Page 1

TURFTRACER®

X-SERIESLP

ForSerialNos.

920,000&Higher

PartNo.4500-714Rev.A

Page 2

Thissparkignitionsystemcomplieswiththe

CanadianstandardICES-002.Cesystèmed’allumage

parètincelledevèhiculeestconformeàlanorme

NMB-002duCanada

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2010ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency ,andpromotesafe

operation.

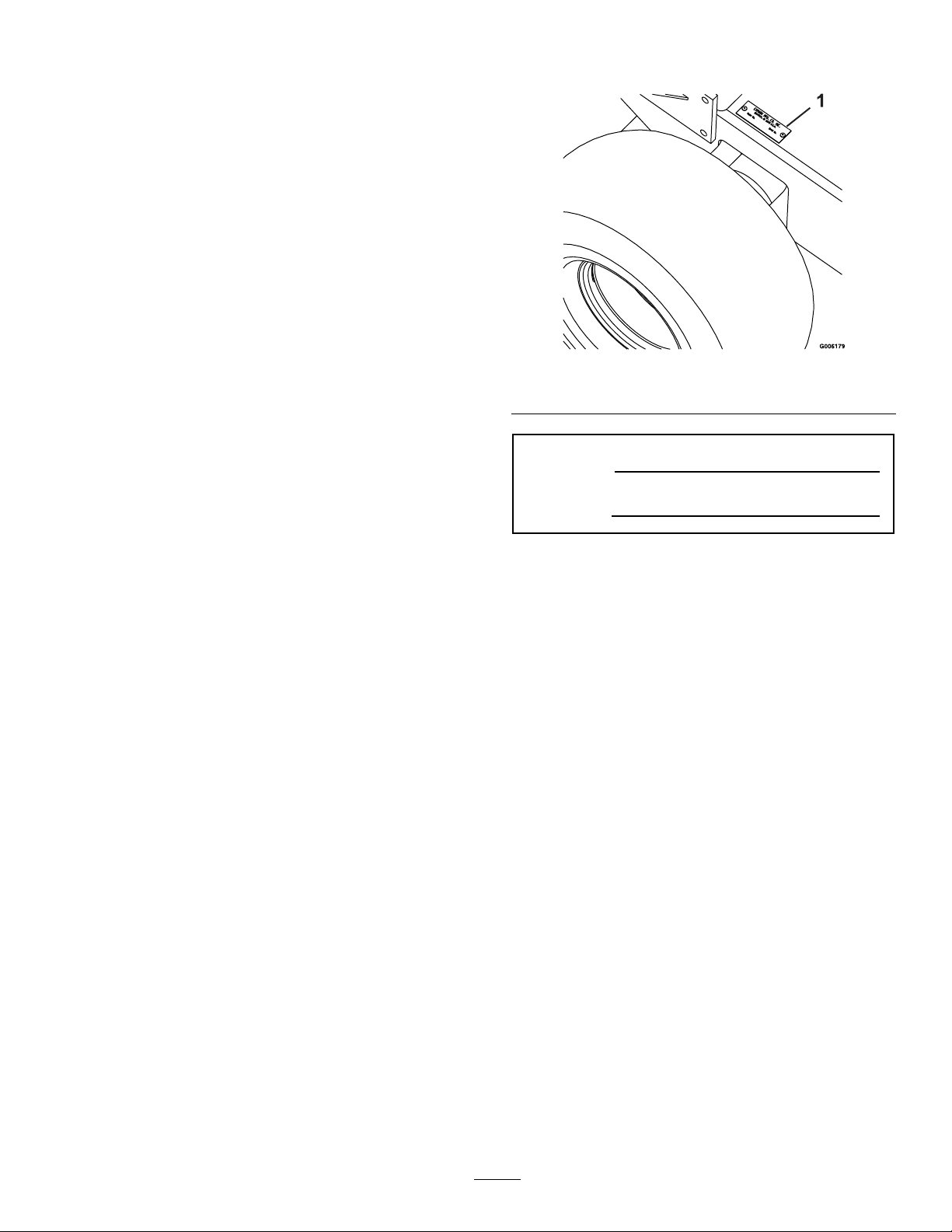

Figure1

1.Modelandserialnumberlocation

ModelNo.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

Exmarkpartsmanualsareavailableonlineat

http://www.exmark.com/manuals.htm

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

SerialNo.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.....................11

Specications.......................................................14

ModelNumbers............................................14

Systems.........................................................14

Dimensions...................................................15

TorqueRequirements....................................16

ProductOverview................................................16

Operation.............................................................17

Controls........................................................17

Pre-Start........................................................18

OperatingInstructions..................................19

Transporting.................................................23

Maintenance.........................................................24

RecommendedMaintenanceSchedule(s)...........24

PeriodicMaintenance.......................................25

CheckEngineOilLevel.................................25

CheckBatteryCharge....................................25

CheckMowerBlades.....................................27

CheckSafetyInterlockSystem.......................27

CheckforLooseHardware............................28

ServiceAirCleaner........................................28

ChangeEngineOil........................................28

CheckHydraulicOilLevel.............................28

CheckTirePressures.....................................28

CheckConditionOfBelts..............................29

LubricateGreaseFittings...............................29

LubricateCasterWheelHubs........................29

RemoveEngineShroudsandCleanCooling

Fins...........................................................30

CheckSparkPlugs.........................................30

CheckLPGTank...........................................30

CheckLPGFuelDeliverySystem..................31

ChangeHydraulicSystemFilter.....................31

WheelHub-SlottedNutTorque

Specication..............................................33

ThreadLockingAdhesives.............................34

MobilHTSGrease(OrFood-Grade

Anti-seize).................................................34

Copper-BasedAnti-seize..............................34

DielectricGrease...........................................34

Adjustments.....................................................35

DeckLeveling...............................................35

PumpDriveBeltTension...............................35

DeckBeltTension.........................................35

BladeDriveBeltTension..............................35

ParkBrakeAdjustment..................................35

HydroDriveLinkageAdjustment..................35

TrackingAdjustment.....................................37

HydroPumpSpringTensionSetting..............37

ElectricClutchAdjustment............................37

LPGRegulator.............................................38

Cleaning...........................................................38

CleanGrassBuild-UpUnderDeck................38

WasteDisposal..............................................38

Troubleshooting...................................................40

Schematics...........................................................43

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThislawnmowermeetsorexceedstheB71.4

specicationsoftheAmericanNationalStandards

Instituteineffectatthetimeofproduction.

Exmarkdesignedandtestedthislawnmowertooffer

reasonablysafeservice;however,failuretocomply

withthefollowinginstructionsmayresultinpersonal

injury.

ThisSafetyAlertSymbol(

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

1.Safetyalertsymbol

Figure2)isusedbothin

Figure2

aliquidfuelthatisstoredinatankunderpressure.

Beforetheliquidleavesthetank,itisconvertedinto

avapor.SinceLPGisstoredasbothliquidandgas,

itmayleakfromjointsorconnectionsthatarenot

sealedproperly.LPGbecomesammablewhenitis

mixedwithair.

TheLPGinformationinthisOperator’smanualis

providedonlyasaguide.ConsulttheNFPA58:

LiqueedPetroleumGasCode,2008Editionfor

additionalsafetyinformation.ThisNationalFire

ProtectionAssociation(NFPA)codepertainstothe

handling,storing,transporting,andusageofLPG.

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

WhatisLPG?LPGstandsforliqueedpetroleum

gasandismorecommonlycalledpropane.LPGis

•Onlyadultsandmatureteenagersshouldoperate

amower,andevenmatureteenagersshouldhave

adultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator’s

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

mowerwithouttakingrisks.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

5

Page 6

Safety

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

DANGER

LPGfuelisextremelyammableandvapors

areexplosive.

AreorexplosionfromLPGfuelcanburn

you,others,andcausepropertydamage.

•Neversmokearoundtank(s)andstay

awayfromanopenameorwherefumes

maybeignitedbyaspark.

DANGER

LPGfuelisextremelyammableandvapors

areexplosive.

•Incaseofretakethefollowingsteps:

1.Ifyoucansafelydoso,stoptheowof

gasasquicklyaspossible.Neverput

outameunlessgascanbeshutoff.

2.NotifytheFireDepartmentandclear

immediateareaofallpeople.

3.Whengasowisstopped,putoutthe

re.Usuallywhenowofgasiscutoff,

rewillautomaticallystop.

4.Ifgasowcannotbeimmediately

stopped,directwaterontankstokeep

themcool,butDoNotputoutre.

•Storagelocationsandtrailersshould

beequippedwithatleastoneapproved

portablereextinguisherhavinga

minimumcapacityof18lb(8.2kg)dry

chemicalwithaB:Crating.DoNot

useCarbonTetrachlorideextinguishers

(Pyreneetc.).

•Extinguishallsourcesofsparkorame

whenapproachingLPGtanksormowers.

Thehazardincreasesforenclosedtrailers

orstoragelocationswherevaporleakage

mayoccurandcollect.

•LPGisheavierthanairandmay

accumulateinlowlyingareas,suchas

ditches,drains,orpits.

•LPGtank(s)shouldbelledbytrained

andqualiedpersonnelONLY .

•Nevertamperwithorrepairthetank(s);

contacttrainedandqualiedpersonnel.

•DoNotchangethetank(s)whenthe

engineisrunning.

•Beforedisconnectingthehose(s),purge

allLPGvaporsfromthesystem,by

closingthefuelvalve(s)onALLtanksand

allowingtheenginetorununtilitstops.

•Storethetank(s)awayfromheat,sparks,

oropenames.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

LPGvaporsandliquidescapingfromthetank

maycauseseriousinjuryordeath.Vapors

orliquidmaycausesuffocation,freezingof

tissue,orfrostbite.

•Storeandservicethemowerinawell

ventilatedarea.

•AnapprovedLPGdetectorinstalledin

trailersandstorageareasisrecommended.

•LPGisheavierthanairandmay

accumulateinlowlyingareas,suchas

ditches,drains,orpits.

•Avoidbreathingofvapors.

•Keepawayfromventvalve.

•Keepawayfromeyesandskin.

•Contacttrainedandqualiedpersonnelif

tankshowssignsoffrostedareas,makesa

hissingsound,oremitsafoulodor.

•Obtainimmediatemedicalattentionif

contactoccurswithvaporsorliquid.

•Checkthattheoperator’spresencecontrols,

safetyswitches,andshieldsareattachedand

6

Page 7

Safety

functioningproperly .DoNotoperateunlessthey

arefunctioningproperly.

Inspection

ItisveryimportanttochecktheLPGtankand

componentsforwearorleaks.

Important:Nevercheckforleaksusinganopen

ame.

Important:Neverusebarehandswhen

checkingthettingorvalve.EscapingLPG

vaporandliquidfreezesskinoncontact.

Important:Onlyhandtightentankconnection

tting.Overtighteningbytheuseoftoolsmay

causedamage.Ifhandtighteningdoesnotstop

aleak,contacttrainedandqualiedpersonnel

immediately.

•Beforeeachuse:

–Visuallyinspectthetank,hose,andttingand

bealerttoafoulodorcomingfromthetank.

–TheLPGtankshouldbefreeofdentsor

damage.Ifthetankshowsignsofdentsor

damage,replaceitimmediately.

–Checkthevalveandttingopeningsfordirt

anddebris.

–Slowlyopenthevalveallthewayandlisten

foracontinuoushissfromtheregulator,it

mayindicatealeak.

–LPGhasarotteneggorskunksmelladded

toittohelpdetectagasleak.Ifyoudetect

agasleak:

◊TurnofftheLPGvalveifyoucansafely

doso.

◊Leavethearea.

–InspecttheLPGtankandthefuelconnection

jointforleaks.Usethefollowingprocedure

belowtodetectleaks:

◊Applyanapprovedleakdetectorsolution,

obtainedfromatrainedandqualied

LPGdistributor,orathicknon-ammonia

soapywatersolution(50%non-ammonia

soapand50%water).(Aleakdetector

solutionthatcontainsammoniawillcause

thettingstocorrodeandleak.)

◊Usingasmallbrushorspraybottle,apply

thesolutionaroundallthettingsofthe

LPGtankandthefuelconnectionjoint.

◊Slowlyopenthegasvalveahalf-turn.

◊Ifbubblesaredetected,thejointortting

hasaleak.Shutoffthevalve,tighten

theleakingconnection,andslowlyopen

thevalveagain.Ifbubblesstillappear,

DoNotusethetank.Ifitissafetodo

so,removethetankfromyourmower;

otherwise,contacttrainedandqualied

personnelimmediately.

◊Ifnobubblesaredetected,theLPGtank

maybeused.

•Weekly:

–ChecktheentireLPGfueldeliverysystemfor

damageordeterioration.

–ChecktheentireLPGfueldeliverysystemfor

leaksatalljointsusingthesamemethodas

describedintheprevioussection.

–Followalltheinspectionchecksasspecied

inthetwopreviousinspectionsections.

•TankRequalication:

◊Contacttrainedandqualiedpersonnel

immediately.

–DoNotuseifthehosesareabraded,damaged,

kinked,orattened.

–Makesurethetankissecurelymountedto

themower.Ifthetankisloose,thehoseor

ttingsmayleak.

•Witheachtankchange:

–Checkallgauges,ttings,andvalvesfor

damage.

–Lookfordeterioration,damagedormissing

o-ringsontankconnectiontting.

–USDOT(UnitedStatesDepartmentof

Transportation)regulationsrequireLPG

tankstobeinspected,requalied,andmarked

within12yearsofthemanufacturedateand

onaregularbasisthereafter.Typicallythis

occurswhenthetankisrelled;contacta

trainedandqualiedLPGtankproviderfor

moredetails.

–DoNotlltheLPGtankifitisbeyondthe

requalicationperiod.

–DoNotlldamagedorrustedLPGtanks.

7

Page 8

Safety

Operation

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscanoccur

oncontactanddebris,suchasleaves,grass,

brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,to

coolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcankill

you.

DoNotrunengineindoorsorinasmallconned

areawheredangerouscarbonmonoxidefumes

cancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Neverraisedeckwithbladesrunning.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkmachineonlevelground.Stopengine,wait

forallmovingpartstostop,removekeyand

engageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforechangingtanks.

–Beforedumpingthegrasscatcher.

–Beforemakingheightadjustments.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•DONOToperatethemowerwhenpeople,

especiallychildren,orpetsareinthearea.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

8

Page 9

Safety

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Lossofcontrol

and/orlossofoperator’sfootingcouldresultina

fallwithanarmorleggettingunderthemower

orenginedeckwhichmayresultinserious

injury,deathordrowning.

•Mowacrossslopes,neverupanddown.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan20degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatoperatingonwetgrass,acrosssteep

slopesordownhillmaycausethemowertolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

MaintenanceandStorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•LetenginecoolbeforestoringandDoNotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Storemowerinawellventilatedoutdoorshelter,

building,ortrailer.

•Closefuelvalvewhenmowerisnotinuse,

includingwhilestoringortransporting.

•Theemptytank(s)shouldbetreatedasifitwas

full.

•Storethetank(s)outsideofbuildingsinanopen

wellventilatedarea,awayfromsparkandames.

•DoNotstorethetank(s)ormachinewith

tank(s)inanareawherethetemperaturecanrise

above120°F(49°C).Ifthetemperatureexceeds

approximately160°F(71°C),thetankwillrelease

highlyammablepropanevapor.SeePreparation

intheSafetySection.

•Storethetank(s)inuprightpositionorwith

pressurereliefvalvetowardsthetop.

•DoNotdrag,drop,orabusethetank(s).

•Storageoftheemptytank(s)shouldfollowlocal

andstateregulations.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

9

Page 10

Safety

DANGER

Chargingorjumpstartingthebatterymay

produceexplosivegases.Batterygasescan

explodecausingseriousinjury.

•Keepsparks,ames,orcigarettesaway

frombattery.

•Ventilatewhenchargingorusingbattery

inanenclosedspace.

•Makesureventingpathofbatteryis

alwaysopenoncebatteryislledwith

acid.

•Alwaysshieldeyesandfacefrombattery.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldeyes,and

rubberglovestoprotectskinandclothing

whenhandlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwith

waterandcalladoctorimmediately.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,traction,

andsafetyofthemachine.Failuretouseoriginal

Exmarkpartscouldcauseseriousinjuryor

death.Makingunauthorizedchangestothe

engineorfuelsystem,mayviolateEPAand

CARBregulations.

Replaceallpartsincluding,butnotlimitedto,

tires,belts,blades,andfuelsystemcomponents

withoriginalExmarkparts.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemay

result.

•Ifequipped,makesureallhydraulicuid

hosesandlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretohydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

CAUTION

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagement

ofcomponents.Sparkscouldcausean

explosionormovingpartscouldaccidentally

engagecausingpersonalinjury.

Besureignitionswitchisinthe“OFF”

positionbeforechargingthebattery.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Usecardboardorpaper,notyourhands,to

ndhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembyplacingthemotioncontrollevers

inneutralandshuttingofftheenginebefore

performinganyworkonthehydraulicsystem.

10

Page 11

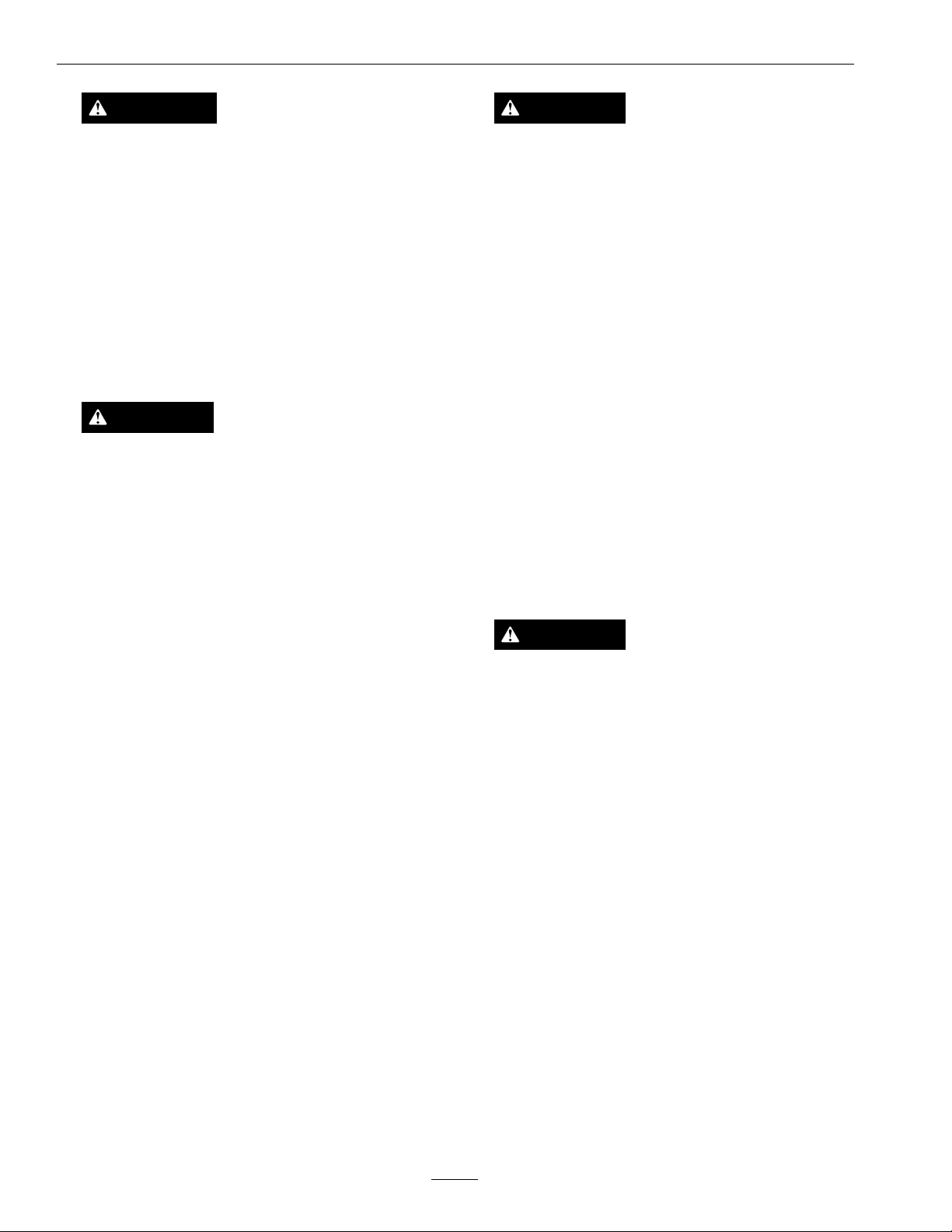

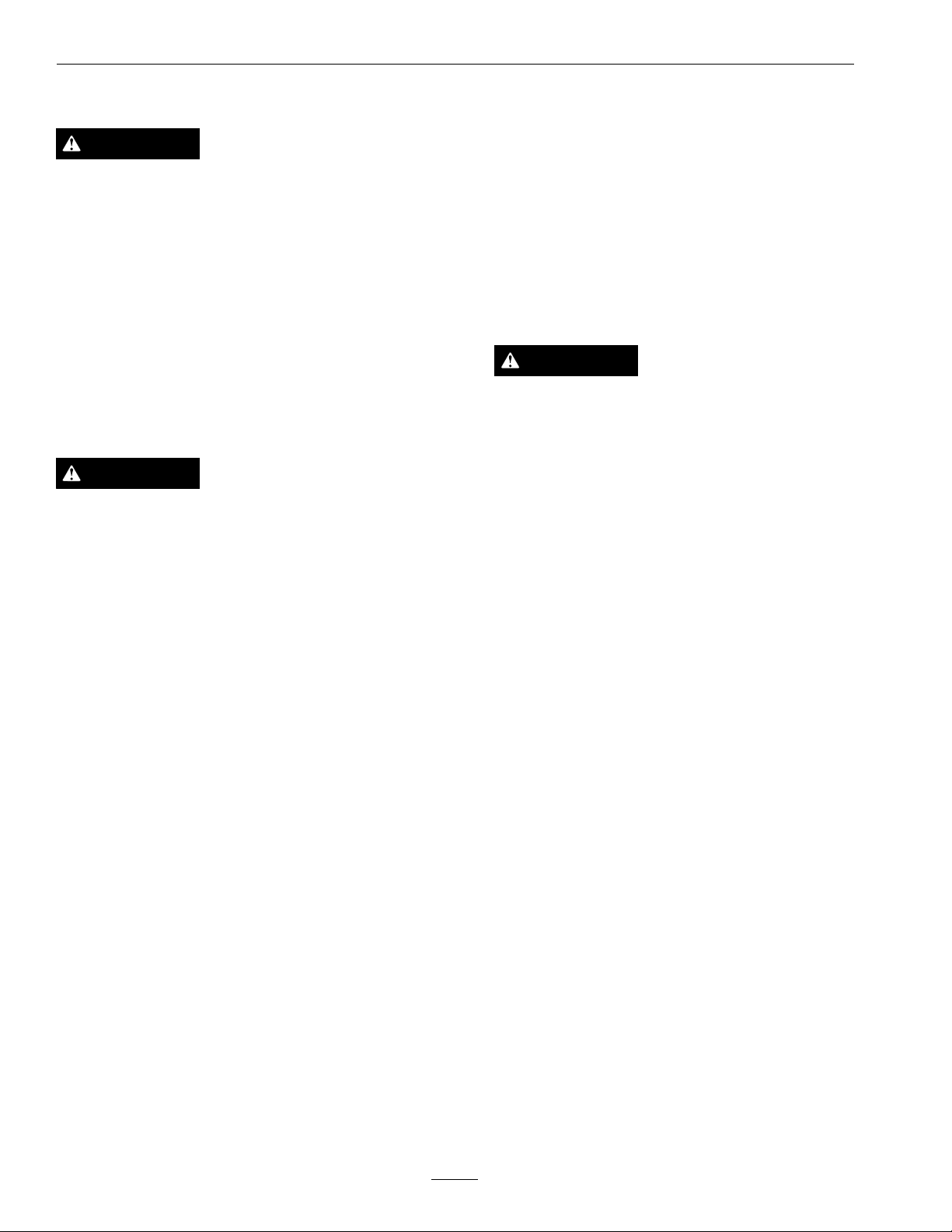

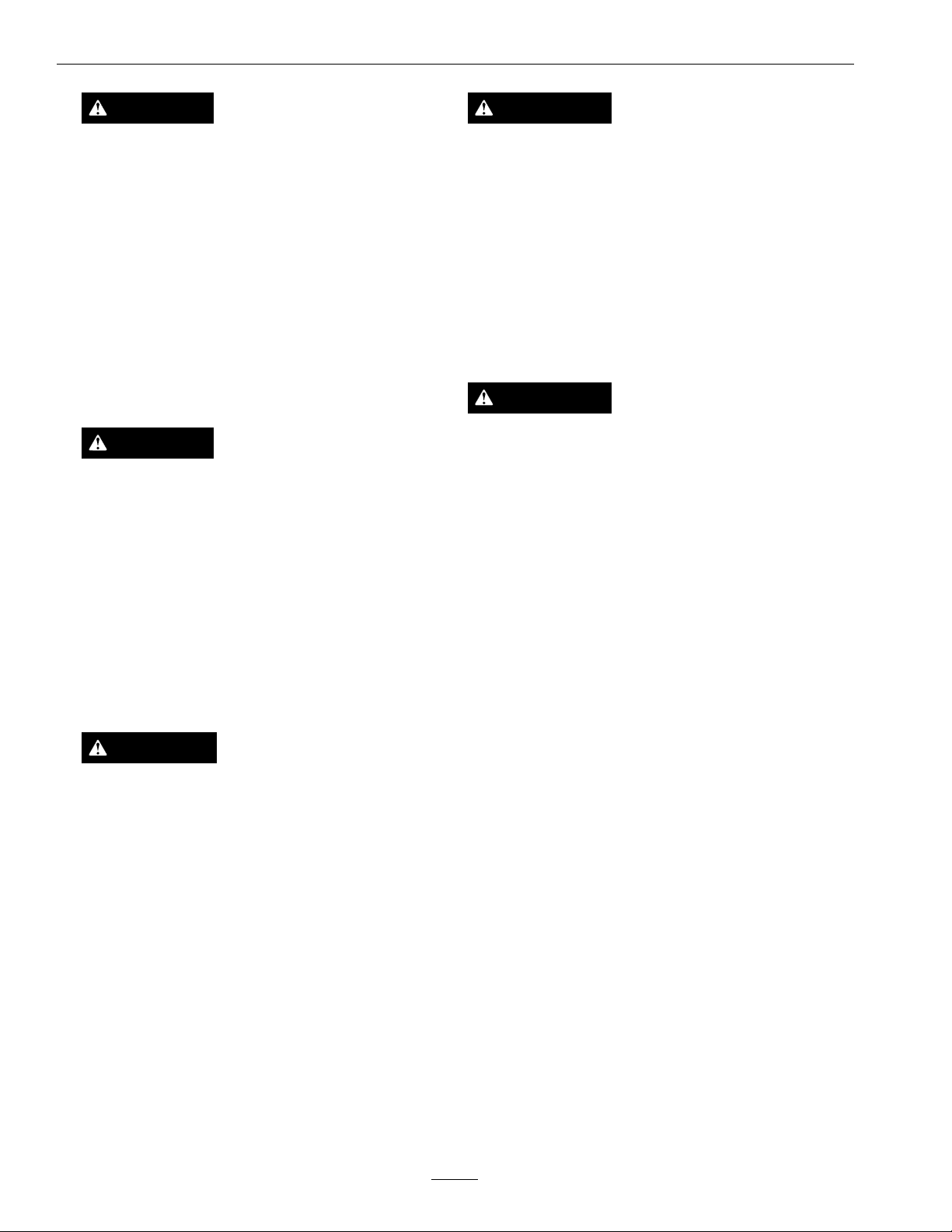

SafetyandInstructionalDecals

Safety

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

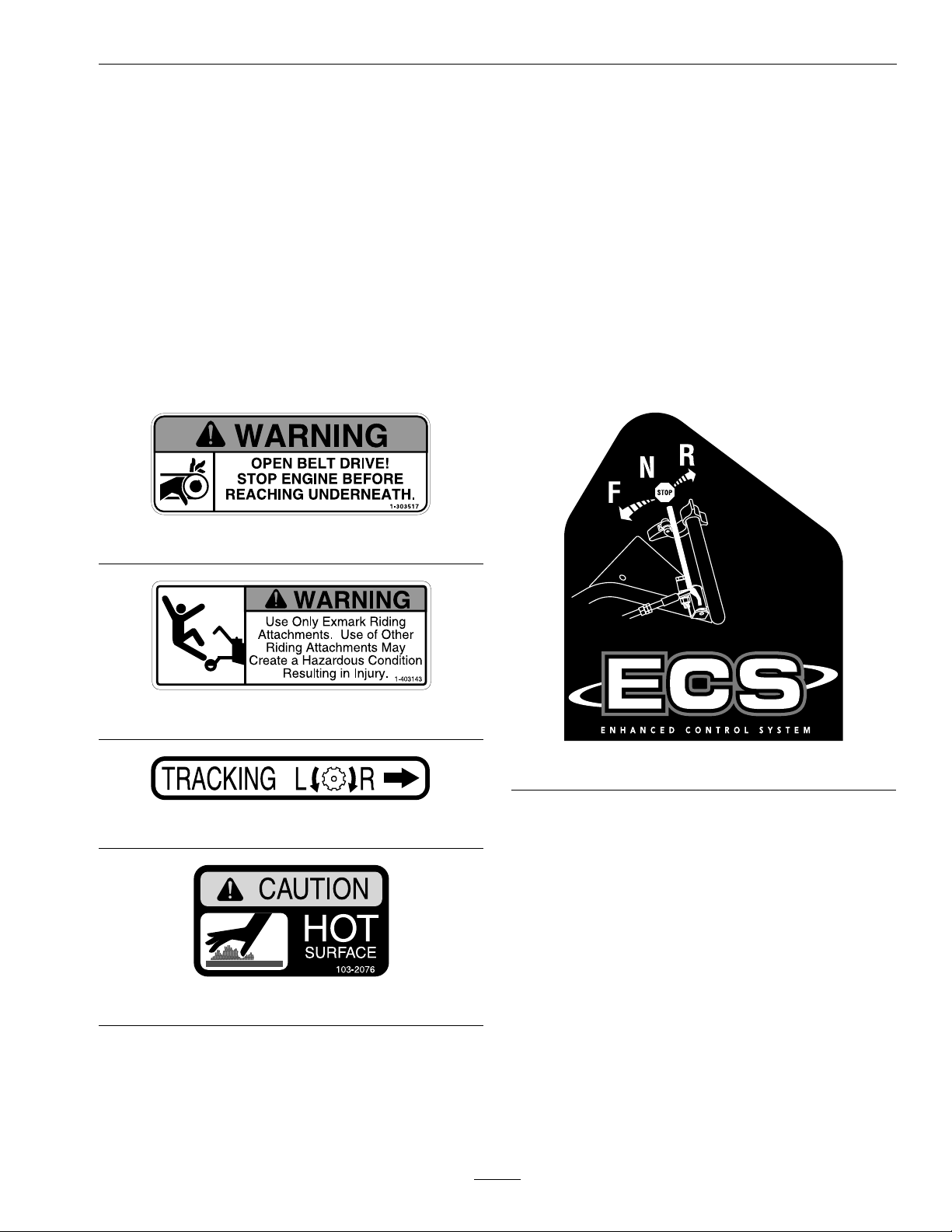

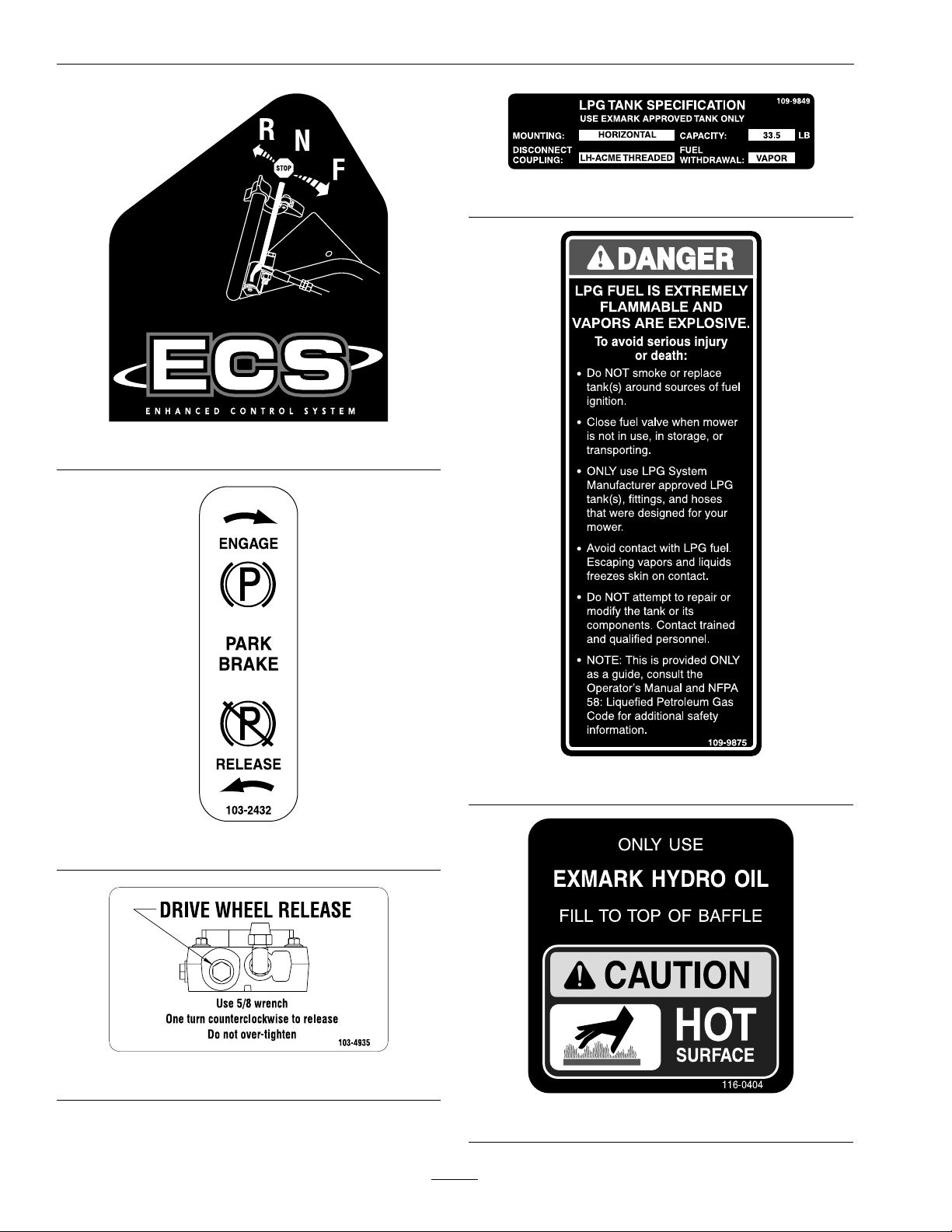

1-303517

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

1-403143

103–2242

1-413214

103-2076

11

Page 12

Safety

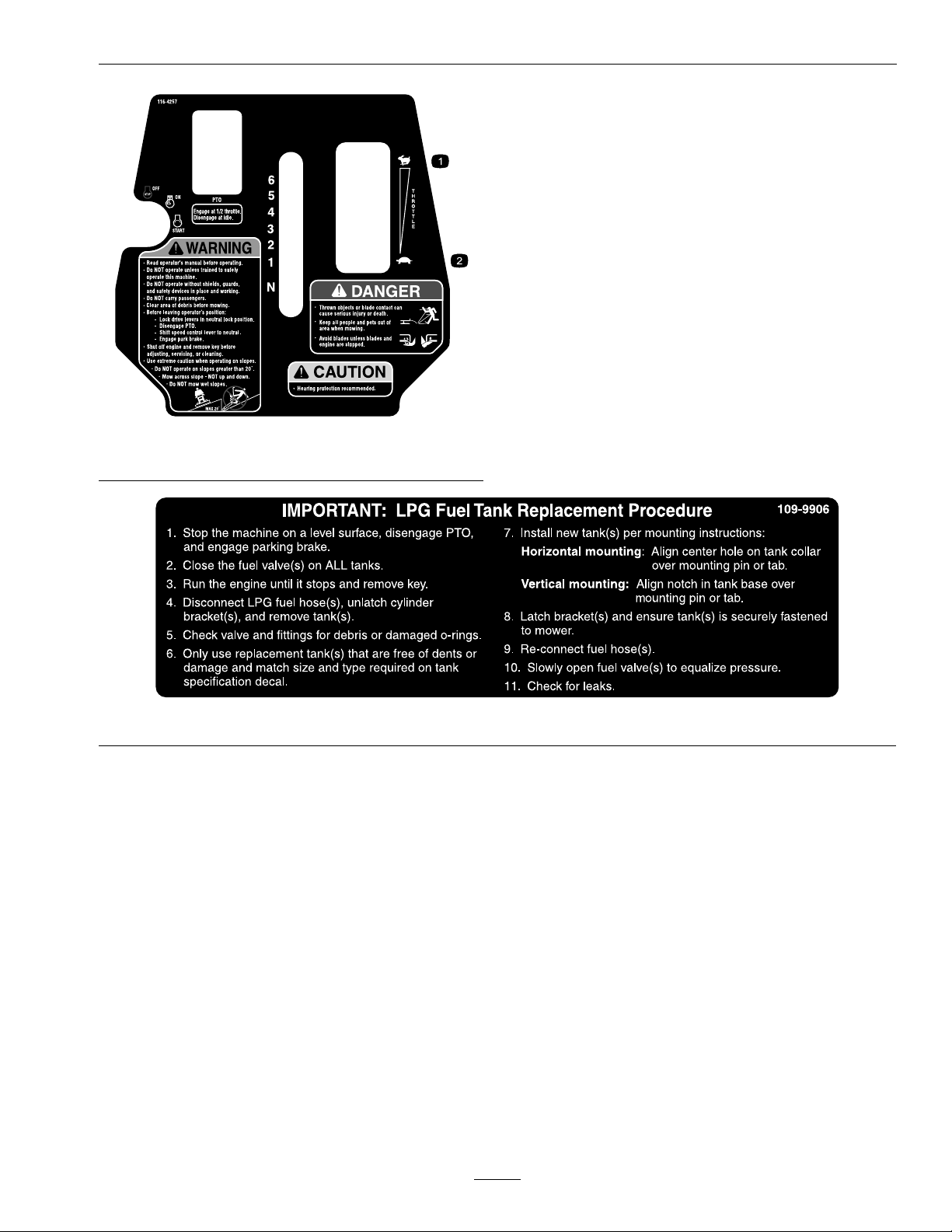

109-9849

103–2243

109-9875

103-2432

103-4935

116-0404

12

Page 13

Safety

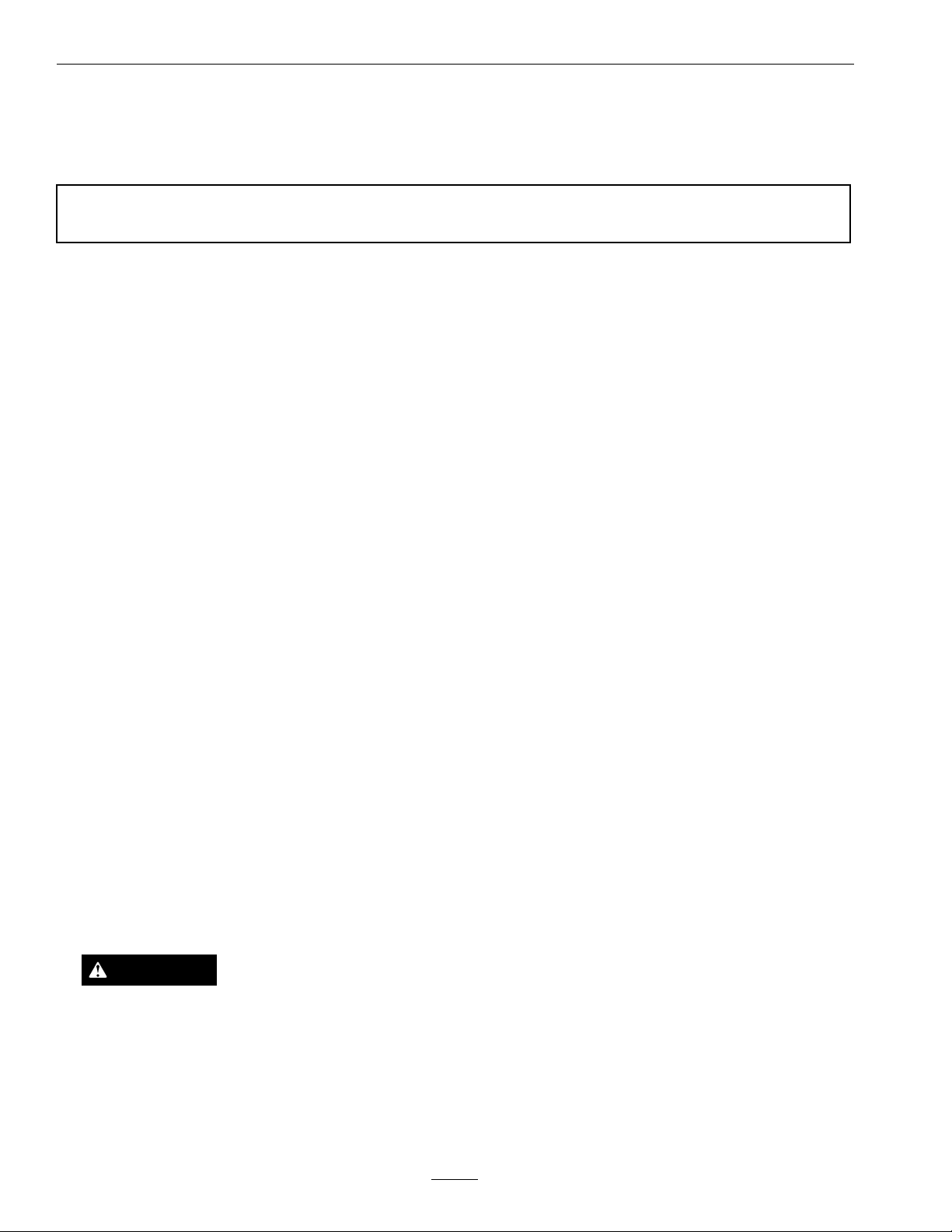

116-4257

1.Fast

2.Slow

109-9906

13

Page 14

Specications

Specications

ModelNumbers

SerialNos:920,000andHigher

TTX24PKAE

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•EngineOilType:Exmark4–CyclePremium

EngineOil

•RPM:FullSpeed:3600(NoLoad)

Idle:1550RPM

TankTypeandRelling

Important:TheLPGtankusedonthismower

isaspecialtankwithinternalbafesdesigned

forthisapplication.

•HorizontalTankSpecications:

–TankMaterial:Aluminum

–Capacity:33.5lb

–DisconnectCoupling:LHACMEThreaded

–FuelWithdrawal:Vapor

–FuelShut-OffValve:Rotateclockwiseto

close.

•TypeofFuel:HD5gradepropane

•Newtanksmustbeproperlylledbytrainedand

qualiedpersonnel.

•OnlyusetanksrecommendedbyExmark.Failure

todosowillresultinimproperoperationofthe

fuelsystem.

CAUTION

Note:Useofa“forklift”typeliquidwithdrawaltank

willresultinicingorfreezingoftheLPGregulator

andpreventtheenginefromoperating.Thismay

alsoresultinpermanentfuelsystemdamageandthe

releaseofhighlyammablepropaneliquidorvapor.

ElectricalSystem

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:15amps

•BatteryType:BCIGroupU1235amps0°F

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuses:Twobladetype,20amptochargingcircuit;

20amptoelectricclutch

SafetyInterlockSystem:

•OperatormusthaveOPC(OperatorPresence

Control)leversheldincontactwithhandle

grips,speedcontrolleverinneutral,andPTO

disengagedtostartengine.ReleaseofOPClevers

willcausetheenginetostopifspeedcontrollever

isnotinneutraland/orPTOisengaged.

•Parkbrakemustbedisengagedtomovespeed

controloutofneutralorenginewillkill.

OperatorControls

SteeringControl:Fingertipdrivecontrollevers

provideindependentspeedcontrol,brakingand

neutraltoeachdrivewheelformovingforwardor

reverse,stopping,andpowerturning.

Undernocircumstancesshouldpropane

tankslledbeyond80%capacitybeusedin

service.

Theuseofoverlledtanksmayresultinthe

releaseofhighlyconcentratedandextremely

ammableliquidpropane.RefertotheSafety

section.

Transmission

•TwoHydroGearvariabledisplacementpiston

pumpsindependentlycoupledtotwohigh

efciencyParkerwheeldrivemotors.

•HydraulicOil:UseExmarkPremiumHydroOil.

•HydraulicOilCapacity:2.4qt.(2.2L)

14

Page 15

Specications

•HydraulicFilterisreplaceablecartridgetype.

P/N109–4180:25microns,10psibypass

(Summeruseabove32°F(0°C))

P/N1–523541:40microns,18psibypass(Winter

usebelow32°F(0°C))

•Speeds:

–0-6.75mph(10.9km/hr)forward.

–0-2.25mph(3.6km/hr)reverse.

•Drivewheelreleasevalvesallowmachinetobe

movedwhenengineisnotrunning.

WheelDriveSystem

DrivewheelsaredirectcoupledtoParkerwheeldrive

motorswith1inch(25.4mm)taperedshaft.

Tires&Wheels

DriveFrontCaster

Pneumatic

(Air-Filled)

Quantity

Tread

Size18x8.50-811x4.00-5

PlyRating

Pressure

22

TurfMasterSmooth

4

14psi(96kPa)

SemiPneumatic

–Bladesdrivenbytwobelts(w/self-tensioning

idlers).

•Deck:

Fulloatingdeckisattachedtoout-frontsupport

frame,removableforservice.Anti-scalprollers

providemaximumturfprotection.Deckdesign

allowsforbagging,mulchingorsidedischarge.

•DeckDepth:

–52inchDeck:5.5inches(14.0cm)

–60inchDeck:5.5inches(14.0cm)

•CuttingHeightAdjustment:

Adjustsfrom11/2inches(3.8cm)to41/2

inches(11.4cm)in1/2inch(1.3cm)increments.

•MulchingKit:Optional

•Bagger:Optional

Dimensions

OverallWidth:

52inchDeck60inchDeck

DeectorUp53.4inches

(135.6cm)

DeectorDown64.8inches

(164.6cm)

61.4inches

(156.0cm)

73.0inches

(185.4cm)

CuttingDeck

•ModelNumbers:

–FMD524

–FMD604

•CuttingWidth:

–52inch(132.1cm)

–60inch(152.4cm)

•Discharge:Side

•BladeSize:(3ea.)

–52inchDeck:18.00inches(45.7cm)

–60inchDeck:20.50inches(52.1cm)

•BladeSpindles:Solidsteelspindleswith1inch

(25.4mm)I.D .bearings.

•DeckDrive:

–Electricclutchmountedonengineshaft.

OverallLength:

52inchDeck60inchDeck

83.4inches(211.8cm)83.4inches(211.8cm)

OverallHeight:

52inchDeck60inchDeck

45inches(114.3cm)45inches(114.3cm)

TreadWidth:(OutsidetoOutsideof

Tires,Widthwise)

52inchDeck60inchDeck

45.8inches(116.3cm)45.8inches(116.3cm)

15

Page 16

ProductOverview

WheelBase:(CenterofCasterTireto

CenterofDriveTire)

52inchDeck60inchDeck

43.3inches(110.0cm)43.3inches(110.0cm)

CurbWeight:

52inchDeck60inchDeck

740lb(336kg)780lb(354kg)

TorqueRequirements

BoltLocation

CutterHousingSpindle

Nut

BladeMountingBolt

(lubricatewithanti-seize)

EngineDeck/Mower

DeckSupportMount

Bolts

Torque

140–145ft-lb(190–197

N-m)

55-60ft-lb(75-81N-m)

30-35ft-lb(41-47N-m)

ProductOverview

Figure3

1.Controls

2.LPGFuelT ank4.Height-of-CutPins

3.ParkBrakeLever

Anti-ScalpRollerNyloc

NutSee

Anti-ScalpRollerWhizlock

NutSeeFigure9

EngineMountingBolts

WheelLugNuts

WheelHubSlottedNuts

(StyleA)

WheelHubSlottedNuts

(StyleB)

ClutchRetainingBolt

(securedwiththreadlocker)

WheelMotorMounting

Bolts

Figure9

30-35ft-lb(41-47N-m)

30-35ft-lb(41-47N-m)

15-20ft-lb(20-27N-m)

90-95ft-lb(122-129N-m)

140-155ft-lb(190-210

N-m)

minimum100ft-lb(136

N-m)

55-60ft-lb(75-81N-m)

30-35ft-lb(41-47N-m)

16

Page 17

Operation

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

OperatorPresenceControl(OPC)

Levers

Locatedontheupperhandleassemblydirectlyabove

thehandlegrips.

Whentheseleversaredepressed,theOPCsystem

sensesthattheoperatorisinthenormaloperator’ s

position.Whentheleversarereleased,theOPC

systemsensesthattheoperatorhasmovedfromthe

normaloperatingpositionandwillkilltheengineif

eitherthespeedcontrolleverisnotintheneutral

positionorthePTOisengaged(see

Figure4).

asshowninFigure4,andthedriveleversarereleased,

thedrivewheelsareengagedintheforwarddirection.

Squeezingthelefthandand/orrighthandlever

causesthelefthandand/orrighthanddrivewheel

respectivelytoslowdown,stop,orreverse,depending

onhowfareachdriveleveris“squeezed”.Squeezing

thedriveleversbeyondtheneutralpositioncauses

thedrivewheelstoengageinthereversedirection

regardlessofthepositionoftheneutrallocklatches

andthespeedcontrollever.

NeutralLockLatches

Locatedontheupperhandleassemblyontheends

ofthehandlegrips.

Theselatchesallowtheoperatortolockthedrive

leversina“neutral”positionwherethedrivewheels

arenotengagedineitheraforwardorreverse

direction.

ThrottleControl

Figure4

1.OPCLever

2.Rotateneutrallocklatch

downwardforneutral

lockposition

3.NeutralLockLatch

4.DriveLeverinneutral

position

DriveLevers

Locatedoneachsideoftheupperhandleassembly

aheadofandbelowthehandlegrips.

Theseleversindividuallycontrolthespeedand

directionofeachdrivewheel.Whenthespeedcontrol

leverismovedoutoftheneutralpositionandthe

neutrallocklatchesaremovedintothedriveposition,

Locatedonthecontrolconsole’ srightside.

Thethrottleisusedtocontrolenginespeed.Moving

thethrottlecontrolforwardwillincreaseengine

speedandmovingittotherearwilldecreaseengine

speed.Movingthethrottleforwardintothedetent

isfullposition.

SpeedControlLever

Locatedinmiddleofcontrolconsole.

Thespeedcontrollevercontrolsthemaximum

forwardspeedandisinnitelyvariablefromneutral

0–6.75mph(10.9km/hr).

Parkbrakemustbedisengagedtomovespeedcontrol

outofneutralorenginewillkill.

BrakeLever

Locatedontheleftsideoftheunit.

Thebrakeleverengagestheparkbrakeonthedrive

wheels.

Pulltheleverupandrearwardtoengagethebrake.

Pushtheleverforwardanddowntodisengagethe

brake.

Whenparkingonasteepslope,thewheelsmustbe

chockedorblockedinadditiontothebrakebeing

17

Page 18

Operation

engaged.Theunitmustbetieddownandbrake

engagedwhentransporting.

Parkbrakemustbedisengagedtomovespeedcontrol

outofneutralorenginewillkill.

IgnitionSwitch

Locatedontheleftsideofthecontrolconsole.

Theignitionswitchisusedtostartandstopthe

engine.Theignitionswitchhasthreepositions,

“Off”,“On”and“Start”.Insertkeyintoswitch

androtateclockwisetothe“On”position.Rotate

clockwisetothenextpositiontoengagethestarter

(keymustbeheldagainstspringpressureinthis

position).Operatormusthavespeedcontrolleverin

neutral,OPCleversdepressedandPTOdisengaged

tostartengine.Whenenginestarts,releasekey .

HourMeter

Locatedonthefrontlefthandsideofconsolejust

abovethePTOswitch.

Thehourmeterisconnectedtoapressureswitch

installedintheengineblockanditrecordsthe

numberofhoursthattheenginehasrun.Ifignition

switchisleftonwithoutenginerunning,hourmeter

willnotrun.

Witha5/8wrench,turnbothvalvesoneturn

counterclockwisetoreleasethedrivesystem.

Turnclockwisetoresetthedrivesystem.DoNot

overtighten.

TrackingAdjustmentKnob

Locatedontheright-handsideoftherearofthefuel

tanksupport.

Theknobcanbeadjustedsothatmachinewill

“track”straightaheadwiththedriveleversreleased.

PTOEngagementSwitch

Switchislocatedonleftsideofcontrolconsole.

Theswitchmustbepulledouttothe“Rotate”

positiontoengagetheblades.Theswitchispushed

intothe“Stop”positiontostoptheblades.Operator

musthaveoperatorpresencecontrolleversdepressed

whenPTOisengagedorenginewillstop.

LPGCylinderBrackets

Thebracketsarelocatedontheenginedeck.

TheLPGcylinderbracketsareusedtofastenthe

removableLPGtanktothemower.

Note:Thisswitchisnotalowoilsensorandwillnot

alerttheoperatoriftheengineoilislow.

FuelValve

LocatedontheLPGfueltank.

Thefuelvalveisusedtoopenandclosethefuel

supplywhenthemachineisnotinuse,during

transporttoandfromthejobsite,andwhenparked

insideawell-ventilatedbuilding.

Rotatethefuelvalveclockwisetoturnoffthefuel.

Rotatefuelvalvecounter-clockwisetoturnonthe

fuel.

DriveWheelReleaseValves

Locatedontheleftrearcornerofthehydrostatic

pumps.

Drivewheelreleasevalvesareusedtoreleasethe

hydrostaticdrivesystemtoallowthemachinetobe

movedbyhandwithouttheenginerunning.

FuelGauge

LocatedontheLPGfueltank.

ThisgaugemonitorstheamountofliquidLPGin

thefueltank.

SafetyPressureReliefValve

LocatedontheLPGfueltank.

Thesafetypressurereliefvalverelievestheexcess

pressureintheLPGtank.

Important:Thisvalvehasaprotectiveplastic

capthatshouldNEVERberemoved.Ifthe

capisdamagedormissing,contacttrainedand

qualiedpersonnelimmediately.

Pre-Start

LPGtankssuppliedfromExmarkDoNotcontain

LPGfuelforshippingreasonsandsafety.Havethe

18

Page 19

Operation

LPGtankslledbytrainedandqualiedpersonnel.

Forbestresults,useclean,freshHD5gradepropane.

DoNotallowtheLPGtankstobeoverlled.

OverllingLPGtanksbuildsexcesspressurewithin

thetankwhichcausesthereliefvalvetoopen.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

Important:Ifatanytimeyousensesomething

iswrongwiththeLPGequipment,stopthe

mowerinasafelocationandturnthemoweroff.

Ifyoucansafelydoso,closethefuelvalveand

trytondthecause;otherwise,getawayfrom

themowerandcontacttrainedandqualied

personnelimmediately.

Note:Itishelpfultohavetheleftandright

neutrallocklatcheslockedinneutralwhen

startingtheengine.RefertoNeutralLock

LatchessectioninControls.

EngagingthePTO

DANGER

Therotatingbladesunderthemowerdeckare

dangerous.Bladecontactcancauseserious

injuryorkillyou.

DoNotputhandsorfeetunderthemoweror

mowerdeckwhenthebladesareengaged.

DANGER

Anuncovereddischargeopeningwillallow

objectstobethrowninanoperator’sor

bystander’sdirection.Also,contactwiththe

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryordeath.

OpentheFuelValve

1.Slowlyopenthefuelvalvetoequalizethepressure

inthetank.ThefuelvalveislocatedontheRH

sideoftheLPGtank.Ifthefuelvalveisopened

tooquickly,thepressurereliefvalveisequipped

withabackpressurecheckvalvethatwillshutoff

thefuelsupply.Ifthishappens,closethefuel

valvecompletelyandwaitveseconds.Slowly

openthefuelvalve.

2.Rotatethefuelvalvecounter-clockwisetoturnon

thefuel.Ifleaksaredetected,refertotheleak

informationintheInspectionsectioninSafety .

StartingtheEngine

1.PushinonthePTOswitchtothe“STOP”

position.

2.Placethethrottleinthe“SLOW”position.

3.Turnignitionswitchto“Start”position.Release

theswitchassoonastheenginestarts.

Important:DoNotcranktheengine

continuouslyformorethantensecondsat

atime.Iftheenginedoesnotstart,allowa

60secondstartercool-downperiodbetween

startingattempts.Failuretofollowthese

guidelinescanburnoutthestartermotor.

Neveroperatethemowerwiththedischarge

deectorraised,removed,oralteredunlessthere

isagrasscollectionsystemormulchkitinplace

andworkingproperly.

ThePTOswitchengagesthecuttingblades.Besure

thatallpersonsareclearofmowerdeckanddischarge

areabeforeengagingthePTO.

1.Setthrottleto“MIDW AY”position.

2.PullthePTOswitchoutwardtothe“ROTATE”

positiontoengagetheblades.

3.Placethethrottleinthe“FAST”positiontobegin

mowing.

DisengagingthePTO

1.Setthethrottletothe“MIDWAY”position.

2.PushthePTOswitchintothe“STOP”position

todisengagetheblades.

StoppingtheEngine

1.Bringthemowertoafullstop.

2.Lockdriveleversinneutral.

3.DisengagethePTO.

19

Page 20

Operation

4.Movespeedcontrollevertoneutral.

5.Engagetheparkingbrake.

6.Placethethrottleinthe“SLOW”position.

7.Turnoffthefuelvalve(s)andallowtheengineto

runoutoffuel.Failuretodothismaycausethe

engineto“ood”whenre-starting.

8.Turntheignitionswitchtothe“OFF”position

oncetheenginehasstopped.

9.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

Important:ThereareNOadjustments

necessaryfortheLPGmower.DoNotmakeany

adjustmentstotheregulatororcarburetor.If

theengineisnotrunningproperly,contactan

AuthorizedServiceDealer.

DrivingtheMachine

DriveLever/NeutralLockLatchOperation

Tolockthedriveleversin“neutrallock”,squeezethe

driveleverstothe“neutral”position(DoNotsqueeze

thedriveleversallthewaybackasthiswillcausethe

drivewheelstogointofullreversedirection).See

Figure5position1.Placethumbsontheinnerlobe

oftheneutrallocklatchesandrotatethemunder

thedriveleversintothe“neutrallock”position.See

Figure5position2.Releasethedrivelevers.

CAUTION

Iftheneutrallocklatchesarenotcompletely

engagedthedriveleverscouldunexpectedlyslip

intotheforwarddriveposition.Ifthedrivelevers

slipintothedrivepositiontheunitcouldlurch

forwardandcauseinjuryorpropertydamage.

Besurethedriveleversarepasttherollerand

securelyseatedatthebottomoftheneutrallock

latches.

Toplacethedriveleversinthe“forward”position,

slightlysqueezethedriveleverswhileplacingthumbs

ontheouterthumblobeoftheneutrallocklatches

(ortheindexngeronthefrontlobe)androtatethem

fromunderthedrivelevers.Slowlyandcarefully

releasethedrivelevers.See

Toplacethedriveleversinthe“reverse”position,

squeezethedriveleverspasttheneutralposition.See

Figure5position4.

Figure5position3.

Figure5

1.DriveLeverinneutral

position

2.DriveLeverlockedin

neutralposition

3.DriveLeverinforward

position

4.DriveLeverinreverse

position

DrivingForward

1.Releasetheparkingbrake.

2.Withdriveleverslockedin“neutral”,shiftspeed

controllevertodesiredforwardspeed.

3.Slowlysqueezeandholdbothdriveleversin

theneutralpositionandrotatebothneutrallock

latchesfromtheneutrallockpositiontothe

forwardposition.

Note:DoNotsqueezebothdriveleversallthe

wayback.Thiswillcausethedrivewheelsto

engageinthereversedirection.

4.Tomoveforwardinastraightline,smoothly

releasebothdriveleverstoengagedrivewheels.

Toturnleftorright,squeezetherighthanddrive

levertoturnrightandthelefthanddrivelever

toturnleft.

Tomakea“zeroturn”,squeezeeithertheleft

handortherighthanddriveleverbackintothe

reversepositionwhiletheoppositedriveleverisin

aforwardpositionatanequalbutoppositespeed.

Note:Forsmoothoperationofthismachine,

avoidquick,jerkymovementsofthedrivelevers.

Movethedriveleverssmoothlyanddeliberately.

Tostop,squeezedriveleversbacktothe“neutral”

position.Movetheneutrallocklatchesintothe

“neutrallock”positionandreleasedrivelevers.

Movethespeedcontrollevertotheneutral

position.

20

Page 21

DrivinginReverse

Tomoverearwardinastraightline,squeezedrive

leversintothereverseposition.

Toturnleftorright,squeezetherighthanddrivelever

toturnleftandthelefthanddrivelevertoturnright.

Tomakea“zeroturn”,squeezeeitherthelefthand

ortherighthanddriveleverbackintothereverse

positionwhiletheoppositedriveleverisinaforward

positionatanequalbutoppositespeed.

Note:Forsmoothoperationofthismachine,avoid

quick,jerkymovementsofthedrivelevers.Movethe

driveleverssmoothlyanddeliberately.

Tostop,squeezedriveleversbacktothe“neutral”

position.Movetheneutrallocklatchesintothe

“neutrallock”positionandreleasedrivelevers.Move

thespeedcontrollevertotheneutralposition.

AdjustingtheCuttingHeight

WARNING

Whenthetwofrontsupportrodhairpinsare

removedfromthemowerdeck,theweightofthe

tractorsectionmaycausethefrontframeofthe

unittorisesuddenly.Iftheunitrisessuddenly,

injurymayoccur.

Securelyholddownthefrontoftheunitwhenthe

frontsupportrodhairpinsareremoved.

Operation

Figure6

1.Decksupportpin

B.ThetirepressuresaresetasdirectedinCheck

TirePressuresintheMaintenancesection.

C.Thelengthofthereardecksupportlink

assembliesaverage6.89inches(approximately

67/8inches)(175.01mm)fromthecenterof

theballjointtothecenterofthefarthesthole.

Figure7.

See

Note:Allfourpinsmustequallysupportthe

weightofthedeck.Adjustmentinthelength

ofthereardecksupportassembliesmaybe

necessary.Ifonesideislongerthan6.89

inches(approximately67/8inches)(175.01

mm),thantheoppositesidemustbeshorter

bythesameamount.

2.CuttingHeight

Thecuttingheightofthemowerdeckisadjusted

from11/2to41/2inches(3.81cmto11.4cm)in

1/2inchincrements.

1.Stopthemachineandmovethedriveleverstothe

neutrallockedposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Installhairpinclipsintheholesforthedesired

cuttingheight.See

Figure6.

Important:T omaintaincorrectcutting

heightandrake,checkthefollowingfor

properadjustment.

A.Thefrontandrearhairpinsareinthesame

holeswiththeproperspacersunderthehair

pins.See

Figure6.

21

Page 22

Operation

Figure8

Forcuttingheightsabove3.5inches(90mm)usethe

bottomhole.Therollerswillstillbeeffectiveagainst

scalping.

Figure7

LeftHandSideShown

AdjustingtheAnti-ScalpRollers

Itisrecommendedtochangetheanti-scalproller

position,whentheheightofcuthaschanged.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthewhizlocknut

andspringdiscwasher.

6.Adjusttheanti-scalprollersforNormalOperating

Conditions.Placetherollersinoneofthe

positionsshown(

3/4inch(19mm)clearancetothegroundto

minimizegougingandrollerwearordamage.

Figure8).Rollerswillmaintain

1.Anti-scalproller

mountingbracket

2.Cuttingheight

ForMaximumDeckFlotation,placetherollers

oneholepositionlower.Rollersshouldmaintain

1/4inch(6.4mm)clearancetotheground.Do

Notadjusttherollerstosupportthedeck.

7.Besurethewhizlocknutsareinstalledwiththe

springdiscwasherbetweentheangeofthenut

andthemountingbracket.

8.Torquethe3/8–16whizlocknutto30-35ft-lb

(41-47N-m)(

Figure9).

9.Ifthe3/8nylocnuthasbeenremoved,reinstall

andtorqueto30–35ft-lb(41-47N-m).

Figure9

1.Springdiscwasher

(conetowardsnut)

2.Frontrightanti-scalp

bracketshown

3.3/8nyloc-torqueto30-35

ft-lb(41-47N-m)

4.3/8-16whizlocknut

torqueto30-35ft-lb

(41-47N-m)

22

Page 23

Operation

Transporting

TransportingaUnit

WARNING

Loadingthemowerontoatrailerwithoutstrong

enoughorproperlysupportedrampscouldbe

dangerous.Therampscouldcollapsecausing

theunittofall,whichcouldcauseinjury.

•Useproperrampsthataresecuredtothe

truckortrailer.

•Keepfeetandlegsoutfromundertheunit

whenloadingandunloading.

•Ifnecessary,useassistancewhenloading.

ConsulttheNFPA58:LiqueedPetroleumGas

CodeforadditionalinformationregardingLPG

transportation.

•Besurethefuelvalveisclosed.

•PlacespareLPGtank(s)inaDOTapproved

storagecage.

•Securelyfastenthemachinetothetrailerwith

straps,chains,cables,orropes.

•DoNotrelysolelyontheparkingbraketohold

themachineonthetrailer.

•Besurethatthetrailerhasallnecessarylighting

andmarkingasrequiredbylawanduseasafety

chain.

–Transporttanksinanupright,verticaland

securepositiontominimizemovement,

tipping,orphysicaldamagerelativetoother

tanksortothestoragecagewhileintransit.

–Placetankssothatvalves,ttings,orgauges

areprotectedfromphysicaldamageduring

transport.

•Placetank(s)inawell-ventilatedtrailer.

•DoNotstorethetank(s)ormachinewith

tank(s)inanareawherethetemperaturecanrise

above120°F(49°C).Ifthetemperatureexceeds

approximately160°F(71°C),thetankwillrelease

highlyammablepropanevapor.SeePreparation

intheSafetySection.

•DoNottransportLPGtank(s)inthepassenger

spaceofavehicle.

•DoNottransportleakingfueltanks.

•Trailersmusthaveappropriatemarkingsto

transportLPG.

•FollowNFPA58andstateandlocalregulations

fortransportingLPG.

•Useaheavydutytrailertotransportthemachine.

Engageneutrallocklatchesandparkbrake,then

blockwheels.

23

Page 24

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecouldseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitch,engage

parkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenance.Also

pushthewire(s)asidesoitdoesnotaccidentally

contactthesparkplug(s).

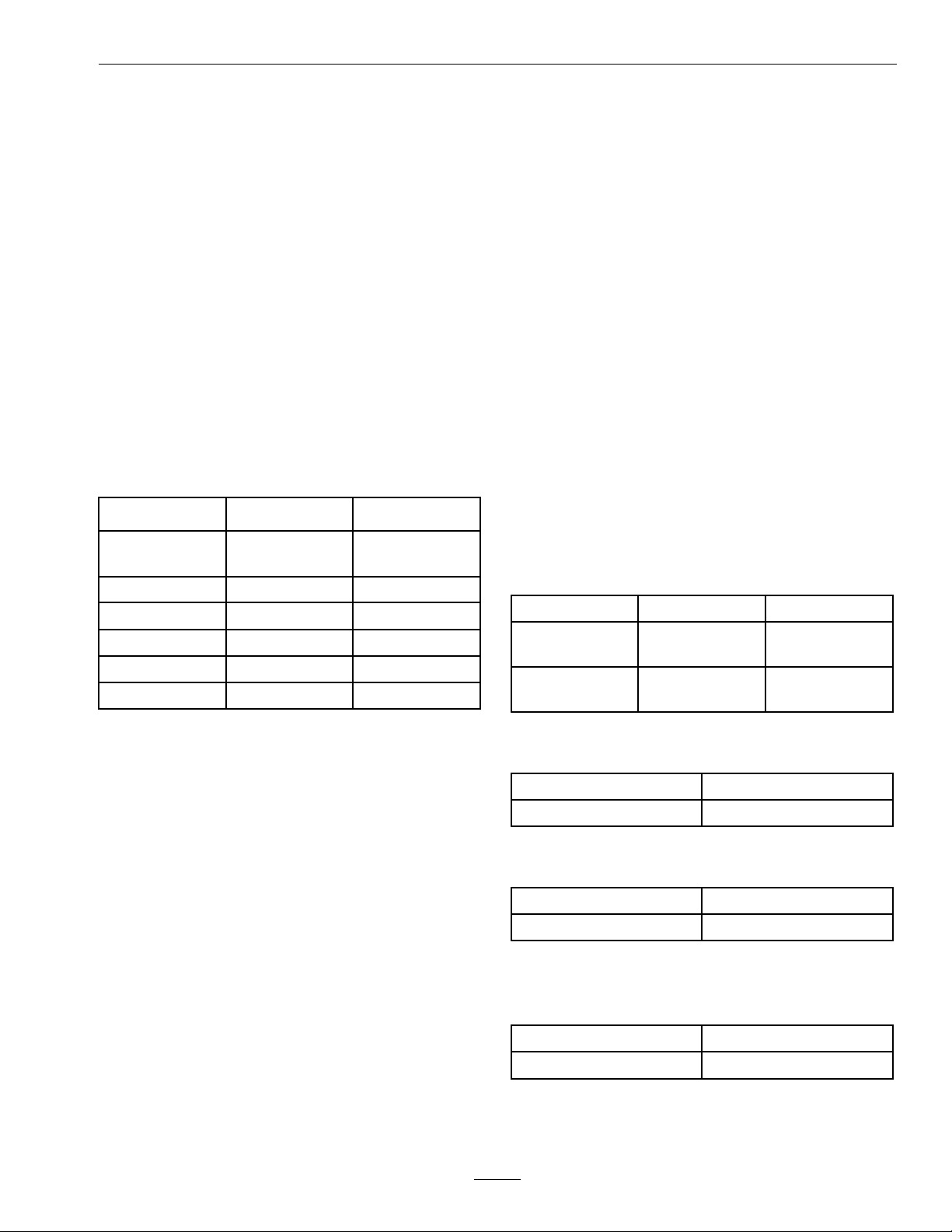

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst100hours

Aftertherst250hours

Beforeeachuseordaily

MaintenanceProcedure

•Changetheengineoil.

•Checkwheelhub-slottedtorquespecication.

•Changethehydrauliclter.

•Checktheengineoillevel.

•Checkthemowerblades.

•Checkthesafetyinterlocksystem.

•Checkforloosehardware.

•ChecktheLPGtankandcomponents.

•Cleanthegrassbuild-upfromunderthedeck.

WARNING

Theenginecanbecomeveryhot.Touchingahot

enginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheenginearea.

Every40hours

Every80hours

Every100hours

Every160hours

Every250hours

Every500hours

•Checkthehydraulicoillevel.

•Checkthetirepressures.

•Checktheconditionofthebelts.

•Greasethehydrocontrolarmsupportbushings.

•ChecktheentireLPGfueldeliverysystem.

•Removeengineshroudsandcleancoolingns.

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Checkthesparkplugs.

•Replacetheprimaryaircleanerelement—checksecondaryaircleanerelement;replaceif

dirty.(Mayneedmoreoftenundersevereconditions.SeetheEnginemanualforadditional

information.)

•Replacethesecondaryaircleanerelement.(Mayneedmoreoftenundersevereconditions.

SeetheEnginemanualforadditionalinformation.)

•Changethehydrauliclter(Every250hours/yearlyifusingMobil115W50)

•Checkwheelhub-slottedtorquespecication.

24

Page 25

Maintenance

MaintenanceService

Interval

Monthly

Yearly

MaintenanceProcedure

•Checkthebatterycharge.

•Greasethefrontcasterwheelhubs.

•Greasefrontcasterpivots.

•Greasetheidlerpivots(MowerDeck).

•Greasetheidlerpivot(PumpDrive).

•Lubricatethecasterwheelhubs.

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Cleanareaarounddipstick.Removedipstickand

wipeoiloff.Reinsertthedipstickandpushitall

thewaydownintothetube.DoNotscrewinto

place.Removethedipstickandreadtheoillevel.

4.Iftheoillevelislow ,wipeofftheareaaroundthe

oilllcap,removecapandlltothe“FULL”

markonthedipstick.Exmark4-CyclePremium

EngineOilisrecommended;refertotheEngine

Owner’smanualforanacceptablealternative.Do

Notoverll.

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

CheckBatteryCharge

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

batteryperformanceandlife,rechargebatteriesin

storagewhentheopencircuitvoltagedropsto12.4

volts.

Note:Topreventdamageduetofreezing,battery

shouldbefullychargedbeforeputtingawayfor

winterstorage.

Checkthevoltageofthebatterywithadigital

voltmeter.Locatethevoltagereadingofthebatteryin

thetableandchargethebatteryfortherecommended

timeintervaltobringthechargeuptoafullcharge

of12.6voltsorgreater.

Important:Makesurethenegativebatterycable

isdisconnectedandthebatterychargerusedfor

chargingthebatteryhasanoutputof16voltsand

7ampsorlesstoavoiddamagingthebattery(see

chartforrecommendedchargersettings).

Voltage

Reading

12.6or

greater

12.4–12.675–100%

12.2–12.450–75%

12.0–12.225–50%

11.7–12.00–25%

11.7orless

Percent

Charge

100%

0%

Maximum

Charger

Settings

16volts/7

amps

16volts/7

amps

16volts/7

amps

14.4volts/4

amps

14.4volts/4

amps

14.4volts/2

amps

Charging

Interval

No

Charging

Required

30Minutes

1Hour

2Hours

3Hours

6Hoursor

More

Allowingbatteriestostandforanextendedperiodof

timewithoutrechargingthemwillresultinreduced

performanceandservicelife.Topreserveoptimum

25

Page 26

Maintenance

RecommendedJump

StartingProcedure

ServiceInterval:Asrequired

1.Checktheweakbatteryforterminalcorrosion

(white,green,orblue“snow”),itmustbecleaned

offpriortojumpstarting.Cleanandtighten

connectionsasnecessary.

CAUTION

Corrosionorlooseconnectionscancause

unwantedelectricalvoltagespikesatanytime

duringthejumpstartingprocedure.

DoNotattempttojumpstartwithlooseor

corrodedbatteryterminalsordamagetothe

enginemayoccur.

DANGER

Jumpstartingaweakbatterythatiscracked,

frozen,haslowelectrolytelevel,oran

open/shortedbatterycell,cancausean

explosionresultinginseriouspersonalinjury.

WARNING

Batteriescontainacidandproduceexplosive

gases.

•Shieldtheeyesandfacefromthebatteries

atalltimes.

•DoNotleanoverthebatteries.

Note:Besuretheventcapsaretightandlevel.

Placeadampcloth,ifavailable,overanyvent

capsonbothbatteries.Besurethevehiclesdo

nottouchandthatbothelectricalsystemsare

offandatthesameratedsystemvoltage.These

instructionsarefornegativegroundsystemsonly .

3.Connectthepositive(+)cabletothepositive(+)

terminalofthedischargedbatterythatiswiredto

thestarterorsolenoidasshowninFigure10.

DoNotjumpstartaweakbatteryifthese

conditionsexist.

2.Makesuretheboosterisagoodandfullycharged

leadacidbatteryat12.6voltsorgreater.Use

properlysizedjumpercables(4to6A WG)with

shortlengthstoreducevoltagedropbetween

systems.Makesurethecablesarecolorcodedor

labeledforthecorrectpolarity.

CAUTION

Connectingthejumpercablesincorrectly

(wrongpolarity)canimmediatelydamagethe

electricalsystem.

Becertainofbatteryterminalpolarityand

jumpercablepolaritywhenhookingup

batteries.

Note:Thefollowinginstructionsareadapted

fromtheSAEJ1494Rev .Dec.2001–Battery

BoosterCables–SurfaceVehicleRecommended

Practice(SAE–SocietyofAutomotive

Engineers).

Figure10

1.Positive(+)cableondischargedbattery

2.Positive(+)cableonboosterbattery

3.Negative(–)cableontheboosterbattery

4.Negative(–)cableontheengineblock

5.Boosterbattery

6.Dischargedbattery

7.Engineblock

4.Connecttheotherendofthepositivecabletothe

positiveterminaloftheboosterbattery.

5.Connecttheblacknegative(–)cabletotheother

terminal(negative)oftheboosterbattery.

6.MAKETHEFINALCONNECTIONON

THEENGINEBLOCKOFTHESTALLED

VEHICLE(NOTTOTHENEGATIVEPOST)

AWAYFROMTHEBATTERY .STANDBACK.

7.Startthevehicleandremovethecablesinthe

reverseorderofconnection(theengineblock

(black)connectionisthersttodisconnect).

26

Page 27

Maintenance

CheckMowerBlades

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Liftdeckandsecureinraisedpositionasstated

intheCleanGrassBuild-UpUnderDeck

procedure.

3.Inspectbladesandsharpenorreplaceasrequired.

4.Reinstallblades(iftheywereremoved)inthe

followingorder:

A.Installbushingthroughbladewithbushing

angeonbottom(grass)sideofblade.

Figure11

1.Installbushinginbladepriortoinstallingbushingin

spindle.

anti-seizepreferable.Greaseacceptable

substitute.Installbladeboltngertight.Place

wrenchonthetopspindlenutthentorquethe

bladeboltsto55-60ft-lb(75-81N-m).

WARNING

Incorrectinstallationofthebladeor

componentsusedtoretainthebladecan

bedangerous.Failuretousealloriginal

componentsandassembledasshowncould

allowabladeorbladecomponenttobe

thrownoutfromunderthedeckresultingin

seriouspersonalinjuryordeath.

AlwaysinstalltheoriginalExmarkblades,

bladebushings,andbladeboltsasshown.

CheckSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

1.Checkstartingcircuit.Startershouldcrankwith:

OperatorPresenceControlleversdepressed,

speedcontrolleverinneutral,andPTO

disengaged.

B.Installbushing/bladecombointospindle.

Figure12

1.Usewrenchherefor

bladeinstallation.This

nuthasbeentorquedto

90–110ft-lb(122–149

N-m)

2.Torqueto55-60ft-lb

(75-81N-m)Apply

lubricanttothreads

asneededtoprevent

seizing.Copper-based

anti-seizepreferable.

Greaseacceptable

substitute.

C.Applylubricanttothreadsofbladeboltas

neededtopreventseizing.Copper-based

TrytostarttheenginewithOPClevers

disengaged,speedcontrolleverinneutraland

PTOdisengaged-startermustnotcrank.

Trytostartwith,OPCleversdepressed,speed

controlleverinanyspeedbutneutralandPTO

disengaged-startermustnotcrank.

TrytostartwithOPCleversdepressed,

speedcontrolleverinneutralandPTO

engaged-startermustnotcrank..

2.CheckOPCcircuits.Clearthearea.Runengine

atone-thirdthrottle,then,withdriveleversand

neutrallocklatchesinneutrallockposition,

movethespeedcontrolleveroutofneutraland

releaseOPCleversenginemuststop.Again,

runengineatone-thirdthrottle,movethespeed

controllevertoneutral,engagePTOandrelease

OPClevers-enginemuststop.

Note:Parkbrakemustbedisengagedbeforethe

speedcontrolleverismovedoutofneutralorengine

willkill.

Note:Ifmachinedoesnotpassanyofthesetests,

donotoperate.ContactyourauthorizedEXMARK

SERVICEDEALER.

27

Page 28

Maintenance

Important:Itisessentialthatoperatorsafety

mechanismsbeconnectedandinproper

operatingconditionpriortouseformowing.

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

ServiceAirCleaner

ServiceInterval:Every250hours—Replace

theprimaryaircleaner

element—check

secondaryaircleaner

element;replaceifdirty.

(Mayneedmoreoften

undersevereconditions.

SeetheEnginemanualfor

additionalinformation.)

Every500hours—

Replacethesecondary

aircleanerelement.(May

needmoreoftenunder

severeconditions.See

theEnginemanualfor

additionalinformation.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.SeetheEngineOwner’ sManualformaintenance

instructions.

ChangeEngineOil

todrainandreplaceoildrainplug.Torqueplug

to20-24ft-lb.

4.Replacetheoilltereveryotheroilchange.Clean

aroundoillterandunscrewltertoremove.

Beforereinstallingnewlter,applyathincoating

ofExmark4–CyclePremiumEngineOilonthe

surfaceoftherubberseal.Turnlterclockwise

untilrubbersealcontactsthelteradapterthen

tightenlteranadditional1/2to3/4turn.

5.Cleanaroundoilllcapandremovecap.Fillto

speciedcapacityandreplacecap.

6.UseoilrecommendedintheCheckEngineOil

Levelsection.DoNotoverll.Starttheengine

andcheckforleaks.Stopengineandrecheckoil

level.

CheckHydraulicOilLevel

ServiceInterval:Every40hours

1.Stopengineandwaitforallmovingpartstostop,

andremovekey.Engageparkingbrake.

2.Cleanareaaroundhydraulicreservoircapand

removecap.Oillevelshouldbetothetopofthe

bafeinsidethetank.Ifnot,addoil.UseExmark

PremiumHydroOil.Replacehydraulicreservoir

capandtightenuntilsnug.DoNotovertighten.

Note:Thebafeislabeled“HOT”and

“COLD”.Theoillevelvarieswiththe

temperatureoftheoil.The“HOT”levelshows

thelevelofoilwhenitisat225°F(107°C).The

“COLD”levelshowstheleveloftheoilwhen

itisat75°F(24°C).Filltotheappropriatelevel

dependinguponthetemperatureoftheoil.For

example:Iftheoilisabout150°F(65°C),llto

halfwaybetweenthe“HOT”and“COLD”levels.

Iftheoilisatroomtemperature(about75°F

(24°C)),llonlytothe“COLD”level.

ServiceInterval:Aftertherst5hours

Every100hours(May

needmoreoftenunder

severeconditions.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Drainoilwhileengineiswarmfromoperation.

3.Theoildrainhoseislocatedontherighthand

side.Placepanundermachinetocatchoil.

Removeplugfromendofdrainhose.Allowoil

CheckTirePressures

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto12–14psi(83–97kPa).

4.Inatetirestopressuresstatedabove.Measure

thecircumferenceofeachdrivetire.Adjusttire

28

Page 29

Maintenance

pressureswithintheaboverangetotrytomake

tirecircumferencesmatchascloselyaspossible.

Semi-pneumaticcastertiresdonotneedtobe

inated.

Note:DoNotaddanytypeoftirelinerorfoam

llmaterialtothetires.Excessiveloadscreatedby

foamlledtiresmaycausefailurestothehydrodrive

system,frame,andothercomponents.Foamlling

tireswillvoidthewarranty.

CheckConditionOfBelts

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Removethethreemowerdeckbeltshields

tocheckmowerprimaryandsecondarybelt

condition.

3.Lookunderenginedecktocheckthepumpdrive

beltcondition.

LubricationChart

Fitting

Locations

4.Idler

Pivot(Pump

Drive)

5.Hydro

Control

Arm

Support

Bushings

Initial

Pumps

21

22

Numberof

Places

*Seestep3forspeciallubricationinstructionson

thefrontcasterpivotsandtheLubricateCaster

WheelHubssectionforspeciallubrication

instructionsonthefrontcasterswheelhubs.

Service

Interval

Yearly

40Hours

4.Checkallidlerarmstobesuretheypivotfreely.

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lubricatettingswithonetotwopumpsof

NGLIgrade#2multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.Front

Caster

WheelHubs

2.Front

Caster

Pivots

3.Idler

Pivots

(Mower

Deck)

Initial

Pumps

*0

*0

12

Numberof

Places

2

2

Service

Interval

*Yearly

*Yearly

Yearly

Number4(IdlerPivot(PumpDrive)Located

UnderEngineDeck

3.Lubricatefrontcasterpivotsonceayear.Remove

hexplugandcap.Threadgreasezerkinholeand

pumpwithgreaseuntilitoozesoutaroundtop

bearing.Removegreasezerkandthreadplugback

in.Placecapbackon.

LubricateCasterWheelHubs

ServiceInterval:Yearly

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

29

Page 30

Maintenance

Figure13

1.Sealguard2.Spacernutwithwrench

ats

2.Removecasterwheelfromcasterforks.

3.Removesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethatthread

lockingadhesivehasbeenappliedtolockthe

spacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)from

thewheelassembly.

5.Pryoutseals,andinspectbearingsforwearor

damageandreplaceifnecessary.

6.PackthebearingswithaNGLIgrade#1

multi-purposegrease.

7.Insertonebearing,onenewsealintothewheel.

Note:Seals(ExmarkP/N103-0063)mustbe

replaced.

8.Iftheaxleassemblyhashadbothspacernuts

removed(orbrokenloose),applyathreadlocking

adhesivetoonespacernutandthreadontothe

axlewiththewrenchatsfacingoutward.Do

Notthreadspacernutallofthewayontotheend

oftheaxle.Leaveapproximately1/8inch(3mm)

fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

NGLIgrade#1multi-purposegrease.

11.Insertthesecondbearingandnewsealintothe

wheel.

12.Applyathreadlockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrenchats

facingoutward.

13.Torquethenutto75-80in-lb(8-9N-m),loosen,

thenre-torqueto20-25in-lb(2-3N-m).Make

sureaxledoesnotextendbeyondeithernut.

14.Reinstallthesealguardsoverthewheelhuband

insertwheelintocasterfork.Reinstallcasterbolt

andtightennutfully .

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjusttorqueon

spacernutuntilthereisaslightamountofdrag.

Reapplythreadlockingadhesive.

RemoveEngineShroudsand

CleanCoolingFins

ServiceInterval:Every80hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Removecoolingshroudsfromengineandclean

coolingns.Alsocleandust,dirt,andoilfrom

externalsurfacesofenginewhichcancause

impropercooling.

3.Makesurecoolingshroudsareproperly

reinstalled.Operatingtheenginewithout

coolingshroudswillcauseenginedamagedueto

overheating.

CheckSparkPlugs

ServiceInterval:Every160hours

Removesparkplugs,checkconditionandresetgaps,

orreplacewithnewplugs.SeeEngineOwner’s

Manualforcorrectsparkplugpartnumber.Set

thesparkpluggapto.025inch(.64mm)forLPG

poweredengine.

CheckLPGTank

ServiceInterval:Beforeeachuseordaily

ChecktheLPGtankandcomponentsforwearor

leaks.Followalltheinspectionchecksasspeciedin

theInspectionsectioninSafety.

30

Page 31

CheckLPGFuelDelivery

System

ServiceInterval:Every40hours

ChecktheentireLPGfueldeliverysystemfordamage

ordeterioration.Followalltheinspectionchecksas

speciedintheInspectionsectioninSafety .

ChangeLPGTank

ServiceInterval:Asrequired

Maintenance

ChangetheLPGtanksoutdoorsinawellventilated

area.

1.Stopthemachineonlevelground,disengagethe

PTO,andengagetheparkingbrake.

2.Closethefuelvalvetothetank.

3.Purgeallvaporsfromthehose(s),byrunning

theengineuntilitstops,turnkeyto“OFF”and

removeitfromtheignition.

4.CarefullydisconnecttheLPGfuelhose.

5.Unlatchthecylinderbracketsandremovethe

tank.

WARNING

Fuelsystemcomponentsareunderhigh

pressure.Theuseofdamagedorimproper

componentscancausesystemfailure,fuel

leakage,andpossibleexplosion,whichmay

resultinseriousinjuryordeath.

•DoNotattempttorepairormodifythe

valves,ttings,orothertankcomponents.

Figure14

1.Hydraulicreservoir

2.Mountingtab

3.Tankslot

Important:Valvesandgaugesmaynot

functionproperlyiftheLPGtankisnot

installedcorrectly.

10.Latchthebracketsandmakesurethetankis

securelyfastenedtothemower.

11.Carefullyconnectthefuelhose.Makesurethe

hoseisnotkinked.

12.Slowlyopenthefuelvalvetoequalizethepressure

inthetank.Ifthefuelvalveisopenedtooquickly,

thepressurereliefvalveisequippedwithaback

pressurecheckvalvethatwillshutoffthefuel

supply.Ifthishappens,closethefuelvalve

completelyandwaitveseconds.Slowlyopen

thefuelvalve.

13.CheckforleaksasdescribedintheInspection

sectioninSafety.

4.LPGTank

5.Cylinderbracket

•ONLYusetheExmarkapprovedLPG

tank,ttings,andhosesthatwere

designedforyourmower.

6.Inspectthelledtankvalveandttingopenings

fordirt,debris,ordamage.

7.Inspectthetankhoseconnectionttingfor

damagedormissingo-rings.

8.Makesurethereplacementtanktypeandsize

matchthetankspecicationdecal.

9.Mountthetankbyaligningtheslotwiththe

mountingtabasshowninFigure14

ChangeHydraulicSystem

Filter

ServiceInterval:Aftertherst250hours

Every500hours/Yearly

(whichevercomes

rst)thereafter

(Every250hours/Yearlyif

usingMobil115W50)

Note:UseonlyExmarkPartNo.109-4180for

Summeruseabove32°F(0°C)orP/N1-523541for

Winterusebelow32°F(0°C)(RefertoTransmission

sectioninSpecicationsforlterspecications).

31

Page 32

Maintenance

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Carefullycleanareaaroundlter.Itisimportant

thatnodirtorcontaminationenterhydraulic

system.

3.Unscrewltertoremoveandallowoiltodrain

fromreservoir.

Important:Beforereinstallingnewlter,

llitwithExmarkPremiumHydroOiland

applyathincoatofoilonthesurfaceofthe

rubberseal.

Turnlterclockwiseuntilrubbersealcontactsthe

lteradapter,thentightenthelteranadditional

2/3to3/4turn.

4.FillreservoirasstatedinCheckHydraulicOil

Level.

ExmarkPremiumHydroOilisrecommended.

Refertothechartforanacceptablealternative:

HydroOil

ExmarkPremiumHydro

Oil(Preferred)

Mobil115W50

ChangeInterval

500Hours

250Hours

their“prime”.RefertoHydraulicSystemAir

Purgesection.

Note:DoNotchangehydraulicsystemoil(except

forwhatcanbedrainedwhenchanginglter),unless

itisfelttheoilhasbeencontaminatedorbeen

extremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

HydraulicSystemAirPurge

ServiceInterval:Asrequired

Airmustbepurgedfromthehydraulicsystem

whenanyhydrauliccomponents,includingoil

lter,areremovedoranyofthehydrauliclinesare

disconnected.

Thecriticalareaforpurgingairfromthehydraulic

systemisbetweentheoilreservoirandeach

chargepumplocatedonthetopofeachvariable

displacementpump(

thehydraulicsystemwillbepurgedthroughnormal

operationoncethechargepumpis“primed”.

Figure15).Airinotherpartsof

5.Loosenlter1/2turnandallowasmallamount

ofoiltoleakfromtheoillter(thisallowsairto

bepurgedfromtheoillterandsupplyhosefrom

thehydraulicreservoir).Turnlterclockwise

untilrubbersealcontactsthelteradapter.Then

tightenthelteranadditional2/3to3/4turn.

6.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

CAUTION

Raisingthemowerforserviceormaintenance

relyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalor

hydraulicjacksmaynotbeenoughsupport

ormaymalfunctionallowingtheunittofall,

whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

7.Ifeitherdrivewheeldoesnotrotate,oneorboth

ofthechargepumps(locatedonthetopofthe

mainpumpasshowninFigure15)mayhavelost

Figure15

1.Chargepumpcap2.Loosen11/2turnsonly

1.Stopengineandwaitforallmovingpartstostop.

Raisetherearofthemachineupontojackstands

highenoughtoraisethedrivewheelsoffthe

ground.

32

Page 33

Maintenance

2.CheckoillevelasstatedinCheckHydraulicOil

Levelsection.

3.Startengineandmovethrottlecontrolaheadto

fullthrottleposition.Movethespeedcontrol

levertothemiddlespeedpositionandplacethe

driveleversinthe“drive”position.

Ifeitherdrivewheeldoesnotrotate,itispossible

toassistthepurgingofthechargepumpby

carefullyrotatingthetireintheforwardposition.

Note:Itisnecessarytolightlytouchthecharge

pumpcapwithyourhandtocheckthepump

temperature.Ifthecapistoohottotouch,turn

offengine.Thepumpsmaybedamagedifthe

pumpbecomestoohot.

Ifeitherdrivewheelstilldoesnotrotatecontinue

withstep

4.

4.Thoroughlycleantheareaaroundeachofthe

chargepumphousings.

5.To“prime”chargepump,loosentwohexsocket

headcapscrews(showninFigure15)11/2turns

only.Makesureengineisnotrunning.Lift

thechargepumphousingupwardandwaitfor

asteadyowofoiltoowoutfromunderthe

housing.Retightenthecapscrews.Dothisfor

bothpumps.

SeeFigure16todeterminewhichslottednuthas

beeninstalledontheunit.

Figure16

1.StyleA(blacknish)3.StyleB(yellowzinc)

2..03inch(.76mm)4..24inch(6mm)

•StyleA(blacknish):

Torquetheslottednutto140-155ft-lb(190-210

N-m).

Note:DoNotuseanti-seizeonwheelhub.

•StyleB(yellowzinc):

1.Removeanddiscardthecotterpin.

2.Torquetheslottednutto100ft-lb(136N-m).

3.Checkdistancefrombottomofslotinnutto

insideedgeofhole.Twothreads(0.1inch)or

lessshouldbeshowing.

Note:Hydraulicreservoircanbepressurizedup

to5psitospeedthisprocess.

6.Ifeitherdrivewheelstilldoesnotrotate,stop

andrepeatsteps4and5abovefortherespective

pump.Ifwheelsrotateslowly,thesystemmay

primeafteradditionalrunning.Checkoillevel

asstatedinChecktheHydraulicOilLevel

section.

7.Allowunittorunseveralminutesafterthecharge

pumpsare“primed”withdrivesysteminthefull

speedposition.CheckoillevelasstatedinCheck

theHydraulicOilLevelsection.

8.Checkhydrodrivelinkageadjustmentasstatedin

HydroDriveLinkageAdjustmentsectionin

Adjustments.

WheelHub-SlottedNut

TorqueSpecication

ServiceInterval:Aftertherst100hours

Figure17

1.0.1inchmax2.Nomorethantwo

threads(0.1inchmax)

shouldbeshowinghere.

4.Ifmorethantwothreads(0.1inch)are

showingremovenutandinstallwasher(P/N

1-523157)betweenhubandnut.

5.Torquetheslottednutto100ft-lb(136N-m).

6.Thentightennutuntilthenextsetofslotsline

upwiththecrossholeinshaft.DoNotloosen

nuttoaligntheslot.Ifrequired,tightento