

Qty.

19

Page 24

8. 2-Year Limited Warranty

Exmark Turf Equipment

Conditions and Products Covered

Exmark Mfg. Co. Inc. and its affiliate, Exmark Warranty

Company, pursuant to an agreement between them, jointly

warrant on the terms and conditions herein, that we will repair,

replace or adjust any part manufactured by Exmark and found

by us (in the exercise of our reasonable discretion) to be

defective in factory materials or workmanship for a period of

two years.

This warranty applies to Exmark turf equipment purchased on

or after October 1, 2004 sold in the US or Canada. This

warranty may only be assigned or transferred to a second (or

third) owner by an authorized Exmark dealer. The warranty

period commences upon the date of the original retail

purchase.

Products

• All Products (except as noted below) 2 years

• All Attachments and Accessories 1 year

• Metro 21 and Metro 26 Series 1 year

• Belts and Tires 90 days

• Battery 1 Year Prorated

• Engine* Warranty is covered by engine manufacturer

*Please refer to the engine manufacturer’s warranty statement

that is included in the literature packet. We are not authorized

to handle warranty adjustments on engines.

This warranty only includes the cost of parts and labor.

This warranty does not cover the following:

• Pickup and delivery charges to and from any authorized

• Any damage or deterioration due to normal use, wear

• Cost of regular maintenance service or parts, such as

• Any product or part which has been altered or misused

• Any repairs necessary due to use of parts, accessories

All warranty work must be performed by an authorized Exmark

Service Dealer using Exmark approved replacement parts.

1. Contact any Exmark Service Dealer to arrange service at

their dealership. To locate a dealer convenient to you,

access our website at www.exmark.com. U.S. Customers

may also call 402-223-6375.

2. Bring the product and your proof of purchase (sales

receipt) to the Exmark Service Dealer.

If for any reason you are dissatisfied with the Service Dealer’s

analysis or with the assistance provided, contact us at:

Exmark Customer Service Department

The Exmark W arranty Company

2101 Ashland Avenue

Beatrice, NE 68310

402-223-6375 or

service@exmark.com

Warranty Period

Items and Conditions Not Covered

Exmark Service Dealer.

and tear, or exposure.

filters, fuel, lubricants, tune-up parts, and adjustments.

or required replacement or repair due to normal wear,

accidents, or lack of proper maintenance.

or supplies, including gasoline, oil or lubricants,

incompatible with the turf equipment or other than as

recommended in the operator's manual or other

operational instructions provided by Exmark.

Instructions for Obtaining Warranty Service

(For units purchased on or after October 1, 2004)

Owner’s Responsibilities

The Exmark turf equipment, including any defective part,

must be returned to an authorized Exmark service dealer

within the warranty period. This warranty extends only to

turf equipment operated under normal conditions. You

must properly service and maintain your Exmark product

as described in the operator’s manual. Such routine

maintenance, whether performed by a dealer or by you, is

at your expense.

As a condition to this warranty, customer shall have read

the operator's manual and shall have completed and

submitted to Exmark Warranty Company, within the

prescribed time, the Exmark warranty registration.

General Conditions

The sole liability of Exmark and Exmark Warranty Company

with respect to this warranty shall be repair and replacement

as set forth herein. Neither Exmark nor Exmark Warranty

Company shall have any liability for any other cost, loss

or damage, including but not limited to, any incidental

or consequential loss or damage.

In particular, we shall have no liability or responsibility for:

• Expenses related to gasoline, oil or lubricants.

• Travel time, overtime, after hours time or other

extraordinary repair charges or charge relating to

repairs or replacements outside of normal business

hours at the place of business of the authorized

Exmark service dealer.

• Rental of like or similar replacement equipment

during the period of any warranty, repair or

replacement work.

• Any telephone or telegram charges or travel charges.

• Loss or damage to person or property other than that

covered by the terms of this warranty.

• Any claims for lost revenue, lost profit or additional

cost as a result of a claim of breach of warranty.

• Attorney's fees.

No Claim of breach of warranty shall be cause for

cancellation or rescission of the contract of sale of any

Exmark mower.

There are no understandings, agreements, representations,

or warranties, express or implied, including but not limited to

any regarding the merchantability (that product is fit for

ordinary use) or fitness for use (that product is fit for a

particular purpose), not specified herein, respecting the

equipment which is the subject of this warranty.

Some states do not allow exclusions of incidental or

consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions and

limitations may not apply to you.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

20

Page 25

NOTES

21

Page 26

SERVICE RECORD

Date Description of Work Done Service Done By

22

Page 27

23

Page 28

M

SEE EXMARK’S COMPLETE

LINE OF ACCESSORIES

RIDING ACCESSORIES

CUSTOM RIDE SEAT SUSPENSION SYSTEM

DECK LIFT ASSIST KIT

HITCH KIT

LIGHT KIT

MICRO-MULCH SYSTEM

ROLL OVER PROTECTION SYSTEM (ROPS)

SNOW BLADE

SUN SHADE

TRASH CONTAINER

TURF STRIPER

ULTRA VAC COLLECTION SYSTEM

ULTRA VAC QUICK DISPOSAL SYSTEM

WALK BEHIND ACCESSORIES

GRASS CATCHER

MICRO-MULCH SYSTEM

STEERABLE SULKY

SULKY HITCH KIT

TURF STRIPER

STANDON

Check us out on the Web:

www.exmark.com

© 2006

EXMARK MFG. CO. INC. PART NO. 109-4823 Rev B.

INDUSTRIAL PARK BOX 808 (402) 223-6300

BEATRICE, NE 68310 FAX (402) 223-5489

ALL RIGHTS RESERVED PRINTED IN U.S.A.

FG. CO. INC.

®

Loading...

Loading...