Page 1

METRO®21

ForSerialNos.

790,000&Higher

PartNo.4500-400Rev.A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,or

otherreproductiveharm.

Important:Whenthemowerisusedoroperated

onanyCaliforniaforest,brushorgrasscovered

land,aworkingsparkarrestermustbeattached

tothemufer.Ifnot,theoperatorisviolating

statelaw,Section4442PublicResourceCode.To

acquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

ThissparkignitionsystemcomplieswithCanadian

ICES-002Cesystèmed’allumageparètincellede

vèhiculeestconformeàlanormeNMB-002du

Canada

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2008—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

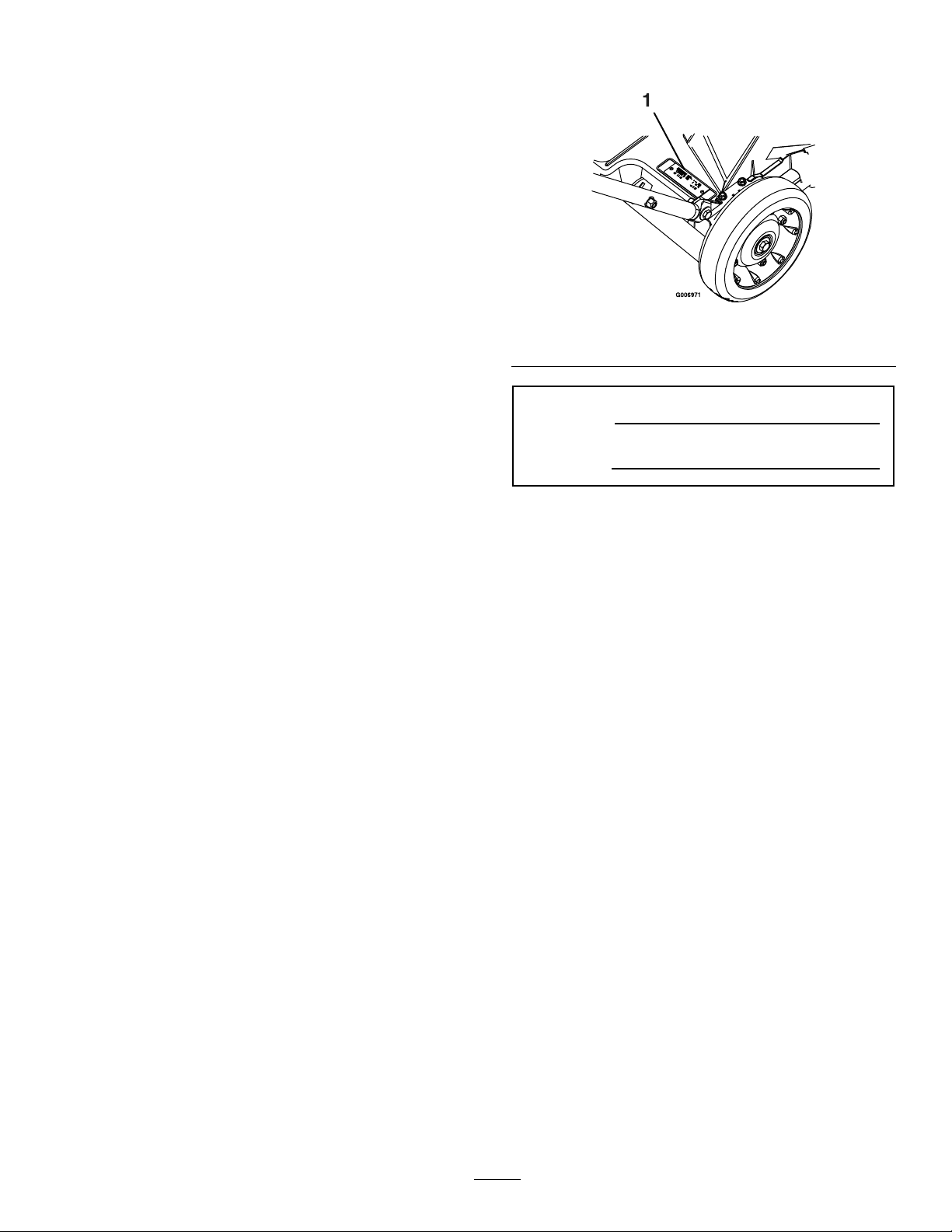

Figure1

1.Modelandserialnumberlocation

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency,andpromotesafe

operation.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

ModelNo.

SerialNo.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.......................9

Specications.......................................................12

ModelNumbers............................................12

Systems.........................................................12

Dimensions...................................................12

ProductOverview................................................13

Operation.............................................................14

Controls........................................................14

Pre-Start........................................................15

OperatingInstructions..................................16

Maintenance.........................................................23

RecommendedMaintenanceSchedule(s)...........23

PeriodicMaintenance.......................................24

CheckEngineOilLevel.................................24

CheckingtheBladeBrakeClutch(For

UnitswithaBladeBrakeClutch

Only).........................................................24

ChecktheMowerBlade.................................24

CheckforLooseHardware............................26

ServiceAirFilter(KawasakiUnits).................26

ServiceAirFilter(HondaUnits).....................27

ChangeEngineOil........................................28

ChangingtheOilFilter(KawasakiUnits

Only):........................................................28

ServicingtheWheels.....................................29

CheckConditionOfBelt(Self-Propelled

UnitsOnly)...............................................29

LubricatethePivotArms...............................29

LubricatetheGearCase(Self-Propelled

UnitsOnly)...............................................30

CheckSparkPlugs.........................................30

Adjustments.....................................................31

AdjustingtheSelf-Propel

Drive(Self-PropelledUnitsOnly)...............31

AdjustingtheBladeBrakeCable....................31

Cleaning...........................................................32

CleanGrassBuild-UpUnderDeck................32

CleaningtheDischargeTunneland

Plug...........................................................32

CleaningUndertheBelt

Cover(Self-PropelledModelsOnly)...........33

CleaningtheBladeBrakeClutch

Shield........................................................33

EmptyingtheFuelTankandCleaning

theFuelFilter(KawasakiUnits

Only).........................................................34

WasteDisposal..............................................34

Storage.................................................................35

PreparingtheFuelSystem..............................35

PreparingtheEngine.....................................35

GeneralStorageInformation.........................35

RemovingtheLawnMowerfrom

Storage......................................................35

Troubleshooting...................................................36

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThislawnmowermeetsorexceedstheCPSCblade

safetyrequirementsforwalk-behindrotarymowers

andtheB71.4specicationsoftheAmericanNational

StandardsInstituteineffectatthetimeofproduction

Exmarkdesignedandtestedthislawnmowertooffer

reasonablysafeservice;however,failuretocomply

withthefollowinginstructionsmayresultinpersonal

injury.

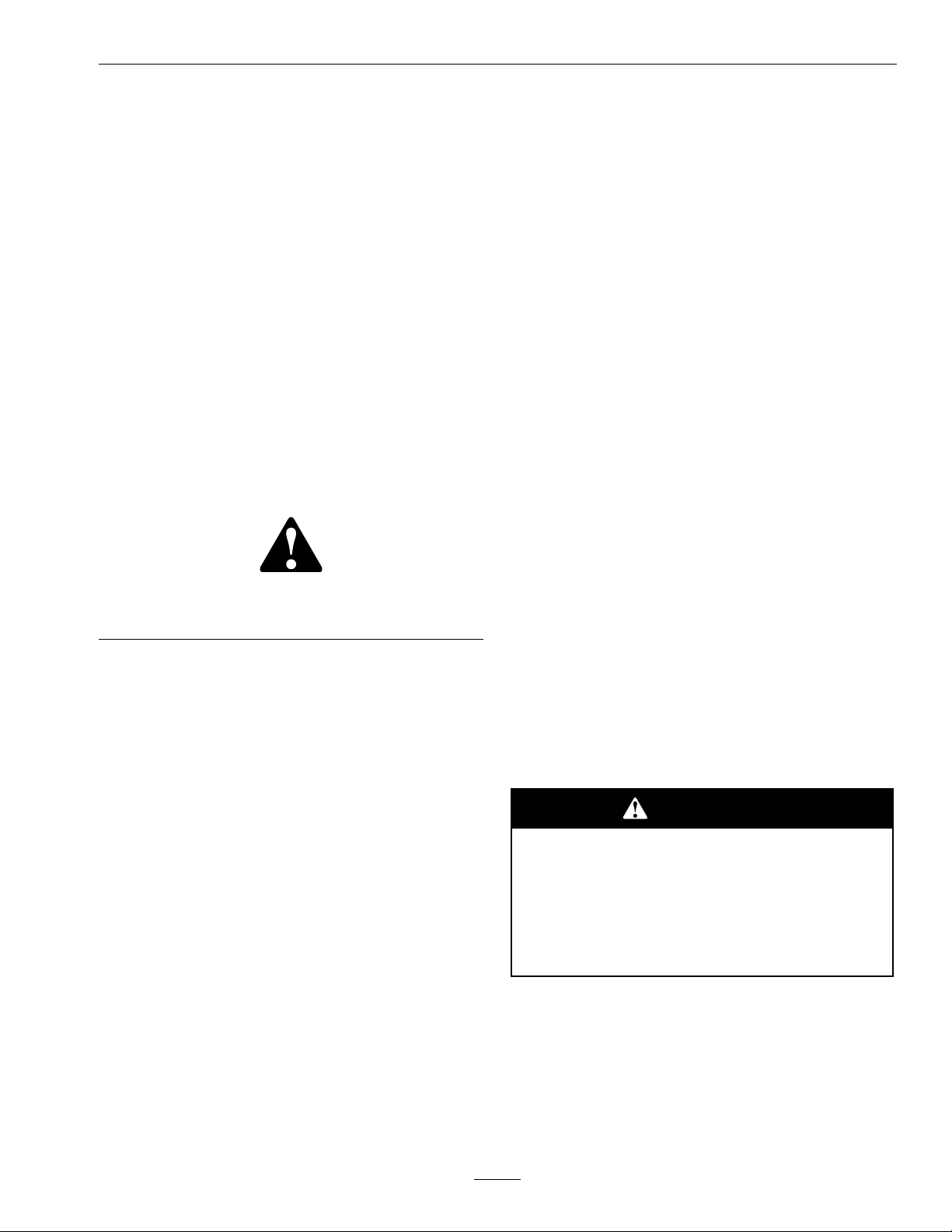

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

Figure2

1.Safetyalertsymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Y ellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

5

Page 6

Safety

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsinanopen

area,whentheengineiscold.Wipeup

anygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletely

full.Addgasolinetothefueltankuntil

thelevelis1/4to1/2inch(6–13mm)

belowthebottomofthellerneck.This

emptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,

andstayawayfromanopenameor

wheregasolinefumesmaybeignitedby

spark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.

Neverremovethecapofthefueltankor

addfuelwhenengineisrunningorwhen

theengineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperator’spresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly .DoNotoperateunlessthey

arefunctioningproperly.

6

Page 7

Safety

Operation

WARNING

Operatingengineparts,especiallythe

mufer,becomeextremelyhot.Severeburns

canoccuroncontactanddebris,suchas

leaves,grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Starttheenginecarefullyaccordingtoinstructions

withfeetwellawayfromtheblades.

•Neverraisedeckwithbladesrunning.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly .

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.

Frequentlycheckthecomponentsandreplace

themwiththemanufacturer’srecommendedparts

whennecessary.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Neverattempttomakewheelheightadjustments

whiletheengineisrunning.

•Stopengine,waitforallmovingpartstostop,

removethesparkplugwire(s)and/orremovekey .

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

–Beforemakingheightadjustments.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•Keepclearofthedischargeopeningatalltimes.

•Toextendthelifetheenginebrake,placethe

throttlecontrolinthe“slow”position;thenstop

theengine.

•Thismowerwasdesignedforoneoperator

only.Keepallothersawayfrommowerduring

operation.

•DONOToperatethemowerwhenpeople,

especiallychildren,orpetsareinthearea.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

7

Page 8

Safety

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Lossof

controland/orlossofoperator’sfooting

couldresultinafallwithanarmorleg

gettingunderthemowerorenginedeck

whichmayresultinseriousinjury,deathor

drowning.

•Mowacrossslopes,neverupanddown.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowexcessivelysteepslopes.

•Reducespeedanduseextremecaution

onslopes.

•Avoidsuddenturnsorrapidspeed

changes.

•Whenfeasible,avoidoperatingtheequipmentin

wetgrass.

•Progressivelygreatercareisneededastheslope

increases.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

MaintenanceandStorage

•Stoptheengineandremovethesparkplugwire(s)

and/orremovekey.Waitforallmovementto

stopbeforeadjusting,cleaningorrepairing.

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•LetenginecoolbeforestoringandDoNotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Removesparkplugwirebeforemakingany

repairs.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplaceblades.Neverstraightenor

weldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Allreplacementpartsmustbethesameas

orequivalenttothepartssuppliedasoriginal

equipment.

8

Page 9

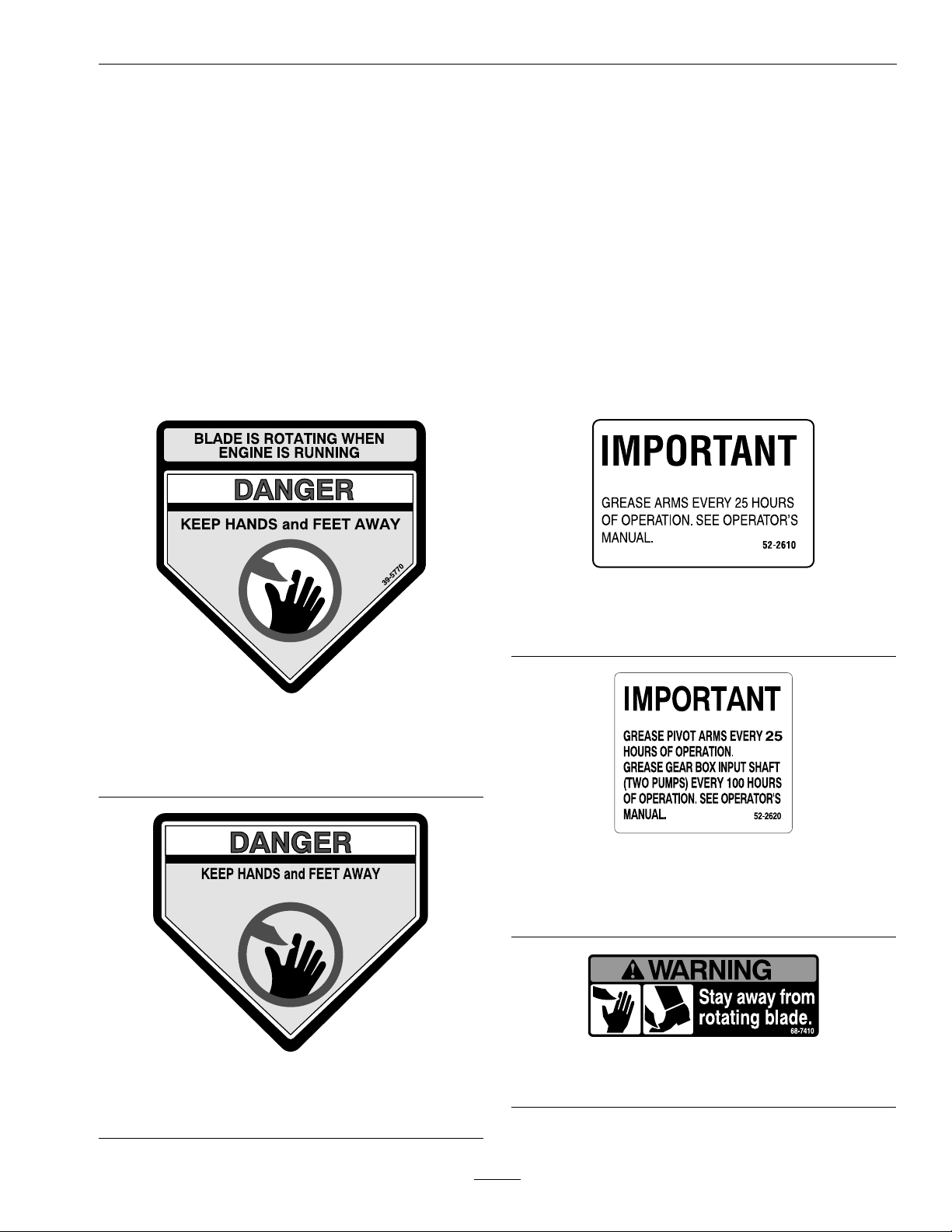

SafetyandInstructionalDecals

Safety

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

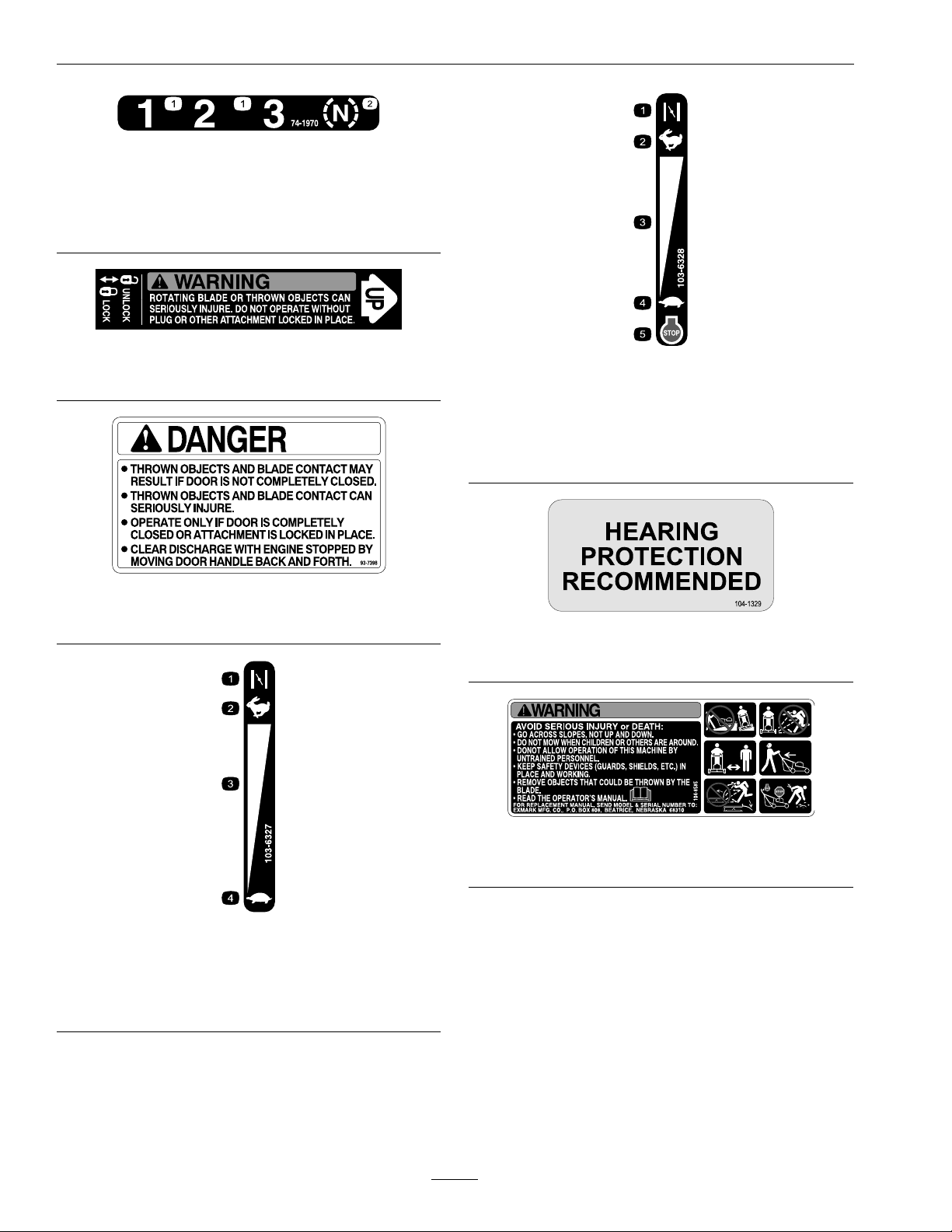

52-2610

ForPushUnits

(MPKA21andMPKA21CA)

39-5770

ForUnitswithoutaBladeBrakeClutch

(MPKA21,MPKA21CA,MSKA21,MSKA21CA,

andMSHN21)

43-8480

ForUnitswithaBladeBrakeClutch

(MSKA21B,MSHN21B,andMSKA21BCA)

52-2620

ForSelf-PropelledUnits

(MSKA21,MSKA21CA,MSKA21B,MSKA21BCA,

MSHN21,andMSHN21B)

68-7410

CommontoAllUnits

9

Page 10

Safety

ForSelf-PropelledUnits

(MSKA21,MSKA21CA,MSKA21B,MSKA21BCA,

MSHN21,andMSHN21B)

1.Transmissionspeeds2.Neutral

74-1970

77-0500

CommontoAllUnits

93-7398

CommontoAllUnits

103-6328

ForMSKA21BandMSHN21BUnitsOnly

1.Choke4.Slow

2.Fast5.Engine—stop

3.Continuousvariable

setting

104-1329

CommontoAllUnits

103-6327

ForMPKA21,MSKA21,andMSHN21UnitsOnly

1.Choke3.Continuousvariable

2.Fast

setting

4.Slow

104-8585

CommontoAllUnits

10

Page 11

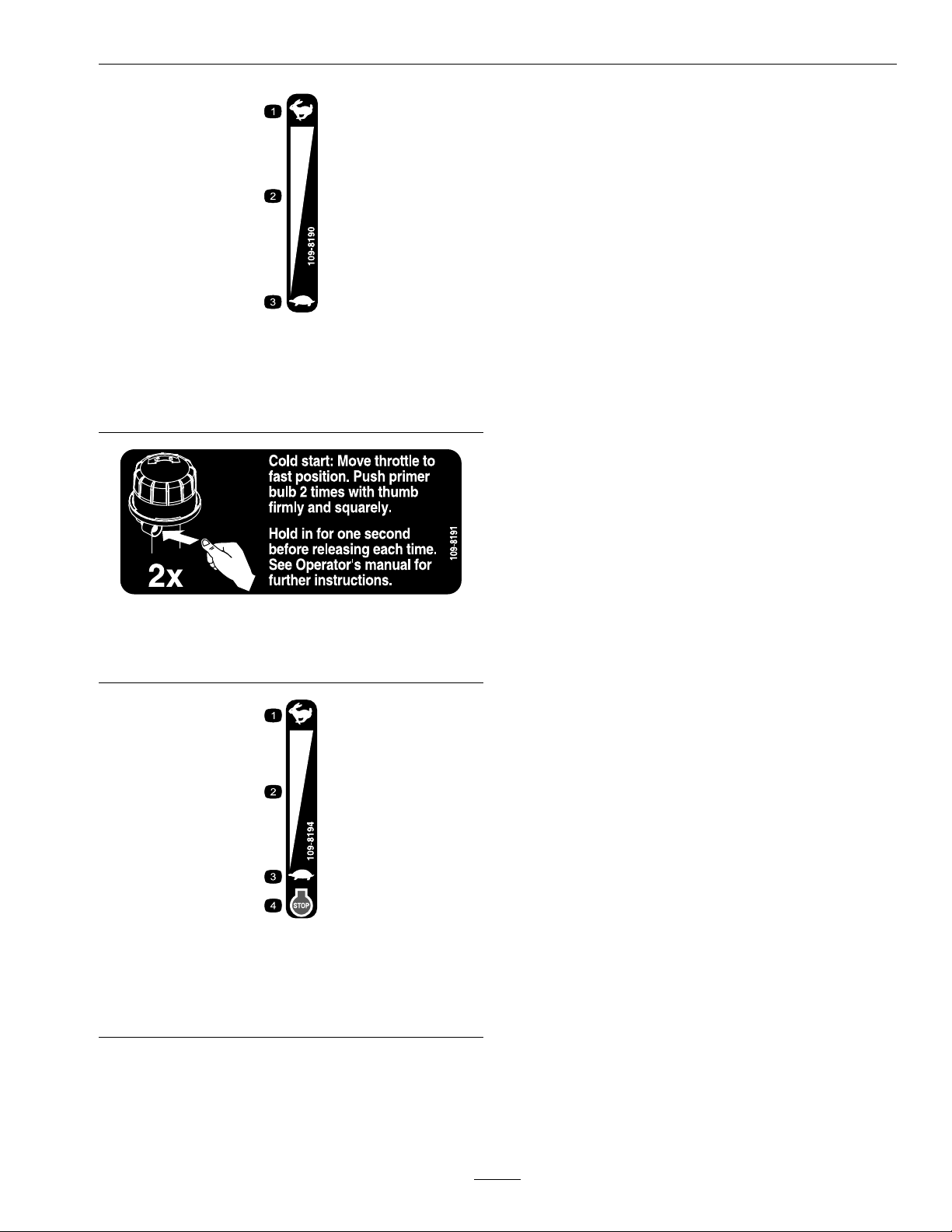

109-8190

OnMPKA21CAandMSKA21CAUnitsOnly

1.Fast

2.Continuousvariable

setting

3.Slow

Safety

1.Fast

2.Continuousvariable

setting

109-8191

OnMPKA21CA,MSKA21CA,

andMSKA21BCAUnitsOnly

109-8194

OnMSKA21BCAUnitsOnly

3.Slow

4.Engine—stop

11

Page 12

Specications

Specications

ModelNumbers

SerialNos:790,000andHigher

MPKA21;MPKA21CA;MSKA21;MSKA21CA;MSKA21B;MSKA21BCA;MSHN21;MSHN21B

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•RPM:3300(NoLoad)

FuelSystem

•Capacity:

MPKA21,MSKA21,andMSKA21BUnits:

4.0qt(3.8L)

MPKA21CA,MSKA21CA,andMSKA21BCA

Units:2.1qt(2.0L)

HondaUnits:2.1qt(2.0L)

•TypeofFuel:Regularunleadedgasoline,87

octaneorhigher.

•FuelFilter:Non-replaceable,intank

•FuelShut-OffValve:MPKA21,MSKA21,and

MSKA21BandHondaUnits:In-line1/4turn

increments.

MPKA21CA,MSKA21CA,andMSKA21BCA

UnitsDoNothaveashut-offvalve.

CuttingDeck

•CuttingWidth:21inches(53.3cm)

•BladeBrake:Whenthebladeengagementcontrol

ismovedtothedisengagedpositionafriction

brakepadstopstherotationoftheblades.

•BladeSize:(1ea.):20.88inches(53.0cm)

•Deck:21inchesrigid.Deckdesignallowsfor

bagging,mulchingorsidedischarge.

•CuttingHeightAdjustment:

Adjustsfrom3/4inches(1.9cm)to31/4inches

(8.3cm)in1/2inch(1.3cm)increments.

•MulchingKit:Standard

•SideDischargeKit:Optional

Dimensions

CurbWeight:

122lb(55kg)Weightsmayvaryslightlydepending

onengineoption.

OverallWidth:

SafetyInterlockSystem

ForunitswithoutaBladeBrakeClutch:Operator

musthavethebladecontrolbaildepressedtostart

theengine.Releasingthebladecontrolbailwillcause

theenginetostop.

Transmission(SelfPropelledUnits)

3speedsforward

SpeedRange:

•1st–2.0mph(3.2km/hr)

•2nd–2.9mph(4.6km/hr)

•3rd–4.1mph(6.6km/hr)

22.25inches(56.5cm)

12

Page 13

ProductOverview

OverallLengthandHeightat

21/4inchCuttingHeight:

HandleSettingLengthHeight

High60.50inches

(153.7cm)

Medium

Low

64.25inches

(163.2cm)

67.00inches

(170.2cm)

OverallLengthandHeightat

AlternateHandleMountingPosition:

HandleSettingLengthHeight

High62.63inches

(159.1cm)

Medium

Low

64.38inches

(163.5cm)

66.25inches

(168.3cm)

42.75inches

(108.6cm)

40.38inches

(102.6cm)

37.88inches

(96.2cm)

37.50inches

(95.3cm)

35.50inches

(90.2cm)

33.63inches

(85.4cm)

ProductOverview

Figure3

1.Sparkplug

2.Oilll/dipstick9.Throttle/Chokecontrol

3.Dischargedoorhandle10.Fueltank

4.Grassbag11.Oillter

5.BladeControlLever

(BladeBrakeUnitsOnly)

6.BladeControlBail13.Cuttingheightlever

7.Handle

8.DriveBail

(Self-PropelledUnits

Only)

12.Airlter

13

Page 14

Operation

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

BladeControlBail

LocatedontheupperhandleasshowninFigure4.

Whenthebladecontrolbailisdepressed,thesystem

sensesthattheoperatorisinthenormaloperator’s

position.

•ForUnitswithaBladeBrakeClutch:When

thebladecontrolbailisreleased,thesystem

sensesthattheoperatorhasmovedfromthe

normaloperatingpositionandwillstoptheblade.

•ForUnitswithoutaBladeBrakeClutch:

Whenthebladecontrolbailisreleased,thesystem

sensesthattheoperatorhasmovedfromthe

normaloperatingpositionandwillkilltheengine.

controllever.Whenthisbailisreleasedtheunitwill

stopmoving.

Throttle-ChokeControl

Thethrottle-chokecontrolislocatedontheleftside

ofthehandlesasshowninFigure4.

Theleverisusedtocontrolenginespeed.Moving

thelevertothefullforward(Choke)positionwill

placetheleverinthechokeposition.Thechokeaids

instartingacoldengine.Movingthethrottlecontrol

forwardwillincreaseenginespeedandmovingitto

therearwilldecreaseenginespeed.

ForunitswithaBladeBrakeControl:The

throttle-chokecontrolalsoincludesanenginekill

position.Movingtheleverintothefullrearward

(Off)positionwillkilltheengine.

Note:MPKA21CA,MSKA21CA,and

MSKA21BCAUnitsDoNothaveachoke.

BladeControlLever(BladeBrake

ClutchUnitsOnly):

Figure4

1.Throttle-ChokeControl

2.BladeControlLever

(BladeBrakeUnitsOnly)

3.BladeControlBail

Self-PropelDriveBail(For

Self-PropelledUnitsOnly)

4.Handle

5.DriveBail

(Self-PropelledUnits

Only)

Thebladecontrolleverislocatedontherightsideof

thehandlenexttotheBladeControlBailasshown

inFigure4.

Movingthebladecontrolleverintothefullforward

positionwhiledepressingthebladecontrolbail

engagestheblade.Releasingthebladecontrolbail

automaticallydisengagestheblades.

GroundSpeed(Shifter)Control

(Self-PropelledUnitsOnly):

Thegroundspeedcontrolislocatedattherearofthe

beltcoverasshowninFigure5.

Thegroundspeedcontrolhasthreesettingswhich

controlthegroundspeedofthemower:1isslow,2

ismedium,and3isfast.

LocatedontheupperhandleasshowninFigure4.

Whentheself-propeldrivebailissqueezed,theunit

willmoveforwardatthespeedsetonthespeed

14

Page 15

Figure5

1.Groundspeedcontrol

FuelShut-OffValve

ForMPKA21,MSKA21,andMSKA21BUnits:

Thefuelshutoffvalveisinstalledonthefuelline

midwaybetweenthefueltankandtheengineas

showninFigure6.

Operation

Figure7

MSHN21andMSHN21BUnits

1.Fuelvalve

ForMPKA21CA,MSKA21CA,andMSKA21BCA

Units:Donothaveafuelshutoffvalve.

Figure6

MPKA21,MSKA21,andMSKA21BUnits

1.Fuelline

2.Fuelvalve

3.Elbowtting

ForMSHN21andMSHN21BUnits:Thefuel

shutoffvalveislocatedontheengineasshownin

Figure7.

Thefuelshutoffvalveshutsofftheowoffuel

whenthemachinewillnotbeusedforafewdays,

whenparkinginsideabuilding,andduringtransport

toandfromthejob.Rotatethevalve1/4turn

clockwisetoshutofffuel.Rotatethevalve1/4turn

counterclockwisetoturnonfuel.

Pre-Start

Fillfueltank.Forbestresultsuseonlyclean,fresh

regulargradeunleadedgasolinewithanoctanerating

of87orhigher.Toensurefreshness,purchaseonly

thequantityofgasolinethatyouexpecttousein

30days.Usingunleadedgasolineresultsinfewer

combustiondepositsandlongerenginelife.See

EngineOwner’sManual.

DoNotaddoiltogasoline.

DoNotusemethanol,gasolinecontainingmethanol,

gasoholcontainingmorethe10%ethanol,premium

gasolineorwhitegas.Usingthesefuelscandamage

theengine’sfuelsystem.

DoNotusegasolinethathasbeenstoredsincethe

lastmowingseasonorlonger.

DoNotoverllfueltank.Neverllthefueltankso

thatthefuellevelrisesabovealevelthatis1/2inch

belowthebottomofthellernecktoallowforfuel

expansionandpreventfuelspillage.

15

Page 16

Operation

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

HandleAdjustment

Thehandlemaybeadjustedtodifferentheightsfor

comfortableoperation.Standbehindthehandleto

determinetheheight.toadjustthehandleheight,

positionthecapscrewsandthelocknutsthatsecure

thehandlelatchestothehandleintotheother

mountingholesinthelatches.

SeeFigure8Aforthehighestpossiblehandleheights.

SeeFigure8Bforthelowestpossiblehandleheights.

1.Installthehardwareinthelowerholesinthe

handleandlatchesasshowninFigure8.

2.Installhardwareinoneofthethreeadjustment

holesintheupperendsofeachofthehandle

latchestoobtainthedesiredhandleheightwithin

theselectedrange.

3.Slidethebagsupportrodthroughintotheupper,

middle,orlowermountingholesinthehandle

andsecureeachendwithacaplocknut.Thebag

supportrodmountingholelocationcorresponds

withthemountingholelocationforthehandle

latchesasshowninthetable.

BagSupportRod

MountingHoleLocation

LowerLower

MiddleMiddle

UpperUpper

HandleLatchMounting

HoleLocation

OpentheFuelShut-OffValve

1.Handlelatch

2.Adjustmentholesin

upperendofhandle

latch

3.Handle

Rotatethevalve1/4turncounterclockwisetoturn

thefuelon.

StartingtheEngine

1.Connectthewiretothesparkplug.

ForMSHN21andMSHN21BUnits:see

Figure9.

ForMPKA21,MSKA21,MSKA21B,

MPKA21CA,MSKA21CA,andMSKA21BCA

Units:seeFigure10.

Figure8

4.Springdiscwasher

5.5/16-18x13/8inchhex

capscrew

6.5/16-18x11/4inchhex

capscrew

16

Page 17

Figure9

AllHondaUnits

Operation

ForMSHN21andMSHN21BUnits:see

Figure7.

MPKA21CA,MSKA21CA,andMSKA21BCA

Units:DoNothaveafuelvalve.

3.ForMSHN21MSHN21B,MPKA21,MSKA21,

andMSKA21BUnits:Movethethrottle-choke

controltotheChokeposition.

Note:DoNotusethechokewhentheengineis

warmsup.

ForMPKA21CA,MSKA21CA,and

MSKA21BCAUnits:Movethethrottlecontrol

totheFastposition.Presstheprimerbulbtwo

times(seeFigure11).

1.Oilll/dipstick

2.Recoilstarterhandle

3.Fueltankcap

AllKawasakiUnits

1.Mufer5.Oillter

2.Oilll/dipstick

3.Fueltankcap

4.Recoilstarterhandle

4.Aircleaner

5.Sparkplug

Figure10

6.Aircleaner

7.Sparkplug

2.Openthefuelvalve.

ForMPKA21,MSKA21,andMSKA21BUnits:

seeFigure6.

Figure11

4.ForunitswithoutaBladeBrakeClutch:Hold

thebladecontrolbailtothehandle.

5.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullitsharply.Allowtheropeto

returnslowly.

6.Whentheenginestarts,movethethrottlecontrol

totheFastposition,andsetthegroundspeed

controlasdesired.

Note:Iftheenginefailstostartafterthreepulls,

repeatsteps3through6).

StoppingtheEngine

1.Bringtheunittoafullstop.

•ForunitswithoutaBladeBrakeClutch:

Releasethebladecontrolbail.Boththe

engineandthebladeshouldstopwithinthree

seconds.

•ForunitswithaBladeBrakeClutch:

Releasethebladecontrolbail.Theblade

shouldstopwithinthreeseconds.Movethe

throttletothe(Off)positiontokilltheengine.

17

Page 18

Operation

Note:Ifthebladedoesnotstopwithin3

secondsafterreleasingthebladecontrolbail,

contactanAuthorizedServiceDealer.

2.Closethefuelshut-offvalve,ifequippedwith,

whenthemachinewillnotbeinuseforafew

days,whentransporting,orwhentheunitis

parkedinsideabuilding.

UsingtheSelf-PropelDrive

(Self-PropelledUnitsOnly)

Thelawnmowerhasthreegroundspeeds:1isslow ,

2ismedium,and3isfast.

1.Starttheengine.

2.Usingthegroundspeedcontrol,selectthedesired

groundspeed.

3.Squeezethedrivebailagainstthehandle(see

Figure4).

Note:DoNotshiftspeedswhilesqueezingthe

groundspeedcontrolagainstthehandle.This

candamagethetransmission.Releasetheground

speedcontrolbeforechangingspeeds.

Note:Thebladecontrolleverwillreleaserapidly

whenthebladecontrolbailisreleased.Toavoid

minorinjury,keephandsclearofthebladecontrol

leverwhenthebladecontrolbailisreleased.

UsingtheDischargeTunnel

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Inserttheplug.(RefertoInstallingthe

DischargePlugsection).

3.Toremovetheplug,movethedischargedoor

handlerearwardandliftupthespringcliponthe

bottomoftheplug.Whentheplugisunlocked,

pullitoutofthedischargetunnel.

Note:Whengrassisthickandlush,clippings

maycollectonandaroundthedischargetunnel

plug.Thismaymakeremovingtheplugdifcult.

Cleantheplugthoroughlyaftereachuse.

CheckingtheBladeBrakeClutch

(BladeBrakeClutchUnitsOnly)

Note:Youcanvarythegroundspeedby

increasingordecreasingthedistancebetweenthe

groundspeedcontrolandthehandle.Lowerthe

controlbartodecreasethegroundspeedwhen

youaremakingaturnorifthelawnmoweris

movingtoofastforyou.Ifyoulowerthecontrol

bartoofarthelawnmowerstopsself-propelling.

Squeezethegroundspeedcontrolclosertothe

handletoincreasethegroundspeed.When

youholdthegroundspeedcontroltightagainst

thehandle,thelawnmowerself-propelsatthe

maximumgroundspeed.Movethegroundspeed

controltotheNeutralpositionwhenyouusethe

lawnmowerfortrimmingorwheneveryouleave

thelawnmower.

OperatingtheBladeControlLever

(BladeBrakeClutchUnitsOnly)

1.Starttheengine.

2.Squeezethebladecontrolbailagainstthehandle

(Figure4).

ChecktheBladeBrakeClutch(BBC)systembefore

eachusetoensurethatitisoperatingproperly.

NormalTest:

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Movethelawnmowerontoapavedsurfacein

anon-windyarea.

3.Setallfourwheelsintothe21/2inches(6.4cm)

cuttingheight(seeFigure13).

4.SetthegroundspeedselectortotheN(Neutral)

position.

5.Takeahalfsheetofnewspaperandcrumple

itintoballsmallenoughtogounderthedeck

(about3inchesor7.6cmindiameter)asshown

inFigure12.

3.Movethebladecontrollevertothefullforward

Latchposition.Bladesshouldengage.

4.Releasethebladecontrolbailtodisengagethe

blades.

18

Page 19

Operation

DANGER

Ifthebladebrakeclutchsystemis

inoperative,thebladewillcontinuetorotate

whenyoureleasethebladecontrolbail.

Contactwiththebladecouldoccur,causing

seriousinjury.

•ChecktheBBCoperationbeforeeach

use.

•NeverusetheBBC-equippedlawnmower

withaninoperativesafetysystem.

Figure12

1.Crumplednewspaper2.5inches(12.7cm)

6.Placetheballofnewspaper5inches(12.7cm)in

frontofthelawnmower.

7.Starttheengine.

8.Squeezethebladecontrolbailagainstthehandle.

9.Movethebladecontrollevertothefullforward

Latchposition.Bladesshouldengage.

10.Releasethebladecontrolbail.Youshouldheara

“bang.”Thebladeshouldstopinthreeseconds.

11.Immediatelypushthelawnmoweroverthe

newspaperball.

12.Stoptheengineandwaitforallmovingpartsto

stop.

13.W alkaroundthelawnmowertocheckforthe

newspaperball.Iftheballdidnotgounderthe

deck,repeatsteps7through12.

•TakeyourlawnmowertoanAuthorized

ServiceDealerforrepairifthesafety

systemfailstooperateproperly.

TestUsingtheGrassBag

1.Installtheemptygrassbagonthedischarge

tunnel.

2.Starttheengine.

3.Squeezethebladecontrolbailagainstthehandle.

4.Movethebladecontrollevertothefullforward

Latchposition.Thebagshouldbegintoinate,

indicatingthatthebladeisengagedandrotating.

5.Releasethebladecontrolbail.Ifthebagdoesnot

immediatelydeate,itindicatesthatthebladeis

stillrotating.Thebladebrakeclutchmechanism

maydeteriorating,and,ifignoredcouldresultin

anunsafeoperatingcondition.Havethelawn

mowerinspectedandservicedbyanAuthorized

ServiceDealer.

14.Pullthelawnmowerawayfromthenewspaper.

Ifthenewspaperballunravelsorisshredded,

thebladehasnotproperlystopped,resulting

inanunsafeoperatingcondition.Contactan

AuthorizedServiceDealer.

AdjustingtheCuttingHeight

Eachwheelisadjustedindividuallywithawheel

heightadjustmentlever.Thecuttingheightsarelisted

inthefollowingtable.

CuttingHeights

3/4inch(19mm)21/4inches(57mm)

11/4inches(32mm)23/4inches(70mm)

13/4inches(44mm)31/4inches(83mm)

19

Page 20

Operation

WARNING

Adjustingthecuttingheightleverscould

bringyourhandsintocontactwithamoving

blade.Amovingbladecancauseserious

injury.

•Stoptheengineandwaitforallmovement

tostopbeforeadjustingthecutting

height.

•DoNotputyourngersunderthe

housingwhenadjustingthecutting

height.

1.Pullthewheelheightadjustmentlevertoward

thewheel(Figure13)andmoveittothedesired

setting.

Figure14

1.BagFrameonretaining

post.

2.Pinengagedincatch.

3.Handlefully

forward—discharge

doorclosed.

3.Slidetheholeinthebagframeontothe

retainingpostonthedischargetunnel.

Figure13

1.Pulltowardswheel3.Notches

2.WheelHeight

AdjustmentLever

2.Releasethewheelheightadjustmentleverandset

itsecurelyinthenotch.

3.Adjustallthewheelstothesamecuttingheight

setting.

UsingtheGrassBag

Occasionally,youmaywishtousethegrassbagfor

baggingextralonggrass,lushgrass,orleaves.

•InstallingtheGrassBag

4.Settherearofthebagframeontothebag

supportrod.

5.Pullthedischargedoorhandleforwarduntil

thepinclearsthecatch,andmovethehandle

rearwarduntilthepinlocksinthebagnotch

(Figure15).

Figure15

1.Pinlockedinbagnotch.

1.Stoptheengineandwaitforallmovingparts

tostop.

2.Ensurethatthedischargedoorhandleisfully

forwardandthatthepinisengagedinthe

catch(Figure14).

Note:Thedischargedoorinthelawnmower

housingisnowopen.

20

Page 21

Operation

•MowingwiththeGrassBag

WARNING

Aworngrassbagcouldallowsmallstones

andothersimilardebristobethrowninthe

operator’sorbystander’sdirection.Thrown

objectscanresultseriouspersonalinjuryor

deathtotheoperatororbystanders.

Checkthegrassbagfrequently.Ifitis

damaged,installanewExmarkreplacement

bag.

Cutthegrassuntilthebagisfull.

Note:DoNotoverllthebag.

•RemovingtheGrassBag

1.Stoptheengineandwaitforallmovingparts

tostop.

2.Raisethedischargedoorhandleandmove

itforwardtoengagethepinwiththecatch

(Figure14).

3.Graspthehandlesatthefrontandtherearof

thebagandliftthebagoffthelawnmower.

4.Graduallytipthebagforwardtoemptythe

clippings.

5.Toinstallthebag,refertotheInstallingthe

GrassBagsection.

DANGER

Ifthedischargedoordoesnotclose

completely,thelawnmowercouldthrow

objects.Thrownobjectscanresultserious

personalinjuryordeathtotheoperatoror

bystanders.

•Neveropenthedoortothedischarge

openingwhentheengineisrunning.

•Ifyoucannotclosethedoorbecausethe

grassclippingsclogthedischargearea,

stoptheengineandgentlymovethe

dischargedoorhandlebackandforth

untilyoucanclosethedoorcompletely .If

youstillcannotclosethedoor,removethe

obstructionwithastick,notyourhand.

DANGER

Ifthedischargedoordoesnotclose

completely,thelawnmowercouldthrow

objects.Thrownobjectscanresultserious

personalinjuryordeathtotheoperatoror

bystanders.

Neveropenthedooronthedischargetunnel

whentheengineisrunning.

OperatingTips

•ReviewtheSafetysectionandreadthismanual

carefullybeforeoperatingthelawnmower.

•Settheenginespeedtothefastestpositionfor

thebestcuttingresults.

•Maintainasharpbladethroughoutthecutting

season.Periodicallyledownnicksontheblade.

Replacethebladewhennecessarywithanoriginal

Exmarkreplacementblade.

•Cleantheairlterfrequently.Mulchingstirsup

moreclippingsanddustwhichclogstheairlter

andreducesengineperformance.

CuttingGrass

•Grassgrowsatdifferentratesatdifferenttimes

oftheyear.Inthesummerheat,itisbestto

cutgrassatthe21/4inch(57mm),23/4inch

(70mm),or31/4inch(83mm)cuttingheight

settings.Cutonlyaboutathirdofthegrassblade

atatime.DoNotcutbelowthe21/4inch(57

mm)settingunlessthegrassissparseoritislate

fallwhengrassgrowthbeginstoslowdown.

•Whencuttinggrassover6inches(15cm)tall,

rstmowatthehighestcuttingheightsettingand

walkslower;thenmowagainatalowersettingfor

thebestlawnappearance.Ifthegrassistoolong

andtheleavesclumpontopofthelawn,thelawn

mowermayplugandcausetheenginetostall.

•Alternatethemowingdirection.Thishelps

dispersetheclippingsoverthelawnforeven

fertilization.

Ifthenishedlawnappearanceisunsatisfactory,

tryoneormoreofthefollowing:

•Sharpentheblade.

•Walkataslowerpacewhilemowing.

•Cutthegrassmorefrequently .

21

Page 22

Operation

•Overlapcuttingswathsinsteadofcuttingafull

swathwitheachpass.

•Setthecuttingheightonthefrontwheelsone

notchlowerthantherearwheels.Forexample,

setthefrontwheelsat21/4inches(57mm)and

therearwheelsatthe23/4inches(70mm).

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthe

lawnshowsthroughthecutleafcover.Youmay

needtomakemorethanonepassovertheleaves.

•Forlightleafcoverage,setallthewheelsatthe

samecuttingheightsetting.

•Iftherearemorethan5inches(12.7cm)ofleaves

onthelawn,setthefrontcuttingheight1or2

notcheshigherthantherearcuttingheight.This

makesiteasiertofeedtheleavesunderthelawn

mowerdeck.

•Slowdownyourmowingspeedifthelawnmower

doesnotcuttheleavenelyenough.

•Ifyoumowoveroakleaves,youcanaddlimeto

thegrassinthespringtoreducetheacidityofthe

oakleaves.

22

Page 23

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Maintenance

WARNING

Ifyouleavethewireonthesparkplug,

someonecouldaccidentallystarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Disconnectthewirefromthesparkplug

beforeyoudoanymaintenance.Setthewire

asidesothatitdoesnotaccidentallycontact

thesparkplug.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Checkthestoppingtimeofthebladebrake.Theblademuststopwithin3secondsof

releasingthebail;ifitdoesnot,contactandAuthorizedServiceDealerforrepair.

•Checkthemowerbladesandtheenginemountingfasteners.

•Checkforloosehardware.

•Cleanthegrassbuild-upfromunderthedeck.

•Cleanthedischargetunnelandplug.

WARNING

Theenginecanbecomeveryhot.Touching

ahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

Every25hours

Every40hours

Every50hours

Every100hours

Every250hours

Every300hours

Yearly

Yearlyorbeforestorage

•Cleanthefoampre-cleaner(KawasakiUnits).

•Cleanthecover,base,foamandpaperelements(HondaUnits).

•Checktheconditionofthebelt(s).

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Greasethepivotarms.

•Cleanunderthebeltcover(self-propelledmodelsonly).

•Cleanthebladebrakeclutchshield.

•Checkforleaksinthefuelsystemsand/ordeterioratingfuelhose.

•Changetheoillter(KawasakiUnitsOnly).

•Servicethewheels.

•Greasethegearcase(self-propelledunitsonly).

•Checkthesparkplugs.

•ForBladeBrakeClutchUnits:Adjustthebladebrakecable.

•Cleanthefuellterelement(KawasakiUnitsOnly).

•Replacetheairlterelements(HondaUnits).(Mayneedmoreofteniftheyaredamaged

orexcessivelydirty.)

•Replacethepaperairlter(KawasakiUnits).(Mayneedmoreoftenindustyconditions.

SeetheEnginemanualforadditionalinformation.)

•Lubricatethegearcase(self-propelledunitsonly)

•Emptythefueltankbeforerepairsasdirectedorbeforestorage.

23

Page 24

Maintenance

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Cleanareaarounddipstick.Removedipstickand

wipeoiloff.Reinsertthedipstickandpushitall

thewaydownintothetube.DoNotscrewinto

place.Removethedipstickandreadtheoillevel.

Figure17

KawasakiEngine

1.Dipstick3.Add

2.Full

Figure16

HondaEngine

1.Lowerlimitmark3.Dipstick

2.Upperlimitmark

4.Iftheoillevelislow ,wipeofftheareaaroundthe

oilllcap,removecapandlltothe“FULL”

markonthedipstick.Useoilasspeciedin

EngineOwner’ sManual.DoNotoverll.

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

CheckingtheBladeBrake

Clutch(ForUnitswitha

BladeBrakeClutchOnly)

ServiceInterval:Beforeeachuseordaily

RefertoCheckingtheBladeBrakeClutchinthe

OperatingInstructionssection.

ChecktheMowerBlade

ServiceInterval:Beforeeachuseordaily

Alwaysmowwithasharpblade.Asharpbladecuts

cleanlyandwithouttearingorshreddingthegrass

blades.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug(Figure9

andFigure10).

3.Drainthegasolinefromthefueltank.

24

Page 25

4.Tipthelawnmowerontoitsrightside(see

Figure18andFigure19).

Figure18

BladeBrakeClutchUnitsOnly

Maintenance

Figure20

1.Sail

2.Flat

3.Wear

4.Slot

1.Accelerator3.Blade

2.Anti-ScalpCup

UnitsWithoutaBladeBrakeClutchOnly

1.Blade3.Accelerator

2.BladeBolt

4.BladeNuts

Figure19

5.Inspectthebladeforsharpnessandwear,

especiallywheretheatandthecurvedparts

meet(seeFigure20A).Becausesandandabrasive

materialcanwearawaythemetalthatconnects

theatandcurvedpartsoftheblade,check

thebladebeforeusingthelawnmower.Ifyou

noticeaslotorwear(Figure20BandFigure20C),

replacetheblade.

Note:Forthebestperformance,installanew

bladebeforethecuttingseasonbegins.During

theyear,ledownanysmallnickstomaintainthe

cuttingedge.

DANGER

Awornordamagedbladecanbreak.A

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Ifitisnecessarytoremovethebladefor

replacementorsharpening,completethe

followingsteps:

6.Removetheblade.Makesuretograsptheendof

thebladeusingaragorathicklypaddedglove.

•ForBladeBrakeClutchUnits:Removethe

bladenuts,anti-scalpcup,accelerator,andthe

blade(Figure18).

•ForUnitswithoutaBladeBrakeClutch:

Removethebladebolt,accelerator,andblade

(Figure19).

7.ForSharpening:Filethetopsideofthebladeto

maintainitsoriginalcuttingangle(Figure21A)

andinnercuttingedgeradius(Figure21B).The

bladewillremainbalancedifyouremovethesame

amountofmaterialfrombothcuttingedges.

25

Page 26

Maintenance

10.Returnthelawnmowertoitsuprightposition.

11.Connectthewiretothesparkplug.

Figure21

1.Cuttingangle2.Cuttingedgeradius

8.Checkthebalanceofthebladebyplacingthe

centerholeofthebladeoveranailorscrewdriver

shankclampedhorizontallyinavise(Figure22).

Ifeitherendofthebladerotatesdownward,le

thatend(notthecuttingedge).Thebladeis

properlybalancedwhenneitherenddrops.

Figure22

1.Blade

2.Vise

9.ForInstallation:Makesuretograsptheendof

thebladeusingaragorathicklypaddedglove.

ForBladeBrakeClutchUnits:Installasharp,

balancedExmarkblade,theaccelerator,the

anti-scalpcup,andthebladenuts.Thesailof

theblademustpointtowardthetopofthelawn

mowerhousingforproperinstallation.Torque

thebladenutsto15-27ft-lb(20-37Nm).

ForUnitswithoutaBladeBrakeClutch:Installa

sharp,balancedExmarkblade,theaccelerator,

andbladebolt.Thesailoftheblademustpoint

towardthetopofthelawnmowerhousingfor

properinstallation.Torquethebladenutsto50

ft-lb(68Nm).

3.Screwdriver

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

ServiceAirFilter

(KawasakiUnits)

ServiceInterval:Every25hours—Clean

thefoampre-cleaner

(KawasakiUnits).

Every300hours—

Replacethepaperair

lter(KawasakiUnits).

(Mayneedmoreoftenin

dustyconditions.See

theEnginemanualfor

additionalinformation.)

Note:DoNotoperatetheenginewithouttheair

lterassembly;extremeenginedamagewilloccur.

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug

(Figure10).

3.Removethecoverandcleanitthoroughly .

DANGER

Operatingthelawnmowerwithoutthe

acceleratorinplacecancausethebladeto

ex,bend,orbreak.Thrownobjectsfroma

brokenbladecanresultinseriousinjuryor

deathtotheoperatororbystanders.

DoNotoperatethelawnmowerwithoutthe

accelerator.

26

Page 27

Figure23

1.Cover3.Paperairlter

2.Foampre-cleaner

4.Airlterbase

4.Removethepaperairlteranddiscarditas

required.

Maintenance

2.Disconnectthewirefromthesparkplug

(Figure9).

3.Removethetwowingnutsthatsecurethecover

(Figure24).

Note:DoNottrytocleanapaperairlter.

5.Removethefoampre-cleanerandwashitwitha

milddetergentandwater,thenblotitdry.

6.Saturatethepre-cleanerwithcleanengineoil,then

squeezeit(DoNottwist)toremovetheexcessoil.

7.Installthefoampre-cleaner.

8.Installthenewpaperairlter.

9.Installthecover.

ServiceAirFilter

(HondaUnits)

ServiceInterval:Every25hours—Clean

thecover,base,foamand

paperelements(Honda

Units).

Every250hours—Replace

theairlterelements

(HondaUnits).(Mayneed

moreofteniftheyare

damagedorexcessively

dirty.)

Note:DoNotoperatetheenginewithouttheair

cleanerassembly;extremeenginedamagewilloccur.

1.Stoptheengineandwaitforallmovingpartsto

stop.

Figure24

1.Wingnuts4.Foamelement

2.Cover

3.Paperelement

5.Base

4.Removethecover.

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamandpaperelementsfromthe

base.

6.Removethefoamelementfromthepaper

element.

7.Inspectthefoamandpaperelements,andreplace

themiftheyaredamagedorexcessivelydirty.

8.Tapthepaperelementonahardsurfaceseveral

timesorusecompressedairnotexceeding30

psi(207kPa)throughthelterfromthewire

screensidetoremoveanyexcessdirt.Ifthepaper

elementisexcessivelydirty,replaceit.

Note:Nevertrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

9.Cleanthefoamelementinwarm,soapywateror

inanonammablesolvent.

10.Rinseanddrythefoamelementthoroughly.

27

Page 28

Maintenance

11.Dipthefoamelementincleanengineoil,then

squeezeouttheexcessoil.

Note:Excessoilinthefoamelementrestricts

theairowthroughtheelementandmayreach

thepaperlterandclogit.

12.Wipedirtfromthebaseandthecoverwitha

moistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

13.Installtheaircleanerelementsandensurethat

theyareproperlypositioned.

14.Securelyinstallthecoverwiththetwowingnuts.

ChangeEngineOil

ServiceInterval:Aftertherst5hours

Every50hours(Mayneed

moreoftenundersevere

conditions.)

1.Runtheenginetowarmtheengineoil.

Note:Warmoilowsbetterandcarriesmore

contaminates.

11.Wipeupanyspilledoil.

12.Connectthewiretothesparkplug.

13.Recycletheusedoilaccordingtolocalcodes.

ChangingtheOilFilter

(KawasakiUnitsOnly):

ServiceInterval:Every100hours

1.Runtheenginetowarmtheoil.

2.Stoptheengineandwaitforallmovingpartsto

stop.

3.Disconnectthewirefromthesparkplug.

4.Draintheengineoil.

5.Placearagundertheoilltertocatchanyoilthat

mayleakoutasyouremovethelter.

6.Removetheoillter.

7.Useyourngertocoatthegasketonthenew

lterwithcleanengineoil(seeFigure25).

WARNING

Oilmaybehotafterenginehasbeen

run.Contactwithhotoilcancausesevere

personalinjury.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stopengine,waitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug.

4.Placeasuitabledrainpanunderthedipstick/oil

drain.

5.Cleanaroundthedipstick.

6.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

7.Raisetheleftsideofthelawnmowertodrainthe

oilfromthedipsticklltubeintothedrainpan.

8.Afterdrainingtheoil,returnthelawnmowerto

theoperatingposition.

9.Fillthecrankcasewithfreshoiltotheupperlimit

markonthedipstick.

10.Insertthedipstickintothellerneckandrotate

thecapclockwiseuntilitistight.

Figure25

1.Gasket

8.Installthenewlterandhandtightenit2/3turn

only.

9.FillthecrankcasetotheFulllineonthedipstick

withfreshoil.

10.Connectthewiretothesparkplug.

11.Runtheengineforabout3minutes.

12.Stoptheengine,waitforallmovingpartstostop,

andcheckforoilleakagearoundthelter.

13.Addoiltocompensatefortheoilintheoillter.

14.Recycletheusedoillteraccordingtolocalcodes.

28

Page 29

Maintenance

ServicingtheWheels

ServiceInterval:Every100hours

RemovingtheWheels

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Removethebolt,thewheelspacer,andthe

locknutmountingthewheeltothepivotarm

(Figure26).

Figure26

1.PlasticCover6.BearingSpacer

2.Locknut

3.Wheelhalf

4.Bolt

5.Bearing

7.Bearing/HubAssembly

8.Lug

9.WheelSpacer

wheelhalvesandtighten.Removethetwolong

screwsorboltsandreplacethemwithtwocap

screwsandtwolocknuts.

7.Installthewheeltothepivotarmwiththecap

screws,aspacer,andalocknut.Ensurethatthe

spacerispositionedbetweenthewheelhuband

thepivotarm.

8.Connectthewiretothesparkplug.

CheckConditionOfBelt

(Self-PropelledUnitsOnly)

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop.

2.Removetheboltsthatsecurethebeltcovertothe

lawnmowerhousing.

3.Checkthebeltforcracks,frayededges,burn

marksoranyotherdamage.

4.Replacethedamagedbelt.

LubricatethePivotArms

4.Separatethewheelhalvesfromthetireby

removingfourboltsandfourlocknuts.

Note:Ifyouremovethebearingsfromthe

bearing/hubassembly ,removethembypressing

onthebearingspacer.

AssemblingtheWheels

1.Positionthetireontoonewheelhalf,aligningthe

lugsoneach.

2.Placethebearing/hubassemblyintothecenter

holeofthewheelhalf.Ensurethatthelegsofthe

hubarepositionedovertheangeofthehole.

3.Placetheotherwheelhalfontothebearing/hub

assembly,aligningthewheelandthetirelugsand

themountingholes.

4.Usingtwofullythreadedscrewsorboltsand

non-lockingnuts,looselysecurethewheelhalves

together.Mountthescrewsorboltsinthe

opposingholes.

5.Checkthealignmentofallpartsandtightenthe

screws,alternatingfromsidetosideforauniform

tuntilthewheelhalvesaredrawntogether.

6.Installthetwocapscrewsandtwolocknuts

previouslyremovedintheremainingholesinthe

1.Movetherearwheelcuttingheightleverstothe

centersetting.

2.Wipethegreasettingswithacleanrag

(Figure27).

Figure27

1.Greasetting

3.Installagreasegunontothettingandgently

apply2or3pumpsof#2multi-purposelithium

basegrease.

Note:Excessivegreasepressuremaydamagethe

seals.

29

Page 30

Maintenance

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lubricatettingswithonetotwopumpsof

NGLIgrade#2multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.Pivot

Arms

2.Gear

Case

Initial

Pumps

22

11

Numberof

Places

Service

Interval

50Hours

100Hours

LubricatetheGearCase

(Self-PropelledUnitsOnly)

ServiceInterval:Yearly

CheckSparkPlugs

ServiceInterval:Every100hours

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug(Figure9

andFigure10).

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Note:Replaceacracked,fouled,ordirtyspark

plug.DoNotcleantheelectrodesbecausegrit

enteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.030inch(0.76mm)

(Figure29).

1.Stopengine,waitforallmovingpartstostop.

2.Removethegrassbag.

3.Installagreasegunontothettingthroughthe

beltcoveropening

Figure28

1.Greasetting

2.Beltcover

4.Gentlyapplyonetotwopumpsof#2

multi-purposelithium-basegrease.

Figure29

1.Sideelectrode

2.Centerelectrode

insulator

3.Airgap—0.030inch

(0.76mm)

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto17ft-lb(23N-m).

8.Connectthewiretothesparkplug.

5.Installthegrassbag.

30

Page 31

Maintenance

Adjustments

Note:Waitforallmovingpartstostopandremove

sparkplugwirebeforeservicing,cleaning,ormaking

anyadjustmentstotheunit.

AdjustingtheSelf-Propel

Drive

(Self-PropelledUnitsOnly)

Ifthelawnmowerdoesnotself-propelorhasa

tendencytocreepforwardwhenthecontrolbaris

released,adjustthewheeldrivecontrolknobonthe

rearofthegearbox.

1.Closethedoorinthelawnmowerhousingand

removethegrassbag.

2.Ifthelawnmowerdoesnotselfpropel,rotate

thecontrolknobclockwise1/2turntotighten

thebelt.

Ifthelawnmowercreepsforward,rotatethe

knob1/2turncounterclockwisetoloosenthebelt

•ForBladeBrakeClutchUnits:

1.Loosenthecableclampscrewuntilthecable

conduitslides(seeFigure31).

Figure31

1.Spring3.Cableclampscrew

2.Cableconduit

2.Pullthecabletoremovetheslack,butDo

Notputtensiononthespring.

3.Tightenthescrewtolocktheadjustmentin

place.

4.Connectthewiretothesparkplug.

•ForSelf-PropelledUnitswithoutaBlade

BrakeClutch:

1.Loosenthenutonthecablebracket(see

Figure31).

Figure30

1.Controlknob

AdjustingtheBladeBrake

Cable

ServiceInterval:Every100hours

Adjustwheneveranewbladebrakecableassembly

isinstalled.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Inserta3/16to1/4inch(5to6mm)object

betweenthebrakecontrolleverandthe

handle.

3.Turnthecableadjusteronthebrakecable

untilyouremovetheslack.

4.Tightenthejamnut.

5.Connectthewiretothesparkplug.

•ForHand-PushUnits:

1.Loosenthejamnutonthebladebrakecable

clamp(seeFigure31).

2.Inserta3/16to1/4inch.(5to6mm)object

betweenthebrakecontrolleverandthe

handle.Pulldownonthecableconduituntil

youremovetheslackfromthewire.

3.Tightenthenut.

4.Connectthewiretothesparkplug.

2.Disconnectthewirefromthesparkplug.

31

Page 32

Maintenance

Cleaning

CleanGrassBuild-UpUnder

Deck

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removesparkplugwire.

2.Toensurethebestperformance,keepthe

undersideofthelawnmowerhousingclean

(Figure32).

Figure32

BladeBrakeUnitShownforReferenceOnly

WashingMethod

1.Positionthelawnmoweronaatconcreteor

asphaltsurfacenearagardenhose.

2.Starttheengine.

6.Turnoffthewater.

7.Startthelawnmower,engagetheblade,andlet

thelawnmowerrunforafewminutestodryout

itscomponents.

ScrapingMethod

Ifwashingdoesnotremovealldebrisfromunderthe

lawnmower,scrapeitclean.

1.Disconnectthewirefromthesparkplug.

2.Drainthefuelfromthefueltank.Referto

EmptyingtheFuelTankandCleaningthe

FuelFiltersection.

WARNING

Tippingthelawnmowermaycausethefuel

toleakfromthecarburetororthefueltank.

Gasolineisextremelyammable,highly

explosive,andundercertainconditions,can

causepersonalinjuryorpropertydamage.

Avoidfuelspillsbyrunningtheenginedryor

byremovingthegasolinewithahandpump;

neversiphon.

3.Tipthelawnmowerontoitsrightside.

4.Removethedirtandgrassclippingswitha

hardwoodscraper.Avoidburrsandsharpedges.

3.Holdtherunninggardenhoseathandleleveland

directthewatertoowonthegroundjustin

frontoftherightreartire(Figure33).

Figure33

4.Engagetheblade.

Note:Thebladewilldrawinwaterandwashout

clippings.Letthewaterrununtilyounolonger

seeclippingsbeingwashedoutfromunderthe

housing.

5.Disengagetheblade,stoptheengineandwaitfor

allmovingpartstostop.

5.Turnthelawnmowerupright.

6.Fillthefueltank.

7.Connectthewiretothesparkplug.

CleaningtheDischarge

TunnelandPlug

ServiceInterval:Beforeeachuseordaily

Alwaysbesurethatthedischargetunneldoorcloses

securelywhenyoureleasethehandle.Ifthedebris

preventsthedischargedoorfromclosingsecurely,

cleantheinsideofthedischargetunnelandthedoor

thoroughly.

32

Page 33

Maintenance

WARNING

Grassclippingsandotherobjectscanbe

thrownfromanopendischargetunnel.

Thrownobjectscancauseseriousinjuryor

killtheoperatororbystanders.

Neverstartoroperatethelawnmowerunless

oneofthefollowingistrue:

•Thedischargetunnelplugislocked

securelyinthedischargetunnel.

•Thegrassbagislockedinplace.

•Theoptionalsidedischargechuteis

lockedinplace.

•Thedischargetunneldoorislockedin

place.

CleaningUnder

theBeltCover

(Self-PropelledModels

Only)

ServiceInterval:Every50hours

1.Stoptheengineandwaitforallmovingpartsto

stop.

5.Installthebeltcover.

6.Connectthewiretothesparkplug.

CleaningtheBladeBrake

ClutchShield

ServiceInterval:Every50hours

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug(see

Figure9andFigure10).

3.Drainthegasolinefromthefueltank.

4.Tipthelawnmowerontoitsrightside(airlter

up).

WARNING

Tippingthelawnmowermaycausethefuel

toleakfromthecarburetororthefueltank.

Gasolineisextremelyammable,highly

explosive,andundercertainconditions,can

causepersonalinjuryorpropertydamage.

Avoidfuelspillsbyrunningtheenginedryor

byremovingthegasolinewithahandpump;

neversiphon.

2.Disconnectthewirefromthesparkplug(see

Figure9andFigure10).

3.Removetheboltsthatsecurethebeltcovertothe

lawnmowerhousing(Figure34).

Figure34

1.Beltcover

4.Liftoffthecoverandbrushoutallthedebris

aroundthebeltarea.

5.Removethebladenuts,theanti-scalpcup,the

accelerator,andtheblade(seeFigure35).

Figure35

1.Tabsandnuts3.Tabandbolt.

2.BBCShield

6.LoosenthetabsthatsecuretheBBCshieldtothe

deckbylooseningthenutsortheboltsonthe

tabs(Figure35).Rotatethetabs180°tomove

themoutoftheway.

33

Page 34

Maintenance

7.RemovetheBBCshieldandbrushorblowall

thedebrisfromundertheshieldandaroundthe

BBCsystem.

8.InstalltheBBCshield.Rotatethetabs180°back

intoposition.Tightenthenutstotheboltson

tabstosecuretheBBCshieldtothedeck.

9.Installtheblade,theaccelerator,theanti-scalp

cup,andthetwobladenuts.

10.Turnthelawnmowerupright.

11.Connectthewiretothesparkplug.

EmptyingtheFuelTank

andCleaningtheFuelFilter

(KawasakiUnitsOnly)

ServiceInterval:Every100hours

Thefuellter(screen)elementislocatedinsidethe

fueltank.

1.Stoptheengineandwaitforittocooldown.

Note:Draingasolineforacoldengineonly.

2.Disconnectthewirefromthesparkplug

(Figure10).

3.Closethefuelvalve(Figure7).

4.Disconnectthefuellinebylooseningthetube

clampatthecarburetor.

5.Openthefuelvalvebyturningthelevertothe

openposition.

6.Drainthegasolinecompletelyfromthetankand

fuellineintoanapprovedfuelcontainer.

7.Removethefueltankfromthemower.

8.Closethefuelvalve.

9.Pourasmallamountoffuelinthefueltank,move

thefuelaroundinthetank,andpouritoutinto

anapprovedfuelcontainer.

10.Installthefueltankandfuelline.

WasteDisposal

MotorOilDisposal

Engineoilandhydraulicoilarebothpollutantsto

theenvironment.Disposeofusedoilatacertied

recyclingcenteroraccordingtoyourstateandlocal

regulations.

34

Page 35

Storage

Storage

PreparingtheFuelSystem

Topreparethelawnmowerforoffseasonstorage,

performtherecommendedmaintenanceprocedures.

Storethelawnmowerinacool,clean,dryplace.

Coverthelawnmowertokeepitcleanandprotected.

WARNING

Gasolinecanvaporizeifyoustoreitoverlong

periodsoftime.Gasolinevaporscanexplode

iftheycomeintocontactwithanopename.

•DoNotstoregasolineoverlongperiods

oftime.

•DoNotstorethelawnmowerwith

gasolineinthefueltankorthecarburetor

inanenclosurewithanopename.(For

example,afurnaceorawaterheaterpilot

light.)

•Allowtheenginetocoolbeforestoring

itinanyenclosure.

GeneralStorageInformation

1.Cleanthelawnmowerhousing.Referto

CleaningtheUndersideoftheLawnMower

HousingsectioninCleaning.

2.Cleananydirtandchafffromthecylinder,

cylinderheadns,andblowerhousing.

3.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheengine,theshrouding,and

thetopofthelawnmowerhousing.

4.CleantheBBCshield.RefertoCleaningthe

BladeBrakeClutchShieldsectioninCleaning.

5.Checktheconditionoftheblade.Refer

toMaintainingtheBladesectioninthe

Maintenance.

6.Servicetheairlter.RefertoServicingtheAir

FilterinMaintenance.

7.Lubricatethepivotarms.RefertoLubricating

thePivotArmssectioninMaintenance.

8.Tightenallnuts,bolts,andscrews.

9.Touchupallrustedorchippedpaintsurfaceswith

paintavailablefromanAuthorizedServiceDealer.

Emptythefueltankwhenmowingthelasttime

beforestoringthelawnmower.

1.Runthelawnmoweruntiltheenginestopsfrom

runningoutoffuel.

2.Primetheengineandstartitagain.

3.Allowtheenginetorununtilitstops.Whenyou

cannolongerstarttheengineitissufcientlydry.

PreparingtheEngine

1.Whiletheengineisstillwarm,changetheoilfrom

thecrankcase.RefertoChangingtheEngine

OilsectioninMaintenance.

2.Removethesparkplug.

3.Usinganoilcan,addaboutonetablespoonofoil

tothecrankcasethroughthesparkplughole.

4.Slowlyrotatetheengineseveraltimes,usingthe

starterrope,todistributetheoil.

5.InstallthesparkplugbutDoNotconnectthe

wiretothesparkplug.

RemovingtheLawnMower

fromStorage

1.Checkandtightenallfasteners.

2.Removethesparkplugandspintheenginerapidly

bypullingthestarterropetoblowexcessoilfrom

thecylinder.

3.Cleanthesparkplugorreplaceitifitiscracked,

broken,oriftheelectrodesareworn.

4.Installthesparkplugandtorqueitto17ft-lb(23

N-m).

5.Performanyneededmaintenanceprocedures.

6.Fillthefuelinthefueltankwithfreshgasoline.

7.Checktheengineoillevel.

8.Connectthewiretothesparkplug.

35

Page 36

Troubleshooting

Troubleshooting

Important:Itisessentialthatalloperatorsafetymechanismsbeconnectedandinproperoperating

conditionpriortomoweruse.

Whenaproblemoccurs,DoNotoverlookthesimplecauses.Forexample:startingproblemscouldbe

causedbyanemptyfueltank.

Thefollowingtablelistssomeofthecommoncausesoftrouble.Ifaproblemcontinues,contactanAuthorized

ServiceDealer.

ProblemPossibleCauseCorrectiveAction

Enginewillnotstart,startshard,orfailsto

keeprunning.

Enginelosespower.

Enginerunsrough.

Lawnmowerorenginevibratesexcessively .

1.Fueltankisempty.1.Fillthefueltank.

2.Fuelshutoffvalveisclosed.

3.Thethrottleleverisnotinthecorrect

position.

4.Dirt,water,orstalefuelisinthefuel

system.

5.Faultysparkplug.

6.Sparkplugwireisnotconnected.

1.Aircleanerisdirty.

2.Oillevelinthecrankcaseislow .

3.Ventholeinthefuelcapisplugged.

4.Dirtinfuellter.4.Replacethefuellter.

5.Dirt,water,orstalefuelisinthefuel

system.

6.Theundersideofthelawnmowerdeck

containsclippingsanddebris

1.Thewireisnotconnectedtothespark

plug.

2.Faultysparkplug.

3.ThethrottleleverisnotintheFast

position.

4.Theairlterelementisdirtyandis

restrictingtheairow.

1.Thebladeisbentorisoutofbalance.1.Balancetheblade.Ifthebladeisbent,

2.Theblademountingboltisloose.2.Tightentheblademountingbolt.

3.Theundersideofthelawnmowerdeck

containsclippingsanddebris.

4.Theenginemountingboltsareloose.4.Tightentheenginemountingbolts.

2.Openthefuelshutoffvalve.

3.MovethethrottlelevertotheChoke

position.

4.ContactanAuthorizedServiceDealer.

5.Clean,adjustorreplacesparkplug.

6.Checkthesparkplugwireconnection.

1.Cleanorreplacetheaircleanerelement.

2.Addoiltothecrankcase.

3.Cleanorreplacethefuelcap.

5.ContactanAuthorizedServiceDealer.

6.Cleantheundersideofthelawnmower

deck.

1.Connectthewiretothesparkplug.

2.Clean,adjustorreplacesparkplug.

3.MovethethrottlelevertotheFast

position.

4.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

replaceit.

3.Cleantheundersideofthelawnmower

deck.

Unevencuttingpattern.

Dischargechuteplugs

1.Allfourwheelsarenotatthesameheight.

2.Thebladeisdull.2.Sharpenandbalancetheblade.

3.Mowinginthesamepatternrepeatedly.

4.Theundersideofthelawnmowerdeck

containsclippingsanddebris.

1.ThethrottleleverisnotintheFast

position.

2.Thecuttingheightistoolow .2.Raisethecuttingheight.

3.Mowingtoofast.

4.Thegrassiswet.

5.Theundersideofthelawnmowerdeck

containsclippingsanddebris.

1.Placeallfourwheelsatthesameheight.

3.Changethemowingpattern.

4.Cleantheundersideofthelawnmower

deck.

1.MovethethrottlelevertotheFast

position.

3.Slowdown.

4.Allowthegrasstodrybeforemowing.

5.Cleantheundersideofthelawnmower

deck.

36

Page 37

Troubleshooting

ProblemPossibleCauseCorrectiveAction

Lawnmowerdoesnotself-propel

(Self-PropelledModelsOnly)

1.Theself-propeldrivecableisoutof

adjustmentorisdamaged.

2.Thereisdebrisunderthebeltcover.2.Cleanthedebrisfromunderthebelt

1.Adjusttheself-propeldrivecable.Replace

thecableifnecessary.

cover.

37

Page 38

Conditions and Products Covered

Exmark Mfg. Co. Inc. and its affiliate, Exmark Warranty

Company, pursuant to an agreement between them, jointly

warrant on the terms and conditions herein, that we will repair,

replace or adjust any part on these products and found by us

(in the exercise of our reasonable discretion) to be defective in

factory materials or workmanship for a period of one year.

This warranty applies to Exmark commercial turf equipment

sold in the U.S. or Canada. This warranty may only be

assigned or transferred to a second (or third) owner by an

authorized Exmark dealer. The warranty period commences

upon the date of the original retail purchase.

Warranty Exceptions Warranty Period

• Bags, Belts and Tires 90 days

• Engine 2 years*

* The Engine warranty is covered by the engine manufacturer.

Please refer to the engine manufacturer’s warranty statement

that is included in the literature packet.

This warranty only includes the cost of parts and labor.

Items and Conditions Not Covered

This warranty does not cover the following:

• Pickup and delivery charges to and from any authorized

Exmark Service Dealer.

• Any damage or deterioration due to normal use, wear and

tear, or exposure.

• Cost of regular maintenance service or parts, such as filters,

fuel, lubricants, tune-up parts, and adjustments.

• Any product or part which has been altered or misused or

required replacement or repair due to normal wear,

accidents, or lack of proper maintenance.

• Any repairs necessary due to use of parts, accessories or

supplies, including gasoline, oil or lubricants, incompatible

with the turf equipment or other than as recommended in

the operator's manual or other operational instructions

provided by Exmark.

There are no other express warranties except for engine and

special emission system coverage.

All warranty work must be performed by an authorized

Exmark Service Dealer using Exmark approved replacement

parts.

Instructions for Obtaining Warranty Service

The product must be registered with original proof of purchase

by an Exmark Service Dealer before obtaining any warranty

service.

Contact any Exmark Service Dealer to arrange service at their

dealership. To locate a dealer convenient to you, access our

website at www.exmark.com. U.S. or Canada customers may

also call 402-223-6375.

If for any reason you are dissatisfied with the Service Dealer’s

analysis or with the assistance provided, contact us at:

Exmark Customer Service Department

The Exmark Warranty Company

2101 Ashland Avenue

Beatrice, NE 68310

402-223-6375 or

service@exmark.com

Owner’s Responsibilities

The Exmark turf equipment, including any defective part,

must be returned to an authorized Exmark service dealer

within the warranty period. This warranty extends only to turf

equipment operated under normal conditions. You must read

the operator’s manual. You must also properly service and

maintain your Exmark product as described in the operator’s

manual. Such routine maintenance, whether performed by a

dealer or by you, is at your expense.

General Conditions

The sole liability of Exmark and Exmark Warranty Company

with respect to this warranty shall be repair or replacement of

defective components as set forth herein. Neither Exmark

nor Exmark Warranty Company shall be liable for any

incidental or consequential loss or damage.

Such damages include but are not limited to:

• Expenses related to gasoline, oil or lubricants.

• Travel time, overtime, after hours time or other

extraordinary repair charges or charges relating to repairs or

replacements outside of normal business hours at the place

of business of the authorized Exmark Service Dealer.

• Rental of like or similar replacement equipment during the

period of any warranty, repair or replacement work.

• Any telephone or telegram charges or travel charges.

• Loss or damage to person or property other than that

covered by the terms of this warranty.

• Any claims for lost revenue, lost profit or additional cost as

a result of a claim of breach of warranty.

• Attorney's fees.

No Claim of breach of warranty shall be cause for cancellation

or rescission of the contract of sale of any Exmark mower.

All implied warranties of merchantability (that the

product is fit for ordinary use) and fitness for use (that the

product is fit for a particular purpose) are limited to the

duration of the express warranty.

Some states do not allow exclusions of incidental or

consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions and

limitations may not apply to you.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Exmark Commercial Turf Equipment

1 Year Limited Warranty

G4500-426

38

Page 39

ServiceRecord

Date:

DescriptionofWorkDone:ServiceDoneBy:

39

Page 40

MI D-MOUNT RIDING ACCE SSORIES AND OPTIONS

SEE EXMARK’S COMPLETE LINE OF ACCESSORIES AND OPTIONS

WALK-BEHIND ACCESSORIES AND OPTIONS

GRASS CATCHER

MICRO-MULCH SYSTEM

TURF STRIPER

STANDON

CUSTOM RIDE SEAT SUSPENSION SYSTEM