Page 1

LAZERZ®HP

465,505,AND565MODELS

ForSerialNos.

720,000&Higher

PartNo.4500-251Rev.A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,or

otherreproductiveharm.

Important:Whenthemowerisusedoroperated

onanyCaliforniaforest,brushorgrasscovered

land,aworkingsparkarrestermustbeattached

tothemufer.Ifnot,theoperatorisviolating

statelaw,Section4442PublicResourceCode.To

acquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

ThissparkignitionsystemcomplieswithCanadian

ICES-002Cesystèmed’allumageparètincellede

vèhiculeestconformeàlanormeNMB-002du

Canada

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©1997–2007—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency,andpromotesafe

operation.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

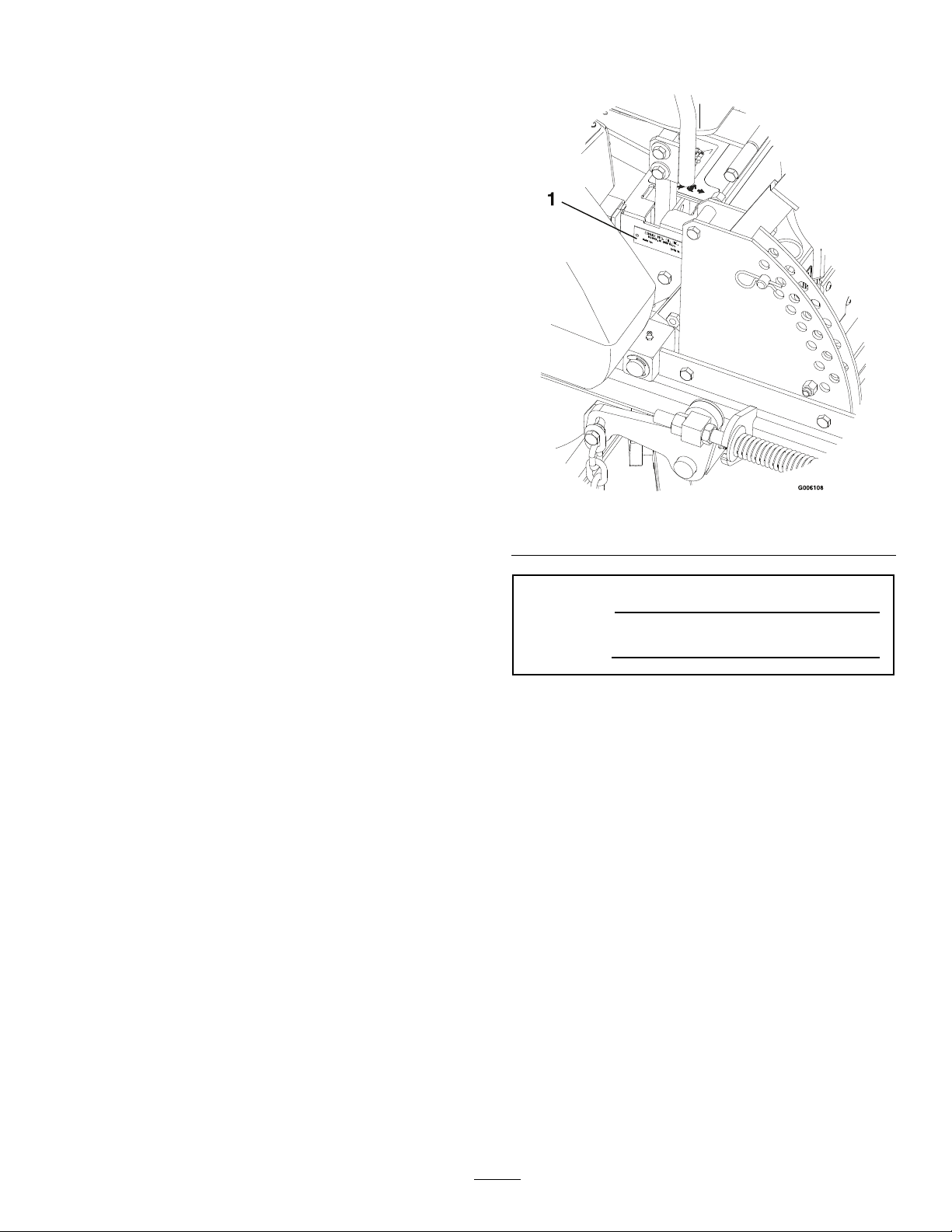

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.....................10

Specications.......................................................14

ModelNumbers............................................14

Systems.........................................................14

Dimensions...................................................16

TorqueRequirements....................................17

ProductOverview................................................17

Operation.............................................................18

Controls........................................................18

Pre-Start........................................................19

OperatingInstructions..................................19

Transporting.................................................23

Maintenance.........................................................25

RecommendedMaintenanceSchedule(s)...........25

PeriodicMaintenance.......................................26

CheckEngineOilLevel.................................26

CheckBatteryCharge....................................26

CheckMowerBlades.....................................27

CheckSafetyInterlockSystem.......................27

CheckRolloverProtectionSystem(Roll

Bar)Pins...................................................28

CheckSeatBelt..............................................28

CheckforLooseHardware............................28

ServiceAirCleaner........................................28

ChangeEngineOil........................................28

CheckHydraulicOilLevel.............................29

CheckTirePressures.....................................29

CheckConditionOfBelts..............................29

LubricateGreaseFittings...............................29

LubricateCasterWheelHubs........................30

LubricateBrakeHandlePivot........................31

LubricateBrakeRodBushings.......................31

LubricateMotionControlBronze

Bushings...................................................31

LubricateSeatSwitchActuator......................31

CheckSparkPlugs.........................................31

ChangeHydraulicSystemFilter.....................31

WheelHub-SlottedNutTorque

Specication..............................................32

ThreadLockingAdhesives.............................32

MobilHTSGrease(OrFood-Grade

Anti-seize).................................................32

Copper-BasedAnti-seize..............................32

DielectricGrease...........................................32

Adjustments.....................................................33

DeckLeveling...............................................33

PumpDriveBeltTension...............................33

DeckBeltTension........................................33

BrakeLinkAdjustment..................................34

BrakeAdjustment..........................................34

ElectricClutchAdjustment............................34

ReverseIndicatorAdjustment........................34

MotionControlLinkageAdjustment.............35

AdjustSeatSwitch........................................36

CasterPivotBearingsPre-Load

Adjustment...............................................36

Cleaning...........................................................37

CleanEngineCoolingSystem........................37

RemoveEngineShroudsandCleanCooling

Fins...........................................................37

CleanGrassBuild-UpUnderDeck................37

WasteDisposal..............................................37

Troubleshooting...................................................39

Schematics...........................................................41

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

1.Safetyalertsymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

CAUTION

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Y ellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

5

Page 6

Safety

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsinanopen

area,whentheengineiscold.Wipeup

anygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletely

full.Addgasolinetothefueltankuntil

thelevelis1/4to1/2inch(6–13mm)

belowthebottomofthellerneck.This

emptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,

andstayawayfromanopenameor

wheregasolinefumesmaybeignitedby

spark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.

Neverremovethecapofthefueltankor

addfuelwhenengineisrunningorwhen

theengineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperator’spresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly .DoNotoperateunlessthey

arefunctioningproperly.

6

Page 7

Safety

Operation

WARNING

Operatingengineparts,especiallythe

mufer,becomeextremelyhot.Severeburns

canoccuroncontactanddebris,suchas

leaves,grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.Useseatbelts.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly .

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Stopengine,waitforallmovingpartstostop,

removekeyandengageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry ,orclothing

awayfromrotatingparts.

•NEVERcarrypassengers.DONOToperate

themowerwhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

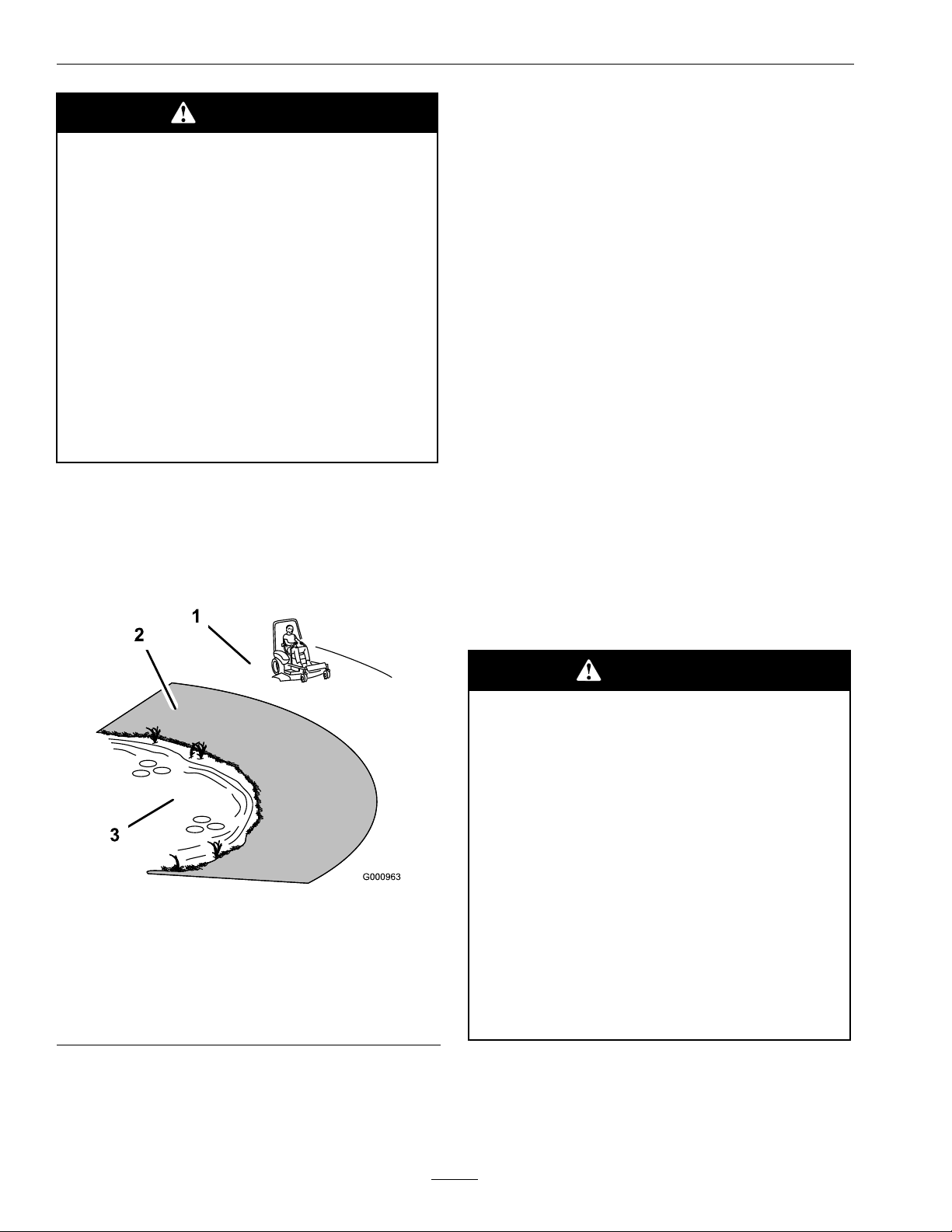

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

7

Page 8

Safety

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Wheels

droppingoveredges,ditches,steepbanks,or

watercancauserollovers,whichmayresult

inseriousinjury,deathordrowning.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan15

degrees.

•Reducespeedanduseextremecaution

onslopes.

•Avoidsuddenturnsorrapidspeed

changes.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

(Figure3).

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheels

maycausedrivewheelstoslipandcauselossof

brakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

UsingtheRolloverProtectionSystem

(ROPS)

ARolloverProtectionSystem(rollbar)isinstalled

ontheunit.

Figure3

1.SafeZone-Usethe

mowerhereonslopes

lessthan15degrees

2.DangerZone-Useawalk

behindmowerand/or

handtrimmernear

drop-offsandwater.

3.Water

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

WARNING

Thereisnorolloverprotectionwhentheroll

barisdown.Wheelsdroppingoveredges,

ditches,steepbanks,orwatercancause

rollovers,whichmayresultinseriousinjury,

deathordrowning.

•Keeptherollbarintheraisedandlocked

positionanduseseatbelt.

•Lowertherollbaronlywhenabsolutely

necessary.

•DoNotwearseatbeltwhentherollbar

isdown.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,andelectricalwires)before

drivingunderanyobjectsanddonotcontactthem.

8

Page 9

Safety

MaintenanceandStorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.W aitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Keepengine,enginearea,andpumpdrivebelt

compartmentfreefromaccumulationofgrass,

leaves,excessivegreaseoroil,andotherdebris

whichcanaccumulateintheseareas.These

materialscanbecomecombustibleandmayresult

inare.

•Letenginecoolbeforestoringanddonotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbya

doctorfamiliarwiththisformofinjuryor

gangrenemayresult.

•Makesureallhydraulicuidhoses

andlinesareingoodconditionand

allhydraulicconnectionsandttings

aretightbeforeapplyingpressureto

hydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,

tondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembyplacingthemotioncontrol

leversinneutralandshuttingoffthe

enginebeforeperforminganyworkon

thehydraulicsystem.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplaceblades.Neverstraightenor

weldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Allreplacementpartsmustbethesameas

orequivalenttothepartssuppliedasoriginal

equipment.

9

Page 10

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

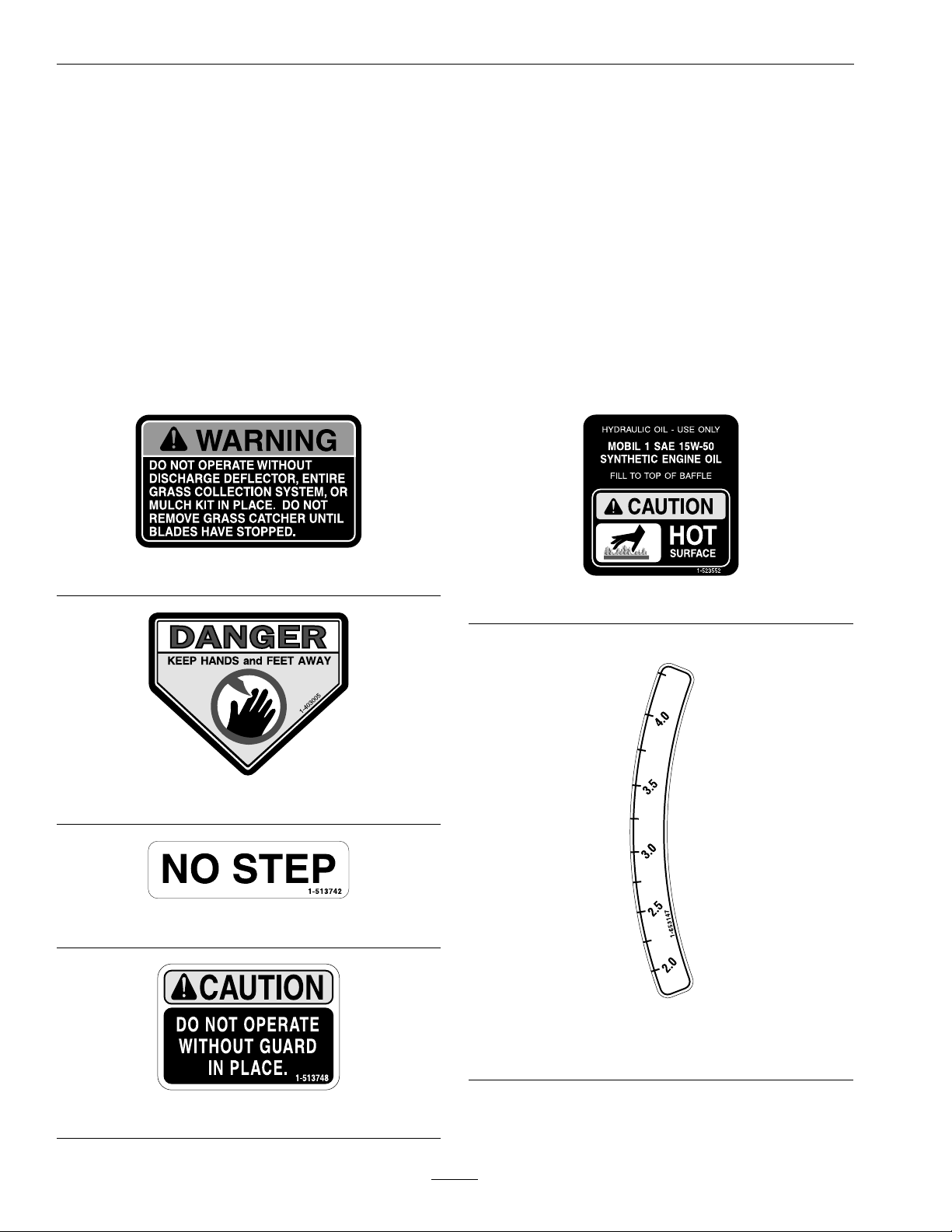

1-303508

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

1-523552

1-403005

1-513742

1–653147

1-513748

10

Page 11

Safety

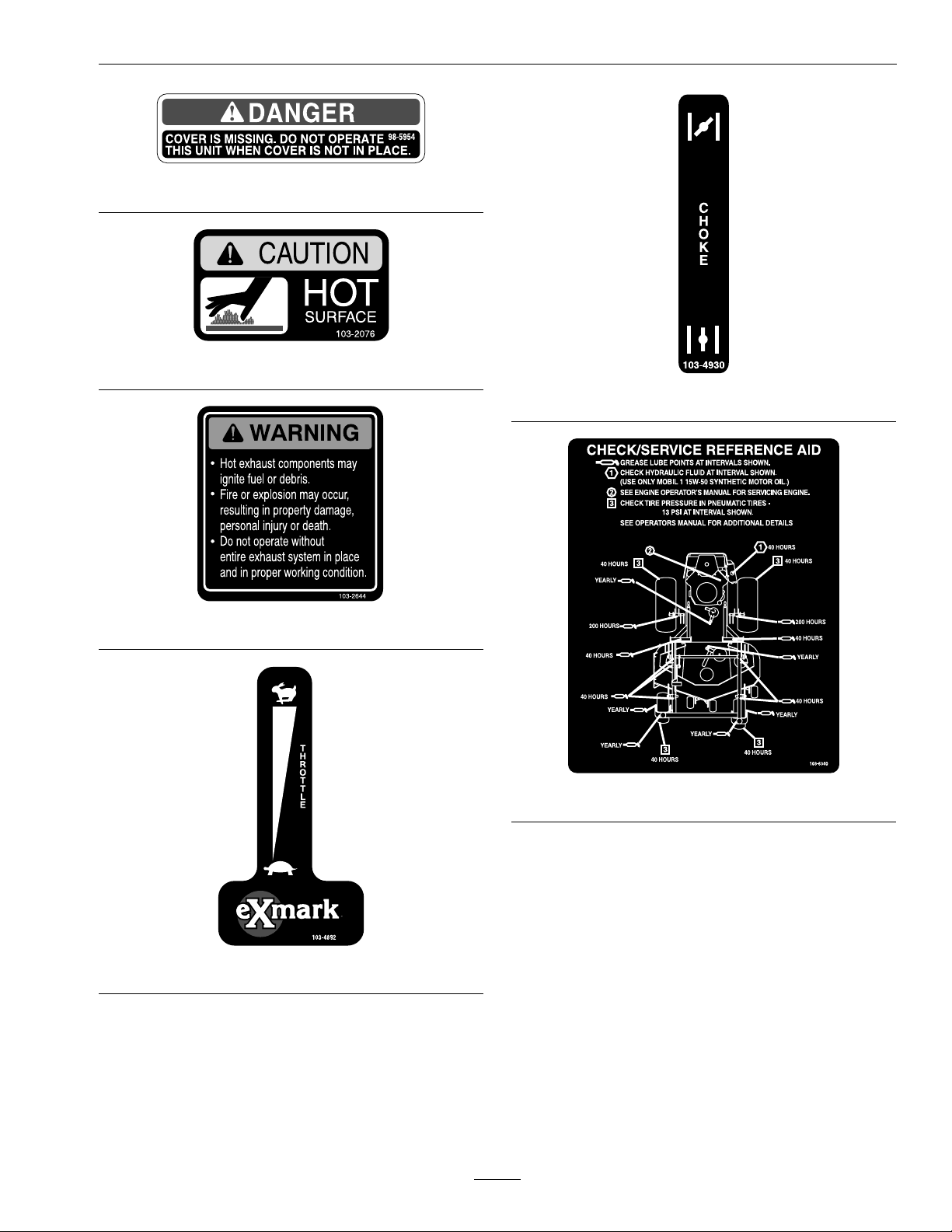

98-5954

103–2076

103–4930

103–2644

103–6340

103–4892

11

Page 12

Safety

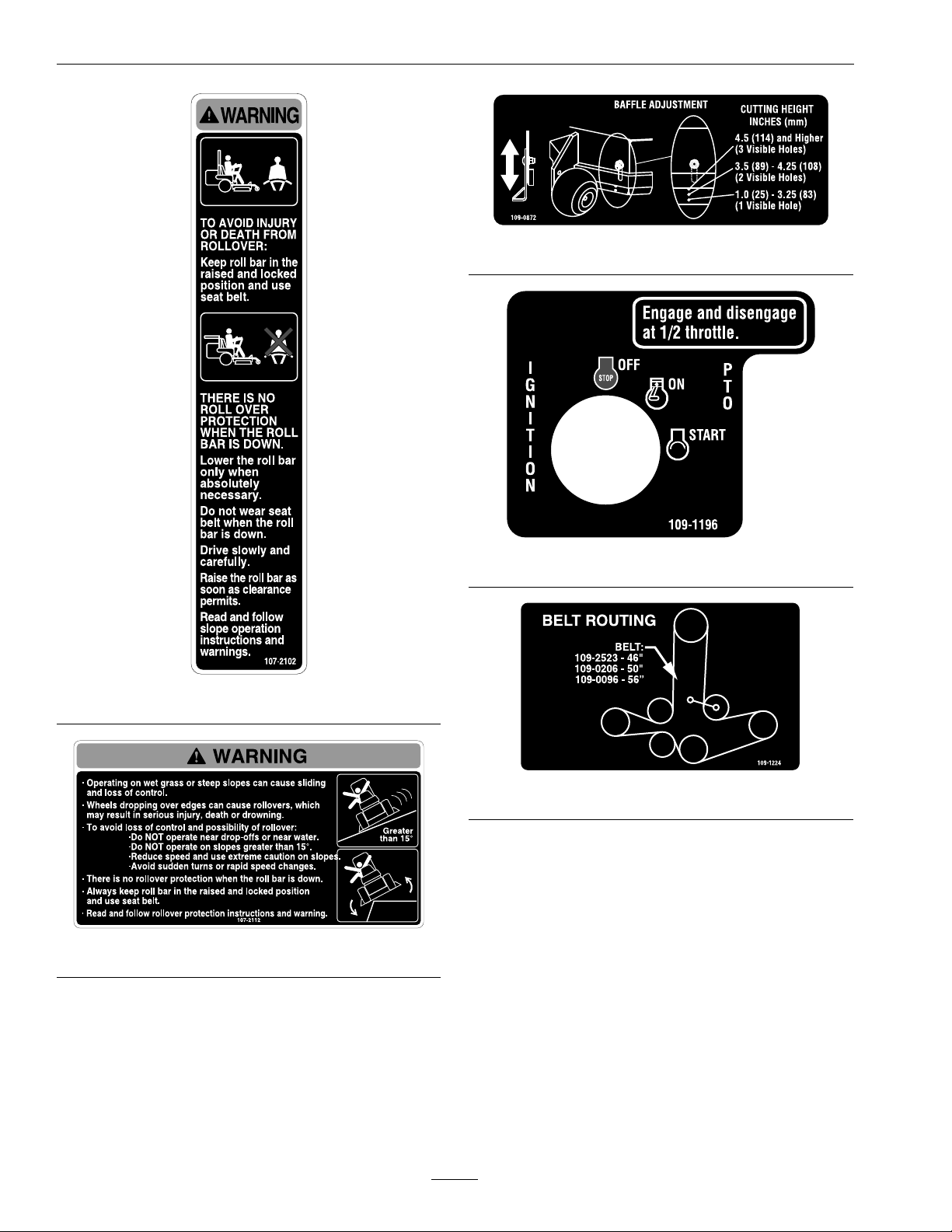

109-0872

107-2102

107-2112

109–1196

109–1224

12

Page 13

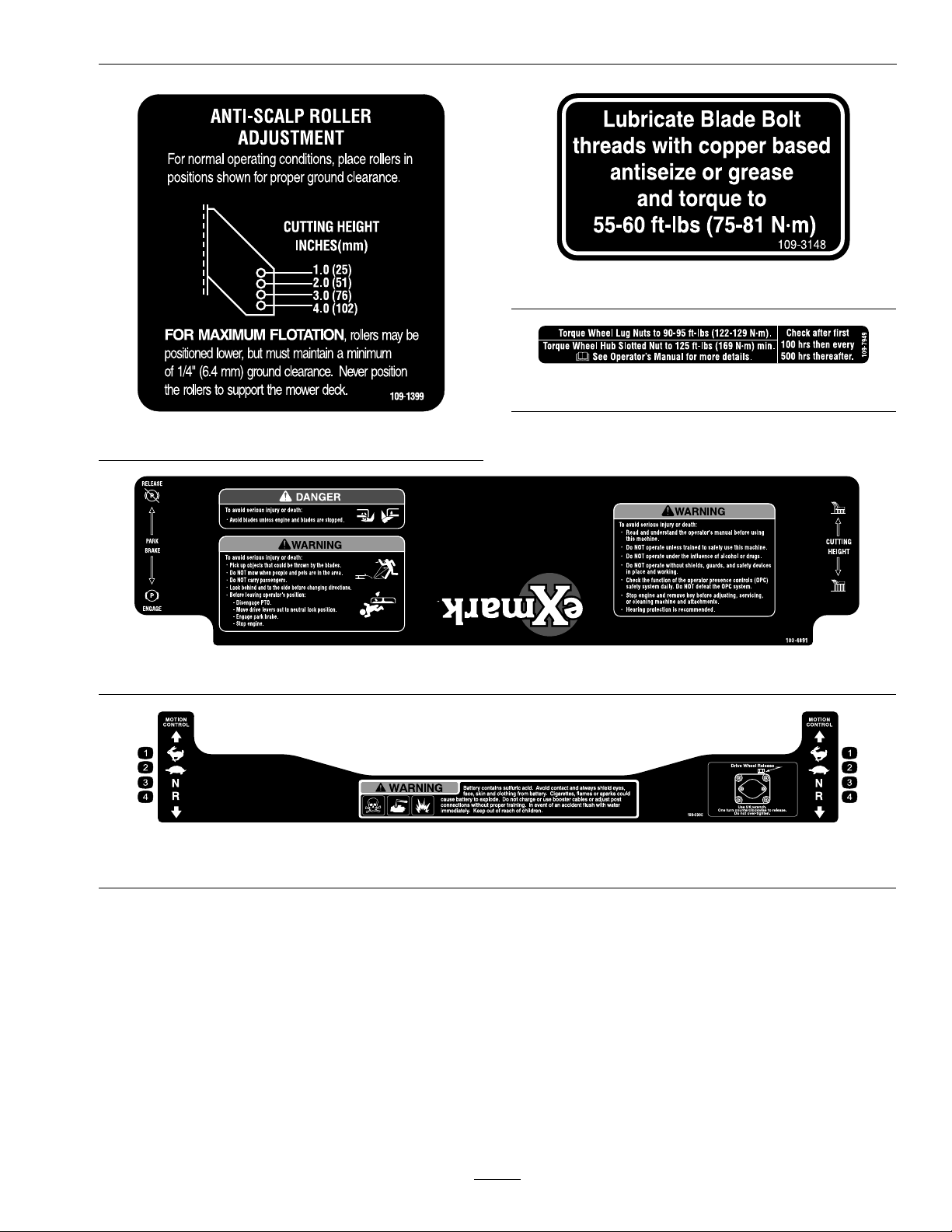

Safety

109-3148

109–7949

109–1399

103–4891

108–5995

1.Fast

2.Slow

3.Neutral4.Reverse

13

Page 14

Specications

Specications

ModelNumbers

SerialNos:720,000andHigher

LHP19KA465;LHP19KA465CA;LHP23KA465;LHP23KA505;LHP23KA565;LHP27KC505;LHP27KC505R;

LHP27KC565

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•RPM:FullSpeed:3600±50RPM(NoLoad)

Idle:1500RPM

FuelSystem

•Capacity:11.2gal.(42.0L)

•TypeofFuel:Regularunleadedgasoline,87

octaneorhigher.

•FuelFilter:

–Kohler:

In-line15MicronKohlerP/N2405010.

–Kawasaki:

In-lineKawasakiP/N49019–7001

•FuelShut-OffValve:1/4turnincrements(“ON”,

“OFF”)

•Fuelgaugeinlefthandfueltank.

•OperatormustbeinseatwhenPTOisengaged,

brakeisdisengaged,ormotioncontrolleversare

movedinorenginewillstop.

•Enginewillstopifeithertheleft,theright,or

bothleversaremovedfromneutrallockposition

whilebrakeisengaged.

OperatorControls

•SteeringandMotionControl:

Note:Motioncontrolleversareadjustableto

twoheights.

–Separatelevers,oneachsideoftheconsole,

controlspeedanddirectionoftravelofthe

respectivedrivewheels.

–Steeringiscontrolledbyvaryingtheposition

oftheleversrelativetoeachother.

–Movingmotioncontrolleversoutward(in

slots)locksthedrivesysteminneutral.

•PTOEngagementSwitch:Engageselectricclutch

(todrivebelt)whichengagesmowerblades.

•ParkingBrakeLever:Engagesparkingbrake.

ElectricalSystem

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:15amps

•BatteryType:BCIGroupU1

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuses:Two20ampbladetype

SafetyInterlockSystem

•PTOmustbedisengaged,brakeengaged,and

motioncontrolleversout(neutrallock)tostart

engine.(Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.)

•DeckHeightAdjustmentLever:Setscutting

heighttodesiredposition.

•DeckLiftAssistLever:Footpedalthatassists

inraisingthedeck.

Seat

•Type:Standardseatwithhighback,foampadded

(internalsuspension)andarmrests.

Optionalseataccessories:

–Customridesuspensionsystemtoenhance

StandardSeat.

–Deluxesuspensionseatwithhighback,low

prolefoam-in-placecushion(dampened,

adjustablespringsuspension)andarmrests.

14

Page 15

Specications

•Mounting:Hingedtotiltupforaccessto

hydraulicpumps,batteryandothercomponents.

Heldintiltedpositionwithproprod.Adjustable

foreandaftseattrack.

•Armrests:

–Standardseat:foampaddedip-uparmrests.

–Optionalsuspensionseat:moldedadjustable

ip-uparmrests.

•SeatSafetySwitch:Incorporatedintothe

SafetyInterlockSystem.Timedelayseatswitch

eliminatesroughgroundcut-outs.

HydrostaticGroundDriveSystem

•HydrostaticPumps:TwoHydroGearvariable

displacementpistonpumps.

•WheelMotors:TwoParkerwith11/4inch

taperedshafts.

•HydraulicOilType:UseMobil115W-50

Syntheticmotoroil.

•HydraulicOilCapacity:2.1qt.(2.0L)

•HydraulicFilter:Replaceablecartridgetype.

–Summeruseabove32°F(0°C)

P/N109-4180:25microns,10psibypass

–Winterusebelow32°F(0°C)

P/N1-523541:40microns,18psibypass

•Speeds:

–0-9.5mph(15.3km/hr)forward.

–0-5.5mph(8.9km/hr)reverse.

•Drivewheelreleasevalvesallowmachinetobe

movedwhenengineisnotrunning.

Tires&Wheels

Drive

Pneumatic(Air-Filled)

ModelNumberLHP19KA465*;

LHP19KA465CA;

LHP23KA465;

LHP23KA505;

LHP23KA565;

LHP27KC505;

LHP27KC505R;

LHP27KC565

Quantity

Tread

Size24x9.50-1223x9.50-12

PlyRating

Pressure

FrontCaster

ModelNumberLHP19KA465*;

Quantity

Tread

Size13x5.00-613x5.00-6

PlyRating

Pressure

22

“MultiTracC/S”

44

13psi(90kPa)13psi(90kPa)

Semi-PneumaticPneumatic

LHP19KA465CA;

LHP23KA465;

LHP23KA505;

LHP23KA565;

LHP27KC505;

LHP27KC505R;

LHP27KC565

22

SmoothSmooth

LHP19KA465**

TurfMaster

(Air-Filled)

LHP19KA465**

4

13psi(90kPa)

*Forserialnumbers739052andLower

**Forserialnumbers739053andHigher

CuttingDeck

•CuttingWidth:

–46inchDeck:46inches(116.8cm)

–50inchDeck:50inches(127.0cm)

–56inchDeck:56inches(142.2cm)

•Discharge:Side

•BladeSize:(3ea.)

15

Page 16

Specications

–46inchDeck:16.25inches(41.3cm)

–50inchDeck:17.50inches(44.5cm)

–56inchDeck:19.50inches(49.5cm)

•BladeSpindles:Solidsteelspindleswith1inch

(25.4mm)I.D.bearings.

•DeckDrive:

–Electricclutchmountedonverticalengine

shaft.“B”Sectionbelt(withself-tensioning

idler)directfromtheengine.

–Bladesaredrivenbyone“B”Sectionbelt

(w/self-tensioningidler)directfromthe

engine.

•Deck:

Fulloatingdeckisattachedtoout-frontsupport

frame.Maximumturfprotectionisprovidedwith

anti-scalprollers:

–46inchDecks:Quantity3

–50inchDecks:Quantity3

–56inchDecks:Quantity5

46inch

Deck

Deector

Up

Deector

Down

49.5inches

(125.7cm)

58.5inches

(148.6cm)

50inch

Deck

51.1inches

(129.8cm)

62.7inches

(159.3cm)

OverallLength:

RollBarUp

RollBarDown

46inch

Deck

76.4inches

(194.1cm)

82.4inches

(209.3cm)

50inch

Deck

76.9inches

(195.3cm)

82.9inches

(210.6cm)

OverallHeight:

RollBar-UpRollBar-Down

69.9inches(177.5cm)51.8inches(131.6cm)

56inch

Deck

57.3inches

(145.5cm)

68.9inches

(175.0cm)

56inch

Deck

82.0inches

(208.3cm)

88.0inches

(223.5cm)

Deckdesignallowsforbagging,mulchingorside

discharge.

•DeckDepth:

–46inchDeck:6.0inches(15.2cm)

–50inchDeck:6.0inches(15.2cm)

–56inchDeck:6.0inches(15.2cm)

•CuttingHeightAdjustment:

Anextra-longcushionedleverisusedtoadjust

thecuttingheightfrom11/2inch(3.8cm)to

41/2inches(11.4cm)in1/4inch(6.4mm)

increments.Thecuttingheightadjustmenthandle

hasatransportpositionandalladjustmentscan

bemadewhiletheoperatorremainsseated.Units

alsohaveafootoperateddeckliftassistleverto

aidinraisingthedeck.

•MulchingKit:Optional.

Dimensions

TreadWidth:(CentertoCenterof

Tires,Widthwise)

Drive

Wheels

Caster

Wheels

46inch

Deck

34.4inches

(88.6cm)

29.8inches

(75.6cm)

50inch

Deck

36.4inches

(92.5cm)

31.9inches

(81.0cm)

56inch

Deck

38.4inches

(97.5cm)

33.3inches

(84.6cm)

WheelBase:(CenterofCasterTireto

CenterofDriveTire)

46inchDeck50inchDeck56inchDeck

48.0inches

(121.9cm)

48.5inches

(123.2cm)

52.0inches

(132.1cm)

CurbWeight:

46inchDeck50inchDeck56inchDeck

OverallWidth:

Without

Deck

46inch

Deck

44.9inches

(114.1cm)

50inch

Deck

46.5inches

(118.1cm)

56inch

Deck

48.5inches

(123.2cm)

1080lb(490kg)1135lb(515kg)1190lb(540kg)

LHP19KA465:1065lb(483kg)

16

Page 17

ProductOverview

TorqueRequirements

BoltLocation

BladeDriveSheave

MountingNut

CutterHousingSpindle

Nut

BladeMountingBolt

(lubricatewithanti-seize)

EngineDeck/FrontFrame

MountBolts

Anti-ScalpRollerNyloc

NutSeeFigure10

Anti-ScalpRollerHex

CapscrewSeeFigure10

EngineMountingBolts

WheelLugNuts

WheelMotorMounting

Bolts

WheelHubSlottedNutminimum125ft-lb

RolloverProtectionSystem

(RollBar)MountingBolts

ClutchRetainingBolt

(securedwiththreadlocker)

Torque

90–110ft-lb

(122–149N-m)

160-185ft-lb

(217–251N-m)

55-60ft-lb(75-81N-m)

30-35ft-lb(41-47N-m)

30-35ft-lb(41-47N-m)

50-55ft-lb(68-75N-m)

15-20ft-lb(20-27N-m)

90-95ft-lb(122-129N-m)

72-77ft-lb(98-104N-m)

(169N-m)

30-35ft-lb(41-47N-m)

55-60ft-lb(75-81N-m)

ProductOverview

1.MotionControlLever5.Controls

2.ParkingBrakeLever

3.Height-of-CutLever

4.FuelCap(BothSides)

Figure4

6.SeatBelt

7.RollBar

17

Page 18

Operation

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

MotionControlLevers

Themotioncontrolleverslocatedoneachsideofthe

consolecontroltheforwardandreversemotionof

themachine.Theleverscontroltheowofhydraulic

oilfromthehydrostaticpumptothedrivewheel

motorforeachside.

Movingtheleversforwardorbackwardturnsthe

wheelonthesamesideforwardorinreverse.Wheel

speedisproportionaltotheamounttheleveris

moved.

Movingtheleversoutwardfromthecenterposition

intotheT-slotlocksthemintheneutralposition

(Figure6).

ChokeControl

Locatedonrightfueltank.

Thechokeisusedtoaidinstartingacoldengine.

Movingthechokeleverforwardwillputthechokein

the“ON”positionandmovingthechokelevertothe

rear,tothedetent,willputthechokeinthe“OFF”

position.DoNotrunawarmenginewithchokein

the“ON”position.

Theunitmustbetieddownandbrakeengagedwhen

transporting.

IgnitionSwitch

Locatedonrightfueltank.

Theignitionswitchisusedtostartandstopthe

engine.Theswitchhasthreepositions“OFF”,“ON”

and“START”.Insertkeyintoswitchandrotate

clockwisetothe“ON”position.Rotateclockwiseto

thenextpositiontoengagethestarter(keymustbe

heldagainstspringpressureinthisposition).

Note:Brakemustbeengaged,motioncontrollevers

out(neutrallockposition)andPTOswitch“OFF”to

startengine.(Itisnotnecessaryfortheoperatorto

beintheseattostarttheengine.)

HourMeter

Locatedontherightfueltank.

Thehourmeterisconnectedtoapressureswitch

installedintheengineblockanditrecordsthe

numberofhoursthattheenginehasrun.Ifthe

ignitionswitchisleftonwithoutenginerunning,

hourmeterwillnotrun.

Note:Thisswitchisnotalowoilsensorandwillnot

alerttheoperatoriftheengineoilislow .

FuelShut-OffValve

Thevalveislocatedinthefuellinebesidetheengine,

nearthefuellter.

ThrottleControl

Locatedonrightfueltank.

Thethrottleisusedtocontrolenginespeed.Moving

thethrottleleverforwardwillincreaseenginespeed

andmovingthethrottlelevertotherearwilldecrease

enginespeed.Movingthethrottleforwardintothe

detentisfullthrottle.

BrakeLever

Locatedonleftsideoftheconsole.

Thebrakeleverengagesaparkingbrakeonthedrive

wheels.

Pulltheleverupandrearwardtoengagethebrake.

Pushtheleverforwardanddowntodisengagethe

brake.

Thefuelshut-offvalveisusedtoshutoffthefuel

whenthemachinewillnotbeusedforafewdays,

duringtransporttoandfromthejobsite,andwhen

parkedinsideabuilding.

Rotatethevalve1/4turnclockwisetoshutofffuel.

Rotatethevalve1/4turncounterclockwisetoturn

onfuel.

FuelGauge

Locatedontheleftfueltank.

Thefuelgaugemonitorstheamountoffuelinboth

tanks.Fuelisusedevenlyfrombothtanks.

DriveWheelReleaseValves

Locatedontherightfrontcornerofhydrostatic

pumps.

18

Page 19

Operation

Drivewheelreleasevalvesareusedtoreleasethe

hydrostaticdrivesystemtoallowthemachinetobe

pushedwithouttheenginerunning.Unhookseat

latchandtiltseatuptogainaccesstopumps.

Witha5/8inchwrench,turnbothvalvesoneturn

counterclockwisetoreleasedrivesystem.Turn

clockwisetoresetsystem.DoNotovertighten.Do

Nottowmachine.

TrackingAdjustmentKnob

LocatedundertheseatontheLHpumpcontrollink.

Rotatingthisknoballowsnetuningadjustmentsso

thatthemachinetracksstraightwiththedrivelevers

inthefullforwardposition.

Stopmachineandwaitforallmovingpartstostop.

Engageparkbrake.Unhookseatlatchandtiltseat

forwardtogainaccesstothetrackingknob.Rotate

theknobclockwise(asviewedfromtherearofthe

machine)tocausethemachinetotrackmoretothe

rightandcounterclockwisetocausethemachine

totrackmoretotheleft.Adjustinquarter-turn

incrementsuntilthemachinetracksstraight.Check

thatthemachinedoesnotcreepwheninneutralwith

theparkbrakesdisengaged.

Important:DoNotrotatetheknobtoofar,as

thismaycausethemachinetocreepinneutral.

RefertotheMotionControlLinkageAdjustment

sectioninMaintenance.

(13mm)belowthebottomofthellernecktoallow

forfuelexpansionandpreventfuelspillage.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

RaisetheRolloverProtectionSystem

(ROPS)

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.Removethehairpincotterpinsandremovethe

tworollbarpins(Figure5).

2.Raisetherollbartotheuprightpositionand

installthetwopinsandsecurethemwiththe

hairpincotterpins(Figure5).

Important:Alwaysusetheseatbeltwiththe

rollbarintheraisedposition.Ensurethatthe

rearpartoftheseatissecuredwiththeseat

latch.

PTOEngagementSwitch

Locatedontherightfueltank.

Switchmustbepulledouttothe“ROTATE”

positiontoengagetheblades.Switchispushedinto

the“STOP”positiontostoptheblades.

Pre-Start

Fillfueltanks.Forbestresultsuseonlyclean,fresh

regulargradeunleadedgasolinewithanoctanerating

of87orhigher.Regulargradeleadedgasolinemay

alsobeused;however,combustionchamberand

cylinderheadwillrequiremorefrequentservice.See

EngineOwner’sManual.

DoNotaddoiltogasoline.

DoNotoverllfueltank.Neverllthefueltankso

thatthefuellevelrisesabovealevelthatis1/2inch

19

Page 20

Operation

Figure5

1.Rollbar3.Pin

2.Raisedposition4.Hairpincotterpin

Important:DoNotcranktheengine

continuouslyformorethantensecondsata

time.Iftheenginedoesnotstart,allowa60

secondcool-downperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor.

7.Ifthechokeisinthe“ON”position,gradually

returnchoketothe“OFF”positionastheengine

warmsup.

EngagingthePTO

DANGER

Therotatingbladesunderthemowerdeck

aredangerous.Bladecontactcancause

seriousinjuryorkillyou.

DoNotputhandsorfeetunderthemower

ormowerdeckwhenthebladesareengaged.

DANGER

OpentheFuelShut-OffValve

Thefuelshutoffvalveislocatedinthefuelline

besidetheengine,nearthefuellter.Rotatethevalve

1/4turncounterclockwisetoturnonfuel.

StartingtheEngine

1.Movethemotioncontrolleversouttotheneutral

lockposition.

2.Pullupandbackontheparkingbrakeleverto

engagetheparkingbrake.

3.PushinonthePTOswitchtothe“STOP”

position.

Note:Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.

4.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

5.Onacoldengine,pushthechokeleverforward

intothe“ON”position.

Anuncovereddischargeopeningwillallow

objectstobethrowninanoperator’sor

bystander’sdirection.Also,contactwiththe

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryordeath.

Neveroperatethemowerwiththedischarge

deectorraised,removed,oralteredunless

thereisagrasscollectionsystemormulch

kitinplaceandworkingproperly.

ThePTOpush-pullswitchengagesthecuttingblades.

Besurethatallpersonsareclearofthemowerdeck

anddischargeareabeforeengagingPTO.

Important:Operatormustbeinseatbeforethe

PTOcanbeengaged.

1.Setthethrottletothe“MIDW AY”position.

2.PullthePTOswitchoutwardtothe“ROTATE”

position.

3.Placethethrottleinthe“FAST”positiontobegin

mowing.

Onawarmengine,leavethechokeinthe“OFF”

position.

6.Turnignitionswitchtothe“START”position.

Releasetheswitchassoonastheenginestarts.

DisengagingthePTO

1.Setthethrottletothe“MIDW AY”position.

2.PushthePTOswitchintothe“STOP”position

todisengagetheblades.

20

Page 21

StoppingtheEngine

1.Bringtheunittoafullstop.

2.DisengagethePTO.

3.Movethemotioncontrolleversouttotheneutral

lockposition.

4.Engagetheparkingbrake.

5.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

6.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

7.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

8.Closethefuelshut-offvalvewhenthemachine

willnotbeinuseforafewdays,when

transporting,orwhentheunitisparkedinside

abuilding.

1.HandlesOut(Neutral

Lock)

2.HandlesIn(Neutral)

3.FrontofUnit

4.Forward

Operation

Figure6

5.Neutral

6.Reverse

7.NeutralLock

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioning

onelevertoomuchaheadoftheother.

Operatormaylosecontrolofthemachine,

whichmaycausedamagetothemachine

orinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Important:Tobeginmovement(forwardor

backward)theoperatormustbeintheseat,the

brakelevermustbedisengaged(pusheddown)

beforethemotioncontrolleverscanbemovedin

ortheenginewillstop.

WhenleversarecenteredintheT-slotthedrive

systemisintheneutralposition.Withleversmoved

outintheT-slotthedrivesystemisintheneutrallock

position(Figure6).

DrivingForward

1.Releasetheparkingbrake.

2.Movethemotioncontrolleversinwardtothe

centertotheneutralunlockedposition.

3.Tomoveforwardinastraightlineapplyequal

forwardpressuretobothlevers.

Toturnleftorright,pullthemotioncontrollever

backtowardneutralinthedirectiondesired.

Themachinewillmovefasterthefartherthe

motioncontrolleversaremovedawayfrom

neutral.

4.Tostop,pullthemotioncontrolleversbackto

theneutralposition.

21

Page 22

Operation

1.HandlesOut(Neutral

Lock)

2.HandlesIn(Neutral)

3.FrontofUnit

Figure7

deckliftassistleverlocatedatthefrontright

corneroftheoorpan.

Note:Whenchangingthecuttingheight

positions,alwayscometoacompletestop

anddisengagethePTO.

Figure8

1.Leverintransportand41/2inch(1 1.4cm)cutting

heightposition

4.Forward

5.Reverse

4.Inserttheheightadjustmentpinintothehole

correspondingtothedesiredcuttingheightand

installthehairpincotterpin.

DrivinginReverse

1.Movethemotioncontrolleversinwardtothe

centertotheneutralunlockedposition.

2.Tomoverearwardinastraightlineapplyingequal

pressurepullbothmotioncontrolleversrearward.

Toturnleftorright,releasepressureonthe

motioncontrollevertowardthedirectiondesired.

3.Tostop,pushthemotioncontrolleverstothe

neutralposition.

AdjustingtheCuttingHeight

Thecuttingheightofthemowerdeckisadjusted

from11/2inchto41/2inches(3.8cmto11.4cm)

in1/4inch(6.4mm)increments.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO.

3.Raisethedeckheightlevertothetransport

position(alsothe41/2inch(11.4cm)cutting

heightposition)(Figure8).

Thedeckcanberaisedbypullingthedecklever

upand/orbypushingdownonthefootoperated

Seethedecalonthesideofthedeckliftplatefor

cutheights.

5.Movethedeckheightleveroutofthetransport

position(or41/2inch(11.4cm)cuttingheight)

anddownontotheheightadjustmentpintomow

atselectedheight.

Note:Thefootoperateddeckliftassistlever

canbeusedtomomentarilyliftthedecktoclear

objects.BesurethatPTOisdisengaged.

AdjustingtheAnti-ScalpRollers

Itisrecommendedtochangetheanti-scalproller

position,whentheheightofcuthaschanged.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingtheboltandspring

discwasher.

22

Page 23

6.Placetherollersinoneofthepositionsshown

(Figure9).Rollerswillmaintain3/4inch(19mm)

clearancetothegroundtominimizegougingand

rollerwearordamage.

Figure9

Forcuttingheightsabove4.0inches(102mm)usethe

bottomhole.Therollerswillstillbeeffectiveagainst

scalping.

1.Anti-scalproller

mountingbracket

2.Cuttingheight

1.Springdiscwasher

(conetowardsbolthead)

2.Frontrightanti-scalp

bracketshown

Operation

Figure10

3.3/8nyloc-torqueto30-35

ft-lb(41-47N-m)

4.3/8-24x2GR8torqueto

50-55ft-lb(68-75N-m)

ForMaximumDeckFlotation,placetherollers

oneholepositionlower.Rollersshouldmaintain

1/4inch(6.4mm)clearancetotheground.Do

Notadjusttherollerstosupportthedeck.

7.Besuretherollerboltsareinstalledwiththe

springdiscwasherbetweentheheadofthebolt

andthemountingbracket.

Note:Thefootoperateddeckliftassistlever

canbeusedtomomentarilyliftthedecktoclear

objects.BesurethatPTOisdisengaged.

8.Torquethe3/8–24x2Gr8hexcapscrewto

50–55ft-lb(68–75N-m)(Figure10).

9.Ifthe3/8nylocnuthasbeenremoved,

reinstallandtorqueto30–35ft-lb(41–47

N-m).(Figure10).

Transporting

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Securely

fastenthemachinetothetrailerortruckwithstraps,

chains,cable,orropes.Besurethatthetrailerortruck

hasallnecessarylightingandmarkingasrequiredby

law .Secureatrailerwithasafetychain.

CAUTION

Thisunitdoesnothaveproperturn

signals,lights,reectivemarkings,ora

slowmovingvehicleemblem.Drivingona

streetorroadwaywithoutsuchequipment

isdangerousandcanleadtoaccidents

causingpersonalinjury.Drivingonastreet

orroadwaywithoutsuchequipmentmayalso

beaviolationofStatelawsandtheoperator

maybesubjecttotrafcticketsand/ornes.

DoNotdriveaunitonapublicstreetor

roadway.

23

Page 24

Operation

WARNING

Loadingaunitonatrailerortruckincreases

thepossibilityofbackwardtip-over.

Backwardtip-overcouldcauseseriousinjury

ordeath.

•Useextremecautionwhenoperatinga

unitonaramp.

•Useonlyasingle,fullwidthramp;Do

Notuseindividualrampsforeachside

oftheunit.

•Ifindividualrampsmustbeused,use

enoughrampstocreateanunbroken

rampsurfacewiderthantheunit.

•DoNotexceeda15°anglebetweenramp

andgroundorbetweenrampandtrailer

ortruck.

•Avoidsuddenaccelerationwhiledriving

unituparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

unitdownaramptoavoidtipping

backward.

Important:DoNotattempttoturntheunit

whileontheramp,youmaylosecontroland

driveofftheside.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdownaramp.

Bothmaneuverscancausetheunittotipbackward.

LoadingaUnit

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinstead

ofindividualrampsforeachsideoftheunit.The

lowerrearsectionofthetractorframeextendsback

betweentherearwheelsandservesasastopfor

tippingbackward.Havingafullwidthrampprovides

asurfacefortheframememberstocontactifthe

unitstartstotipbackward.Ifitisnotpossibletouse

onefullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Rampshouldbelongenoughsothattheangles

betweentherampandthegroundandtherampand

thetrailerortruckdonotexceed15°.Asteeperangle

maycausemowerdeckcomponentstogetcaughtas

theunitmovesfromramptotrailerortruck.Steeper

anglesmayalsocausetheunittotipbackward.If

loadingonornearaslope,positionthetraileror

trucksoitisonthedownsideoftheslopeandthe

rampextendsuptheslope.Thiswillminimizethe

rampangle.Thetrailerortruckshouldbeaslevel

aspossible.

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Maintenance

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)aside

soitdoesnotaccidentallycontactthespark

plug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthewheelhubslottednuttorquespecications.

•Checkthewheellugnuts.

WARNING

Theenginecanbecomeveryhot.Touching

ahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

Aftertherst250hours

Beforeeachuseordaily

Every40hours

Every50hours

Every100hours

Every160hours

•Changethehydrauliclter.

•Checktheengineoillevel.

•Checkthemowerblades.

•Checkthesafetyinterlocksystem.

•Checktherolloverprotectionsystem(rollbar)pins.

•Checktheseatbelt.

•Checkforloosehardware.

•Cleantheenginecoolingsystem.

•Cleanthegrassbuild-upfromunderthedeck.

•Checkthehydraulicoillevel.

•Checkthetirepressures.

•Checktheconditionofthebelts.

•Greasetheheightadjustmentshaftbearings.

•Greasedeckrearstruts.

•Servicetheaircleaner.(Mayneedmoreoftenundersevereconditions.SeetheEngine

Owner’sManualforadditionalinformation.)

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Removetheengineshroudsandcleanthecoolingns.

•Lubricatethebrakehandlepivot.

•Lubricatethebrakerodbushings.

•Lubricatethemotioncontrolbronzebushings.

•Lubricatetheseatswitchactuator.

•Checkthesparkplugs.

Every200hours

•Greasebrakebrackets.

25

Page 26

Maintenance

MaintenanceService

Interval

Every500hours

Monthly

Yearly

MaintenanceProcedure

•Checkthewheelhubslottednuttorquespecications.

•Checkthewheellugnuts.

•Checkthebatterycharge.

•Greasethefrontcasterwheelhubs.

•Greasefrontcasterpivots.

•Greasethedeckdrivebeltidlerarm.

•Greasethepumpdrivebeltidlerarm.

•Lubricatethecasterwheelhubs.

•Changethehydrauliclter.

PeriodicMaintenance

CheckEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopengineandwaitforallmovingpartstostop.

Makesureunitisonalevelsurface.

2.Checkwithenginecold.

3.Cleanareaarounddipstick.Removedipstickand

wipeoiloff.Reinsertthedipstick.Donotscrew

intoplace.Removethedipstickandreadtheoil

level.

4.Iftheoillevelislow ,wipeofftheareaaroundthe

oilllcap,removecapandlltothe“FULL”

markonthedipstick.Useoilasspeciedin

EngineOwner’ sManual.DoNotoverll.

Important:DoNotoperatetheenginewiththe

oillevelbelowthe“LOW”(or“ADD”)markon

thedipstick,oroverthe“FULL”mark.

Allowingbatteriestostandforanextendedperiodof

timewithoutrechargingthemwillresultinreduced

performanceandservicelife.Topreserveoptimum

batteryperformanceandlife,rechargebatteriesin

storagewhentheopencircuitvoltagedropsto12.4

volts.

Note:Topreventdamageduetofreezing,battery

shouldbefullychargedbeforeputtingawayfor

winterstorage.

Checkthevoltageofthebatterywithadigital

voltmeter.Locatethevoltagereadingofthebatteryin

thetableandchargethebatteryfortherecommended

timeintervaltobringthechargeuptoafullcharge

of12.6voltsorgreater.

Important:Makesurethenegativebattery

cablesaredisconnectedandthebatterycharger

usedforchargingthebatteryhasanoutputof

16voltsand7ampsorlesstoavoiddamaging

thebattery(seechartforrecommendedcharger

settings).

CheckBatteryCharge

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

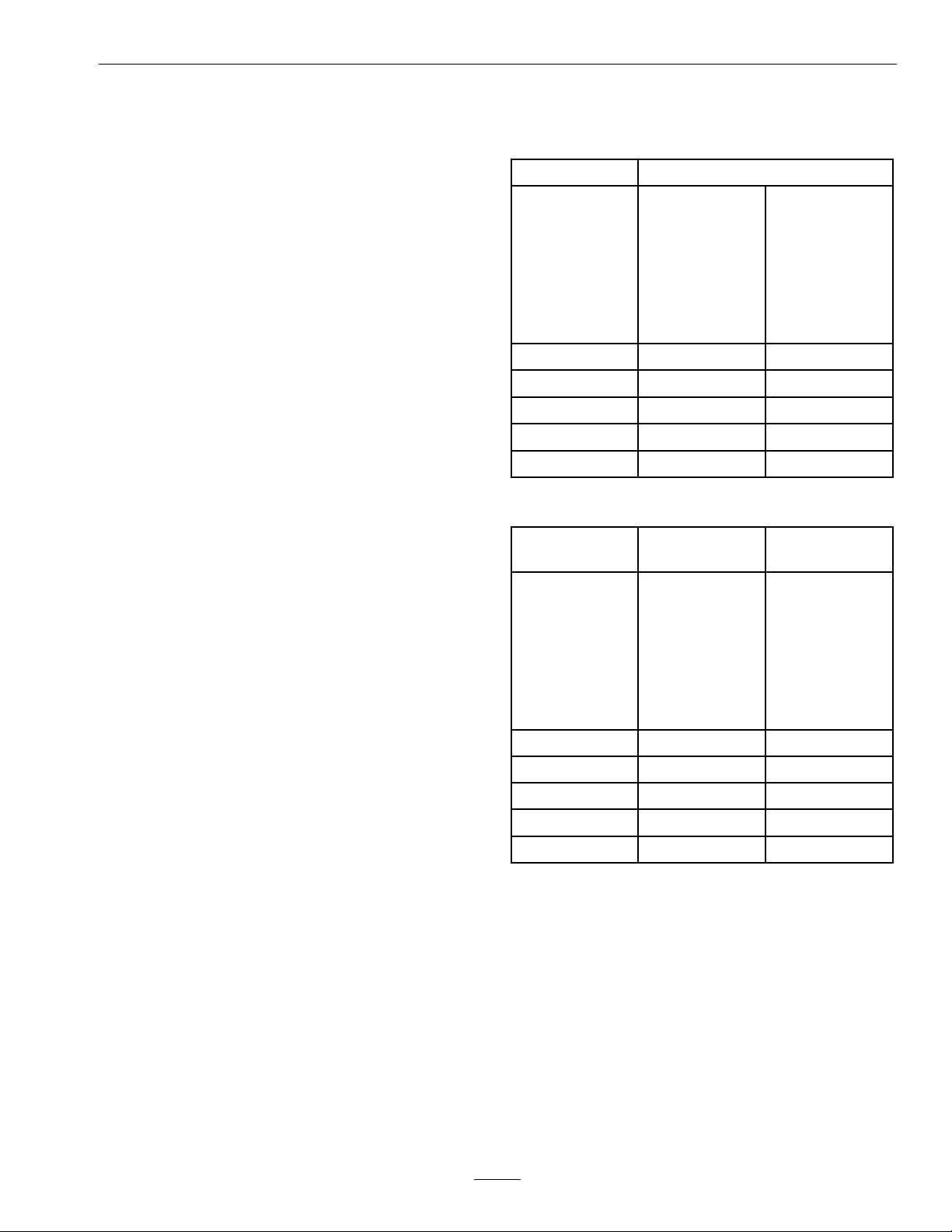

Voltage

Reading

12.6or

greater

12.4–12.675–100%

12.2–12.450–75%

12.0–12.225–50%

26

Percent

Charge

100%

Maximum

Charger

Settings

16volts/7

amps

16volts/7

amps

16volts/7

amps

14.4volts/4

amps

Charging

Interval

No

Charging

Required

30Minutes

1Hour

2Hours

Page 27

Maintenance

Voltage

Reading

11.7–12.00–25%

11.7orless

Percent

Charge

0%

Maximum

Charger

Settings

14.4volts/4

amps

14.4volts/2

amps

Charging

Interval

3Hours

6Hoursor

More

CheckMowerBlades

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Liftdeckandsecureinraisedpositionasstatedin

theCleanGrassBuild-UpUnderDecksection.

3.Inspectbladesandsharpenorreplaceasrequired.

4.Reinstalltheblades(iftheywereremoved)inthe

followingorder:

A.Installbushingthroughbladewithbushing

angeonbottom(grass)sideofblade.

Figure12

1.Usewrenchherefor

bladeinstallation.This

nuthasbeentorquedto

90–110ft-lb(122–149

N-m)

2.Torqueto55-60ft-lb

(75-81N-m)Apply

lubricanttothreads

asneededtoprevent

seizing.Copper-based

anti-seizepreferable.

Greaseacceptable

substitute.

C.Applylubricanttothreadsofbladeboltas

neededtopreventseizing.Copper-based

anti-seizepreferable.Greaseacceptable

substitute.Installbladeboltngertight.Place

wrenchonthetopspindlenutthentorquethe

bladeboltsto55-60ft-lb(75-81N-m).

Figure11

1.Installbushinginbladepriortoinstallingbushingin

spindle.

B.Installbushing/bladeassemblyintospindle.

WARNING

Incorrectinstallationofthebladeor

componentsusedtoretainthebladecan

bedangerous.Failuretousealloriginal

componentsandassembledasshowncould

allowabladeorbladecomponenttobe

thrownoutfromunderthedeckresultingin

seriouspersonalinjuryordeath.

AlwaysinstalltheoriginalExmarkblades,

bladebushings,andbladeboltsasshown.

CheckSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

Note:Topreventenginecut-outsonroughterrain

theseatkillswitchhasa1/2seconddelay.

1.Checkstartingcircuit.Startershouldcrankwith,

parkingbrakeengaged,PTOdisengagedand

27

Page 28

Maintenance

motioncontrolleversmovedoutintheneutral

lockposition.Theoperatordoesnotneedtobe

intheseattostarttheengine.

Trytostartwithoperatorinseat,parkingbrake

disengaged,PTOdisengagedandmotioncontrol

leversintheneutrallockposition-startermust

notcrank.

Trytostartwithoperatorinseat,parkingbrake

engaged,PTOengagedandmotioncontrol

leversintheneutrallockposition-startermust

notcrank.

Trytostartwithoperatorinseat,parking

brakeengaged,PTOdisengaged,andtheleft

motioncontrolleverin,startermustnotcrank,

repeatagainwiththerightleverin,thenwith

bothleversin-startermustnotcrank.

2.Checkthekillcircuits.Runengineatone-third

throttle,disengageparkingbrakeandraiseoff

ofseat(butdonotgetoffofmachine)engine

mustinitiateshutdownafterapproximately1/2

secondhaselapsed(seathastimedelaykillswitch

topreventcut-outsonroughterrain).

CheckRolloverProtection

System(RollBar)Pins

ServiceInterval:Beforeeachuseordaily

Makesurelatchpinandhairpinarefullyinstalled

andlanyardisingoodcondition.

CheckSeatBelt

ServiceInterval:Beforeeachuseordaily

Visuallyinspectseatbeltforwear,cuts,andproper

operationofretractorandbuckle.Replacebefore

operatingifdamaged.

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

Runengineatone-thirdthrottle,engagePTO

andraiseoffofseat(butdonotgetoffof

machine)enginemustinitiateshutdownafter

1/2secondhaselapsed.

Runengineatone-thirdthrottle,withbrake

disengaged,moveleversinandraiseoffseat(but

donotgetoffofmachine)enginemustinitiate

shutdownafter1/2secondhaselapsed.

Again,runengineatone-thirdthrottle,brake

engaged,andmoveleftmotioncontrolleverin

-enginemustinitiateshutdown.

Repeatagainmovingtherightleverin,then

movingbothleversin-enginemustinitiate

shutdownwhetheroperatorisonseatornot.

Note:Ifmachinedoesnotpassanyofthesetests,

donotoperate.ContactyourauthorizedEXMARK

SERVICEDEALER.

Important:Itisessentialthatoperatorsafety

mechanismsbeconnectedandinproper

operatingconditionpriortouseformowing.

ServiceAirCleaner

ServiceInterval:Every50hours—Service

theaircleaner.(May

needmoreoftenunder

severeconditions.See

theEngineOwner’s

Manualforadditional

information.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.SeeEngineOwner’sManualforcleaning

instructions.

ChangeEngineOil

ServiceInterval:Aftertherst5hours

Every100hours/Yearly

(whichevercomesrst)

(Mayneedmoreoften

undersevereconditions.)

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Drainoilwhileengineiswarmfromoperation.

3.Theoildrainhoseislocatedonlefthandsideof

KohlerengineandrighthandsideofKawasaki

28

Page 29

Maintenance

engine.Placepanundermachinetocatchoil.

Removeplugfromendofdrainhose.Allowoil

todrainandreplaceoildrainplug.Torqueplug

to20-24ft-lb.

4.Replacetheoilltereveryotheroilchange.Clean

aroundoillterandunscrewltertoremove.

Beforereinstallingnewlter,applyathincoating

ofoilonthesurfaceoftherubberseal.Turn

lterclockwiseuntilrubbersealcontactsthelter

adapterthentightenlteranadditional1/2to

3/4turn.

5.Cleanaroundoilllcapandremovecap.Fillto

speciedcapacityandreplacecap.

6.Useoilrecommendedinengineowner’smanual.

DoNotoverll.Starttheengineandcheckfor

leaks.

CheckHydraulicOilLevel

ServiceInterval:Every40hours

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.

2.Cleanareaaroundhydraulicreservoircapand

removecap.Oillevelshouldbetothetopofthe

bafeinsidethetank.Ifnot,addoil.Useonly

Mobil115W -50syntheticmotoroil.Replace

hydraulicreservoircapandtightenuntilsnug.Do

Notovertighten.

Note:Thebafeislabeled“HOT”and

“COLD”.Theoillevelvarieswiththe

temperatureoftheoil.The“HOT”levelshows

thelevelofoilwhenitisat225°F(107°C).The

“COLD”levelshowstheleveloftheoilwhen

itisat75°F(24°C).Filltotheappropriatelevel

dependinguponthetemperatureoftheoil.For

example:Iftheoilisabout150°F(65°C),llto

halfwaybetweenthe“HOT”and“COLD”levels.

Iftheoilisatroomtemperature(about75°F

(24°C)),llonlytothe“COLD”level.

CheckTirePressures

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto13psi(90kPa).

4.Checktirepressureincastertires.

5.Inatecastertiresto13psi(90kPa).

6.Semi-pneumaticcastertiresdonotneedtobe

inated.

Note:DoNotaddanytypeoftirelinerorfoam

llmaterialtothetires.Excessiveloadscreatedby

foamlledtiresmaycausefailurestothehydrodrive

system,frame,andothercomponents.Foamlling

tireswillvoidthewarranty.

CheckConditionOfBelts

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checkunderenginedecktocheckpumpdrive

belt.

3.Removeleftandrightbeltshieldsondeckandlift

upoorpantoinspectdeckdrivebelt.

4.Forbeltadjustment,seethePumpDriveBelt

andDeckBeltT ensionAdjustmentsections.

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lubricatettingswithonetotwopumpsof

NGLIgrade#2multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.Front

Casterwheel

hubs

2.Front

Caster

Pivots

3.Height

Adjustment

Shaft

Bearings

4.Deck

DriveBelt

IdlerArm

Initial

Pumps

*0

*0

1

11

Numberof

Places

2

2

540Hours

Service

Interval

*Yearly

*Yearly

Yearly

29

Page 30

Maintenance

LubricationChart

Fitting

Locations

5.Brake

Brackets

6.Pump

DriveBelt

IdlerArm

7.Deck

RearStruts

Initial

Pumps

12

11

12

Numberof

Places

*Seestep3forspeciallubricationinstructionson

thefrontcasterpivotsandtheLubricateCaster

WheelHubssectionforspeciallubrication

instructionsonthefrontcasterswheelhubs.

Service

Interval

200Hours

40Hours

Yearly

Figure13

1.Sealguard2.Spacernutwithwrench

ats

2.Removecasterwheelfromcasterforks.

3.Removesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethatthread

lockingadhesivehasbeenappliedtolockthe

spacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)from

thewheelassembly .

5.Pryoutseals,andinspectbearingsforwearor

damageandreplaceifnecessary.

6.PackthebearingswithaNGLIgrade#1

multi-purposegrease.

7.Insertonebearing,onenewsealintothewheel.

Number6(PumpDriveBeltIdlerArm)Located

UnderEngineFrame-Greasethroughholeintop

ofengineframe,betweenpumps.

3.Lubricatefrontcasterpivotsonceayear.Remove

hexplugandcap.Threadgreasezerkinholeand

pumpwithgreaseuntilitoozesoutaroundtop

bearing.Removegreasezerkandthreadplugback

in.Placecapbackon.

LubricateCasterWheelHubs

ServiceInterval:Yearly

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

Note:Seals(ExmarkP/N103-0063)mustbe

replaced.

8.Iftheaxleassemblyhashadbothspacernuts

removed(orbrokenloose),applyathreadlocking

adhesivetoonespacernutandthreadontothe

axlewiththewrenchatsfacingoutward.Do

Notthreadspacernutallofthewayontotheend

oftheaxle.Leaveapproximately1/8inch(3mm)

fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

NGLIgrade#1multi-purposegrease.

11.Insertthesecondbearingandnewsealintothe

wheel.

12.Applyathreadlockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrenchats

facingoutward.

30

Page 31

Maintenance

13.T orquethenutto75-80in-lb(8-9N-m),loosen,

thenre-torqueto20-25in-lb(2-3N-m).Make

sureaxledoesnotextendbeyondeithernut.

14.Reinstallthesealguardsoverthewheelhuband

insertwheelintocasterfork.Reinstallcasterbolt

andtightennutfully .

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjusttorqueon

spacernutuntilthereisaslightamountofdrag.

Reapplythreadlockingadhesive.

LubricateBrakeHandlePivot

ServiceInterval:Every160hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lubricatebronzebushingsonbrakehandlepivot

withaspraytypelubricantorlightoil.

LubricateBrakeRod

Bushings

ServiceInterval:Every160hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

LubricateSeatSwitch

Actuator

ServiceInterval:Every160hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Unhookseatlatchandtiltseatup.

3.Lubricateswitchactuatorrodwithspraytype

lubricantorlightoil.

CheckSparkPlugs

ServiceInterval:Every160hours

Removesparkplugs,checkconditionandresetgaps,

orreplacewithnewplugs.SeeEngineOwner’s

Manual.

ChangeFuelFilter

ServiceInterval:Asrequired

Afuellterisinstalledbetweenthefueltanksandthe

engine.Replacewhennecessary.

ReplacementFilters

Kohler

Kawasaki

KohlerP/N2405010

KawasakiP/N

49019–7001

2.Unhookseatlatchandtiltseatup.

3.Lubricatebronzebushingsoneachendofbrake

rodshaftwithaspraytypelubricantoralightoil

(bushingsarelocatedtotheinsideoftheange

bearings).

LubricateMotionControl

BronzeBushings

ServiceInterval:Every160hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Unhookseatlatchandtiltseatup.

3.Lubricatebronzebushingsonangebearings

securingthemotioncontrolarmshaftswitha

lightoiloraspraytypelubricant.

ChangeHydraulicSystem

Filter

ServiceInterval:Aftertherst250hours

Yearlythereafter

Note:Summeruseabove32°F(0°C)useonly

ExmarkPartNo.109–4180.

Winterusebelow32°F(0°C)useonlyExmarkPart

No.1-523541.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Locatelterunderleftrearcornerofenginedeck.

3.Carefullycleanareaaroundlter.Itisimportant

thatnodirtorcontaminationenterhydraulic

system.

31

Page 32

Maintenance

4.Unscrewltertoremoveandallowoiltodrain

fromreservoir.

Important:Beforereinstallingnewlter,ll

itwithMobil115W-50andapplyathincoat

ofoilonthesurfaceoftherubberseal.

Turnlterclockwiseuntilrubbersealcontactsthe

lteradapter,thentightenthelteranadditional

2/3to3/4turn.

5.FillreservoirasstatedinCheckHydraulicOil

Levelsection.

6.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

7.Startengineandmovethrottlecontrolaheadto

fullthrottleposition.Movethespeedcontrol

leverstothefullspeedandrunforseveral

minutes.Shutdownmachineandrecheckoil

level.

Note:DoNotchangehydraulicsystemoil(except

forwhatcanbedrainedwhenchanginglter),unless

itisfelttheoilhasbeencontaminatedorbeen

extremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

FuelTank—Mounting

HardwareSpecications

ServiceInterval:Asrequired

Wheninstallingthenutsonthefueltankstuds,fully

tightenthenylocnutandbackoff1/2turn.This

allowsfornormalfueltankexpansionandcontraction

withchangesintemperatureandfuellevels.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

•Pumpdrivesheavesetscrews.

•SquareheadsetscrewsonHydropumpcontrol

arms.

•Sheaveretainingboltintheendofengine

crankshaft.

•Casterwheelspacernuts.

•Fueltankbulkheadttingnuts.

Adhesivessuchas“LoctiteRC/609orRC/680”or

“Fel-ProPro-LockRetainingIorRetainingII”are

usedonthefollowing:

WheelHub-SlottedNut

TorqueSpecication

ServiceInterval:Aftertherst100hours

Every500hoursthereafter

Whentighteningtheslottednutonthewheelmotor

taperedshaft:

1.Torquetheslottednutto125ft-lb(169N-m).

2.Checkdistancefrombottomofslotinnutto

insideedgeofhole.Twothreads(0.1inch)orless

shouldbeshowing.

3.Ifmorethantwothreads(0.1inch)areshowing

removenutandinstallwasher(P/N1-523157)

betweenhubandnut.

4.Torquetheslottednutto125ft-lb(169N-m).

5.Thentightennutuntilthenextsetofslotslineup

withthecrossholeinshaft.

6.Replacecotterpin.

Note:DoNotuseanti-seizeonwheelhub.

Fueltankstuds,wherestudsareinsertedintotank.

MobilHTSGrease(Or

Food-GradeAnti-seize)

MobilHTSgrease(orfood-gradeanti-seize)isused

inthefollowinglocations:

•Betweenthecutterhousingspindleandbearings.

•Betweenthecutterhousingspindleandsheave.

•Undertopcutterhousingbearingguard.

Copper-BasedAnti-seize

Copper-basedanti-seizeisusedinthefollowing

location:

OnthreadsofBladeBolts.SeeCheckMower

Bladessection.

DielectricGrease

Dielectricgreaseisusedonallbladetypeelectrical

connectionstopreventcorrosionandlossofcontact.

32

Page 33

Maintenance

Adjustments

Note:DisengagePTO,shutoffengine,waitfor

allmovingpartstostop,engageparkingbrake,and

removekeybeforeservicing,cleaning,ormakingany

adjustmentstotheunit.

DeckLeveling

1.Positionmoweronaatsurface.

2.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

3.Checktirepressureindrivetires.Properination

pressurefortiresis13psi(90kPa).Checktire

pressureincastertires.Properinationpressure

fortiresis13psi(90kPa).Adjustifnecessary.

Semi-pneumaticcastertiresdonotneedtobe

inated.

4.Setanti-scalprollerstotopholesorremovethem

completelyforthisadjustment.

5.Raisethedecktothe41/2inch(11.4cm)height

positionandtakeasmuchforceaspossibleoffof

thetwolargedeckliftspringsbylooseningthe

nutsatthefrontofeachspring.(Figure14).

6.Lowerthedecktothe11/2inch(3.8cm)

heightposition.Placetwo15/16inch(3.3cm)

thickblocksundertherearedgeofthecutting

deckskirt;oneoneachsideofthecuttingdeck

(Figure14).

7.Placea11/8inch(2.9cm)blockunderthecenter

frontedge,butnotundertheanti-scalproller

brackets

8.Loosenthetwotopchainboltsinslotsinthe

reardeckliftarms.Loosenjamnutsandbackoff

thesocketheadadjustingscrewsonthebottom

ofthearmsuntilthechainsarejustloosewhen

pressureisappliedtoforcereardecksupport

armsdown.Continuetopressdownonreardeck

supportarmsandturnthesocketheadadjusting

screwsinuntilslackistakenoutofeachchain.

Tightenthejamnuts.Tightenthechainboltsin

thedeckliftarmsmakingsuretheydonotmove

whiletightening.

9.Loosenfournutswhichsecurefrontswivels(two

perside),untilfrontchainsarelooseandfront

ofdeckissupportedbythe11/8inch(2.9cm)

block.Donotloosenfrontchainhardware.

10.Onleftside,adjustfrontswivelusingthelocking

nutbehindtheswiveluntilthefrontchainistight

andallslackisremovedfromlinkage.Donot

liftfrontofdeckoff11/8inch(2.9cm)block.

Securefrontswivelusinglockingnutinfrontof

swivel.Repeatforrightside.

Figure14

1.Swivel

2.Adjustfrontdeckheighthere

3.Adjustspringtensionhere

4.101/2inches(26.7cm)for46inchdeck;10inches

(25.4cm)for50inchdeck;91/2inches(24.1cm)for

56inchdecks

5.Applydownwardpressurehere

6.Jamnut

7.Socketheadadjustingscrew

8.Slottedhole

9.Frontoftheunit

11.Recheckthatblockstjustsnuglyunderthe

deckskirtandthatthetensiononallthechains

areapproximatelyequal.Makesureallchain

attachmentboltsaretight.

12.Raisedeckliftlevertothe41/2inch(11.4cm)

cuttingheightposition(alsotransportposition

(Figure8).Adjustspringcompressionuntil

properdistanceisobtainedbetweenthetwo

washersbyturningthenutatthefrontofeach

spring(Figure14).Locknutsinpositionwithjam

nuts.

13.Repositionanti-scalprollersandtightensecurely .

Note:Whenaboveadjustmentshavebeenmade,

thefrontofthedeckwillbeslightlylowerthanthe

rearofthedeck.

PumpDriveBeltTension

Self-tensioning-Noadjustmentnecessary.

DeckBeltTension

Self-tensioning-Noadjustmentnecessary.

33

Page 34

Maintenance

BrakeLinkAdjustment

Checktomakesurebrakeisadjustedproperly.

1.Disengagebrakelever(leverdown).

2.Measurethelengthofthespring.Measurement

shouldbe23/4inches(7.0cm)betweenwashers.

(Figure15).

3.Ifadjustmentisnecessary,tightenthenutdirectly

belowtheyokeandloosenthebottomnut

(bottomoneofthetwotightenedtogether)below

thespring.Turnthenutdirectlybelowthewasher

(topnutofthetwotightenedtogether)untilthe

correctmeasurementisobtained.Tightenthetwo

nutstogetherandrepeatonoppositesideofunit.

Turnclockwisetoshortenspringlengthandturn

counterclockwisetolengthenthespring.

betweenthespringretainerbracketandthe

adjacentnylocnut.Tightenthejamnutabove

thetrunnionroller.

4.Ifadjustmentisnecessary,loosenthenut

directlybelowtheyoke.Turnthebottomnut

(belowwasher)untilthecorrectmeasurement

isobtainedseeFigure15turnnutclockwiseto

lengthenthegap(screwsrodintoyoke)andturn

counterclockwisetoshortenthegap(screws

rodoutofyoke).Tightennutagainstyokeand

checkoppositesideofunit,repeatifnecessary.

Lengthen(orshorten)thebrakeroduntilthe

correctgapcanbeachievedbyfollowingsteps

2and3.

ElectricClutchAdjustment

Noadjustmentnecessary.

ReverseIndicator

Adjustment

Figure15

1.Leverdown

(disengaged)

2.Leverup(engaged)

3.1/4to5/16inch(6.4to

7.9mm)

4.Collar9.2.75inches(7.0cm)

5.Trunnionroller

6.Yoke

7.Locknut

8.Springadjustment

BrakeAdjustment

1.Checkforbrakelink23/4inches(7.0cm)

measurementasdescribedintheBrakeLink

Adjustmentsection.

2.Engagethebrakelever(leverup).Thespace

betweenthetrunnionrollerandtherodcollar

shouldmeasure1/4inchto5/16inch(6.4–7.9

mm).

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Unhookseatlatchandtiltseatforward.

3.Beginwitheithertheleftorrightmotioncontrol

lever.Movelevertotheneutralpositionandpull

leverbackuntiltheclevispin(onarmbelowpivot

shaft)contactstheendoftheslot(justbeginning

toputpressureonspring).(Figure16).

4.Checkwhereleverisrelativetonotchinconsole

(shouldbecenteredallowinglevertopivot

outwardtotheneutrallockposition).

5.Ifadjustmentisneeded,loosenthenutagainstthe

yokeandwhileapplyingslightrearwardpressure

onthemotioncontrollever,turntheheadofthe

adjustmentboltintheappropriatedirectionuntil

leveriscentered(keepingrearwardpressureon

theleverwillkeepthepinattheendoftheslot

andallowtheadjustmentbolttomovethelever

totheappropriateposition).Tightenlocknut.

6.Repeatonoppositesideofunit.

3.Ifadjustmentisnecessary,loosennutabovethe

trunnionroller.Adjustthenylocnutunderthe

trunnionrolleruntildistancelistedaboveexists

34

Page 35

MotionControlLinkage

Adjustment

WARNING

Enginemustberunninganddrive

wheelsmustbeturningsomotioncontrol

adjustmentcanbeperformed.Contactwith

movingpartsorhotsurfacesmaycause

personalinjury

Keepngers,hands,andclothingclearof

rotatingcomponentsandhotsurfaces.

CAUTION

Maintenance

Figure16

1.Turnbolthere

2.Reverseindicator

3.Loosenhere7.Turnheretoadjust

4.Yoke

5.Endofslot

6.Loosenhere(right-hand

thread)

8.Loosenhere(left-hand

thread)

Raisingthemowerdeckforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

theunittofall,whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport

1.Thisadjustmentmustbemadewiththedrive

wheelsturning.Firstraisetheframeandblockup

sothatdrivewheelscanrotatefreely.

2.Removetheelectricalconnectionfromtheseat

safetyswitch,locateddirectlytotheleftoftheseat

switchassemblybesidethehydraulicoilreservoir.

3.Temporarilyinstallajumperwireacrossthe

terminalsintheconnectorofthemainwiring

harness.

4.Runtheunitatleast5minuteswiththedrive

leversatfullforwardspeedtobringhydraulic

systemoiluptooperatingtemperature.

7.Startengine.Brakemustbeengagedand

motioncontrolleversouttostartengine.

Operatordoesnothavetobeintheseat

becauseofthejumperwirebeingused.Run

engineatfullthrottleandreleasebrake.

8.Thereverseindicatorspringmustbecorrect

beforethefollowingadjustmentscanbemade.

SeetheReverseIndicatorAdjustmentsection.

Note:Themotioncontrolleverneedstobein

neutralwhilemakinganynecessaryadjustments.

9.Bringthemotioncontrolleverintotheneutral

position.AdjustRHpumpcontrolrodlength

byrotatingthedoublenutsontherodinthe

appropriatedirectionuntilthewheelsslightly

creepinreverse(Figure16).Movethemotion

controllevertothereversepositionandwhile

applyingslightpressuretothelever,allowthe

reverseindicatorspringtobringtheleversbackto

neutral.Thewheelmuststopturningorslightly

creepinreverse.

Theleftrodassemblycontrolstheleftwheeland

therightrodassemblycontrolstherightwheel.

5.Unhookseatlatchandtiltseatforward.

6.Loosenlocknutsfromtheballjointsateachend

oftheRHpumpcontrollinkage(Figure16).

Note:Thenutstotherearoftheunitoneach

rodhaveleft-handthreads.

10.AdjustmentfortheRHmotioncontrollever: