Page 1

ULTRAV AC®QDS

FRONTRUNNERTMMODELS

ForUltraVacSerialNos.

720,000&Higher

PartNo.4500-274Rev.A

Page 2

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2006–2008—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

2

Contactusatwww.Exmark.com.

PrintedintheUSA.

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkUltraVacQDS.Thisproducthasbeen

carefullydesignedandmanufacturedtogiveyou

amaximumamountofdependabilityandyearsof

trouble-freeoperation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

UltraVacQDS.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourUltra

VacQDS,maintainitsmaximumefciency,and

promotesafeoperation.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready .

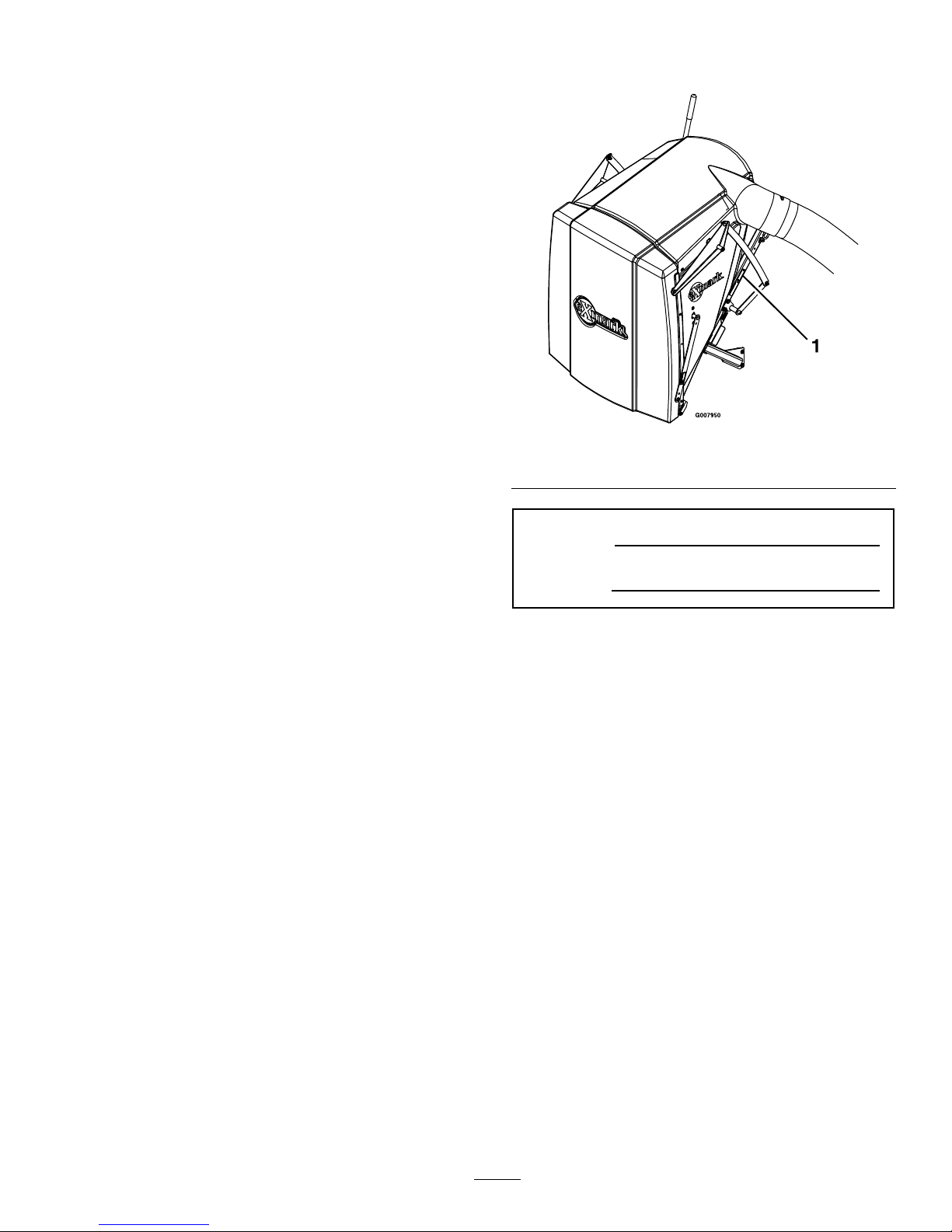

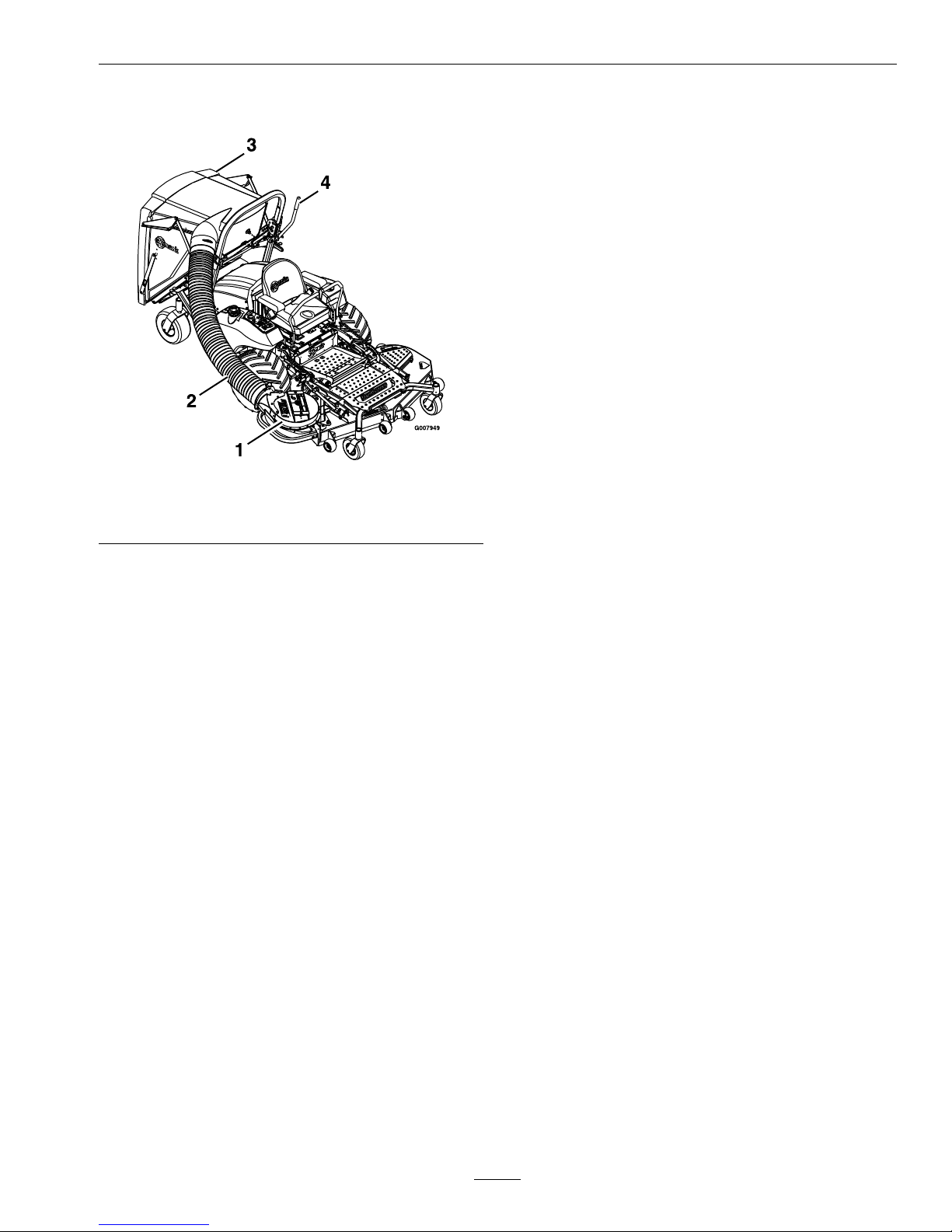

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.......................8

Specications.......................................................10

ModelNumbers............................................10

Systems.........................................................10

Dimensions...................................................10

TorqueRequirements....................................10

ProductOverview................................................11

Operation.............................................................11

Pre-Start........................................................11

OperatingInstructions..................................11

Transporting.................................................14

Maintenance.........................................................16

RecommendedMaintenanceSchedule(s)...........16

PeriodicMaintenance.......................................16

CheckBlowerHousing/Impeller...................16

LubricateGreaseFittings...............................16

CheckConditionofBelt................................17

Adjustments.....................................................18

Cleaning...........................................................19

CleanMuferandRearFrameArea................19

CleanRearScreenInHopper.........................19

CleanBlower.................................................19

Troubleshooting...................................................20

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

1.Safetyalertsymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadthetractorandUltraVacQDSOperator’s

Manualsandothertrainingmaterial.Ifthe

operator(s)ormechanic(s)cannotreadEnglish

itistheowner’sresponsibilitytoexplainthis

materialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyandsafely

performthejob.Onlyuseonmachinesapproved

byExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

Operation

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly.

5

Page 6

Safety

DANGER

Therearerotatingbladesintheblowerand

underthemowerdeck.Bladecontactcan

causeseriousoperatororbystanderinjury

orevendeath.

•DoNotreachintoblowerunlessrotation

indicatorhasstopped.DisengagePTO,

stopengine,removekey ,waitforall

movingpartstostop.engageparking

brake.

•Neveroperatemowerunlessdischarge

deector,entiregrasscollectionsystem,

ormulchkitisinstalled.

•Stopengine,waitforallmovingpartstostop,

removekeyandengageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

SlopeOperation

WARNING

Usingasingletailwheelmaycontactthe

collectionsystemandcausedifcultsteering

andreducethemachinestability.Thesingle

tailwheeltiremaycontactthebottomofthe

collectionsystemcausingdifcultsteering .

Asingletailwheelwithacollectionsystem

islessstableandapotentialtip-overcould

causeseriousinjuryordeath.

Operatemachineonlywithadualtailwheel

installed.

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Wheels

droppingoveredges,ditches,steepbanks,or

watercancauserollovers,whichmayresult

inseriousinjury,deathordrowning.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan15

degrees.

•Reducespeedanduseextremecaution

onslopes.

•Avoidsuddenturnsorrapidspeed

changes.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

(Figure3).

6

Page 7

Safety

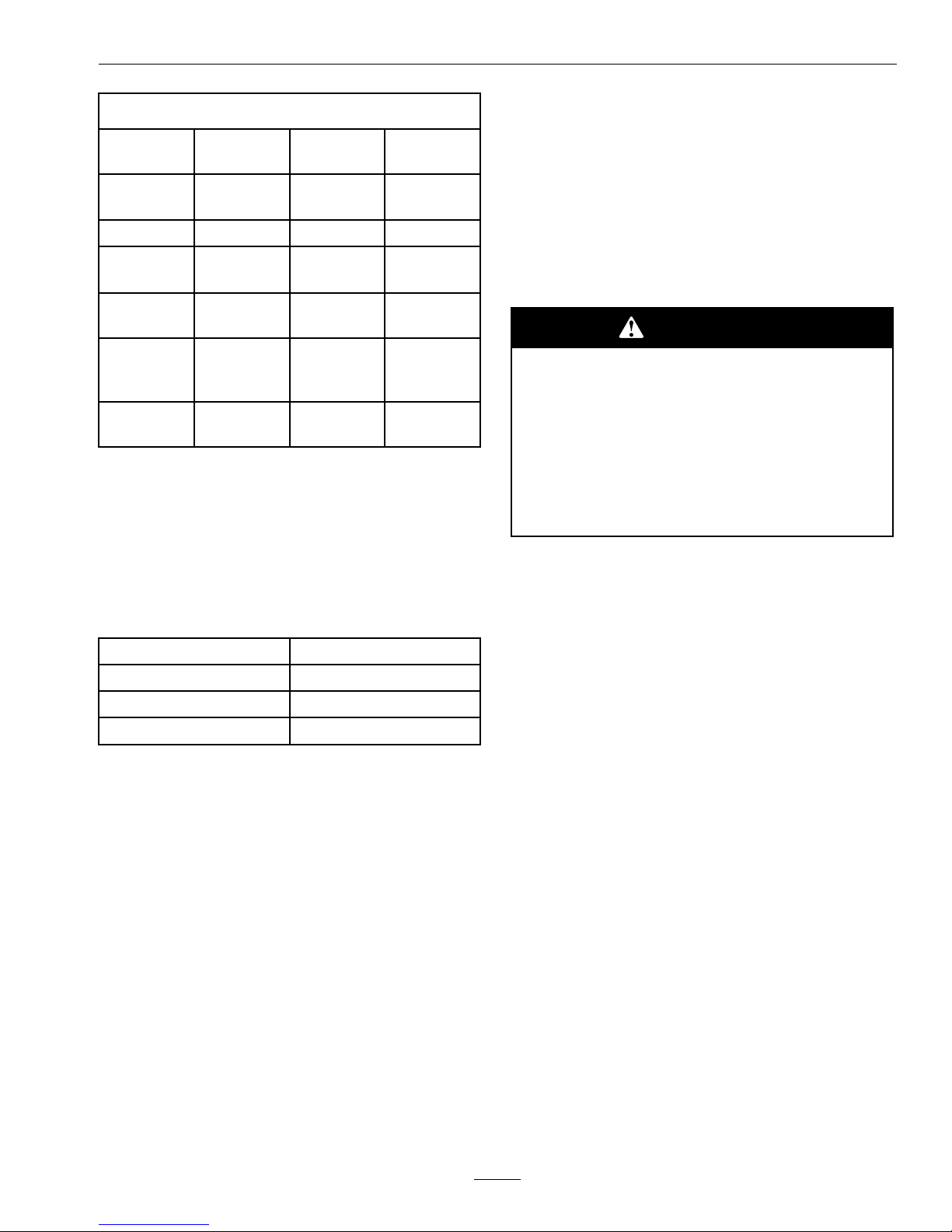

Figure3

1.SafeZone-Usethemowerhereonslopeslessthan15

degrees

2.DangerZone-Useawalkbehindmowerand/orhand

trimmerneardrop-offsandwater.

3.Water

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.W eighttransfertothefrontwheels

maycausedrivewheelstoslipandcauselossof

brakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.AlwaysinstallandremovetheUltraVac

QDS,includingcounterweights,asinstructed.

Failuretodosowillcauseareductioninstability

ortraction.DoNotoperatethemowerwithonly

aportionoftheUltraVacQDSinstalled.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.Thestability

andtractionofthemachinewillchangeasthe

UltraVacQDShopperllswithgrassclippings.

Useprogressivelygreatercareonslopesasthe

hopperlls.

MaintenanceandStorage

•Disengagedrives,setparkingbrake,stopengine

andremovekeyordisconnectsparkplugwire.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplaceblades.Neverstraightenor

weldthem.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Allreplacementpartsmustbethesameas

orequivalenttothepartssuppliedasoriginal

equipment.

7

Page 8

Safety

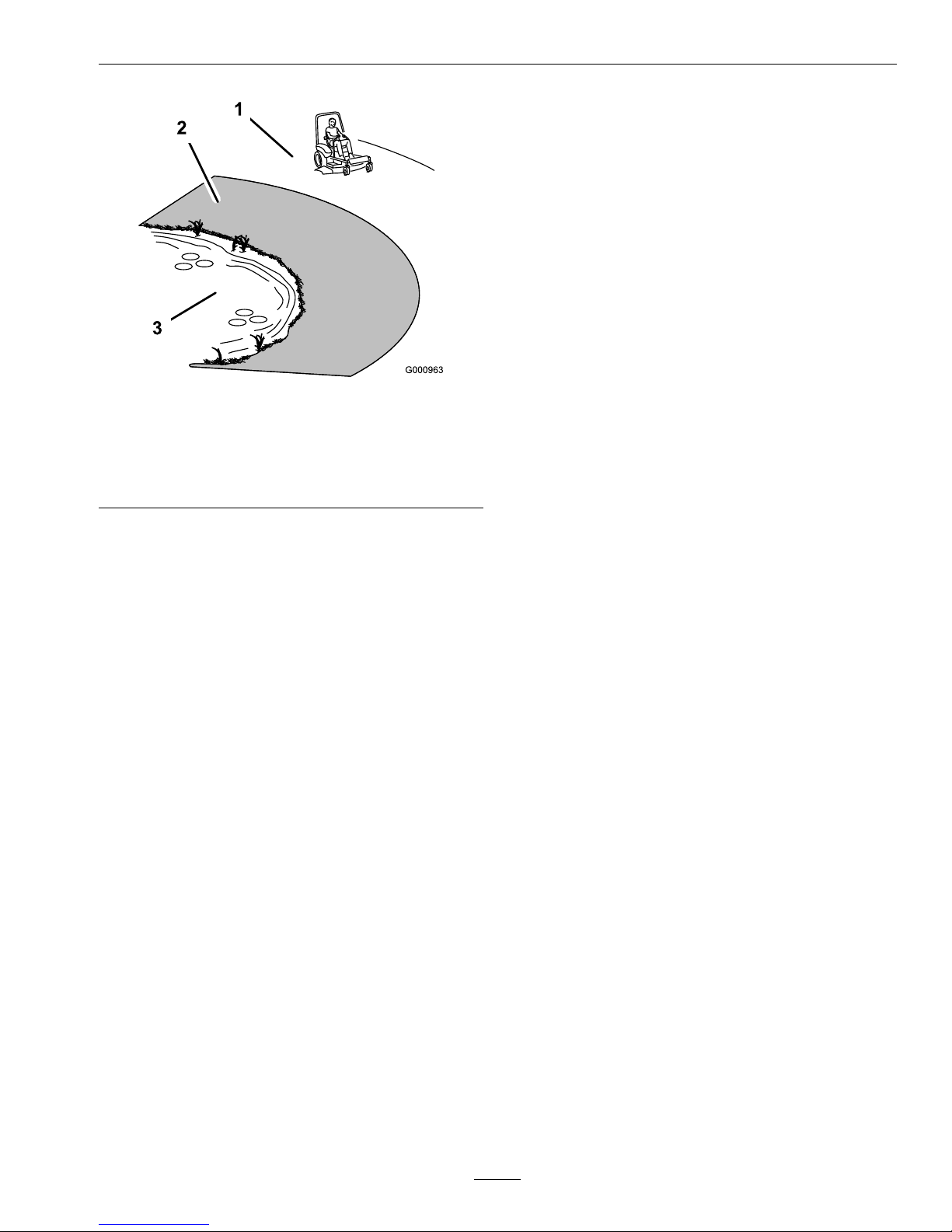

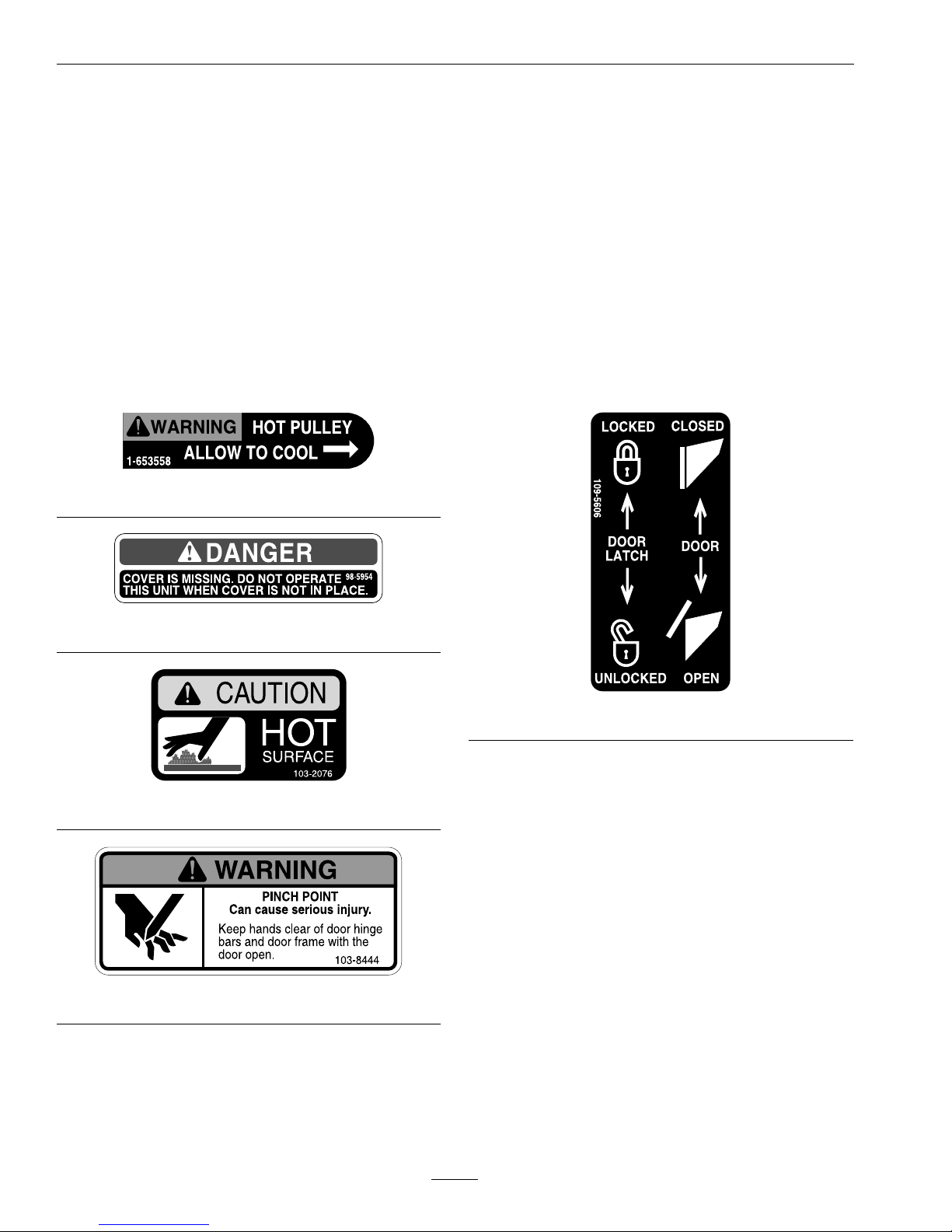

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

1-653558

98-5954

103-2076

103-8444

109-5606

8

Page 9

Safety

109-5890

9

Page 10

Specications

Specications

ModelNumbers

SerialNos:720,000andHigher

FRUVD–FitsFrontRunnerwith52,60,or72inchdecks

FRCK524–Completingkitfor52inchdeck

FRCK604–Completingkitfor60inchdeck

FRCK724–Completingkitfor72inchdeck

Note:DualtailwheelsareREQUIREDformaximumstability,clearance,andcapacity .

FRDTWK–Completekittoinstalldualtailwheels

FRDTWA–Partialkittoinstalldualtailwheels,re-usessomecomponentsfromsingletailwheel.

Systems

BaggingSystem

•CollectionHopper:

–Commercialgraderotationallymoldedplastic.

–Capacity:12.0bushels

•DumpMechanism:Manualdumpfromseat

•BlowerTube:Flexible,abrasionresistantEPDM

rubberwithpolypropylenehelix.

•Impeller:5–bladed,1/4inch(6.4mm)thick

abrasionresistantsteel,withverticalaxis.

•Impellerbearings:1inch(2.5cm)sealed

non-greaseablebearings.

Dimensions

OverallWidth:

w/UltraV acQDS

52inchDeck66.85inches(169.8cm)

60inchDeck74.44inches(189.1cm)

72inchDeck87.10inches(221.2cm)

OverallLength:

w/UltraV acQDS

52inchDeck118.21inches(300.3cm)

60inchDeck118.32inches(300.5cm)

72inchDeck121.2inches(307.8cm)

CurbWeight:

52inchDeck

264lb(119kg)

60inchDeck

265lb(120kg)

72inchDeck

265lb(120kg)

TorqueRequirements

BoltLocation

Torque

ImpellerSpindleBottom

Nut

32-40ft-lb(43-54N-m)

ImpellerSpindleT opNut75-80ft-lb(102-108N-m)

10

Page 11

Operation

ProductOverview

Figure4

1.Blower3.Hopperassembly

2.Flexibletube4.Doorhandle

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Pre-Start

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

Ensuretheblower,beltcover,exibletube,hopper,

anddoorareingoodcondition,properlyattached,

andlatched.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

Mowing

1.TheUltraVacQDSbloweroperateswhendeck

driveisengaged.Besurethatallpersonsareclear

ofthemowerdeckbeforeengagingthecutting

blades.Setthethrottleto“midway”position.Pull

outwardonthePTOswitchtothe“ROTATE”

position.Acceleratetofullthrottletobegin

mowing.

2.TodisengagethePTOandblower,setthe

throttleto“midway”position.Pushinonthe

PTOswitchtothe“STOP”positiontostopthe

cuttingbladesandblower.Thecuttingbladeswill

requireaslightlylongeramountoftimetocome

toacompletestopwhentheblowerisinstalled

onthedeck.Verifythatallrotationindicators

havestoppedbeforeclearingblowerassemblyor

mowerdeck

3.Toemptythehopper,rstshutoffdeckdrive.

Liftuponthehandletoopenthedoorandempty

thehopper.Iftheunitistobedrivenontoatruck

ortrailerwiththehopperfull,alwaysbackthe

unituptheramp.Thiswillreducethechanceof

rearwardtipup.SeetheTransportingsection

foradditionalinformationregardingloadinga

unitonatruckortrailer.

4.Closeandlatchthedoorbeforecontinuing

mowing.DoNotengagethecuttingbladeswhile

thedoorisintheopenposition.

Tipsformowingconditions:

11

Page 12

Operation

•Whenmowinginareaswithsandysoil,use

lowliftbladesonthecuttingdeckandhigher

cuttingheightstominimizewearontheblower

components.

•Whenmowinginwetconditions,suchasjustafter

arainorinheavydew ,uselowliftbladesonthe

cuttingdecktominimizepluggingoftheblower.

•Maintainingagroundspeedthatdoesnotpull

downtheengineRPMwillallowforthehighest

productivityandbestqualityofcut.Boggingthe

engineRPMdownbygoingtoofastwillcause

pluggingandqualityofcutissues.

•Whenthehoppergetfull,thesoundoftheblower

willchangeandtherewillbeslightblowoutfrom

thefrontrightcornerofthedeck.Emptyingthe

hopperatthispointwillminimizethepotential

forthetubetoplug.

BaggerRemovalforSideDischarge

1.Shutoffthedeckdrive,stopengineandwaitfor

allmovingpartstostop.Removekey.

2.Removethedischargetubebyreleasingthelock

pinattheblower.Rotateandpullthetubeaway

fromthebloweroutletadapter(seeFigure5).

Figure5

1.Hopperassembly6.Dischargechutepinand

hairpin

2.Lowerhopperlinks7.Belt

3.Alarm8.Blower

4.Decksheave9.Flexibletube

5.Beltcover

3.Removethebeltcoverbylooseningtherearknob

andremovingthefrontknob.Therearknobdoes

notneedtoberemovedcompletelytoremove

thebeltcover.

CAUTION

Thedecksheavewillbecomeveryhot.

Touchingahotdecksheavecancausesevere

burns.

Allowthedecksheavetocoolcompletely

beforeremovingthebelt.

4.Pulltheidlerreleasehandleandremovethebelt

fromtheuppergrooveofthedecksheave.

5.Unlatchthefrontendoftheblower.Pivotthe

blowerbackandliftitoffthedeck.

6.Installthedischargechuteusingthechutepivot

pinandhairpin(seeFigure6).

Figure6

Viewedfromtherightside

1.Hairpin

3.DischargeChute

2.ChutePivotPin

Note:Installchutewiththetabstotherearof

thedecktabsasshown.

WARNING

Anuncovereddischargeopeningwill

allowobjectstobethrowninoperator’sor

bystander’sdirection.Also,contactwith

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryorkillyou

orbystanders.

Neveroperatemowerunlessdischarge

deector,orentiregrasscollectionsystem,or

mulchkitisinstalled.

12

Page 13

Operation

7.Re-installtheplasticbeltcoverandtightenthe

knobs.

8.Unplugthewiringforthellsensoratthefront

ofthehopper.Secureloosewireharnessby

routinglooseendpartiallybackdownROPStube.

9.Removethehairpinsandclevispinsholdingthe

hopperassemblytotheROPSweldment.

10.Rotatethehopperassemblyrearwarduntilthe

backofthedoorrestsontheground.Remove

thehairpinsholdingthelowerhopperlinksto

thelowerframemount(Figure7).

11.Thebracketboltedtotherearoftheframeatthe

ROPSremainsontheunit

Note:TheportionsoftheFrontRunnerUltra

Vacthatarenotboltedtothemoweraredesigned

tobeinstalledorremovedintheirentirety.Failure

todosowillcauseareductioninstabilityor

traction.DoNotoperatethemowerwithonlya

portionoftheFrontRunnerUltraVacinstalled.

12.Themachinecannowbeusedforsidedischarge

mowing.

BaggerInstallationforBagging

1.Stopengine,removekey ,andwaitforallmoving

partstostop.

2.Removehairpinandchutepivotpin.Remove

dischargechute.Pivotpinandhairpinmaybe

storedinthepivotholesofthedischargechute

duringbaggingoperation.

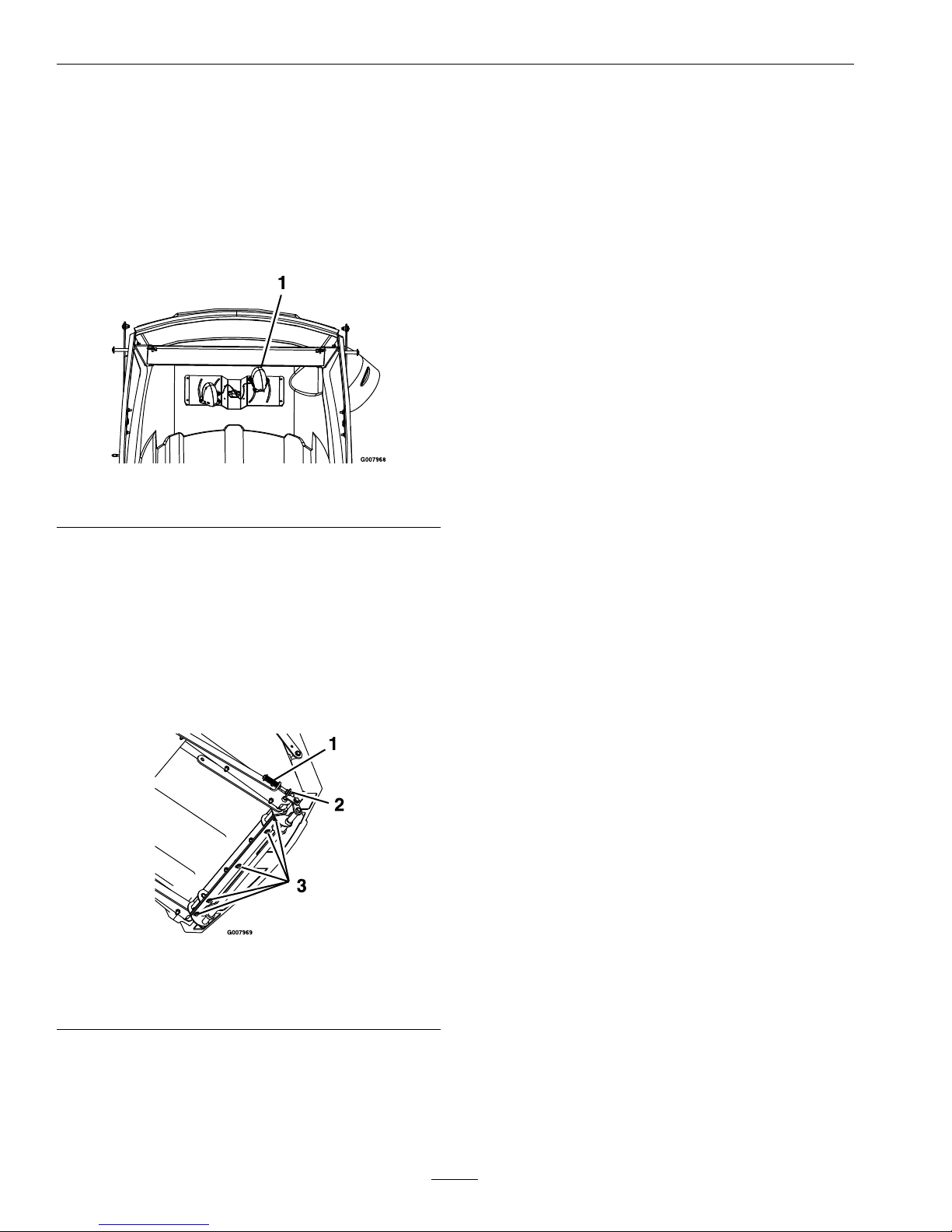

3.Laythehopperassemblyonthedoorasshownin

(seeFigure7).

Figure7

1.Secureinthislocation

3.Hopperassembly

2.Lowerlinks

4.Installthehopperassemblyontothemountby

rotatingthelowerhopperlinksforwardand

slippingthemoverthepinsofthelowermount

weldment.Securethelowerlinkstothemount

usingthehairpins.

5.Liftandrotatethehopperassemblyupandalign

theupperpinholeswiththeholesintheROPS

mount.InstalltheupperpinsthroughtheROPS

platesandhopperframetubes.Securetheupper

pinswiththeattachedhairpins.

Figure8

1.Rotatehopperassembly2.Hopperassembly

6.Mountthebloweronthedeckbyslidingthe

mountingpinintothetubeattherearrightcorner

ofthedeck.Swingtheblowerclosed.Adjustthe

positionofthefrontpintoengagetheslotinthe

frontofthedeck.Usethelatchtolocktheblower

inthisposition.Adjustthetensiononthelatch

toholdthebloweruptothedeck,yetallowfor

releasebyhand.

7.Removetheplasticbeltcover.Pullthespring

loadedidlerbackandslipthebeltoverthetop

spindledecksheave.

8.Installtheplasticbeltcover.Therearofthecover

isslottedandcanslipbehindtheplasticknobon

thebeltshieldstud.Theplasticknobdoesnot

needtoberemoved.Thefronthorizontalplastic

knobfortheplasticbeltcovermustbeinstalled

afterthecoverhasbeenpositioned.

Thefrontverticalplasticknobontheoriginal

steelbeltcovercanbeusedforplasticbeltcover.

9.Thehopperinlethasribstoengagethespiral

reinforcementoftheexibletube.Usingamarker

orpaintpen,marktheexibletubeapproximately

4inchesfromtheend.Inserttheendofthe

tubeintothehopperinlet,androtateclockwise

toengage.Rotateandthreadthetubeintothe

hopperinletuptothe4inchmark.Itmaybe

easierto“push”thetubeintotheinletratherthan

rotating(Figure9).

13

Page 14

Operation

Figure9

1.Hopper3.Flexibletube

2.Rotateclockwiseto

engage

10.Slidethelowerendofthetubeassemblyontothe

bloweroutletadapterandrotatetolockinplace.

Installthelockpinthroughthetubeandblower

adapter.

Figure10

1.Lockpin2.Rotatetolock

Note:TheportionsoftheUltraVacthatarenot

boltedtothemoweraredesignedtobeinstalled

orremovedintheirentirety.DoNotoperate

themowerwithonlyaportionoftheUltraVac

installed.

Transporting

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Securely

fastenthemachinetothetrailerortruckwithstraps,

chains,cable,orropes.Besurethatthetrailerortruck

hasallnecessarylightingandmarkingasrequiredby

law .Secureatrailerwithasafetychain.

CAUTION

Thisunitdoesnothaveproperturn

signals,lights,reectivemarkings,ora

slowmovingvehicleemblem.Drivingona

streetorroadwaywithoutsuchequipment

isdangerousandcanleadtoaccidents

causingpersonalinjury.Drivingonastreet

orroadwaywithoutsuchequipmentmayalso

beaviolationofStatelawsandtheoperator

maybesubjecttotrafcticketsand/ornes.

DoNotdriveaunitonapublicstreetor

roadway.

WARNING

Loadingaunitonatrailerortruckincreases

thepossibilityoftip-over.Tip-overcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

unitonaramp.

•Useonlyasingle,fullwidthramp;Do

Notuseindividualrampsforeachside

oftheunit.

•Ifindividualrampsmustbeused,use

enoughrampstocreateanunbroken

rampsurfacewiderthantheunit.

•DoNotexceeda15°anglebetweenramp

andgroundorbetweenrampandtrailer

ortruck.

•Avoidsuddenaccelerationwhiledriving

unitonaramp.

LoadingaUnit

Iftheunitistobedrivenontoatruckortrailer

withthehopperfull,alwaysbacktheunitupthe

ramp.Thiswillreducethechanceofrearward

tipup.Useextremecautionwhenloadingunits

ontrailersortrucks.Onefullwidthrampthatis

wideenoughtoextendbeyondthereartiresis

recommendedinsteadofindividualrampsforeach

sideoftheunit.Thelowerrearsectionofthetractor

frameextendsbackbetweentherearwheelsand

servesasastopfortippingbackward.Havingafull

widthrampprovidesasurfacefortheframemembers

tocontactiftheunitstartstotipbackward.Ifitis

14

Page 15

Operation

notpossibletouseonefullwidthramp,useenough

individualrampstosimulateafullwidthcontinuous

ramp.

Rampshouldbelongenoughsothattheangles

betweentherampandthegroundandtherampand

thetrailerortruckDoNotexceed15°.Asteeper

anglemaycausemowerdeckcomponentstoget

caughtastheunitmovesfromramptotraileror

truck.Steeperanglesmayalsocausetheunittotip

backward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideofthe

slopeandtherampextendsuptheslope.Thiswill

minimizetherampangle.Thetrailerortruckshould

beaslevelaspossible.

Important:DoNotattempttoturntheunit

whileontheramp,youmaylosecontroland

driveofftheside.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdownaramp.

Bothmaneuverscancausetheunittotipbackward.

Dumpcontentsofhopperbeforetransport.DoNot

transporttheunitwiththehopperfull.

15

Page 16

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)aside

soitdoesnotaccidentallycontactthespark

plug(s).

WARNING

Theenginecanbecomeveryhot.Touching

ahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Beforeeachuseordaily

•Checktheblowerhousing/impeller.

•Cleanmuferandrearframearea.

•Cleanrearscreeninthehood.

Every25hours

•Lubricategreasettings.

Every50hours

•Checkconditionofbelt.

Yearlyorbeforestorage

•Cleanblower.

PeriodicMaintenance

CheckBlower

Housing/Impeller

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Inspectforwearordamagedaily.Replaceor

repairwornpartsasneeded

Note:Whenmowinginareaswithsandysoil,

uselowliftbladesonthecuttingdeckandhigher

cuttingheightstominimizewearontheblower

components.

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.LubricatettingswithNGLIgrade#2

multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

Initial

Pumps

Numberof

Places

Service

Interval

1.Blower

Housing/

Impeller

——

Daily

16

Page 17

Maintenance

LubricationChart

Fitting

Locations

Initial

Pumps

Numberof

Places

Service

Interval

2.Idler

Bushings

1–21

25Hours

3.Belts

——

50Hours

4.Mufer/

RearFrame

——

Daily

5.Hopper

Screen

——

Daily

6.Flexible

Discharge

Tube

——

Daily

7.Fill

Sensor

——

Daily

CheckConditionofBelt

ServiceInterval:Every50hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Inspectthebeltfordamageorwear.Replacebelt

withoneofthefollowing:

Deck

PartNo.

52inchDeck

109-4948

60inchDeck

103-0866

72inchDeck

103-0867

3.Inspectthebeltpositionontheidlerarm.

Theidlerarmmaybecomebentduringuseor

transport.Abentidlerarmcouldcausethebelt

tojumpoffoftheidlerandbedamaged.

A.Makesurethebeltcoverisinstalledandrun

theblowerforonetotwominutes.

B.Shutoffthedeckdrive,stopengine,wait

forallmovingpartstostopandremovekey .

Engageparkingbrake.Removethebeltcover

andchecktomakesurethatthebeltisriding

nearthecenteroftheatidlerontheidler

arm.

C.Ifthebeltisnotridingnearthecenterofthe

idler,removetheblower,andbendtheidler

armslightly.

Note:Idlerstillneedstoclearthedeck

stiffenerduringoperation.

D.Reinstalltheblowerandbeltcoverandrepeat

stepsAthroughCuntilthebeltispositioned

nearthecenteroftheidler.

FlexibleDischargeTube

ServiceInterval:Asrequired

Inspecttheexibledischargetubeforwearor

damage.

WARNING

Undernormalusetheexibledischargetube

willwear.Objectscouldexitawornexible

dischargetubeathighspeeds.Thrown

objectscancauseseriousinjuryorkillyou

orbystanders.

Checktheexibledischargetubefortears

andholes.Replacewornexibledischarge

tube.

FillSensor

ServiceInterval:Asrequired

Thellsensorislocatedatthefrontofthehopper,

andiswiredintothePTOcircuit.Whengrasslls

thehopperenoughtoblockoneorbothsensors,

analarmwillsound.Thellsensortestingmustbe

madewiththePTOengaged,buttheenginedoes

nothavetoberunning.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Unlatchthedoorandpullthedoorhandle

engagementpintoraisethedoortothetopofthe

hopper(seeFigure13).

3.Reachintothehopperandplaceapieceof

maskingorducttapeovertheLHsensor.

4.Closethedoor.

5.SitintheseatandturnthekeytotheRUN

position,butDONOTSTARTtheunit.

6.PulluponthePTOswitchtoengagepowertothe

clutch;youshouldhearaclickfromtheclutch.

7.Thereisasplitseconddelaybeforethellsensor

alarmwillsound.

8.Repeatsteps2through4toremovethetapefrom

thesensor.

17

Page 18

Maintenance

Adjustments

Note:TheUltraVacQDSwasadjustedatthefactorytooperateproperly.However,therearethreebasic

adjustmentsthatcanbemade,shouldyourunitrequirethem:

1.Fillsensors:Locatedinsidethehopper,they

soundanalarmwhenthehopperisfull.Theycan

beadjustedforvaryinggrassconditionsthatll

thehopperdifferently(seeFigure11).

Figure11

1.Fillsensor

MovingtheLHsensorupworksbetterinwetter

conditions.

MovingtheLHsensordownworksbetterin

dryerconditions.

2.Latches:Thelatches(Figure12)canbeadjusted.

Withthedoorclosed,thelatchplateshouldbe

setsothatthelatchcamscompletelyengageand

contactthelatchplatesboltedtothedoor.

Figure12

1.Over-centerspring3.Theseveboltsadjust

thelatchcamweldment

2.Whizlocknuts

3.Latchhandlelink:Thelatchhandleneedstobe

abletosnapover-centertokeepthelatchcams

tightagainstthedoorlatchplatesandthedoor

pulledshut.Thelengthofthelatchlinkageis

controlledbythetwowhizlocknutsoneitherside

ofthelatchlink(Figure12).Thewhizlocknuts

shouldbeadjustedsothatreasonableforceon

thehandleisrequiredtoover-centerandlatch

thedoor.DoNotadjustsothattheover-center

springcollapsescompletelywhenthedoorisfully

latched.

18

Page 19

Maintenance

Cleaning

CleanMuferandRear

FrameArea

ServiceInterval:Beforeeachuseordaily

Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

WARNING

Operatingengineparts,especiallythe

mufer,becomeextremelyhot.Severeburns

canoccuroncontactanddebris,suchas

leaves,grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,

brush-coveredunimprovedland.

CleanRearScreenInHopper

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Openhopperdoorbyremovingpinsasshown

andremoveclippingsthatarestucktoscreenas

showninFigure13.Screencanberemovedby

removingpinsatrearofscreen.

Figure13

1.Putpinhereforstorage3.Screen

2.Pin

CleanBlower

ServiceInterval:Yearlyorbeforestorage

Grassbuildupmaycauseproblemswiththeimpeller

whentheunitisputbackintooperation.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Removegrassbuildupfromaroundtheimpeller

beforeplacingitinstorage.

19

Page 20

Troubleshooting

Troubleshooting

Important:Itisessentialthatalloperatorsafetymechanismsbeconnectedandinproperoperating

conditionpriortomoweruse.

Whenaproblemoccurs,DoNotoverlookthesimplecauses.Forexample:startingproblemscouldbe

causedbyanemptyfueltank.

Thefollowingtablelistssomeofthecommoncausesoftrouble.DoNotattempttoserviceorreplacemajor

itemsoranyitemsthatcallforspecialtimingoradjustmentprocedures(suchasvalves,governor,etc.).Have

thisworkdonebyyourEngineServiceDealer.

Note:WhendisconnectingelectricalconnectorsDoNotpullonthewirestoseparatetheconnectors.

ProblemPossibleCauseCorrectiveAction

1.Cuttingblade(s)is/arebentorunbalanced.

1.Installnewcuttingblade(s).

2.Blademountingboltisloose.2.Tightentheblademountingbolt.

3.Looseblowerpulleyorpulleyassembly.

3.Tightentheappropriatepulley .

Abnormalvibration.

4.Blowerimpellerbladesarebent.4.ContactanAuthorizedServiceDealer.

Blowerdrivebeltsnapsorbreaksfrequently.

1.Idlerarmisoutofalignment.1.Correctthealignmentoftheidlerarm.

1.Hopperisfull.1.Dumpmorefrequently.

2.Pluggedscreeninbaggerhood.2.Removedebris,leavesorgrassclippings

fromthescreen.

3.Groundspeedistoofast.

3.Drivesloweratfullthrottle.

4.Blowerbeltisworn,loose,orbroken.4.Installnewblowerbelt.

5.Pluggedtubeorblower.5.Locateandremovepluggeddebris.

Excessivegrassblowoutfromthedeck.

6.Conditionsaredry.6.Uselowerliftblade.

1.Hopperistoofull.1.Dumpmorefrequently

2.Groundspeedistoofast.

2.Drivesloweratfullthrottle.

3.Grassistoowet.

3.Cutgrasswhenitisdry.

4.Grassistoolong.4.Cutgrassmorefrequentlyorathighercut

height.

5.Pluggedscreeninbaggerhood.5.Removedebris,leaves,orgrassclippings

fromthescreen.

6.Blowerdrivebeltisworn,loose,or

broken.

6.Installnewbelt.

Blowerandtubesplugtoofrequently.

7.Blowerisplugged.7.Uselowliftbladesinwetconditions.

1.Pluggedblower.1.Removedebris,leaves,orgrassclippings

fromtheblowerimpeller.

Blowerimpellerdoesnotspinfreely.

2.Impellernotaligned.2.ContactanAuthorizedServiceDealer.

Plowingleaves.

1.Deckistoolow.

1.Raisethedeckslightly.

Chasingleaves.

1.Blowoutfromdeck.1.Installananti-blowoutkit–contactan

AuthorizedServiceDealer.

Blowercomponentsshowsignsofwear

and/oraircleanersandcoolingnsaredirty.

1.Sandordryconditions.1.Uselowliftbladesonthecuttingdeckand

highercuttingheights.

20

Page 21

Conditions and Products Covered

Exmark Mfg. Co. Inc. and its affiliate, Exmark Warranty

Company, pursuant to an agreement between them, jointly

warrant on the terms and conditions herein, that we will repair,

replace or adjust any part manufactured by Exmark and found

by us (in the exercise of our reasonable discretion) to be

defective in factory materials or workmanship for a period of

two years.

This warranty applies to Exmark turf equipment purchased on

or after October 1, 2004 sold in the US or Canada. This

warranty may only be assigned or transferred to a second (or

third) owner by an authorized Exmark dealer. The warranty

period commences upon the date of the original retail

purchase.

Products Warranty Period

• All Products (except as noted below) 2 years

• All Attachments and Accessories 1 year

• Metro 21 and Metro 26 Series 1 year

• Belts and Tires 90 days

• Battery 1 Year Prorated

• Engine* Warranty is covered by engine manufacturer

* Please refer to the engine manufacturer’s warranty statement

that is included in the literature packet. We are not authorized

to handle warranty adjustments on engines.

This warranty only includes the cost of parts and labor.

Items and Conditions Not Covered

This warranty does not cover the following:

• Pickup and delivery charges to and from any authorized

Exmark Service Dealer beyond first warrantable service.

• Any damage or deterioration due to normal use, wear and

tear, or exposure.

• Cost of regular maintenance service or parts, such as filters,

fuel, lubricants, tune-up parts, and adjustments.

• Any product or part which has been altered or misused or

required replacement or repair due to normal wear,

accidents, or lack of proper maintenance.

• Any repairs necessary due to use of parts, accessories or

supplies, including gasoline, oil or lubricants, incompatible

with the turf equipment or other than as recommended in

the operator's manual or other operational instructions

provided by Exmark.

There are no other express warranties except for engine and

special emission system coverage stated elsewhere herein or

included with the product.

All warranty work must be performed by an authorized

Exmark Service Dealer using Exmark approved replacement

parts.

Instructions for Obtaining Warranty Service

The product must be registered with original proof of purchase

by an Exmark Service Dealer before obtaining any warranty

service.

Contact any Exmark Service Dealer to arrange service at their

dealership. To locate a dealer convenient to you, access our

website at www.exmark.com. U.S. Customers may also call

402-223-6375.

If for any reason you are dissatisfied with the Service Dealer’s

analysis or with the assistance provided, contact us at:

Exmark Customer Service Department

The Exmark Warranty Company

2101 Ashland Avenue

Beatrice, NE 68310

402-223-6375 or

service@exmark.com

Owner’s Responsibilities

The Exmark turf equipment, including any defective part,

must be returned to an authorized Exmark service dealer

within the warranty period. This warranty extends only to turf

equipment operated under normal conditions. You must read

the operator’s manual. You must also properly service and

maintain your Exmark product as described in the operator’s

manual. Such routine maintenance, whether performed by a

dealer or by you, is at your expense.

General Conditions

The sole liability of Exmark and Exmark Warranty Company

with respect to this warranty shall be repair and replacement

of defective components as set forth herein. Neither Exmark

nor Exmark Warranty Company shall have any liability

for any other cost, loss or damage, including but not

limited to, any incidental or consequential loss or damage.

In particular, we shall have no liability or responsibility for:

• Expenses related to gasoline, oil or lubricants.

• Travel time, overtime, after hours time or other

extraordinary repair charges or charge relating to repairs or

replacements outside of normal business hours at the place

of business of the authorized Exmark Service Dealer.

• Rental of like or similar replacement equipment during the

period of any warranty, repair or replacement work.

• Any telephone or telegram charges or travel charges.

• Loss or damage to person or property other than that

covered by the terms of this warranty.

• Any claims for lost revenue, lost profit or additional cost as

a result of a claim of breach of warranty.

• Attorney's fees.

No Claim of breach of warranty shall be cause for cancellation

or rescission of the contract of sale of any Exmark mower.

Some states do not allow exclusions of incidental or

consequential damages, so the above exclusions and

limitations may not apply to you.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

2-Year Limited Warranty

Exmark Turf Equipment

(For units purchased on or after October 1, 2004)

G006117

21

Page 22

ServiceRecord

Date:

DescriptionofWorkDone:ServiceDoneBy:

22

Page 23

23

Page 24

MI D-MO UNT RIDI NG ACCESSORIES

SEE EXMARK’S COMPLETE LINE OF ACCESSORIES

WALK-BEHIND ACCESSORIES

GRASS CATCHER

LAZERLOCKER

MICRO-MULCH SYSTEM

TURF STRIPER

STANDON

CUSTOM RIDE SEAT SUSPENSION SYSTEM

DECK LIFT ASSIST KIT

HITCH KIT

LAZERLOCKER

LIGHT KIT

MICRO-MULCH SYSTEM

OPERATOR CONTROLLED DISCHARGE

ROLL OVER PROTECTION SYSTEM (ROPS)

SNOW BLADE

SUN SHADE

TRASH CONTAINER

TURF STRIPER

ULTRA VAC COLLECTION SYSTEM

ULTRA VAC QUICK DISPOSAL SYSTEM

OU T-FRONT RIDING AC CESS ORIE S

CUSTOM RIDE SEAT SUSPENSION SYSTEM

DUAL-TAIL WHEEL

FLOOR PAN EXTENDER

HITCH KIT

LIGHT KIT

MICRO-MULCH SYSTEM

ROLL OVER PROTECTION SYSTEM (ROPS)

ROTARY BROOM

SNOW BLADE

SNOWBLOWER

SUN SHADE

TRASH CONTAINER

ULTRA VAC COLLECTION SYSTEM

ULTRA VAC QUICK DISPOSAL SYSTEM

WEATHER CAB

PlaceModelNo.andSerialNo.

LabelHere(IncludedintheLiterature

Pack)orFillinBelow

DatePurchased

ModelNo.

SerialNo.

©2006–2008ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

AllRightsReserved

PartNo.4500-274Rev.A

(402)223-6300

Fax(402)223-5489

PrintedintheUSA.

www.exmark.com

Loading...

Loading...