Page 1

NA VIGATOR®

ForSerialNos.

850,000&Higher

PartNo.4500-628Rev.B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,or

otherreproductiveharm.

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

(CPRC)Section4442touseoroperatethis

engineonanyforest-covered,brush-covered,or

grass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilar

laws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002Cesystèmed’allumageparètincellede

vèhiculeestconformeàlanormeNMB-002du

Canada

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2010—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency ,andpromotesafe

operation.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

Exmarkpartsmanualsareavailableonlineat

http://www.exmark.com/manuals.htm.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

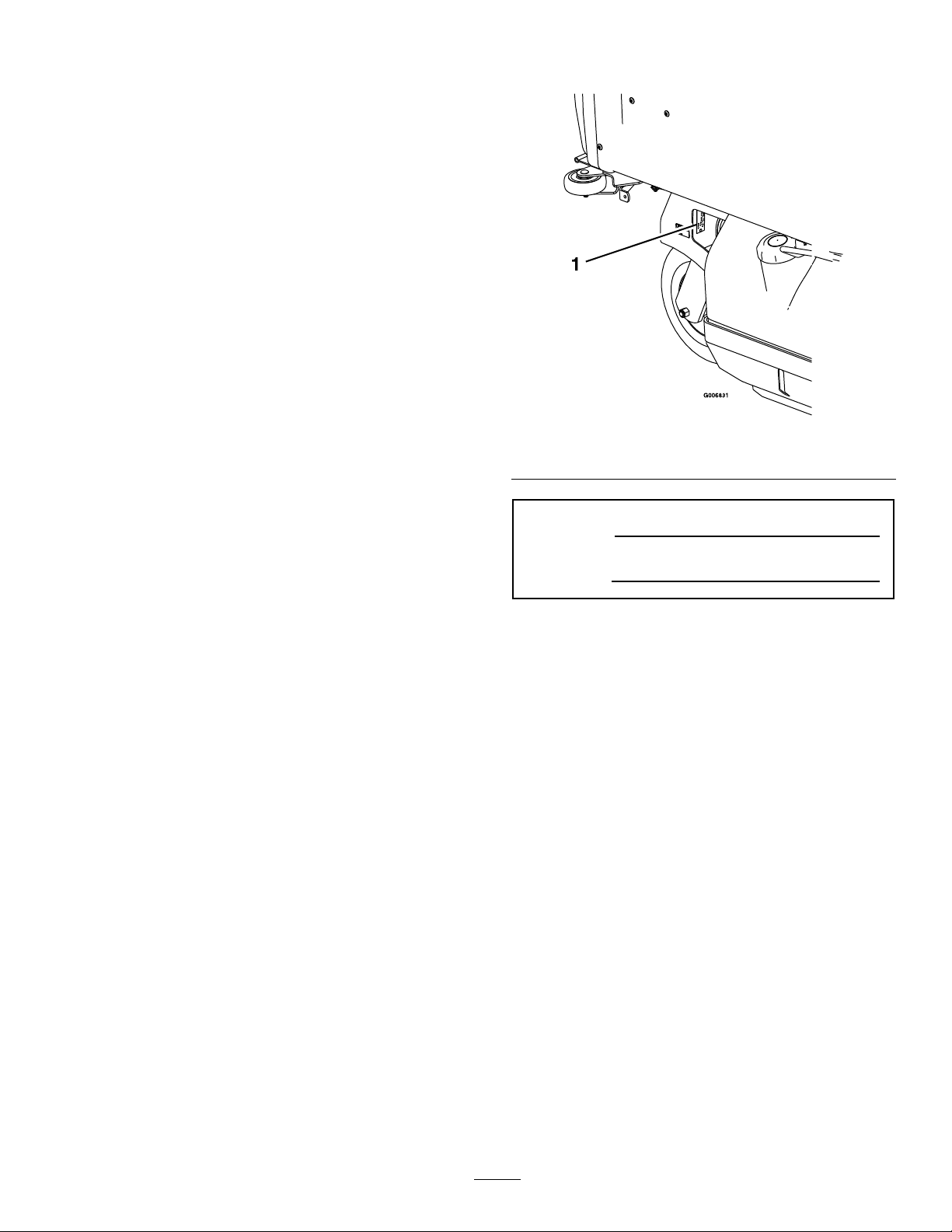

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.....................11

Specications.......................................................14

ModelNumbers............................................14

Systems.........................................................14

Dimensions...................................................15

TorqueRequirements....................................16

ProductOverview................................................16

Operation.............................................................17

Controls........................................................17

Pre-Start........................................................18

OperatingInstructions..................................18

Transporting.................................................20

Maintenance.........................................................22

RecommendedMaintenanceSchedule(s)...........22

PeriodicMaintenance.......................................23

CheckEngineOilLevel.................................23

CheckBatteryCharge....................................23

CheckSafetyInterlockSystem.......................24

CheckforLooseHardware............................25

ServiceAirCleaner........................................25

ChangeEngineOil........................................25

CheckHydraulicOilLevel.............................26

CheckTirePressures.....................................26

CheckConditionOfBelts..............................26

LubricateGreaseFittings...............................26

LubricateRearCasterWheelHubs.................27

LubricateBrakeHandlePivot........................28

LubricateBrakeRodBushings.......................28

LubricateSteeringLinkageRodEnds.............28

LubricateHopperActuator............................28

CheckSparkPlugs.........................................28

ChangeHydraulicSystemFilter.....................29

CheckWheelHubLocknuts..........................29

CheckWheelLugNuts..................................29

ThreadLockingAdhesives.............................29

DielectricGrease...........................................30

Adjustments.....................................................30

PTODriveBeltTension................................30

PumpDriveBeltTension...............................30

PTOBeltReplacement..................................30

PumpDriveBeltReplacement......................31

BeltGuideAdjustment..................................31

AdjustSafetySwitch......................................32

BrakeAdjustment..........................................32

AdjustSpeedControlLeverTension..............32

SpeedControlLinkageAdjustment................33

SteeringControlLeverResponse

Adjustment...............................................34

TrackingAdjustment.....................................35

PTODrivePulleyAlignment.........................35

PumpDrivePulleyAlignment........................35

RearCasterPivotBearingsPre-Load

Adjustment...............................................36

HopperDoorAdjustment.............................36

PTOBrakeSpringAdjustment......................36

Cleaning...........................................................37

CleanEngineandExhaustSystem

Area..........................................................37

RemoveEngineShroudsandCleanCooling

Fins...........................................................37

CleanDebrisFromMachine..........................37

WasteDisposal..............................................37

Troubleshooting...................................................38

Schematics...........................................................40

4

Page 5

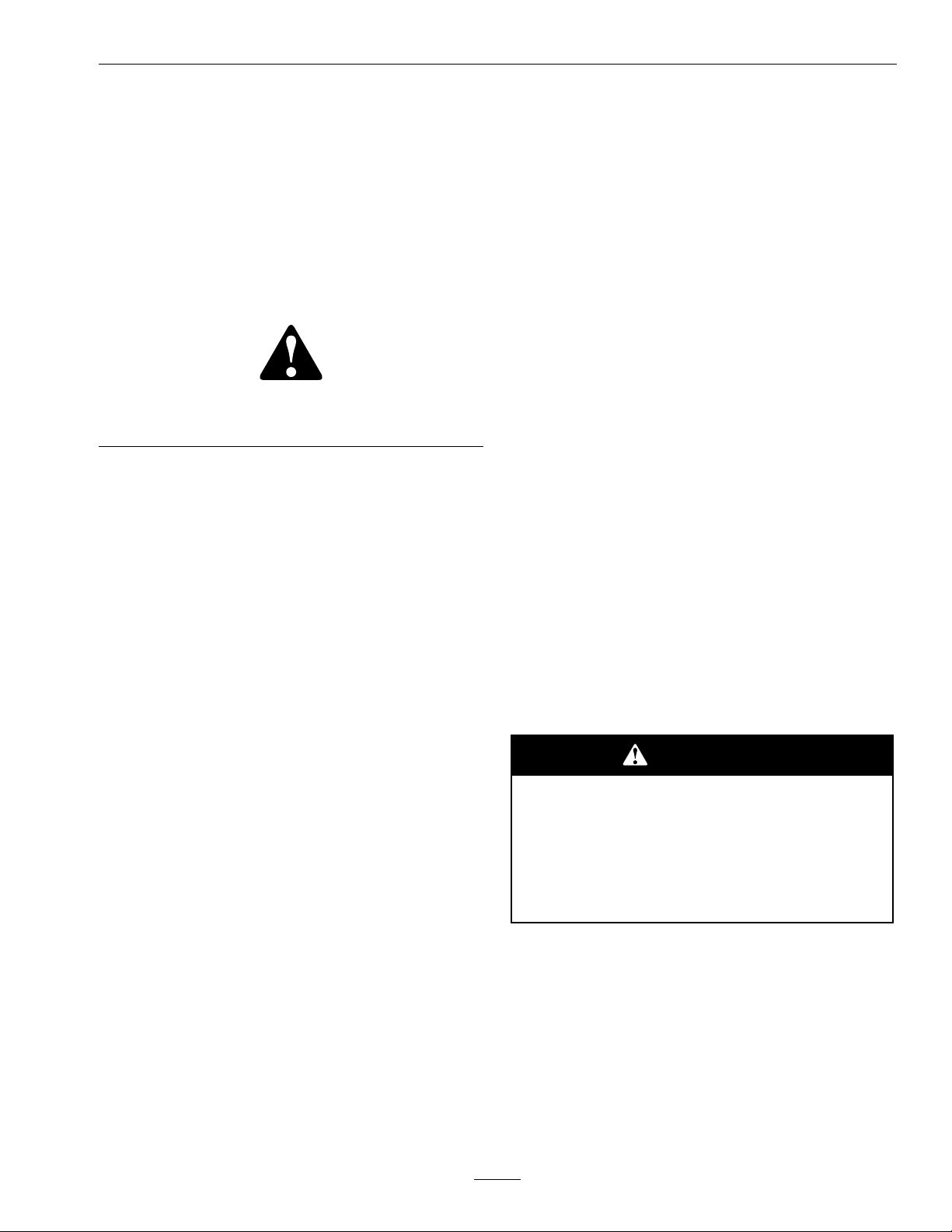

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

1.Safetyalertsymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

amower,andevenmatureteenagersshouldhave

adultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator’s

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

mowerwithouttakingrisks.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

5

Page 6

Safety

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevel

ground,inanopenarea,whentheengine

iscold.Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengine

oremissionsystem(ifequipped).

•Neversmokewhenhandlinggasoline,

andstayawayfromanopenameor

wheregasolinefumesmaybeignitedby

spark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.

Neverremovethecapofthefueltankor

addfuelwhenengineisrunningorwhen

theengineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

6

Page 7

Safety

•Checkthattheoperator’spresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

Operation

WARNING

Operatingengineparts,especiallythe

mufer,becomeextremelyhot.Severeburns

canoccuroncontactanddebris,suchas

leaves,grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

OperatingaNavigatortractorwithoutan

approvedExmarkfrontmountattachment

increasesthepossibilityofoperator

entanglementindrivewheelsorforwardtip

over.Entanglementortip-overcouldcause

seriousinjuryordeath.

WhenoperatingaNavigatortractor

withoutanapprovedExmarkfrontmount

attachment,observethefollowing:

•Keepfeetandclothingawayfromtires.

•Limitoperationtominimumrequiredto

installadifferentfrontmountattachment.

•Minimizespeedanduseextremecaution.

•Onlyoperateonaatlevelsurface.

•Donotoperateupordownatrailerramp.

•Avoidsuddenaccelerationordeceleration.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Neverraisedeckwithbladesrunning.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowunlessthereisagrasscollection

systemormulchkitinplaceandworkingproperly .

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Stopengine,waitforallmovingpartstostop,

removekeyandengageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

7

Page 8

Safety

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•NEVERcarrypassengers.DONOToperate

themowerwhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

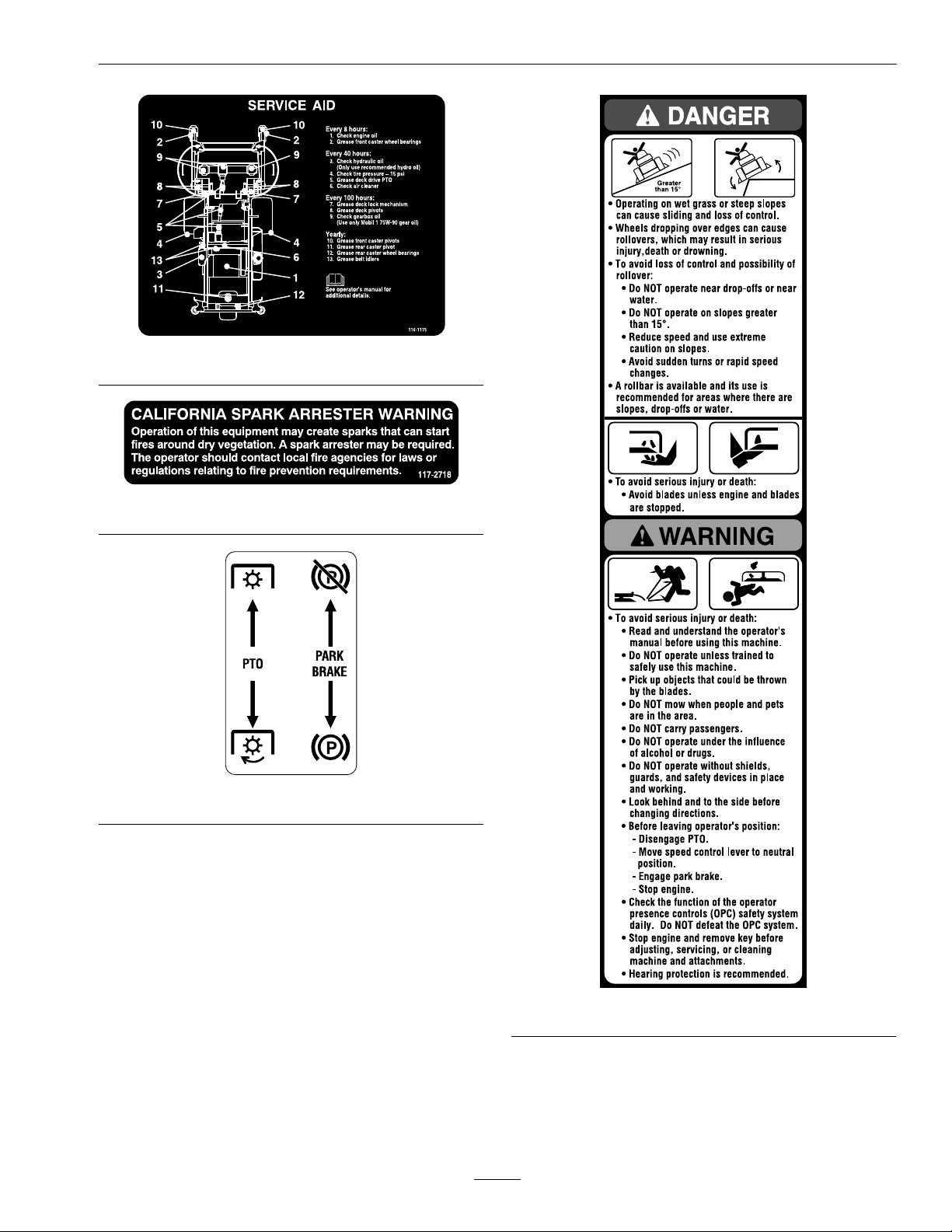

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Wheels

droppingoveredges,ditches,steepbanks,or

watercancauserollovers,whichmayresult

inseriousinjury,deathordrowning.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan15

degrees.

•Reducespeedanduseextremecaution

onslopes.

•Avoidsuddenturnsorrapidspeed

changes.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

(Figure3).

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

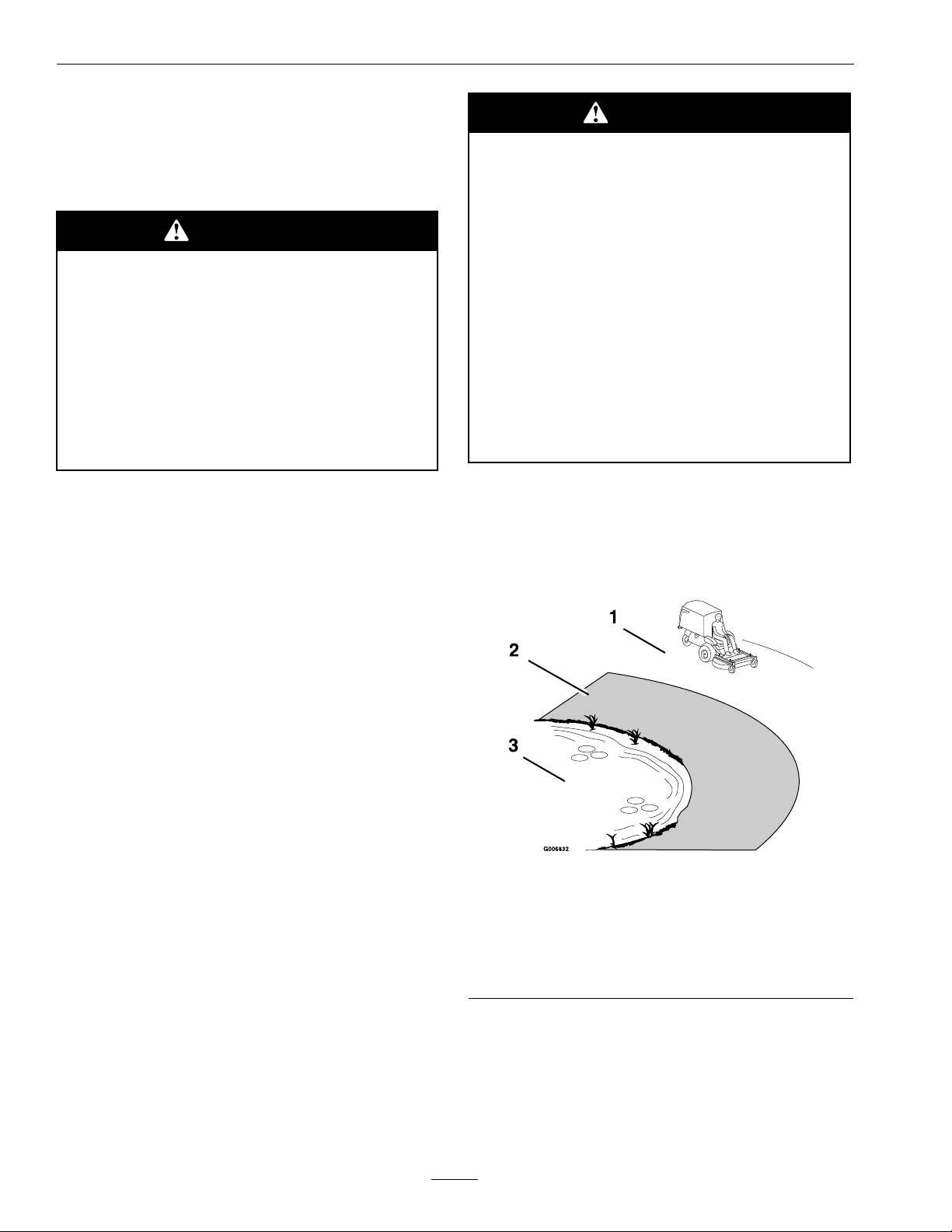

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

Figure3

1.SafeZone-Usethemowerhereonslopeslessthan15

degrees

2.DangerZone-Useawalkbehindmowerand/orhand

trimmeronslopesgreaterthan15degrees,near

drop-offsandwater.

3.Water

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

8

Page 9

Safety

•Avoidsuddenstartswhenmowingdownhill.

Mowermaytipforwards.

•Beawarethatoperatingonwetgrass,acrosssteep

slopesordownhillmaycausethemowertolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithattachments.Thesecan

changethestabilityofthemachineandcauseloss

ofcontrol.

Note:A2–postfoldableROPS(RolloverProtection

System)isavailablefortheNavigatorasanaccessory.

AROPSisrecommendedifyouwillbemowing

nexttodrop-offs,nearwater,oronsteepbanks

whichcouldresultinarollover.Themodelnumber

fortheROPSattachmentisFRPSNAV .Contactan

AuthorizedExmarkServiceDealerformoredetails.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

DANGER

Chargingorjumpstartingthebatterymay

produceexplosivegases.Batterygasescan

explodecausingseriousinjury.

•Keepsparks,ames,orcigarettesaway

frombattery.

MaintenanceandStorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Keepengine,enginearea,andpumpdrivebelt

compartmentfreefromaccumulationofgrass,

leaves,excessivegreaseoroil,andotherdebris

whichcanaccumulateintheseareas.These

materialscanbecomecombustibleandmayresult

inare.

•Letenginecoolbeforestoringanddonotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Ventilatewhenchargingorusingbattery

inanenclosedspace.

•Makesureventingpathofbatteryis

alwaysopenoncebatteryislledwith

acid.

•Alwaysshieldeyesandfacefrombattery.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldeyes,and

rubberglovestoprotectskinandclothing

whenhandlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwith

waterandcalladoctorimmediately .

•Carefullyreleasepressurefromcomponentswith

storedenergy.

9

Page 10

Safety

CAUTION

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagement

ofcomponents.Sparkscouldcausean

explosionormovingpartscouldaccidentally

engagecausingpersonalinjury

Besureignitionswitchisinthe“OFF”

positionbeforechargingthebattery.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

WARNING

Removingstandardoriginalequipment

parts,orusingnon-Exmarkreplacement

partsandaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failure

touseoriginalExmarkpartscouldcause

seriousinjuryordeath.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbya

doctorfamiliarwiththisformofinjuryor

gangrenemayresult.

•Makesureallhydraulicuidhoses

andlinesareingoodconditionand

allhydraulicconnectionsandttings

aretightbeforeapplyingpressureto

hydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,

tondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembyplacingthemotioncontrol

leversinneutralandshuttingoffthe

enginebeforeperforminganyworkon

thehydraulicsystem.

Replaceallpartsincluding,butnotlimited

to,tires,belts,andbladeswithoriginal

Exmarkparts.

10

Page 11

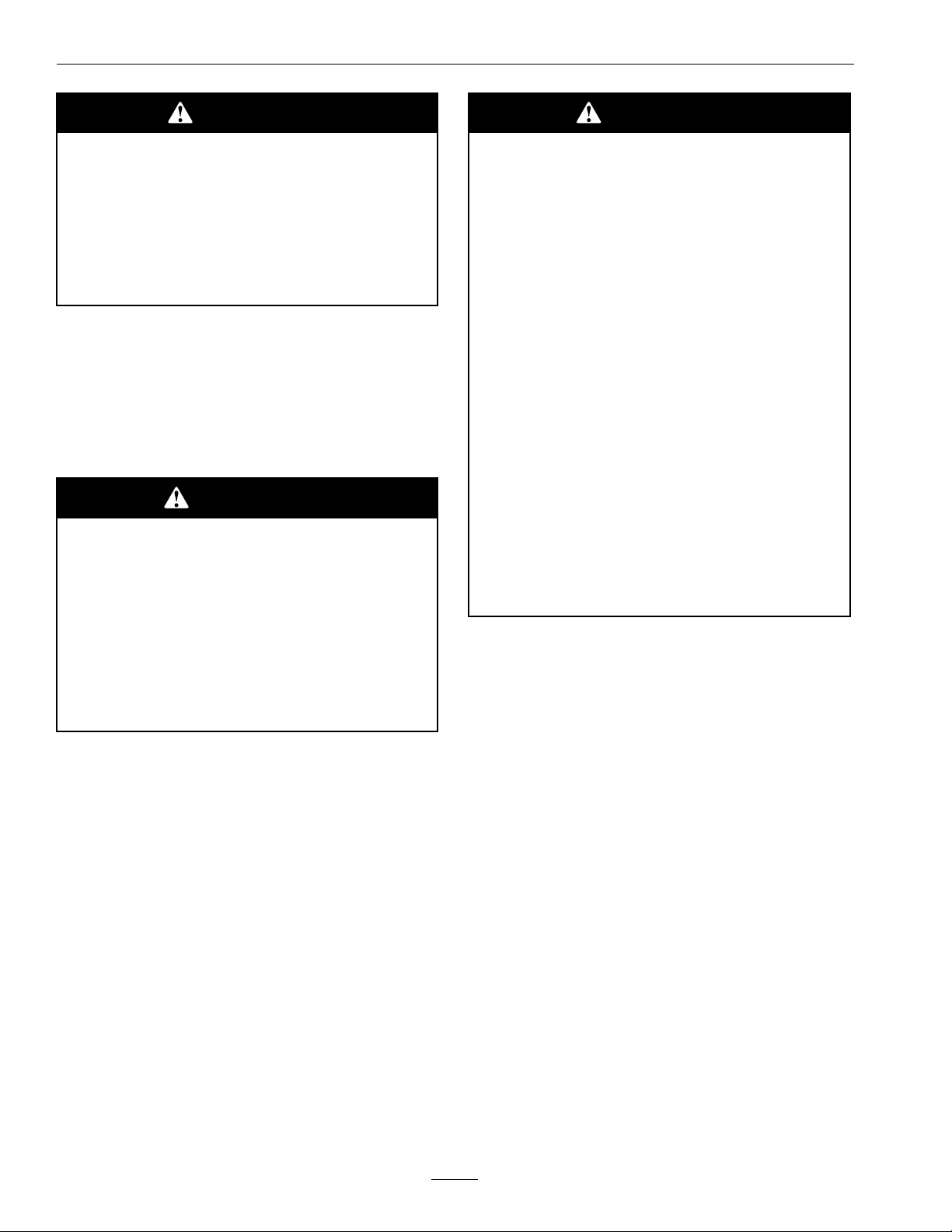

SafetyandInstructionalDecals

Safety

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

1-513747

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

103-8444

65-2690

98-4361

103-8451

98-5954

103-8495

103-8611

103-8425

11

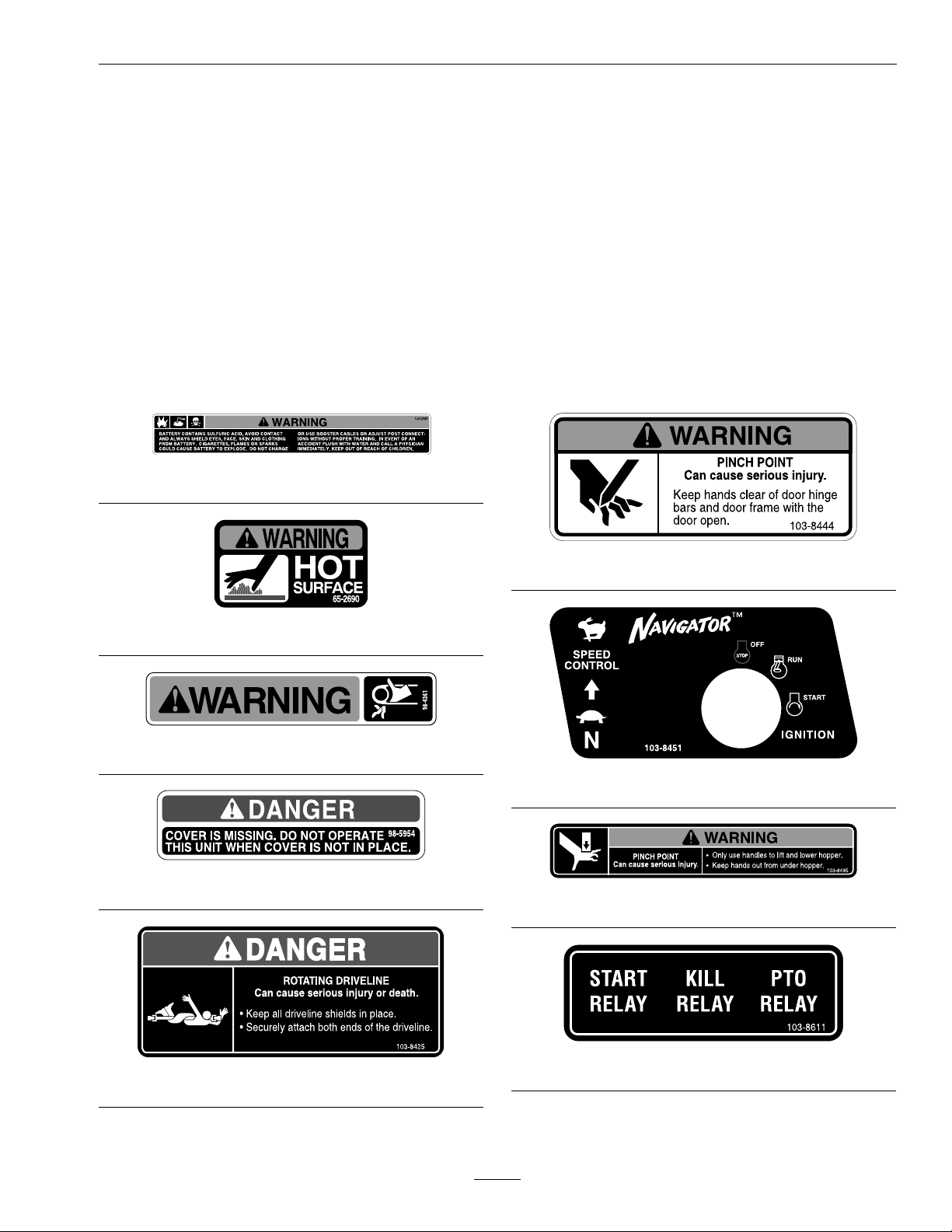

Page 12

Safety

103-9034

109-4638

103-9724

109-7318

109-4273

116-0404

12

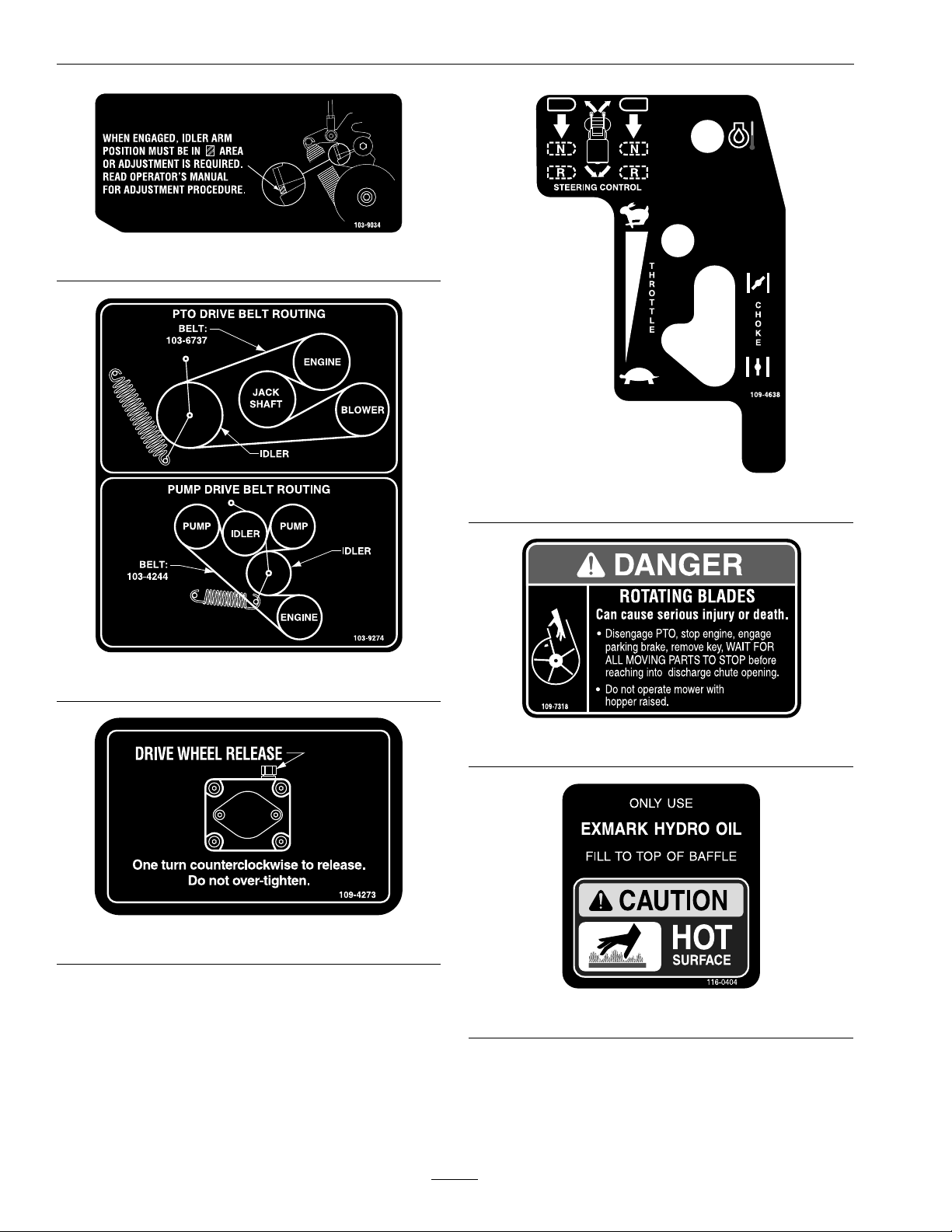

Page 13

Safety

116-1175

117–2718

MoldedinLHConsole

MoldedintoFrontofHopper

13

Page 14

Specications

Specications

ModelNumbers

SerialNos:850,000andHigher

NAV20KC;NAV27KC

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•RPM:FullSpeed:3600±50RPM(NoLoad)

Idle:1500RPM

FuelSystem

•Capacity:7.5gal.(28L)

•TypeofFuel:Regularunleadedgasoline,87

octaneorhigher;containingnomorethan10%

methanolorethanol.

•FuelFilter:In-line30MicronKohlerP/N

2405010.

•FuelShut-OffValve:1/4turnincrementsin-line

valvebyfuellter.

ElectricalSystem

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:15amps

•BatteryType:BCIGroupU1

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuses:Two20ampandone30ampbladetype

•SafetyInterlockSystem:

–PTOmustbedisengaged,brakeengaged,and

speedcontrolleverinneutralpositiontostart

engine.(Itisnotnecessaryfortheoperatorto

beintheseattostarttheengine.)

–OperatormustbeinseatwhenPTOis

engaged,brakeisdisengaged,orspeedcontrol

leverismovedoutofneutralorenginewill

stop.

–Enginewillstopinthefollowingconditions:

◊Ifthespeedcontrolleverismovedfrom

neutralpositionwhilebrakeisengaged.

◊IfthePTOisengagedwhilethehopper

istiltedup.

OperatorControls

•SteeringandMotionControl:

–SpeedControllever,locatedonRHconsole,

setsmaximumforwardspeed.

–Steeringlevers,centeredinfrontoftheseat,

controlthespeedanddirectionoftravelof

therespectivedrivewheels.

–Movingspeedcontrolleverrearwardtothe

neutralpositionplacesthedrivesystemin

neutral.

Note:Theunitmaybemovedinreverse

whilethespeedcontrolisintheneutral

positionbypullingbackonthesteeringlevers.

•PTOEngagementLever:EngagesdrivetoPTO

(mowerdeck)andblower.

•ParkingBrakeLever:Pullbacktoengageparking

brake.

Seat

•Type:Standardseatwithhighback,foampadded

(internalsuspension).

•Mounting:Seatishingedtotiltupforaccessto

hydraulicpumpsandothercomponents.Theseat

isheldinthetiltedpositionwithalink.

•Armrests:None.

•SeatSafetySwitch:Internaltothebottomseat

cushion,nonserviceable.Timedelaymodule

incorporatedintotheSafetyInterlockSystem

eliminatesroughgroundcut-outs.

HydrostaticGroundDriveSystem

•HydrostaticPumps:TwoHydroGearvariable

displacementpistonpumps.

•WheelMotors:HydroGearplanetaryreduction

motors.

14

Page 15

Specications

•HydraulicOilType:UseExmarkPremiumHydro

oil.

•HydraulicOilCapacity:4.0qt.(3.8L)

•HydraulicFilter:Replaceablecartridgetype.

–Summeruseabove32°F(0°C):

P/N109-0071:25microns,10psibypass

–Winterusebelow32°F(0°C):

P/N1-523541:40microns,18psibypass

•Speeds:

–0-7.0mph(11.3km/hr)forward.

–0-5.5mph(8.6km/hr)reverse.

•Drivewheelreleasevalvesallowmachinetobe

movedwhenengineisnotrunning.

Tires&Wheels

Drive

Pneumatic

(Air-Filled)

Quantity

221

Front

Caster

SemiPneumatic

RearCaster

SemiPneumatic

–Clutchingbeltonhorizontalengineshaft.

Dual“ A ”sectionhexagonbeltwithspring

tensionedidlertojackshaftandblower.

–Heavy-dutycastiron,spiralbevelgearboxis

naldrivetoblades.

•Deck:

Fulloatingdeckisattachedtoout-frontsupport

frame.Deckdesignallowsforbaggingor

mulching.

•DeckDepth:

–42inchDeck:45/8inches(11.7cm)

–48inchDeck:45/8inches(11.7cm)

Dimensions

OverallWidth:

WithoutDeck42inchDeck48inchDeck

42.6inches

(108.2cm)

43.2inches

(109.7cm)

49.2inches

(125.0cm)

Tread

Size

PlyRating

Pressure

“Multi-Trac

C/S”

18x

10.50-10

4

15psi(103

kPa)

SmoothSmooth

8x3.00-413x8.00-6

CuttingDeck

(Soldseparately)

•ModelNumbers:

–CD42CD

–CD48CD

•CuttingWidth:

–42inchDeck:42inch(106.7cm)

–48inchDeck:48inch(121.9cm)

•Discharge:Center

•BladeSize:(2ea.)

–w/42inchDeck:22.00inches(55.9cm)

–w/48inchDeck:25.00inches(63.5cm)

•DeckDrive:

OverallLength:

WithoutDeck42inchDeck48inchDeck

67.3inches

(170.9cm)

91.8inches

(233.2cm)

94.5inches

(240.0cm)

OverallHeight:

WithoutDeck42inchDeck48inchDeck

51.2inches

(130.0cm)

51.2inches

(130.0cm)

51.2inches

(130.0cm)

TreadWidth:(CentertoCenterof

Tires,Widthwise)

42inchDeck48inchDeck

DriveWheels32.7inches

(83.1cm)

32.7inches

(83.1cm)

WheelBase:(CenterofDriveWheel

toCenterofRearCasterWheel)

42inchDeck48inchDeck

44.2inches(112.3cm)44.2inches(112.3cm)

15

Page 16

ProductOverview

CurbWeight:

42inchDeck48inchDeck

850lb(386kg)1145lb(519kg)

TorqueRequirements

BoltLocation

BladeMountingBolt85-110ft-lb(115-149N-m)

EngineMountingBolts

WheelLugNuts

WheelMotorMounting

Bolts

WheelHubLocknut210-250ft-lb

Torque

30-35ft-lb(41-47N-m)

90-95ft-lb(122-129N-m)

72-77ft-lb(98-104N-m)

(285-339N-m)

ProductOverview

Figure4

1.SpeedControlLever4.SteeringLevers

2.Controls5.PTOEngagementLever

3.FuelCap

6.ParkingBrakeLever

16

Page 17

Operation

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

SteeringLevers

Locatedinthecenterinfrontoftheseat.

Pullingbackonthesteeringlevers,progressively

slows,thenreversesthedirectionoftravelofthe

respectivedrivewheels.

Bymovingbothsteeringleversanequalamountback,

themachinecanbesloweddownortravelbackward

inastraightline.

Steeringiscontrolledbyvaryingthepositionofthe

steeringleversrelativetoeachother.

SpeedControlLever

Locatedonrighthandconsole.

Thespeedcontrolleversetsmaximumforwardspeed.

Movingspeedcontrolleverrearwardtotheneutral

positionplacesthedrivesysteminneutral.

BrakeLever

Locatedonleftsideofunit,betweentheseatand

console.

Thebrakeleverengagesaparkingbrakeonthedrive

wheels.

Pulltheleverupandrearwardtoengagethebrake.

Pushtheleverforwardanddowntodisengagethe

brake.

Theunitmustbetieddownandbrakeengagedwhen

transporting.

IgnitionSwitch

Locatedontherighthandconsole.

Theignitionswitchisusedtostartandstopthe

engine.Theswitchhasthreepositions“OFF”,“ON”

and“START”.Insertkeyintoswitchandrotate

clockwisetothe“ON”position.Rotateclockwiseto

thenextpositiontoengagethestarter(keymustbe

heldagainstspringpressureinthisposition).

Note:Brakemustbeengaged,speedcontrollever

rearward(neutralposition)andPTOdisengagedto

startengine.(Itisnotnecessaryfortheoperatorto

beintheseattostarttheengine.)

HourMeter

ChokeControl

Locatedonrighthandconsole.

Thechokeisusedtoaidinstartingacoldengine.

Movingthechokeleverforwardwillputthechokein

the“ON”positionandmovingthechokelevertothe

rearwillputthechokeinthe“OFF”position.DO

NOTrunawarmenginewithchokeinthe“ON”

position.

ThrottleControl

Locatedonrighthandconsole.

Thethrottleisusedtocontrolenginespeed.Moving

throttleleverforwardwillincreaseenginespeedand

movingthrottlelevertotherearwilldecreaseengine

speed.

Locatedontherighthandconsole.

Thehourmeterisconnectedtoapressureswitch

installedintheengineblockanditrecordsthe

numberofhoursthattheenginehasrun.Ifthe

ignitionswitchisleftonwithoutenginerunning,

hourmeterwillnotrun.

Note:Thisswitchisnotalowoilsensorandwillnot

alerttheoperatoriftheengineoilislow .

FuelShut-OffValve

Locatedinfuellinebyfueltankandfuellter

(accessiblebyraisingthehopper).

Thefuelshut-offvalveisusedtoshutoffthefuel

whenthemachinewillnotbeusedforafewdays,

duringtransporttoandfromthejobsite,andwhen

parkedinsideabuilding.

Rotatethevalve1/4turnclockwisetoshutoffthe

fuel.rotatethevalve1/4turncounterclockwiseto

turnonthefuel.

17

Page 18

Operation

DriveWheelReleaseValves

Locatedonthetopleftfrontcornerofhydrostatic

pumps.

Drivewheelreleasevalvesareusedtoreleasethe

hydrostaticdrivesystemtoallowthemachinetobe

pushedwithouttheenginerunning.Tiltseatupto

gainaccesstopumps.

Witha7/16wrench,turnbothvalvesoneturn

counterclockwisetoreleasedrivesystem.Turn

clockwisetoresetsystem.DoNotovertighten.Do

Nottowmachine.

TrackingAdjustmentKnob

Locatedundertheseatontheleftpumpcontrollink.

Rotatingthisknoballowsnetuningadjustmentsso

thatthemachinetracksstraightwiththedrivelevers

inthefullforwardposition.

Rununitat3/4speedforatleast5minutesto

bringhydraulicoiluptooperatingtemperature.

Stopmachineandwaitforallmovingpartstostop.

Engageparkbrake.Tiltseatforwardtogainaccess

tothetrackingknob.Rotatetheknobtowardsthe

righttosteerrightandrotatetowardstheleftto

steerleft.Adjustin1/8turnincrementsuntilthe

machinetracksstraight.Checkthatthemachine

doesnotcreepwheninneutralwiththeparkbrakes

disengaged.

Important:DoNotrotatetheknobtoofar,as

thismaycausethemachinetocreepinneutral.

RefertotheMotionControlLinkageAdjustment

sectioninMaintenance.

PTOEngagementLever

Locatedimmediatelyleftoftheleftconsole.

Levermustbemoveduptothe“ROTATE”position

toengagethePTOandblowerdrives.Leverismoved

downtothe“STOP”positiontostopthedrives.

EngineOilTemperatureLightand

Buzzer

Locatedontherightconsole.

Theengineoiltemperaturelightmonitorsthe

temperatureoftheengineoil.Anilluminatedengine

oiltemperaturelightandintermittentbuzzingsound

signalstheengineisoverheating.

Pre-Start

Fillfueltanks.Forbestresultsuseonlyclean,fresh

regulargradeunleadedgasolinewithanoctanerating

of87orhigher.

Important:Neverusemethanol,gasoline

containingmethanol,gasoholcontainingmore

than10%ethanol,premiumgasoline,orwhite

gasbecausethefuelsystemcouldbedamaged.

DoNotaddoiltogasoline.

DoNotoverllfueltank.Fillthefueltanktothe

bottomofthellerneck.Theemptyspaceinthe

tankallowsgasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineoremission

system(ifequipped).

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

OpentheFuelShut-OffValve

Thefuelshut-offvalveislocatedontherightsideof

unitinfuellinenexttothefuellter.Raisethehopper

toaccess.Rotatethevalve1/4counterclockwiseto

turnonfuel.

StartingtheEngine

1.Movethespeedcontrollevertotheneutral

position.

2.Pullupandbackontheparkingbrakeleverto

engagetheparkingbrake.

3.PushthePTOengagementleverdowntothe

“STOP”position.

Note:Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.

4.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

5.Onacoldengine,pushthechokeleverforward

intothe“ON”position.

Onawarmengine,leavethechokeinthe“OFF”

position.

18

Page 19

Operation

6.Turnignitionswitchtothe“START”position.

Releasetheswitchassoonastheenginestarts.

Important:DoNotcranktheengine

continuouslyformorethantensecondsata

time.Iftheenginedoesnotstart,allowa60

secondcool-downperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor.

7.Ifthechokeisinthe“ON”position,gradually

returnchoketothe“OFF”positionastheengine

warmsup.

EngagingthePTO

DANGER

Therotatingbladesunderthemowerdeck

aredangerous.Bladecontactcancause

seriousinjuryorkillyou.

DoNotputhandsorfeetunderthemower

ormowerdeckwhenthebladesareengaged.

DisengagingthePTO

1.Setthethrottletothe“MIDWAY”position.

2.PushPTOleverdowntothe“STOP”position

stoppingthePTOandblower.

StoppingtheEngine

1.Bringtheunittoafullstop.

2.DisengagethePTO.

3.Movespeedcontrollevertotheneutralposition.

4.Engagetheparkingbrake.

5.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

6.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

7.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

8.Closethefuelshut-offvalvewhenthemachine

willnotbeinuseforafewdays,when

transporting,orwhentheunitisparkedinside

abuilding.

DANGER

Anuncovereddischargeopeningwillallow

objectstobethrowninanoperator’sor

bystander’sdirection.Also,contactwiththe

blowerbladescouldoccur.Thrownobjects

orbladecontactcancauseseriousinjuryor

death.

Neveroperatethemowerwiththehopper

orhopperdoorraised,removed,oraltered

unlessthereisamulchkitinplaceand

workingproperly.

ThePTOleverengagesthePTOandblower.Besure

thatthehopperisdown,thehopperdoorissecurely

closed,andallpersonsareclearofthemowerdeck

anddischargeareabeforeengagingPTO.

Important:Operatormustbeinseatbeforethe

PTOcanbeengaged.

1.Setthethrottletothe“MIDWAY”position.

2.PullthePTOleverupwarduntillockedover

center.

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioning

onelevertoomuchaheadoftheother.

Operatormaylosecontrolofthemachine,

whichmaycausedamagetothemachine

orinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Important:Tobeginmovement(forwardor

backward)theoperatormustbeintheseat,the

brakelevermustbedisengaged(pusheddown)

beforethespeedcontrollevercanbemoved

forwardortheenginewillstop.

DrivingForward

1.Starttheengine.

2.Releasetheparkingbrake.

3.Placethethrottleinthe“FAST”positiontobegin

mowing.

3.Tomoveforwardinastraightlinemovethespeed

controlleverforward.

19

Page 20

Operation

Toturnleftorright,pulloneofthesteeringlevers

backtowardneutralinthedirectiondesired.

Themachinewillmovefasterthefartherthe

speedcontrolleverismovedawayfromneutral.

4.Tostop,pullthespeedcontrolleverbacktothe

neutralposition.

DrivinginReverse

1.Tomoverearwardinastraightlineapplyingequal

pressurepullbothsteeringleversrearward.

Toturnleftorright,releasepressureonthe

steeringlevertowardthedirectiondesired.

2.Tostop,releasethesteeringleverstotheneutral

position.

EmptyingHopper

1.Afullhopperisindicatedbyabuzzerlocated

behindtheoperatorinthehopper.Emptyhopper

whenbuzzersoundstopreventcloggingofthe

blowerordeck.

2.DisengagePTO,movespeedcontroltoneutral,

setparkbrakeanddismountunittodumphopper.

3.Makesureunitisonadrylevelsurface.

4.Liftthereardoorupandallowittorestontop

ofhopper.

5.Dumphopperbyrmlygraspingoneofthe

hopperhandlesoneithersideoftheunitand

liftingthehopper.

ClearingHopperScreen

Screenmayberemovedbyrmlyliftingscreen

handles(seeFigure5).

Pullscreentowardsthebacktoremove.Gentlytap

debrisfromthescreenasneeded.

Excessivebuild-uponthescreencancausethe

blowertoplug.

Figure5

1.Frontremovablescreen

canberotatedand

storedforwetcondtions

2.Frontremovablescreen4.Handles.

3.Primaryscreen

Transporting

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Securely

fastenthemachinetothetrailerortruckwithstraps,

chains,cable,orropes.Besurethatthetrailerortruck

hasallnecessarylightingandmarkingasrequiredby

law .Secureatrailerwithasafetychain.

CAUTION

Thisunitdoesnothaveproperturn

signals,lights,reectivemarkings,ora

slowmovingvehicleemblem.Drivingona

streetorroadwaywithoutsuchequipment

isdangerousandcanleadtoaccidents

causingpersonalinjury.Drivingonastreet

orroadwaywithoutsuchequipmentmayalso

beaviolationofStatelawsandtheoperator

maybesubjecttotrafcticketsand/ornes.

DoNotdriveaunitonapublicstreetor

roadway.

Note:Inconditionswherethescreenclogsquickly,

thefrontremovablescreenpanelcanbeturnedand

reinstalledundertheprimaryscreentoallowfreeair

owfromthehopper.

20

Page 21

WARNING

Loadingaunitonatrailerortruckincreases

thepossibilityoftip-over.Tip-overcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

unitonaramp.

•Useonlyasingle,fullwidthramp;Do

Notuseindividualrampsforeachside

oftheunit.

•Ifindividualrampsmustbeused,use

enoughrampstocreateanunbroken

rampsurfacewiderthantheunit.

•DoNotexceeda15°anglebetweenramp

andgroundorbetweenrampandtrailer

ortruck.

•Avoidsuddenaccelerationwhiledriving

unitonaramp.

Operation

LoadingaUnit

Useextremecautionwhenloadingunitsontrailers

ortrucks.Onefullwidthrampisrequired.Ifitis

notpossibletouseonefullwidthramp,useenough

individualrampstosimulateafullwidthcontinuous

ramp.

Rampshouldbelongenoughsothattheangles

betweentherampandthegroundandtherampand

thetrailerortruckdonotexceed15°.Asteeperangle

maycausemowerdeckcomponentstogetcaughtas

theunitmovesfromramptotrailerortruck.Steeper

anglesmayalsocausetheunittotip.Ifloadingonor

nearaslope,positionthetrailerortrucksoitison

thedownsideoftheslopeandtherampextendsup

theslope.Thiswillminimizetherampangle.The

trailerortruckshouldbeaslevelaspossible.

Important:DoNotattempttoturntheunit

whileontheramp,youmaylosecontroland

driveofftheside.

Avoidsuddenaccelerationwhendrivingonaramp.

21

Page 22

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)aside

soitdoesnotaccidentallycontactthespark

plug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthewheelhublocknutstorquespecication.

•Checkthewheellugnuttorquespecication.

WARNING

Theenginecanbecomeveryhot.T ouching

ahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

Aftertherst250hours

Beforeeachuseordaily

Every40hours

Every50hours

Every80hours

Every100hours

Every160hours

Every500hours

•Changethehydrauliclter.

•Checktheengineoillevel.

•Checkthesafetyinterlocksystem.

•Checkforloosehardware.

•Removeaccumulateddebrisfromengine(seeCleaningsection.)

•Cleanthegrassanddebrisbuild-upfromthemachine.

•Checkthehydraulicoillevel.

•Checkthetirepressures.

•Checktheconditionofthebelts.

•Servicetheaircleaner.(Mayneedmoreoftenundersevereconditions.SeetheEngine

Owner’sManualforadditionalinformation.)

•Removeengineshroudsandcleancoolingns(seeCleaningsection.)

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Lubricatethebrakehandlepivot.

•Lubricatethebrakerodbushings.

•Lubricatethesteeringlinkagerodends.

•Lubricatehopperactuator

•Checkthesparkplugs.

•Changethehydrauliclter(Every250hours/yearlyifusingMobil115W50)

•Checkthewheelhublocknutstorquespecication.

•Checkthewheellugnuttorquespecication.

22

Page 23

Maintenance

MaintenanceService

Interval

Monthly

Yearly

MaintenanceProcedure

•Checkthebatterycharge.

•Lubricategreasettings.

•Lubricatethecasterwheelhubs.

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Raisehopper.

4.Cleanareaarounddipstick.Removedipstickand

wipeoiloff.Reinsertthedipstickandpushitall

thewaydownintothetube.Removethedipstick

andreadtheoillevel.

5.Iftheoillevelislow ,wipeofftheareaaroundthe

oilllcap,removecapandlltothe“FULL”

markonthedipstick.Useoilasspeciedin

EngineOwner’ sManual.DoNotoverll.

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

CheckBatteryCharge

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

Allowingbatteriestostandforanextendedperiodof

timewithoutrechargingthemwillresultinreduced

performanceandservicelife.T opreserveoptimum

batteryperformanceandlife,rechargebatteriesin

storagewhentheopencircuitvoltagedropsto12.4

volts.

Note:Topreventdamageduetofreezing,battery

shouldbefullychargedbeforeputtingawayfor

winterstorage.

Checkthevoltageofthebatterywithadigital

voltmeter.Locatethevoltagereadingofthebatteryin

thetableandchargethebatteryfortherecommended

timeintervaltobringthechargeuptoafullcharge

of12.6voltsorgreater.

Important:Makesurethenegativebattery

cablesaredisconnectedandthebatterycharger

usedforchargingthebatteryhasanoutputof

16voltsand7ampsorlesstoavoiddamaging

thebattery(seechartforrecommendedcharger

settings).

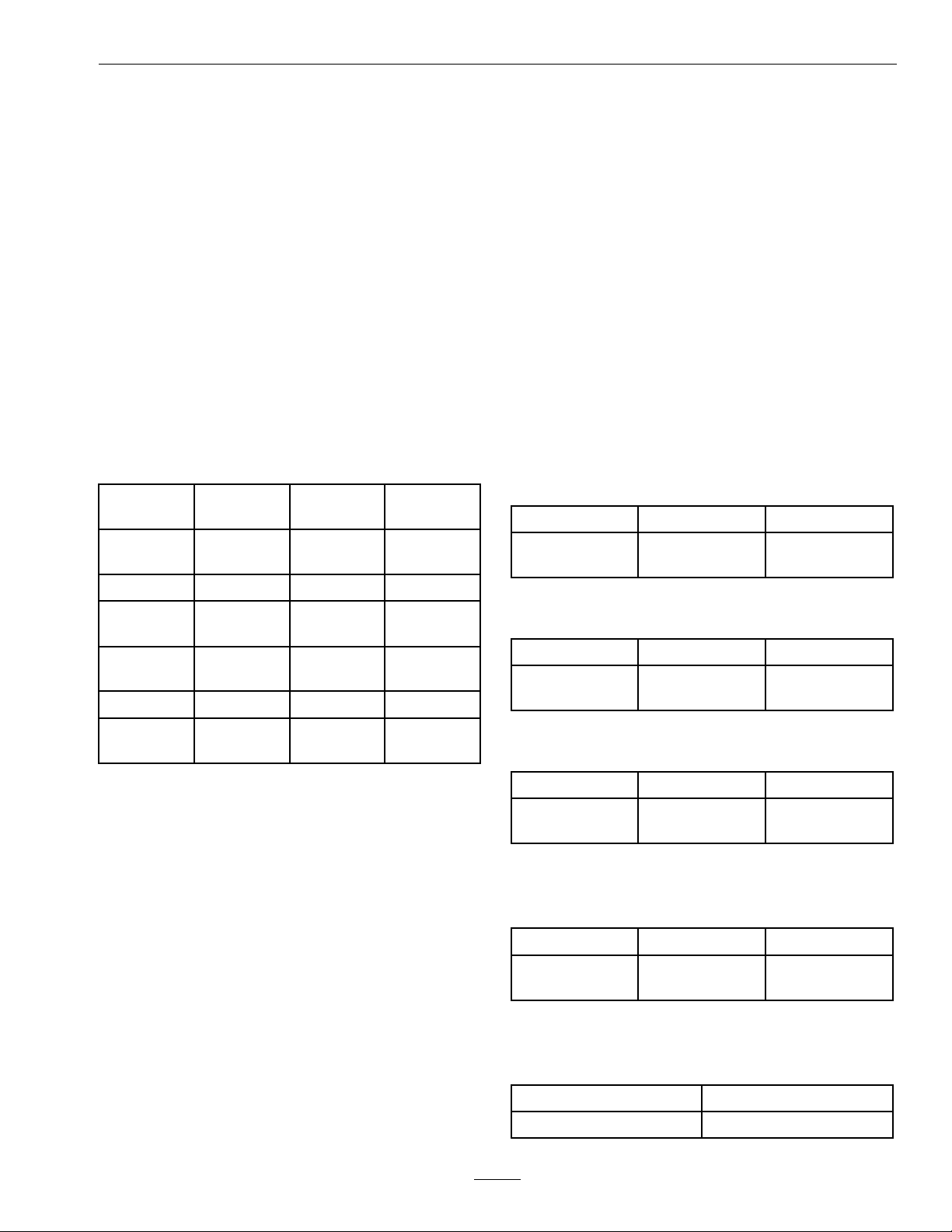

Voltage

Reading

12.6or

greater

12.4–12.675–100%

12.2–12.450–75%

12.0–12.225–50%

11.7–12.00–25%

11.7orless

Percent

Charge

100%

0%

Maximum

Charger

Settings

16volts/7

amps

16volts/7

amps

16volts/7

amps

14.4volts/4

amps

14.4volts/4

amps

14.4volts/2

amps

Charging

Interval

No

Charging

Required

30Minutes

1Hour

2Hours

3Hours

6Hoursor

More

RecommendedJump

StartingProcedure

ServiceInterval:Asrequired

1.Checktheweakbatteryforterminalcorrosion

(white,green,orblue“snow”),itmustbecleaned

offpriortojumpstarting.Cleanandtighten

connectionsasnecessary.

23

Page 24

Maintenance

CAUTION

Corrosionorlooseconnectionscancause

unwantedelectricalvoltagespikesatanytime

duringthejumpstartingprocedure.

DoNotattempttojumpstartwithlooseor

corrodedbatteryterminalsordamagetothe

enginemayoccur.

DANGER

Jumpstartingaweakbatterythatiscracked,

frozen,haslowelectrolytelevel,oran

open/shortedbatterycell,cancausean

explosionresultinginseriouspersonalinjury.

DoNotjumpstartaweakbatteryifthese

conditionsexist.

2.Makesuretheboosterisagoodandfullycharged

leadacidbatteryat12.6voltsorgreater.Use

properlysizedjumpercables(4to6AWG)with

shortlengthstoreducevoltagedropbetween

systems.Makesurethecablesarecolorcodedor

labeledforthecorrectpolarity .

CAUTION

Note:Besuretheventcapsaretightandlevel.

Placeadampcloth,ifavailable,overanyvent

capsonbothbatteries.Besurethevehiclesdo

nottouchandthatbothelectricalsystemsare

offandatthesameratedsystemvoltage.These

instructionsarefornegativegroundsystemsonly.

3.Connectthepositive(+)cabletothepositive(+)

terminalofthedischargedbatterythatiswiredto

thestarterorsolenoidasshowninFigure6.

Figure6

1.Positive(+)cableondischargedbattery

2.Positive(+)cableonboosterbattery

3.Negative(–)cableontheboosterbattery

4.Negative(–)cableontheengineblock

5.Boosterbattery

6.Dischargedbattery

7.Engineblock

Connectingthejumpercablesincorrectly

(wrongpolarity)canimmediatelydamage

theelectricalsystem.

Becertainofbatteryterminalpolarityand

jumpercablepolaritywhenhookingup

batteries.

Note:Thefollowinginstructionsareadapted

fromtheSAEJ1494Rev.Dec.2001–Battery

BoosterCables–SurfaceVehicleRecommended

Practice(SAE–SocietyofAutomotive

Engineers).

WARNING

Batteriescontainacidandproduceexplosive

gases.

•Shieldtheeyesandfacefromthebatteries

atalltimes.

•DoNotleanoverthebatteries.

4.Connecttheotherendofthepositivecabletothe

positiveterminaloftheboosterbattery.

5.Connecttheblacknegative(–)cabletotheother

terminal(negative)oftheboosterbattery.

6.MAKETHEFINALCONNECTIONON

THEENGINEBLOCKOFTHESTALLED

VEHICLE(NOTTOTHENEGATIVEPOST)

AWAYFROMTHEBATTERY .STANDBACK.

7.Startthevehicleandremovethecablesinthe

reverseorderofconnection(theengineblock

(black)connectionisthersttodisconnect).

CheckSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

Note:Topreventenginecut-outsonroughterrain

theseatkillswitchhasa1/2seconddelay.

1.Checkstartingcircuit.Startershouldcrankwith,

parkingbrakeengaged,PTOdisengagedand

24

Page 25

Maintenance

speedcontrolleverintheneutralposition.The

operatordoesnotneedtobeintheseattostart

theengine.

Trytostartwithoperatorinseat,parking

brakedisengaged,PTOdisengagedandspeed

controlleverintheneutralposition-starter

mustnotcrank.

Trytostartwithoperatorinseat,parkingbrake

engaged,PTOengagedandspeedcontrollever

intheneutralposition-startermustnotcrank.

Trytostartwithoperatorinseat,parkingbrake

engaged,PTOdisengaged,andthespeed

controlleverforward(outofneutral),starter

mustnotcrank.

2.Checkthekillcircuits.Runengineatone-third

throttle,disengageparkingbrakeandraiseoff

ofseat(butdonotgetoffofmachine)engine

mustinitiateshutdownafterapproximately1/2

secondhaselapsed(seathastimedelaykillswitch

topreventcut-outsonroughterrain).

Runengineatone-thirdthrottle,engagePTO

andraiseoffofseat(butdonotgetoffof

machine)enginemustinitiateshutdownafter

1/2secondhaselapsed.

Manualforadditional

information.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Tilthopperuptogainaccesstotheaircleaner.

3.Loosenretainingclipsandremoveaircleaner

compartmentcover.

4.Removepaperelement.Checkthecondition

ofthepaperelement.Replaceifdirty,bentor

damaged.

5.Checktheconditionoftheinnerelement.Replace

wheneveritappearsdirty,typicallyeveryother

timethepaperelementisreplaced.Cleanthebase

aroundtheinnerelementbeforeremoving,so

dirtdoesnotgetintotheengine.

6.DoNotwashorusepressurizedairtoclean

paperelementorinnerelement.

7.Reinstallelements.Positionthecoversothatthe

rubberdustejectorispointingdownwardand

securewithretainingclips.

ChangeEngineOil

Note:Ifmachinedoesnotpassanyofthesetests,

donotoperate.ContactyourauthorizedEXMARK

SERVICEDEALER.

Important:Itisessentialthatoperatorsafety

mechanismsbeconnectedandinproper

operatingconditionpriortouseformowing.

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

ServiceAirCleaner

ServiceInterval:Every50hours—Service

theaircleaner.(May

needmoreoftenunder

severeconditions.See

theEngineOwner’s

ServiceInterval:Aftertherst5hours

Every100hours(May

needmoreoftenunder

severeconditions.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Drainoilwhileengineiswarmfromoperation.

3.Tilthopperuptogainaccesstotheenginearea.

4.Theoildrainvalveislocatedonrighthandside

ofengineatthebackoftheunit.Removetwo

nutsnearrighthanddrivetireandswingoutthe

fueltank.Installoildrainhose,suppliedinthe

literaturepack,ontooildrainvalve.Placepan

undermachinetocatchoil.Openvalvetoallow

oiltodrainandthenclosevalve

5.Replacetheoilltereveryotheroilchange.Clean

aroundoillterandunscrewltertoremove.

Beforereinstallingnewlter,applyathincoating

ofoilonthesurfaceoftherubberseal.Turn

lterclockwiseuntilrubbersealcontactsthelter

adapterthentightenlteranadditional1/2to

3/4turn.

25

Page 26

Maintenance

6.Cleanaroundoilllcapandremovecap.Fillto

speciedcapacityandreplacecap.

7.Removedrainhose,closefueltank,andlower

hopper.

8.Useoilrecommendedinengineowner’smanual.

DoNotoverll.Starttheengineandcheckfor

leaks.

9.Wipeupanyspilledoilfromenginedeck

mountingsurfaces.

CheckHydraulicOilLevel

ServiceInterval:Every40hours

WARNING

Oilspilledorventedfromanoverlled

hydraulicreservoirontothePTObrakeband

willcausealongerstoppingtimeforthedeck

andblowerrotatingcomponents.Thedeck

andblowerrotatingcomponentscancause

seriousinjury.

•Waitforallmovingpartstocometoa

completestopbeforeservicing.

halfwaybetweenthe“HOT”and“COLD”levels.

Iftheoilisatroomtemperature(about75°F

(24°C)),llonlytothe“COLD”level.DoNot

overll.

CheckTirePressures

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto15psi(103kPa).

4.Therearcastertireissemi-pneumaticanddoes

notneedtobeinated.

Note:DoNotaddanytypeoftirelinerorfoam

llmaterialtothetires.Excessiveloadscreatedby

foamlledtiresmaycausefailurestothehydrodrive

system,frame,andothercomponents.Foamlling

tireswillvoidthewarranty.

CheckConditionOfBelts

ServiceInterval:Every40hours

•DoNotoverllthehydraulicreservoir.

Carefullyllonlytotherecommended

level.

•Replacethebrakebandifitbecomes

contaminatedwithoil.

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.

2.Tilthopperup.

3.Cleanareaaroundhydraulicreservoircapand

removecap.Oillevelshouldbetothetopofthe

bafeinsidethetank.Ifnot,addoil.Useonly

ExmarkPremiumHydrooil.Replacehydraulic

reservoircapandtightenuntilsnug.DoNot

overtighten.DoNotoverll.

Note:Thebafeislabeled“HOT”and

“COLD”.Theoillevelvarieswiththe

temperatureoftheoil.The“HOT”levelshows

thelevelofoilwhenitisat225°F(107°C).The

“COLD”levelshowstheleveloftheoilwhen

itisat75°F(24°C).Filltotheappropriatelevel

dependinguponthetemperatureoftheoil.For

example:Iftheoilisabout150°F(65°C),llto

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.TilthopperupandcheckpumpandPTOdrive

beltsforwear,cracking,orcontamination.

3.Beltsarespringtensionedandnoadjustmentis

necessaryunlessbeltsarereplaced.SeePTO

BeltReplacementandPumpDriveBelt

Replacementsectionsforbeltreplacement.

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lubricatettingswithonetotwopumpsof

NGLIgrade#2multi-purposegungrease.

RefertotheLubricationChartforttinglocations

andlubricationschedule.

26

Page 27

Maintenance

LubricationChart

Fitting

Locations

1.Caster

Pivot

2.PTO

Idler

3.Pump

Idler

4.Rear

CasterHub

Initial

Pumps

*03

11

11

*0

Numberof

Places

1

*Seestep3forspeciallubricationinstructionson

thefrontandrearcasterpivotsandtheLubricate

RearCasterWheelHubssectionforspecial

lubricationinstructionsontherearcasterwheel

hubs.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

Service

Interval

*Yearly

Yearly

Yearly

*Yearly

Figure7

1.Sealguard2.Spacernutwithwrench

ats

2.Removecasterwheelfromcasterforks.

3.Removesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethatthread

lockingadhesivehasbeenappliedtolockthe

spacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)from

thewheelassembly .

Deckshownforreferenceonly.Seeattachment

manualforlubricationschedule.

3.Lubricatecasterpivotsonceayear.Removehex

plugandcap.Threadgreasezerkinholeand

pumpwithgreaseuntilitoozesoutaroundtop

bearing.Removegreasezerkandthreadplugback

in.Placecapbackon.

LubricateRearCasterWheel

Hubs

ServiceInterval:Yearly

5.Pryoutseals,andinspectbearingsforwearor

damageandreplaceifnecessary.

6.PackthebearingswithaNGLIgrade#1

multi-purposegrease.

7.Insertonebearing,onenewsealintothewheel.

Note:Seals(ExmarkPN103-0063)mustbe

replaced.

8.Iftheaxleassemblyhashadbothspacernuts

removed(orbrokenloose),applyathreadlocking

adhesivetoonespacernutandthreadontothe

axlewiththewrenchatsfacingoutward.Do

Notthreadspacernutallofthewayontotheend

oftheaxle.Leaveapproximately1/8inch(3mm)

fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

NGLIgrade#1multi-purposegrease.

27

Page 28

Maintenance

11.Insertthesecondbearingandnewsealintothe

wheel.

12.Applyathreadlockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrenchats

facingoutward.

13.T orquethenutto75-80in-lb(8-9N-m),loosen,

thenre-torqueto20-25in-lb(2-3N-m).Make

sureaxledoesnotextendbeyondeithernut.

14.Reinstallthesealguardsoverthewheelhuband

insertwheelintocasterfork.Reinstallcasterbolt

andtightennutfully .

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjusttorqueon

spacernutuntilthereisaslightamountofdrag.

Reapplythreadlockingadhesive.

LubricateBrakeHandlePivot

ServiceInterval:Every160hours

LubricateBrakeRod

Bushings

ServiceInterval:Every160hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Unhookseatlatchandtiltseatup.

3.Lubricatebronzebushingsoneachendofbrake

rodshaftwithaspraytypelubricantoralightoil

(bushingsarelocatedtotheinsideoftheange

bearings).

LubricateSteeringLinkage

RodEnds

ServiceInterval:Every160hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Unhookseatlatchandtiltseatup.

3.Lubricateeachendofbothsteeringlinkagerods

withaspraylubricantoralightoil.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lubricatebronzebushingsonbrakehandle

pivotwithaspraytypelubricantorlightoil(see

Figure8).

Figure8

LeftSideofUnitShown

1.BrakeHandlePivot

2.PTOHandlePivot

3.SpringArmPivot

4.TogglePivot

LubricateHopperActuator

ServiceInterval:Every160hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Raisehopperandlocateactuatoronrighthand

sideofmainframe.

3.Lubricateswitchactuatorrodwithaspray

lubricantoralightoil.

CheckSparkPlugs

ServiceInterval:Every160hours

Removesparkplugs,checkconditionandresetgaps,

orreplacewithnewplugs.SeeEngineOwner’s

Manual.

ChangeFuelFilter

ServiceInterval:Asrequired

Afuellterisinstalledbetweenthefueltankandthe

engine.Replacewhennecessary.

ReplacementFilters

Kohler

KohlerP/N2405010

28

Page 29

Maintenance

ChangeHydraulicSystem

Filter

ServiceInterval:Aftertherst250hours

Every500hours/Yearly

(whichevercomes

rst)thereafter

(Every250hours/Yearlyif

usingMobil115W50)

Note:UseonlyExmarkPartNo.109-0071for

Summeruseabove32°F(0°C)orP/N1-523541

forWinterusebelow32°F(0°C).(Refertothe

HydrostaticGroundDriveSystemsectionin

Specicationsforlterspecications.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Carefullycleanareaaroundlter.Itisimportant

thatnodirtorcontaminationenterhydraulic

system.

3.Unscrewltertoremoveandallowoiltodrain

fromreservoir.

Note:DoNotchangehydraulicsystemoil(except

forwhatcanbedrainedwhenchanginglter),unless

itisfelttheoilhasbeencontaminatedorbeen

extremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

CheckWheelHubLocknuts

ServiceInterval:Aftertherst100hours

Every500hoursthereafter

Torqueto210–250ft-lb(285–339N-m).

CheckWheelLugNuts

ServiceInterval:Aftertherst100hours

Every500hoursthereafter

Torqueto90–95ft-lb(122–129N-m)crosspattern.

FuelTank—Mounting

Important:Beforereinstallingnewlter,ll

itwithExmarkPremiumHydrooilandapply

athincoatofoilonthesurfaceoftherubber

seal.

Turnlterclockwiseuntilrubbersealcontactsthe

lteradapter,thentightenthelteranadditional

2/3to3/4turn.

4.FillreservoirasstatedinCheckHydraulicOil

Levelsection.

ExmarkPremiumHydroOilisrecommended.

Refertothechartforanacceptablealternative:

HydroOil

ExmarkPremiumHydro

Oil(Preferred)

Mobil115W50

5.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

6.Startengineandmovethrottlecontrolaheadto

fullthrottleposition.Movethespeedcontrol

leverstothefullspeedandrunforseveral

minutes.Shutdownmachineandrecheckoil

level.

ChangeInterval

500Hours

250Hours

HardwareSpecications

ServiceInterval:Asrequired

Wheninstallingthenutsonthefueltankstuds,fully

tightenthenylocnutandbackoff1/2turn.This

allowsfornormalfueltankexpansionandcontraction

withchangesintemperatureandfuellevels.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

•Pumpdrivesheavesetscrews.

•SquareheadsetscrewsonHydropumpcontrol

arms.

•Sheaveretainingboltintheendofengine

crankshaft,blowershaftandjackshaft.

•Casterwheelspacernuts.

•Fueltankbulkheadttingnuts.

Adhesivessuchas“LoctiteRC/609orRC/680”or

“Fel-ProPro-LockRetainingIorRetainingII”are

usedonthefollowing:

29

Page 30

Maintenance

Fueltankstuds,wherestudsareinsertedintotank.

DielectricGrease

Dielectricgreaseisusedonallbladetypeelectrical

connectionstopreventcorrosionandlossofcontact.

Adjustments

Note:DisengagePTO ,shutoffengine,waitfor

allmovingpartstostop,engageparkingbrake,and

removekeybeforeservicing,cleaning,ormakingany

adjustmentstotheunit.

PTODriveBeltTension

Self-tensioning-Noadjustmentnecessary.

PumpDriveBeltTension

Self-tensioning-Noadjustmentnecessary.

PTOBeltReplacement

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Withengine“off”,engagePTOlever,then

removethehairpinandclevispinatthebottom

ofthePTObrakeband.

3.Rotatethebrakebandupwardsoutofthewayof

thebeltskeepingclearofthebeltdrive.

4.DisengagePTOlever.

5.Loosenbeltguides“ A ”and“B”(SeeFigure9).

6.Removecurrentbelts

7.Routenewbeltsontosheavesasshowninthe

decallocatedonthebackoftheleftdriveshield

(seeFigure9).

Figure9

1.Idler5.Engine

2.BeltGuide“B”6.BeltGuide“A”

3.PTOBelt

4.Jackshaft

7.Blower

8.EngagethePTOlever

9.Rotatebrakebandbackdownintooriginal

position

30

Page 31

10.Re-installclevispinandhairpintosecurebrake

band.

11.EngagethePTOlever.

12.Loosenthejamnutsandadjustlinkageuntilthe

topoftheidlerarmisalignedwiththebottomof

notchontensionarmasshowninFigure10.

Maintenance

Figure11

1.PumpDriveBelt4.Pump

2.Pump5.Idler

3.Idler6.Engine

Figure10

1.TensionArm

2.Loosenjamnuts

3.WhenPTOisengaged,aligntopofidlerarmwithbottom

ofnotchontensionarm,asshown.

4.IdlerArm

13.TightenjamnutsanddisengagePTOlever.

Re-engagePTOleverandcheckalignment.

14.CheckandadjustbeltguidesasstatedinBelt

GuideAdjustmentsection.

PumpDriveBelt

Replacement

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.RemovePTOBelts.SeePTOBeltReplacement

sectionforremovalinstructions.

3.Pullspringidlerorremovespringtorelievepump

drivebelttension.Removeoldbelt.

5.ReinstallPTOBeltsasstatedinthePTOBelt

Replacementsection

BeltGuideAdjustment

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.EngagePTOlever.

3.AdjustbeltguidesasshowninFigure12.

Figure12

1.1/8inch(3mm)4.Rotatewireformguideto

2.7/16inch(11mm)5.1/4inch(6mm)

3.1/8inch(3mm)

Clearance

centerbeltsinguide.

6.5/16inch(8mm)

4.Routenewbeltontosheavesasshowninthe

decallocatedonthebackoftheleftdriveshield

(seeFigure11).

31

Page 32

Maintenance

AdjustSafetySwitch

Adjustallsafetyswitchessoplungerextends3/16

inchto1/4inch(4.8mm-6.4mm)fromswitchbody

whenplungeriscompressed(seeFigure13).

Figure13

1.3/16inchto1/4inch(4.8mm-6.4mm)

BrakeAdjustment

Checktomakesureeachbrakeisadjustedproperly.

1.Pullthebrakeleverupandbacktotheengaged

position.

2.Agapmustexistbetweenthebottomofthebrake

boltheadandthetopsurfaceofthebrakeswivel

asshowninFigure14.Ifagapdoesnotexist,

adjustthelinkagetoamaximumgapof1/2inch

±1/8inch(1.3cm±0.33cm)asshown.

3.Thebrakesonbothsidescanbesimultaneously

adjustedbylengtheningorshorteningthelinkage

showninFigure15.

Figure15

BrakeAdjustmentforBothSides

(Atthesametime)

1.BrakeLeverinengaged

position

2.Removeclevispin4.Loosennuthere

3.Rotateyoke

4.Ifindividualadjustmentisnecessary,loosenthe

jamnutonthebrakeboltthatisagainsttheclevis

connectedtothebrakearmonthewheelmotor.

Turnthebrakebolttoachieveproperadjustment.

BrakeAdjustmentforEachSide(Separately)

1.BrakeLeverinengaged

position

2.Loosennuthere

3.1/2inch±1/8inch(1.3

cm±0.33cm)

Figure14

4.BrakeBolt

5.BrakeSwivel

5.Tightenthejamnutagainsttheclevis.

6.Repeatforothersideofunit.

7.Engageanddisengagethebrakestocheckfor

properengagementanddisengagement.Readjust

ifnecessary.Whenthebrakesaredisengaged,

thereshouldbefreeplayinthebrakelinkagewith

nodragginginthebrakes.

AdjustSpeedControlLever

Tension

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Tensioninspeedcontrollevercanbeadjusted

byadjustingthetightnessoftheleverpivotbolt,

whichislocatedundertheseatnearthespeed

controllever(seeFigure16).

3.Setthetensionhighenoughthatthespeedcontrol

leverpositionismaintainedduringoperationand

32

Page 33

Maintenance

looseenoughtobemovedcomfortablybythe

operator.

Figure16

1.SpeedControlLever3.Springdiscwashers

2.FrictionPlate4.Hexlocknut

CAUTION

Raisingthemowerdeckforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

theunittofall,whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

•Adjuststeeringlevers

1.Stopengineandwaitforallmovingpartsto

stop.

2.Pullthespeedcontrollevercompletelybackto

theneutralposition.Thetwosteeringlevers

shouldbestraightupanddown(vertical).If

necessary,adjuststeeringleversbychanging

thelengthofthelinkbetweenthespeed

controlleverandthecontrolarmontheend

ofthesteeringcontrolshaft(seeFigure17).

SpeedControlLinkage

Adjustment

WARNING

Enginemustberunninganddrive

wheelsmustbeturningsomotioncontrol

adjustmentcanbeperformed.Contactwith

movingpartsorhotsurfacesmaycause

personalinjury.

Keepngers,hands,andclothingclearof

rotatingcomponentsandhotsurfaces.

Figure17

1.Loosenjamnutshereto

adjustlinkage

•Setneutral:

1.Removetheelectricalconnectionfromthe

seatsafetyswitch,locateddirectlyinfrontof

theseatswitchassembly.

2.Theneutraladjustmentmustbemadewith

thedrivewheelsturning.Raisetheframeand

placeonjackstandssothatdrivewheelscan

rotatefreely.Temporarilyinstallajumperwire

2.Steeringleversshould

bevertical

33

Page 34

Maintenance

acrosstheterminalsintheconnectorofthe

wiringharness.

3.Starttheengine.

4.Runtheunitatleast5minuteswiththe

speedcontrolleveratfullforwardspeedto

bringhydraulicsystemoiluptooperating

temperature.Returnspeedcontrolleverto

neutral(fullrear)position.

5.Toobtaintheneutralposition,adjustthe

leftandrightpumpcontrolrodlinkagesthat

connectthesteeringcontroltothepump

controlarmsuntilthewheelsstop,orcreep

slightlyinreverse.

6.Adjusttheleftpumplinkagebyrotatingthe

trackingadjustmentknob.

7.Adjusttherightpumplinkagebyusing

awrenchtoturnthedoublenutsonthe

assembly(seeFigure18)

Setforwardstopbolt:

1.Removeseatdeck(withseatattached)toobtain

aclearviewofthesteeringcontrolshaftto

completethisadjustment.

2.Pushthespeedcontrolleverforwardtofull

forwardspeedposition.

3.Ifeithersteeringcontrolleversurfacedoesnot

contactthestopbaratthefullforwardspeed

position,adjustthestopboltuntilcontactoccurs

(seeFigure19).Oncecontactoccurs,turnthe

stopboltonemorefullturntopreventbottoming

ofthehydraulicpumpinternalstops.

Figure18

1.Rotatetrackingknobon

leftside

2.Rotatedoublenutson

rightside

8.Movethesteeringleverstothereverse

position.Whileapplyingslightpressureto

thelevers,allowthesteeringleverstoreturn

toneutral.Thewheelsmuststopturning(or

slightlycreepinreverse).

9.Stopengineandwaitforallmovingpartsto

stop.Removejumperwirefromwireharness

connectorandplugconnectorintoseatswitch.

Figure19

1.SpeedcontrolLever

forwardstopbolt

2.Contactmustbe

maintainedbetween

thesecomponentsatfull

forwardspeedcondition

SteeringControlLever

ResponseAdjustment

1.Stopengine,waitforallmovingpartstostopand

removekey.Engageparkingbrake.

2.Movethespeedcontrollevertothefullforward

position.

3.Lifttheseatandlocatethepumpcontrolsprings.

Toincreaseresponsiveness,increasespring

tensionbyhookingtherearspringanchordirectly

totheanchorbolt.Todecreaseresponsiveness,

hooktherearspringanchortotheanchortab.

Note:Besurebothspringsmaintainthesame

adjustment.

10.Lowerfromjackstands.

34

Page 35

Figure20

1.Toincreasesteeringresponsivenesshook

pumpcontrolsprintsdirectlyonanchorbolt.

Todecreasesteeringresponsivenesshookpump

controlspringsonanchortabsasshown.

Maintenance

inchto1/16inch(0.8-1.6mm).Useastraight

edgetoalignallthreesurfaces(seeFigure21).

Figure21

1.Alignthreepumpdrive

pulleysurfacesshown

withthispatternwithin

1/32inchto1/16inch

(0.8-1.6mm).

2.AlignthreePTOdrive

pulleysurfacesshown

withthispatternwithin

1/32inchto1/16inch

(0.8-1.6mm).

TrackingAdjustment

SeeMotionControlLinkageAdjustmentsection

PTODrivePulleyAlignment

PTOdrivepulleyalignmentisnecessaryforanyof

thefollowingconditions:

•Theblowerhasbeenremovedorreplaced.

•Theenginemountingboltshavebeenloosened

ortheenginehasbeenmovedorreplaced.

•Thejackshaftmountingboltshavebeenloosened

orthejackshafthasbeenmovedorreplaced.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Movethespeedcontrollevertotheneutral

position.

3.DisengagethePTOlever.

4.Removefueltankmountingnutsandswingout

fueltank.

5.Verifythattheblowerisinstalledandsecured

tightly.

6.Loosenthe4enginemountingbolts.

7.Unhookthepumpbelttensionspring.

8.Loosenthe4jackshaftmountingbolts.

9.Measuringfromtheblowerpulleyasabaseline,

movetheengineandjackshaftuntiltherear

surfaceofall3pulleysarealignedwithin1/32

10.Tightenthefourenginemountingboltsandfour

jackshaftmountingbolts.Checkalignmentafter

tightening.

11.Re-installpumpbelttensionspring.

12.Swingfueltankinandre-installtankmounting

nuts.

13.CompletethePumpDrivePulleyAlignment

section.

PumpDrivePulleyAlignment

Pumpdrivepulleyalignmentisnecessaryforanyof

thefollowingconditions:

•Theenginemountingboltshavebeenloosened

ortheenginehasbeenmovedorreplaced.

•Thepumppulleyshavebeenloosened,moved,

orreplaced.

•ThePTOpulleyalignmenthasbeenperformed

(seePTODrivePulleyAlignmentsection).

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Loosensetscrewsonbothpumppulleys.

3.Usingastraightedge,aligneachpumppulleywith

theenginepulleybyslidingalongthepumpshaft

(seeFigure21).

4.Re-tightenpulleysetscrewsandrecheck

alignment.

35

Page 36

Maintenance

RearCasterPivotBearings

Pre-LoadAdjustment

Removedustcapfromcasterandtightennyloc

nutuntilwashersareat.Backoff1/4ofaturn

toproperlysetthepre-loadonthebearings.If

disassembled,makesurethespringdiscwashersare

reinstalledasshowninFigure22.

1.Loosendoorhinge

nuts-threeperside

PTOBrakeSpring

Figure23

2.Placeapieceof3/8inch

(9.5mm)rubberonthis

surface

Figure22

1.Springdiscwashers

HopperDoorAdjustment

DoorClosing:

Loosensixdoorhingenuts(seeFigure23).

Opendoorandplacea3/8inchrubberstripor3/8

inchdiameterhosebetweenthehopperandhopper

door(seeFigure23).

Closedoorandpushtightagainsthopper.

Tightenhingehardware.Openhopperdoorand

removerubberstrip.

Adjustment

PTObrakespringadjustmentisonlynecessaryifthe

blowerhasbeenremovedorreplacedorifthePTO

driveidlerarmhasbeendisassembled.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Locatethebrakespringandthreadthetwojam

nutsouttotheendofthebrakespringrod(see

Figure24).

3.Tightenjamnutstogetheratendofbrakespring

rod.

1.Tightenjamnutshere

2.PTOBrakespringassembly

36

Figure24

Page 37

Maintenance

Cleaning

CleanEngineandExhaust

SystemArea

ServiceInterval:Beforeeachuseordaily

(Mayberequiredmore

oftenindryordirty

conditions.)

CAUTION

Excessivedebrisaroundtheenginecooling

airintakeandinsideofthepumpdrive

beltcompartmentanddamagedormissing

rubberbafescancausetheengineand

hydraulicsystemtooverheatwhichcan

createarehazard.

Cleanalldebrisfrominsideofpumpdrive

beltcompartmentdaily.

1.Stopengine,waitforallmovingpartstostop,and