Page 1

COMMERCIAL21

ForSerialNos.

850,000&Higher

PartNo.4500-674Rev.A

Page 2

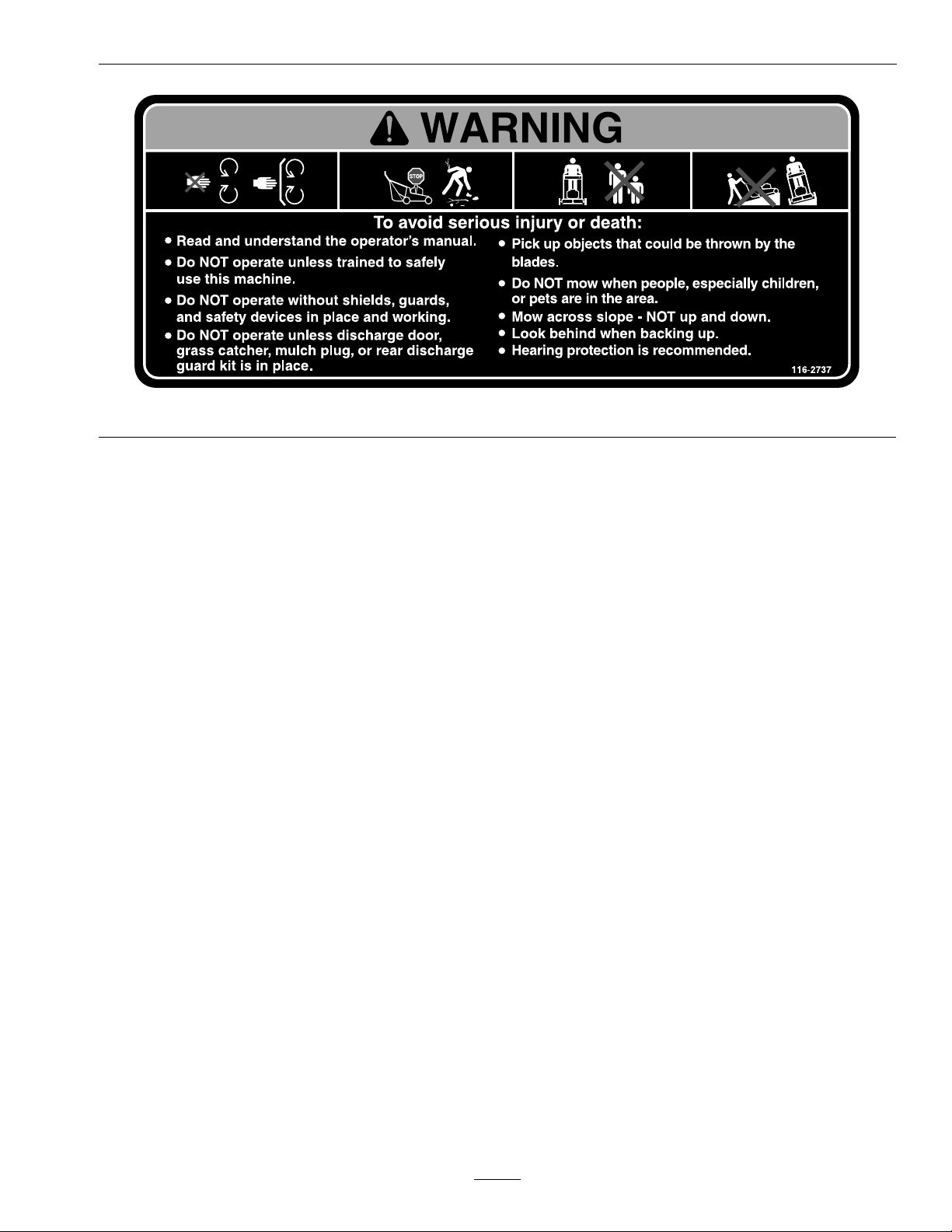

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,or

otherreproductiveharm.

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

(CPRC)Section4442touseoroperatethis

engineonanyforest-covered,brush-covered,or

grass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilar

laws.

Toacquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

ThissparkignitionsystemcomplieswithCanadian

ICES-002Cesystèmed’allumageparètincellede

vèhiculeestconformeàlanormeNMB-002du

Canada.

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EP A)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately .

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2010—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency ,andpromotesafe

operation.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

Exmarkpartsmanualsareavailableonlineat

http://www.exmark.com/manuals.htm.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

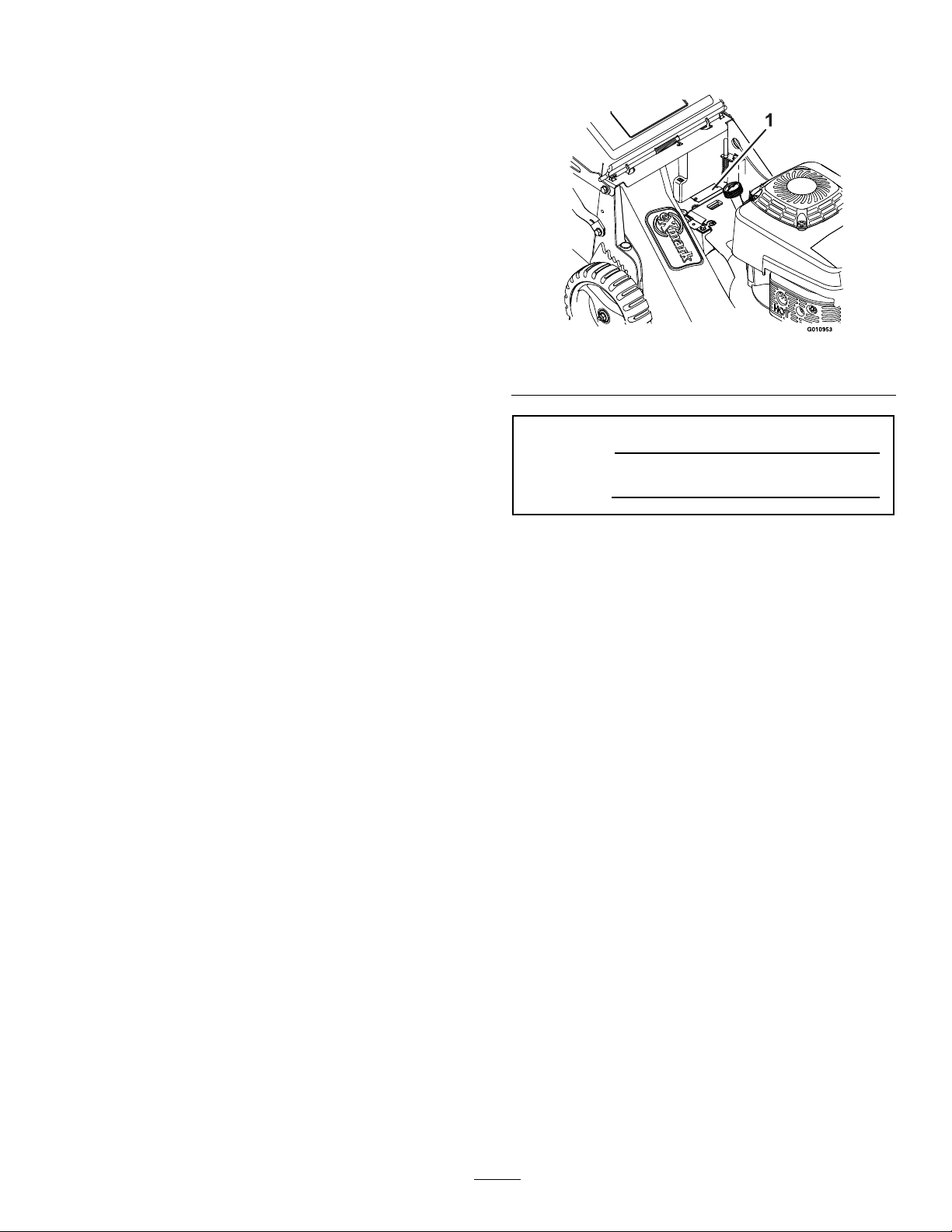

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.......................9

Specications.......................................................12

ModelNumbers............................................12

Systems.........................................................12

Dimensions...................................................12

ProductOverview................................................13

Operation.............................................................13

Controls........................................................13

Pre-Start........................................................15

OperatingInstructions..................................15

Maintenance.........................................................22

RecommendedMaintenanceSchedule(s)...........22

PeriodicMaintenance.......................................23

CheckEngineOilLevel.................................23

CheckingtheBladeBrakeClutch(Blade

BrakeClutchOnly)....................................23

ChecktheMowerBlade.................................24

CheckforLooseHardware............................25

ChecktheBladeBrakeClutchBail

Operation(BladeBrakeClutchUnits

Only).........................................................25

ServiceAirFilter(KawasakiUnits).................26

ServiceAirFilter(EC21ASHNUnits)............26

ServiceAirFilter(EC21HNBBCand

EC21HNBBCXUnits)..............................27

ChangeEngineOil........................................28

ChangeOilFilter(EC21KA,

EC21KABBC,EC21KAX,

EC21KAY,EC21KABBCX,

EC21KABBCY ,EC21KACA,and

EC21KABBCCA).....................................29

CheckConditionOfBelt(Self-Propelled

UnitsOnly)...............................................29

CheckSparkPlugs.........................................29

EmptyingtheFuelTankandCleaningthe

FuelFilter..................................................29

Adjustments.....................................................30

AdjustingtheSelf-PropelDrive

(Self-PropelledUnitsOnly)........................30

AdjustingtheBladeBrakeCable(Blade

BrakeClutchUnitsOnly)...........................31

Cleaning...........................................................32

CleanGrassBuild-UpUnderDeck................32

CleaningtheDischargeTunneland

Plug...........................................................32

CleaningUndertheBeltCover

(Self-PropelledUnitsOnly)........................33

CleaningtheBladeBrakeClutchShield

(BladeBrakeClutchUnitsOnly)................33

CleaningUndertheCoverPlate

(Non-BladeBrakeClutchUnits

Only).........................................................33

WasteDisposal..............................................34

Storage.................................................................35

PreparingtheFuelSystem..............................35

PreparingtheEngine.....................................35

GeneralStorageInformation.........................35

RemovingtheLawnMowerfrom

Storage......................................................35

Troubleshooting...................................................36

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThislawnmowermeetsorexceedstheConsumer

ProductSafetyCommissionbladesafety

requirementsforwalk-behindrotarymowersand

theB71.4specicationsoftheAmericanNational

StandardsInstituteineffectatthetimeofproduction.

Exmarkdesignedandtestedthislawnmowertooffer

reasonablysafeservice;however,failuretocomply

withthefollowinginstructionsmayresultinpersonal

injury.

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

1.Safetyalertsymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

amower,andevenmatureteenagersshouldhave

adultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator’s

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

mowerwithouttakingrisks.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

5

Page 6

Safety

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsinanopen

area,whentheengineiscold.Wipeup

anygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletely

full.Addgasolinetothefueltankuntil

thelevelis1/4to1/2inch(6–13mm)

belowthebottomofthellerneck.This

emptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,

andstayawayfromanopenameor

wheregasolinefumesmaybeignitedby

spark.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.

Neverremovethecapofthefueltankor

addfuelwhenengineisrunningorwhen

theengineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperator’spresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly .DoNotoperateunlessthey

arefunctioningproperly .

6

Page 7

Safety

Operation

WARNING

Operatingengineparts,especiallythe

mufer,becomeextremelyhot.Severeburns

canoccuroncontactanddebris,suchas

leaves,grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Starttheenginecarefullyaccordingtoinstructions

withfeetwellawayfromtheblade.

•Neverraisedeckwithbladesrunning.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowwithoutthedischargedoor.DoNot

operateunlessthedischargedoor,grasscatcher,

mulchplug,orreardischargechutekitareinplace

andworkingproperly.

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.

Frequentlycheckthecomponentsandreplace

themwiththemanufacturer’srecommendedparts

whennecessary.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Neverattempttomakewheelheightadjustments

whiletheengineisrunning.

•Stopengine,waitforallmovingpartstostop,

removethesparkplugwire(s).

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

–Beforemakingheightadjustments.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•Keepclearofthedischargeopeningatalltimes.

•Thismowerwasdesignedforoneoperator

only.Keepallothersawayfrommowerduring

operation.

•DONOToperatethemowerwhenpeople,

especiallychildren,orpetsareinthearea.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

7

Page 8

Safety

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Lossof

controland/orlossofoperator’sfooting

couldresultinafallwithanarmorleg

gettingunderthemowerorenginedeck

whichmayresultinseriousinjury,deathor

drowning.

•Mowacrossslopes,neverupanddown.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowexcessivelysteepslopes.

•Reducespeedanduseextremecaution

onslopes.

•Avoidsuddenturnsorrapidspeed

changes.

•Whenfeasible,avoidoperatingtheequipmentin

wetgrass.

•Progressivelygreatercareisneededastheslope

increases.

MaintenanceandStorage

•Stoptheengineandremovethesparkplug

wire(s).Waitforallmovementtostopbefore

adjusting,cleaningorrepairing.

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•LetenginecoolbeforestoringandDoNotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Removesparkplugwirebeforemakingany

repairs.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Allreplacementpartsmustbethesameas

orequivalenttothepartssuppliedasoriginal

equipment.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

8

Page 9

SafetyandInstructionalDecals

Safety

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

68-7410

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

103-6328

EC21KABBCX

1.Choke4.Slow

2.Fast5.Engine—stop

3.Continuousvariable

94-8072

setting

109-8191

EC21KABBC,EC21KAY,EC21KA,EC21KABBCCA,

EC21KACA,EC21KAX,EC21KABBCY

9

Page 10

Safety

1.Fast

2.Continuousvariable

109-8194

EC21KABBCY ,EC21KABBCCA

3.Slow

4.Engine—stop

setting

116-1922

109-9317

116-2685

117-2718

116-1900

10

Page 11

Safety

116-2737

11

Page 12

Specications

Specications

ModelNumbers

SerialNos:850,000andHigher

EC21ASHN;EC21ASKA;EC21ASKAP;EC21HNBBC;EC21HNBBCX;EC21KA;EC21KACA;EC21KAX;

EC21KAY;EC21KABBC;EC21KABBCCA;EC21KABBCX;EC21KABBCY

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•RPM:3000(NoLoad):EC21ASHN

•RPM:3300(NoLoad):Allunitsexcept

EC21ASHN

FuelSystem

•Capacity:

EC21ASHN,EC21KACA,EC21KABBCCA,

EC21ASKAandEC21ASKAPUnits:

2.0qt(1.9L)

Allotherunits:4.0qt(3.8L)

•TypeofFuel:Regularunleadedgasoline,87

octaneorhigher;containingnomorethan10%

methanolorethanol.

CuttingDeck

•CuttingWidth:21inches(53.3cm)

•BladeBrake:Whenthebladeengagementcontrol

ismovedtothedisengagedpositionafriction

brakepadstopstherotationoftheblades.

•BladeSize:(1ea.):20.88inches(53.0cm)

•Deck:21inchesrigid.Deckdesignallowsfor

bagging,mulchingorreardischarge.

•CuttingHeightAdjustment:

Adjustsfrom1inch(2.5cm)to41/2inches(11.4

cm)in1/2inch(1.3cm)increments.

•MulchingKit:StandardonEC21KA,

EC21KABBC,EC21HNBBC,EC21KACA,

EC21KABBCCA,EC21KAX,EC21KAY,

EC21KABBCX,andEC21KABBCYUnits

•RearDischargeKit:Optional

Dimensions

•FuelFilter:Non-replaceable,intank

•FuelShut-OffValve:

EC21KACA,EC21KABBCCA,EC21ASKAand

EC21ASKAPUnitsDoNothaveashut-offvalve.

Allotherunitshaveashut-offvalve.

SafetyInterlockSystem

ForunitswithoutaBladeBrakeClutch:Operator

musthavethebladecontrolbaildepressedtostart

theengine.Releasingthebladecontrolbailwillcause

theenginetostop.

Transmission(SelfPropelledUnits)

Variable

SpeedRange:0–4.2mph(6.8km/hr)

CurbWeight:

98-122lb(44-55kg)Weightsmayvaryslightly

dependingonengineoption.

OverallWidth:

22inches(55.9cm)

OverallLengthandHeightat

21/2inchCuttingHeight:

HandleSettingLengthHeight

High61.00inches

(154.9cm)

Medium

Low

12

63.00inches

(160.0cm)

64.50inches

(163.8cm)

39.00inches

(99.1cm)

37.50inches

(95.3cm)

35.00inches

(88.9cm)

Page 13

Operation

ProductOverview

Figure3

1.Grassbag

2.Handle6.Rearwheelheight

3.DriveBail

(Self-PropelledUnits

Only)

4.BladeControlBail

5.Dischargedoor

adjustment

7.Frontwheelheight

adjuster

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

BladeControlBail

LocatedontheupperhandleasshowninFigure4.

Whenthebladecontrolbailisdepressed,thesystem

sensesthattheoperatorisinthenormaloperator’s

position.

•ForUnitswithaBladeBrakeClutch:When

thebladecontrolbailisreleased,thesystem

sensesthattheoperatorhasmovedfromthe

normaloperatingpositionandwillstoptheblade.

•ForUnitswithoutaBladeBrakeClutch:

Whenthebladecontrolbailisreleased,thesystem

sensesthattheoperatorhasmovedfromthe

normaloperatingpositionandwillkilltheengine.

Figure4

BladeBrakeUnitShown

1.Bladecontrollocklever(BladeBrakeUnitsOnly)

2.Bladecontrolbail

3.Handle

4.Drivebail(Self-PropelledUnitsOnly)

Self-PropelDriveBail(Self-Propelled

UnitsOnly)

LocatedontheupperhandleasshowninFigure4.

Whentheself-propeldrivebailissqueezed,the

unitwillmoveforwardbasedonhowfarthebail

isdepressedtowardthehandle.Whenthisbailis

releasedtheunitwillstopmoving.

13

Page 14

Operation

Throttle-ChokeLever(EC21KABBCX,

EC21KABBCY,EC21KABBCCA)

Locatedontheleftsideoftheengineasshownin

Figure11.

Theleverisusedtocontrolenginespeed.Moving

thethrottletothefullforward(Choke)positionwill

placetheleverinthechokeposition.Thechokeaids

instartingacoldengine.Movingthethrottlecontrol

forwardwillincreaseenginespeedandmovingitto

therearwilldecreaseenginespeed.

Thethrottle-chokecontrolalsoincludesanengine

killposition.Movingtheleverintothefullrearward

(Stop)positionwillkilltheengine.

Note:Someunitswillnothavethechokeposition.

ChokeControl(EC21HNBBC,

EC21HNBBCX)

Locatedonthefrontleftsideoftheengineasshown

inFigure10.

Thechokeaidsinstartingacoldengine.Pulling

outwardwillplacethecontrolinthechokeposition.

Pushingthecontrolinwardshutsoffthechoke.

BladeControlLockLever(Blade

BrakeClutchUnitsOnly)

Thebladecontrollockleverislocatedontheright

sideofthehandlenexttotheBladeControlBailas

showninFigure4.

Figure5

Clearplasticcoverremovedforclarity

1.Enginestopswitch

2.Press“STOP”tokillengine

3.Press“I”beforestartingengine

FuelShut-OffValve

Thefuelshutoffvalveislocatedbetweenthe

carburetorandthefueltank.Thefuelshutoffvalve

shutsofftheowoffuelwhenthemachinewill

notbeusedforafewdays,whenparkinginsidea

building,andduringtransporttoandfromthejob.

Movingthebladecontrollockleverintothefull

forwardpositionreleasesthebladecontrolbail.

Squeezingthebladecontrolbailagainstthehandle

engagestheblade.Releasingthebladecontrolbail

automaticallydisengagestheblade.Thebladecontrol

lockleverwillresettolockthebladecontrolbail.

EngineStopSwitch

Locatedontheleftsideoftheengineinfrontof

thefueltankasshowninFigure5.Theenginestop

switchisusedonEC21HNBBC,EC21HNBBCX,

andEC21KABBC(seeFigure10andFigure11).

Presstheswitchto“STOP”tokilltheengine.Press

“|”beforestartingtheengine.

Figure6

KawasakiUnit

1.Fuelvalve

14

Page 15

Operation

Pre-Start

Fillfueltank.Forbestresultsuseonlyclean,fresh

regulargradeunleadedgasolinewithanoctanerating

of87orhigher.Toensurefreshness,purchaseonly

thequantityofgasolinethatyouexpecttousein

30days.Usingunleadedgasolineresultsinfewer

combustiondepositsandlongerenginelife.See

EngineOwner’sManual.

Figure7

HondaUnit

1.Aircleaner3.Fuelcap

2.Fuelvalve

OnEC21KA,EC21KABBC,EC21KAX,EC21KAY,

EC21KABBCX,EC21KABBCY ,andEC21ASHN

units,rotatethevalve1/4turnclockwisetoshutoff

fuel.Rotatethevalve1/4turncounterclockwiseto

turnonfuel.

Figure8

1.Rotateclockwisetoclose

2.Rotatecounterclockwisetoopen

OnEC21HNBBCandEC21HNBBCXunits,the

fuelshutoffvalveislocatedontheengineasshown

inFigure9.Rotate1/4turnclockwisetoshutoff

fuel.Rotatethevalve1/4turncounterclockwiseto

turnonfuel.

Important:Neverusemethanol,gasoline

containingmethanol,gasoholcontainingmore

than10%ethanol,premiumgasoline,orwhite

gasbecausethefuelsystemcouldbedamaged.

DoNotaddoiltogasoline.

DoNotusegasolinethathasbeenstoredsincethe

lastmowingseasonorlonger.

DoNotoverllfueltank.Neverllthefueltankso

thatthefuellevelrisesabovealevelthatis1/2inch

belowthebottomofthellernecktoallowforfuel

expansionandpreventfuelspillage.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

HandleAdjustment

Theheightofthehandlecanbeadjustedfor

comfortableoperation.Standbehindthehandleto

determinetheheight.Toadjustthehandleheight,

positionthehardwareintooneofthethreeholesin

thehandlebracket.

1.Fuelvalve

Figure9

OpentheFuelShut-OffValve

Rotatethevalve1/4turncounterclockwisetoturn

thefuelon(ifequipped).

StartingtheEngine

1.Connectthewiretothesparkplug.

15

Page 16

Operation

Figure10

Hondaunit

1.Mufer

2.Oilll/dipstick

3.Fueltankcap(fueltankvaries)

4.Recoilstarterhandle(locatedonhandlebarforzone

startunits)

5.Enginestopswitch(ifequipped)

6.Airlter

7.Choke

8.Sparkplug

3.ForEC21KABBCXUnit:Movethechoke

controltotheChokeposition

ForEC21KABBCUnit:Turntheenginestop

switchto“|”(seeFigure5).

ForEC21KABBC,EC21KABBCCA,

EC21KABBCY,EC21KAX,EC21KACA,and

EC21KAYUnits:Presstheprimerbulbtwo

times(seeFigure12).

Figure12

ForEC21HNBBCandEC21HNBBCXUnits:

Turntheenginestopswitchto“|”andpull

outwardonthechokecontrol.

Kawasakiunitswithlargefueltankshown

1.Mufer

2.Oilll/dipstick

3.Recoilstarterhandle

4.Fueltankcap(fueltankvaries)

5.Enginestopswitch(ifequipped)

6.Throttle-Choke(ifequipped)

7.ThrottleOnly(ifequipped)

8.Oillter

9.Aircleaner

10.Primerbulb(ifequipped)

11.Sparkplug

2.Openthefuelvalve.

Figure11

Note:DoNotusethechokewhentheengine

iswarmedup.

4.ForunitswithoutaBladeBrakeClutch:Hold

thebladecontrolbailtothehandle.

5.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullitsharply.Allowtheropeto

returnslowly.

6.ForEC21KABBCCA,EC21KABBCXand

EC21KABBCYUnits:Whentheenginestarts,

movethethrottlecontroltotheFastposition.

7.ForEC21HNBBCandEC21HNBBCXUnits:

Graduallypushinthechokecontrolastheengine

warmsup.

StoppingtheEngine

1.Bringtheunittoafullstop.

•ForunitswithoutaBladeBrakeClutch:

Releasethebladecontrolbail.Boththe

engineandthebladeshouldstopwithinthree

seconds.

•ForunitswithaBladeBrakeClutch:

Releasethebladecontrolbailandtheblade

controllockleverresets.Thebladeshould

stopwithinthreeseconds;theenginewill

continuetorun.

16

Page 17

Operation

EC21KABBCCA,EC21KABBCX,and

EC21KABBCY:Movethethrottletothe

(Stop)positiontokilltheengine.

EC21KABBC,EC21HNBBCX,and

EC21HNBBC:Presstheswitchto“STOP”

tokilltheengine(seeFigure5).

Note:Ifthebladedoesnotstopwithin3

secondsafterreleasingthebladecontrolbail,

contactanAuthorizedServiceDealer.

2.Closethefuelshut-offvalve,ifequipped,when

themachinewillnotbeinuseforafewdays,

whentransporting,orwhentheunitisparked

insideabuilding.

OperatingtheSelf-PropelDrive

(Self-PropelledUnitsOnly)

Thelawnmowerisvariablespeed,themoreyou

squeezethedrivebailthefasterthemachinetravels.

1.Starttheengine.

OperatingtheBladeControlBail

(UnitsWithoutBladeBrakeClutch)

1.Squeezethebladecontrolbailagainstthehandle.

2.Starttheengine.

3.Whenthebladecontrolbailissqueezedagainst

thehandle,thebladeshouldengage.

4.Releasethebladecontrolbail.Boththeengine

andthebladeshouldstop.

OperatingtheBladeControlLever

(BladeBrakeClutchUnitsOnly)

1.Starttheengine.

2.Pushandholdthebladecontrollockleverforward

toreleasethebladecontrolbail(Figure13).

2.Squeezethedrivebailagainstthehandle(see

Figure4).

Note:Youcanvarythegroundspeedby

increasingordecreasingthedistancebetween

thegroundspeedcontrolbailandthehandle.

Lowerthecontrolbailtodecreasetheground

speedwhenyouaremakingaturnorifthelawn

mowerismovingtoofastforyou.Ifyoulower

thecontrolbailtoofarthelawnmowerstops

self-propelling.Squeezethegroundspeedcontrol

bailclosertothehandletoincreasetheground

speed.Whenyouholdthegroundspeedcontrol

bailtightagainstthehandle,thelawnmower

self-propelsatthemaximumgroundspeed.

Releasethedrivebailtostopmovingwhenyou

usethelawnmowerfortrimmingorwhenever

youleavethelawnmower.

3.Todisengagetheself-propeldrive,releasethe

drivebail.

Note:Themowercomeswithfreewheeling

clutcheswhichmakeiteasiertopullthemower

rearward.Todisengagetheclutches,youmay

needtopushthemowerforwardoneinch(2.5

cm)ormoreafteryoureleasetheself-propel

drivebail.

Figure13

1.Bladecontrollocklever

2.Lockedposition5.Unlockedposition

3.Bladecontrolbail

4.Pushforward

6.Squeezeagainsthandle

3.Squeezethebladecontrolbailagainstthehandle

andreleasethebladecontrollocklever;theblade

shouldengage.

4.Releasethebladecontrolbailtodisengagethe

blade.Thebladecontrollockleverwillresetto

lockthebladecontrolbail.

UsingtheMulchPlug

Occasionallyyoumaywishtousethemulchplugto

mulchthegrassandleafclippingsbackintothelawn.

•InstallingtheMulchPlug:

1.Stoptheengineandwaitforallmovingparts

tostop.

2.Removethegrassbagifitisonthemower.

3.Raisethedischargedoorandinsertthemulch

plugintothedischargeopening.Thelipon

theplugwillsnapintothemowerhousing.

17

Page 18

Operation

Figure14

1.Mulchplug3.Lip

2.Dischargedoor4.Mowerhousing

Figure15

1.Crumplednewspaper2.5inches(12.7cm)

5.Placetheballofnewspaper5inches(12.7cm)in

frontofthelawnmower.

4.Lowerthedischargedoor.

•RemovingtheMulchPlug:

Note:Whengrassisthickandlush,clippings

maycollectonandaroundthedischargetunnel

plug.Thismaymakeitdifculttoremovethe

plug.Cleantheplugthoroughlyaftereachuse.

1.Toremovethemulchplug,raisethedischarge

doorandpullthemulchplugoutofthe

dischargetunnel.

2.Lowerthedischargedoor.

CheckingtheBladeBrakeClutch

(BladeBrakeClutchUnitsOnly)

ChecktheBladeBrakeClutch(BBC)systembefore

eachusetoensurethatitisoperatingproperly.

NormalTest:

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Movethelawnmowerontoapavedsurfacein

anon-windyarea.

6.Starttheengine.

7.Pushthebladecontrollockleverforwardto

releasethebladecontrolbail(Figure4).

8.Squeezethebladecontrolbailagainstthehandle.

bladeshouldengage.

9.Releasethebladecontrolbail.Youshouldheara

“bang.”Thebladeshouldstopinthreeseconds.

Thebladecontrollocklevershouldresettolock

thebladecontrolbail.

10.Immediatelypushthelawnmoweroverthe

newspaperball.

11.Stoptheengineandwaitforallmovingpartsto

stop.

12.Walkaroundthelawnmowertocheckforthe

newspaperball.Iftheballdidnotgounderthe

deck,repeatsteps6through11.

13.Pullthelawnmowerawayfromthenewspaper.

Ifthenewspaperballunravelsorisshredded,

thebladehasnotproperlystopped,resulting

inanunsafeoperatingcondition.Contactan

AuthorizedServiceDealer.

3.Setallfourwheelstothe21/2inches(6.4cm)

cuttingheight(seeFigure16andFigure17)

4.Takeahalfsheetofnewspaperandcrumple

itintoballsmallenoughtogounderthedeck

(about3inchesor7.6cmindiameter)asshown

inFigure15.

18

Page 19

Operation

DANGER

Ifthebladebrakeclutchsystemis

inoperative,thebladewillcontinuetorotate

whenyoureleasethebladecontrolbail.

Contactwiththebladecouldoccur,causing

seriousinjury.

•ChecktheBBCoperationbeforeeach

use.

•NeverusetheBBC-equippedlawnmower

withaninoperativesafetysystem.

•TakeyourlawnmowertoanAuthorized

ServiceDealerforrepairifthesafety

systemfailstooperateproperly.

TestUsingtheGrassBag

1.Installtheemptygrassbagonthedischarge

tunnel.

2.Starttheengine.

WARNING

Adjustingthecuttingheightleverscould

bringyourhandsintocontactwithamoving

blade.Amovingbladecancauseserious

injury.

•Stoptheengineandwaitforallmovement

tostopbeforeadjustingthecutting

height.

•DoNotputyourngersunderthe

housingwhenadjustingthecutting

height.

•RearWheelAdjustment:

1.Pullthewheelheightadjustmentrodupward

toreleasethepinfromthenotchinthe

adjustmentbracket(Figure16).

3.ForunitswithaBladeBrakeClutch:Pushthe

bladecontrollockleverforwardtoreleasethe

bladecontrolbail(Figure4).

4.Squeezethebladecontrolbailagainstthehandle.

5.Thebagshouldbegintoinate,indicatingthat

thebladeisengagedandrotating.

6.Releasethebladecontrolbail.Ifthebagdoesnot

immediatelydeate,itindicatesthatthebladeis

stillrotating.Thebladebrakeclutchmechanism

maybedeteriorating,and,ifignoredcouldresult

inanunsafeoperatingcondition.Havethelawn

mowerinspectedandservicedbyanAuthorized

ServiceDealer.

AdjustingtheCuttingHeight

Therearwheelsareadjustedtogetherwithaheight

adjustmentrodlocatedonthemowerhousingby

theleftrearwheel.Thefrontwheelsareadjusted

separatelybyremovingthefrontwheelshaft

assemblies,adjustingtheheight,andthenreplacing

theshaftassemblies.Thecuttingheightcanbe

adjustedfrom1inch(25mm)to41/2inches(114

mm)in1/2inch(12.7mm)increments.

Figure16

1.Pullupward4.Pin

2.Wheelheightadjustment

rod

3.Adjustmentbracket6.Indicator

2.Applydownwardpressureorliftthehousing

torotatetheheightadjustmentbracket.Use

theindicatortodeterminethedesiredsetting.

3.Releasethewheelheightadjustmentrodtoset

thepinsecurelyinthedesirednotch.

•FrontWheelAdjustment

1.Pullupontheheightadjusterandpullthe

frontwheelshaftassemblyoutwardasshown

inFigure17.

5.Rotatetodesiredsetting

19

Page 20

Operation

Figure17

1.Frontwheelshaft

assembly

2.Pullup5.Pulloutward

3.Heightadjuster

4.Frontquadrantblockcut

heights

6.Shaftgroove

•MowingwiththeGrassBag

WARNING

Aworngrassbagcouldallowsmallstones

andothersimilardebristobethrowninthe

operator’sorbystander’sdirection.Thrown

objectscanresultinseriouspersonalinjury

ordeathtotheoperatororbystanders.

Checkthegrassbagfrequently.Ifitis

damaged,installanewExmarkreplacement

bag.

2.Insertthefrontwheelshaftassemblyintothe

desiredcutheightsettinginthefrontquadrant

block.Lowertheheightadjusterintothe

grooveonthefrontwheelshaft.Pulland

pushthewheelshaftassemblytomakesureit

haslockedintoplace.

UsingtheGrassBag

•InstallingtheGrassBag

1.Stoptheengineandwaitforallmovingparts

tostop.

2.Openthereardoor.

3.Graspthehandleonthebagandsettherear

ofthebagframeontothehandlebracket

notch(Figure18).

Cutthegrassuntilthebagisfull.

Note:DoNotoverllthebag.

•RemovingtheGrassBag

1.Stoptheengineandwaitforallmovingparts

tostop.

2.Raisethereardischargedoorandgraspthe

handleonthebag.

3.Liftthebagoffofthelawnmowerandlower

thereardischargedoor.

4.Graduallytipthebagforwardtoemptythe

clippings.

5.Toinstallthebag,refertothesectionon

InstallingtheGrassBag.

DANGER

Ifthedischargedoordoesnotclose

completely,thelawnmowercouldthrow

objects.Thrownobjectscanresultinserious

personalinjuryordeathtotheoperatoror

bystanders.

Figure18

1.Bag4.Handlebracketnotch

2.Handle5.Reardoor

3.Bagframe

6.Lower

4.Oncethebagisseated,lowerthereardoor

ontothebag.

•Neveropenthedoortothedischarge

openingwhentheengineisrunning.

•Ifyoucannotclosethedoorbecausethe

grassclippingsclogthedischargearea,

stoptheengineandgentlymovethe

dischargedoorhandlebackandforth

untilyoucanclosethedoorcompletely .If

youstillcannotclosethedoor,removethe

obstructionwithastick,notyourhand.

20

Page 21

Operation

OperatingTips

•ReviewtheSafetysectionandreadthismanual

carefullybeforeoperatingthelawnmower.

•Settheenginespeedtothefastestpositionfor

thebestcuttingresults.

•Maintainasharpbladethroughoutthecutting

season.Periodicallyledownnicksontheblade.

Replacethebladewhennecessarywithanoriginal

Exmarkreplacementblade.

•Cleantheairlterfrequently.Mulchingstirsup

moreclippingsanddustwhichclogstheairlter

andreducesengineperformance.

CuttingGrass

•Grassgrowsatdifferentratesatdifferenttimes

oftheyear.Inthesummerheat,itisbesttocut

grassatthe21/2inch(64mm),3inch(76mm),

or31/2inch(89mm)cuttingheightsettings.

Cutonlyaboutathirdofthegrassbladeatatime.

DoNotcutbelowthe21/2inch(64mm)setting

unlessthegrassissparseoritislatefallwhen

grassgrowthbeginstoslowdown.

•Forlightleafcoverage,setallthewheelsatthe

samecuttingheightsetting.

•Iftherearemorethan5inches(12.7cm)ofleaves

onthelawn,setthefrontcuttingheight1or2

notcheshigherthantherearcuttingheight.This

makesiteasiertofeedtheleavesunderthelawn

mowerdeck.

•Slowdownyourmowingspeedifthelawnmower

doesnotcuttheleavesnelyenough.

•Ifyoumowoveroakleaves,youcanaddlimeto

thegrassinthespringtoreducetheacidityofthe

oakleaves.

•Whencuttinggrassover6inches(15cm)tall,

rstmowatthehighestcuttingheightsettingand

walkslower;thenmowagainatalowersettingfor

thebestlawnappearance.Ifthegrassistoolong

andtheleavesclumpontopofthelawn,thelawn

mowermayplugandcausetheenginetostall.

•Alternatethemowingdirection.Thishelps

dispersetheclippingsoverthelawnforeven

fertilization.

Ifthenishedlawnappearanceisunsatisfactory,

tryoneormoreofthefollowing:

–Sharpentheblade.

–Walkataslowerpacewhilemowing.

–Cutthegrassmorefrequently .

–Overlapcuttingswathsinsteadofcuttinga

fullswathwitheachpass.

–Setthecuttingheightonthefrontwheels

onenotchlowerthantherearwheels.For

example,setthefrontwheelsat21/2inches

(64mm)andtherearwheelsat3inches(76

mm).

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthe

lawnshowsthroughthecutleafcover.Youmay

needtomakemorethanonepassovertheleaves.

21

Page 22

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Ifyouleavethewireonthesparkplug,

someonecouldaccidentallystarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Disconnectthewirefromthesparkplug

beforeyoudoanymaintenance.Setthewire

asidesothatitdoesnotaccidentallycontact

thesparkplug.

WARNING

Theenginecanbecomeveryhot.T ouching

ahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

WARNING

Tippingthelawnmowermaycausethefuel

toleakfromthecarburetororthefueltank.

Gasolineisextremelyammable,highly

explosive,andundercertainconditions,can

causepersonalinjuryorpropertydamage.

Avoidfuelspillsbyrunningtheenginedryor

byremovingthegasolinewithahandpump;

neversiphon.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Every25hours

Every40hours

Every50hours

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Checkthestoppingtimeofthebladebrake.Theblademuststopwithin3secondsof

releasingthebail;ifitdoesnot,contactanAuthorizedServiceDealerforrepair.

•Checkthemowerbladeandtheenginemountingfasteners.

•Checkforloosehardware.

•ChecktheBladeBrakeClutchBailoperation(BladeBrakeClutchUnitsOnly)

•Cleanthegrassbuild-upfromunderthedeck.

•Cleanthedischargetunnelandplug.

•Cleanthefoampre-cleaner(KawasakiUnits).

•Cleanthecover,base,foamandpaperelements(EC21ASHNUnits).

•Cleanthecover,base,foamandpaperelements(EC21HNBBCandEC21HNBBCXUnits).

•Checktheconditionofthebelt(s).

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Checkforleaksinthefuelsystemsand/ordeterioratingfuelhose.

•Cleanunderthebeltcover(self-propelledunitsonly).

•Cleanthebladebrakeclutchshield.

•Cleanunderthecoverplate(Non-BBCUnits).

22

Page 23

Maintenance

MaintenanceService

Interval

Every100hours

Every250hours

Every300hours

Yearlyorbeforestorage

MaintenanceProcedure

•Changetheoillter(EC21KA,EC21KABBC,EC21KAX,EC21KAY,EC21KABBCX,

EC21KABBCY ,EC21KACA,andEC21KABBCCAUnits).

•Checkthesparkplugs.

•Cleanthefuellterelement.

•Replacetheairlterelements(EC21ASHNUnits).(Mayneedmoreofteniftheyare

damagedorexcessivelydirty.)

•Replacetheairlterelements(EC21HNBBCandEC21HNBBCXUnits).(Mayneedmore

ofteniftheyaredamagedorexcessivelydirty.)

•Replacethepaperairlter(KawasakiUnits).(Mayneedmoreoftenindustyconditions.

SeetheEnginemanualforadditionalinformation.)

•Emptythefueltankbeforerepairsasdirectedorbeforestorage.

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Cleanareaarounddipstick.Removedipstickand

wipeoiloff.Reinsertthedipstickandpushitall

thewaydownintothetube.DoNotscrewinto

place.Removethedipstickandreadtheoillevel.

Figure19

HondaEngine

1.Lowerlimitmark3.Dipstick

2.Upperlimitmark

Figure20

KawasakiEngine

1.Dipstick3.Add

2.Full

4.Iftheoillevelislow ,wipeofftheareaaroundthe

oilllcap,removecapandlltothe“FULL”

markonthedipstick.Useoilasspeciedin

EngineOwner’sManual.DoNotoverll.

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

CheckingtheBladeBrake

Clutch(BladeBrakeClutch

Only)

ServiceInterval:Beforeeachuseordaily

23

Page 24

Maintenance

RefertoCheckingtheBladeBrakeClutchinthe

OperatingInstructionssection.

ChecktheMowerBlade

ServiceInterval:Beforeeachuseordaily

Alwaysmowwithasharpblade.Asharpbladecuts

cleanlyandwithouttearingorshreddingthegrass

blade.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug

(Figure10andFigure11).

3.Drainthegasolinefromthefueltank.Referto

EmptyingtheFuelTankandCleaningthe

FuelFiltersection.

4.Tipthelawnmowerontoitsrightside.

5.Inspectthebladeforsharpnessandwear,

especiallywheretheatandthecurvedparts

meet(seeFigure21).Becausesandandabrasive

materialcanwearawaythemetalthatconnects

theatandcurvedpartsoftheblade,check

thebladebeforeusingthelawnmower.Ifyou

noticeaslotorwear(Figure21BandFigure21C),

replacetheblade.

DANGER

Awornordamagedbladecanbreak.A

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Ifitisnecessarytoremovethebladefor

replacementorsharpening,completethe

followingsteps:

A.Toremovetheblade,useablockofwoodto

holdthebladesteady(seeFigure22).Make

suretograsptheendofthebladeusingarag

orathicklypaddedglove.

•ForBladeBrakeClutchUnits:Remove

thebladenuts,bladesupport,andblade.

•ForUnitswithoutaBladeBrake

Clutch:Removethebladebolt,blade

support,andblade.

Figure21

1.Sail

2.Flat

3.Wear

4.Slot

Note:Forthebestperformance,installanew

bladebeforethecuttingseasonbegins.During

theyear,ledownanysmallnickstomaintainthe

cuttingedge.

Figure22

B.ForSharpening:Filethetopsideofthe

bladetomaintainitsoriginalcuttingangle

(Figure23AandB)andinnercuttingedge

radius(Figure23A).Thebladewillremain

balancedifyouremovethesameamountof

materialfrombothcuttingedges.

24

Page 25

Figure23

1.Innercuttingedgeradius

2.Cuttingangle

C.Checkthebalanceofthebladebyplacing

thecenterholeofthebladeoveranailor

screwdrivershankclampedhorizontallyina

vise(Figure24).Ifeitherendoftheblade

rotatesdownward,lethatend(notthe

cuttingedge).Thebladeisproperlybalanced

whenneitherenddrops.

Maintenance

Figure25

1.BladeBrakeClutchUnits

2.UnitswithoutaBladeBrakeClutch

Figure24

1.Blade

2.Vise

3.Screwdriver

D.ForInstallation:Makesuretograsptheendof

thebladeusingaragorathicklypaddedglove.

ForBladeBrakeClutchUnits:Installasharp,

balancedExmarkblade,bladesupport,and

thebladenuts.Thesailoftheblademust

pointtowardthetopofthelawnmower

housingforproperinstallation.Torquethe

bladenutsto23-27ft-lb(31-37Nm).

ForUnitswithoutaBladeBrakeClutch:

Installasharp,balancedExmarkblade,blade

support,andbladebolt.Thesailoftheblade

mustpointtowardthetopofthelawnmower

housingforproperinstallation.Torquethe

bladeboltto35-45ft-lb(47-61Nm).

6.Returnthelawnmowertoitsuprightposition.

7.Connectthewiretothesparkplug.

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

ChecktheBladeBrake

ClutchBailOperation(Blade

BrakeClutchUnitsOnly)

ServiceInterval:Beforeeachuseordaily

ChecktheBladeBrakeClutch(BBC)bailoperation

foranyoperationproblemsordeteriorating

components,suchasthespring.Replacecomponents

orcorrectanyproblemsbeforeoperating.Referto

OperatingtheBladeControlLeverinOperation.

25

Page 26

Maintenance

ServiceAirFilter

(KawasakiUnits)

ServiceInterval:Every25hours—Clean

thefoampre-cleaner

(KawasakiUnits).

Every300hours—

Replacethepaperair

lter(KawasakiUnits).

(Mayneedmoreoftenin

dustyconditions.See

theEnginemanualfor

additionalinformation.)

Note:DoNotoperatetheenginewithouttheair

lterassembly;extremeenginedamagewilloccur.

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug

(Figure11).

3.Removethecoverandcleanitthoroughly.

Figure26

EC21KA,EC21KACA,EC21KAX,EC21KAY,

EC21KABBC,EC21KABBCCA,EC21KABBCX,

EC21KABBCYUnits

1.Cover3.Paperairlter

2.Foamelement

4.Airlterbase

Figure27

EC21ASKAandEC21ASKAPUnits

1.Cover

2.Paperairlter

3.Foamelement

4.Removethepaperairlteranddiscarditas

required.

Note:DoNottrytocleanapaperairlter.

5.Removethefoamelementandwashitwithamild

detergentandwater,thenblotitdry.

6.Saturatetheelementwithcleanengineoil,then

squeezeit(DoNottwist)toremovetheexcessoil.

7.Installthefoamelement.

8.Installthenewpaperairlter.

9.Installthecover.

ServiceAirFilter

(EC21ASHNUnits)

ServiceInterval:Every25hours—Clean

thecover,base,foam

andpaperelements

(EC21ASHNUnits).

Every250hours—Replace

theairlterelements

(EC21ASHNUnits).(May

needmoreofteniftheyare

26

Page 27

Maintenance

damagedorexcessively

dirty.)

Note:DoNotoperatetheenginewithouttheair

cleanerassembly;extremeenginedamagewilloccur.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug

(Figure10).

3.Pressdownonthelatchtabsontopoftheair

cleanercover.

10.Installthefoamelement.

11.Removedirtfromtheaircleanerhousingand

coverusingamoistrag.DoNotwipedirtinto

theairduct.

12.Installthelter.

13.Closethecover.

ServiceAirFilter

(EC21HNBBCand

EC21HNBBCXUnits)

ServiceInterval:Every25hours—Clean

thecover,base,foam

andpaperelements

(EC21HNBBCand

EC21HNBBCXUnits).

Every250hours—

Replacetheairlter

elements(EC21HNBBC

andEC21HNBBCXUnits).

(Mayneedmoreoften

iftheyaredamagedor

excessivelydirty.)

Figure28

1.Cover4.Paperlter

2.Foamelement5.Aircleanerhousing

3.Screengrid

4.Openthecover

5.Removescreengridandpaperlterassembly.

6.Iftheairlterisdamagedoriswetwithoilor

fuel,replaceit.

7.Iftheairlterisdirty,tapitonahardsurface

severaltimesorblowcompressedairlessthan

30psi(207kPa)throughthesideofthelter

thatfacestheengine.Ifthepaperelementis

excessivelydirty,replaceit.

Note:DoNotbrushthedirtoffthelter;

brushingforcesdirtintothebers.

8.Removethefoamelementandwashitwithamild

detergentandwater,thenblotitdry.

Note:DoNotoperatetheenginewithouttheair

cleanerassembly;extremeenginedamagewilloccur.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug

(Figure10).

3.Removethetwowingnutsthatsecurethecover

(Figure29).

9.Saturatetheelementwithcleanengineoil,then

squeezeit(DoNottwist)toremovetheexcessoil.

27

Page 28

Maintenance

Figure29

1.Wingnuts4.Foamelement

2.Cover

3.Paperelement

4.Removethecover.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

13.Installtheaircleanerelementsandensurethat

theyareproperlypositioned.

14.Securelyinstallthecoverwiththetwowingnuts.

ChangeEngineOil

ServiceInterval:Aftertherst5hours

Every50hours(Mayneed

moreoftenundersevere

conditions.)

1.Runtheenginetowarmtheengineoil.

Note:Warmoilowsbetterandcarriesmore

contaminates.

5.Base

Oilmaybehotafterenginehasbeen

run.Contactwithhotoilcancausesevere

personalinjury.

WARNING

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamandpaperelementsfromthe

base.

6.Removethefoamelementfromthepaper

element.

7.Inspectthefoamandpaperelements,andreplace

themiftheyaredamagedorexcessivelydirty.

8.Tapthepaperelementonahardsurfaceseveral

timesorusecompressedairnotexceeding30

psi(207kPa)throughthelterfromthewire

screensidetoremoveanyexcessdirt.Ifthepaper

elementisexcessivelydirty,replaceit.

Note:Nevertrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

9.Cleanthefoamelementinwarm,soapywateror

inanonammablesolvent.

10.Rinseanddrythefoamelementthoroughly.

11.Dipthefoamelementincleanengineoil,then

squeezeouttheexcessoil.

Note:Excessoilinthefoamelementrestricts

theairowthroughtheelementandmayreach

thepaperlterandclogit.

12.Wipedirtfromthebaseandthecoverwitha

moistrag.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stopengine,waitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug.

4.Drainthegasolinefromthefueltank.Referto

EmptyingtheFuelTankandCleaningthe

FuelFiltersection.

5.Placeasuitabledrainpanunderthedipstick/oil

drain.

6.Cleanaroundthedipstick.

7.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

8.Raisetheleftsideofthelawnmowertodrainthe

oilfromthedipsticklltubeintothedrainpan.

9.Afterdrainingtheoil,returnthelawnmowerto

theoperatingposition.

10.Fillthecrankcasewithfreshoiltotheupperlimit

markonthedipstick.

11.Insertthedipstickintothellerneckandrotate

thecapclockwiseuntilitistight.

12.Wipeupanyspilledoil.

13.Connectthewiretothesparkplug.

14.Recycletheusedoilaccordingtolocalcodes.

28

Page 29

Maintenance

ChangeOilFilter

(EC21KA,EC21KABBC,

EC21KAX,EC21KAY ,

EC21KABBCX,

EC21KABBCY,EC21KACA,

andEC21KABBCCA)

ServiceInterval:Every100hours

1.Runtheenginetowarmtheoil.

2.Stoptheengineandwaitforallmovingpartsto

stop.

3.Disconnectthewirefromthesparkplug.

4.Draintheengineoil.

5.Placearagundertheoilltertocatchanyoilthat

mayleakoutasyouremovethelter.

6.Removetheoillter.

7.Useyourngertocoatthegasketonthenew

lterwithcleanengineoil(seeFigure30).

CheckConditionOfBelt

(Self-PropelledUnitsOnly)

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop.

2.Removethebeltcovertothelawnmowerhousing.

3.Checkthebeltforcracks,frayededges,burn

marksoranyotherdamage.

4.Replacethedamagedbelt.

CheckSparkPlugs

ServiceInterval:Every100hours

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug

(Figure10andFigure11).

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Note:Replaceacracked,fouled,ordirtyspark

plug.DoNotcleantheelectrodesbecausegrit

enteringthecylindercandamagetheengine.

Figure30

1.Gasket

8.Installthenewlterandhandtightenit2/3turn

only.

9.FillthecrankcasetotheFulllineonthedipstick

withfreshoil.

10.Connectthewiretothesparkplug.

11.Runtheengineforabout3minutes.

12.Stoptheengine,waitforallmovingpartstostop,

andcheckforoilleakagearoundthelter.

13.Addoiltocompensatefortheoilintheoillter.

14.Recycletheusedoillteraccordingtolocalcodes.

5.Setthegapontheplugto0.030inch(0.76mm)

(Figure31).

Figure31

1.Sideelectrode

2.Centerelectrode

insulator

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto17ft-lb(23N-m).

8.Connectthewiretothesparkplug.

3.Airgap—0.030inch

(0.76mm)

EmptyingtheFuelTankand

CleaningtheFuelFilter

ServiceInterval:Every100hours

29

Page 30

Maintenance

Thefuellter(screen)elementislocatedinsidethe

fueltank(ifapplicable).

Note:TheEC21ASHNdoesnothavearemovable

fueltank.

1.Stoptheengineandwaitforittocooldown.

Note:Draingasolineforacoldengineonly.

2.Disconnectthewirefromthesparkplug

(Figure11).

3.Closethefuelvalve.

4.Disconnectthefuellinebylooseningthetube

clampatthecarburetor.

5.Openthefuelvalvebyturningthelevertothe

openposition.

6.Drainthegasolinecompletelyfromthetankand

fuellineintoanapprovedfuelcontainer.

7.Removethefueltankfromthemower.

8.Closethefuelvalve.

9.Pourasmallamountoffuelinthefueltank,move

thefuelaroundinthetank,andpouritoutinto

anapprovedfuelcontainer.

10.Installthefueltankandfuelline.

Adjustments

Note:Waitforallmovingpartstostopandremove

sparkplugwirebeforeservicing,cleaning,ormaking

anyadjustmentstotheunit.

AdjustingtheSelf-Propel

Drive

(Self-PropelledUnitsOnly)

Ifthelawnmowerdoesnotself-propelorhasa

tendencytocreepforwardwhenthecontrolbail

isreleased,adjustthedrivecablenutsasshownin

Figure33.

DANGER

Checkingtheoperationofthemowerwith

thebeltcoverremovedwillallowdebristo

bethrownintheoperator’sorbystander’s

directionandcanresultinseriouspersonal

injuryordeath.

DoNotoperatetheunitwhencoverisnot

inplace.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Removethebeltcoverbypullingupwardonthe

backofthecovertounsnapthefrontandback

covertabs.Removeanydebrisunderthecover.

Figure32

1.Beltcovertabs

3.Ifthelawnmowerdoesnotselfpropelwithbail

engaged,tightenthebeltbyturningthedrive

30

Page 31

cablenutsclockwise.Tomaximizebeltlife,Do

Notovertightenthebelt.

Ifthelawnmowercreepsforwardwithoutthe

bailengaged,loosenthebeltbyturningthedrive

cablenutscounterclockwise.

Figure33

1.Adjustmentofdrivecablenuts

4.Reinstallthebeltcoverbypushingdownonthe

rearrstandthensnappingthefrontontothe

mowerhousing.

5.Checktheoperationfordesireddrivecontrol.

6.Repeatsteps2through5asnecessaryforfurther

adjustment.

Note:Adjustmenttoobtaindesiredground

speedatfullbailtravelmaybemadeinorderto

accommodateslowerspeeds.

Maintenance

Figure34

1.Spring3.Cableclampscrew

2.Cableconduit

5.Pullthecableuntilthereisapproximately1/8

inchinslack.DoNotputtensiononthespring.

6.Tightenthescrewtolocktheadjustmentinplace.

7.Reinstallthebeltcoverbypushingdownonthe

rearrstandthensnappingthefrontontothe

mowerhousing.

8.Connectthewiretothesparkplug.

AdjustingtheBlade

BrakeCable

(BladeBrakeClutchUnits

Only)

Adjustwheneveranewbladebrakecableassembly

isinstalledorifthebladecontrollockleverdoesnot

operateproperly.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Removethebeltcoverbypullingupwardonthe

backofthecovertounsnapthefrontandback

covertabs(seeFigure32).Removeanydebris

underthecover.

4.Loosenthecableclampscrewuntilthecable

conduitslides(seeFigure34).

9.Checktheoperationofthebladecontrollock

lever(seeFigure13).Thelevermustresetitself

tolockoutthebladecontrolbail.Ifitdoesnot,

repeatsteps4through8.

10.Performthe“CheckingtheBladeBrakeClutch

(BladeBrakeClutchUnitsOnly)”procedurein

Operation.

31

Page 32

Maintenance

Cleaning

CleanGrassBuild-UpUnder

Deck

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removesparkplugwire.

2.Toensurethebestperformance,keepthe

undersideofthelawnmowerhousingclean.

CAUTION

Themowermaydislodgematerialfrom

underthemowerhousing.

•Weareyeprotection.

•Stayintheoperatingposition(behindthe

handle).

•DoNotallowbystandersinthearea.

6.Turnoffthewater.

7.Startthelawnmower,engagetheblade,andlet

thelawnmowerrunforafewminutestodryout

itscomponents.

ScrapingMethod

Ifwashingdoesnotremovealldebrisfromunderthe

lawnmower,scrapeitclean.

1.Disconnectthewirefromthesparkplug.

2.Drainthefuelfromthefueltank.Referto

EmptyingtheFuelTankandCleaningthe

FuelFiltersection.

3.Tipthelawnmowerontoitsrightside.

4.Removethedirtandgrassclippingswitha

hardwoodscraper.Avoidburrsandsharpedges.

5.Turnthelawnmowerupright.

6.Fillthefueltank.

7.Connectthewiretothesparkplug.

WashingMethod

1.Positionthelawnmoweronaatconcreteor

asphaltsurfacenearagardenhose.

2.Starttheengine.

3.Holdtherunninggardenhoseathandleleveland

directthewatertoowonthegroundjustin

frontoftherightreartire(Figure35).

Figure35

4.Engagetheblade.

Note:Thebladewilldrawinwaterandwashout

clippings.Letthewaterrununtilyounolonger

seeclippingsbeingwashedoutfromunderthe

housing.

5.Disengagetheblade,stoptheengineandwaitfor

allmovingpartstostop.

CleaningtheDischarge

TunnelandPlug

ServiceInterval:Beforeeachuseordaily

Alwaysbesurethatthedischargetunneldoorcloses

securelywhenyoureleasethehandle.Ifthedebris

preventsthedischargedoorfromclosingsecurely ,

cleantheinsideofthedischargetunnelandthedoor

thoroughly.

WARNING

Grassclippingsandotherobjectscanbe

thrownfromanopendischargetunnel.

Thrownobjectscancauseseriousinjuryor

killtheoperatororbystanders.

Neverstartoroperatethelawnmowerunless

oneofthefollowingistrue:

•Thedischargetunnelplugislocked

securelyinthedischargetunnel.

•Thegrassbagislockedinplace.

•Theoptionalreardischargechuteis

lockedinplace.

•Thedischargetunneldoorisclosed.

32

Page 33

CleaningUndertheBelt

Cover(Self-PropelledUnits

Only)

ServiceInterval:Every50hours

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug(see

Figure10andFigure11).

3.Pullupwardonthebackofthecovertounsnap

thefrontandbackcovertabs(seeFigure32).

4.Liftoffthecoverandbrushoutallthedebris

aroundthebeltarea.

Maintenance

Figure36

1.Screws2.BBCShield

5.Installthebeltcoverbypushingdownontherear

rstandthensnappingthefrontontothemower

housing.

6.Connectthewiretothesparkplug.

CleaningtheBlade

BrakeClutchShield

(BladeBrakeClutchUnits

Only)

ServiceInterval:Every50hours

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug(see

Figure10andFigure11).

3.Drainthegasolinefromthefueltank.Referto

EmptyingtheFuelTankandCleaningthe

FuelFiltersection.

4.Tipthelawnmowerontoitsrightside(airlter

up).

5.Removethebladenutsandtheblade(see

Figure25).

6.RemovethethreescrewsholdingtheBBCshield

ontotheunit(seeFigure36).

7.RemovetheBBCshieldandbrushorblowall

thedebrisfromundertheshieldandaroundthe

BBCsystem.

8.InstalltheBBCshield.Tightenthescrewsto

securetheBBCshieldtothedeck.

9.Installthebladeandthetwobladenuts.

10.Turnthelawnmowerupright.

11.Connectthewiretothesparkplug.

CleaningUndertheCover

Plate(Non-BladeBrake

ClutchUnitsOnly)

ServiceInterval:Every50hours

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug(see

Figure10andFigure11).

3.Drainthegasolinefromthefueltank.Referto

EmptyingtheFuelTankandCleaningthe

FuelFiltersection.

4.Tipthelawnmowerontoitsrightside(airlter

up).

5.Removethebladebolt,bladesupport,andthe

blade(seeFigure25).

33

Page 34

Maintenance

Figure37

1.Bladebolt

2.Bladesupport

3.Blade

6.Removethethreescrewsholdingthecoverplate

ontotheunit(seeFigure37).

7.Removethecoverplateandbrushorblowallthe

debrisfromundertheplate.

4.Coverplate

5.Screw

8.Reinstallthecoverplateandtorquethescrewsto

35-45ft-lb(47-61N-m).

9.Installtheblade,bladesupport,andtheblade

bolt.

10.Turnthelawnmowerupright.

11.Connectthewiretothesparkplug.

WasteDisposal

MotorOilDisposal

Engineoilandhydraulicoilarebothpollutantsto

theenvironment.Disposeofusedoilatacertied

recyclingcenteroraccordingtoyourstateandlocal

regulations.

34

Page 35

Storage

Storage

PreparingtheFuelSystem

Topreparethelawnmowerforoffseasonstorage,

performtherecommendedmaintenanceprocedures.

Storethelawnmowerinacool,clean,dryplace.

Coverthelawnmowertokeepitcleanandprotected.

WARNING

Gasolinecanvaporizeifyoustoreitoverlong

periodsoftime.Gasolinevaporscanexplode

iftheycomeintocontactwithanopename.

•DoNotstoregasolineoverlongperiods

oftime.

•DoNotstorethelawnmowerwith

gasolineinthefueltankorthecarburetor

inanenclosurewithanopename.(For

example,afurnaceorawaterheaterpilot

light.)

GeneralStorageInformation

1.Cleanthelawnmowerhousing.Referto

CleaningtheUndersideoftheLawnMower

HousingsectioninCleaning.

2.Cleananydirtandchafffromthecylinder,

cylinderheadns,andblowerhousing.

3.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheengine,theshrouding,and

thetopofthelawnmowerhousing.

4.CleantheBBCshield.RefertoCleaningthe

BladeBrakeClutchShieldsectioninCleaning.

5.Checktheconditionoftheblade.Refer

toMaintainingtheBladesectioninthe

Maintenance.

6.Servicetheairlter.RefertoServicingtheAir

FilterinMaintenance.

7.Tightenallnuts,bolts,andscrews.

8.Touchupallrustedorchippedpaintsurfaceswith

paintavailablefromanAuthorizedServiceDealer.

•Allowtheenginetocoolbeforestoring

itinanyenclosure.

Emptythefueltankwhenmowingthelasttime

beforestoringthelawnmower.

1.Runthelawnmoweruntiltheenginestopsfrom

runningoutoffuel.

2.Primetheengineandstartitagain.

3.Allowtheenginetorununtilitstops.Whenyou

cannolongerstarttheengineitissufcientlydry.

PreparingtheEngine

1.Whiletheengineisstillwarm,changetheoilfrom

thecrankcase.RefertoChangingtheEngine

OilsectioninMaintenance.

2.Removethesparkplug.

3.Usinganoilcan,addaboutonetablespoonofoil

tothecrankcasethroughthesparkplughole.

RemovingtheLawnMower

fromStorage

1.Checkandtightenallfasteners.

2.Removethesparkplugandspintheenginerapidly

bypullingthestarterropetoblowexcessoilfrom

thecylinder.

3.Cleanthesparkplugorreplaceitifitiscracked,

broken,oriftheelectrodesareworn.

4.Installthesparkplugandtorqueitto17ft-lb(23

N-m).

5.Performanyneededmaintenanceprocedures.

6.Fillthefuelinthefueltankwithfreshgasoline.

7.Checktheengineoillevel.

8.Connectthewiretothesparkplug.

4.Slowlyrotatetheengineseveraltimes,usingthe

starterrope,todistributetheoil.

5.InstallthesparkplugbutDoNotconnectthe

wiretothesparkplug.

35

Page 36

Troubleshooting

Troubleshooting

Important:Itisessentialthatalloperatorsafetymechanismsbeconnectedandinproperoperating

conditionpriortomoweruse.

Whenaproblemoccurs,DoNotoverlookthesimplecauses.Forexample:startingproblemscouldbe

causedbyanemptyfueltank.

Thefollowingtablelistssomeofthecommoncausesoftrouble.Ifaproblemcontinues,contactanAuthorized

ServiceDealer.

ProblemPossibleCauseCorrectiveAction

Enginewillnotstart,startshard,orfailsto

keeprunning.

Enginelosespower.

Enginerunsrough.

Lawnmowerorenginevibratesexcessively.

1.Fueltankisempty.1.Fillthefueltank.

2.Fuelshut-offvalveisclosed.

3.Thethrottleleverisnotinthecorrect

position.

4.Dirt,water,orstalefuelisinthefuel

system.

5.Faultysparkplug.

6.Sparkplugwireisnotconnected.

1.Aircleanerisdirty.

2.Oillevelinthecrankcaseislow .

3.Ventholeinthefuelcapisplugged.

4.Dirtinfuellter.4.Replacethefuellter.

5.Dirt,water,orstalefuelisinthefuel

system.

6.Theundersideofthelawnmowerdeck

containsclippingsanddebris

1.Thewireisnotconnectedtothespark

plug.

2.Faultysparkplug.

3.ThethrottleleverisnotintheFast

position.

4.Theairlterelementisdirtyandis

restrictingtheairow .

1.Thebladeisbentorisoutofbalance.1.Balancetheblade.Ifthebladeisbent,

2.Theblademountingboltisloose.2.Tightentheblademountingbolt.

3.Theundersideofthelawnmowerdeck

containsclippingsanddebris.

4.Theenginemountingboltsareloose.4.Tightentheenginemountingbolts.

2.Openthefuelshut-offvalve.

3.MovethethrottlelevertotheChoke

position.

4.ContactanAuthorizedServiceDealer.

5.Clean,adjustorreplacesparkplug.

6.Checkthesparkplugwireconnection.

1.Cleanorreplacetheaircleanerelement.

2.Addoiltothecrankcase.

3.Cleanorreplacethefuelcap.

5.ContactanAuthorizedServiceDealer.

6.Cleantheundersideofthelawnmower

deck.

1.Connectthewiretothesparkplug.

2.Clean,adjustorreplacesparkplug.

3.MovethethrottlelevertotheFast

position.

4.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

replaceit.

3.Cleantheundersideofthelawnmower

deck.

Unevencuttingpattern.

Dischargechuteplugs

1.Allfourwheelsarenotatthesameheight.

2.Thebladeisdull.2.Sharpenandbalancetheblade.

3.Mowinginthesamepatternrepeatedly.

4.Theundersideofthelawnmowerdeck

containsclippingsanddebris.

1.ThethrottleleverisnotintheFast

position.

2.Cuttingtoomuchgrassinonepass2.Raisethecuttingheight.Ifnecessary,cut

3.Mowingtoofast.

4.Thegrassiswet.

5.Theundersideofthelawnmowerdeck

containsclippingsanddebris.

1.Placeallfourwheelsatthesameheight.

3.Changethemowingpattern.

4.Cleantheundersideofthelawnmower

deck.

1.MovethethrottlelevertotheFast

position.

secondtimeatlowercuttingheight.

3.Slowdown.

4.Allowthegrasstodrybeforemowing.

5.Cleantheundersideofthelawnmower

deck.

36

Page 37

Troubleshooting

ProblemPossibleCauseCorrectiveAction

Lawnmowerdoesnotself-propel

(Self-PropelledUnitsOnly)

Difculttopulllawnmowerrearward

(Self-PropelledUnitsOnly).

1.Theself-propeldrivecableisoutof

adjustmentorisdamaged.

2.Thereisdebrisunderthebeltcover.2.Cleanthedebrisfromunderthebelt

1.Transmissionislocked.1.Pushmowerforwardtodisengagethe

1.Adjusttheself-propeldrivecable.Replace

thecableifnecessary .

cover.

transmissionandthenpullrearward.

37

Page 38

Conditions and Products Covered

Exmark Mfg. Co. Inc. and its affiliate, Exmark Warranty

Company, pursuant to an agreement between them, jointly

warrant on the terms and conditions herein, that we will repair,

replace or adjust any part on these products and found by us

(in the exercise of our reasonable discretion) to be defective in

factory materials or workmanship for a period of one year.

This warranty applies to Exmark commercial turf equipment

sold in the U.S. or Canada. This warranty may only be

assigned or transferred to a second (or third) owner by an

authorized Exmark dealer. The warranty period commences

upon the date of the original retail purchase.

Warranty Exceptions Warranty Period

• Bags, Belts and Tires 90 days

• Engine 2 years*

* The Engine warranty is covered by the engine manufacturer.

Please refer to the engine manufacturer’s warranty statement

that is included in the literature packet.

This warranty only includes the cost of parts and labor.

Items and Conditions Not Covered

This warranty does not cover the following:

• Pickup and delivery charges to and from any authorized

Exmark Service Dealer.

• Any damage or deterioration due to normal use, wear and

tear, or exposure.

• Cost of regular maintenance service or parts, such as filters,

fuel, lubricants, tune-up parts, and adjustments.

• Any product or part which has been altered or misused or

required replacement or repair due to normal wear,

accidents, or lack of proper maintenance.

• Any repairs necessary due to use of parts, accessories or

supplies, including gasoline, oil or lubricants, incompatible

with the turf equipment or other than as recommended in

the operator's manual or other operational instructions

provided by Exmark.

There are no other express warranties except for engine and

special emission system coverage.

All warranty work must be performed by an authorized

Exmark Service Dealer using Exmark approved replacement

parts.

Instructions for Obtaining Warranty Service

The product must be registered with original proof of purchase

by an Exmark Service Dealer before obtaining any warranty

service.

Contact any Exmark Service Dealer to arrange service at their

dealership. To locate a dealer convenient to you, access our

website at www.exmark.com. U.S. or Canada customers may

also call 402-223-6375.

If for any reason you are dissatisfied with the Service Dealer’s

analysis or with the assistance provided, contact us at:

Exmark Customer Service Department

The Exmark Warranty Company

2101 Ashland Avenue

Beatrice, NE 68310

402-223-6375 or

service@exmark.com

Owner’s Responsibilities

If your product requires warranty service it must be returned

to an authorized Exmark service dealer within the warranty

period. This warranty extends only to turf equipment operated

under normal conditions. You must read the operator’s

manual. You must also properly service and maintain your

Exmark product as described in the operator’s manual. Such

routine maintenance, whether performed by a dealer or by

you, is at your expense.

General Conditions

The sole liability of Exmark and Exmark Warranty Company

with respect to this warranty shall be repair or replacement of

defective components as set forth herein. Neither Exmark

nor Exmark Warranty Company shall be liable for any

incidental or consequential loss or damage.

Such damages include but are not limited to:

• Expenses related to gasoline, oil or lubricants.

• Travel time, overtime, after hours time or other

extraordinary repair charges or charges relating to repairs or

replacements outside of normal business hours at the place

of business of the authorized Exmark Service Dealer.

• Rental of like or similar replacement equipment during the

period of any warranty, repair or replacement work.

• Any telephone or telegram charges or travel charges.

• Loss or damage to person or property other than that

covered by the terms of this warranty.

• Any claims for lost revenue, lost profit or additional cost as

a result of a claim of breach of warranty.