Page 1

Page 2

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects,

or other reproductive harm.

WARNING

IMPORTANT

When the mower is used or oper ated on any California forest, brush or g rass covered land, a working

spark arrester must be at t ached t o the muffler. If not, the operator is violating state law, Section 442

Public Resource Code. To acquire a spark ar r ester for your unit, see your Engine Service Dealer.

POTENTIAL HAZARD

♦ This product is a piece of power equipment.

WHAT CAN HAPPEN

♦ Failure to follow safe operating pr actices can result in serious

operator injury or even death.

HOW TO AVOID THE HAZARD

♦ Keep all shields, guards and safety devices (especially the grass

discharge system) in place and in proper working condit ion.

♦ Stop engine and remove spark plug wire(s) or r emove key and

wait for all moving parts to stop before adjusting, servicing, or

performing maint enance.

♦ If mower deck becomes clogged, stop engine and remove spark

plug wire(s) or remove key and wait for all m oving par ts to stop

before cleaning blockage.

♦ Keep hands, feet and clothing away from power driven parts.

♦ Keep off mower unless seat platf o r m is pr ovided.

♦ Keep others off mower.

WARNING

WARNING

POTENTIAL HAZARD

♦ Gasoline is harmful or f at a l if swallowed. Long-term exposure to

vapors has caused cancer in laboratory animals.

WHAT CAN HAPPEN

♦ Failure to use caution may cause serious injury or illness.

HOW TO AVOID THE HAZARD

♦ Avoid prolonged breathing of vapors.

♦ Keep face away from nozzle and gas tank/container opening.

♦ Keep away from eyes and skin.

♦ Never siphon by mouth.

Exmark reserves the right to make changes or add improvements to its products at any time without incurring any

obligation to make such changes to products manufactured previously. Exmark, or its distributors and dealers,

accept no responsibility for variations which may be evident in the actual specifications of its products and the

statements and descriptions contained in this publication.

i

Page 3

EXMARK PARTS PLUS

PROGRAM

EFFECTIVE DATE: September 1, 1995

Program

If your Exmark dealer does not have the Exmark part in stock,

Exmark will get the parts to the dealer the next business day or

the part will be FREE* Guaranteed!!

How the Program Works

1. If dealer does not have part in stock for a "down" unit at

the time of request by customer, the dealer contacts his

distributor by 1:00 p.m., local time, and requests Exmark

Parts Plus

shipment of six (6) line items or less.

2. Distributor ships part(s) to dealer or customer, as

requested by dealer, same day, overnight UPS

Distributor bills dealer for part and freight charges where

applicable.

3. If distributor does not have the part(s) in stock to satisfy Exmark Parts Plus

central time, with an Exmark Parts Plus

order of six (6) line items or less.

order, he contacts Exmark by 3:00 p.m.,

4. If order is received by 3:00 p.m. central time, Exmark ships part(s) direct to dealer or customer, as requested by

distributor, same day, overnight UPS, Exmark bills the distributor for parts and shipping charges, where applicable.

5. The customer pays for the part and freight

if it is shipped under the Exmark Parts Plus

and if it arrives in

accordance to the program.

6. Who pays for the part and freight

if it fails to arrive overnight in accordance to the program?

A. Under any circumstance the customer does not pay.

B. If the part does not arrive overnight due to:

1. The dealer not submitting the Exmark Parts Plus

order to his Exmark distributor by 1:00 p.m., the dealer

pays for the part and freight.

2. The Distributor being unable to ship the part the same day or not submitting the Exmark Parts Plus

to Exmark by 3:00 p.m., central time, the Distributor pays for the part and freight.

3. Exmark being unable to ship the part and the Exmark parts order is received by 3:00 p.m., central time,

Exmark pays for the part and freight.

4. If the part does not arrive overnight due to the shipper (UPS), the shipper pays for the freight and Exmark

pays for the part.

The following restrictions apply

-- The Exmark Parts Plus

Program is available only through participating Exmark

Dealers and applies only to orders submitted on this program Monday through Thursday. Parts Plus service is available

only in the 48 contiguous United States. UPS has initiated a Saturday delivery program to many areas of the continental

United States and can be requested for an overnight shipment on Friday to be delivered Saturday. The next day air

charge, plus the Saturday delivery fee will be the responsibility of the purchaser. Exmark Mfg. will assume no

responsibility for Saturday delivery shipments. To qualify, all Exmark Parts Plus

3:00 p.m., central time. Orders must be six (6) line items or less. Exclusions from the Exmark Parts Plus

orders must be received by Exmark by

Program are:

Any wholegood or accessory in its entirety, engines and engine replacement parts, 5-speed Peerless transmissions and

5-speed transaxles, hydraulic or hydrostatic wheel motors, cutter decks and engine decks or any item exceeding United

Parcel Service size and weight restrictions.

order

Due to UPS restrictions, aerosol spray paint is considered a hazardous material and cannot be shipped via UPS next day

or Second Day Air.

Exmark Manufacturing stocks a limited supply of parts for transaxles, pumps and wheel motors. These parts can be

ordered for Next Day Air shipment but will not be guaranteed per the Parts Plus Program.

ii

Page 4

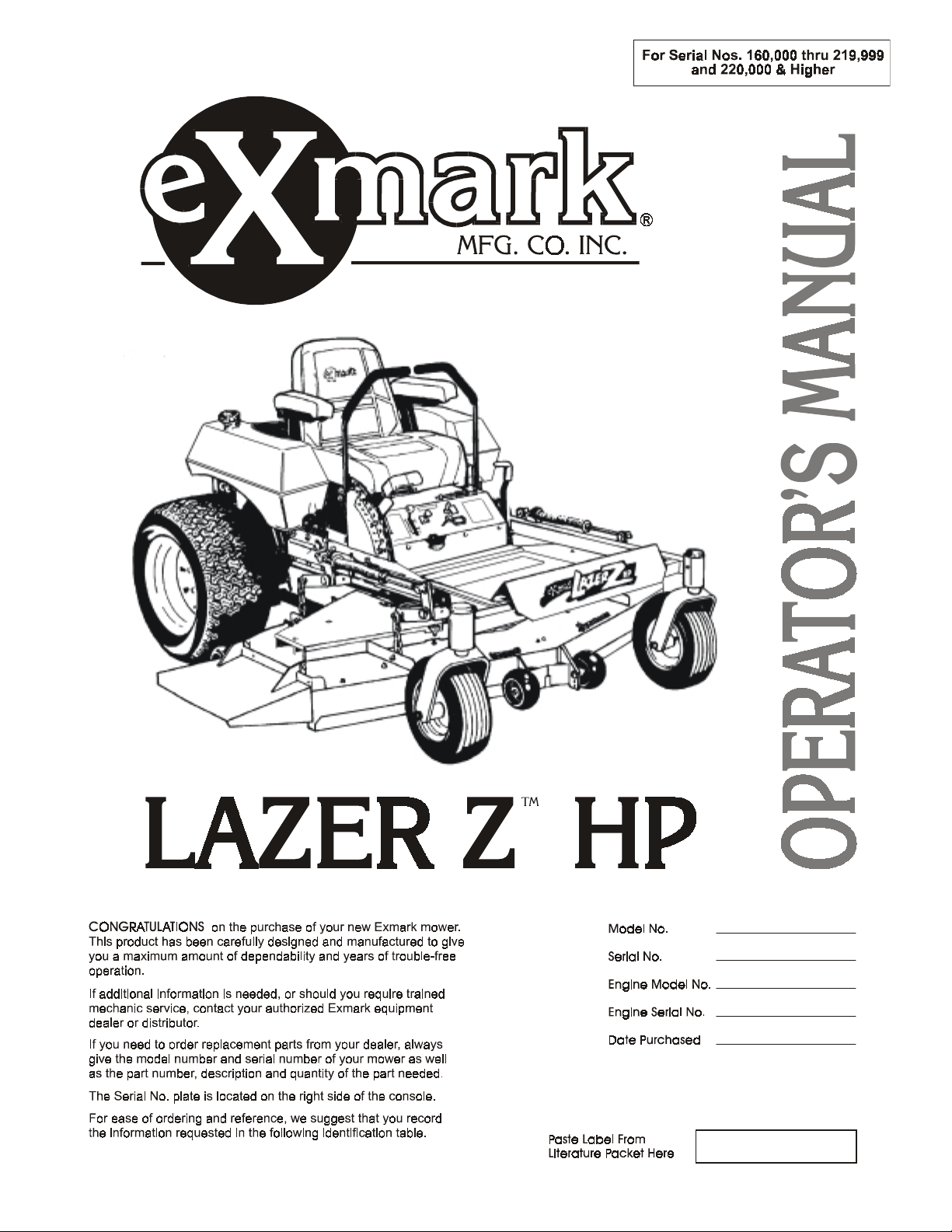

CONGRATULATIONS

designed and manufactured to give you a maximum amount of dependability and years of

trouble-free operation.

on the purchase of your Exmark Mower. This product has been carefully

OPERATOR'S MANUAL

This manual contains assembly, operating, m aint enance, adjustment and safety

instructions for your Exmark m ower.

BEFORE OPERATING YOUR MOWER, CAREFULLY READ THIS MANUAL IN ITS

ENTIRETY.

By following the operating, maintenance and safety instructions, you will prolong the life

of your mower, maintain its maximum ef ficiency and promote safe operation.

If additional information is needed, or should you require trained mechanic service,

contact your authorized Exmark equipment dealer or distributor.

All Exmark equipment dealers and distribut or s are kept informed of the latest methods

of servicing and are equipped to provide prompt and efficient service in the field or at their

service stations. They carry ample stock of ser vice parts or can secur e t hem promptly for you

from the factor y.

All Exmark parts are thoroug hly test ed and inspect ed before leaving the factory,

however, attention is required on your part if you are t o obt ain the fullest measure of

satisfaction and performance.

iii

Page 5

TABLE OF CONTENTS

1. SAFETY PAGE

1.1 Safety Alert Symbol ...........................................................................1

1.2 Training..............................................................................................1

1.3 Preparation.....................................................................................1-3

1.4 Operation........................................................................................3-4

1.5 Maintenance & Storage...................................................................4-5

1.6 Safety Signs....................................................................................6-8

2. SPECIFICATIONS

2.1 Model Numbers..................................................................................8

2.2 Engine ............................................................................................... 8

2.3 Fuel System....................................................................................... 8

2.4 Electrical System............................................................................8-9

2.5 Operator Controls..............................................................................9

2.6 Seat...................................................................................................9

2.7 Hydrostatic Ground Drive System.................................................9-10

2.8 Tires & Wheels ................................................................................ 10

2.9 Cutting Deck.................................................................................... 10

2.10 Dimensions...................................................................................... 10

2.11 Torque Requirements...................................................................... 11

3. ASSEMBLY INSTRUCTIONS

3.1 Uncrate Mower.................................................................................11

3.2 Install Drive Wheels......................................................................... 11

3.3 Check Tire Pressure........................................................................ 11

3.4 Install Seat Retaining Rod................................................................11

3.5 Install Motion Control Levers.......................................................11-12

3.6 Position Discharge Chute.................................................................12

3.7 Service Engine................................................................................. 12

3.8 Service Battery............................................................................12-13

3.9 Service Hydraulic Oil........................................................................ 14

4. OPERATION INSTRUCTIONS

4.1 Controls...................................................................................... 14-16

4.2 Pre-Start..................................................................................... 16-17

4.3 Mowing ............................................................................................ 17

4.4 Transporting................................................................................17-19

5. MAINTENANCE & ADJUSTMENTS

5.1 Periodic Maintenance..................................................................19-26

5.2 Adjustments................................................................................26-31

6. WASTE DISPOSAL

6.1 Motor Oil Disposal............................................................................32

6.2 Mercury Switch Disposal.................................................................. 32

6.3 Battery Disposal............................................................................... 33

7. TROUBLE SHOOTING

8. ELECTRICAL DIAGRAM

9. HYDRAULIC DIAGRAM

.

10

WARRANTY

.......................................................................................37-38

..................................................................

......................................................................... 35

........................................................................... 36

iv

33-34

Page 6

1. SAFETY

1.1 SAFETY ALERT SYMBOL

THIS SAFETY ALERT S YMBOL

THE MACHINE TO IDENTIFY IMPORTANT SAFETY MESSAGES WHICH MUST BE

FOLLOWED TO AVOID ACCIDENTS. THIS

IS USED BOTH IN THIS MANUAL AND ON

ALERT

SYMBOL MEANS:

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The safety alert symbol appears above information which alerts you of unsafe actions

or situations and will be followed by the word

When used with t he word DANGER: IT DENOTES THAT AN EXTREME HAZARD

EXISTS WHICH WOULD RESULT IN HIGH PROBABILITY OF DEATH OR

IRREPARABLE INJURY IF PROPER PRECAUTIONS ARE NOT TAKEN.

When used with t he word WARNING: IT DENOTES THAT A HAZARD EXISTS

WHICH CAN RESULT IN INJURY OR DEATH IF PROPER PRECAUTIONS ARE

NOT TAKEN.

When used with t he word CAUTION: IT DENOTES A REMINDER OF SAFETY

PRACTICES OR DIRECTS ATTENTION TO UNSAFE PRACTICES WHICH COULD

RESULT IN PERSONAL INJURY IF PROPER PRECAUTIONS ARE NOT TAKEN.

DANGER, WARNING

1.2 TRAINING

1.2.1 Regard the Exmark mower as a piece of power equipm ent and teach this

regard to all who operate this unit.

1.2.2 Read the instructions carefully. Familiarize yourself with the cont r ols and the

proper use of the equipment.

1.2.3 Never allow children, teenagers, or people unfamiliar with these inst r uctions to

use the mower.

1.2.4 Avoid mowing while people, especially children, or pets, are nearby. Keep in

mind that the operator or user is responsible for accidents or hazards occurring

to other people or their property.

CAUTION.

, or

1.3 PREPARATION

1.3.1 The use of per sonal pr ot ective equipment, such as (but not limited to)

protection for the eyes, ears, feet and head is recommended.

1.3.2 While mowing, always wear substantial footwear and long trousers. Do not

operate equipment when barefoot or when wearing open sandals.

1.3.3 Thoroughly inspect t he ar ea where the equipment is to be used and remove all

stones, sticks, wires, bones and other f or eign objects which may damage the

equipment or cause personal injury to the operat or or bystander s.

- 1 -

Page 7

POTENTIAL HAZARD

♦ Engine exhaust contains carbon monoxide, which is

an odorless deadly poison.

WHAT CAN HAPPEN

♦ Carbon monoxide can kill you and is also known to the

State of California t o cause birth defects.

HOW TO AVOID THE HAZARD

♦ Do not run engine indoors or in a small confined area

where dangerous carbon monoxide fumes can collect.

WARNING

POTENTIAL HAZARD

♦ In certain conditions gasoline is extremely flammable

and highly explosive.

WHAT CAN HAPPEN

♦ A fire or explosion from gasoline can bur n you, ot hers,

and cause property damage.

HOW TO AVOID THE HAZARD

♦ DO NOT smoke while refueling , and stay away from

an open flame or where gasoline fumes m ay be ignited

by spark.

♦ Refuel only in a well ventilated area, or refuel

outdoors.

♦ Store gasoline in an approved container and keep it

out of the reach of children.

♦ Add fuel before start ing the engine. Never remove the

cap of the fuel tank or add fuel when engine is running

or when the engine is hot.

♦ Never fill the fuel tank so that the gasoline level rises

above a level that is 1/2” below the bottom of the filler

neck to allow for gasoline expansion and prevent fuel

spillage.

♦ If fuel is spilled, DO NOT attempt to start the engine.

Move away from the area of the spill and avoid

creating any source of ignition unt il fuel vapors have

dissipated.

DANGER

- 2 -

Page 8

POTENTIAL HAZARD

♦ In certain conditions gasoline is extremely flammable

and highly explosive.

WHAT CAN HAPPEN

♦ A static charge can ignite g asoline vapors. A fire or

explosion from gasoline can burn you, others, and

cause property damage.

HOW TO AVOID THE HAZARD

♦ Purchase and store gasoline only in an approved

container.

♦ Always place gasoline containers on the ground away

from your vehicle before f illing.

♦ Do not fill gasoline containers inside a vehicle or on a

truck or trailer bed because inter ior car pets or plastic

truck bed liners may insulate the container and slow

the loss of any static charge.

♦ When practical, r emove gas-powered equipment from

the truck or trailer and refuel the equipment with its

wheels on the ground.

♦ If this is not possible, then refuel such equipment on a

truck or trailer from a portable container, rather t han

from a gasoline dispenser nozzle.

♦ If a gasoline dispenser nozzle must be used, keep the

nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

DANGER

1.4 OPERATION

Although hazard control and accident prevention parti al l y are dependent upon

the design and configuration of the equipment, these factors are also dependent

upon the awareness, concern, prudence and proper training of the personnel

involved in the operation, transport, mai nt enance and st orage of the equipment.

It is essential that all Operator Safety Mechanisms be connected and in operating

condition prior to use for mowing.

1.4.1 Give complete, undivided attent ion t o t he job at hand.

1.4.2 Mow only in daylight or good artificial light.

NOT

operate the mower when children or others are in the area.

1.4.3 When feasible, avoid operating the eq uipm ent in wet grass.

1.4.4 Use

EXTREME

traction and/or tipover could occur. Drive slower on slopes

slopes greater than 15 degrees. Watch for dit ches, holes, rocks, dips, and

rises, which change the operating angle. Keep away from drop-offs and steep

banks. Avoid sudden starts when mowing uphill - mower may tip backwards.

Loss of traction may occur going downhill - weight t r ansfer to the front wheels

may cause drive wheels to slip and cause loss of braking.

slopes when grass is wet - slippery conditions affect steering and reduce

traction and braking. T he oper ator is responsible for safe operation on slopes.

See inside back cover to determine the approximate slope ang le of the area to

be mowed.

caution when mowing and/or turning on slopes as loss of

NEVER

carry passengers.

. DO NOT

DO NOT

DO

mow

mow

- 3 -

Page 9

1.4.5 Use

EXTREME

caution when backing up.

LOOK BEHIND YOU!!

1.4.6 Stop the blades when crossing surfaces other than grass; and when

transporting the mower to and fr om the area to be mowed.

1.4.7 Never operate the mower with defective guar ds, shields, or covers. Always

have safety shields, guards, switches, and other devices in place and in proper

working condition.

1.4.8

DO NOT

change the engine governor setting s or overspeed t he engine.

Operating an engine at excessive speed may increase the hazard of personal

injury.

1.4.9 Disengage blade dr ive before starting engine.

1.4.10 Start

the engine carefully with feet well away from the blades.

1.4.11 Keep hands, feet and clothing away from rotating parts while the mower is

being operated.

1.4.12 Stop the engine and remove ignition key:

• Before checking, cleaning or work ing on the mower.

• After striking a foreign object (inspect the mower f or damage and make

repairs before restart ing and operating the mower).

• Before clearing blockages.

• Whenever you leave the mower.

Stop the engine:

• Before refueling.

• Before dumping the grass catcher .

1.4.13 Before stopping the engine, return t he throttle control to the idle position f or 30

seconds to allow the engine to cool down.

1.4.14 The fuel system is provided with a shut-off valve. The fuel shut-off valve is

used to shut off the fuel:

• When the machine will not be used for a few days.

• During transport to and f r om the job.

• When parked inside a building.

1.4.15 This mower was designed for one operator only. Keep all others away fr om

mower during operation.

1.4.16

Do Not

mow without the grass deflector in place.

1.4.17 If jump starting is required:

a) connect the positive (+) power cable from the posit ive post on t he booster

battery to the positive terminal post on the starter solenoid switch (this

post has the positive battery cable attached to it).

b) connect the negative or ground cable (-) from the negative post on the

booster battery to any engine deck gr ound, pr eferably the engine block

as far away from the battery as possible.

c) disconnect battery cables in the reverse order after start ing .

1.5 MAINTENANCE AND STORAGE

1.5.1 For engine maint enance, follow the engine manufacturer’s recomm endations

precisely as stated in the engine manual.

- 4 -

Page 10

1.5.2 When making adjustments while the eng ine is r unning, such as carburetor and

motion control linkage adjust m ent s, stand to one side and keep clear of

moving/rotating components, such as engine screen, drive belts and sheaves.

Do Not

moving/rotating components.

1.5.3 Keep engine and engine area free from accumulation of grass, leaves,

excessive grease or oil and other debris which can accumulate in these areas.

These materials can become flammable and m ay result in a fire.

1.5.4 Store f uel in a container specifically designed for this purpose in a cool, dry

place.

1.5.5 Keep the mower and fuel container in locked storage to prevent children f r om

playing or tampering with them.

1.5.6 Gasoline powered equipment or fuel containers should not be stored in a

basement or any enclosed area, where open pilot lights or heat appliances are

present.

1.5.7 Maximum mowing results and safet y can only be achieved if the m ower is

properly maintained and operated correctly.

1.5.8. Check all bolts frequently to maintain proper tightness.

1.5.9. Keep all guar ds, shields and all safety devices in place and in safe working

condition.

1.5.10 Frequently check for worn or deterior ating components that could create a

hazard.

1.5.11 All replacement parts must be the same as or equivalent to the parts supplied

as original equipment.

wear loose fitting clothing or j ewelry that could get tangled in

POTENTIAL HAZARD

♦ Hydraulic fluid escaping under pressure can penetrat e

skin and cause injury.

WHAT CAN HAPPEN

♦ Fluid accidentally injected into the skin must be

surgically removed within a few hours by a doctor

familiar with this form of injury or gangrene ma y result .

HOW TO AVOID THE HAZARD

♦ Make sure all hydraulic fluid hoses and lines are in

good condition an all hydraulic connections and fittings

are tight before applying pressure to hydraulic system.

♦ Keep body and hands away from pinhole leaks or

nozzles that eject high pressure hydraulic fluid.

♦ Use cardboard or paper to find hydraulic leaks.

♦ Safely relieve all pressure in the hydraulic system

before performing any work on t he hydraulic system.

WARNING

- 5 -

Page 11

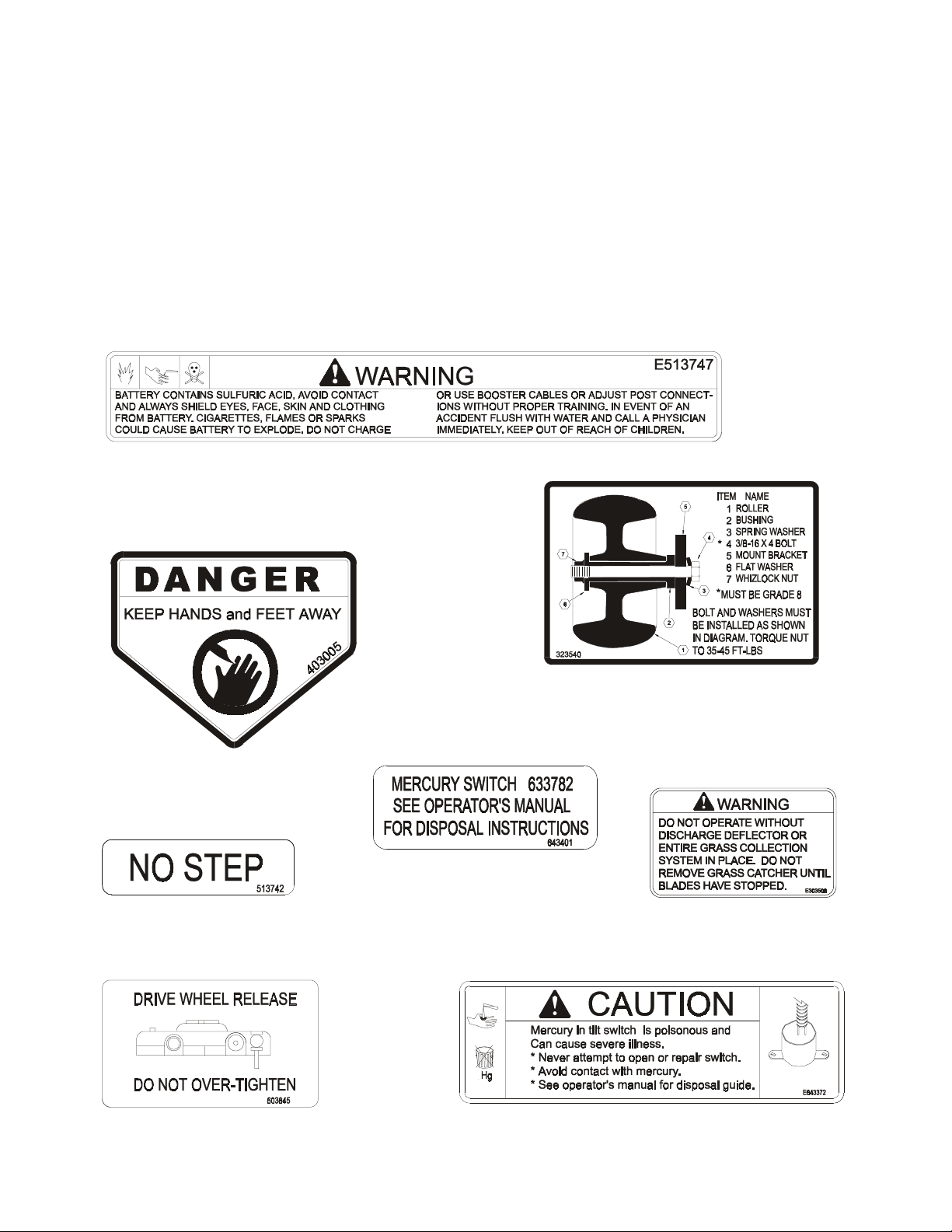

1.6 SAFETY SIGNS

1.6.1 Keep all safety signs legible. Remove all grease, dirt and debris from saf et y

signs and instructional labels.

1.6.2 Safety signs must be replaced if t hey are m issing or illegible.

1.6.3 When new components are installed, be sur e that current safety signs are

affixed to the replaced components.

1.6.4 New safety signs may be obtained from your authorized Exmark equipment

dealer or distributor or fr om Exmar k Mfg. Co. Inc.

1.6.5 Safety signs may be affixed by peeling of f the backing to expose the adhesive

surface. Apply only to a clean, dry surface. Smooth to remove any air bubbles.

1.6.6 Familiarize yourself with the following safety signs and inst r uct ion labels. They

are critical to the safe operation of your Exmark commercial mower.

PART NO. 513747

LOCATION: Top Center of Console Under

Front of Seat

PART NO. 403005

LOCATION: Left and Right Corners

of Mower Deck

PART NO. 513742

LOCATION: On Top of Mower Deck Belt

Shields, Left and Right Sides

PART NO. 603845

LOCATION: Under Seat, on Frame

Adjacent to Right Fuel Tank

PART NO. 323540

LOCATION: Left Front Corner Top of

Serial Nos. 220,000 & Higher

PART NO. 643401

LOCATION: On Tilt Switch

Serial Nos. 220,000 & Higher

PART NO. 643372

LOCATION: Top LH Side of Console, Under Front of Seat

Mower Deck

PART NO. 303508

LOCATION: Front Right Corner

Top of Mower Deck

- 6 -

Page 12

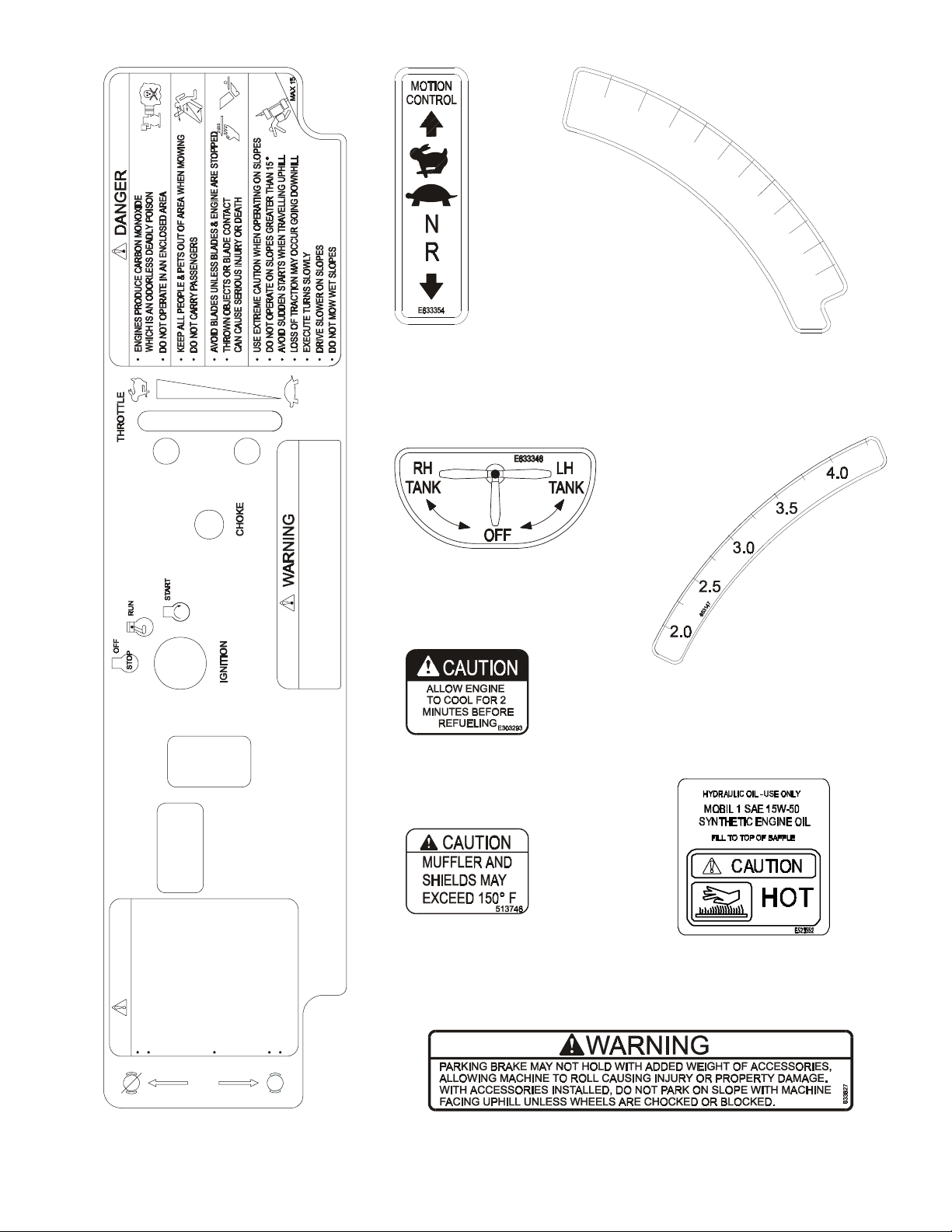

4.5

6

5

3

1

4

0

4.0

3.5

3.0

2.5

2.0

1.5

PTO

DISENGAGE PTO, ENGAGE PARK BRAKE, SHUT OFF ENGINE

AND REMOVE KEY BEFORE MAKING ADJUSTMENTS, SERVICING

OR CLEANING.

PART NO. 633354

LOCATION: Top of Console Left

and Right Side

PART NO. 633346

LOCATION: Below Center of

Console

PART NO. 303293

LOCATION: On Top of Fuel

Tanks

PART NO. 653140

LOCATION: RH Side of Cutting Height

Adjustment Plate

PART NO. 653147

LOCATION: Lefthand Side of Cutting

Height Adjustment Plate

CAUTION

READ MANUAL BEFORE OPERATING.

BEFORE STARTING ENGINE:

-PARK BRAKE MUST BE ENGAGED

-LEVERS MUST BE OUTWARD TO

NEUTRAL LOCK POSITION

-OPERATOR MUST BE IN SEAT

-PTO SWITCH MUST BE OFF

BEFORE LEAVING SEAT:

-PARK BRAKE MUST BE ENGAGED

-PTO SWITCH MUST BE OFF

-LEVERS MUST BE OUTWARD TO

NEUTRAL LOCK POSITION

KEEP ALL GUARDS & SHIELDS IN PLACE.

DO NOT PARK ON SLOPES UNLESS PARK

BRAKE IS ENGAGED.

P

RELEASE

PARK

BRAKE

P

ENGAGE

PART NO. 653245

LOCATION: Center of Console

653245

PART NO. 513746

LOCATION: Rear of Engine Deck,

Left and Right Sides

PART NO. 633827

LOCATION: LH Side Front Support Frame,

Below Brake Handle

- 7 -

PART NO. 523552

LOCATION: Top of Hydraulic

Reservoir

Page 13

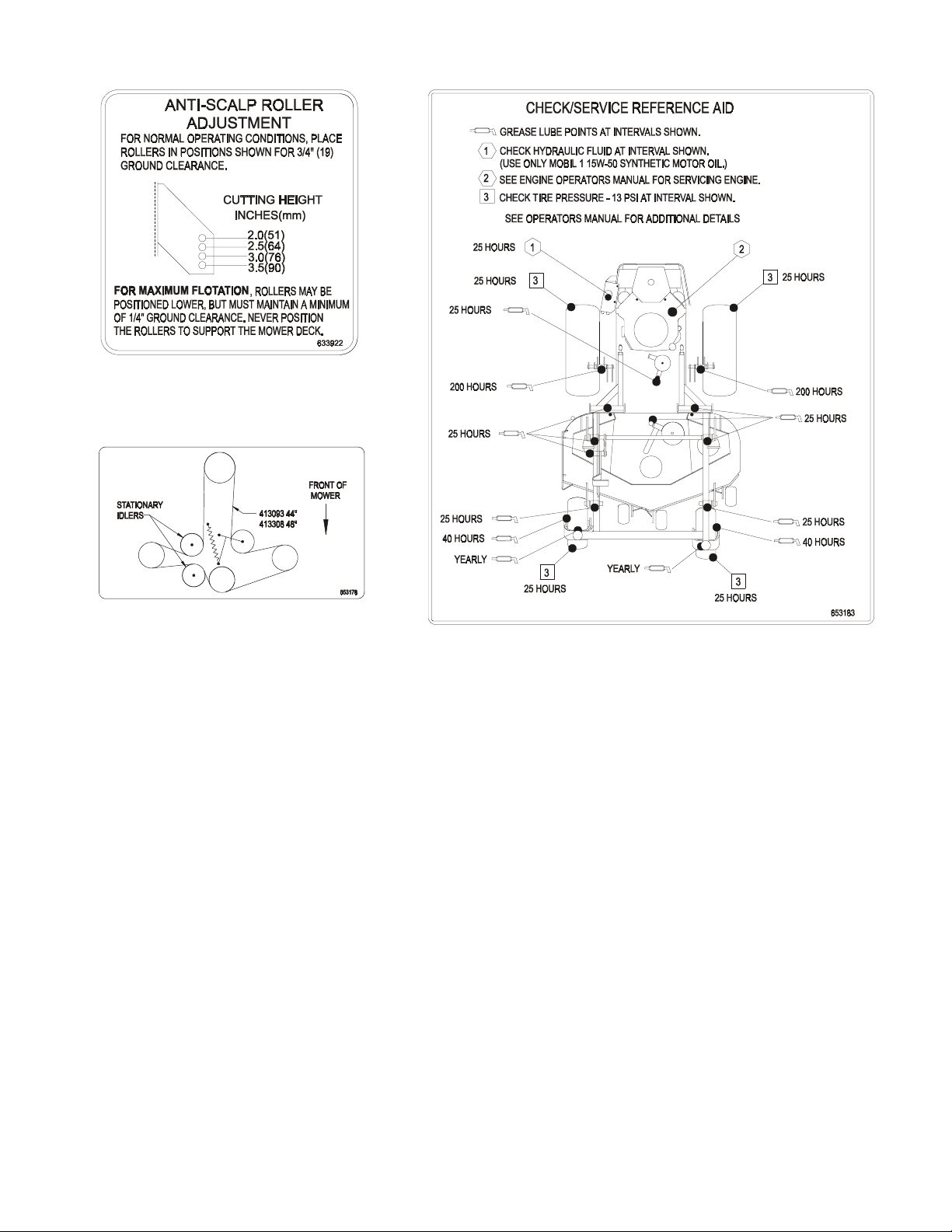

PART NO. 633922

LOCATION: Front Left Corner Top of

Mower Deck

PART NO. 653176

LOCATION: Left of Center on Mower Deck,

Under Floor Pan

2. SPECIFICATIONS

2.1 MODEL NUMBER:

PART NO. 653183

LOCATION: Bottom Side of Floor Pan

Serial Nos. 160,000 & Higher

Serial Nos. 190,000 & Higher

Serial Nos. 190,000

–219,999

Serial Nos. 220,000 & Higher

: LHP4417KA; LHP4818KC

: LHP4418KC

: LHP4819KA

: LHP4419KA; LHP4820KC; LHP4821KA;

LHP5220KC; LHP5223KC; LHP5223KA

2.2 ENGINE:

2.2.1 Engine Specifications: See Your Eng ine O wner’s Manual

2.2.2 RPM: Full Speed: 3600 RPM (No Load) Idle: 1500 RPM

2.3 FUEL SYSTEM

2.3.1 Capacity: 8 gal. (30 L.)

2.3.2 Type of Fuel: Regular

2.3.3 Fuel Filter: For Kohler: Replaceable in-line 15 Micron

For Kawasaki: Replaceable in-line

unleaded

gasoline, 87 octane or higher.

Kohler

Kawasaki

P/N 2405002

P/N 49019-2075

2.3.4 Fuel Shut-Off Valve: 1/4 turn increments (left tank , “OFF”, right tank)

2.4 ELECTRICAL SYSTEM

2.4.1 Charging System: Flywheel Alternator

- 8 -

Page 14

2.4.2 Charging Capacity: 15 amps

2.4.3 Battery Type: BCI Group U1

2.4.4 Battery Voltage: 12 Volt

2.4.5 Polarity: Negative Ground

2.4.6 Fuses: Two 20 amp blade type

2.4.7 Safety Interlock System: Oper at or m ust be in seat with

brake engaged

engine

.

Operator must be in seat

motion control levers are moved in

or

motion control levers out

, and

when Blades are engaged, brake is disengaged

(neutral lock)

or engine will stop.

Engine will stop if either the left, the right, or both levers are

neutral lock position while brake is engaged

.

Blades disengaged

to start

moved from

2.4.8 Tilt Switch: (Serial Nos. 220,000 & Higher) Shuts off the engine when the unit

is tilted more than 60° fr om horizontal.

2.5 OPERATOR CONTROLS

2.5.1 Steering and Motion Control:

Separate levers, on each side of the console, contr ol speed and dir ect ion of

travel of the respective drive wheels.

Steering is controlled by varying the position of the levers relative to each

other.

Moving motion control levers outward

neutral.

2.5.2 Blade Engagement Switch: Engag es elect r ic clutch (to drive belt) which

engages mower blades.

2.5.3 Parking Brake Lever: Sets br akes.

2.5.4 Deck Height Adjustment Lever: Set s cut ting height to desired position.

(in slots) locks the drive system in

,

,

2.6 SEAT

2.6.1 Type: Standard seat: high back , foam padded (internal spring

suspension)with arm rests.

Optional suspension seat: high back, low profile foam-in-place cushion

(dampened, adjustable spring suspension) with armrests.

2.6.2 Mounting: Hinged to tilt up for access to hydraulic pumps, battery and other

components. Held in tilted position with prop rod. Adjustable fore and aft seat

track.

2.6.3 Armrests: Standard seat: foam padded flip-up armrests.

Optional suspension seat: molded adjustable f lip- up armrests.

2.6.4 Seat Safety Switch: Incorporated into t he Safety Interlock System.

Time delay seat switch eliminates rough ground cut- outs.

2.7 HYDROSTATIC GROUND DRIVE SYSTEM

2.7.1 Hydrostatic Pumps: Two Hydro Gear BDP-10L variable displacement piston

pumps.

2.7.2 Wheel Motors: T wo Parker/Ross with 1 1/4” tapered shafts.

2.7.3 Hydraulic Oil Type: Synthetic Mobil 1 15W- 50.

2.7.4 Hydraulic Oil Capacity: 2.1 qt.(2.0 L.)

- 9 -

Page 15

2.7.5 Hydraulic Filter: Replaceable cartridge type.

P/N 513211: 10 microns, 18 psi bypass (Summer use above 32° F)

P/N 523541: 40 microns, 18 psi bypass (Winter use below 32° F)

2.7.6 Speeds: 44” & 48” units: 0 - 8.1 mph (13.1 km/hr) f orward.

0 - 4.2 mph (6.8 km/hr ) r everse.

52” units: 0 – 9.5 mph (15.3 km/hr) forward.

0 – 4.9 mph (7.9 km/hr) r everse.

2.7.7 Drive wheel release valves allow machine to be moved when the engine is not

running.

2.8 TIRES AND WHEELS

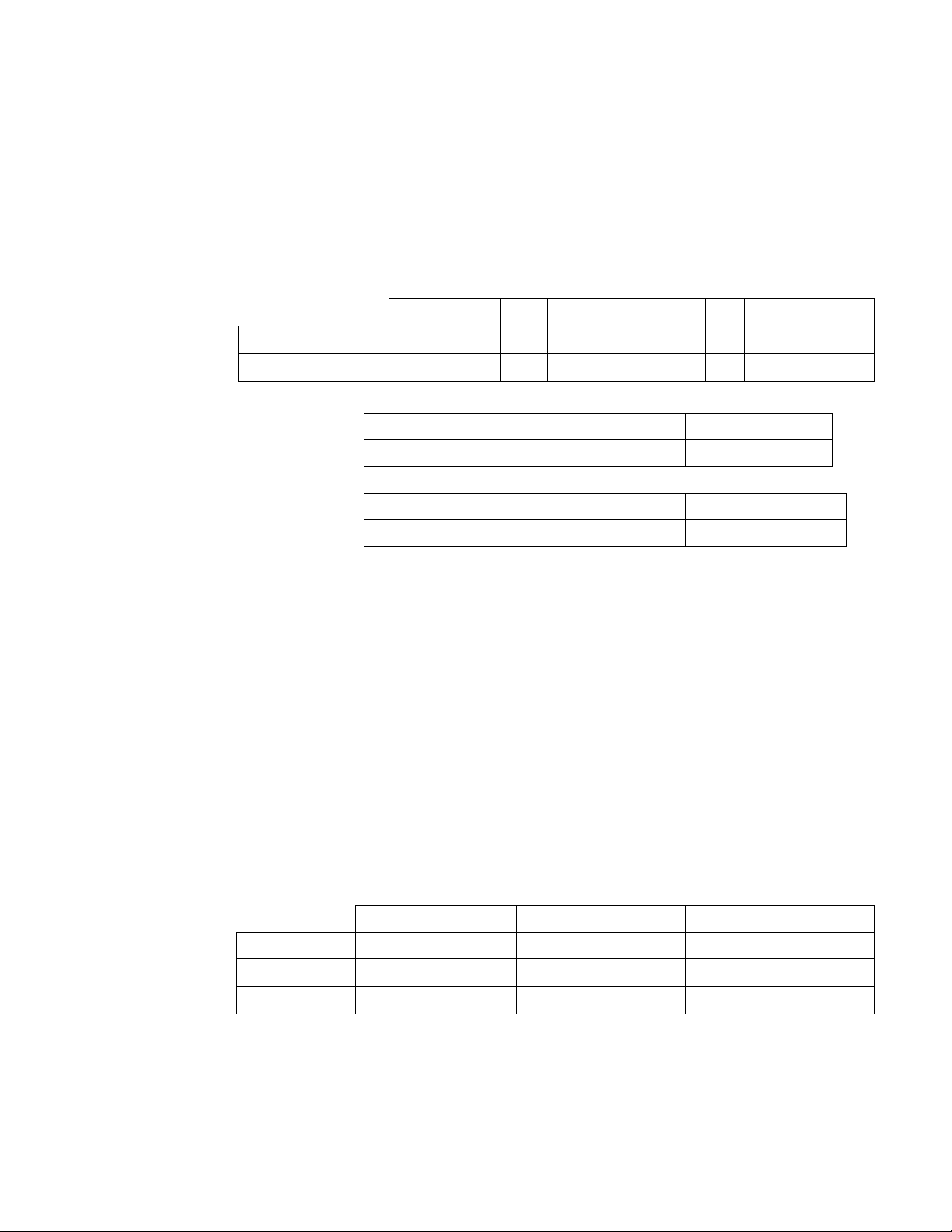

2.8.1 Tires:

Drive Tires 23 x 9.5-12 2 “Turfmaster ” 4 13 psi (90 kPa)

Front Caster Tires 13 x 5.00-6 2 Smooth 4 13 psi (90 kPa)

Size Qty Tread Ply Inflation

2.9 CUTTING DECK

2.9.1 Cutting Width: 44” deck 48” deck 52” deck

44 in.(111.8 cm) 47.24 in. (120.0 cm) 52 in. (132.1 cm)

2.9.2 Discharge: Side (Optional Mulch or Bag)

2.9.3 Blade Size:

(3 ea.)

2.9.4 Blade Spindles: solid steel spindles with 1” I.D. bear ings.

2.9.5 Deck Drive: Electric clutch mount ed on vert ical engine shaft. Blades are driven

by one “B” Section belt (w/self-tensioning idler) direct from the engine.

2.9.6 Deck: Full floating deck is at t ached t o out-front support fr am e.

Maximum turf protection is provided by three anti-scalp roller s on 44” &

48” decks and five anti-scalp rollers on 52” decks.

Deck design allows for bagging, mulching or side discharge.

2.9.7 Cutting Height Adjustment : an extra-long cushioned lever is used to adjust the

cutting height from 1 1/2” (3.8 cm) to 4.5” (11.4 cm . ) in 1/ 4” (.64 cm.)

increments for Serial No.s 190,000 and higher and 1/2” (1.3 cm) increments for

Serial No.s 160,000 through 189,999.

The cutting height adjustment handle has a transport position and all

adjustments can be made while the operator remains seated.

2.9.8 Mulching Kit: Optional.

44” deck 48” deck 52” deck

15.25 in. (38.7 cm) 16.25 in. (41.3 cm) 18.00 in. (45.7 cm)

2.10 DIMENSIONS

2.10.1 Overall Width:

w/44” Deck 43. 9 in. (111.5 cm) 47.4 in. (120.3 cm) 54.7 in. (138.9 cm)

w/48” Deck 45. 9 in. (116.6 cm) 50.3 in. (122.4 cm) 58.1 in. (147.6 cm)

w/52” Deck 47. 9 in. (121.7 cm) 54.3 in. (139.2 cm) 62.8 in. (159.5 cm)

2.10.2 O verall Length: w/44” & 48” decks: 74.1 in. (188. 2 cm )

2.10.3 O verall Height: w/44” & 48” decks: 40.0 in. (196.3 cm.)

Without deck

w/52” deck: 77.31 in. (196.3 cm)

w/52” deck: 40.0 in. (101.6 cm)

- 10 -

Discharge chute up Discharge chute down

Page 16

2.10.4 Tread W idth: (center to center of tires, widthwise)

w/44” Deck w/48” Deck w/52” Deck

Drive Wheels

Front Casters

2.10.5 Wheel Base: (center of caster tire to center of dr ive tire)

w/44” & 48” Deck: 45.9 in. (116.6 cm)

w/52” Deck: 47.2 in. (119.9cm)

2.10.6 Cur b Weight*: w/44” Deck: 887 lbs. (403.2 kg)

w/48” Deck: 907 lbs. (412.3 kg)

w/52” Deck: 1025 lbs. (464.9 kg)

* Note: Weight will vary slightly, depending on engine option.

34.4 in. (87.4 cm) 36.4 in. (92.5 cm) 38.4 in. (97.5 cm)

32.2 in. (81.8 cm) 32.2 in. (81.8 cm) 34.6 in. (87.9 cm)

2.11 TORQUE REQUIREMENTS

Bolt Location Torque Bolt Location Torque

Cutter Housing Spindle Nut......... 75-80 ft-lbs.

Blade Mounting Bolt .................... 75-80 ft-lbs.

Engine Deck/Front Frame Mount. 30-35 ft-lbs.

Anti-Scalp Roller Bolts ................. 40-45 ft-lbs.

Engine Mounting Bolts ................25-30 ft-lbs.

Wheel Motor Mounting Bolts........72-77 ft-lbs.

Wheel Hub Slotted Nut.... minimum125 ft-lbs.

3. ASSEMBLY INSTRUCTIONS

3.1 UNCRATE MOWER

3.2 INSTALL DRIVE WHEELS

3.2.1 Mount drive wheels with the valve stem to the outside of the unit. Secure using

four (4) 1/2-20 x 7/8”UNF wheel bolts (inst alled in hubs) or 1/2-20 wheel nuts

(installed on studs in hubs) for each wheel. Torq ue to 95 ft-lbs (128 N!M).

NOTE: Earlier models req uir e t he UNF wheel bolts. Later models have studs

installed in the wheel hub and require wheel nuts.

.

3.3 CHECK TIRE PRESSURE.

3.3.1 Check tire pressure in caster and drive tires. Pr oper inflation pressure for all

four (4) tires is 13 psi (90 k Pa) . Adjust if necessary.

3.4 INSTALL SEAT RETAINING ROD

3.4.1 Tilt seat up. Remove 5/16” nylock nut from bolt attaching seat ret aining rod to

seat frame. Remove ignit ion keys attached to bolt. Remove retaining rod from

seat and insert the “L” shaped end of t he r od into the hole directly above the

left-side hydraulic pump (the “L” m ust be positioned to the left or pointing up) .

Position the seat retaining rod to t he out side of the mounting tab on the seat

frame and secure with 5/16” x 1” bolt and nyloc nut. Tig hten until snug, then

loosen just enough so the rod pivots fr eely.

3.5 INSTALL MOTION CONTROL LEVERS

3.5.1 Loosen and remove the two (2) 3/8” x 1” bolts and spring disc washers which

attach the motion control levers to the control arm shafts for shipping and the

two (2) 3/8” x 1” bolts and spring disc washers which are screwed into the

control arm shafts.

a) Install the lef t m otion control lever onto the control arm shaft (See Fig 1)

on the left side of the console. Place the lever (with the mounting plate

towards the rear) on the

the bolts and washers. Position the lever so the bolts are in the center of

the slots on the lever mounting plate and tig hten until snug. Repeat on

opposite side of unit.

.

outside

.

of the control arm shaft and secure with

- 11 -

Page 17

If the levers do not align with each other, when in the neutral position,

(See Fig 2) loosen the hardware and make the appropr iat e adjustment by

sliding/tilting the lever(s ) forward or backward until properly aligned and

tighten hardware.

MOTION

CONTROL

LEVER

MOUNT PLATE TO

THE REAR & OUTSIDE

OF ARM SHAFT

LEVERS IN

ALIGNMENT

FIG. 1 FIG. 2

CONTROL ARM SHAFT LEVER ALIGNMENT

b) If the ends of the levers hit against each other, while in the drive position

(levers rotated in as far as possible), make adjustments by moving the

levers outwards to the neutral lock position and carefully bend them

outward. Move them back to the drive position and check for clear ance,

repeat if necessary.

3.6 POSITION DISCHARGE CHUTE.

3. 6.1 Loosen t wo (2) 5/ 16” nylock nuts attaching discharge chute. Lower the discharge

chute into position. Retighten nylock nut s unt il chute is snug but can pivot freely.

3.7 SERVICE ENGINE.

Engine is shipped with oil, check oil level and if necessary fill to t he appropriate

level with SAE 10W-30 or 10W-40, AP1 service class SF or SG f or oper ating in

temperatures above 0° F (-18° C). See Engine Operator' s Manual.

3.8 SERVICE BATTERY.

Machine is shipped with a dry battery.

3.8.1 Remove battery from machine. Tilt seat up to gain access to the battery.

Disconnect

battery cables -

negative(black) cable first

. Remove battery

hold-down and lift battery out.

3.8.2 Place battery on a level surface and r em ove vent caps.

DANGER

POTENTIAL HAZARD

♦ Battery electrolyte contains sulfuric acid, which is

poisonous and can cause severe burns

WHAT CAN HAPPEN

♦ Swallowing electrolyte can be fatal or if it t ouches skin

can cause severe burns.

HOW TO AVOID THE HAZARD

♦ Wear safety glasses to shield eyes, and rubber gloves

to protect skin and clothing when handling elect r olyte.

♦ Do not swallow electrolyte.

♦ Fill the battery where clean water is available for

flushing skin.

- 12 -

Page 18

DANGER

POTENTIAL HAZARD

♦ Charging the battery may produce explosive gasses

WHAT CAN HAPPEN

♦ Battery gasses can explode causing serious injury.

HOW TO AVOID THE HAZARD

♦ Keep sparks, flames, or cigarettes away from battery.

♦ Ventilate when charging or using battery in an

enclosed space.

♦ Make sure venting path of battery is always open once

battery is filled with acid.

3.8.3 Fill cells with battery grade sulfuric acid (1. 265 specific gravity) to halfway

between top of separators and bottom of vent well.

3.8.4 Let battery stand f or 1/2 hour after filling . If battery acid level has fallen, refill to

level above plates.

3.8.5 Charge the batt er y at 4 t o 5 am ps for 3-5 hours.

3.8.6 After charging, install vent caps and wash off any acid with water and dry battery.

CAUTION

POTENTIAL HAZARD

♦ If the ignition is in the “ ON” position there is potential

for sparks and engag em ent of components.

WHAT CAN HAPPEN

♦ Sparks could cause an explosion or moving parts

could accidentally engage causing personal injury.

HOW TO AVOID THE HAZARD

♦ Be sure ignition switch is in the “OFF” position.

3.8.7 Install battery in machine and secure battery hold-down.

Connect battery cables -

cable and green/white wire. Slip insulator boot over the positive terminal.

NOTE:

available, follow steps 3.8.1 through 3.8.4 and install as described in 3.8.7. Then

run the vehicle continuously for 20 to 30 minutes to sufficiently charge the battery.

After charging , if battery acid level has fallen, ref ill bat tery with clean drinking water

(distilled water is preferred – if available).

If time does not permit char ging the battery, or if charging equipment is not

positive (red) cable first

, then the negative (black)

DO NOT

over-tighten

.

PART NO. 513747 LOCATION: Top Center of Console

Under Front of Seat

- 13 -

Page 19

3.9 SERVICE HYDRAULIC OIL

The machine is shipped with hydraulic oil filled to the top of the baffle in reservoir. Run

the machine for approximately 15 minutes to allow any extra air to purge out of the

hydraulic system. Check hydraulic reservoir and if necessary f ill t he r eservoir to the

appropriate level with Mobil 1 15W-50 synthetic motor oil.

4. OPERATION INSTRUCTIONS

4.1 CONTROLS

4.1.1 Familiarize yourself with all controls before operat ing the mower.

4.1.2 Motion Control Levers: Located on each side of the console.

The left lever controls the flow of hydraulic oil from the left hydrosta t ic pum p t o

the left drive wheel motor. The r ight lever controls the flow of hydraulic oil fr om

the right hydrostatic pump to the right drive wheel motor.

IMPORTANT: To begin movement (forward or backward) the operator

must be in the seat, the brake lever must be disengaged (pushed down)

before the motion control levers can be moved in or the engine will kill.

When levers are center ed in the T-slot the drive system is in the neutral

position. W it h levers m oved out in t he T-slot the drive system is in the

lock

position (See Fig 3).

neutral

FIG. 3

MOTION CONTROL POSITIONS

By moving both levers an

the machine can be caused to move forward or backward in a straight line.

Movement of the

a forward direction. Movement of the

drive wheel

levers back to the neutral position.

turn left

To

slow the left drive wheel. To

lever

back toward neutral.

To make a

holding the right lever slight ly ahead of neutral.

To make a

position while holding the left lever slightly ahead of the neutral position.

Pulling the

wheels to rotate in a

into reverse from neutr al) .

To turn to the left while backing, move the left lever for ward toward neut r al. To

turn to the right while backing , m ove the right lever forward toward neutral.

levers back

left lever forward

to rotate in a forward direction. To

while moving forward, move the

zero turn

zero turn

equal

amount forward or back from the neutral position

will cause the

right lever forward

turn right

to the

to the

reverse

left

, pull the left lever back beyond neutra l while

right

, pull the right lever back beyond the neutral

from the neutral position will cause the respective drive

direction (spring tension can be f elt when moving

while moving forward, move the

left drive wheel

stop

forward travel, pull the

left lever

to rotate in

will cause the

back toward neutral to

right

right

- 14 -

Page 20

POTENTIAL HAZARD

♦ Machine can spin very rapidly by positioning one lever

too much ahead of the other.

WHAT CAN HAPPEN

♦ Operator may lose control of the machine, which may

cause damage to the machine or injury.

HOW TO AVOID THE HAZARD

♦ Use caution when making turns.

♦ Slow the machine down before making sharp turns.

4.1.3 Blade Engagement Switch: Located just left of cent er on the console (left side

of ignition switch). Switch must be

engage the blades. Switch is pushed in to the “

blades.

4.1.4 Choke Control: Located at center of console (right side of ignition switch).

Choke is used to aid in starting a cold engine. The choke control is

to be in the “ON” position and

run a warm engine with choke in the “ON” position.

4.1.5 Throttle Control: Located on console just right of center.

Throttle is used to control engine speed. Moving throttle lever

increase engine speed and moving throttle lever

engine speed.

4.1.6 Brake Lever: Located on left side of the console. The brake lever engages a

parking brake on the drive wheels.

Pull

the lever up and

Push

the lever

When parking on a steep slope, the wheels must be chocked or blocked in

addition to the brake being engaged. The unit must be tied down and brake

engaged when transporting.

forward

CAUTION

rearward

down

and

pulled out

pushed in

engage

to

disengage

to

to the “

STOP

to be in the “

to the rear

the brake.

the brake.

ROTATE

” position to stop the

OFF

” position to

pulled out

” position.

forward

will decrease

DO NOT

will

4.1.7 Ignition Switch: Located on the lower center of console.

The ignition switch is used to start and stop the engine. The switch has three

positions “OFF”, “ON” and “START”. Insert the key into switch and rotate

clockwise to the “ON” position.

Rotate clockwise to the next position to engage the starter (key must be held

against spring pressure in this position) .

Operator must be in seat with brake engaged, moti on cont rol levers out

(neutral lock position) and blade engagement switch “OFF” to start

engine.

4.1.8 Hour Meter: Located left on center of console. The hour meter is connected to

a pressure switch installed in the engine block and it recor ds t he num ber of

hours that the engine has run. If ignition switch is left on without engine

running, hour meter will not run.

NOTE: This switch is not a low oil sensor and will not alert the operator if the

engine oil is low.

4.1.9 Fuel Shut-Off Valve: Located directly below center of console.

- 15 -

Page 21

The fuel shut-off valve is used to shut off the f uel when the machine will not be

used for a few days, during transport to and from the jobsite, and when parked

inside a building. The valve has three positions, each position made in 1/ 4

turn increments.

Valve handle down is the “OFF” position. Rotate valve handle 1/4 turn right

(from “Off” position) for fuel flow from the right tank. Rotate valve handle 1/4

turn left (f rom “Off” posit ion) for fuel flow from the left tank.

4.1.10 Dr ive Wheel Release Valves: The drive wheel release valve levers are 1/420x2 screws covered with a black vinyl grip located on the right front corner of

the hydrostatic pumps. Drive wheel release valves are used to release the

hydrostatic drive system to allow the machine to be pushed without the engine

running. Tilt seat up to gain access to pumps.

Loosen both valves one turn to release drive system.

Tighten to reset system.

DO NOT overtighten. DO NOT t ow machine.

4.2 PRE-START

4.2.1 Fill fuel tanks. For best r esults use only clean, fresh regular grade

gasoline with an octane rating of 87 or higher. Regular grade leaded gasoline may

also be used; however, combustion chamber and cylinder head will require more

frequent service. See Engine Owner's Manual.

Never fill the fuel tank so t hat the fuel level rises above a level that is 1/2” below

the bottom of the filler neck to allow for fuel expansion and prevent fuel spillage.

DO NOT

add oil to gasoline.

DANGER

POTENTIAL HAZARD

♦ In certain conditions gasoline is extremely flammable

and highly explosive.

WHAT CAN HAPPEN

♦ A static charge can ignite g asoline vapors. A fire or

explosion from gasoline can burn you, others, and

cause property damage.

HOW TO AVOID THE HAZARD

♦ Purchase and store gasoline only in an approved

container.

♦ Always place gasoline containers on the ground away

from your vehicle before f illing.

♦ Do not fill gasoline containers inside a vehicle or on a

truck or trailer bed because inter ior car pets or plastic

truck bed liners may insulate the container and slow

the loss of any static charge.

♦ When practical, r emove gas-powered equipment from

the truck or trailer and refuel the equipment with its

wheels on the ground.

♦ If this is not possible, then refuel such equipment on a

truck or trailer from a portable container, rather t han

from a gasoline dispenser nozzle.

♦ If a gasoline dispenser nozzle must be used, keep the

nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

unleaded

- 16 -

Page 22

4.2.2 Make sure you understand the controls, their locations, their functions, and

their safety requirements.

4.2.3 Refer to Maintenance, Section 5, and perf or m all the necessary inspection and

maintenance steps.

4.3 MOWING

4.3.1 Open fuel shut -off valve (left or right tank).

4.3.2 Starting Engine:

blade engagement switch disengaged, and the moti on cont rol levers out

(neutral lock position).

cold

On a

“FAST” positions and pull

the “start” position. Release the switch as soon as the engine starts.

IMPORTANT:

(10) seconds at a time. If the engine does not start, allow a 60 second

cool-down period between starting attempts. Failure to f ol low these

guide lines can burn out the starter motor.

After starting a cold engine, gradually return choke to t he “ O FF” position as the

engine warms up.

On a

“FAST” positions and leave the

4.3.3 Engaging Electric Blade Clutch: The electric blade clutch push-pull switch

engages the cutting blades. Be sur e t hat

and discharge area

IMPORTANT: Operator must be in seat before the blades can be engaged.

Set throttle to "midway" position. Pull outward on the switch to the “ROTATE”

position. Accelerate to full throttle to begin mowing.

4.3.4 Stopping Electric Blade Clutch: Set t he throttle to the “IDLE” position. Push in

on the switch to the “STOP” position stopping the cutting blades.

4.3.5 Stopping Engine: Bring unit to a

move motion control levers out

brake

Adjust engine speed to 1/2 throttle or higher.

Rotate ignition switch to “OFF” posit ion. Rem o ve the key to prevent children or

other unauthorized persons from star t ing engine.

Close fuel shut-off valve when machine will not be used for a few days, when

transporting, and when the unit is park ed inside a building.

engine, place the

warm

.

Operator must be in seat

throttle midway

choke

DO NOT

engine, place the

crank the engine continuously for more than ten

throttle midway

before engaging

with the

between the “SLOW” and

to the “ON” position. T ur n ignition switch to

choke

in the “OFF” position.

all

persons are

cutting blades.

full stop. Disengage

to the

neutral lock

brake engaged

between the “SLOW” and

clear

the cutting blades,

position and

, the

of mower deck

set parking

4.4 TRANSPORTING

4.4.1 Transport ing a Unit: Use a heavy-duty trailer or truck to tr anspor t the machine.

Lock brake and block wheels. Securely fasten the machine to the trailer or

truck with straps, chains, cable, or ropes. Be sur e that the trailer or truck has

all necessary lighting and marking as required by law.

Secure a trailer with a safety chain.

- 17 -

Page 23

POTENTIAL HAZARD

♦ This unit does not have proper turn signals, lights,

reflective markings, or a slow moving vehicle emblem.

These items are required t o dr ive on a public str eet or

roadway.

WHAT CAN HAPPEN

♦ Driving on a street or roadway without such equipment

is dangerous and can lead to accidents causing

personal injury.

♦ Driving on a street or roadway without such equipment

may also be a violation of State laws and the operator

may be subject to traffic t ick ets and/or fines.

HOW TO AVOID THE HAZARD

♦ Do not drive a unit on a public street or roadway.

CAUTION

POTENTIAL HAZARD

♦ Loading a unit on a trailer or truck increases the

possibility of backward tip-over.

WHAT CAN HAPPEN

♦ Backward tip-over of the unit could cause serious

injury or death.

HOW TO AVOID THE HAZARD

♦ Use extreme caution when operating a unit on a ramp.

♦ Use only a single, full width ramp; DO NO T use

individual ramps for each side of the unit.

♦ If individual ramps must be used, use enough ram ps t o

create an unbroken ramp surf ace wider than t he unit .

♦ DO NOT exceed a 15° angle between ramp and

ground or between ramp and trailer or truck.

♦ Avoid sudden acceleration while driving unit up a ramp

to avoid tipping backward.

♦ Avoid sudden deceleration while backing unit down a

ramp to avoid tipping backward.

WARNING

4.4.2 Loading a Unit: Use extreme caution when loading units on tr ailer s or trucks.

One full width ramp that is wide enough to extend beyond the rear tir es is

recommended instead of individual ramps f or each side of the unit. The lower

rear section of the tractor frame extends back between the rear wheels and

serves as a stop for tipping backward. Having a full width ramp provides a

surface for the frame members to contact if t he unit starts to tip backward. If it

is not possible to use one full width ramp, use enough individual ramps t o

simulate a full width continuous ramp.

- 18 -

Page 24

Ramp should be long enough so that the angles between the ramp and the

ground and the ramp and the trailer or truck do not exceed 15°. A steeper

angle may cause mower deck components to get caug ht as t he unit moves

from ramp to tr ailer or truck. Steeper angles may also cause the unit to tip

backward. If loading on or near a slope, position the trailer or truck so it is on

the down side of the slope and the ramp extends up the slope. This will

minimize the ramp angle. The tr ailer or truck should be as level as possible.

DO NOT attempt t o turn the unit while on the ramp, you may lose control and

drive off the side.

Avoid sudden acceleration when driving up a ramp and sudden deceleration

when backing down a ramp. Both maneuvers can cause the unit to tip

backward.

5. MAINTENANCE & ADJUSTMENTS

5.1 PERIODIC MAINTENANCE

5.1.1 Check engine oil level:

a) Make sure engine is stopped and on a level surface.

b) Check with engine cold.

c) Clean ar ea ar ound dipst ick. Remove dipstick and wipe oil off. Reinsert

the dipstick. Do not screw into place. Remove the dipstick and r ead t he

oil level.

d) If the oil level is low, wipe off the area ar ound t he oil fill cap, remove cap

and fill to the “F” mark on the dipstick. Use oil as specified in or in Engine

Owner’s Manual.

DO NOT

IMPORTANT:

“L” mark on the dipstick, or over the “F” mark.

5.1.2 Clean engine air cooling system :

overfill.

DO NOT

Service Interval: Daily or more often

operate the engine with the oil level below the

in dry conditions

Service Interval: Daily

CAUTION

POTENTIAL HAZARD

♦ Excessive debris can cause the engine and hydraulic

system to overheat.

WHAT CAN HAPPEN

♦ Excessive debris around the engine cooling air intake

and inside of the pump compartment can cr eate a fire

hazard.

HOW TO AVOID THE HAZARD

♦ Clean all debris from around the eng ine and hydraulic

pumps daily.

a) Stop engine and remove key.

b) Clean all debris from rotating engine air int ake screen and from around

engine shrouding.

- 19 -

Page 25

5.1.3 Clean grass build-up under deck.

Service Interval: Daily

a) Stop engine and remove key.

b) Raise deck to the transport (4.5” cutting height) position.

Lift the front of unit and support unit using jack st ands or equivalent

support.

CAUTION

POTENTIAL HAZARD

♦ Raising the mower deck for service or m aint enance

relying solely on mechanical or hydraulic jacks could

be dangerous.

WHAT CAN HAPPEN

♦ The mechanical or hydraulic jacks may not be enough

support or may misfunction allowing the unit to fall,

which could cause injury.

HOW TO AVOID THE HAZARD

♦ DO NOT rely solely on mechanical or hydraulic jacks

for support. Use adequate jack stands or equivalent

support.

c) Clean out any gr ass build- up from underside of deck and in deck

discharge chute.

5.1.4 Check mower blades.

a) St op engine and remove key.

b) Lift deck and secure in raised position as stated in Section 5. 1.3 .

c) Inspect blades and sharpen or replace as required.

d) Torque blade bolts as shown. Be sure the spring disk washer cone is

installed toward the bolt head.

(See Figure 4).

Service Interval: Daily

FIG. 4

BLADE BOLT INSTALLATION

- 20 -

Page 26

5.1.5 Check safety interlock system.

Service Interval: Daily

a) Check starting circuit. Starter

parking brake

engaged,

levers moved out in the

Try to start with

disengaged

must not crank

Try to start with

disengaged

starter

must not crank

Try to start with

engaged

and motion control levers in the

must not crank

Try to start with

operator out of seat

and motion control levers in

.

operator in seat

and motion control levers in the

.

operator in seat

.

operator in seat

disengaged, and the left motion control lever in,

crank,

starter

repeat again with the

must not crank.

b) Check kill circuits. Run engine at one-third throttle,

brake and

stop

raise off

of seat (but do not get off of machine) engine

after approx. 1/2 second has elapsed (seat has t im e delay k ill switch

to prevent cut-outs on rough terr ain) .

Run engine at one-third throttle,

seat (but do not get of f of machine) engine

has elapsed.

Run engine at one-third throttle, with brake disengaged, move levers in

and raise off seat (but do not get off of m achine) engine

1/2 second has elapsed.

Again, run engine at one-thir d throttle, brake

motion control lever in

Repeat again moving the

engine

NOTE: If machine

must stop

does not

whether operator is

Contact your authorized EXMARK SERVICE DEALER.

should

crank with

cutting blades

neutral lock

position.

, parking brake

, parking brake

, parking brake

right lever in

engage cutting blades

disengaged

, parking brake

neutral lock

neutral lock

operator in seat

disengaged,

neutral lock

engaged,

engaged,

, then with

disengage

must stop

and motion control

engaged

, blades

position - starter

blades

position -

blades

position - starter

blades

starter

must not

both levers in

parking

raise off

and

after 1/2 second

must stop

- engine

must stop.

right lever in

engaged,

, then moving

on seat or not

and move

both levers in

.

pass any of these tests, do not operate.

,

-

must

of

after

left

-

IMPORTANT: It is essential that operator safety mechanisms be

connected and in proper operating condition prior to use for mowing.

5.1.6 Check for loose hardware.

Service Interval: Daily

a) Stop engine and remove key.

b) Visually inspect machine for any loose hardware or any other possible

problem. Tighten hardware or correct the problem before operating.

5.1.7 Service air cleaner.

Service Interval: 25 hrs.

more often under severe conditions.

a) Stop engine and remove key.

b) Remove air cleaner compartment cover.

- 21 -

Page 27

c) Remove foam pr e- cleaner element and wash in warm water with

detergent. Rinse until all traces of detergent are eliminated and sq ueeze

out excess water

squeeze out excess oil.

d) Check paper element.

dislodge any dirt.

element.

Replace if dirty, bent or damag ed.

e) Reinstall foam pre-cleaner to paper element , then reinstall paper element

and cover.

5.1.8 Change engine oil:

NOTE:

a) Stop engine and remove key.

b) Drain oil while engine is warm from operation.

c) Replace the oil filter

d) Clean around oil fill cap and remove cap. Fill to specified capacity and

e) Start the engine and check for leaks.

5.1.9 Check hydraulic oil level:

a) Stop engine.

b) Clean area around hydraulic reservoir cap and remove cap.

Use only Mobil 1 15W-50 synthetic motor oil.

Change oil and filter af t er first five(5) hrs. of operation

unscrew filter to remove. Before reinstalling new filter, apply a thin

coating of oil on the surface of the rubber seal. Turn filter clockwise until

rubber seal contacts the filter adapter then tighten filter an additional 2/3

to 3/4 turn.

replace cap. Use oil recommended in engine owner’s manual.

overfill.

Oil level should be to the top of the baf fle inside the tank. If not , add oil.

(DO NOT wring).

DO NOT

Service Interval: 100 hrs

Service Interval:

Gently

every other

tap the flat side of the paper element to

wash or use pressurized air to clean paper

Air dry. Saturate with engine oil and

.

oil change. Clean around oil filter and

DO NOT

40 hr.

POTENTIAL HAZARD

♦ Hydraulic fluid escaping under pressure can penetrat e

skin and cause injury.

WHAT CAN HAPPEN

♦ Fluid accidentally injected into the skin must be

surgically removed within a few hours by a doctor

familiar with this form of injury or gangrene ma y result .

HOW TO AVOID THE HAZARD

♦ Make sure all hydraulic fluid hoses and lines are in

good condition an all hydraulic connections and fittings

are tight before applying pressure to hydraulic system.

♦ Keep body and hands away from pinhole leaks or

nozzles that eject high pressure hydraulic fluid.

♦ Use cardboard or paper to find hydraulic leaks.

♦ Safely relieve all pressure in the hydraulic system

before performing any work on the hydraulic system.

WARNING

- 22 -

Page 28

5.1.10 Check tire pressures:

Service Interval: 40 hrs.

a) Stop engine and remove key.

b) Inflate all four tires to 13 psi (90 kPa).

5.1.11 Check battery electrolyte level:

Service Interval: 40 hrs.

a) Stop engine and remove key.

b) Tilt seat up.

c) Remove vent caps fr om battery. Fill with water (distilled is recommended)

to bottom of vent wells and replace vent caps.

d) See Assembly Section 3.8, for servicing a new battery.

PART NO. 513747 LOCATION: Top Center of Console

5.1.12 Check condition of belts:

Service Interval: 40 hrs.

a) Stop engine and remove key.

b) Check under engine deck to check pump drive belt.

c) Remove left and right belt shields on deck and lift up floor pan to inspect

deck drive belt.

d) See Sections 5.2.3 and 5.2.4, for belt adjustment.

5.1.13 Lubr icat e grease fittings:

Service Interval: Refer to chart.

a) Stop engine and remove key.

b) Lubricate fittings with one to two pumps of SAE No. 2 m ulti-purpose gun

grease.

Refer to the following chart for fitting locations and lubricat ion schedule.

Under Front of Seat

LUBRICATION CHART

FITTING

LOCATIONS

1. Front Casters 2 2 40 hours

2. Front Caster Pivots 0 2

3. Height Adj. Shaft Brngs. 1 5 40 hours

4. Deck Drive Belt Idler Arm 1 1 40 hours

5. Brake Brackets 1 2 200 hours

6. Pump Drive Belt Idler Arm 1 1 40 hours

7. Deck Rear Struts 1 2 40 hours

∗∗∗∗ More often if operating under severe condit ions.

∗∗

∗∗ See 5.1.13 Section c) for special lubricat ion inst ructions.

∗∗∗∗

INITIAL

PUMPS

- 23 -

NO. of

PLACES

SERVICE

INTERVAL

∗∗yearly

∗

Page 29

No. 6 (Pump Drive Belt Idler Arm)

Located Under Deck - Grease through hole in

top of deck, between pumps.

No. 4 & 6 (Idler Arms)

Monthly dissasemble belt and spring and

grease under a “NO LOAD” condition.

c) Lubricate front caster pivots once a year. Remove hex plug and cap.

Thread grease zerk in hole and pump with grease until it oozes out

around top bearing. Remove grease zerk and t hread plug back in. Place

cap back on.

5.1.14 Lubr icat e seat switch actuator:

Service Interval: 160 hrs.

a) Stop engine and remove key.

b) Tilt seat up.

c) Lubricate switch actuator rod with spray type lubricant or light oil.

5.1.15 Lubr icat e brake handle pivot:

Service Interval: 160 hrs.

a) Stop engine and remove key.

b) Lubricate bronze bushings on brake handle pivot with a spray type

lubricant or light oil.

5.1.16 Lubr icat e br ake rod bushings:

Service Interval: 160 hrs.

a) Stop engine and remove key.

b) Tilt seat up.

c) Lubricate bronze bushing s on each end of brake rod shafts with a spray

type lubricant or a light oil. One shaft is located under the console. The

other is below and behind the seat.

5.1.17 Lubr icat e m o t ion cont r ol br onze bushing s:

Service Interval: 160 hrs.

a) Stop engine and remove key.

b) Tilt seat up.

c) Lubricate bronze bushing s on flange bearings securing the motion control

arm shafts with a light oil or a spr ay type lubricant .

5.1.18 Rem ove engine shrouds and clean cooling fins:

Service Interval: 80 hrs.

a) Stop engine and remove key.

b) Remove cooling shrouds from engine and clean cooling fins. Also clean

dust, dirt and oil from external sur faces of engine which can cause

improper cooling.

c) Make sure cooling shr ouds ar e r einstalled. Operating the engine without

cooling shrouds will cause engine damage due to overheating.

- 24 -

Page 30

5.1.19 Check spark plugs:

Service Interval: 160 hrs.

a) Remove spark plugs, check condition and reset gaps, or replace with

new plugs. See Engine Owners Manual.

5.1.20 Change fuel filter:

Service Interval: As Required

a) A fuel filter is installed between the f uel tanks and the engine. Replace

when necessary.

For Kohler engines use

For Kawasaki engines use

5.1.21 Change hydraulic system filter:

Service Interval: After First 250 hrs.

Kohler

P/N 2405002.

Kawasaki

P/N 49019-2075

Then yearly thereafter

NOTE: Use only Exmark Part No. 513211 for Summer use above

No. 523541 for Winter use below 32°

F.

a) Stop engine and remove key.

b) Locate filter under right rear corner of engine deck.

c) Carefully clean area around filter. It is

contamination

enter hydraulic system.

d) Unscrew filter to remove and allow oil to drain from reservoir.

IMPORTANT

: Before reinstalling new f ilter, fill it with Mobil 1 15W - 50 and

apply a thin coat of oil on the surface of the rubber seal.

Turn filter clock wise until rubber seal contacts the filter adapter then

tighten the filter an addit ional 2/ 3 to 3/4 turn.

e) Fill reservoir as stated in Section 5.1.9.

f) Raise t he r ear of machine up and support with jack stands (or equivalent

support) just high enough t o allow drive wheels to turn freely.

g) Start engine and move throttle control ahead to f ull throttle position.

Move the speed control levers to the full speed and run for several

minutes. Shut down machine and recheck oil level.

Do not change hydraulic system oil (except for what can be drained when

changing filter), unless it is felt the oil has been contaminated or been

extremely hot.

Changing oil unnecessarily

could

damage

contaminates into the system.

5.1.22 Wheel hub - slotted nut torque specification.

When tig ht ening the slotted nut on the wheel motor tapered shaf t:

a) Torque the slotted nut to 125 f t. lbs.

b) Check distance from bottom of slot in nut to inside edge of hole. Two

threads (0.1”) or less should be showing.

c) If more than two threads (0.1”) are showing remove nut and install

washer (PN 523157) between hub and nut.

d) Torque the slotted nut to 125 f t. lbs.

e) Then tighten the nut until the next set of slots line up with the cross hole

in the shaft. Replace cotter pin.

32° F or Part

important

that

no dirt

or

hydraulic system by introducing

- 25 -

Page 31

5.1.23 Fuel Tank – mounting hardware specification.

When installing the nuts onto the fuel tank st uds, fully tighten the nyloc nut and

back off 1/2 t ur n. This allows for normal fuel tank expansion and contraction

with changes in temperature and fuel levels.

5.1.24 Thread locking adhesives such as “Loctite 242” or “Fel-Pro, Pro-Lock Nut

Type” are used on the following fasteners:

a) Pump drive sheave setscrews.

b) Square head setscrews on Hydro pump control arms.

c) Sheave retaining bolt in the end of engine crankshaft .

Adhesives such as “Loctite RC/609 or RC/680” or “Fel-Pr o Pr o- Lock Retaining

I or Retaining II” are used on the following:

b) Fuel tank studs where studs are inser t ed int o tank.

5.1.25 Dielect r ic grease is used on all blade type electrical connections to prevent

corrosion and loss of contact.

5.2 ADJUSTMENTS

IMPORTANT: Disengage blade clutch, shut off engine and remove key

before servicing, cleaning or making adjustments.

5.2.1 Cutting Height Adjustm ent .

a) Stop machine and move drive levers out to neutral lock position.

b) Disengage blades.

c) Raise the deck lever t o t he t ransport position (also the 4.5” cutting height

position). See Fig 5.

NOTE: When changing cutting height positions, al ways come to a

complete stop and disengage the mower bl ades.

FIG. 5

CUTTING HEIGHT POSITION

d) Insert height adjustment pin into hole corresponding to desired cutting

height and install hairpin cotter. See decal on deck lift plate.

e) Move lever out of transport (or 4.5” cutting height) position and down onto

height

adjustment pin to mow at selected height.

f) T o transport, move lever back up to transport (or 4.5” cutting height)

position.

g) Adjust anti-scalp rollers for Nor m al Operating Conditions. Stop engine and

remove key. Place rollers in one of t he posit ions shown in Fig. 6. Rollers

will maintain 3/4 in. (19 mm) clearance to the ground to minimize gouging

and roller wear or damage.

For Maximum Deck Flotation,

place rollers

one hole position lower. Rollers should maintain 1/4 in. (6.4 mm) minimum

clearance to ground.

Do Not

adjust rollers to support the deck. Be sure bolt

is tightened properly or loss of anti-scalp roller may result.

- 26 -

Page 32

ANTI-SCALP ROLLER ADJUSTMENT

5.2.2 Deck Leveling:

a) Position mower on a flat surface.

b) Stop engine and remove key.

c) Check t ire pr essure of all four (4) tires. If needed, adjust to 13 psi (90 kPa).

d) Set anti-scalp rollers to top holes or rem ove them com pletely for this

adjustment.

e) Raise the deck to the 4.5” height position and take as much force as

possible off of the two large deck lift springs by loosening the nut s at t he

front of each spring . See Fig. 7.

f) Lower the deck to the 1-1/2” height position. Place two 1-5/16” thick

blocks under the rear edge of the cutting deck skirt; one on each side of

the cutting deck. Place a 1-1/8” block under the center front edge, but not

under the anti-scalp roller brackets.

g) Loosen the two (2) bottom chain bolts in slots at the rear of the cutting

deck. Loosen four (4) nut s which secure f ront swivels (two per side), until

front chains are loose and front of deck is supported by the 1-1/8” block .

Do not loosen fr ont chain hardware.

h) When hardware is loosened, remaining tension in the large support

springs will tend to rotate the deck lift handle up, out of the 1 1/2”

position. Press down on the rear deck support arm ( as shown in Fig. 7) t o

firmly return the deck lift handle to the 1 1/2”

deck lift handle. While continuing to press down,

rear chains and tighten hardware at the bottom of

Downward pressure may now be released.

i) On lef t side, adjust front swivel using the locking nut behind the swivel

until the front chain is tig ht and all slack is removed from linkage. Do not

lift front of deck off 1-1/ 8” block. Secure front swivel using locking nut in

front of swivel. Repeat for right side.

FIG. 6

position.

DO NOT

take the slack out of t he

the rear chains.

push on

FIG. 7

SWIVEL ADJUSTMENT

SPRING COMPRESSION ADJUSTMENT

- 27 -

Page 33

j) Recheck that blocks fit just snugly under the deck skirt and that the

tension on all the chains are approximately equal. Make sure all chain

attachment bolts are tight .

k) Raise deck lift lever to the 4.5” cutting height position (also transport

position, See Fig 5. Adjust spring com pression until proper distance is

obtained between the two washers (See Fig 7) by turning the nut at the

front of each spring. Lock nuts in position with jam nuts.

l) Reposition anti- scalp r o ller s and tighten securely.

NOTE: When above adjustments have been made, the front of

the deck will be slightly lower than the rear of the deck.

5.2.3 Pump Dr ive Belt Tension.

Self-tensioning - No adjustment necessary.

5.2.4 Deck Belt Tension.

Self-tensioning - No adjustment necessary.

5.2.5 Adjust Seat Switch.

a) If necessary, adjust the seat actuator rod length to where the machine will

shut off when the operator raises off the seat (with

blade switch engaged

slight shift in weight should not shut machine off). Norm al adjustment is

when length of spring is 2.09” (with seat up) .

NOTE: To prevent rough ground cut-outs the unit is equipped w i t h a

time delayed seat switch. When the operator raises of f the seat with

either the brake disengaged or the cutting blades engaged, t he

engine should stop after 1/2 second has elapsed.

b) To adjust seat switch, loosen locknut on bottom of the actuator rod (5/ 16

x 7” bolt) and adjust the nuts to move the actuator plate up or down on

the rod.

5.2.6 Brake Link Adjustment.

Check to make sure brak e is adjusted properly.

a) Disengage brake lever (lever down).

b) Measure the length of the spring . Measurement should be 2. 75” between

washers (see Fig 8).

c) If adjustment is necessary, tighten the lock nut direct ly below the yoke

and loosen the two nuts jammed together below the spring . Turn the nut

directly below the washer until the correct measurement is obtained.

Tighten the two jam nuts below the spring together and repeat on

opposite side of unit.

brake disengaged or

) but will continue to run with operator in seat (a

FIG. 8

BRAKE ADJUSTMENT

- 28 -

Page 34

5.2.7 Brak e Adjustment.

a) Check for brake link 2.75” measurement as described insection 5.2.6.

b) Engage brake lever (lever up).

c) Measure the distance between the trunion roller and the rod collar as

shown in Fig. 8A. Measurement should be 3/16” to 1/4” (See Fig 8) . A

3/16” or 1/4”square k ey works well as a shim guage.

d) If adjustment is necessar y, loosen t he nut directly below the yoke. Turn

the bottom nut(below washer) until the correct m easur em ent is obtained

(See Fig 8) turn nut clockwise to lengt hen t he gap (screws rod into yoke)

and turn counter-clockwise to shorten the gap ( screws rod out of yoke).

Tighten nut against yoke and check opposite side of unit, repeat if

necessary.

5.2.8 Adjust Throttle Lever Tension.

a) Stop engine and remove key.

b) Tension in throttle lever can be adjusted by adjusting the tightness of the

lever pivot bolt, which is located under the console. See Fig. 9.

Fig. 9

THROTTLE TE NSION

5.2.9 Electric Clut ch Adjustment:

No adjustment necessary.

5.2.10 Reverse Indicator Adjustment:

a) Stop engine and remove ignition key.

b) Tilt seat for ward.

c) Begin with either the left or right motion control lever. Move lever to the

neutral position and pull lever back until the clevis pin (on arm below pivot

shaft) contacts the end of the slot (just beginning to put pr essur e on