Page 1

CD42CD/CD48CD

ForSerialNos.

790,000&Higher

PartNo.4500-370Rev.A

Page 2

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2009—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

Contactusatwww.Exmark.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkCuttingDeck.Thisproducthasbeen

carefullydesignedandmanufacturedtogiveyou

amaximumamountofdependabilityandyearsof

trouble-freeoperation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency,andpromotesafe

operation.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

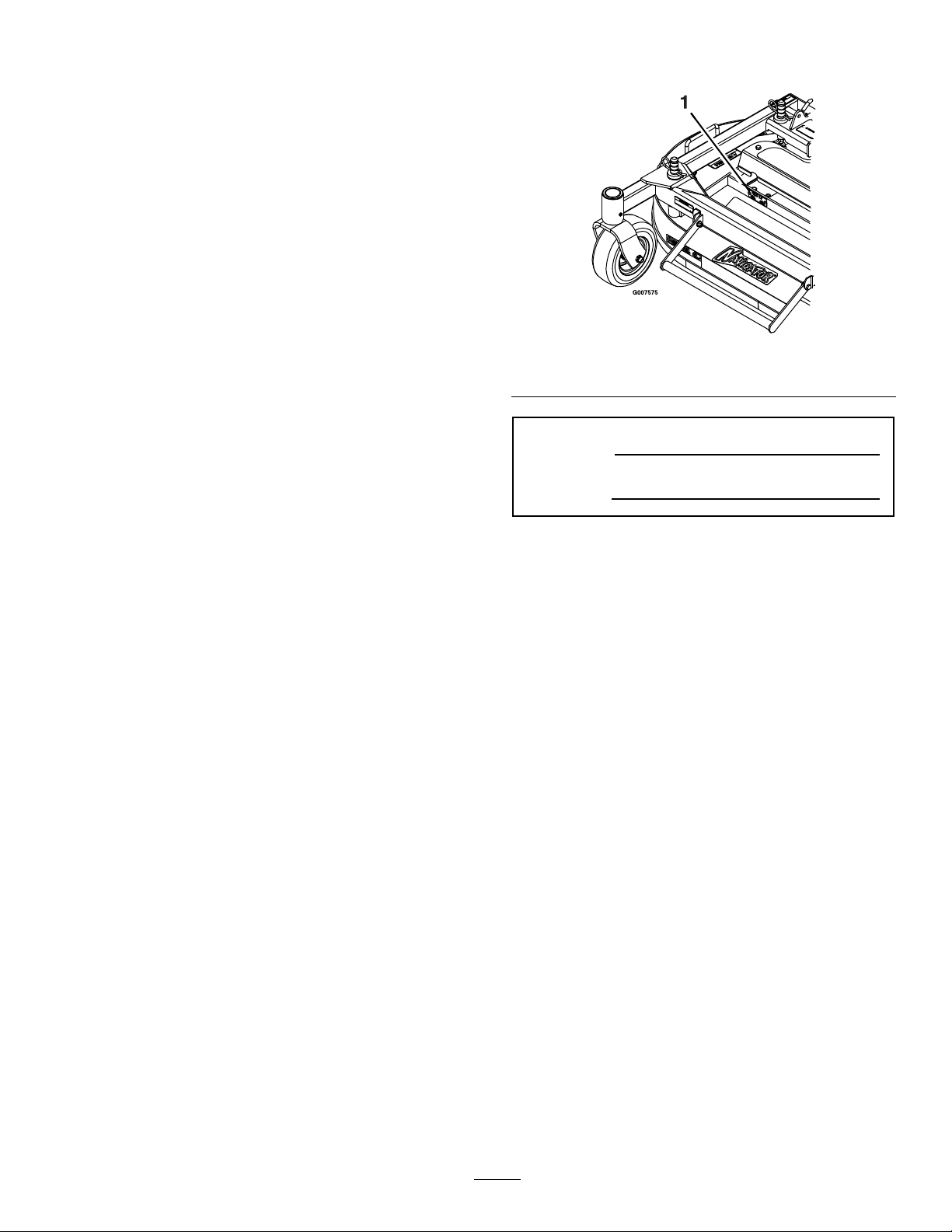

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

3

Page 4

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.......................7

Specications.........................................................8

ModelNumbers..............................................8

Systems...........................................................8

Dimensions.....................................................8

TorqueRequirements......................................8

Setup......................................................................9

AssembleDecktoNavigator...........................9

DeckRemoval...............................................10

ProductOverview................................................11

Operation.............................................................11

AdjustingtheCuttingHeight.........................11

DeckRaisingandLowering...........................11

AdjustingFillReductionSystem(FRS)

Bafes.......................................................12

Maintenance.........................................................14

RecommendedMaintenanceSchedule(s)...........14

PeriodicMaintenance.......................................14

CheckMowerBlades.....................................14

CheckforLooseHardware............................15

CheckTirePressures.....................................15

ChangeGearboxOil......................................15

LubricateGreaseFittings...............................16

LubricateCasterWheelHubs........................16

ThreadLockingAdhesives.............................17

Adjustments.....................................................18

DeckLeveling...............................................18

CasterPivotBearingsPre-load

Adjustment...............................................18

DeckLockingPinStopAdjustment...............18

Cleaning...........................................................19

CleanDebrisFromCuttingDeck...................19

CleanGrassBuild-UpUnderDeck................19

Troubleshooting...................................................20

4

Page 5

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

1.Safetyalertsymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•DoNotmodifytheNavigatorcuttingdeck.

•OnlyuseonmachinesapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadthetractorandcuttingdeckOperator’s

Manualsandothertrainingmaterial.Ifthe

operator(s)ormechanic(s)cannotreadEnglish

itistheowner’sresponsibilitytoexplainthis

materialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

Operation

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Neverraisedeckwithbladesrunning.

•Stopengine,waitforallmovingpartstostop,

removekeyandengageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

5

Page 6

Safety

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

MaintenanceandStorage

•DisengagePTO ,setparkingbrake,stopengine

andremovekeyordisconnectsparkplugwire.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Allreplacementpartsmustbethesameas

orequivalenttothepartssuppliedasoriginal

equipment.

6

Page 7

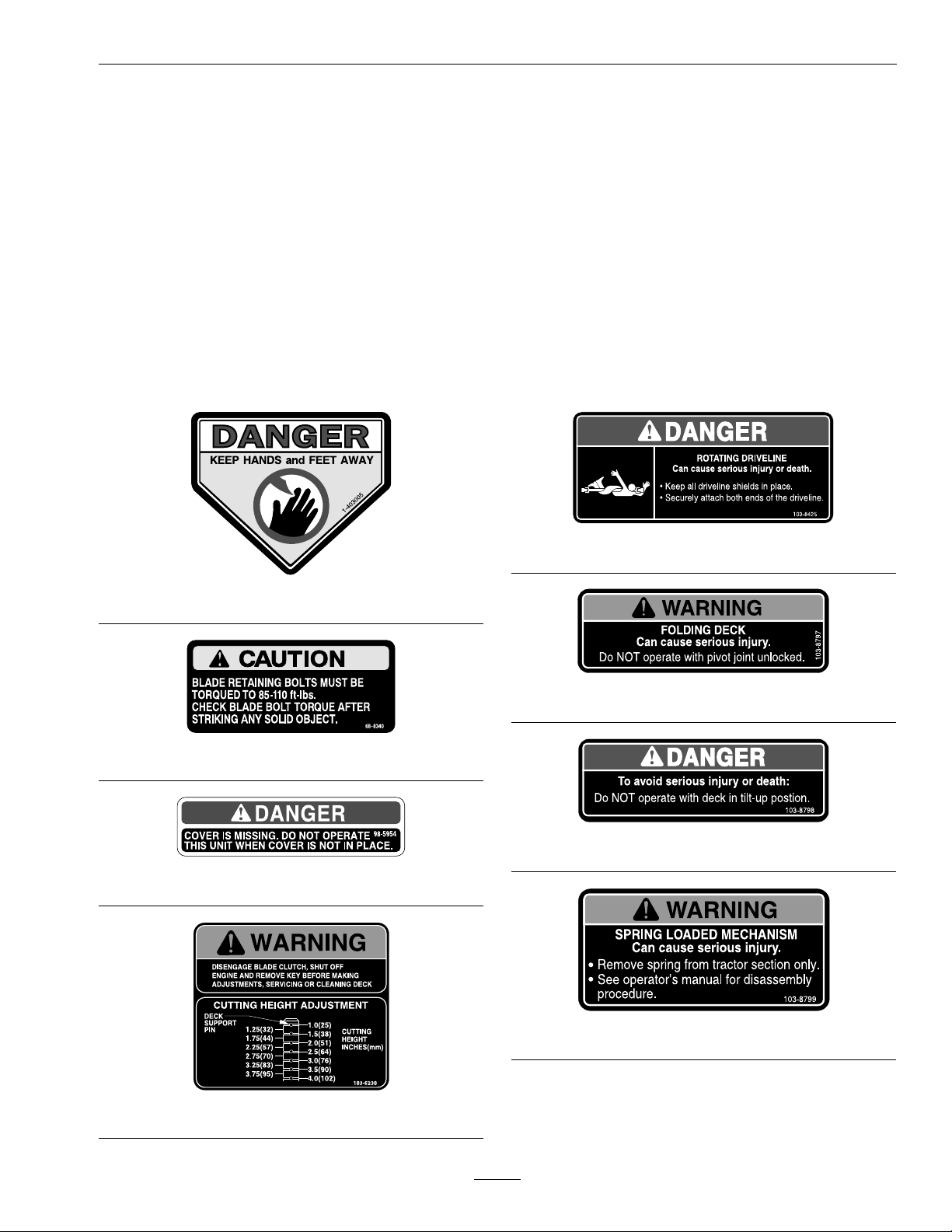

SafetyandInstructionalDecals

Safety

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

1-403005

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

103-8425

103-8797

68-8340

103-8798

98–5954

103-8799

103-6230

7

Page 8

Specications

Specications

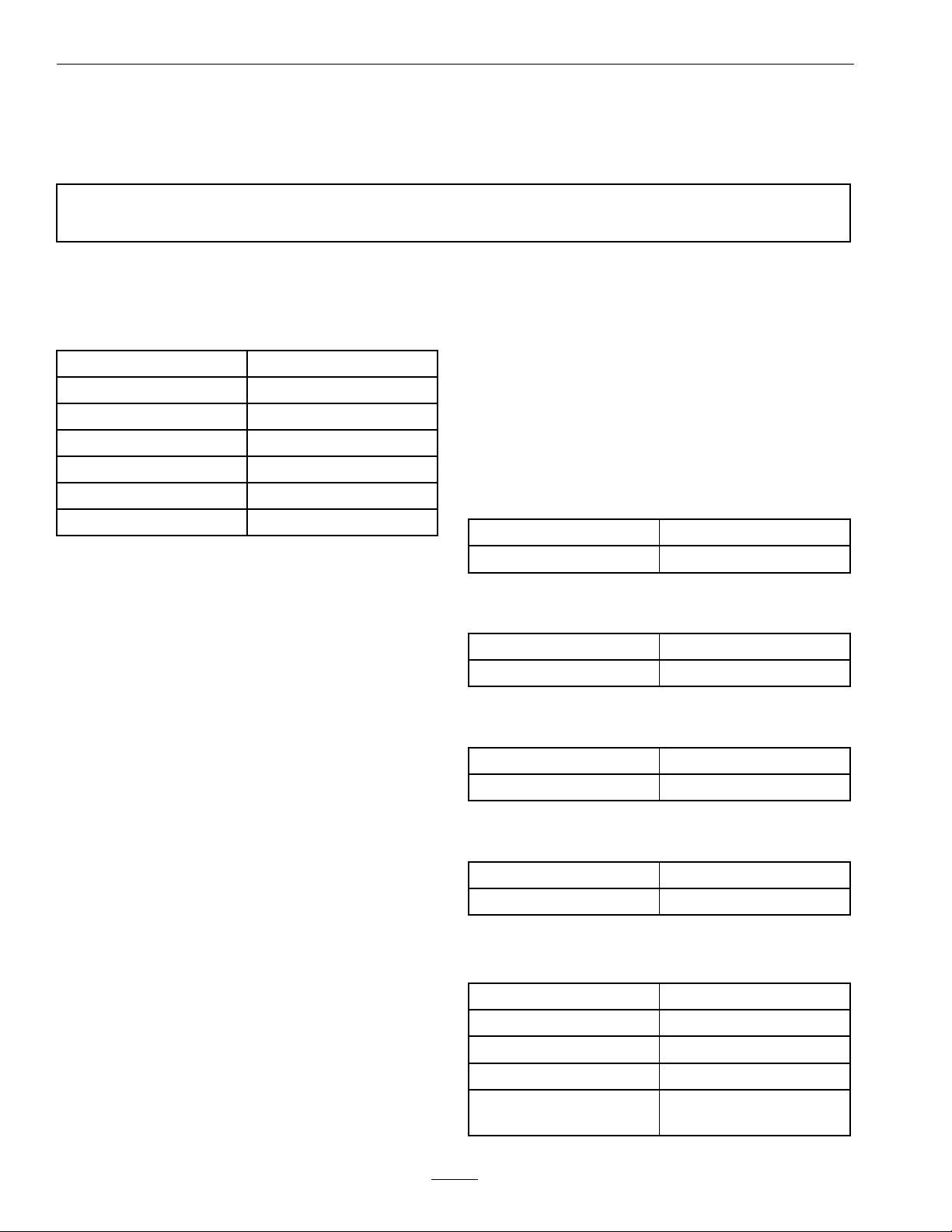

ModelNumbers

SerialNos:790,000andHigher

CD42CD;CD48CD

Systems

Tires&Wheels

Quantity

Tread

Size8x3.00–4

PlyRating

Pressure

CuttingDeck

•ModelNumbers:

–CD42CD

–CD48CD

•CuttingWidth:

–42inchDeck:42inch(106.7cm)

–48inchDeck:48inch(121.9cm)

–48inchDeck:45/8inches(11.7cm)

•CuttingHeightAdjustment:

Adjustsfrom1inch(2.5cm)to4inches(10.2cm)

FrontCaster

Semi-Pneumatic

2

Smooth

in1/4inch(.64cm)increments.

•MulchingKit:Optional

Dimensions

OverallWidth:

42inchDeck48inchDeck

43.2inches(109.7cm)49.2inches(125.0cm)

OverallLength:

42inchDeck48inchDeck

37.2inches(94.4cm)39.9inches(101.3cm)

OverallHeight:

•Discharge:Center

•BladeSize:(2ea.)

–42inchDeck:22.00inches(55.9cm)

–48inchDeck:25.00inches(63.5cm)

•DeckDrive:

–Clutchingbeltonhorizontalengineshaft.

Dual“A”sectionhexagonbeltwithspring

tensionedidlertojackshaftandblower.

–Heavy-dutycastiron,spiralbevelgearboxis

naldrivetoblades.

•Deck:

Fulloatingdeckisattachedtoout-frontsupport

frame.Deckdesignallowsforbaggingor

mulching.

•DeckDepth:

–42inchDeck:45/8inches(11.7cm)

42inchDeck48inchDeck

13.1inches(33.3cm)13.1inches(33.3cm)

CurbWeight:

42inchDeck48inchDeck

295lb(134kg)325lb(147kg)

TorqueRequirements

BoltLocation

BladeMountingBolt85-110ft-lb(115-149N-m)

GearboxMountingBolts30-35ft-lb(41-47N-m)

GearboxAssemblyBolts50-55ft-lb(68-75N-m)

BladeShearBolts80-100in-lb

8

Torque

(922-1130N-cm)

Page 9

Setup

WARNING

OperatingaNavigatortractorwithoutan

approvedExmarkfrontmountattachment

increasesthepossibilityofoperator

entanglementindrivewheelsorforwardtip

over.Entanglementortip-overcouldcause

seriousinjuryordeath.

WhenoperatingaNavigatortractor

withoutanapprovedExmarkfrontmount

attachment,observethefollowing:

•Keepfeetandclothingawayfromtires.

•Limitoperationtominimumrequiredto

installadifferentfrontmountattachment.

•Minimizespeedanduseextremecaution.

•Onlyoperateonaatlevelsurface.

•DoNotoperateupordownatrailerramp.

Setup

Figure3

1.Jackshaft2.Driveshaft

4.Aligndeckpusharmtubestotractorpusharms

andpushdeckrearward.Securepusharmswith

lynchpinsonleftandrightsidesoftheunit(see

Figure4).

•Avoidsuddenaccelerationordeceleration.

AssembleDecktoNavigator

Important:DoNottransportNavigatortractor

withoutandapprovedExmarkfrontmount

attachment.

1.Stopengine,waitforallmovingpartstostopand

removekey.Engageparkingbrake.

2.RollthemowerdeckuptotheNavigatortractor

withthedischargetubedown,makingsurethe

deckspringsarelocatedabovethedrivewheel

andbelowtheconsoleoneachside.

3.Raiseseatandinstalldriveshaftontojackshaft

(seeFigure3)

Figure4

1.Slidethepusharmintothedeckpusharmtube

2.Securethepushpinarmwithlynchpin

5.AlignupperportionofthePTOrubberguardto

thetabsonthefrontoftheconsoleandsecure

withaclevispinandhairpinoneachside(see

Figure5).

9

Page 10

Setup

DeckRemoval

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Raisemowerdeckupandlatchwithdecklocking

pinsperRaisingtheMowerDecktothe

ServicePositionsectioninOperation.

3.Removehairpinsandwashersatthetopofthe

deckliftassistspringoneachsideoftheunit(see

Figure6).

Figure5

1.SecurePTOguardwithclevispinandhairpin

6.Releasethedecklockingpinsoneachside,raise

mowerdecktotheservicepositionandsecure

decklatchontohook.SeeRaisingtheDeckto

theServicePositionsectioninOperation.

7.Installspringsontothespringanchorpinsunder

theleftandrightconsolesandsecurewitha

washerandhairpin(seeFigure6).

4.Removethespringfromthespringanchor.

Repeatforothersideofunit.

5.Un-latchdeckfromraisedpositionandslowly

lowerdecktogroundperLoweringtheMower

DecktotheOperationPositionsectionin

Operation.

Note:Deckwillbecomeheavieroncespringsare

removedfromtheanchors.Lowerdeckcarefully.

6.Removelynchpinsatfrontofpusharmsonboth

sidesoftheunit(seeFigure4).

7.Removehairpinandclevisfrombothsidesofthe

PTOguard(seeFigure5).

8.Raiseseatanddisconnectdriveshaftusingquick

coupleratjackshaft(seeFigure3).

9.Pullmowerdeckforwardtoremovefromunit.

Important:DoNottransportNavigator

tractorwithoutanapprovedExmarkfront

mountattachment.

Figure6

1.Springanchorpinunderconsole

2.Securespringswithawasherandhairpin

3.Slidespringontospringanchorpin

8.Un-latchdeckfromraisedposition,slowlylower

decktogroundandlockdecklockingpinson

eachsideLoweringtheDecktotheOperation

PositionsectioninOperation.

10

Page 11

Operation

ProductOverview

Figure7

1.Cutheightadjustment3.Decklifthandle

2.Casterwheel

Operation

AdjustingtheCuttingHeight

Thecuttingheightofthemowerdeckisadjusted

from1to4inches(2.5cmto10.2cm)in1/4inch

(.63cm)increments.

1.Stopthemachineandmovethespeedcontrol

leverstotheneutralposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Movecotterpinsonfourdecksupportpinsto

properholeforheightofcutdesired.

DeckRaisingandLowering

RaisingtheMowerDeckintoService

Position

1.Stopengine,waitforallmovingpartstostopand

removekey.Engageparkingbrake.

WARNING

Incorrectlyraisingorloweringamowerdeck

canbedangerous.Adroppedmowerdeck

canresultinaseriousinjuryorproperty

damage.

•Alwaysraiseandlowerdeckonat,dry

ground,freeofanyobstructions.

•Firmlygraspthedecklifthandleand

lowerinaslowcontrolledmanner.

•Alwaysmakesurethedeckissecurely

latchedinthe“up”or“down”position.

2.Releasethedecklockingpinsoneachside

(Figure8).

11

Page 12

Operation

Figure8

1.Decklifthandle

2.Rotatethedecklockingpintowardtherearandpull

outwardtounlock.

3.Pushthedecklockingpininandrotatetowardthefront

tolock.

WARNING

Operatingthemowerdeckintheraised

servicepositioncanbedangerous.Engaging

thePTOwithadeckintheraisedposition

canresultinaseriousinjuryorproperty

damage.

Alwayslowerandlockmowerdeckinthe

operationpositionbeforeengagingthePTO.

LoweringtheMowerDecktothe

OperatingPosition

1.Whilermlyholdingontodecklifthandle,

unhookdecklatchfromtractorsectionandslowly

lowerdecktoground(seeFigure9).

2.Pushdecklockingpinsinwardandrotateforward

tosecurelylockdeckinloweredposition(see

Figure8).

3.Usingdecklifthandle,liftdeckupandlatchin

“up”position(latchislocatedatfrontcenterof

seat)(seeFigure9).

Figure9

1.Securethedeckin

theraisedpositionby

securingthedecklatch

ontothehook.

2.Hook

WARNING

Operatingmowerwithoutlockingpins

securelylatchedcanresultinthemowerdeck

foldingupunexpectedly.Themowerdeck

foldingupunexpectedlycancauseserious

injury.

Alwaysoperatemowerwithlockingpins

securelylatched.

AdjustingFillReduction

System(FRS)Bafes

TheNavigator’sexclusiveFillReductionSystemhas

beendesignedtoallowyoutoreducetheamountof

clippingscollectedbyvaryingdegrees.

Advantagesincludelessfrequentemptyingofthe

hopperandreturnofnutrientstothesoil.

PossibleCongurations:

1.Bafesopen,standardblades–Maximum

collection

2.Bafesclosed,standardblades–Partialmulching

3.Bafesclosed,mulchblades–Intermediate

mulching

4.Mulchpluginstalled,mulchblades–Complete

mulching(requiresmulchkit)

12

Page 13

ToadjusttheFRSbafes:

1.Stopengine,waitforallmovingpartstostopand

removekey.Engageparkingbrake.

2.Removehairpinsandclevispinsfrombothsides

ofthePTOguard(seeFigure5).Foldguard

forward.

3.LoosennylocnutsontherearstudsoftheFRS

bafes.

Operation

Figure10

1.PTOguardremovedfor

clarity

2.Loosennylocnuts

4.RaisedeckasstatedinRaisingtheMowerDeck

totheServicePositionsection.

5.Removeboltandwasheratthefrontofeach

oftheFRSbafes.Rotatebafesintodesired

positionandreinstallboltandwasher.

Figure11

1.Bafesshowninclosedposition

2.Bafesshowninopenposition

3.Bolt

4.Washer

5.Bafes

6.LowerdeckperLoweringtheMowerDeckto

theOperatingPositionsection.

7.SnugnylocnutsontherearstudsoftheFRS

bafes.Thesenutsmaybeleftslightlylooseif

frequentbafeadjustmentisanticipated.

8.ReinstallPTOguardusingclevispinsandhair

pinsremovedinstep2.

13

Page 14

Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)aside

soitdoesnotaccidentallycontactthespark

plug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Every40hours

Every100hours

Yearly

MaintenanceProcedure

•Changeoilinallthreegearboxhousings.Addoilasneededuntillevelwithoildrainplug.

•Checkthemowerblades.

•Checkforloosehardware.

•Greasethefrontcasterwheelhub.

•Cleanthegrassanddebrisbuild-upfromthecuttingdeck.

•Cleanthegrassbuild-upfromunderthedeck.

•Checktheconditionofthebelts.

•Greasethedriveshaft.

•Changeoilinallthreegearboxhousings.Addoilasneededuntillevelwithoildrainplug.

thereafter

•Greasethedeckip-up.

•Greasethepivotarmtubes.

•Greasethefrontcasterpivots.

•Lubricatethecasterwheelhubs.

PeriodicMaintenance

CheckMowerBlades

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Liftdeckandsecureinraisedpositionasstated

insectionRaisingtheMowerDecktothe

ServicePosition.

3.Inspectbladesandsharpenorreplaceasrequired.

4.Toremoveblade,useablockofwoodorlocking

plierstoholdbladeinplaceandremovethe

1/2-20x21/4inchbladeboltthatsecuresthe

bladeandbladedriver.

5.Re-installthebladedriver(withnewblades)by

usingablockofwoodorlockingplierstohold

thebladeinplaceandtorquethebladeboltsto

85-110ft-lb(115-149N-m).

14

Page 15

Maintenance

Note:Bladedriveratsmustbealignedwiththe

atsontheshaftwheninstallingbladeonthe

mowerdeck.

6.Lowerthemowerdecktotheoperationposition

(seesectionLoweringtheMowerDecktothe

OperationPosition).

WARNING

Operatingamowerdeckwithlooseor

weakenedbladeboltscanbedangerous.A

looseorweakenedbladeboltcouldallowa

bladerotatingatahighspeedtocomeout

fromunderthedeck,causingseriousinjury

orpropertydamage.

•Replacethebladeboltafterstrikinga

foreignobject.

•UseonlygenuineExmarkreplacement

parts.

•DoNotlubricatethethreadsofthebolt

orspindlebeforeassembly.

•Torquethebladeboltto85-110ft-lb

(115-149N-m).

•Torquetheshearboltsto80-100in-lb

(922-1130N-cm).

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.Tightenhardware

orcorrecttheproblembeforeoperating.

CheckTirePressures

ServiceInterval:Every40hours

Thefrontcastertiresaresemi-pneumaticandDo

Notneedtobeinated.

Note:DoNotaddanytypeoftirelinerorfoam

llmaterialtothetires.Excessiveloadscreatedby

foamlledtiresmaycausefailurestothehydrodrive

system,frame,andothercomponents.Foamlling

tireswillvoidthewarranty.

ChangeGearboxOil

ServiceInterval:Aftertherst50hours

Every100hoursthereafter

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

Figure12

1.1/2-20x21/4bladebolt—torqueto85-110ft-lb

(115-149N-m).

2.Washer

3.Shearbolts—torqueto80–100in-lb(922-1130N-cm)

4.Bladedriver

5.1/4-20nylocnuts

2.Placeunitonalevelsurface.

3.Removethegearboxanddriveshaftassembly

fromthemowerdeck.Retainhardwareforre-use.

4.Removethelargeoildrainplugonthefrontof

eachofthethreegearboxsectionsanddrainoil

(Figure13).

Figure13

1.Smallmagneticplugs

(frontandback)

2.Largeoildrain/llplug

3.Smallmagneticplug

(frontonly)

15

Page 16

Maintenance

5.Removesmallmagneticplugsandwipeawayany

materialaccumulatedontheplugs.

6.ApplyaTeonpipesealanttoallsmallmagnetic

plugsandre-installintothegearbox.

7.Re-installthegearboxanddriveshaftassembly

tothemowerdeck.

8.FillgearboxwithMobilSHC(synthetic)75W -90

gearlubeoiluntillevelwithoildrain/llplug.

Eachofthegearboxsectionsmustbelled

separately.

Note:Mowerdeckshouldremainleveltothe

groundwhenllinggearboxwithoil.DoNotll

gearboxwithdeckraisedintheserviceposition.

9.ApplyaTeonpipesealanttothe3largeoilplugs

andre-installintothegearbox.

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.LubricatettingswithNGLIgrade#2

multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.Drive

Shaft

2.Front

Caster

WheelHub

3.Deck

Flip-Up

4.Push

ArmTubes

5.Front

Caster

Pivots

Initial

Pumps

1

128Hours

1

12

*0

Numberof

Places

340Hours

4100Hours

2

Service

Interval

100Hours

*Yearly

3.Lubricatecasterpivotsonceayear.Removehex

plugandcap.Threadgreasezerkinholeand

pumpwithgreaseuntilitoozesoutaroundtop

bearing.Removegreasezerkandthreadplugback

in.Placecapbackon.

LubricateCasterWheelHubs

ServiceInterval:Yearly

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

Figure14

1.Sealguard2.Spacernutwithwrench

ats

2.Removecasterwheelfromcasterforks.

*Seestep3forspeciallubricationinstructionson

thefrontcasterpivotsandtheLubricateCaster

WheelHubssectionforspeciallubrication

instructionsonthefrontcasterswheelhubs.

3.Removesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethatthread

lockingadhesivehasbeenappliedtolockthe

16

Page 17

Maintenance

spacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)from

thewheelassembly.

5.Pryoutseals,andinspectbearingsforwearor

damageandreplaceifnecessary.

6.PackthebearingswithaNGLIgrade#1

multi-purposegrease.

7.Insertonebearing,onenewsealintothewheel.

Note:Seals(ExmarkPN103-0063)mustbe

replaced.

8.Iftheaxleassemblyhashadbothspacernuts

removed(orbrokenloose),applyathreadlocking

adhesivetoonespacernutandthreadontothe

axlewiththewrenchatsfacingoutward.Do

Notthreadspacernutallofthewayontotheend

oftheaxle.Leaveapproximately1/8inch(3mm)

fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

Casterwheelspacernuts.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

NGLIgrade#1multi-purposegrease.

11.Insertthesecondbearingandnewsealintothe

wheel.

12.Applyathreadlockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrenchats

facingoutward.

13.Torquethenutto75-80in-lb(8-9N-m),loosen,

thenre-torqueto20-25in-lb(2-3N-m).Make

sureaxledoesnotextendbeyondeithernut.

14.Reinstallthesealguardsoverthewheelhuband

insertwheelintocasterfork.Reinstallcasterbolt

andtightennutfully.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjusttorqueon

spacernutuntilthereisaslightamountofdrag.

Reapplythreadlockingadhesive.

17

Page 18

Maintenance

Adjustments

Note:DisengagePTO,shutoffengine,waitfor

allmovingpartstostop,engageparkingbrake,and

removekeybeforeservicing,cleaning,ormakingany

adjustmentstotheunit.

DeckLeveling

1.Positionmoweronaatsurface.

2.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

3.Inatedrivetiresto15psi(103kPa).

4.Verifyallhairpinsareinthe3inchdeckheight

holeswiththespacersunderthehairpins

(Figure15).

Figure16

1.Springdiscwashers

DeckLockingPinStop

Adjustment

Figure15

RightHandSideShown

1.Hairpin3.Decksupportpin

2.Spacer

5.Shorten/lengtheneachdecksupportpintoobtain

bladetipheightof3inchesatthefrontofthe

deckand31/4inchesattherearofthedeck.

1.Slidedecklockingpinsinonbothsidesandrotate

tolockthedeckinthe“operation”position.

2.Loosenthejamnutandturnthestopscrew

clockwiseuntilthelockingpinsistightandcannot

berotatedbyhand(Figure17).

Figure17

1.Rotatestopscrewclockwiseuntillockingpinistight,

thenbackoff1/2turn.

2.Loosenjamnut

CasterPivotBearings

Pre-loadAdjustment

Removedustcapfromcasterandtightennylocnut

untilwashersareat.Backthenylocoff1/4ofa

turntoproperlysetthepre-loadonthebearings.

Note:Ifdisassembled,makesurethespringwashers

arereinstalledasshowninFigure16.

3.Loosenthestopscrewcounterclockwise1/2

turnandtightenthejamnut

4.Testthelockingpintomakesureitslidesfreely .

Readjustifnecessary.

18

Page 19

Cleaning

CleanDebrisFromCutting

Deck

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Cleanoffanyoil,debris,orgrassbuild-uponthe

cuttingdeck,especiallyunderdeckbeltshields.

CleanGrassBuild-UpUnder

Deck

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

Maintenance

2.Raisemowerdeckandsecureinlatchedposition

(seeRaisingtheMowerDecktotheService

PositionsectioninOperation).

3.Cleanoutanygrassbuild-upfromundersideof

deckandindischargechute.

4.Lowerdecktocuttingpositionandlockdeck

lockingpins(seeLoweringtheMowerDeckto

theOperationPositionsectioninOperation.

19

Page 20

Troubleshooting

Troubleshooting

Important:Itisessentialthatalloperatorsafetymechanismsbeconnectedandinproperoperating

conditionpriortomoweruse.

Whenaproblemoccurs,donotoverlookthesimplecauses.Forexample:startingproblemscouldbecaused

byanemptyfueltank.

Thefollowingtablelistssomeofthecommoncausesoftrouble.DoNotattempttoserviceorreplacemajor

itemsoranyitemsthatcallforspecialtimingofadjustmentsprocedures(suchasvalves,governor,etc.).Have

thisworkdonebyyourEngineServiceDealer.

Note:WhendisconnectingelectricalconnectorsDoNotpullonthewirestoseparatetheconnectors.

ProblemPossibleCauseCorrectiveAction

Unevencuttingheight.

Abnormalvibration.

BladesDoNotrotate.

1.Blade(s)notsharp.1.Sharpentheblade(s).

2.Cuttingblade(s)is/arebent.

3.Mowerdeckisnotlevel.3.Levelmowerdeckfromside-to-sideand

4.Undersideofmowerisdirty.4.Cleantheundersideofthemower.

5.Tirepressureindrivetiresnotcorrect.5.Adjusttirepressureinthedrivetires.

6.Spacersareinwronglocation.

7.Tipsofadjacentbladesareatanuneven

cuttingheight.Bladestipsshouldbeeven

within3/16inchwhichisapproximately

onebladethickness.

1.Cuttingblade(s)is/arebentorunbalanced.

2.Blademountingboltisloose.2.Tightentheblademountingbolt.

3.Enginemountingboltsareloose.3.Tightentheenginemountingbolts.

4.Enginepulleyisdamaged.4.ContactanAuthorizedServiceDealer.

5.Bladespindleisbent.5.ContactanAuthorizedServiceDealer.

1.PTObeltisworn,loose,orbroken.1.Checkbelttensionorreplacebelt

2.PTOshaftisnotconnected.

3.PTObeltisoffpulley .3.Checkbeltfordamage.Installbeltand

2.Installnewcuttingblade(s).

front-to-rear.

6.Positionspacersunderhairpins.

7.Replaceblades,spindlesand(or)check

fordamagetomowerdeck.

1.Installnewcuttingblade(s).

2.ConnectPTOshaft.

checkadjustingshaftsandbeltguidesfor

correctposition.

20

Page 21

Conditions and Products Covered

Exmark Mfg. Co. Inc. and its affiliate, Exmark Warranty

Company, pursuant to an agreement between them, jointly

warrant on the terms and conditions herein, that we will repair,

replace or adjust any part on these products and found by us

(in the exercise of our reasonable discretion) to be defective in

factory materials or workmanship for a period of two years.

This warranty applies to Exmark commercial turf equipment

sold in the U.S. or Canada. This warranty may only be

assigned or transferred to a second (or third) owner by an

authorized Exmark dealer. The warranty period commences

upon the date of the original retail purchase.

Warranty Exceptions Warranty Period

• Bags, Belts and Tires 90 days

• Battery 1 Year Prorated

• Engine 2 years*

* The Engine warranty is covered by the engine manufacturer.

Please refer to the engine manufacturer’s warranty statement

that is included in the literature packet.

This warranty only includes the cost of parts and labor.

Items and Conditions Not Covered

This warranty does not cover the following:

• Pickup and delivery charges to and from any authorized

Exmark Service Dealer.

• Any damage or deterioration due to normal use, wear and

tear, or exposure.

• Cost of regular maintenance service or parts, such as filters,

fuel, lubricants, tune-up parts, and adjustments.

• Any product or part which has been altered or misused or

required replacement or repair due to normal wear,

accidents, or lack of proper maintenance.

• Any repairs necessary due to use of parts, accessories or

supplies, including gasoline, oil or lubricants, incompatible

with the turf equipment or other than as recommended in

the operator's manual or other operational instructions

provided by Exmark.

There are no other express warranties except for engine and

special emission system coverage.

All warranty work must be performed by an authorized

Exmark Service Dealer using Exmark approved replacement

parts.

Instructions for Obtaining Warranty Service

The product must be registered with original proof of purchase

by an Exmark Service Dealer before obtaining any warranty

service.

Contact any Exmark Service Dealer to arrange service at their

dealership. To locate a dealer convenient to you, access our

website at www.exmark.com. U.S. or Canada customers may

also call 402-223-6375.

If for any reason you are dissatisfied with the Service Dealer’s

analysis or with the assistance provided, contact us at:

Exmark Customer Service Department

The Exmark Warranty Company

2101 Ashland Avenue

Beatrice, NE 68310

402-223-6375 or

service@exmark.com

Owner’s Responsibilities

The Exmark turf equipment, including any defective part,

must be returned to an authorized Exmark service dealer

within the warranty period. This warranty extends only to turf

equipment operated under normal conditions. You must read

the operator’s manual. You must also properly service and

maintain your Exmark product as described in the operator’s

manual. Such routine maintenance, whether performed by a

dealer or by you, is at your expense.

General Conditions

The sole liability of Exmark and Exmark Warranty Company

with respect to this warranty shall be repair or replacement of

defective components as set forth herein. Neither Exmark

nor Exmark Warranty Company shall be liable for any

incidental or consequential loss or damage.

Such damages include but are not limited to:

• Expenses related to gasoline, oil or lubricants.

• Travel time, overtime, after hours time or other

extraordinary repair charges or charges relating to repairs or

replacements outside of normal business hours at the place

of business of the authorized Exmark Service Dealer.

• Rental of like or similar replacement equipment during the

period of any warranty, repair or replacement work.

• Any telephone or telegram charges or travel charges.

• Loss or damage to person or property other than that

covered by the terms of this warranty.

• Any claims for lost revenue, lost profit or additional cost as

a result of a claim of breach of warranty.

• Attorney's fees.

No Claim of breach of warranty shall be cause for cancellation

or rescission of the contract of sale of any Exmark mower.

All implied warranties of merchantability (that the

product is fit for ordinary use) and fitness for use (that the

product is fit for a particular purpose) are limited to the

duration of the express warranty.

Some states do not allow exclusions of incidental or

consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions and

limitations may not apply to you.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Exmark Commercial Turf Equipment

2 Year Limited Warranty

G4500-425

21

Page 22

ServiceRecord

Date:

DescriptionofWorkDone:ServiceDoneBy:

22

Page 23

23

Page 24

MI D-MOUNT RIDING ACCE SSORIES AND OPTIONS

SEE EXMARK’S COMPLETE LINE OF ACCESSORIES AND OPTIONS

WALK-BEHIND ACCESSORIES AND OPTIONS

GRASS CATCHER

MICRO-MULCH SYSTEM

TURF STRIPER

STANDON

CUSTOM RIDE SEAT SUSPENSION SYSTEM

FULL SUSPENSION SEAT

DECK LIFT ASSIST KIT

HITCH KIT

LIGHT KIT

12

V POWER PORT

MICRO-MULCH SYSTEM

OPERATOR CONTROLLED DISCHARGE

ROLL OVER PROTECTION SYSTEM (ROPS)

SUN SHADE

TRASH CONTAINER

TURF STRIPER

ULTRA VAC COLLECTION SYSTEM

ULTRA VAC QUICK DISPOSAL SYSTEM

OU T-FRO NT RIDING ACCESSORI ES AND OPTI ONS

CUSTOM RIDE SEAT SUSPENSION SYSTEM

DUAL-TAIL WHEEL

FLOOR PAN EXTENDER

HITCH KIT

LIGHT KIT

MICRO-MULCH SYSTEM

ROLL OVER PROTECTION SYSTEM (ROPS)

SNOW BLADE

SNOWBLOWER

SUN SHADE

TRASH CONTAINER

ULTRA VAC COLLECTION SYSTEM

ULTRA VAC QUICK DISPOSAL SYSTEM

WEATHER CAB

PlaceModelNo.andSerialNo.

LabelHere(IncludedintheLiterature

Pack)orFillinBelow

ModelNo.

SerialNo.

©2009ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

AllRightsReserved

DatePurchased

PartNo.4500-370Rev.A

(402)223-6300

Fax(402)223-5489

PrintedintheUSA

www.exmark.com

Loading...

Loading...