Page 1

LAZERZ®S-SERIES

ForSerialNos.

312,000,000&Higher

LazerZ(LZS)Units

PartNo.4501-199Rev.A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

(CPRC)Section4442touseoroperatethis

engineonanyforest-covered,brush-covered,

orgrass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilar

laws.

Toacquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

Thissparkignitionsystemcomplieswiththe

CanadianstandardICES-002.Cesystèmed’allumage

parètincelledevèhiculeestconformeàlanorme

NMB-002duCanada.

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2012ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Figure1

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency,andpromotesafe

operation.

Ifadditionalinformationisneeded,orshould

yourequiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

Exmarkpartsmanualsareavailableonlineat

http://www.exmark.com

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

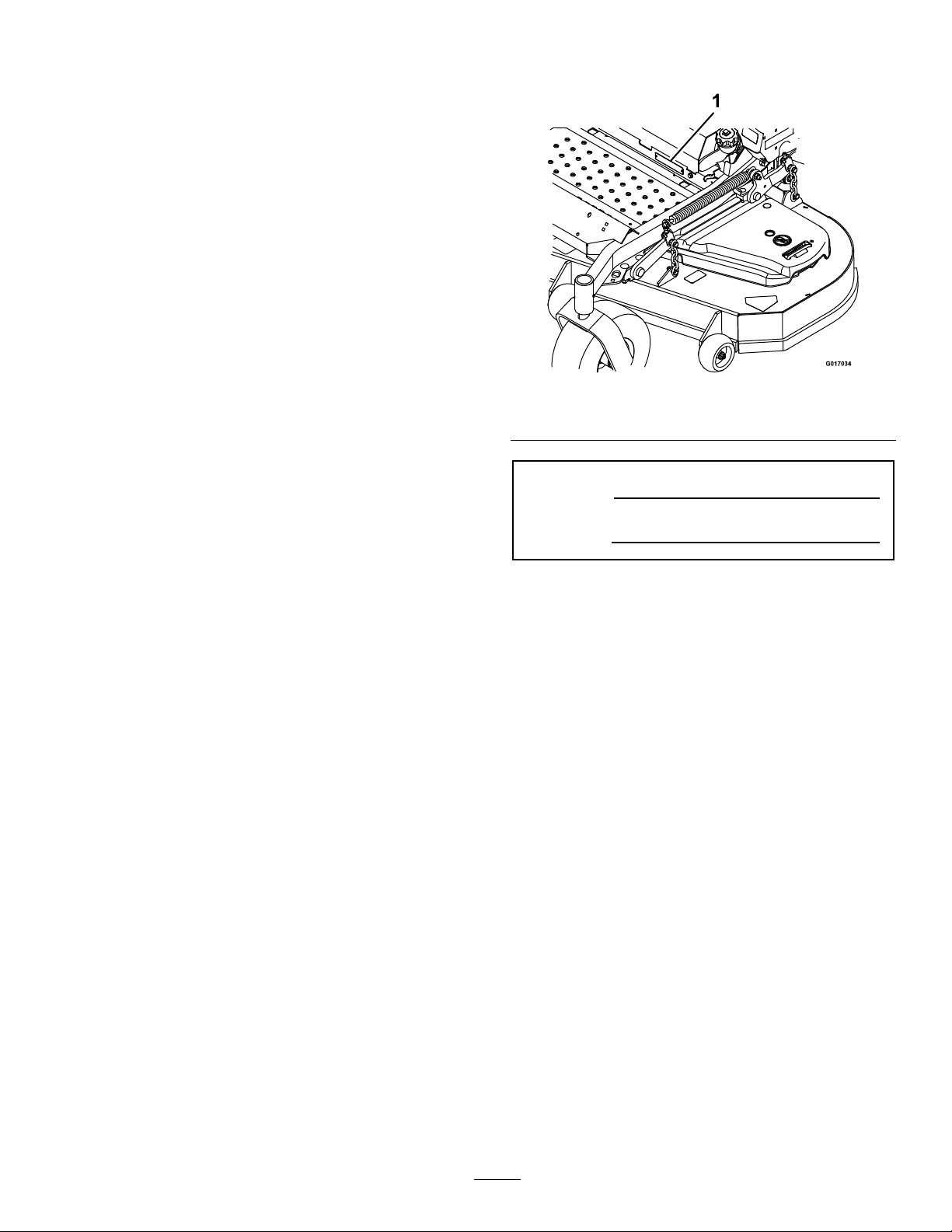

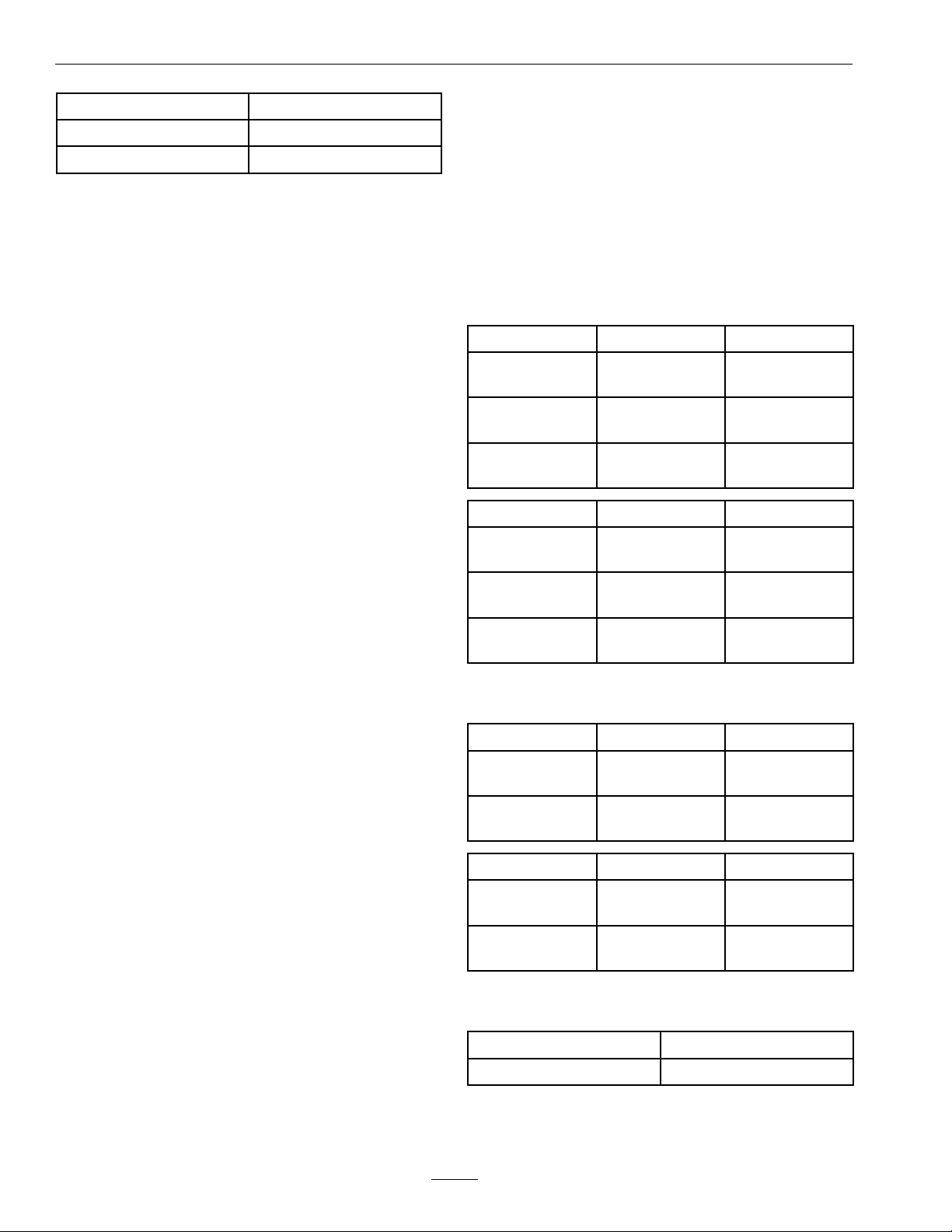

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals......................11

Specications........................................................16

ModelNumbers.............................................16

Systems..........................................................16

Dimensions....................................................18

TorqueRequirements.....................................20

ProductOverview.................................................21

Operation..............................................................21

Controls.........................................................21

Pre-Start.........................................................24

OperatingInstructions...................................25

Transporting..................................................29

Maintenance..........................................................30

RecommendedMaintenanceSchedule(s)............30

PeriodicMaintenance........................................31

CheckEngineOilLevel..................................31

CheckMowerBlades......................................33

CheckSafetyInterlockSystem........................34

CheckRolloverProtectionsSystems(Roll

Bar)Knobs.................................................34

CheckSeatBelt...............................................35

CheckforLooseHardware.............................35

ServiceAirCleaner.........................................35

ChangeEngineOil.........................................35

CheckHydraulicOilLevel..............................35

CheckTirePressures......................................36

CheckConditionOfBelts...............................36

LubricateGreaseFittings................................36

LubricateDeckLiftPivot...............................37

CheckSparkPlugs..........................................37

ChangeHydraulicSystemFilterand

Fluid..........................................................38

WheelHub-SlottedNutTorque

Specication...............................................38

CheckSparkArrester(ifequipped)..................38

ThreadLockingAdhesives..............................39

Copper-BasedAnti-seize...............................39

DielectricGrease............................................39

Adjustments......................................................39

DeckLeveling................................................39

PumpDriveBeltTension................................41

DeckBeltTension..........................................41

AdjustingtheParkingBrake............................41

ElectricClutchAdjustment.............................42

MotionControlLinkageAdjustment..............43

MotionControlDamperAdjustment..............44

MotionControlNeutralLockPivot

Adjustment................................................45

MotionControlHandleAdjustment...............45

MotionControlFullForwardTracking

Adjustment................................................45

CasterPivotBearingsPre-Load

Adjustment................................................46

Cleaning............................................................47

CleanEngineandExhaustSystem

Area...........................................................47

RemoveEngineShroudsandClean

CoolingFins...............................................47

CleanHydroFanCoolingFins........................47

CleanDebrisFromMachine...........................47

CleanGrassBuild-UpUnderDeck.................47

WasteDisposal...............................................47

Troubleshooting....................................................49

Schematics............................................................52

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThislawnmowermeetsorexceedstheB71.4

specicationsoftheAmericanNationalStandards

Instituteineffectatthetimeofproduction.

Exmarkdesignedandtestedthislawnmowertooffer

reasonablysafeservice;however,failuretocomply

withthefollowinginstructionsmayresultinpersonal

injury.

ThisSafetyAlertSymbol(

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

SafetyAlertSymbol

Figure2)isusedbothin

Figure2

SafeOperatingPractices

Training

•ReadtheOperator’ sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

amower,andevenmatureteenagersshouldhave

adultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator's

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

mowerwithouttakingrisks.

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

5

Page 6

Safety

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengine

oremissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoradd

fuelwhenengineisrunningorwhenthe

engineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

6

Page 7

Safety

CAUTION

Fueltankventislocatedinsidetheroll

bartube.Removingormodifyingtheroll

barcouldresultinfuelleakageandviolate

emissionsregulations.

•DoNotremoverollbar.

•DoNotweld,drill,ormodifyrollbarin

anyway .

•Checkthattheoperator'spresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly .DoNotoperateunlessthey

arefunctioningproperly.

Operation

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscanoccur

oncontactanddebris,suchasleaves,grass,

brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,to

coolbeforetouching.

•Removeaccumulateddebrisfrommuferand

enginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcankill

you.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkmachineonlevelground.Stopengine,wait

forallmovingpartstostop,removekeyand

engageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesinplace

andworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

DoNotrunengineindoorsorinasmallconned

areawheredangerouscarbonmonoxidefumes

cancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.Useseatbelts

withtherollbarintheraisedandlockedposition.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•NEVERcarrypassengers.DONOToperate

themowerwhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecaution

whencrossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

7

Page 8

Safety

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.Wheelsdroppingover

edges,ditches,steepbanks,orwatercancause

rollovers,whichmayresultinseriousinjury,

deathordrowning.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

•Keeptherollbarintheraisedandlocked

positionanduseseatbelt.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

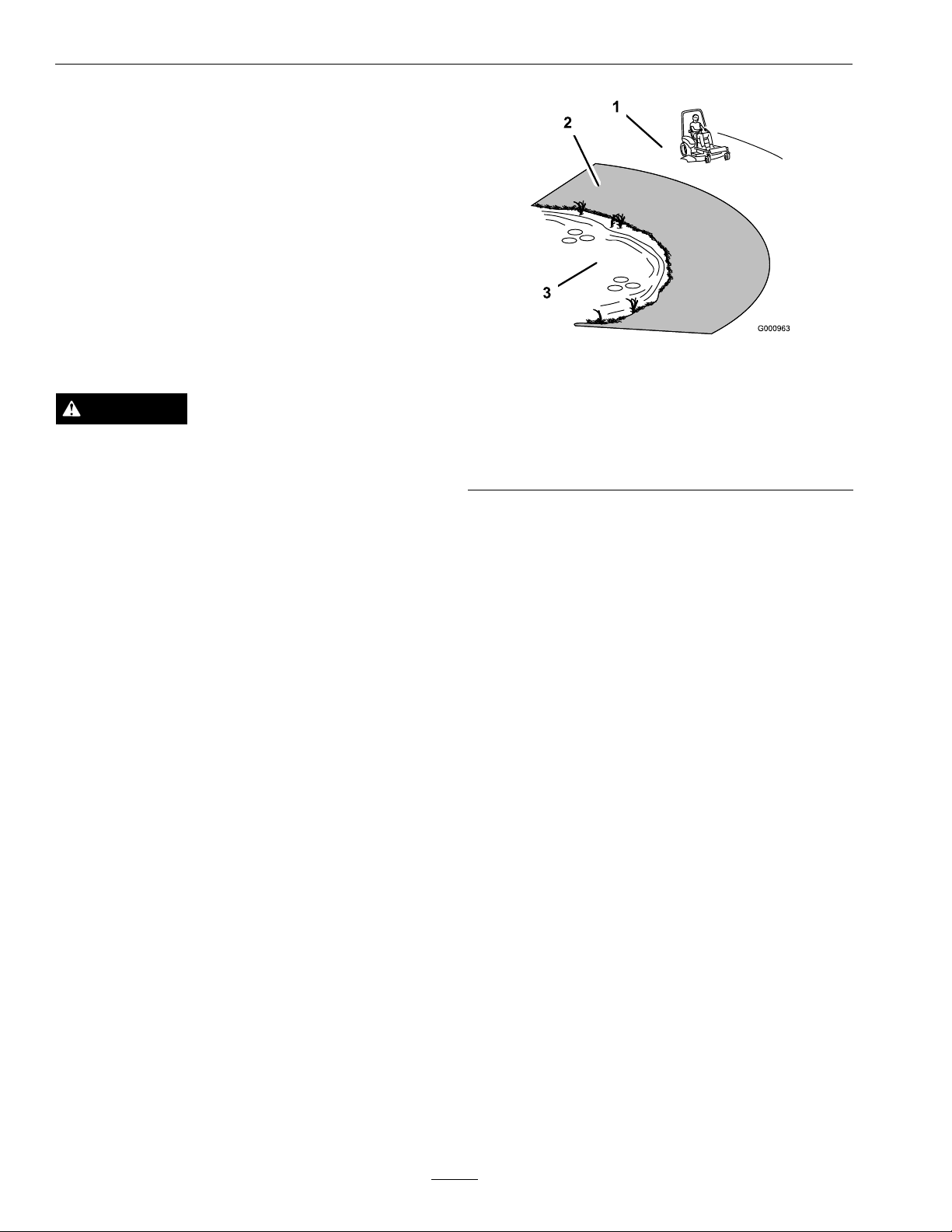

Figure3).

(

Figure3

1.SafeZone-Usethemowerhereonslopeslessthan15

degrees

2.DangerZone-Useawalkbehindmowerand/orhand

trimmeronslopesgreaterthan15degrees,near

drop-offsandwater.

3.Water

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatoperatingonwetgrass,acrosssteep

slopesordownhillmaycausethemowertolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

UsingtheRolloverProtectionSystem

(ROPS)

ARolloverProtectionSystem(rollbar)isinstalled

ontheunit.

8

Page 9

Safety

WARNING

Thereisnorolloverprotectionwhentherollbar

isdown.Wheelsdroppingoveredges,ditches,

steepbanks,orwatercancauserollovers,which

mayresultinseriousinjury,deathordrowning.

•Keeptherollbarintheraisedandlocked

positionanduseseatbelt.

•Lowertherollbaronlywhenabsolutely

necessary.

•DoNotwearseatbeltwhentherollbaris

down.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,andelectricalwires)before

drivingunderanyobjectsandDoNotcontact

them.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

DANGER

Chargingorjumpstartingthebatterymay

produceexplosivegases.Batterygasescan

explodecausingseriousinjury.

•Intheeventofarollover,taketheunittoan

AuthorizedServiceDealertohavetheROPS

inspected.

MaintenanceandStorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•LetenginecoolbeforestoringandDoNotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Keepsparks,ames,orcigarettesaway

frombattery.

•Ventilatewhenchargingorusingbattery

inanenclosedspace.

•Makesureventingpathofbatteryis

alwaysopenoncebatteryislledwith

acid.

•Alwaysshieldeyesandfacefrombattery.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldeyes,and

rubberglovestoprotectskinandclothing

whenhandlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwith

waterandcalladoctorimmediately.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

9

Page 10

Safety

CAUTION

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagementof

components.Sparkscouldcauseanexplosion

ormovingpartscouldaccidentallyengage

causingpersonalinjury.

Besureignitionswitchisinthe“OFF”

positionbeforechargingthebattery.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,traction,

andsafetyofthemachine.Failuretouseoriginal

Exmarkpartscouldcauseseriousinjuryor

death.Makingunauthorizedchangestothe

engine,fuelorventingsystem,mayviolateEPA

andCARBregulations.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemay

result.

•Ifequipped,makesureallhydraulicuid

hosesandlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretohydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,to

ndhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembyplacingthemotioncontrollevers

inneutralandshuttingofftheenginebefore

performinganyworkonthehydraulicsystem.

ForKohlerEFI(ElectronicFuelInjection)Units:

WARNING

Replaceallpartsincluding,butnotlimitedto,

tires,belts,blades,andfuelsystemcomponents

withoriginalExmarkparts.

Fuelsystemcomponentsareunderhigh

pressure.Theuseofimpropercomponentscan

resultinsystemfailure,gasolineleakageand

possibleexplosion.

Useonlyapprovedfuellinesandfuelltersfor

highpressuresystems.

10

Page 11

SafetyandInstructionalDecals

Safety

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

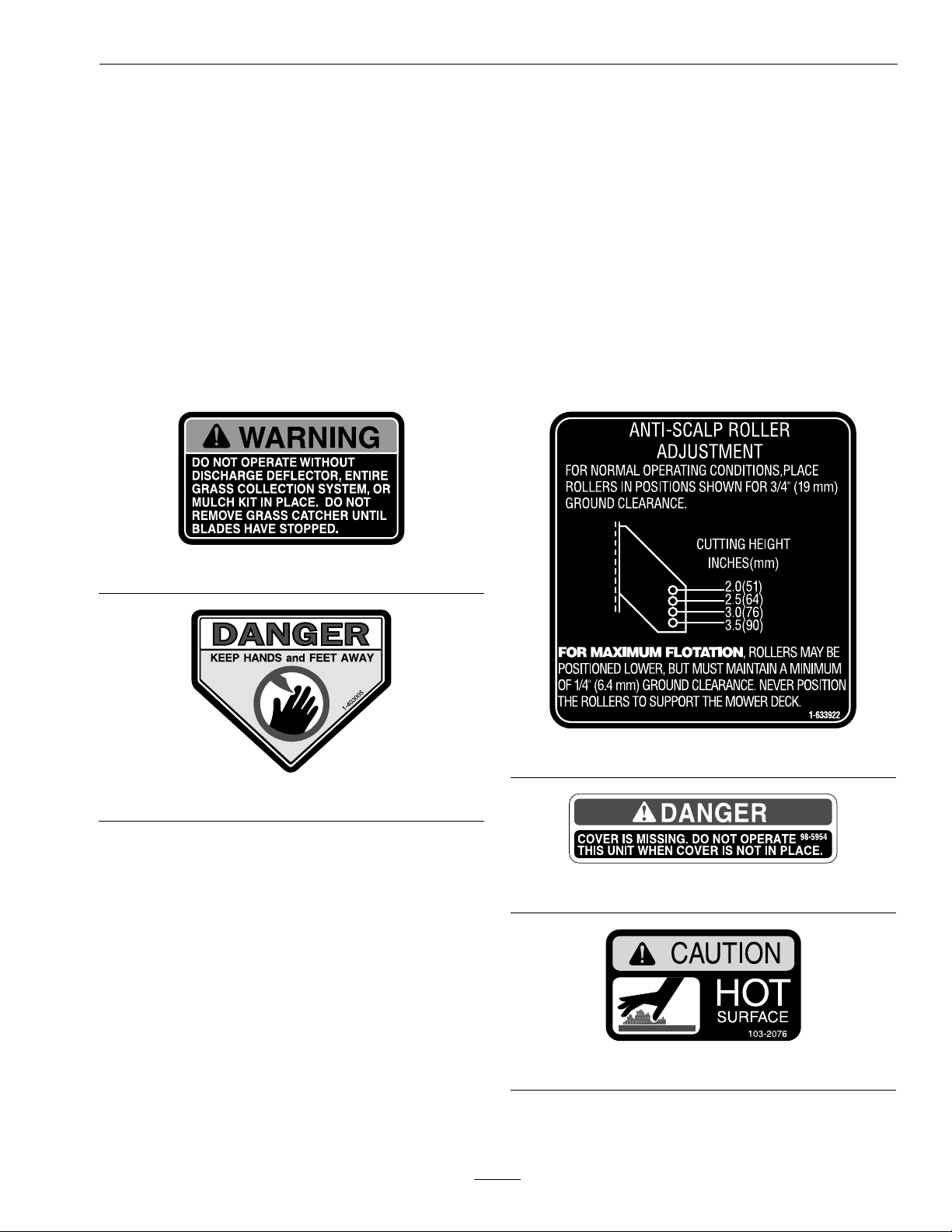

1-303508

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

1-633922

1-403005

98-5954

103-2076

11

Page 12

Safety

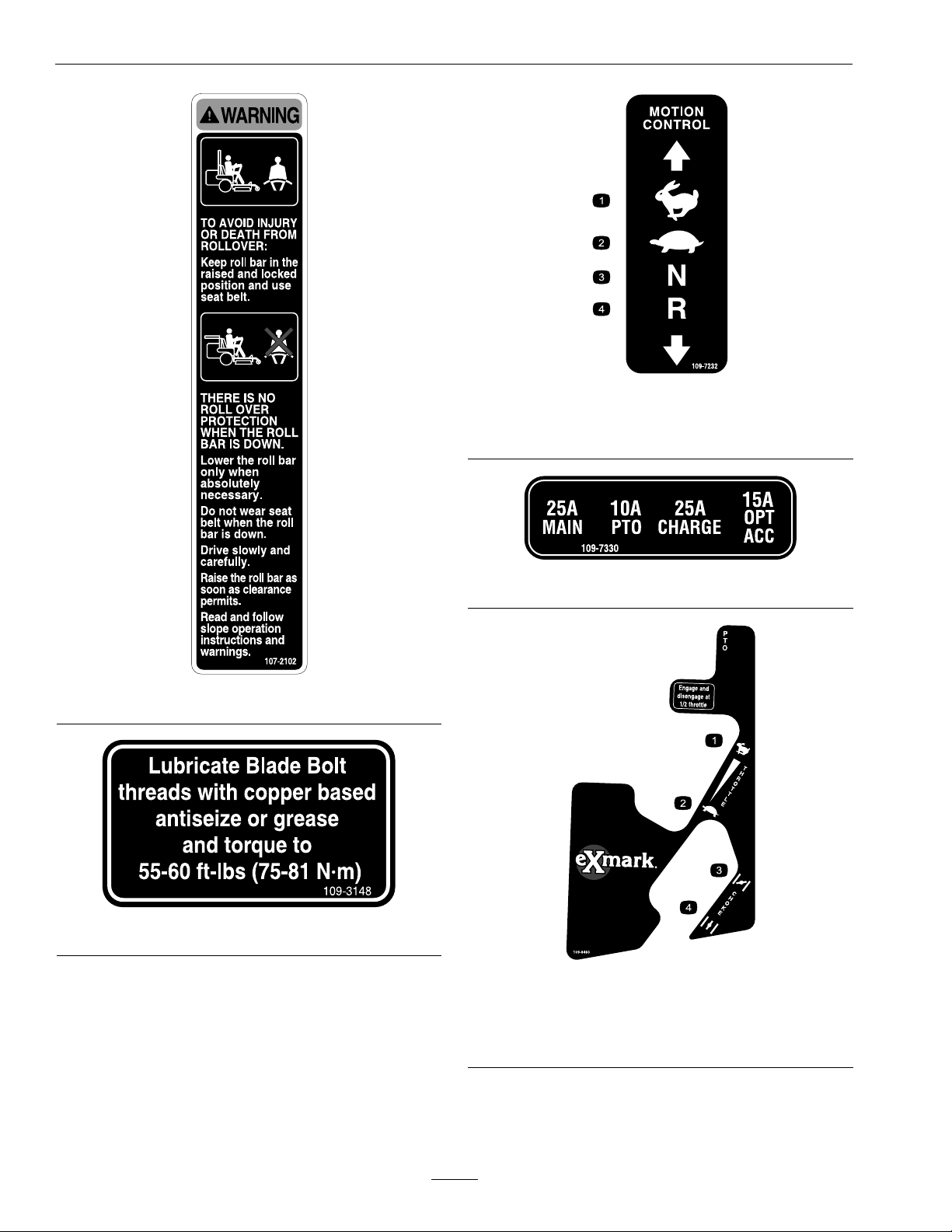

109-7232

1.Fast3.Neutral

2.Slow

4.Reverse

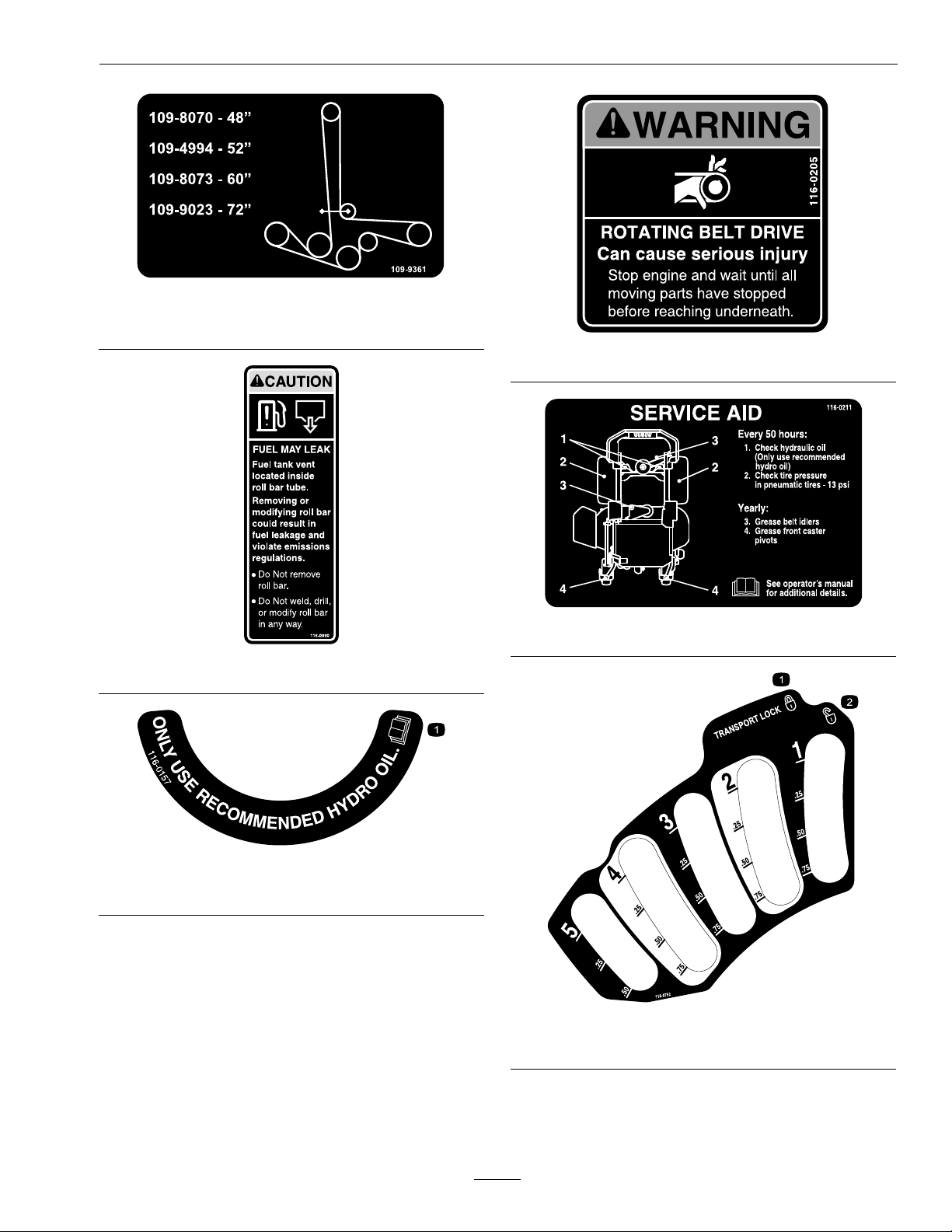

109-7330

107-2102

109-3148

109-8483

AllUnitsExceptEFI

1.Throttle–fast3.Choke–on

2.Throttle–slow

4.Choke–off

12

Page 13

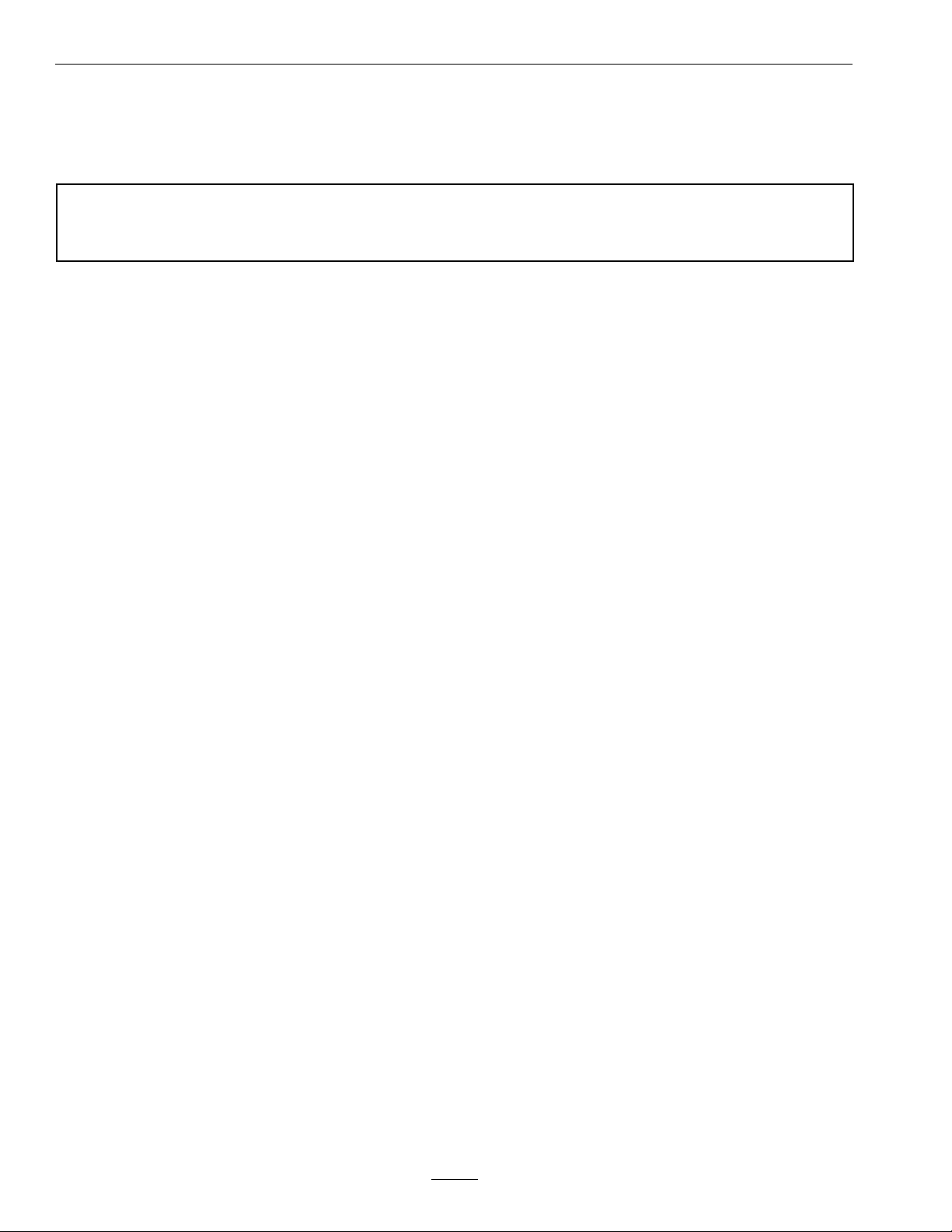

DeckDriveBeltRouting

Safety

109-9361

116-0205

1.SeeOperator'sManual

116-0211

116-0090

116-0157

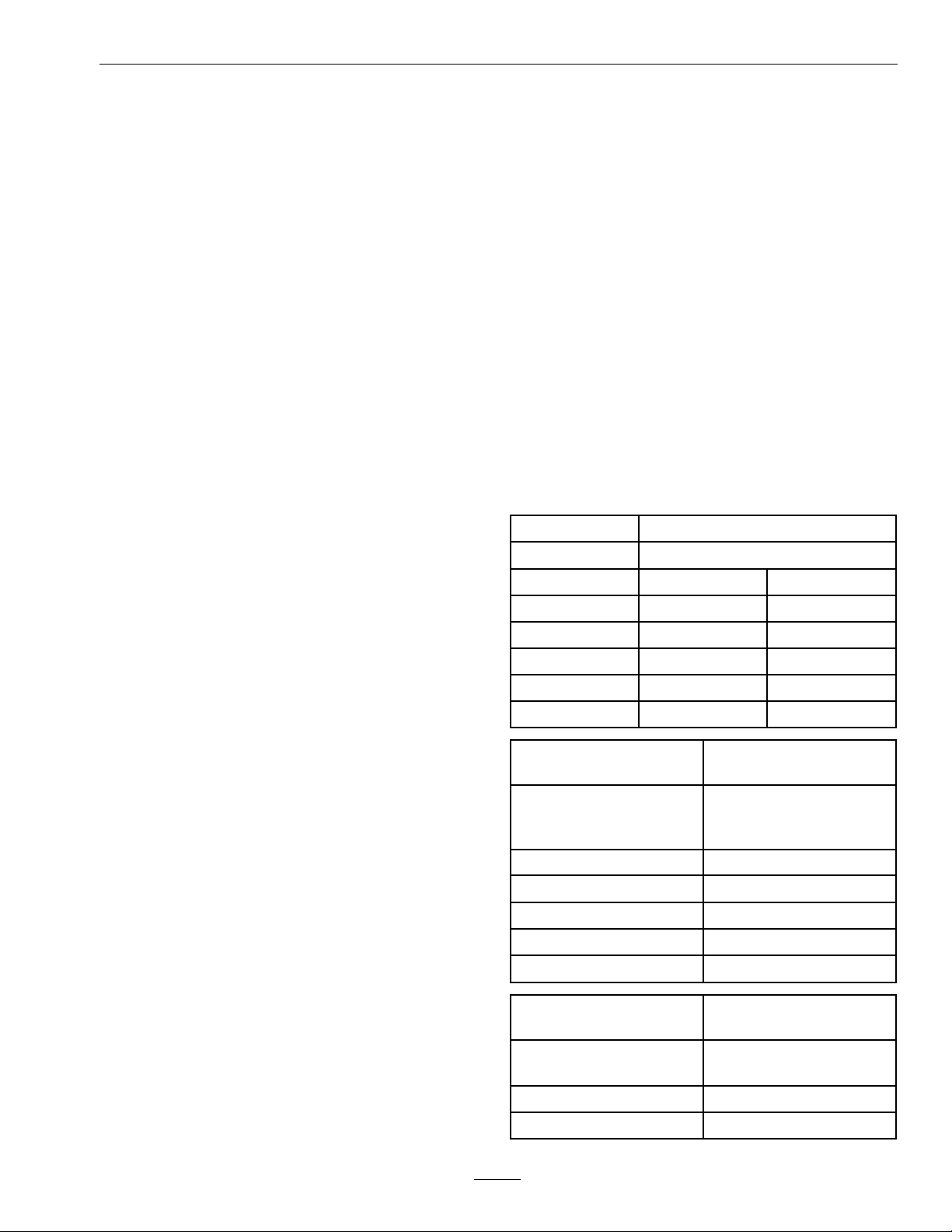

116-0752

1.Latch2.Unlatch

13

Page 14

Safety

117–2718

116-1654

116-2643

116-5944

MessageDisplay

1.Fuel6.Hourmeter

2.Empty

116-2844

EFIUnitsOnly

1.Throttle–fast

2.Throttle–slow

3.Half

4.Full9.Neutral

5.Battery

7.PTO

8.Parkingbrake

10.Operatorpresence

switch

PTOSwitchSymbols

1.PTO–disengage2.PTO–engage

116-3303

14

Page 15

Safety

109-7069

15

Page 16

Specications

Specications

ModelNumbers

SerialNos:312,000,000andHigher

LZS651KA484;LZS651KA484CA;LZS680KC524;LZS691KA524CA;LZS740KC524;LZS740KC604;

LZS740KC604CA;LZS801KA724;LZS730EKC604;LZS749EKC724

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’ s

Manual

•EngineOilType:Exmark4–CyclePremium

EngineOil

•RPM:FullSpeed:3750±50RPM(PTOnot

engaged)Idle:1500+100/-250RPM

FuelSystem

•Capacity:

–AllUnitsExceptLZS730EKC604:12.0gal.

(45.4L)

–LZS730EKC604:8.0gal.(30.3L)

•TypeofFuel:Regularunleadedgasoline,87

octaneorhigher;containingnomorethan10%

methanolorethanol.

•FuelFilter:

–Kohler:

KohlerP/N2405013

–Kawasaki:

KawasakiP/N49019-7005

–KohlerEFI:

KohlerP/N2505042

•FuelShut-OffValve:

AllUnits:1/4turnincrements(“ON”,“OFF”).

•Fuelleveleightsegmentdisplay—righthand

controlpanel.

–KohlerandKawasaki:15amps

–KohlerEFI:20amps

•BatteryType:BCIGroupU1

•RecommendedMinimumBatteryCCA:260CCA

•BatteryVoltage:12Volt

•LowVoltageLight—RHcontrolpanel

•Polarity:NegativeGround

•Fuses:

Allunits:

–25ampmainfuse

–25ampchargingsystemfuse

–10ampPTOfuse

–15ampaccessoryfuse

SafetyInterlockSystem

•LCDindicatorsappearforthePTO ,parkbrake,

drivelevers,andoperatorpresenceinthemessage

displayontheRHcontrolpanel.

•PTOmustbedisengaged,brakeengaged,and

motioncontrolleversout(neutrallock)tostart

engine.(Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.)

•OperatormustbeinseatwhenPTOisengaged,

brakeisdisengaged,ormotioncontrolleversare

movedinorenginewillstop.

•Enginewillstopifeithertheleft,theright,or

bothleversaremovedfromneutrallockposition

whilebrakeisengaged.

•Lowfuelindicatorlight.

ElectricalSystem

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:

OperatorControls

•SteeringandMotionControl:

Note:Motioncontrolleversareadjustableto

twoheights.

16

Page 17

Specications

–Separatelevers,oneachsideoftheconsole,

controlspeedanddirectionoftravelofthe

respectivedrivewheels.

–Steeringiscontrolledbyvaryingtheposition

oftheleversrelativetoeachother.

–Movingmotioncontrolleversoutward(in

slots)locksthedrivesysteminneutral.

•PTOEngagementSwitch:Engageselectricclutch

(todrivebelt)whichengagesmowerblades.

•ParkingBrakeLever:Engages/Disengages

parkingbrake.

•DeckHeightAdjustmentLever:Setscutting

heighttodesiredposition.

•DeckLiftPedal:Footpedalthatliftsdeck.

•TransportLock:

–Latchingposition:Automaticallylatchesat

thetransportposition.

–Unlatchingposition:Deckdoesnotlatchat

thetransportposition.

Integratedseatswitch.Timedelayseatswitch

eliminatesroughgroundcut-outs.

HydrostaticGroundDriveSystem

•Twounitizedhydrostatictransmissions:

12ccParkeraxialpistonpump

240ccParkergerolermotor

•HydraulicOilType:ExmarkPremiumHydroOil.

•HydraulicOilCapacity:52oz(1.5L)perside

•HydraulicFilter:P/N116-0164

•Speeds:

–0-10mph(16.1km/hr)forward.

–0-5.5mph(8.9km/hr)reverse.

•Drivewheelreleasevalvesallowmachinetobe

movedwhenengineisnotrunning.

TiresandWheels

Drive

Seat

•Type:Standardseatwithhighback,extra

widefoampaddedseatcushionwithinternal

suspension,thickbolstering,armrests,integral

safetyswitch.

Optionalseataccessoriesforunitswithstandard

seats:

–Customridesuspensionsystemtoenhance

StandardSeat.Addsapproximately3inches

(7.6cm)toseatheight.

–Deluxesuspensionseatwithhighback,

(adjustablespringsuspension),armrests,and

integralsafetyswitch.Addsapproximately

1/2inch(1.3cm)toseatheight.

–SeatIsolationSystemforreducedvibration,

toenhancerideofstandardseat,standardseat

withCustomRideSeatSuspensionorDeluxe

SuspensionSeat.Addsapproximately1inch

(2.5cm)toseatheight.

•Mounting:Adjustableforeandaftonseattracks.

•Armrests:

–Standardseat:foampaddedadjustableip-up

armrests.

–Suspensionseat:foampaddedadjustable

ip-uparmrests.

•SeatSafetySwitch:

Pneumatic(Airlled)

DeckSize

Quantity

Tread

Size24x9.50-1224x12.00-12

PlyRating

Pressure

DeckSize

Quantity

Tread

Size13x5.00-6

PlyRating

Pressure

DeckSize

Quantity

Tread

48&5260&72

22

TurfMasterTurfMaster

44

13psi(90kPa)13psi(90kPa)

48,52,&60(except

LZS740KC604&

LZS740KC604CA)

2

Smooth

4

N/A

72,LZS740KC604&

LZS740KC604CA

2

Smooth

FrontCaster

Semi-Pneumatic

FrontCaster

Semi-Pneumatic

17

Page 18

Specications

Size13x6.50-6

PlyRating

Pressure

4

N/A

CuttingDeck

•CuttingWidth:

–48inchDeck:(121.9cm)

–52inchDeck:(132.1cm)

–60inchDeck:(152.4cm)

–72inchDeck:(182.9cm)

•Discharge:Side

•BladeSize:(3ea.)

–48inchDeck:16.25inches(41.3cm)

–52inchDeck:18.00inches(45.7cm)

–60inchDeck:20.50inches(52.1cm)

–72inchDeck:24.50inches(62.2cm)

•BladeSpindles:Solidsteelspindleswith1.00inch

(25mm)I.D.bearings.

•DeckDrive:

Electricclutch:

•CuttingHeightAdjustment:

Footactivatedleverisusedtoadjustthecutting

heightfrom1inch(2.5cm)to51/2inches(14

cm)in1/4inch(6.4mm)increments.

•MulchingKit:Optional.

Dimensions

OverallWidth:

48inchDeck52inchDeck

WithoutDeck45.7inches

(116.1cm)

DeectorUp51.8inches

(131.6cm)

DeectorDown59.6inches

(151.4cm)

60inchDeck72inchDeck

WithoutDeck53.0inches

(134.6cm)

DeectorUp62.5inches

(158.8cm)

DeectorDown72.8inches

(184.9cm)

45.7inches

(116.1cm)

56.3inches

(143.0cm)

64.8inches

(164.6cm)

59.1inches

(150.1cm)

73.5inches

(186.7cm)

84.9inches

(215.6cm)

–48and52inchDecks:“B”Sectionbeltwith

self-tensioningidler.

–60and72inchDecks:5VSectionbeltwith

self-tensioningidler.

•Deck:

Fulloatingdeckisattachedtoout-frontsupport

frame.Anti-scalprollersprovidemaximumturf

protection.Deckdesignallowsforbagging,

mulchingorsidedischarge.

–48inchDeck:3anti-scalprollers

–52inchDeck:3anti-scalprollers

–60inchDeck:4anti-scalprollers

–72inchDeck:6anti-scalprollers

•DeckDepth:

–48inchDeck:5.5inches(14cm)

–52inchDeck:5.5inches(14cm)

–60inchDeck:5.5inches(14cm)

OverallLength:

48inchDeck52inchDeck

RollBar-Up79.2inches

(201.2cm)

RollBar-Down80.9inches

(205.5cm)

60inchDeck72inchDeck

RollBar-Up83.1inches

(211.1cm)

RollBar-Down84.8inches

(215.4cm)

79.2inches

(201.2cm)

80.9inches

(205.5cm)

86.1inches

(218.7cm)

87.8inches

(223.0cm)

OverallHeight:

RollBar-UpRollBar-Down

70.5inches(179.1cm)46.8inches(118.9cm)

–72inchDeck:5.5inches(14cm)

18

Page 19

Specications

TreadWidth:(CentertoCenterof

Tires,Widthwise)

48inchDeck52inchDeck

DriveWheels36.2inches

(91.9cm)

CasterWheels32.8inches

(83.3cm)

60inchDeck72inchDeck

DriveWheels41.6inches

(105.7cm)

CasterWheels39.5inches

(100.3cm)

38.5inches

(97.8cm)

32.8inches

(83.3cm)

43.6inches

(110.7cm)

47.1inches

(119.6cm)

WheelBase:(CenterofCasterTireto

CenterofDriveTire)

48inch

Deck

48.0inches

(121.9cm)

52inch

Deck

48.0inches

(121.9cm)

60inch

Deck

51.6inches

(131.1cm)

72inch

Deck

53.6inches

(136.1cm)

CurbWeight:

48inch

Deck

Kawasaki

651Units

Kawasaki

691Units

Kohler

680Units

Kohler

EFI730

Units

Kohler

740Units

Kawasaki

801Units

Kohler

EFI749

Units

1089lb

(494kg)

—

—

——

—

———

———

52inch

Deck

———

1066lb

(484kg)

1088lb

(494kg)

1088lb

(494kg)

60inch

Deck

——

——

1133lb

(514kg)

1133lb

(514kg)

72inch

Deck

—

—

1208lb

(548kg)

1191lb

(540kg)

19

Page 20

Specications

AccessoryWeightTableWorksheet:

Usethetablebelowtodetermineifextraweight

isrequiredfortheunit.Identifytheaccessories

andcorrectdecksizeandplacethecorresponding

valuesintheAccessoryScorecolumn.IftheTotal

AccessoryScoremeetsthefollowing,addthe

recommendedweightkit.

Note:The72inchdeckdoesnotrequireaweightkit.

LightKit

Michigan

Seat/CRSS

Bagger

Pneumatic

CasterTires

MulchKit

StriperKit

OCD02-5

HitchKit

Sunshade

Kit

48inch

Deck

1112

-3-4-5

-2

52inch

Deck

2

003

6

121

2

TotalAccessoryScore

3

8

00

-7

3

60inch

Accessory

Deck

-4

Score

2

3

5

2

TorqueRequirements

BoltLocation

BladeDriveSheave

MountingNut

BladeMountingBolt

(lubricatewithanti-seize)

Anti-ScalpRollerNyloc

NutSeeFigure18

Anti-ScalpRollerWhizlock

NutSeeFigure18

EngineMountingBolts

(Kohler680&740)

(Kawasaki651&691)

(KohlerEFI)

(Kawasaki801)

WheelLugNuts

WheelMotorMounting

Bolts

WheelHubSlottedNut211-260ft-lb

RolloverProtection

System(RollBar)1/2

inchMountingBolts

Torque

130–160ft-lb(176-217

N-m)

50-60ft-lb(68-81N-m)

30-35ft-lb(41-47N-m)

30-35ft-lb(41-47N-m)

27-33ft-lb(37-45N-m)

17-23ft-lb(23-31N-m)

27-33ft-lb(37-45N-m)

27-33ft-lb(37-45N-m)

90-95ft-lb(122-129N-m)

72-77ft-lb(98-104N-m)

(286-352N-m)

75-80ft-lb(102-108N-m)

TotalAccessoryScoreRequiredWeightKit(s)

0–9

10–19

20andHigher*Two116-1173Undertoe

Nonerequired

*116-1173Undertoeboard

mountweightkit

boardmountweightkitsor

one116-1173Undertoe

boardmountweightkit

andone116-1238Front

toeboardmountweightkit

*48and52inchunitsthatcomewithanundertoe

boardweightasstandard,canaddanadditionaltoe

boardweightforprimaryaccessoryweighting(scores

10-19);andfronttoeboardweightkitforsecondary

accessoryweighting(scores20andhigher).Other

unitsshouldinstallarstundertoeboardkitfor

primaryaccessoryweighting(scores10-19);anda

secondundertoeboardkitforsecondaryaccessory

weighting(scores20andhigher).

ClutchRetainingBolt

(securedwiththreadlocker)

HydroParkBrake

CableAnchor1/2inch

MountingBolt(secured

withthreadlocker)

55-60ft-lb(75-81N-m)

67-89ft-lb(91-121N-m)

20

Page 21

Operation

ProductOverview

1.RolloverProtection

System(ROPS)

2.EngineControls(right

console)

3.Seatbelt

4.Motioncontrollevers

Figure4

5.Fuelcap

6.Heightofcutadjustment

7.Parkingbrake

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

MotionControlLevers

Themotioncontrolleverslocatedoneachsideof

theconsolecontroltheforwardandreversemotion

ofthemachine.

Movingtheleversforwardorbackwardturns

thewheelonthesamesideforwardorreverse

respectively.Wheelspeedisproportionaltothe

amounttheleverismoved.

Movingtheleversoutwardfromthecenterposition

intotheT-slotlocksthemintheneutralposition

(Figure5).

Whenthemotioncontrolleversareintheneutral

position,theLCDindicatorappearsinthemessage

displayontheRHconsole(seeFigure8).

1.Neutrallockposition

2.Neutraloperateposition

3.FrontofUnit

21

Figure5

4.Forward

(handlesout)

5.Neutral(operate)

(handlesin)

6.Reverse

Page 22

Operation

ChokeControl(AllUnitsExcept

KohlerEFI)

Locatedonrightconsole(blacklever)(seeFigure6).

Thechokeisusedtoaidinstartingacoldengine.

Movingthechokeleverforwardwillputthechokein

the“ON”positionandmovingthechokelevertothe

rear,tothedetent,willputthechokeinthe“OFF”

position.DoNotrunawarmenginewithchokein

the“ON”position.

Pushtheleverforwardanddowntodisengagethe

brake.

Theunitmustbetieddownandbrakeengagedwhen

transporting.

IgnitionSwitch

Locatedonrightconsole(seeFigure6).

Theignitionswitchisusedtostartandstopthe

engine.Theswitchhasthreepositions“OFF”,“ON”

and“START”.Insertkeyintoswitchandrotate

clockwisetothe“ON”position.Rotateclockwiseto

thenextpositiontoengagethestarter(keymustbe

heldagainstspringpressureinthisposition).Allow

thekeytoreturntothe“on”positionimmediately

aftertheenginestarts.

Figure6

RightConsole

1.Fuses

2.Messagedisplay5.Throttle

3.Ignitionswitch

4.PTOengagementswitch

6.Choke

ThrottleControl

Locatedonrightconsole(redlever)(seeFigure6).

Thethrottleisusedtocontrolenginespeed.Moving

thethrottleleverforwardwillincreaseenginespeed

andmovingthethrottlelevertotherearwilldecrease

enginespeed.Movingthethrottleforwardintothe

detentisfullthrottle.

BrakeLever

Locatedonrightsideofunit,justtothefrontofthe

RHmotioncontrollever.

Thebrakeleverengagesaparkingbrakeonthedrive

wheels.

Figure7

1.Off3.Start

2.On

Note:Brakemustbeengaged,motioncontrol

leversout(neutrallockposition)andPTOswitch

disengagedtostartengine.(Itisnotnecessaryforthe

operatortobeintheseattostarttheengine.)

HourMeter

Locatedontherightconsoleinthemessagedisplay

(seeFigure6andFigure8).

Thehourmeterrecordsthenumberofhoursthat

theenginehasrun.

Note:TheLCDindicatorappearsinthemessage

displayontheRHconsolewhentheparkbrakeis

engaged(seeFigure8).

Pulltheleverupandrearwardtoengagethebrake.

22

Page 23

Figure8

Operation

DriveWheelReleaseValves

WARNING

Handsmaybecomeentangledintherotating

drivecomponentsbelowtheenginedeck,which

couldresultinseriousinjuryordeath.

Stopengine,removekey,allowallthemoving

partstostopbeforeaccessingthedrivewheel

releasevalves.

1.LCDIndicators

2.Lowfuelindicatorlight

3.Fuellevelbardisplay

4.Lowvoltageindicatorlight

5.Hour/Voltagedisplay

Thehourmeterisrecordingwhenthedecimalpoint

isashinginHour/Voltagedisplay.

Hoursaredisplayedwhenthekeyisofforwhenthe

machineisrunning.

Note:Iftheignitionkeyisturnedtothe“ON”

positionforafewsecondsbeforecrankingtheengine,

thebatteryvoltagewilldisplayintheareawherethe

hoursarenormallydisplayed.

Note:TheLCDindicatorsappearwheneachcontrol

meetsthe“safetostart”mode(e.g.theindicator

turnsonwhentheoperatorisintheseat.)

FuelShut-OffValve

WARNING

Theengineandhydraulicdriveunitscanbecome

veryhot.T ouchingahotengineorhydraulic

driveunitscancausesevereburns.

Allowtheengineandhydraulicdriveunitsto

coolcompletelybeforeaccessingthedrivewheel

releasevalves.

Locatedonthebackoftheunitizedhydraulicdrive

units,belowtheenginedeck.

Duringnormaloperatingconditions,thedrivewheel

releasevalvesarepositionedhorizontally.Ifthe

machinehastobepushedbyhand,thevalvesmust

beinthe“released”position(seeFigure9).

Locatedbehindandbelowtheseat.

Thefuelshut-offvalveisusedtoshutoffthefuel

whenthemachinewillnotbeusedforafewdays,

duringtransporttoandfromthejobsite,andwhen

parkedinsideabuilding.

Alignvalvehandlewiththefuellinetoopen.Rotate

90°toclose.

FuelGauge

Locatedontherightconsoleinthemessagedisplay

(seeFigure6andFigure8).

Thefuellevelisshownonabardisplay.Theindicator

lightappearswhenthefuellevelislow(approximately

onegallonremaininginthetank).

Figure9

1.Handlein“released”position

2.Handlein“operating”position

Toreleasethedrivesystem(seeitem1inFigure9),

rotatethehandle1/4turntotheverticalposition

untilithitsagainstthestop.

Toresetthedrivesystem(seeitem2in

Figure9),

rotatethehandle1/4turntothehorizontalposition

untilithitsagainstthestop.

23

Page 24

Operation

Note:Thehandlemustbehorizontalandagainst

thestopforoperation.

DoNottowmachine.

PTOEngagementSwitch

Locatedonrightconsole(seeFigure6).

Switchmustbepulledout(up)toengagetheblades.

Switchispushedintodisengagetheblades.

TheLCDindicatorwillappearwhenthePTOswitch

isdisengaged(seeFigure8).

LowVoltageIndicator

Locatedontherightconsoleinthemessagedisplay

(seeFigure6andFigure8).

Alowvoltagecondition(lessthan12.3volts)exists

whentheLCDindicatorappearsonthemessage

displaywhiletheengineisrunning.

Iftheignitionkeyisturnedtothe“ON”positionfor

afewsecondsbeforecrankingtheengine,thebattery

voltagewilldisplayintheareawherethehoursare

normallydisplayed.

Note:Theindicatornormallyappearswhenthe

engineisoffandthekeyswitchisturnedtothe

“ON”position.

DeckLiftPedal

Locatedattherightfrontcorneroftheoorpan.

Pushthepedalforwardwithyourfoottoraisethe

cuttingdeck.Allowthepedaltomoverearwardto

lowerthecuttingdecktothecutheightthathasbeen

set.

TransportLock

Figure10

1.Latchingposition3.Non-latchingposition

2.Transportlockcontrol

ElectronicControlUnitMalfunction

Indicator

KohlerEFIUnitsOnly:

Theelectroniccontrolunit(ECU)continuously

monitorsoperationoftheEFIsystem.Ifaproblem

orfaultwithinthesystemisdetected,themalfunction

indicatorlight(MIL)isilluminated.TheMIListhe

lightlocatedintherightconsolepaneltotherightof

thethrottlecontrol.Followthetroubleshootingsteps

outlinedintheKohlerengineoperator’smanualifthe

MILisilluminated.

Pre-Start

Fillfueltankonlevelground.Forbestresultsuse

onlyclean,freshregulargradeunleadedgasolinewith

anoctaneratingof87orhigher.

Important:Neverusemethanol,gasoline

containingmethanol,gasoholcontainingmore

than10%ethanol,premiumgasoline,orwhite

gasbecausethefuelsystemcouldbedamaged.

Locatedontheheightofcutadjustmentplatestothe

rightoftheparkingbrake.

Positioninthetransportlatchingpositionto

automaticallylatchthecuttingdeckwhenraisedto

thetransportposition(seeitem1inFigure10).

Inthenon-latchingposition,thedeckwill

automaticallyreturntothecuttingheightwhenthe

pedalislowered(seeitem3inFigure10).

DoNotaddoiltogasoline.

DoNotoverllfueltank.Fillthefueltanktothe

bottomofthellerneck.Theemptyspaceinthe

tankallowsgasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineoremission

system.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

24

Page 25

Operation

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

RaisetheRolloverProtectionSystem

(ROPS)

Important:Therollbarisanintegraland

effectivesafetydevice.Keeptherollbarinthe

raisedandlockedpositionwhenoperatingthe

mower.Lowertherollbartemporarilyonlywhen

absolutelynecessary.

1.Theknobmustbecompletelylatchedwiththe

tabsinterlockingasshownin

therollbarintheraised,operateposition.

2.Applyforwardpressuretotheupperhoopofthe

rollbar.

3.Pulltheknobandrotate90°toholdinthe

unlatchedpositiontolowertherollbar.

4.Toreturntotheoperateposition,raisetheroll

bar,andthenrotateknobs90°sothatthetabs

interlockpartially.Applyforwardpressuretothe

rollbarupperhoopandobservethattheknobs

returntothecompletelylatchedposition.

Figure11tolock

pulledrearwardtogetbothknobsfullyengaged

(seeFigure12).

Figure12

1.Engaged2.Partiallyengaged—Do

NotoperatewithROPS

inthiscondition.

Important:Alwaysusetheseatbeltwiththe

rollbarintheoperate(raised)position.Ensure

thattherearpartoftheseatissecuredwiththe

seatlatch.

OpentheFuelShut-OffValve

Rotatethevalveandalignwiththefuellinetoopen.

StartingtheEngine

Figure11

1.Rollbarupperhoop

2.Knobin“latched”position

3.Pullknobtounlatch

4.Rotate90°toholdunlatched

5.Knobin“unlatched”position

5.Makesuretheknobsarefullyengagedwiththe

rollbarintheraisedposition.Theupperhoopof

therollbarmayneedtobepushedforwardor

1.Movethemotioncontrolleversouttotheneutral

lockposition.

2.Pullupandbackontheparkingbrakeleverto

engagetheparkingbrake.

3.PushdownonthePTOswitchtothe“disengage”

position.

Note:Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.

4.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

5.Onacoldengine,pushthechokeleverforward

intothe“ON”position(exceptKohlerEFIunits).

Onawarmengine,leavethechokeinthe“OFF”

position.

6.Turnignitionswitchtothe“START”position.

Releasetheswitchassoonastheenginestarts.

Important:DoNotcranktheengine

continuouslyformorethantensecondsata

time.Iftheenginedoesnotstart,allowa60

secondcool-downperiodbetweenstarting

25

Page 26

Operation

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor.

7.Ifthechokeisinthe“ON”position,gradually

returnchoketothe“OFF”positionastheengine

warmsup.

EngagingthePTO

DANGER

Therotatingbladesunderthemowerdeckare

dangerous.Bladecontactcancauseserious

injuryorkillyou.

DoNotputhandsorfeetunderthemoweror

mowerdeckwhenthebladesareengaged.

DANGER

Anuncovereddischargeopeningwillallow

objectstobethrowninanoperator’sor

bystander’sdirection.Also,contactwiththe

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryordeath.

Neveroperatethemowerwiththedischarge

deectorraised,removed,oralteredunlessthere

isagrasscollectionsystemormulchkitinplace

andworkingproperly.

ThePTOpush-pullswitchengagesthecuttingblades.

Besurethatallpersonsareclearofthemowerdeck

anddischargeareabeforeengagingPTO.

Important:Operatormustbeinseatbeforethe

PTOcanbeengaged.

1.Setthethrottlemidwaybetweenthe“SLOW”and

“FAST”positions.

2.PullthePTOswitchoutwardtoengagetheblades.

3.Placethethrottleinthe“FAST”positiontobegin

mowing.

DisengagingthePTO

1.Setthethrottlemidwaybetweenthe“SLOW”and

“FAST”positions.

2.PushthePTOswitchintodisengagetheblades.

2.Movethemotioncontrolleversouttotheneutral

lockposition.

3.Engagetheparkingbrake.

4.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

5.DisengagethePTO.

6.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

7.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

8.Closethefuelshut-offvalvewhenthemachine

willnotbeinuseforafewdays,when

transporting,orwhentheunitisparkedinside

abuilding.

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioningone

levertoomuchaheadoftheother.Operatormay

losecontrolofthemachine,whichmaycause

damagetothemachineorinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Important:Tobeginmovement(forwardor

backward)theoperatormustbeintheseat,the

brakelevermustbedisengaged(pusheddown)

beforethemotioncontrolleverscanbemovedin

ortheenginewillstop.

Whenthemotioncontrolleversarepositionedfully

outward(apart)intheT-slot,thedrivesystemisin

theneutrallockposition(

Note:The“N”LCDindicatorappearswhenboth

leversareintheneutrallockposition.

Whenthemotioncontrolleversaremoveddirectly

inward(together)thedrivesystemisintheneutral

operateposition.

Figure13).

StoppingtheEngine

1.Bringtheunittoafullstop.

26

Page 27

Figure14

Operation

Figure13

1.Neutrallockposition

(handlesout)

2.Neutraloperateposition

(handlesin)

3.FrontofUnit

4.Forward

5.Neutral(operate)

6.Reverse

DrivingForward

1.Releasetheparkingbrake.

2.Movethemotioncontrolleversinwardtothe

centertotheneutralposition.

3.Tomoveforwardinastraightline,moveboth

leversforwardwithequalpressure.

Toturnleftorright,pullthemotioncontrollever

backtowardneutralinthedesiredturndirection.

Themachinewillmovefasterthefartherthe

motioncontrolleversaremovedfromtheneutral

position.

4.Tostop,positionbothmotioncontrolleversin

theneutraloperateposition.

DrivinginReverse

1.Movethemotioncontrolleversinwardtothe

neutraloperateposition.

2.Tomoverearwardinastraightline,moveboth

leversrearwardwithequalpressure.

Figure15

27

Page 28

Operation

Toturnright,releasepressureontheRHmotion

controlleverandtherearofthemachinewill

movetowardstherearandtotheright.

Toturnleft,releasepressureontheLHmotion

controlleverandtherearofthemachinewill

movetowardstherearandtotheleft.

3.Tostop,positionbothmotioncontrolleversin

theneutraloperateposition.

AdjustingtheCuttingHeight

Thecuttingheightofthemowerdeckisadjusted

from1to51/2inches(2.5cmto14cm)in1/4inch

(6.4mm)increments.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO.

3.Positionthetransportlockinthelatching

position.

4.Raiseandlockthedecktothe51/2inch(14cm)

transportposition(

Figure16).

Seethedecalonthesideofthedeckliftplatefor

cutheights.

6.Pushthedeckliftpedal,releasethetransportlock

andallowthedecktolowertothecuttingheight.

AdjustingtheAnti-ScalpRollers

Itisrecommendedtochangetheanti-scalproller

position,whentheheightofcuthaschanged.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthenylocnut,

bushing,springdiscwasherandwhizlocknut.

6.Placetherollersinoneofthepositionsshown

(Figure17).Rollerswillmaintain3/4inch(19

mm)clearancetothegroundtominimizegouging

androllerwearordamage.

Thedeckisraisedbypushingthefootoperated

deckliftpedalforward.Thepedalislocatedatthe

frontrightcorneroftheoorpan.

Note:Whenchangingthecuttingheight

positions,alwayscometoacompletestop

anddisengagethePTO.

Figure16

1.Deckfootpedal3.Heightofcutdecal

2.Heightadjustmentpin4.Transportlockcontrol

5.Inserttheheightadjustmentpinintothehole

correspondingtothedesiredcuttingheight.

Figure17

Forcuttingheightsabove3.5inches(90mm)usethe

bottomhole.Therollerswillstillbeeffectiveagainst

scalping.

1.Anti-scalproller

mountingbracket

2.Cuttingheight

ForMaximumDeckFlotation,placetherollers

oneholepositionlower.Rollersshouldmaintain

1/4inch(6.4mm)clearancetotheground.Do

Notadjusttherollerstosupportthedeck.

7.Besurethewhizlocknutsareinstalledwiththe

springdiscwasherbetweentheheadofthenut

andthemountingbracket.

Note:Thefootoperateddeckliftassistlever

canbeusedtomomentarilyliftthedecktoclear

objects.BesurethatPTOisdisengaged.

28

Page 29

Operation

8.Torquethe3/8–16whizlocknutto30-35ft-lb

(41-47N-m)(Figure18).

9.Torquethe3/8nylocnutto30–35ft-lb(41-47

N-m).

Figure18

1.Springdiscwasher

(conetowardsnut)

2.Frontrightanti-scalp

bracketshown

3.3/8nyloc-torqueto30-35

ft-lb(41-47N-m)

4.3/8-16whizlocknut

torqueto30-35ft-lb

(41-47N-m)

Transporting

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Securely

fastenthemachinetothetrailerortruckwithstraps,

chains,cable,orropes.Besurethatthetrailerortruck

hasallnecessarylightingandmarkingasrequiredby

law .Secureatrailerwithasafetychain.

CAUTION

Thisunitdoesnothaveproperturnsignals,

lights,reectivemarkings,oraslowmoving

vehicleemblem.Drivingonastreetorroadway

withoutsuchequipmentisdangerousand

canleadtoaccidentscausingpersonalinjury.

Drivingonastreetorroadwaywithoutsuch

equipmentmayalsobeaviolationofStatelaws

andtheoperatormaybesubjecttotrafctickets

and/ornes.

DoNotdriveaunitonapublicstreetorroadway.

WARNING

Loadingaunitonatrailerortruckincreases

thepossibilityofbackwardtip-over.Backward

tip-overcouldcauseseriousinjuryordeath.

•Useextremecautionwhenoperatingaunit

onaramp.

•Useonlyasingle,fullwidthramp;DoNot

useindividualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurface

widerthantheunit.

•DoNotexceeda15°anglebetweenrampand

groundorbetweenrampandtrailerortruck.

•Avoidsuddenaccelerationwhiledrivingunit

uparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

LoadingaUnit

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinstead

ofindividualrampsforeachsideoftheunit.The

lowerrearsectionofthetractorframeextendsback

betweentherearwheelsandservesasastopfor

tippingbackward.Havingafullwidthrampprovides

asurfacefortheframememberstocontactifthe

unitstartstotipbackward.Ifitisnotpossibletouse

onefullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Rampshouldbelongenoughsothattheangles

betweentherampandthegroundandtherampand

thetrailerortruckDoNotexceed15°.Asteeper

anglemaycausemowerdeckcomponentstoget

caughtastheunitmovesfromramptotraileror

truck.Steeperanglesmayalsocausetheunittotip

backward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideofthe

slopeandtherampextendsuptheslope.Thiswill

minimizetherampangle.Thetrailerortruckshould

beaslevelaspossible.

Important:DoNotattempttoturntheunit

whileontheramp,youmaylosecontroland

driveofftheside.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdownaramp.

Bothmaneuverscancausetheunittotipbackward.

29

Page 30

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecouldseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitch,engage

parkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenance.Also

pushthewire(s)asidesoitdoesnotaccidentally

contactthesparkplug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst100hours

Aftertherst250hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthewheelhubslottednuttorquespecications.

•Checkthewheellugnuts.

•Checktheparkbrakeadjustment.

•Changethehydrauliclteranduid.

WARNING

Theenginecanbecomeveryhot.T ouchingahot

enginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheenginearea.

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every250hours

•Checktheengineoillevel.

•Checkthemowerblades.

•Checkthesafetyinterlocksystem.

•Checktherolloverprotectionssystems(rollbar)knobs.

•Checktheseatbelt.

•Checkforloosehardware.

•Cleantheengineandexhaustsystemarea.

•Cleanthehydrofancoolingguards.

•Cleanthegrassanddebrisbuild-upfromthemachineandcuttingdeck.

•Cleanthegrassbuild-upfromunderthecuttingdeck.

•Checkthehydraulicoillevel.

•Checkthetirepressures.

•Checktheconditionofthebelts.

•Checksparkarrester(ifequipped).

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Lubricatethedeckliftpivots.

•Removetheengineshroudsandcleanthecoolingns.

•Checkthesparkplugs.

•Replacetheprimaryaircleanerelement—checksecondaryaircleanerelement;replaceif

dirty.(Mayneedmoreoftenundersevereconditions.SeetheEngineOwner'sManualfor

additionalinformation.)

30

Page 31

Maintenance

MaintenanceService

Interval

Every500hours

Yearly

MaintenanceProcedure

•Replacethesecondaryaircleanerelement(Mayneedmoreoftenundersevereconditions.

SeetheEngineOwner'sManualforadditionalinformation.)

•Changethehydrauliclteranduid.(Mayneedmoreoftenundersevereconditions.)

•Checkthewheelhubslottednuttorquespecications.

•Checkthewheellugnuts.

•Checktheparkbrakeadjustment.

•Greasethedeckandpumpidlerpivots.

•Greasethefrontcasterpivots.

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Cleanareaarounddipstick.Removedipstick

andwipeoiloff.Reinsertthedipstickaccording

totheenginemanufacturer'srecommendations.

Removethedipstickandreadtheoillevel.

4.Iftheoillevelislow,wipeofftheareaaroundthe

oilllcap,removecapandlltothe“FULL”

markonthedipstick.Exmark4-CyclePremium

EngineOilisrecommended;refertotheEngine

Owner'smanualforanacceptablealternative.Do

Notoverll.

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

CheckBatteryCharge

ServiceInterval:Asrequired

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

Allowingbatteriestostandforanextendedperiodof

timewithoutrechargingthemwillresultinreduced

performanceandservicelife.Topreserveoptimum

batteryperformanceandlife,rechargebatteriesin

storagewhentheopencircuitvoltagedropsto12.4

volts.

Note:Topreventdamageduetofreezing,battery

shouldbefullychargedbeforeputtingawayfor

winterstorage.

Checkthevoltageofthebatterywithadigital

voltmeterorwiththemessagedisplay.Iftheignition

keyisturnedtothe“on”positionforafewseconds,

thebatteryvoltagewillbedisplayedintheareawhere

thehoursarenormallydisplayed.Locatethevoltage

readingofthebatteryinthetableandchargethe

batteryfortherecommendedtimeintervaltobring

thechargeuptoafullchargeof12.6voltsorgreater.

Important:Makesurethenegativebatterycable

isdisconnectedandthebatterychargerusedfor

chargingthebatteryshouldhaveanoutputof

16voltsand7ampsorlesstoavoiddamaging

thebattery(seechartforrecommendedcharger

settings).ThisisespeciallyimportantonKohler

EFI(ElectronicFuelInjection)units.Failureto

dosomaydamagetheECU(ElectronicControl

Unit).

Voltage

Reading

12.6or

greater

12.4–12.675–100%

12.2–12.450–75%

Percent

Charge

100%

Maximum

Charger

Settings

16volts/7

amps

16volts/7

amps

16volts/7

amps

Charging

Interval

No

Charging

Required

30Minutes

1Hour

31

Page 32

Maintenance

Voltage

Reading

12.0–12.225–50%

11.7–12.00–25%

11.7orless

Percent

Charge

0%

Maximum

Charger

Settings

14.4volts/4

amps

14.4volts/4

amps

14.4volts/2

amps

Charging

Interval

2Hours

3Hours

6Hoursor

More

Important:ForKohlerEFIunits:Unplugthe

harnessfromtheECUbeforeperformingany

weldingontheequipment.

RecommendedJump

StartingProcedure

ServiceInterval:Asrequired

1.Checktheweakbatteryforterminalcorrosion

(white,green,orblue“snow”),itmustbecleaned

offpriortojumpstarting.Cleanandtighten

connectionsasnecessary.

CAUTION

Corrosionorlooseconnectionscancause

unwantedelectricalvoltagespikesatanytime

duringthejumpstartingprocedure.

CAUTION

Connectingthejumpercablesincorrectly

(wrongpolarity)canimmediatelydamagethe

electricaland/orEFIsystem.

Becertainofbatteryterminalpolarityand

jumpercablepolaritywhenhookingup

batteries.

Note:Thefollowinginstructionsareadapted

fromtheSAEJ1494Rev.Dec.2001–Battery

BoosterCables–SurfaceV ehicleRecommended

Practice(SAE–SocietyofAutomotive

Engineers).

WARNING

Batteriescontainacidandproduceexplosive

gases.

•Shieldtheeyesandfacefromthebatteries

atalltimes.

•DoNotleanoverthebatteries.

Note:Besuretheventcapsaretightandlevel.

Placeadampcloth,ifavailable,overanyvent

capsonbothbatteries.Besurethevehiclesdo

nottouchandthatbothelectricalsystemsare

offandatthesameratedsystemvoltage.These

instructionsarefornegativegroundsystemsonly .

DoNotattempttojumpstartwithlooseor

corrodedbatteryterminalsordamagetothe

engineorEFImayoccur.

DANGER

Jumpstartingaweakbatterythatiscracked,

frozen,haslowelectrolytelevel,oran

open/shortedbatterycell,cancausean

explosionresultinginseriouspersonalinjury.

DoNotjumpstartaweakbatteryifthese

conditionsexist.

2.Makesuretheboosterisagoodandfullycharged

leadacidbatteryat12.6voltsorgreater.Use

properlysizedjumpercables(4to6AWG)with

shortlengthstoreducevoltagedropbetween

systems.Makesurethecablesarecolorcodedor

labeledforthecorrectpolarity .

3.Connectthepositive(+)cabletothepositive(+)

terminalofthedischargedbatterythatiswiredto

thestarterorsolenoidasshownin

Figure19.

32

Page 33

Figure19

1.Positive(+)cableondischargedbattery

2.Positive(+)cableonboosterbattery

3.Negative(–)cableontheboosterbattery

4.Negative(–)cableontheengineblock

5.Boosterbattery

6.Dischargedbattery

7.Engineblock

Maintenance

CheckMowerBlades

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Liftdeckandsecureinraisedpositionasstatedin

theCleanGrassBuild-UpUnderDecksection.

3.Inspectbladesandsharpenorreplaceasrequired.

4.Reinstalltheblades(iftheywereremoved)inthe

followingorder:

A.Installbushingthroughbladewithbushing

angeonbottom(grass)sideofblade.

4.Connecttheotherendofthepositivecabletothe

positiveterminaloftheboosterbattery.

5.Connecttheblacknegative(–)cabletotheother

terminal(negative)oftheboosterbattery.

6.MAKETHEFINALCONNECTIONON

THEENGINEBLOCKOFTHESTALLED

VEHICLE(NOTTOTHENEGATIVEPOST)

AWAYFROMTHEBATTERY .STANDBACK

Figure20).

(see

Figure21

1.Installbushinginbladepriortoinstallingbushingin

spindle.

B.Installbushing/bladeassemblyintospindle.

Makesurethesplinesonthebushingare

engagedinthespindlebeforetighteningthe

bolt.

Figure20

1.Engineblock

2.Negative(–)cable

7.Startthevehicleandremovethecablesinthe

reverseorderofconnection(theengineblock

(black)connectionisthersttodisconnect).

Figure22

1.Usewrenchhereforbladeinstallation.Thisnuthas

beentorquedto130–160ft-lb(176–217N-m)

2.Torqueto50-60ft-lb(68-81N-m)Applylubricantto

threadsasneededtopreventseizing.Copper-based

anti-seizepreferable.Greaseacceptablesubstitute.

33

Page 34

Maintenance

C.Applylubricanttothreadsofbladeboltto

preventseizing.Copper-basedanti-seize

preferable.Greaseacceptablesubstitute.

Installbladeboltngertight.Placewrench

onthetopspindlenutthentorquetheblade

boltsto50-60ft-lb(68-81N-m).

WARNING

Incorrectinstallationofthebladeor

componentsusedtoretainthebladecan

bedangerous.Failuretousealloriginal

componentsandassembledasshowncould

allowabladeorbladecomponenttobe

thrownoutfromunderthedeckresultingin

seriouspersonalinjuryordeath.

AlwaysinstalltheoriginalExmarkblades,

bladebushings,andbladeboltsasshown.

CheckSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

Note:Topreventenginecut-outsonroughterrain

theseatkillswitchhasa1/2seconddelay.

1.Checkstartingcircuit.Startershouldcrankwith,

parkingbrakeengaged,PTOdisengagedand

motioncontrolleversmovedoutintheneutral

lockposition.Theoperatordoesnotneedtobe

intheseattostarttheengine.

Trytostartwithoperatorinseat,parkingbrake

disengaged,PTOdisengagedandmotioncontrol

leversintheneutrallockposition-startermust

notcrank.

Trytostartwithoperatorinseat,parkingbrake

engaged,PTOengagedandmotioncontrol

leversintheneutrallockposition-startermust

notcrank.

Runengineatone-thirdthrottle,engagePTO

andraiseoffofseat(butdonotgetoffof

machine)enginemustinitiateshutdownafter

onesecondhaselapsedifthehandlesarein.The

delaywillbe1/2secondifthehandlesareout.

Runengineatone-thirdthrottle,withbrake

disengaged,moveleversinandraiseoffseat(but

donotgetoffofmachine)enginemustinitiate

shutdownafter1/2secondhaselapsed.

Again,runengineatone-thirdthrottle,brake

engaged,andmoveleftmotioncontrollever

in-enginemustinitiateshutdownafter1/2

secondhaselapsed.

Repeatagainmovingtherightleverin,then

movingbothleversin-enginemustinitiate

shutdownafter1/2secondhaselapsedwhether

operatorisonseatornot.

Note:Ifmachinedoesnotpassanyofthesetests,

donotoperate.ContactyourauthorizedEXMARK

SERVICEDEALER.

Important:Itisessentialthatoperatorsafety

mechanismsbeconnectedandinproper

operatingconditionpriortouseformowing.

CheckRolloverProtections

Systems(RollBar)Knobs

ServiceInterval:Beforeeachuseordaily

Checkthatboththemountinghardwareandthe

knobsareingoodworkingcondition.Makesurethe

knobsarefullyengagedwiththeROPSintheraised

position.Theupperhoopoftherollbarmayneed

tobepushedforwardorpulledrearwardtogetboth

knobsfullyengaged.

Trytostartwithoperatorinseat,parking

brakeengaged,PTOdisengaged,andtheleft

motioncontrolleverin,startermustnotcrank,

repeatagainwiththerightleverin,thenwith

bothleversin-startermustnotcrank.

2.Checkthekillcircuits.Runengineatone-third

throttle,disengageparkingbrakeandraiseoff

ofseat(butdonotgetoffofmachine)engine

mustinitiateshutdownafterapproximately1/2

secondhaselapsed(seathastimedelaykillswitch

topreventcut-outsonroughterrain).

34

Page 35

Figure23

1.Engaged2.Partiallyengaged—Do

NotoperatewithROPS

inthiscondition.

CheckSeatBelt

ServiceInterval:Beforeeachuseordaily

Visuallyinspectseatbeltforwear,cuts,andproper

operationofretractorandbuckle.Replacebefore

operatingifdamaged.

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

ServiceAirCleaner

ServiceInterval:Every250hours—Replace

theprimaryaircleaner

element—check

secondaryaircleaner

element;replaceifdirty.

(Mayneedmoreoften

undersevereconditions.

SeetheEngineOwner's

Manualforadditional

information.)

Every500hours—Replace

thesecondaryaircleaner

element(Mayneedmore

oftenundersevere

conditions.Seethe

Maintenance

EngineOwner'sManual

foradditionalinformation.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.SeetheEngineOwner'sManualformaintenance

instructions.

ChangeEngineOil

ServiceInterval:Aftertherst5hours

Every100hours/Yearly

(whichevercomesrst)

(Mayneedmoreoften

undersevereconditions.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Drainoilwhileengineiswarmfromoperation.

3.Theoildrainhoseislocatedonrighthandside

ofengineattherear.Placepanundermachine

tocatchoil.Removeplugfromendofdrain

hose.Allowoiltodrainandreplaceoildrainplug.

Torqueplugto20-24ft-lb.

4.Replacetheoilltereveryotheroilchange.Clean

aroundoillterandunscrewltertoremove.

Beforereinstallingnewlter,applyathincoating

ofExmark4–CyclePremiumEngineoilonthe

surfaceoftherubberseal.Turnlterclockwise

untilrubbersealcontactsthelteradapterthen

tightenlteranadditional1/2to3/4turn.

5.Cleanaroundoilllcapandremovecap.Fillto

speciedcapacityandreplacecap.

6.UseoilrecommendedintheCheckEngineOil

Levelsection.DoNotoverll.Starttheengine

andcheckforleaks.

7.Wipeupanyspilledoilfromenginedeck

mountingsurfaces.

CheckHydraulicOilLevel

ServiceInterval:Every50hours

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.

2.Waituntiltheunitcoolsbeforecheckingthe

hydraulicoil.

3.Slidetheseatalltheforwardtoaccessthecapson

theLHandRHhydrodrives.

4.Cleantheareaaroundhydraulicreservoircapand

removecap.

35

Page 36

Maintenance

5.Wipethedipstickcleanandre-insertthecapback

intothehydro.Lightlytightenthecap.

6.Removethecapagainandcheckthelevelofthe

oilonthedipstick.See

1.Full2.Add

Figure24foroillevels.

Figure24

Note:Theoillevelonthedipstickwillbe

incorrectiftheoilischeckedwhentheunitishot.

7.Ifthedipstickoillevelisatthe“add”markadd

ExmarkPremiumHydroOil.

8.Replacehydraulicreservoircapandtightenuntil

snug.DoNotovertighten.

2.Removeleftandrightbeltshieldsondeckandlift

upoorpantoinspectdeckdrivebelt.

3.Checkundermachinetoinspectthepumpdrive

belt.

Note:Noadjustmentsarerequiredforbelt

tension.

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lubricatettingswithonetotwopumpsof

NGLIgrade#2multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.Deckand

PumpIdler

Pivots

2.Front

Caster

Pivots

Initial

Pumps

12

*0

Numberof

Places

2

Service

Interval

Yearly

*Yearly

CheckTirePressures

ServiceInterval:Every50hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto13psi(90kPa).

4.Semi-pneumaticcastertiresDoNotneedtobe

inated.

Note:DoNotaddanytypeoftirelinerorfoam

llmaterialtothetires.Excessiveloadscreatedby

foamlledtiresmaycausefailurestothehydrodrive

system,frame,andothercomponents.Foamlling

tireswillvoidthewarranty.

CheckConditionOfBelts

ServiceInterval:Every50hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

*Seestep3forspeciallubricationinstructionson

thefrontcasterpivots.

3.Lubricatefrontcasterpivotsonceayear.Remove

hexplugandcap.Threadgreasezerkinholeand

pumpwithgreaseuntilitoozesoutaroundtop

bearing.Removegreasezerkandthreadplugback

in.Placecapbackon.

36

Page 37

Maintenance

LubricateCasterWheelHubs

ServiceInterval:Asrequired

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

Figure25

1.Sealguard2.Spacernutwithwrench

ats

2.Removecasterwheelfromcasterforks.

3.Removesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethatthread

lockingadhesivehasbeenappliedtolockthe

spacernutstotheaxle.Removetheaxle(withthe

otherspacernutstillassembledtoit)fromthe

wheelassembly.

5.Pryoutseals,andinspectbearingsforwearor

damageandreplaceifnecessary.

6.PackthebearingswithaNGLIgrade#1

multi-purposegrease.

7.Insertonebearing,onenewsealintothewheel.

Note:Seals(ExmarkP/N103-0063)mustbe

replaced.

8.Iftheaxleassemblyhashadbothspacernuts

removed(orbrokenloose),applyathreadlocking

adhesivetoonespacernutandthreadontothe

axlewiththewrenchatsfacingoutward.Do

Notthreadspacernutallofthewayontotheend

oftheaxle.Leaveapproximately1/8inch(3mm)

fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

NGLIgrade#1multi-purposegrease.

11.Insertthesecondbearingandnewsealintothe

wheel.

12.Applyathreadlockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrenchats

facingoutward.

13.Torquethenutto75-80in-lb(8-9N-m),loosen,

thenre-torqueto20-25in-lb(2-3N-m).Make

sureaxledoesnotextendbeyondeithernut.

14.Reinstallthesealguardsoverthewheelhuband

insertwheelintocasterfork.Reinstallcasterbolt

andtightennutfully .

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjusttorqueon

spacernutuntilthereisaslightamountofdrag.

Reapplythreadlockingadhesive.