Page 1

STAND-ON

AERATOR

24INCHMODEL

ForSerialNos.

402,082,300&Higher

PartNo.4503-596Rev.B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442or4443touse

oroperatetheengineonanyforest-covered,

brush-covered,orgrass-coveredlandunlessthe

engineisequippedwithasparkarrester,as

denedinSection4442,maintainedineffective

workingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionof

re.

Toacquireasparkarresterforyourmachine,seeyour

EngineServiceDealer.

ForallmodelsthatdonothaveExmarkengines,

pleaserefertotheenginemanufacturer's

informationincludedwiththemachine.

FormodelswithExmarkengines,refertothis

manualforinformation.

Thegrossornethorsepower(ortorque)of

thisenginewaslaboratoryratedbytheengine

manufacturerinaccordancewiththeSociety

ofAutomotiveEngineers(SAE)J1940orJ2723.

Asconguredtomeetsafety,emission,and

operatingrequirements,theactualengine

horsepower(ortorque)onthisclassofmachine

willbesignicantlylower.

©2018ExmarkMfg.Co.,Inc.

2101AshlandAve

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkAerator.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

aerator.

BEFOREOPERATINGYOURAERATOR,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyouraerator,

maintainitsmaximumefciency,andpromotesafe

operation.

Important:Tomaximizesafety,performance,

andproperoperationofthismachine,itis

essentialthatalloperatorscarefullyreadand

fullyunderstandthecontentsoftheOperator’s

manualprovidedwiththeproduct.Safe

operationofExmarkequipmentisessential.

Failuretocomplywiththeoperatinginstructions

orreceivepropertrainingmayresultininjury.

Gotohttp://www.Exmark.comforadditional

safeoperationinformation,suchassafetytips,

trainingmaterials,andOperator’smanuals.

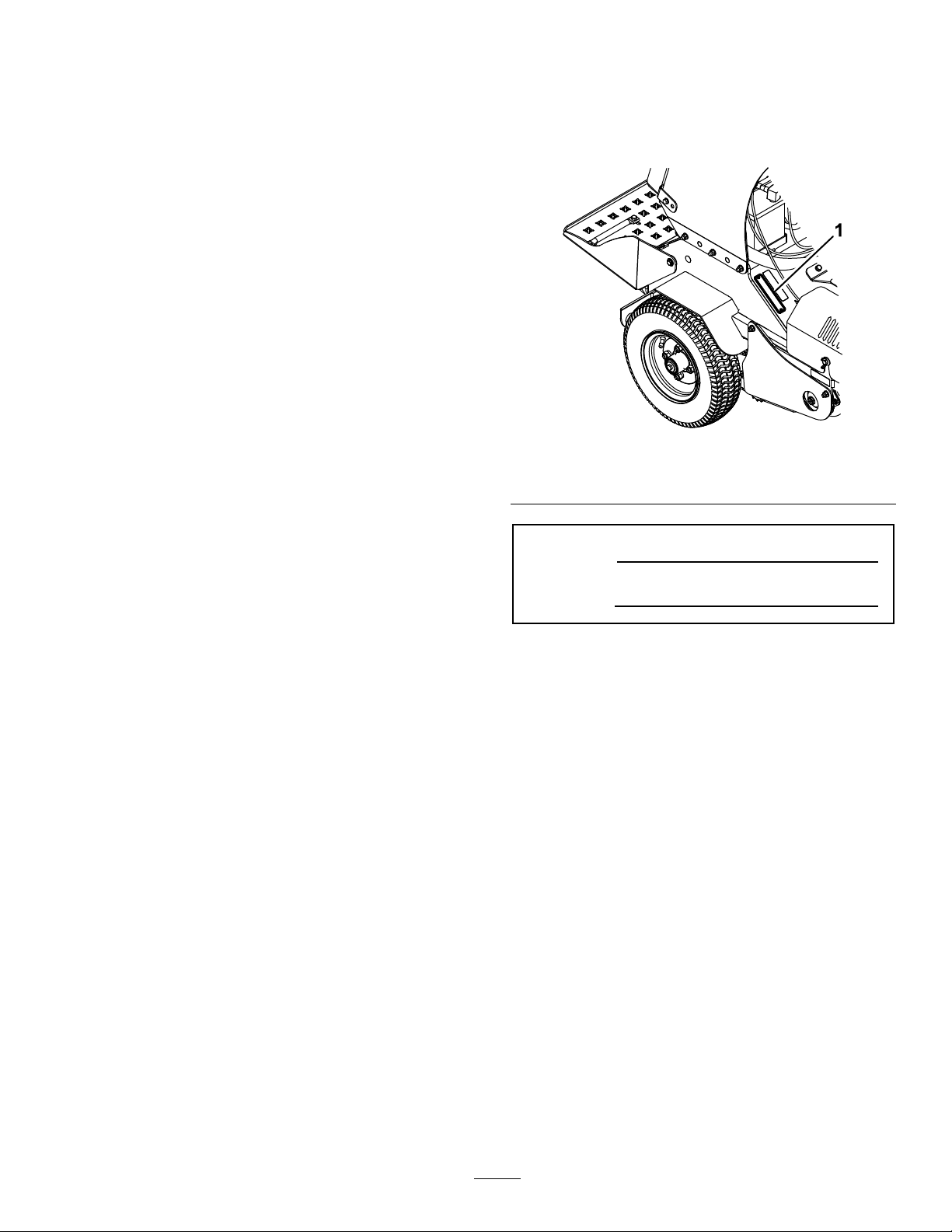

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

g231322

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Forcompletewarrantydetails,see

http://www.Exmark.com.Youmayalsocall

us402-223-6375torequestawrittencopyofthe

product’swarranty.

Ifadditionalinformationisneeded,orshould

yourequiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals......................10

Specications........................................................14

Systems..........................................................14

Dimensions....................................................15

TorqueRequirements.....................................15

ProductOverview.................................................16

Operation..............................................................16

Controls.........................................................16

Pre-Start.........................................................20

OperatingInstructions...................................20

Transporting..................................................23

Maintenance..........................................................25

RecommendedMaintenanceSchedule(s)............25

PeriodicMaintenance........................................26

CheckEngineOilLevel..................................26

CheckBatteryCharge.....................................26

CheckTines...................................................28

ChecktheSafetyInterlock..............................29

CheckforLooseHardware.............................30

ServiceAirCleaner.........................................30

ChangeEngineOil.........................................30

CheckAuxiliaryHydraulicOilLevel................30

CheckHydraulicTransmissionOil

Level..........................................................30

CheckTirePressures......................................31

CheckConditionandTensionOf

Belts...........................................................31

CheckConditionOfChains............................31

CheckConditionOfSprockets.......................31

LubricatingtheChains....................................31

LubricatingtheGreaseFittings.......................31

CheckSparkPlug...........................................32

ChangeAuxiliaryHydraulicReservoirFluid

andFilter....................................................32

ChangeHydraulicTransmissionFiltersand

Fluid..........................................................32

CheckTransmissionOutputShaftNut

TorqueSpecication...................................33

CheckWheelHubBoltTorque

Specication...............................................33

CheckTransmissionMountBolt

Torque.......................................................33

CheckSparkArrester(ifequipped)..................34

ThreadLockingAdhesives..............................34

Adjustments......................................................35

AuxiliaryPumpDriveBeltAdjustment...........35

TransmissionDriveBeltTension....................35

DriveWheelChainTension

Adjustment................................................35

TineDriveChainAdjustment.........................35

AdjustingtheParkingBrake............................35

MotionControlLinkageAdjustment..............36

MotionControlTrackingAdjustment.............36

Return-to-UpSpringAdjustment....................37

Cleaning............................................................38

CleanEngineandExhaustSystem

Area...........................................................38

RemoveEngineShroudsandClean

CoolingFins...............................................38

CleanDebrisFromMachine...........................38

WasteDisposal...............................................38

Troubleshooting....................................................39

Schematics............................................................41

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

SafetyAlertSymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Indicatesanimminentlyhazardous

situationwhich,ifnotavoided,Willresultindeathor

seriousinjury.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

anaerator,andevenmatureteenagersshouldhave

adultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator's

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

g000502

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

aeratorwithouttakingrisks.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

WARNING:Indicatesapotentiallyhazardous

situationwhich,ifnotavoided,Couldresultindeath

orseriousinjury.

CAUTION:Indicatesapotentiallyhazardous

situationwhich,ifnotavoided,Mayresultinminor

ormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readthismanualitistheowner’ sresponsibilityto

explainthismaterialtothem;otherlanguagesmay

beavailableonourwebsite.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Wearappropriateclothingincludingsafetyglasses,

substantialslip-resistantfootwear,andhearing

protection.Longhair,looseclothingorjewelry

maygettangledinmovingparts.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

•Markandavoidhiddenobjectssuchassprinkler

heads,undergroundwires/cables,invisiblefences,

etc.topreventdamagetothesesystemswhen

aerating.

5

Page 6

Safety

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengine

oremissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoradd

fuelwhenengineisrunningorwhenthe

engineishot.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Do

Notuseanozzlelockopendevice.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperatorpresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

6

Page 7

Safety

Operation

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscanoccur

oncontactanddebris,suchasleaves,grass,

brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,to

coolbeforetouching.

•Removeaccumulateddebrisfrommuferand

enginearea.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcankill

you.

DoNotrunengineindoorsorinasmallconned

areawheredangerouscarbonmonoxidefumes

cancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

DoNotoperatethemachine;seekshelter.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkmachineonlevelground.Stopengine,wait

forallmovingpartstostop,removekeyand

engageparkingbrake:

–Beforechecking,cleaningorworkingonthe

machine.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemachinefor

damageandmakerepairsbeforerestarting

andoperatingthemachine).

–Beforeclearingblockages.

–Wheneveryouleavethemachine.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesinplace

andworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•NEVERcarrypassengers.DONOToperate

themachinewhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.

•Raisethetines,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemachinetoandfromthework

area.

•DoNotoperatethemachineundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,theoperatormust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachine

onaslope.

•Operateacrossslopes,neverupanddown.Avoid

operationonexcessivelysteeporwetslopes.

7

Page 8

Safety

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardropoffs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalkbehind

machineorahandheldtooltooperateinthese

areas.

•Useextracarewhileoperatingwithaccessories

orattachments.Thesecanchangethestabilityof

themachineandcausealossofcontrol.Follow

directionsforcounterweights.

•Ifyoulosecontrolofthemachine,stepoffand

awayfromthedirectionoftravelofthemachine.

MaintenanceandStorage

•Raisethetines,settheparkingbrake,stopengine

andremovekeyordisconnectsparkplugwire.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Keepengineandengineareafreefromexcessive

greaseoroilandotherdebriswhichcan

accumulateintheseareas.Thesematerialscan

becomecombustibleandmayresultinare.

•Letenginecoolbeforestoringanddonotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

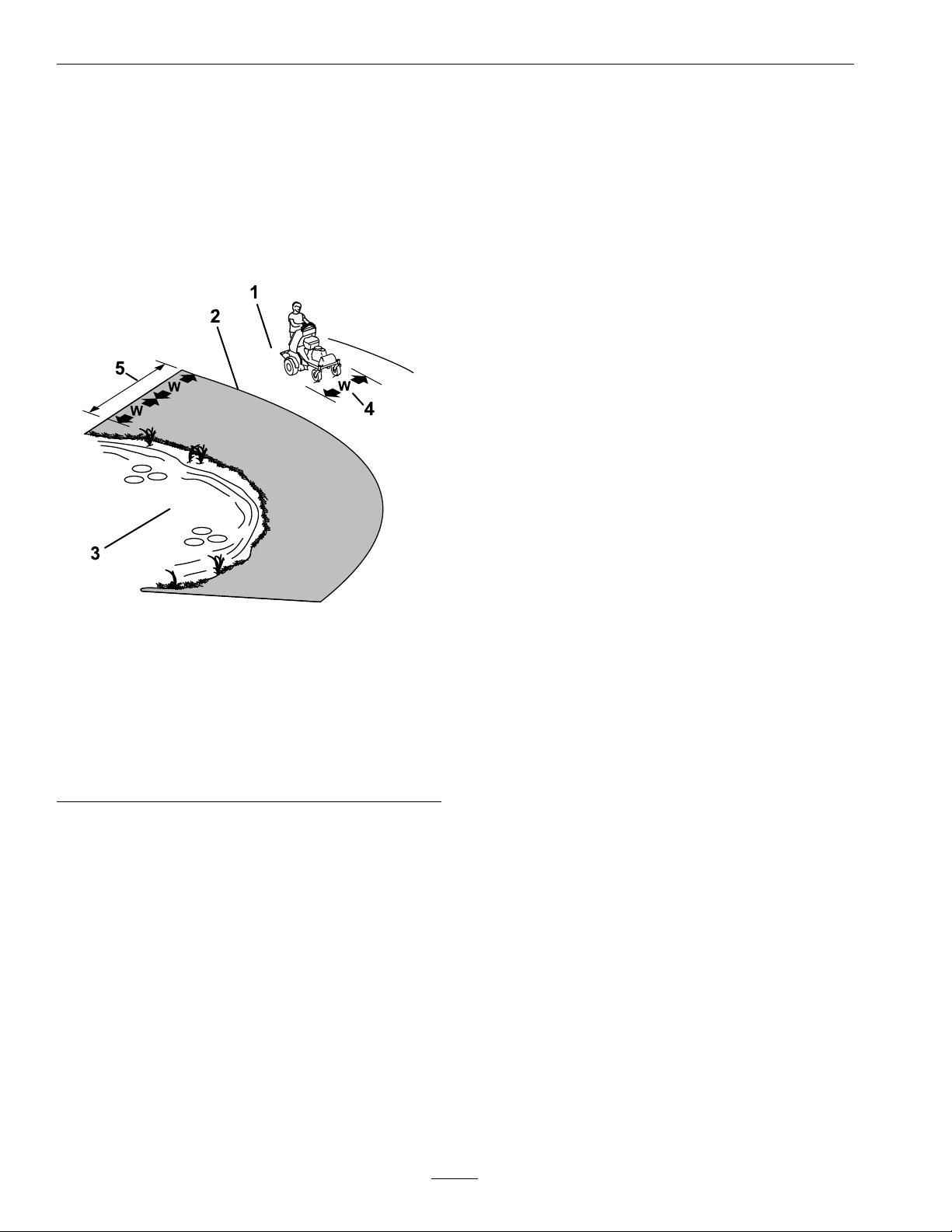

Figure3

1.SafeZone—Usethemachinehere

2.DangerZone-Useawalkbehindmachineorahand

heldtoolneardropoffs,ditches,embankments,water

orotherhazards.

3.Water

4.W=widthofthemachine

5.Keepasafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

•Avoidstarting,stoppingorturningthemachine

onslopes.Avoidmakingsuddenchangesinspeed

ordirection;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwetgrass,

acrossslopesordownhillmaycausethemachine

tolosetraction.Lossoftractiontothedrive

wheelsmayresultinslidingandalossofbraking

andsteering.Themachinecanslideevenifthe

drivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.Tall

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

g222486

•Parkmachineonlevel,hardground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingandservicingtines.Wrap

thetine(s)orweargloves,andusecautionwhen

servicingthem.Onlyreplacedamagedtines.

Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

8

Page 9

Safety

DANGER

Chargingorjumpstartingthebatterymay

produceexplosivegases.Batterygasescan

explodecausingseriousinjury.

•Keepsparks,ames,orcigarettesaway

frombattery.

•Ventilatewhenchargingorusingbattery

inanenclosedspace.

•Makesureventingpathofbatteryis

alwaysopenoncebatteryislledwith

acid.

•Alwaysshieldeyesandfacefrombattery.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldeyes,and

rubberglovestoprotectskinandclothing

whenhandlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwith

waterandcalladoctorimmediately.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,traction,

andsafetyofthemachine.Failuretouseoriginal

Exmarkpartscouldcauseseriousinjuryor

death.Makingunauthorizedchangestothe

engine,fuelorventingsystem,mayviolateEP A

andCARBregulations.

Replaceallpartsincluding,butnotlimitedto,

tires,belts,tines,andfuelsystemcomponents

withoriginalExmarkparts.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemay

result.

•Ifequipped,makesureallhydraulicuid

hosesandlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretohydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

CAUTION

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagementof

components.Sparkscouldcauseanexplosion

ormovingpartscouldaccidentallyengage

causingpersonalinjury.

Besureignitionswitchisinthe“OFF”

positionbeforechargingthebattery.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Usecardboardorpaper,notyourhands,to

ndhydraulicleaks.

•Beforeperforminganyworkonthehydraulic

system:

–Safelyrelieveallpressureintheground

drivehydraulicsystembyplacingthemotion

controlleversinneutralandshuttingoffthe

engine.

–Safelyrelieveallpressureintheauxiliary

hydraulicsystembyshuttingofftheengine,

turningtheignitionswitchtothe“ON”

position,andpressingthetineground

engagementswitch.Oncethetineshave

loweredtotheground,releasethetineground

engagementswitchandturntheignition

switchtothe“OFF”position.

9

Page 10

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialaerator.

115-4212

1.Hydraulicoillevel3.Warning—donottouch

thehotsurface.

2.ReadtheOperator's

Manual.

117–2718

120-9570

1.Warning—stayawayfrommovingparts,keepallguards

andshieldsinplace.

decal115-4212

decal121-6150

121-6150

1.Cuttinghazardofhandandfoot–stayawayfrommoving

parts.

decal117-2718

decal121-6161

121–6161

1.Entanglementhazard,belt—stayawayfrommoving

parts;keepallguardsinplace.

decal120-9570

10

Page 11

Safety

decal135-3183

135-3183

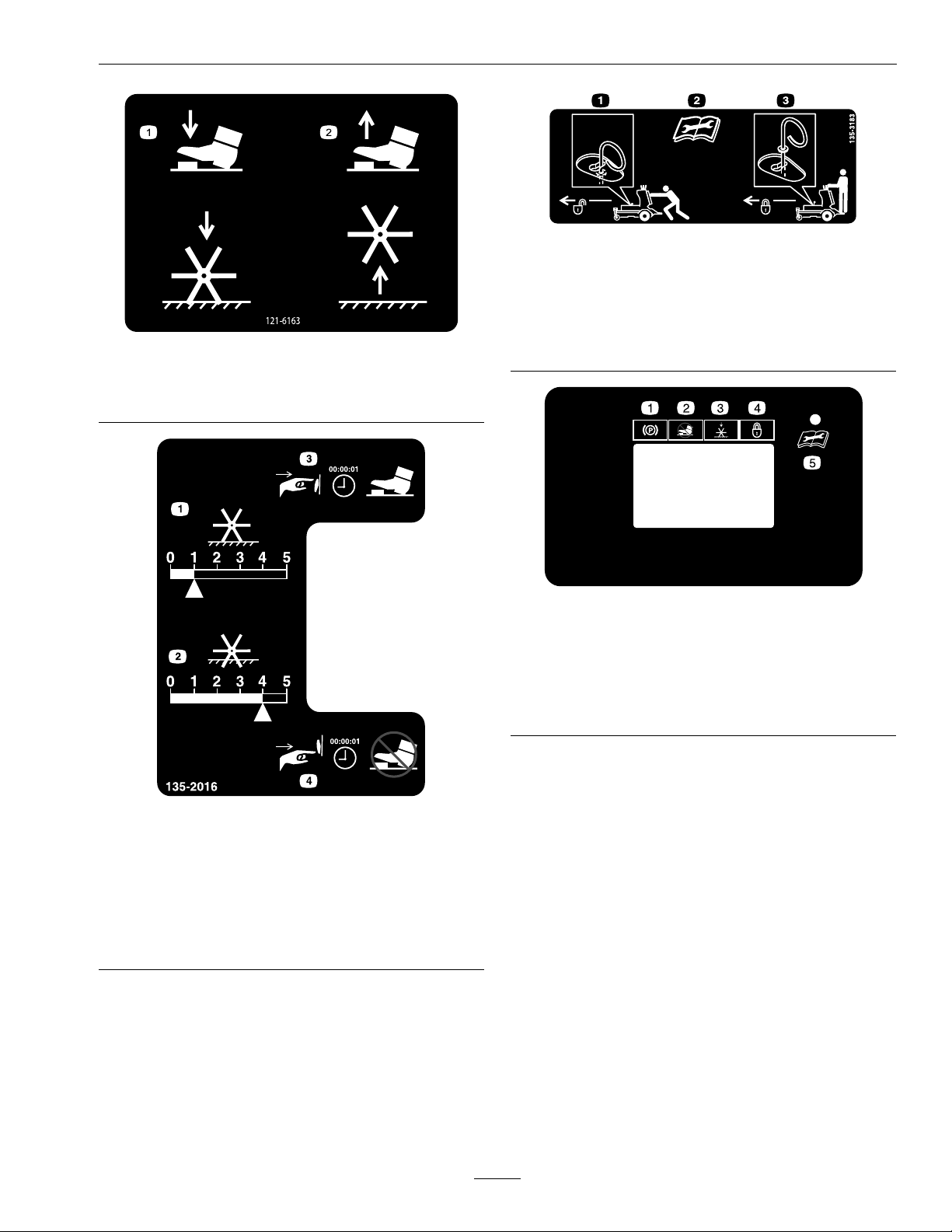

121–6163

1.Presstolowerthetines.2.Releasetoraisethe

tines.

1.Bypassleverpositionfor

pushingthemachine.

3.Bypassleverpositionfor

operatingthemachine.

2.Readtheinstructions

decal121-6163

beforeservicingor

performingmaintenance.

g211619

HourMeter/TineEngagementDisplay

1.Parkingbrake4.Depthsettinglock

2.Tinegroundengagement

footswitchlockout

3.Tinedownposition

5.SeeOperator’smanual

foroperatingconditions

code

135-2016

1.Electronictinedepth-decrease

2.Electronictinedepth-increase

3.Pressandhold1secondtoturnon—tineground

engagementfootswitchunlock

4.Pressandhold1secondtoturnoff—tineground

engagementfootswitchlock

decal135-2016

11

Page 12

Safety

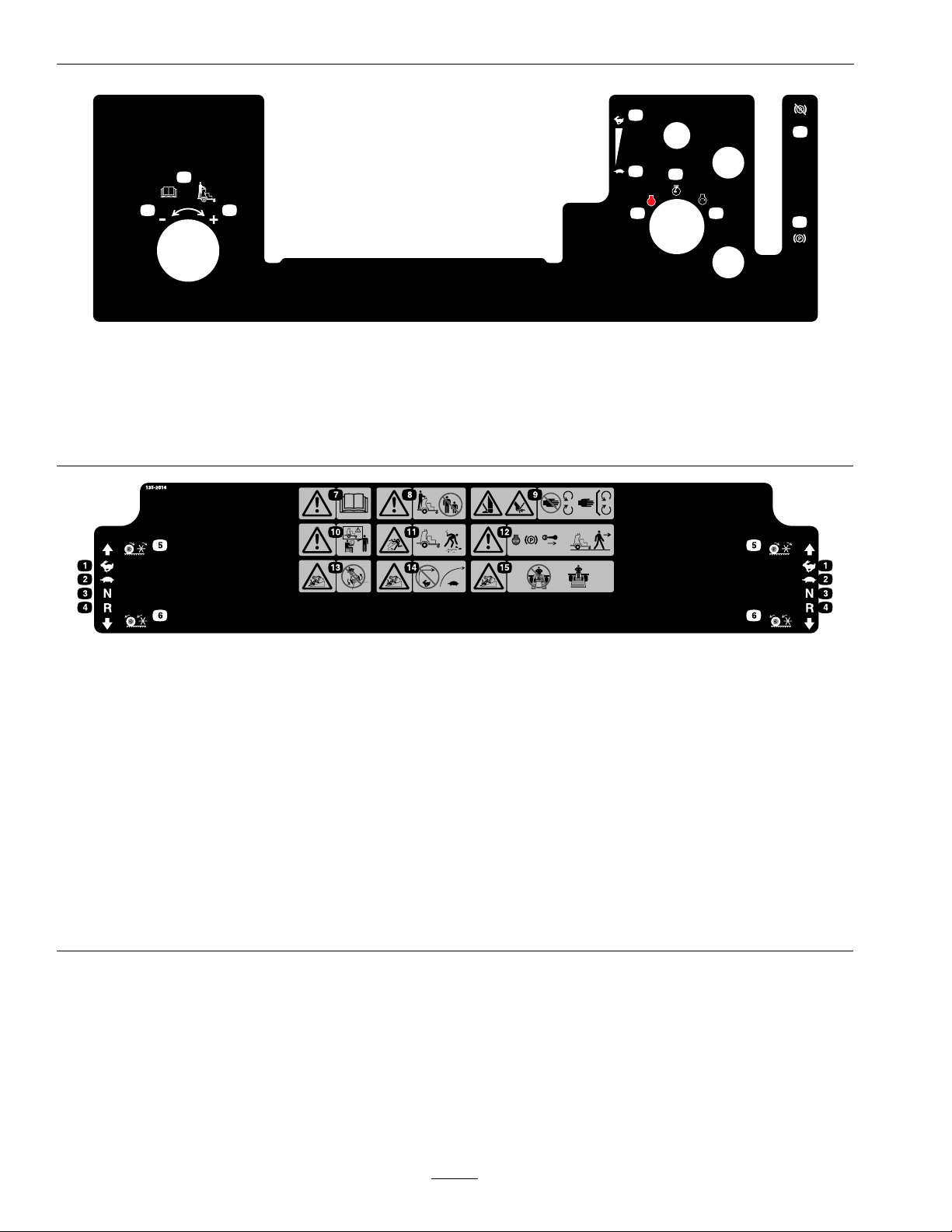

STOP

LB

KG

135-2013

2

1

3

4

5

6

7

8

9

10

decal135-2013-1

135-2013

1.Operatorweightadjustment

5.Throttle—slow9.Parkingbrake—engage

2.Increase6.Engine—on10.Parkingbrake—release

3.Decrease7.Engine—start

4.Throttle—fast8.Engine—off

135-2014

1.Fast6.Wheelsandtinesrotatewhen

2.Slow7.Warning—readtheOperator’s

3.Neutral

4.Reverse

5.Wheelsandtinesrotatewhen

movingforward

movingbackward

Manual.

8.Warning—keepbystandersasafe

distanceawayfromthemachine.

9.Warning—Cutting/dismemberment

hazardofhandorfoot;tines—stay

awayfrommovingparts;keepall

guardsinplace.

10.Warning—Donotoperatethe

machineunlessyouaretrained.

decal135-2014b

11.Thrownobjecthazard—pickup

debrisbeforeoperatingthemachine.

12.Warning—shutofftheengine,

engagetheparkingbreak,and

removetheignitionkeybefore

leavingthemachine.

13.Tippinghazard–DoNotoperatethe

machineneardrop-offs.

14.Tippinghazard–DoNotturnsharply

whiletravelingfast;slowdownand

turngradually.

15.Tippinghazard–DoNotusesplit

ramps;usefullwidthrampstoload

amachinefortransport.

12

Page 13

Safety

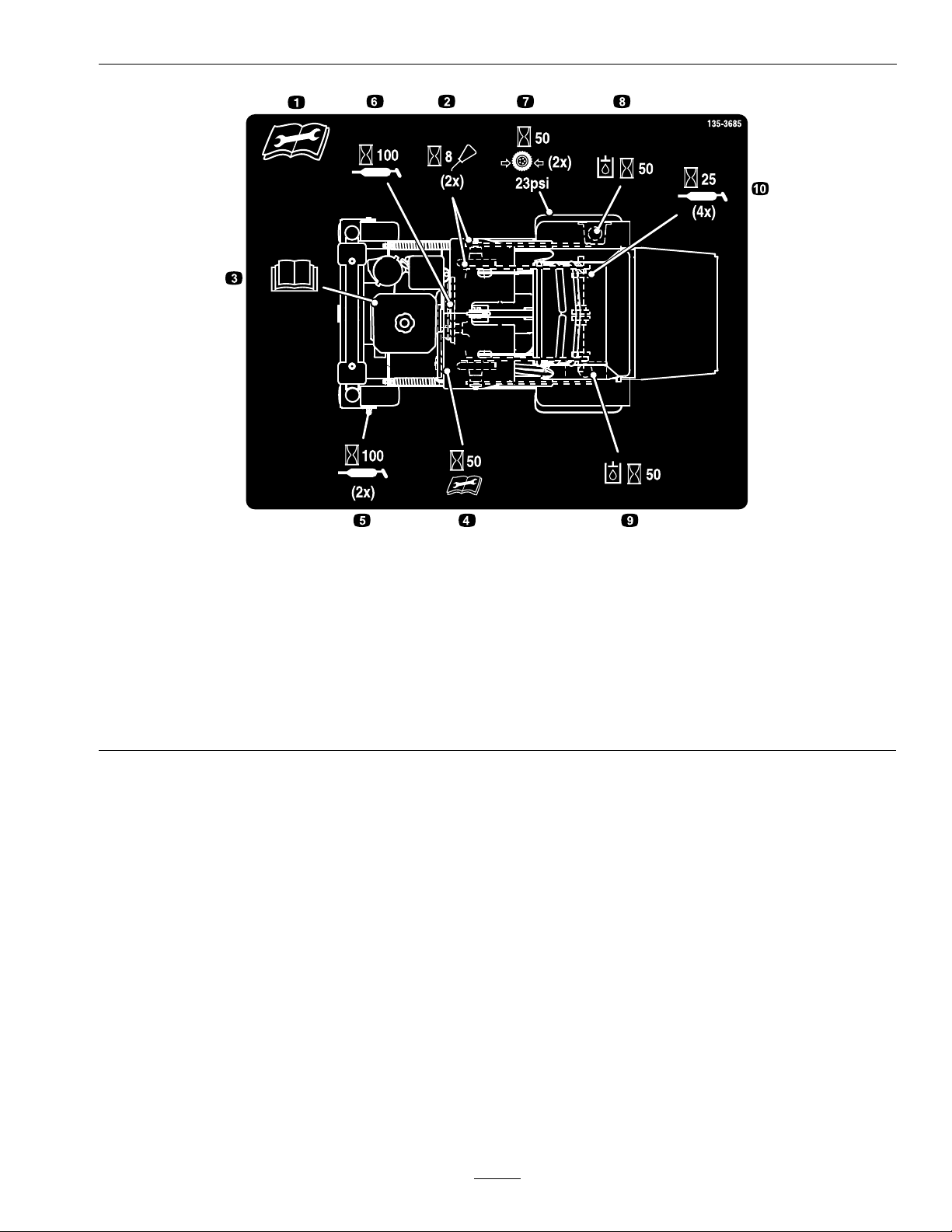

135-3685

1.Readandunderstandtheoperator’smanualbefore

servicingthismachine.

2.Cleanandoilchainsandcheckchaintension(2x)every8

hours

3.Seeengineowner’smanualforservice8.Checkhydraulicoillevel(2x)(Onlyuserecommended

4.Checkauxiliarypumpdrivebelttensionevery50hours9.Checkauxiliaryhydraulictank(OnlyuseAW-32hydrooil)

5.Greasefrontcasterwheelbearings(2x)every100hours10.Greasetineshaftbearings(4x)every25hours

6.Greasebeltidlerpivotevery100hours

7.Checktirepressure-23psi(2x)every50hours

hydrooil)every50hours

every50hours

decal135-3685

13

Page 14

Specications

Specications

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•EngineOilType:Exmark4–CyclePremium

EngineOil

•RPM:FullSpeed:3800±100RPM(NoLoad)

FuelSystem

•Capacity:1.9gal.(7L)

•FuelRecommendations:

–Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

–Oxygenatedfuelwithupto10%ethanolor

15%MTBEbyvolumeisacceptable.

–DoNotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanol

byvolume.Performanceproblemsand/or

enginedamagemayresultwhichmaynotbe

coveredunderwarranty.

–DoNotusegasolinecontainingmethanol.

OperatorControls

•SteeringandMotionControl

–Separatelevers,oneachsideoftheconsole,

controlspeedanddirectionoftravelofthe

respectivedrivewheels.

–Steeringiscontrolledbyvaryingtheposition

oftheleversrelativetoeachother.

•TineGroundEngagement:Engagesthetines

withtheground.

•ParkingBrakeLever:Engagestheparkingbrake.

•TineDownPressureControl:Adjuststinedown

pressure.

•ElectronicDepthControl:Adjustsactualtine

depthelectronically.

Transmission

•Twointegratedhydrostatictransmissions:Hydro

GearZT3100.

•HydraulicOilCapacity:78oz.(2.3L)per

transmission

•HydraulicFilterisreplaceablecartridgetype

•Speeds:

–0-7.0mph(11.3km/hr)forward.

–0-4.0mph(6.4km/hr)reverse.

–DoNotstorefueleitherinthefueltankor

fuelcontainersoverthewinterunlessafuel

stabilizerisused.

–DoNotaddoiltogasoline.

•FuelShut-OffValve:1/4turn

ElectricalSystem(ElectricStart)

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:Kohler,10amps

•BatteryType:BCIGroupU1

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuse:20ampmainfuse

SafetyInterlockSystem

Enginewillnotstartunlesstheparkbrakeisengaged.

WheelandTineDriveSystem

Drivewheelsandtheoutsideaerationtinesare

driventhroughrollerchainsbythetwohydrostatic

transmissions.

14

Page 15

Specications

TiresandWheels

Drive

Pneumatic

(Air-Filled)

Quantity

Tread

Size16.5x4.50-8113x4.00-6

PlyRating

Pressure

22

TurfSaverSmooth

4

23psi

(159kPa)

Aeration

AerationWidth:24inches(61.0cm)

Tines:Qty:36

CoreDepth:.5-5inches(1.3-12.7cm)

Holespersquarefoot:4.6

TorqueRequirements

FrontCaster

Semi-Pneumatic

BoltLocation

EngineMountingBolts

WheelLugNuts

WheelHubBolt27-33ft-lb(37-45N-m)

TransmissionOutput

ShaftNuts

TineShaftNut

WheelAxleBolt135-165ft-lb

TransmissionBracket

Bolts(4xwithspacers)

Torque

27-33ft-lb(37-45N-m)

85-105ft-lb(115-142

N-m)

211-260ft-lb

(286-352N-m)

211-260ft-lb

(286-352N-m)

(183-224N-m)

38-48ft-lb

(52-65N-m)

Dimensions

OverallWidth:

35.5inches(90.2cm)

OverallLength:

68.6inches(173.2cm)

OverallHeight:

51.0inches(129.5cm)

TreadWidth:(OutsidetoOutsideof

Tires,Widthwise)

35.5inches(90.2cm)

CurbWeight:

856lb(388kg)

15

Page 16

Operation

ProductOverview

Figure4

1.Platform

2.Parkbrakelever5.Fuelcap

3.Enginecontrols

4.Motioncontrollevers

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

MotionControlLevers

Themotioncontrollevers,locatedoneachsideofthe

topconsole,controltheforwardandreversemotion

ofthemachine.

Movingtheleversforwardorbackwardturns

thewheelonthesamesideforwardorreverse

respectively.Wheelspeedisproportionaltothe

amounttheleverismoved.

g231324

Important:Thetinesarerotatingwhenthe

motioncontrolleversaremovedoutofthe

neutralposition.

Figure5

1.LHMotioncontrollever5.Forward

2.RHMotioncontrollever6.Neutral

3.Frontreferencebar

4.Frontofunit8.Rearreferencebar

7.Reverse

ChokeControl

Locatedonthecontrolconsole(blackknob)(see

Figure6).

Thechokeisusedtoaidinstartingacoldengine.

Pullingthechokeknobupwardwillputthechoke

inthe“ON”positionandpushingthechokeknob

downward,willputthechokeinthe“OFF”position.

16

g223330

Page 17

Operation

DoNotrunawarmenginewithchokeinthe“ON”

position.

Pullleverrearwardtoengagethebrake.

Pushtheleverforwardtodisengagethebrake.

Whenparkingonasteepslope,thewheelsmustbe

chockedorblockedinadditiontothebrakebeing

engaged.Theunitmustbetieddownandbrake

engagedwhentransporting.

IgnitionSwitch

Locatedontherightsideofthecontrolconsole.

Theignitionswitchisusedtostartandstopthe

engine.Theswitchhasthreepositions“OFF”,“ON”

and“START”.Insertkeyintoswitchandrotate

clockwisetothe“ON”position.Rotateclockwiseto

thenextpositiontoengagethestarter(keymustbe

heldagainstspringpressureinthisposition).Allow

thekeytoreturntothe“ON”positionimmediately

aftertheenginestarts.

Figure6

1.Tinegroundengagement

footswitch

2.Operatorweight

adjustmentcontrol

3.Multi-functionswitch

4.LHMotioncontrollever10.Parkbrake

5.Frontreferencebar

6.Throttle

7.Choke

8.RHMotioncontrollever

9.Hourmeter

11.Ignitionswitch

ThrottleControl

Locatedonthecontrolconsole(redlever)(see

Figure6).

Thethrottleisusedtocontrolenginespeed.Moving

thethrottleleverforwardwillincreaseenginespeed

andmovingthethrottlelevertotherearwilldecrease

enginespeed.Movingthethrottleforwardintothe

detentisfullthrottle.

g231368

g008610

Figure7

1.Off3.Start

2.On

Note:Tostarttheengine,theparkingbrakemust

beengaged.(Itisnotnecessaryfortheoperatorto

beontheplatform.)

HourMeter/TineEngagementDisplay

Locatedtotheleftoftheignitionswitchonthe

controlconsole.

•Thehourmetermonitorsanddisplaysengine

hours.

ParkBrakeLever

Locatedontherightsideoftheignitionswitchon

thecontrolconsole.

Thebrakeleverengagesaparkingbrakeinthe

transmissions.

17

Page 18

Operation

Therearetwowaystoactivatethedisplay .

1.Tapthemulti-functionswitcheitherupordown

todisplaythetineengagementmeter.

2.Steponthetinegroundengagementfootswitch.

Ahighernumberonthestatusbarincreasesthe

lengthoftheaerationplugandalowernumber

decreasesit.

Note:Ifthepluglengthisnotdesiredlength,the

machinemayneedtobeadjustedtoaccommodate

g211730

Figure8

HourMeterDisplay

fortheweightoftheoperator(refertotheOperator

WeightAdjustmentControlsectionformore

information).

1.LCDIndicators/Informationscreen

2.Hourdisplay

3.LEDstatuslight

Hoursaredisplayedwhenthekeyisofforwhen

themachineisrunning.Hoursarenotdisplayed

whenthemachineisaerating.

Note:TheLCDindicatorwillappearinthepark

brakesettingwhenitmeetsthe“safetostart”

mode(parkbrakeengaged).

•Thetineengagementdisplaymonitorsand

displaystheelectronictinedepthsetting.

Note:RefertotheHourMeter/TineEngagement

User’sGuidefordetailedinformationexplaining

theOperatorinterfaceallowinguserstoaccess

information,resetcounters,modifysystemsettings,

andtroubleshoottheequipment.

LEDStatusLights

Locatedontherightsideofthehourmeter/tine

engagementdisplay.

TheLEDismulti-coloredtoindicatethesystem

statusandislocatedontherightsideofthepanel.

•SolidGreen—indicatesnormaloperating

activity.

•BlinkingRed—indicatesafaultisactive.

•SolidRed—indicatesmaintenanceisrequired.

Note:RefertotheHourMeter/TineEngagement

User’sGuideformoreinformation.

Multi-FunctionSwitch

TineEngagementDisplay

1.LCDIndicators/Informationscreen

2.Tinedepthstatusbar

3.Tinedepthsettingindicator

4.LEDstatuslight

Figure9

Locatedtotheleftofthehourmeter/tineengagement

display.

g211731

Thisswitchallowstheoperatorto:

•increase/decreasethedepthofaerationplug.

•lockorunlockthetinedepthsetting.

•lockorunlocktheTineGroundEngagement

FootSwitch.

FuelShut-OffLever

LocatedundertheaircleaneronthefrontRHside.

Thefuelshut-offleverisusedtoshutoffthefuel

whenthemachinewillnotbeusedforafewdays,

18

Page 19

duringtransporttoandfromthejobsite,andwhen

parkedinsideabuilding.

Rotatethehandlecounterclockwisetoopen;rotate

clockwiseto90°toclose.

DriveWheelReleaseValves

WARNING

Handsmaybecomeentangledintherotating

drivecomponentsbelowtheenginedeck,which

couldresultinseriousinjuryordeath.

Stopengine,removekey,allowallthemoving

partstostopbeforeaccessingthedrivewheel

releasevalves.

Operation

g211754

Figure10

WARNING

Theengineandhydraulicdriveunitscanbecome

veryhot.T ouchingahotengineorhydraulic

driveunitscancausesevereburns.

Allowtheengineandhydraulicdriveunitsto

coolcompletelybeforeaccessingthedrivewheel

releasevalves.

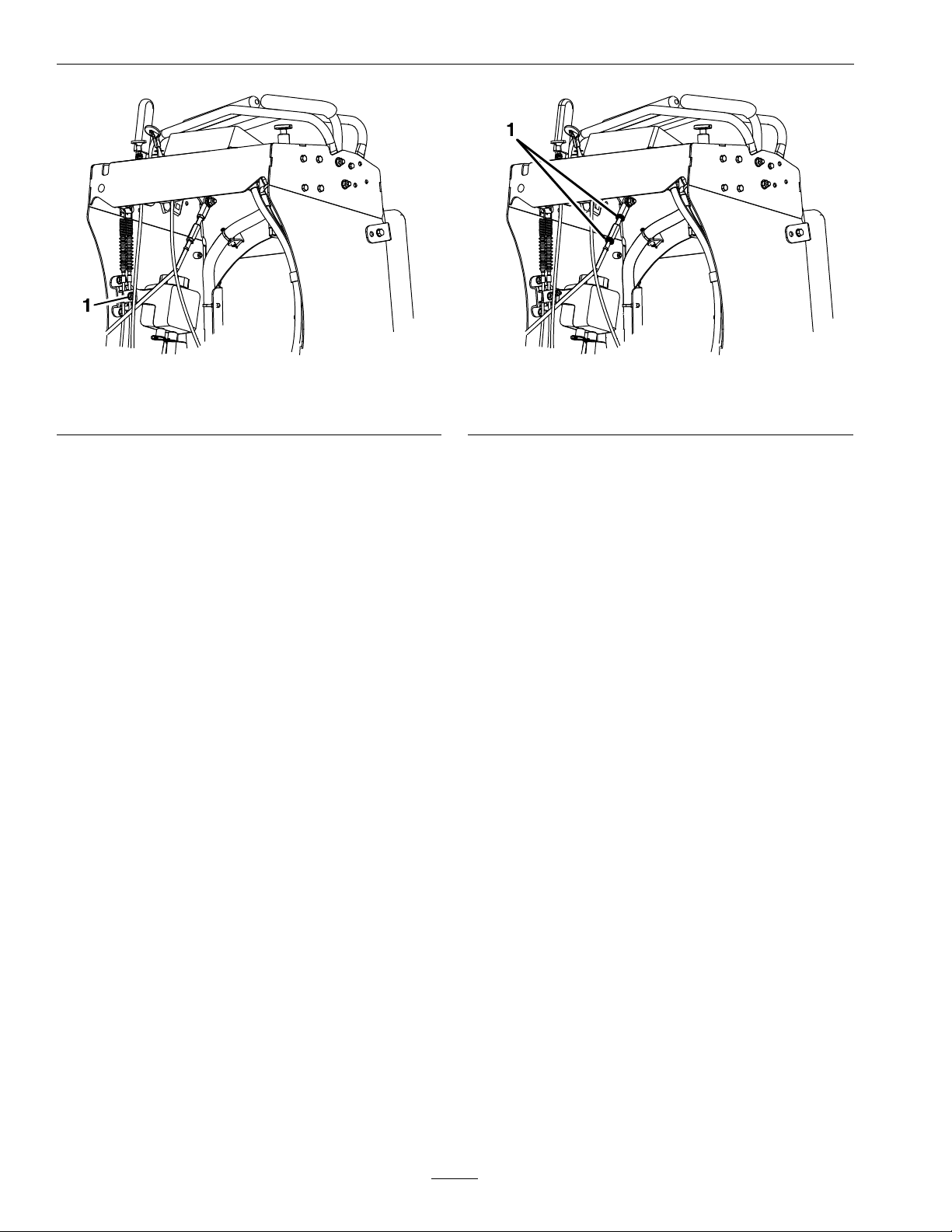

Locatedontheleftandrightsidesabovethe

transaxles.

Duringnormaloperatingconditions,thewasher

ontheleverispositionedoutsidetheslots.Ifthe

machinehastobepushedbyhand,thevalvesmust

beinthe“released”position(seeFigure10).

1.Leverpositionfor

operatingthemachine

2.Washeroutsideofslot

3.Leverpositiontopush

themachine

4.Washerinsideslot

Toreleasethedrivewheels,movethelevertothe

largeropeningoftheslot,pushitinuntilthewasher

isinsidetheframe,thenmovetheleverbacktothe

narrowportionoftheslot.Repeatthisoneachside

ofthemachine.

Releasetheparkingbrake.Themachineisnowable

tobepushedbyhand.

DoNottowmachine.

Toresetthedrivesystembacktotheoperating

position:movethelevertothelargeropeningof

theslot,pulloutwarduntilthewasherisoutsideof

theframe,thenmovetheleverbacktothenarrow

portionoftheslot.Repeatthisoneachsideofthe

machine.

TineGroundEngagementFoot

Switch

Keephandsandfeetawayfromthetines.Ensure

thatthetinesareaisclearofanyobstructions

beforeloweringit.

Theswitchislocatedontheoperatorplatform.

Tolowerthetinesintotheground,standonthetine

groundengagementswitch.TheLEDilluminates

inthehourmeter/tineengagementdisplaywhen

thetineengagementisactivated.Toraisethetines,

removeyourfootfromtheswitch.

19

Page 20

Operation

Thisswitchcanbelockedout(disabled)withthe

multi-functionswitch.

•Tapandholdthebottomoftheswitchtooverride

andlockout(disable)thefootswitch.TheLED

illuminatesinthehourmeter/tineengagement

display.Usethisfeaturewhentransportingthe

aerator.

•Tounlock,tapandholdthetopofthe

multi-functionswitchuntiltheLEDlight

disappears.

Note:Thelockoutfeatureisengagedeachtimethe

engineisswitchedoff.

OperatorWeightAdjustmentControl

Locatedontheleftsideofthecontrolconsole(see

Figure6).

Thisfeaturetakesintoaccounttheweightofthe

operatorsothatthecorrectaeratingpressureandplug

lengthisachievedandtomaximizelateralmachine

stability.Rotatingthecontrolcounterclockwise

decreasesthepressureandrotatingitclockwise

increasesit(SeeAdjustingtheOperatorWeight

ControlSetting).

OperatingInstructions

OpentheFuelShut-OffValve

Rotatethelevercounterclockwisetoopen.

StartingtheEngine

1.Leavethemotioncontrolleversinneutraland

engagetheparkingbrake.

2.Setthethrottletothe“FAST”position.

3.Onacoldengine,pullthechokeknobupward

intothe“ON”position.Onawarmengine,leave

thechokeinthe“OFF”position.

4.Turnignitionswitchtothe“START”position.

Releasetheswitchassoonastheenginestarts.

Important:DoNotcranktheengine

continuouslyformorethantensecondsata

time.Iftheenginedoesnotstart,allowa60

secondcool-downperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor

Enginemaybedifculttostartin

temperaturesunder30°F(-1°C).

Note:Eachoperatormustadjustthesystempressure

sothatthedrivetireslightlytouchtheground.

Important:Keepthedrivetiresonthegroundat

alltimestomaximizelateralmachinestability.

Pre-Start

Fillfueltankonlevelground.SeeFuel

RecommendationsintheSpecicationssectionfor

additionalgasolineinformation.

DoNotaddoiltogasoline.

DoNotoverllfueltank.Fillthefueltanktothe

bottomofthellerneck.Theemptyspaceinthe

tankallowsgasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineoremission

system.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

5.Ifthechokeisinthe“ON”position,gradually

returnchoketothe“OFF”positionastheengine

warmsup.

LoweringtheTines

DANGER

Therotatingtinesundertheenginedeckare

dangerous.Tinecontactcancauseseriousinjury

orkillyou.

DoNotputhandsorfeetundertheunitwhen

theengineisrunning.

1.Disengagetheparkingbrake.Setthrottleto

“FAST”position.

2.Thelockoutfeatureisengagedeachtimethe

engineisswitchedoff.T ounlock,tapandhold

thetopofthemulti-functionswitchuntilthe

LEDlightdisappears.

3.Taptheswitchoncetodisplaythetineengagement

depthsetting;adjustifnecessary.

20

Page 21

Operation

4.Lowerthetinesbypressingonthetineground

engagementfootswitch.TheLEDindicator

shouldilluminateunderthetinedownposition

onthehourmeter.

5.Standontheswitchandmovethemotioncontrol

leversforwardtoaerate.

Note:Thefootrockerbar,locatedbehindthe

tinegroundengagementfootswitch,canbe

adjustedforoperatorcomfort.Toadjust,loosen

thefootrockerbarhardware,slidethebarforward

orrearward,andretightenhardware.

Locking/UnlockingtheTineDepth

Setting

Thesettingscanbelockedtoensurethetinedepth

isnotinadvertentlychangedbytheoperatororleft

unlocked.

•Toactivatethedepthlock:turntheignitionkey

from“OFF”to“ON”vetimes(stopatthe

“ON”).Usethemulti-functionswitchtoadjust

thetinedepthtothedesiredsetting.Pressand

holdthemulti-functionswitchdownforone

secondtolock.

•Toinactivatethedepthlock:turntheignition

keyfrom“OFF”to“ON”vetimes(stopatthe

“ON”).Pressandholdthemulti-functionswitch

upforonesecondtounlock.

Switchthekeytothe“OFF”or“START”position

whenyouarenished.

AdjustingtheOperatorWeight

ControlSetting

adjustmentcontrolcounterclockwisetolower

themachineuntilthetirestouchtheground.

•Ifthetinesarenottouchingtheground,

rotatetheoperatorweightadjustmentcontrol

clockwiseuntilthetineslowerandtouchthe

ground(butnotraisethemachine).

Important:Keepthedrivetiresonthe

groundatalltimestomaximizelateral

machinestabilityandaerationquality .

5.Releasethetinegroundengagementfootswitch.

AdjustingtheTineDepthSetting

Tapthemulti-functionswitchupordowntosetthe

aerationdepth.Tapthebottomofthemulti-function

switchtoincreasethetinedepthtoremovealonger

plug.Tapthetopoftheswitchtodecreasethetine

depthtoremoveashorterplug.

Note:Tinedepthadjustmentscannowbemade

withthemulti-functionswitchonly.Theidealplug

depthis2.5–3inches(6.4–7.6cm).Adjustcontrolsto

adapttothesoilconditions.

RaisingtheTines

Toraisethetines:

•Removeyourfootfromthetineground

engagementfootswitch

•Theignitionkeyisswitchedfromthe“ON”

positiontothe“OFF”position.

Important:Thetinesarerotatingwhenthe

motioncontrolleverismovedoutoftheneutral

position.

1.Withthetinesraised,drivetheaeratortoa

hard,atsurface(suchasconcrete)andstopthe

aerator,butleaveitrunning.

2.Setthrottletothe“FAST”positionanddisengage

theparkbrake.

3.Usethemulti-functionswitchtosetthetinedepth

to3.0(seeAdjustingtheTineDepthSetting

section.

4.Pressandholdthetinegroundengagementfoot

switchtolowerthetines.

•Ifthemachineraisesandthegroundtiresare

nolongertouching,rotatetheoperatorweight

StoppingtheEngine

1.Movethemotioncontrolleversbacktothe

neutralpositionandbringtheunittoafullstop.

2.Liftyourfootoffofthetinegroundengagement

footswitchcontroltoraisethetines.

3.Activatethetineengagementfootswitchlockout.

4.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

5.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

6.Engagetheparkingbrake.

21

Page 22

Operation

7.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingtheengine.

8.Closethefuelshut-offvalvewhenthemachine

willnotbeinuseforafewdays,when

transporting,orwhentheunitisparkedinside

abuilding.

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioningone

levertoomuchaheadoftheother.Operatormay

losecontrolofthemachine,whichmaycause

damagetothemachineorinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

g016672

Figure12

Important:Tobeginmovement(forwardor

backward),thebrakelevermustbedisengaged

(pushedforward)beforethemotioncontrol

leverscanbemoved.

Figure11

1.LHMotioncontrollever5.Forward

2.RHMotioncontrollever6.Neutral

3.Frontreferencebar

4.Frontofunit

7.Reverse

DrivingForward

Toturnleftorright,pullthemotioncontrollever

backtowardneutralinthedesiredturndirection.

Thetinescanbeinthedownpositionwhen

makinggradualturns.

Tomakezeroturns,liftyourfootoffofthetine

engagementfootswitchcontroltoraisethetines.

Theheadwillraiseinonesecond.

Important:DoNotmakeazeroturnwhen

thetinesaredownasturftearingwillresult.

Themachinewillmovefasterthefartherthe

motioncontrolleversaremovedfromtheneutral

position.

g223330

4.Tostop,positionbothmotioncontrolleversin

theneutraloperateposition.

DrivinginReverse

1.Movethemotioncontrolleverstotheneutral

operateposition.

2.Tomoverearwardinastraightline,slowlymove

bothleversrearwardwithequalpressure.

1.Makesurethemotioncontrolleversareinthe

neutralposition.

2.Releasetheparkingbrake.

3.Tomoveforwardinastraightline,moveboth

leversforwardwithequalpressure.

Important:DoNotdriveinreversewhenthe

tinesaredownasturftearingwilloccur.

22

Page 23

Figure13

Operation

g016673

g231460

Figure14

Toturnleftorright,releasepressureonthe

motioncontrollevertowardthedesiredturn

direction.

Tomakezeroturns,liftyourfootoffofthetine

groundengagementfootswitchtoraisethetines.

Theheadwillraiseinhalfsecond.

Important:DoNotmakeazeroturnwhen

thetinesareinthedownposition.

3.Tostop,positionbothmotioncontrolleversin

theneutraloperateposition.

AdjustingtheFrontReference/Speed

ControlBar

Adjustthefrontreference/speedcontrolbarfor

desiredmaximumforwardspeed.

1.Stopthemachineandmovethemotioncontrol

leverstotheneutralposition.

2.Loosentheboltsonbothsidesofthecontrol

towerbylooseningthetwonutsoneachside

(fourtotal)oftheconsole(seeFigure14).

1.Twonuts

2.Frontreference/speed

controlbar

3.Movethebarforwardtoobtainthefastestspeed.

Movethebarbackwardtoobtaintheslowest

speed.

4.Onbothsides,tightenthenutsandbolts.

Important:Makesurethenutsandboltsare

tightsothefrontreference/speedcontrolbar

doesnotmoveduringoperation.

Transporting

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Besure

thefuelshut-offvalveisclosed.Securelyfastenthe

machinetothetrailerortruckwithstraps,chains,

cable,orropes.Ifpossible,bothfrontandrear

strapsshouldbedirecteddownandoutwardfrom

themachine.Onlyusethefourdesignatedtie-down

locationsonthemachine-twoontheleftsideandtwo

ontheright(see).Besurethatthetrailerortruckhas

allnecessarylightingandmarkingasrequiredbylaw .

Secureatrailerwithasafetychain.

23

Page 24

Operation

Figure15

Leftsideshown

1.Tie-downlocation

CAUTION

Thisunitdoesnothaveproperturnsignals,

lights,reectivemarkings,oraslowmoving

vehicleemblem.Drivingonastreetorroadway

withoutsuchequipmentisdangerousand

canleadtoaccidentscausingpersonalinjury.

Drivingonastreetorroadwaywithoutsuch

equipmentmayalsobeaviolationofStatelaws

andtheoperatormaybesubjecttotrafctickets

and/ornes.

wideenoughtoextendbeyondthereartiresis

recommendedinsteadofindividualrampsforeach

sideofthemachine.Withtheplatformup,afull

widthrampprovidesasurfacetowalkonbehindthe

machine.Ifitisnotpossibletouseonefullwidth

ramp,useenoughindividualrampstosimulateafull

widthcontinuousramp.

Asteeprampanglemaycausecomponentstoget

g212139

caughtasthemachinemovesfromramptotraileror

truck.Steeperanglesmayalsocausethemachineto

tipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideofthe

slopeandtherampsextendsuptheslope.Thiswill

minimizetherampangle.Thetrailerortruckshould

beaslevelaspossible.

Important:DoNotattempttoturnthemachine

whileontheramp,youmaylosecontroland

driveofftheside.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdowna

ramp.Bothmaneuverscancausethemachinetotip

backward.

DoNotdriveaunitonapublicstreetorroadway.

WARNING

Loadingamachineonatrailerortruckincreases

thepossibilityofbackwardtip-over.Backward

tip-overcouldcauseseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyasingle,fullwidthramp;DoNotuse

individualrampsforeachsideofthemachine.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurface

widerthanthemachine.

•Avoidsuddenaccelerationwhiledriving

machineuparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

machinedownaramptoavoidtipping

backward.

LoadingaMachine

Useextremecautionwhenloadingmachineson

trailersortrucks.Onefullwidthrampthatis

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Maintenance

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecouldseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitch,engage

parkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenance.Also

pushthewire(s)asidesoitdoesnotaccidentally

contactthesparkplug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthetransmissionoutputshaftnuttorquespecication.

•Checkthewheelhubbolttorquespecication.

•Checktransmissionmountbolttorque.

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethehydraulictransmissionlteranduid.

WARNING

Theenginecanbecomeveryhot.Touchingahot

enginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheenginearea.

Beforeeachuseordaily

Every25hours

Every50hours

Every80hours

Every100hours

Every160hours

•Checktheengineoillevel.

•Checkthetines.

•Checkforloosehardware.

•Checktheconditionandtensionofthechains.

•Checktheconditionofthesprockets.

•Lubricatethechains.

•Cleantheengineandexhaustsystemarea.

•Cleanthegrassanddebrisbuild-upfromthemachine.

•Greasethefrontwheelbearings.

•Greasetineshaftbearings.

•Greasetransmissionoutputshaftangedbearings.

•Greasehydrooutputshaftangedbearings.

•Checktheauxiliaryhydraulicoillevel.

•Checkthehydraulictransmissionoillevel.

•Checkthetirepressures.

•Checktheconditionandtensionofthebelts.

•Checksparkarrester(ifequipped).

•Removeengineshroudsandcleancoolingns.

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Checkthesparkplug.

25

Page 26

Maintenance

MaintenanceService

Interval

Every250hours

Every500hours

Monthly

Yearly

MaintenanceProcedure

•Replacetheprimaryaircleanerelement—checksecondaryaircleanerelement;replaceif

dirty.(Mayneedmoreoftenundersevereconditions.SeetheEnginemanualforadditional

information.)

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethehydraulictransmissionlteranduid.

•Replacethesecondaryaircleanerelement.(Mayneedmoreoftenundersevereconditions.

SeetheEnginemanualforadditionalinformation.)

•Checkthebatterycharge.

•Greasebeltidlerpivot.

•Greasefrontcasterhubs.

•Checkthetransmissionoutputshaftnuttorquespecication.

•Checkthewheelhubbolttorquespecication.

•Checktransmissionmountbolttorque.

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Cleanareaarounddipstick.Removedipstick

andwipeoiloff.Reinsertthedipstickaccording

totheenginemanufacturer'srecommendations.

Removethedipstickandreadtheoillevel.

4.Iftheoillevelislow,wipeofftheareaaroundthe

oilllcap,removecapandlltothe“FULL”

markonthedipstick.Exmark4-CyclePremium

EngineOilisrecommended;refertotheEngine

Owner'smanualforanappropriateAPIrating

andviscosity .DoNotoverll.

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

CheckBatteryCharge

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

Allowingbatteriestostandforanextendedperiodof

timewithoutrechargingthemwillresultinreduced

performanceandservicelife.Topreserveoptimum

batteryperformanceandlife,rechargebatteriesin

storagewhentheopencircuitvoltagedropsto12.4

volts.

Note:Topreventdamageduetofreezing,battery

shouldbefullychargedbeforeputtingawayfor

winterstorage.

Checkthevoltageofthebatterywithadigital

voltmeter.Locatethevoltagereadingofthebatteryin

thetableandchargethebatteryfortherecommended

timeintervaltobringthechargeuptoafullcharge

of12.6voltsorgreater.

Important:Makesurethenegativebatterycable

isdisconnectedandthebatterychargerusedfor

chargingthebatteryhasanoutputof16voltsand

7ampsorlesstoavoiddamagingthebattery(see

chartforrecommendedchargersettings).

26

Page 27

Maintenance

Voltage

Reading

12.6or

greater

12.4–12.675–100%

12.2–12.450–75%

12.0–12.225–50%

11.7–12.00–25%

11.7orless

Percent

Charge

100%

0%

Maximum

Charger

Settings

16volts/7

amps

16volts/7

amps

16volts/7

amps

14.4volts/4

amps

14.4volts/4

amps

14.4volts/2

amps

RecommendedJump

StartingProcedure

ServiceInterval:Asrequired

1.Checktheweakbatteryforterminalcorrosion

(white,green,orblue“snow”),itmustbecleaned

offpriortojumpstarting.Cleanandtighten

connectionsasnecessary.

CAUTION

Corrosionorlooseconnectionscancause

unwantedelectricalvoltagespikesatanytime

duringthejumpstartingprocedure.

Charging

Interval

No

Charging

Required

30Minutes

1Hour

2Hours

3Hours

6Hoursor

More

shortlengthstoreducevoltagedropbetween

systems.Makesurethecablesarecolorcodedor

labeledforthecorrectpolarity.

CAUTION

Connectingthejumpercablesincorrectly

(wrongpolarity)canimmediatelydamagethe

electricalsystem.

Becertainofbatteryterminalpolarityand

jumpercablepolaritywhenhookingup

batteries.

Note:Thefollowinginstructionsareadapted

fromtheSAEJ1494Rev .Dec.2001–Battery

BoosterCables–SurfaceVehicleRecommended

Practice(SAE–SocietyofAutomotive

Engineers).

WARNING

Batteriescontainacidandproduceexplosive

gases.

•Shieldtheeyesandfacefromthebatteries

atalltimes.

•DoNotleanoverthebatteries.

Note:Besuretheventcapsaretightandlevel.

Placeadampcloth,ifavailable,overanyvent

capsonbothbatteries.Besurethevehiclesdo

nottouchandthatbothelectricalsystemsare

offandatthesameratedsystemvoltage.These

instructionsarefornegativegroundsystemsonly.

DoNotattempttojumpstartwithlooseor

corrodedbatteryterminalsordamagetothe

enginemayoccur.

DANGER

Jumpstartingaweakbatterythatiscracked,

frozen,haslowelectrolytelevel,oran

open/shortedbatterycell,cancausean

explosionresultinginseriouspersonalinjury.

DoNotjumpstartaweakbatteryifthese

conditionsexist.

2.Makesuretheboosterisagoodandfullycharged

leadacidbatteryat12.6voltsorgreater.Use

properlysizedjumpercables(4to6AWG)with

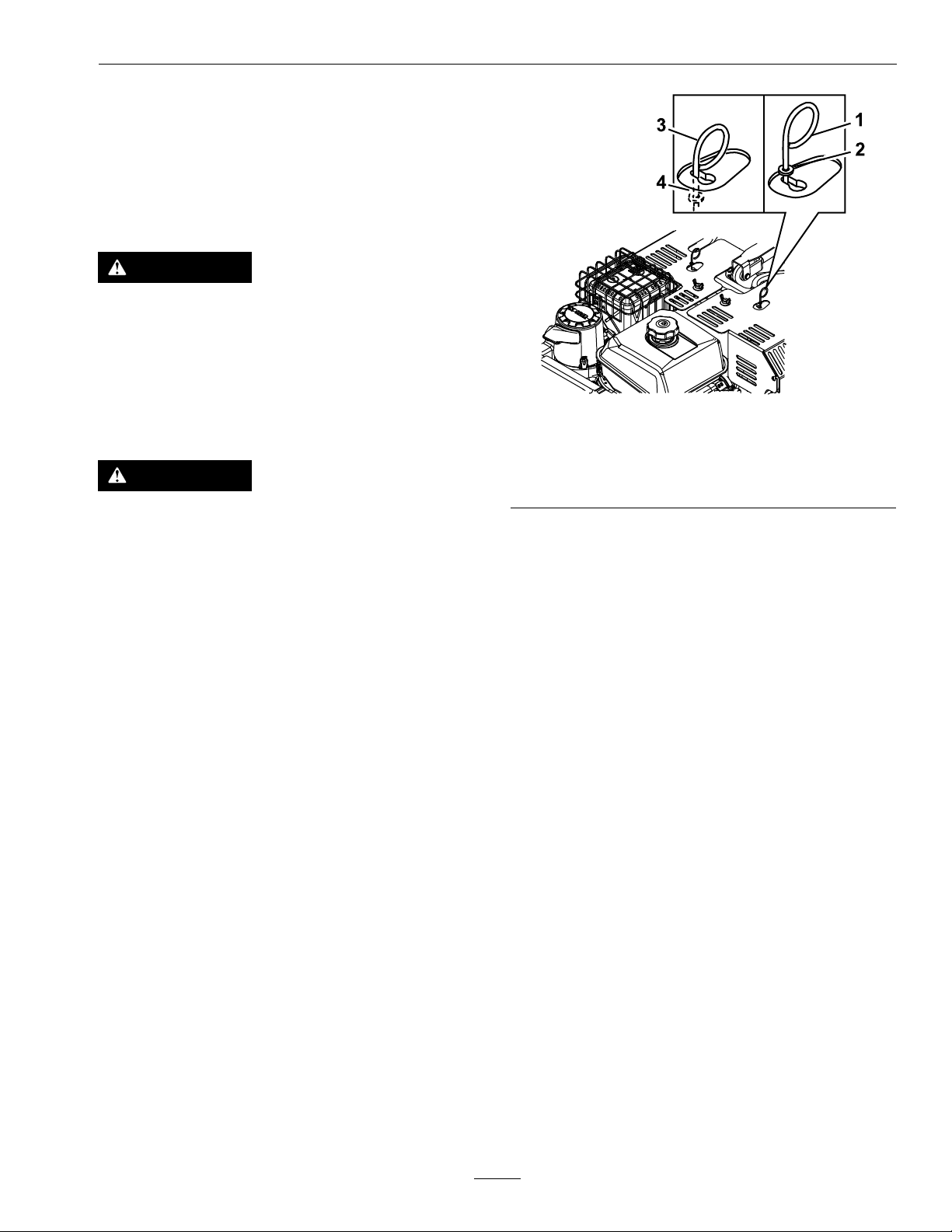

3.Connectthepositive(+)cabletothepositive(+)

terminalofthedischargedbatterythatiswiredto

thestarterorsolenoidasshowninFigure16.

27

Page 28

Maintenance

CAUTION

Raisingtheunitforserviceormaintenance

relyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalor

hydraulicjacksmaynotbeenoughsupport

ormaymalfunctionallowingtheunittofall,

whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

g012785

Figure16

jacksforsupport.Useadequatejackstands

orequivalentsupport.

1.Positive(+)cableondischargedbattery

2.Positive(+)cableonboosterbattery

3.Negative(–)cableontheboosterbattery

4.Negative(–)cableontheengineblock

5.Boosterbattery

6.Dischargedbattery

7.Engineblock

4.Connecttheotherendofthepositivecabletothe

positiveterminaloftheboosterbattery.

5.Connecttheblacknegative(–)cabletotheother

terminal(negative)oftheboosterbattery.

6.MAKETHEFINALCONNECTIONON

THEENGINEBLOCKOFTHESTALLED

VEHICLE(NOTTOTHENEGATIVEPOST)

AWAYFROMTHEBATTERY .STANDBACK.

7.Startthevehicleandremovethecablesinthe

reverseorderofconnection(theengineblock

(black)connectionisthersttodisconnect).

3.Removeandretainthetwoboltsfromtherear

coverpanel.

4.Removerocksandotherdebrisfromthetines.

5.Inspectthetinesandreplaceasrequired.

CheckTines

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lifttherearoftheunitandsupportusingjack

standsorequivalentsupport.

28

Page 29

Maintenance

ChecktheSafetyInterlock

Important:Itisessentialthattheoperatorsafetymechanismsbeconnectedandinproperoperating

conditionpriortouse.

Note:Ifmachinedoesnotpassanyofthesetests,DoNotoperate.ContactanAuthorizedServiceDealer.

ChecktheNormalEngineStartingCircuit

System

ParkingBrakeOutcome

EngagedStartershouldcrank

StateofSystem

CheckEngineStartingCircuitChart

Note:IntheCheckEngineStartingCircuitChart,thestateofsystemitemthatisboldisbeingchecked.

System

ParkingBrakeOutcome

Disengaged

StateofSystem

Startershouldnotcrank

29

Page 30

Maintenance

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

ServiceAirCleaner

ServiceInterval:Every250hours—Replace

theprimaryaircleaner

element—check

secondaryaircleaner

element;replaceifdirty.

(Mayneedmoreoften

undersevereconditions.

SeetheEnginemanualfor

additionalinformation.)

Every500hours—

Replacethesecondary

aircleanerelement.(May

needmoreoftenunder

severeconditions.See

theEnginemanualfor

additionalinformation.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.SeetheEngineOwner'sManualformaintenance

instructions.

ChangeEngineOil

ServiceInterval:Aftertherst5hours

Every100hours(May

needmoreoftenunder

severeconditions.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Drainoilwhileengineiswarmfromoperation.

3.Theoildrainplugislocatedontheleftsideof

theengine.

Placepanundermachinetocatchoil.Removeoil

drainplug.Allowoiltodrainandreplaceoildrain

plug.Torqueplugto13ft-lb(18N-m).

4.ReplacetheoillterpertheEngineOwner's

Manual.Cleanaroundtheoillterandcarefully

removethelterbyunscrewingit.Makesureno

oildrainsontothebeltdrivesthroughtheholesin

theenginedeck.Beforethenewlterisinstalled,

applyathincoatingofExmark4–CyclePremium

EngineOilonthesurfaceoftherubberseal.

Turnlterclockwiseuntilrubbersealcontacts

thelteradapter,thentightenlteranadditional

2/3to3/4turn.

5.Cleanaroundoilllcapandremovecap.Fillto

speciedcapacityandreplacecap.

6.UseoilrecommendedintheCheckEngineOil

Levelsection.DoNotoverll.Starttheengine

andcheckforleaks.Stopengineandrecheckoil

level.

7.Wipeupanyspilledoilfromenginedeck

mountingsurfaces.

CheckAuxiliaryHydraulic

OilLevel

ServiceInterval:Every50hours

1.Stopengineandwaitforallmovingpartstostop,

andremovekey.Engageparkingbrake.

2.Cleanareaaroundhydraulicreservoircapand

removecap.Oillevelshouldbetothetopofthe

bafeinsidethetank.Ifnot,addoil.UseAW -32

hydrooil.Replacehydraulicreservoircapand

tightenuntilsnug.DoNotovertighten.

Note:Thebafeislabeled“HOT”and

“COLD”.Theoillevelvarieswiththe

temperatureoftheoil.The“HOT”levelshows

thelevelofoilwhenitisat225°F(107°C).The

“COLD”levelshowstheleveloftheoilwhen

itisat75°F(24°C).Filltotheappropriatelevel

dependinguponthetemperatureoftheoil.For

example:Iftheoilisabout150°F(65°C),llto

halfwaybetweenthe“HOT”and“COLD”levels.

Iftheoilisatroomtemperature(about75°F

(24°C)),llonlytothe“COLD”level.

CheckHydraulic

TransmissionOilLevel

ServiceInterval:Every50hours

1.Stopengineandwaitforallmovingpartstostop,

andremovekey.Engageparkingbrake.

2.Withtheunitcold,checktheexpansiontankand

ifnecessaryaddExmarkPremiumHydroOilto

theFULLCOLDline.

30

Page 31

Maintenance

CheckTirePressures

ServiceInterval:Every50hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto22-24psi(152-165kPa).

4.Semi-pneumaticcastertiresdonotneedtobe

inated.

CheckConditionandTension

OfBelts

ServiceInterval:Every50hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktheauxiliarypumpdrivebeltconditionand

tension;beltshouldbesnug.SeeAuxiliaryPump

DriveBeltAdjustmentintheAdjustments

section.

3.Checkconditionofthetransmissiondrivebelt.

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey.Engagetheparking

brake.

2.Lifttherearofthemachineandsupportusing

jackstandsorequivalentsupport.

CAUTION

Raisingthemachineforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

themachinetofall,whichcouldcauseinjury.

Donotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

3.Starttheengineandmovethrottlecontrolahead

to1/2throttleposition.Disengagetheparking

brake.

WARNING

CheckConditionOfChains

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checkthechainsonbothsidesoftheunitfor

propertension.Thechainsshouldbeableto

moveupanddown1/4-1/2inch(6-12mm).

3.IfchainspoporsnapseeDriveChain

TensionAdjustmentorTineDriveT ension

AdjustmentintheAdjustmentssection.

CheckConditionOf

Sprockets

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Inspectsprocketsforwearandreplaceasrequired.

LubricatingtheChains

ServiceInterval:Beforeeachuseordaily

Important:Donotlubricatethechainswith

penetratingoilorsolvents.Useanoilorchain

lubricant.

Theenginemustberunningandthedrive

wheelsmustbeturningsothatadjustments

canbeperformed.Contactwithmovingparts

orhotsurfacesmaycausepersonalinjury.

Keepyourngers,hands,andclothingclear

ofrotatingcomponentsandhotsurfaces.

4.Withtheenginerunning,slowlymovethemotion

controlleversforwardandlubricateallfour

chains.

5.Checktheconditionandtensionofthechains

(seeCheckConditionofChains).

LubricatingtheGrease

Fittings

Note:Seethechartbelowforserviceintervals.

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey.Engagetheparking

brake.

2.LubricatethettingswithNLGIgradeNo.2

multi-purposegrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

31

Page 32

Maintenance

LubricationChart(cont'd.)

Fitting

Locations

1.FrontWheel

CasterHubs

2.TineShaft

Bearings

3.BeltIdler

Pivot

Initial

Pumps

12

1

11

Numberof

Places

4

Service

Interval

Yearly

25hours

Yearly

Important:Applyathincoatofoilonthe

surfaceoftherubberseal.

Turnlterclockwiseuntilrubbersealcontactsthe

lteradapter,thentightenthelteranadditional

2/3to3/4turn.

5.Reinstallthehoseandtorqueto37ft-lb(50N-m).

6.AddA W-32hydrooiluntilthelevelreachesthe

“coldllline”locatedonthereservoirtank.Start

engineandraiseandlowerthetines.Lowerthe

tinestothegroundandrellthereservoirtothe

“coldllline”.

ChangeHydraulic

TransmissionFiltersand

Fluid

ServiceInterval:Aftertherst100hours

Every250hoursthereafter

1.Stopengine,waitforallmovingpartstostop,and

removekeyorsparkplugwire(s).Engageparking

brake.

CheckSparkPlug

ServiceInterval:Every160hours

Removethesparkplug,checkconditionandreset

gaps,orreplacewithanewplug.SeeEngineOwner's

Manual.

ChangeAuxiliaryHydraulic

ReservoirFluidandFilter

ServiceInterval:Aftertherst100hours

Every250hoursthereafter

1.Stopengine,waitforallmovingpartstostop,and

removekeyorsparkplugwire(s).Engageparking

brake.

2.Carefullycleanareaaroundthefrontofthe

auxiliarypumpandllcap;alsocleanaroundthe

lter.Itisimportantthatnodirtorcontamination

enterhydraulicsystem.

3.Unscrewthesuctionhosefromthepumptting,

cleanaroundthepumptting,andallowoilto

drain.

4.Unscrewtheltertoremoveandallowoilto

drain.

2.Placeacatchpanbetweenthetransmissions.

3.Removethetwodrainplugs,locatedatthebottom

ofeachtransmission,tofullydraintheoil.

4.Locatethetwoltersunderthetransmissions.

5.Carefullycleanareaaroundlters.Itisimportant

thatnodirtorcontaminationenterhydraulic

system.

6.Unscrewlterstoremoveandallowoiltonish

drainingfromdrivesystem.

Important:Beforereinstallingnewlters,

applyathincoatofExmarkPremiumHydro

Oilonthesurfaceoftheltersrubberseal.

Turntheltersclockwiseuntilrubberseal

contactsthelteradapterthentightenthelter

anadditional3/4to1fullturn.

7.Reinstallthetwodrainplugs.

8.Removetheventplugoneachtransmissionand

llthroughexpansionreservoir,whenoilcomes

outofventreinstallplug.

ExmarkPremiumHydroOilisrecommended.

Refertothechartforanacceptablealternative:

32

Page 33

Maintenance

HydroOil

ExmarkPremiumHydro

Oil(Preferred)

Mobil115W50

Torqueplugsto180in-lb(20N-m).Continueto

addExmarkPremiumHydroOiluntilitreaches

theFULLCOLDlineontheexpansionreservoir.

9.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

ChangeInterval

250Hours

250Hours

CAUTION

Raisingtheunitforserviceormaintenance

relyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalor

hydraulicjacksmaynotbeenoughsupport

ormaymalfunctionallowingtheunittofall,

whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminantsintothesystem.

CheckTransmission

OutputShaftNutTorque

Specication

ServiceInterval:Aftertherst5hours

Yearlythereafter

Torquethenutonthetransmissionoutputtapered

shaftto211-260ft-lb(286-352N-m).

CheckWheelHubBolt

TorqueSpecication

ServiceInterval:Aftertherst5hours

Yearlythereafter

Torquethewheelhubboltto27-33ft-lb(37-45N-m).

Note:DoNotuseanti-seizecompoundonthe

wheelhub.

10.Startengineandmovethrottlecontrolaheadto

1/2throttleposition.Disengageparkingbrake.

WARNING

Enginemustberunninganddrivewheels

mustbeturningsomotioncontroladjustment

canbeperformed.Contactwithmovingparts

orhotsurfacesmaycausepersonalinjury.

Keepngers,hands,andclothingclearof

rotatingcomponentsandhotsurfaces.

A.Withtheenginerunning,slowlymovethe

directionalcontrolinbothforwardand

reversedirections(5to6times).Checktheoil

level,andaddoilasrequiredafterstopping

theengine.

B.ItmaybenecessarytorepeatstepA.untilall

theairiscompletelypurgedfromthesystem.

Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardand

reverseatnormalspeeds,thenthetransaxle

isconsideredpurged.

Note:DoNotchangethehydraulicsystemoil

(exceptforwhatcanbedrainedwhenchanginglter

andremovingthedrainplugs),unlessitisfelttheoil

hasbeencontaminatedorbeenextremelyhot.

CheckTransmissionMount

BoltTorque

ServiceInterval:Aftertherst5hours

Yearlythereafter

Torquethefourtransmissionboltsto41-51ft-lb

(56-69N-m)(referenceFigure17).

Note:DoNotuseanti-seizecompoundonthe

wheelhub.

g233601

Figure17

1.Transmissionbolt

33

Page 34

Maintenance

CheckSparkArrester

(ifequipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresult

inpersonalinjuryorpropertydamage.

DoNotrefuelorrunengineunlesssparkarrester

isinstalled.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Waitformufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacearrester.

4.Ifpluggingofthescreenisobserved,remove

arresterandshakelooseparticlesoutofthe

arresterandcleanscreenwithawirebrush(soak

insolventifnecessary).Reinstallarresteron

exhaustoutlet.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

Sheaveretainingboltinendofenginecrankshaft.

Allsetscrews.

34

Page 35

Maintenance

Adjustments

Note:Shutoffengine,waitforallmovingpartsto

stop,engageparkingbrake,andremovekeybefore

servicing,cleaning,ormakinganyadjustmentsto

theunit.

CAUTION

Raisingtheunitforserviceormaintenance

relyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalor

hydraulicjacksmaynotbeenoughsupportor

maymalfunctionallowingtheunittofall,which

couldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstandsor

equivalentsupport.

AuxiliaryPumpDriveBelt

Adjustment

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Totightenbelt,loosenboth3/8inchnutson

auxiliarypump.Slidepumpoutwardinslotsand

retightennuts.

3.Whenproperlyadjusted,thebeltshouldhave1/2

inch(1.3cm)ofdeectionwiththreepoundsof

forceonthebeltmidwaybetweentheauxiliary

pumpandenginepulley .

3.Checkthechainsoneachsideoftheidler

sprocket,onbothsidesofthemachine,forproper

tension.Thechainsshouldbeabletomoveup

anddown1/4-1/2inch(6-12mm).

4.Toadjust,loosentheidlerboltandpushupon

thesprockettotensionthechain.

Note:DoNotovertightenthechain.

5.Recheckthechaintensionandtightentheidler

bolt.

TineDriveChainAdjustment

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lifttherearofthemachineandsupportusing

jackstandsorequivalentsupport.

3.Checkthechainsoneachsideoftheidler

sprocket,onbothsidesofthemachine,forproper

tension.Thechainsshouldbeabletomoveup

anddown1/4-1/2inch(6-12mm).

4.Toadjust,loosentheidlerboltandpushupon

thesprockettotensionthechain.

Note:DoNotovertightenthechain.

5.Recheckthechaintensionandtightentheidler

bolt.

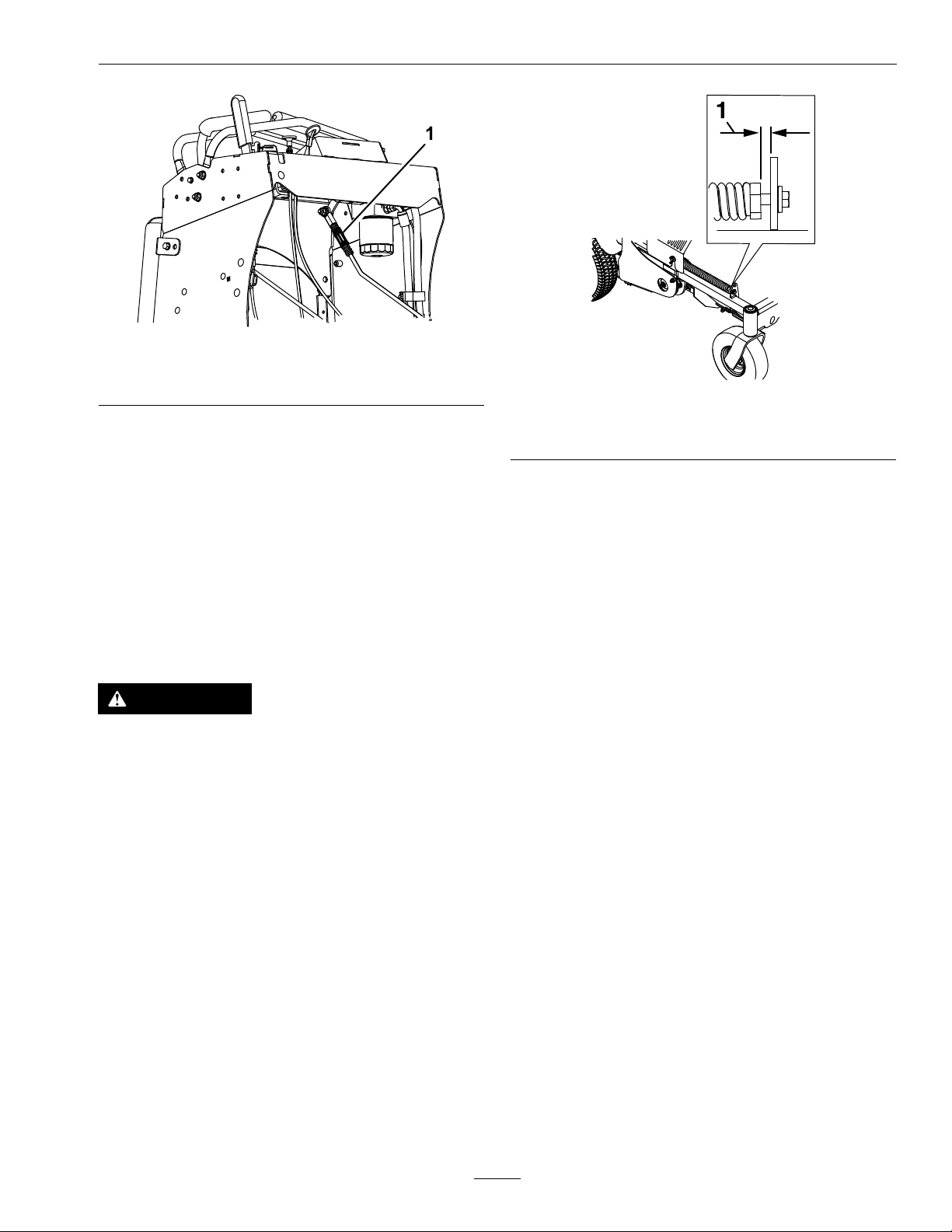

AdjustingtheParkingBrake

TransmissionDriveBelt

Tension

Note:Noadjustmentsarerequiredforbelttension.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Installthenewbelt.

3.Makesuretheidlerarmandpulleycanmove

freely.

DriveWheelChainTension

Adjustment

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lifttherearofthemachineandsupportusing

jackstandsorequivalentsupport.

Iftheparkingbrakedoesnotholdsecurely ,an

adjustmentisrequired.

1.Parkthemachineonalevelsurface.

2.Shutoffengineandwaitforallmovingpartsto

stop.

3.Checktheairpressureinthedrivetires.Ifneeded,

adjusttotherecommendedination;referto

CheckTirePressuresection.

4.Disengagetheparkbrake.

5.Loosentheadjustmentnutonthebrakecable

bracketundertheconsole.

6.Adjustbothcableconduitsdownward

approximately1/8–1/4inch(3–6mm).See

Figure18.

35

Page 36

Maintenance

Figure18

1.Adjustmentnut

7.Tightenthecableadjustmentnutandengagethe

parkbrake.

8.Checktheparkbrake;repeatsteps5through7if

necessary.

MotionControlLinkage

Adjustment

1.Parkthemachineonalevelsurface.

2.Shutoffengineandwaitforallmovingpartsto

stop.

3.Pushthecontrolleversallthewayforwardtothe

frontreferencebar.

Ifeitherofthecontrolleverscontactthe

referencebar,allowthecontrolleverstoreturn

toneutral.Loosenthetwojamnutsonthe

RHhexadjustmentlinkage.Notethatone

jamnutisaright-handthreadandtheotheris

left-hand.Turnthehexadjustmentlinkageuntil

therecommendedgapisachieved.Retightenthe

jamnuts.Repeatthisstepuntilthereis1/8-1/4

inch(3–6mm)gapbetweentheRHcontrollever

andthefrontreferencebar.Oncethegapis

achieved,proceedwithstep4.

g233407

Figure19

1.Hexadjustmentlinkagejamnut

4.Allowthecontrolleverstoreturntoneutral.

TurntheLHhexadjustmentlinkuntilthemotion

controlleversareapproximatelyevenwitheach

other.

5.Repeatsteps3and4forothermotioncontrol

linkage.

MotionControlTracking

Adjustment

Ifthemachinetravelsorpullstoonesidewhenthe

motioncontrolleversareinthefullforwardposition,

adjustthetracking.

1.Pushbothcontrolleversforwardthesame

distance.

2.Checkifthemachinepullstooneside.Ifitdoes,

stopthemachineandsettheparkingbrake.

3.LoosenthelocknutsontheRHmotioncontrol

linkage(asviewedfromtherearofthemachine.

PushtheRHcontrolleverforwardandrotatethe

adjustmentroduntilthereis1/8-1/4inch(3–6

mm)gapbetweentheRHcontrolleverandthe

frontreferencebar.

4.SeeAdjustingtheFrontReference/Speed

ControlBarinOperation.Placethefront

reference/speedcontrolbarinthemaximum

forwardposition.

g231567

5.RotatetheadjustmentrodontheLHsideofthe

machine(asviewedfromtherearofthemachine

—seeFigure20).

36

Page 37

Figure20

Maintenance

g233418

1.Adjustmentrod

6.Lookingdowntowardstheadjustmentrod—