Page 1

EXMARK V-TWIN AIR COOLED

ENGINE SERVICE MANUAL

P/N 127-9041 (708cc)

Page 2

About this Manual

This service manual was written expressly for

Exmark service technicians. Exmark Mfg. Co. Inc.

has made every effort to make the information in

this manual complete and correct. Basic shop safety

knowledge and mechanical/electrical skills are

assumed. The Table of Contents lists the systems

and the related topics covered in this manual. An

electronic version of this service manual is available

on the Exmark Dealer Extranet. We are hopeful that

you will find this manual a valuable addition to your

service shop. If you have any questions or

comments regarding this manual, please contact us

at the following address:

Exmark Mfg. Co. Inc.

2101 Ashland Ave.

Beatrice, NE 68357

Customer Service All Call: 402-223-6375

e-mail - service@exmark.com

NOTES:

Page 3

Maintenance

Chapter 1 – General Service Information

1

Chapter 2 - Specifications

2

Chapter 3 - Engine Service and Maintenance

3

Chapter 4 – Engine Disassembly and Service

4

Chapter 5 - Electrical

5

– General Service Information

Safety

Safety Precautions

Service Rules

Engine Model / Serial Number Location

Torque Values

Engine Specifications

General Torque Specifications

Safety

Safety Information

Chapter 1

This symbol means WARNING or PERSONAL SAFETY INSTRUCTION – read the instruction because it has to do with

your safety. Failure to comply with the instruction may result in personal injury or even death.

This manual is intended as a service and repair manual only. The safety instructions provided herein are for

troubleshooting, service, and repair of the Toro engine. The Toro operator’s manual contains safety information and

operating tips for safe operating practices.

Avoid Unexpected Engine Start - Turn off engine and disconnect the spark plug before servicing engine.

Avoid Lacerations and Amputations - Stay clear of all moving parts while the engine is running.

Avoid Burns - Do not touch the engine, muffler, or other components which may increase in temperature during

operation, while the unit is running or shortly after it has been running.

Avoid Fires and Explosions - Avoid spilling fuel and never smoke while working with any type of fuel or lubricant. Wipe

up any spilled fuel or oil immediately. Never remove the fuel cap or add fuel when the engine is running. Always use

approved, labeled containers for storing or transporting fuel and lubricants.

Avoid Asphyxiation - Never operate an engine in a confined area without proper ventilation.

Avoid Injury From Batteries - Battery acid is poisonous and can cause burns. Avoid contact with skin, eyes, and

clothing. Battery gases can explode. Keep cigarettes, sparks, and flames away from the battery.

Avoid Injury Due To Inferior Parts - Use only original equipment parts to ensure that important safety criteria are met.

Avoid Injury To Bystanders - Always clear the area of bystanders before starting or testing power equipment.

Avoid Injury Due To Projectiles - Always clear the area of sticks, rocks, or any other debris that could be picked up and

thrown by the power equipment.

Avoid Modifications - Never alter or modify any part unless it is a factory approved procedure.

Page 4

Maintenance

WARNING

Explosive Fuel can cause

fires and severe burns.

Do not fill fuel tank while

engine is hot or running.

Gasoline is extremely flammable

and its vapors can explode if

ignited. Store gasoline only in

approved containers, in well

ventilated, unoccupied buildings,

away from sparks or flames.

Spilled fuel could ignite if it comes

in contact with hot parts or sparks

from ignition. Never use gasoline

WARNING

Accidental Starts can

cause severe injury or

death.

Disconnect and ground

spark plug lead(s) before

servicing.

Before working on engine or

equipment, disable engine as

follows: 1) Disconnect spark plug

lead(s). 2) Disconnect negative (–)

battery cable from battery.

CAUTION

Damaging Crankshaft

and Flywheel can cause

personal injury.

Using improper procedures can

lead to broken fragments. Broken

fragments could be thrown from

engine. Always observe and use

precautions and procedures when

installing flywheel.

WARNING

Hot Parts can cause

severe burns.

Do not touch engine

while operating or just

after stopping.

Never operate engine with heat

shields or guards removed.

WARNING

Rotating Parts can cause

severe injury.

Stay away while engine

is in operation.

Keep hands, feet, hair, and

clothing away from all moving

parts to prevent injury. Never

operate engine with covers,

shrouds, or guards removed.

WARNING

Carbon Monoxide can

cause severe nausea,

fainting or death.

Avoid inhaling exhaust

fumes.

Engine exhaust gases contain

poisonous carbon monoxide.

Carbon monoxide is odorless,

colorless, and can cause death if

inhaled.

SAFETY PRECAUTIONS

WARNING: A hazard that could result in death, serious injury, or substantial property damage.

CAUTION: A hazard that could result in minor personal injury or property damage.

NOTE: is used to notify people of important installation, operation, or maintenance information.

CAUTION

Electrical Shock can

cause injury.

Do not touch wires while

engine is running.

Page 5

Maintenance

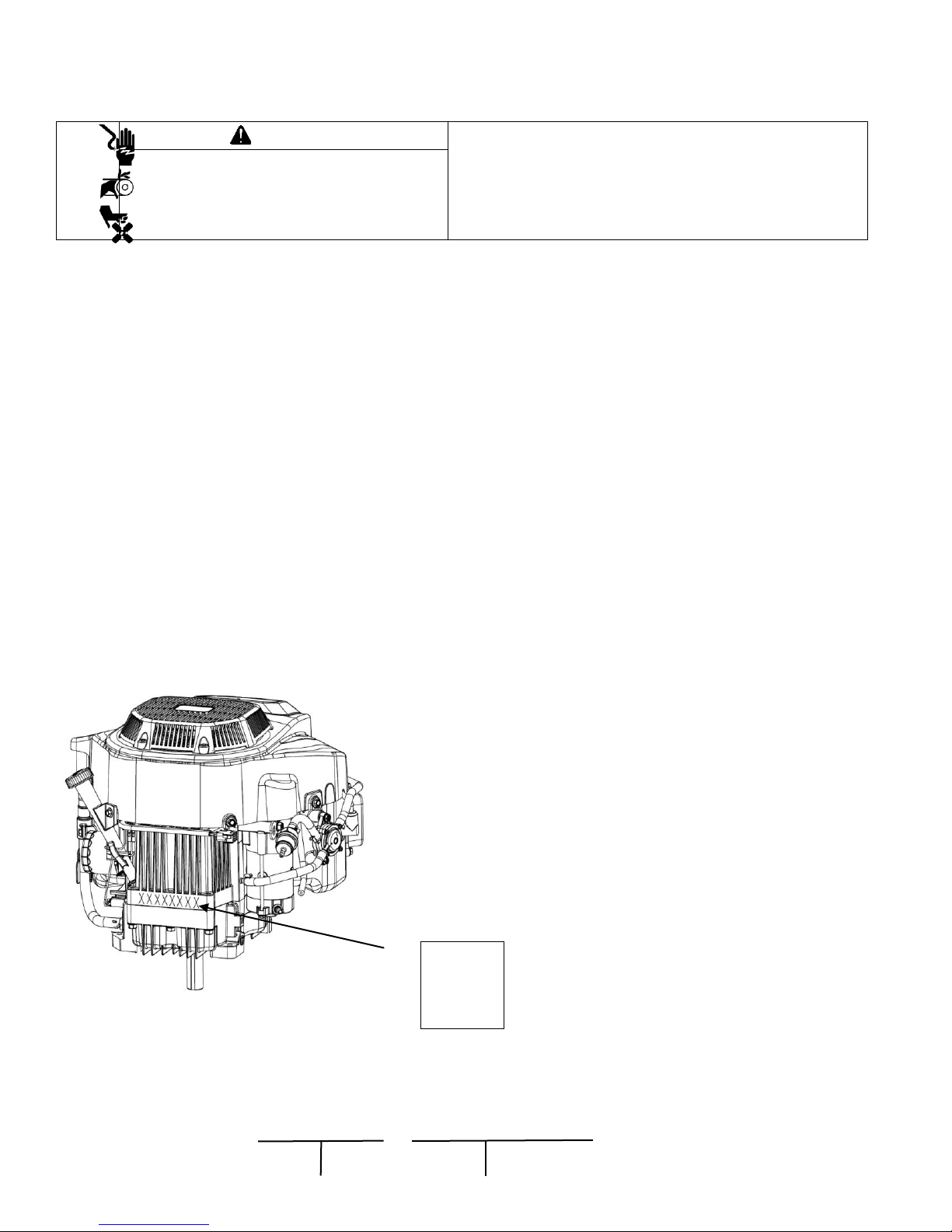

WARNING

Before working on engine or equipment, disable engine as

follows: 1) Disconnect spark plug lead(s). 2) Disconnect

negative (–) battery cable from battery.

Accidental Starts can cause severe injury or

death.

Disconnect and ground spark plug lead(s)

before servicing.

Engine

Model

& Serial

Number

1. Only use genuine Exmark parts and lubrication products.

2. Always install new gaskets, O-rings and seals when assembling engine.

3. Always torque fasteners to specification and in sequence.

4. Always lubricate friction components with clean engine oil or engine assembly lube

when assembling engine.

MAINTENANCE INSTRUCTIONS

Normal maintenance, replacement or repair of emission control devices and systems may be performed by any repair

establishment or individual; however, warranty repairs must be performed by an authorized Exmark dealer.

Service Rules

Engine Model / Serial Number Location

The engine model and serial number are stamped into the block, there will also be a label attached to

a new engine with this information on it as well.

XXX-XXXX XXXXXXXXXXX

Page 6

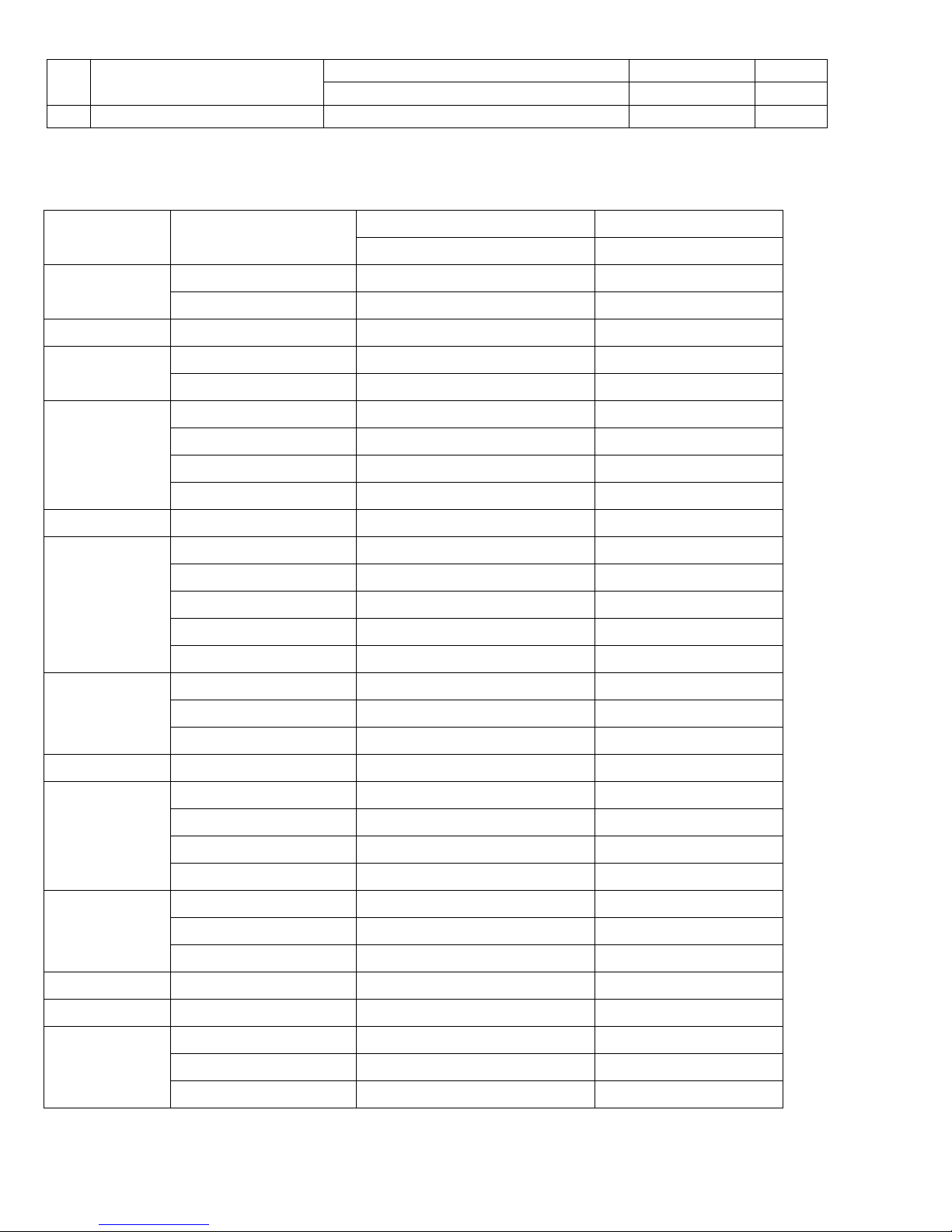

Maintenance

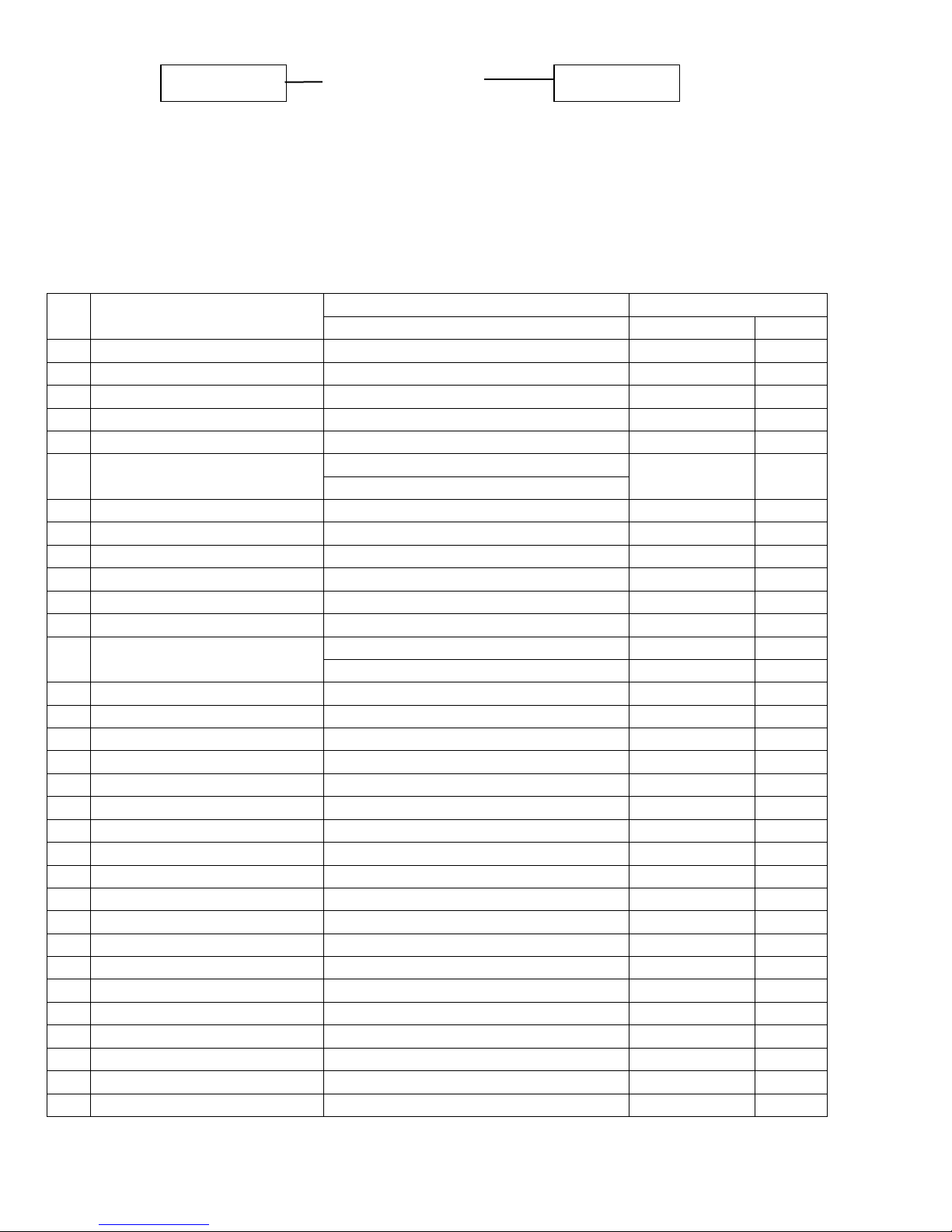

No.

Process Description

Bolt Specification

Torque Range

1

Oil Drain Plug Assy.

Oil Drain Plug

20 Ft. Lbs.

26 N.m

2

Spark Plug

M14×1

21 Ft. Lbs.

28 N.m

3

Connecting Rod Cover

Hex Flange Bolt M6×35

9 Ft. Lbs.

12 N.m

4

Crankcase Cover Bolt

Hex Flange Bolt M8×55

21 Ft. Lbs.

28 N.m

5

Fuel Pump Assy.

Hex Flange Bolt M6×16

5 Ft. Lbs.

7 N.m

6

Breather Valve Assy.

Hex Flange Bolt M6×12

8 Ft. Lbs.

10 N.m

7

Cylinder Head

Hex Flange Bolt M10×1.25×70

38 Ft. Lbs.

52 N.m

Hex Flange Bolt M10×1.25×50

8

Push Rod Location Limit Plate

Valve Adjust Stud

22 Ft. Lbs.

30 N.m

9

Valve Lash Inspection(Q1)

Valve Lock Nut M6

10 Ft. Lbs.

14 N.m

10

Valve Cover

Hex Flange Bolt M6×25

8 Ft. Lbs.

10 N.m

11

Flywheel

Hex Flange Bolt M12×35

62 Ft. lbs.

82 N.m

12

Ignition Coil

Hex Flange Bolt M6×20

8 Ft. Lbs.

10 N.m

13

Electric Starter Motor

Hex Flange Bolt M8×80

20 Ft. Lbs.

26 N.m

14

Inlet Pipe

Hex Flange Bolt M6×35

8 Ft. lbs.

10 N.m

Stud Bolt M6×106

5 Ft. Lbs.

7 N.m

15

Air Box

Nut, Flange M6

6 Ft. Lbs.

8 N.m

16

Cooling Fan

Hex Flange Nut M8×20

15 Ft. Lbs.

22 N.m

17

Cooling Fan Cover

Hex Flange Nut M5×16

3 Ft. lbs.

4 N.m

18

Fan Shroud

Hex Flange Step Bolt 6×21.8-8×10.8

6 Ft. Lbs.

8 N.m

19

Shroud Comp

Hex Flange Step Bolt 6×16.8-8×5.8

8 Ft. Lbs.

10 N.m

20

Starter Shroud

Screw ST4.0×15

10 – 11 In. Lbs.

1 N.m

21

Charging Coil

Screw Inner Six Angle M6×25

8 Ft. Lbs.

10 N.m

22

Engine Shroud

Hex Flange Bolt M6×16

8 Ft. Lbs.

10 N.m

23

Breather Valve Cover

Hex Flange Bolt M6×16

8 Ft. lbs.

10 N.m

24

Ignition Coil

Hex Flange Bolt M6×20

8 Ft. Lbs.

10 N.m

25

Regulator

Hex Flange Bolt M6×16

5 Ft. Lbs.

7 N.m

26

Oil Drain Fitting

/

20 Ft. lbs.

26 N.m

27

Oil Pump Cover

Hex Flange Bolt M6×16

8 Ft. Lbs.

10 N.m

28

Oil Screen Cover

Hex Flange Bolt M6×16

8 Ft. Lbs.

10 N.m

29

Oil Tube Plate

Hex Flange Bolt M6×16

8 Ft. lbs.

10 N.m

30

Governor Throttle

Hex Flange Bolt M6×16

8 Ft. Lbs.

10 N.m

31

Governor Arm

Nut M6

8 Ft. Lbs.

10 N.m

32

Tube Clip

Hex Flange Bolt M6×16

5 Ft. Lbs.

7 N.m

33

Connector, Oil Filter

M20

30 Ft. Lbs.

42 N.m

Engine Model

Serial Number

1.1 Torque values

Note: For unspecified bolts and nuts listed, refer to the table of standard torque values.

Page 7

Maintenance

34

Cylinder Head

Stud Bolt M8×39

11 Ft. Lbs.

14 N.m

Nut M8

13 Ft. Lbs.

17 N.m

35

Oil Filter

/

9 Ft. Lbs.

12 N.m

Part

Item

Standard

Service Limit

P/N 127-9041

P/N 127-9041

Engine

Ile speed

1800 RPM’s

+ or – 100 RPM’s

Operating RPM

3600 RPM’s

+ or – 50 RPM’s

Cylinder head

Warpage

0.0020” (0.05 mm)

Cylinder

Sleeve Taper / Out of Round

3.0315”-3.0319” (77 – 77.01 mm)

3.0354” (77.1 mm)

(Inside Diameter)

Piston

Skirt outside diameter

3.0301-3.0305” (76.965-76.975 mm)

3.0219” (76.755 mm)

Clearance to cylinder

0.00098-0.0017” (0.025-0.045 mm)

0.01000” (.255 mm)

Piston pin bore inside diameter

0.66937- 0.66961” (17.002-17.008 mm)

0.67402” (17.12 mm)

Piston – pin clearance

0..00016-0.00063” (0.004-0.016 mm)

0.0014” (0.029 mm)

Piston pin

Outside diameter

0.6689-0.6692” (16.992-16.998 mm)

0.6654” (16.9 mm)

Piston ring

Ring to Groove (Top and Middle

0.0008-0.0024” (0.02-0.06 mm)

0.0043” (0.11 mm)

End gap (top and middle )

0.0079-0.01578” (0.20-0.40 mm)

0.0177” (0.45 mm)

Width (top)

0.0382-0.0390” (0.97-0.99 mm)

0.0354” (0.9 mm)

Width (second)

0.0460-0.0469” (1.17-1.19 mm)

0.0433” (1.1 mm)

Width (oil ring)

0.0650-0.0728” (1.65-1.85 mm)

0.0630” (1.6 mm)

Connecting rod

Small end inside diameter

0.6695-0.670” (17.006-17.017 mm)

0.6712” (17.05 mm)

Big end inside diameter

1.575-1.576” (40.015-40.025 mm)

1.577” (40.065 mm)

Big end side clearance

0.0010-0.0031” (0.024-0.079 mm)

0.0051” (0.129 mm)

Crankshaft

Connecting Rod Journal Diameter

1.5735-1.5744” (39.966-39.991 mm)

1.555” (39.5 mm)

Valve

Clearance(cold) (intake)

0.004-0.006” (0.10-0.15 mm)

-

Clearance(cold) (exhaust)

0.006-0.008” (0.15-0.20 mm)

-

Stem diameter (intake)

0.258-0.259” (6.565-6.58 mm)

0.256” (6.515 mm)

Stem diameter (exhaust)

0.257-0.258” (6.545-6.56 mm)

0.258” (6.495 mm)

Valve guide

Inside diameter (intake, exhaust)

0.259-0.260” (6.6-6.615 mm)

0.262” (6.665 mm)

Stem to guide clearance (intake)

0.0008-0.0020” (0.02-0.05 mm)

0.006” (0.15 mm)

Stem to guide clearance exhaust)

0.0016-0.0027” (0.04-0.07 mm)

0.007” (0.17 mm)

Valve seat

Seat width

0.0027-0.0031” (0.7-0.8 mm)

0.051” (1.3 mm)

Valve spring

Free length

1.55-1.60” (39.5-40.5 mm)

1.535” (39 mm)

Cam shaft

Height (intake)

1.15-1.18” (29.95-30.05 mm)

1.17” (29.75 mm)

Height (exhaust)

1.15-1.18” (29.95-30.05 mm)

1.17” (29.75 mm)

Outside diameter (bearing)

0.628-0.629” (15.966-15.984 mm)

0.626” (15.916 mm)

1.2 Engine Specifications

Page 8

Maintenance

Crankcase cover

Camshaft hole diameter

0.629-0.630” (16-16.018 mm)

0.633” (16.068 mm)

Crankshaft hole diameter

1.575-1.576” (40.009-40.025 mm)

1.578” 40.075 mm)

Spark plug

Gap

0.0027-0.0031” (0.7-0.8 mm)

-

Ignition coils

Resistance (primary)

(1.6-1.9Ω)

-

Resistance (secondary)

(6.27.1kΩ)

-

Gap to flywheel

0.015-0.016” (0.4±0.1 mm)

-

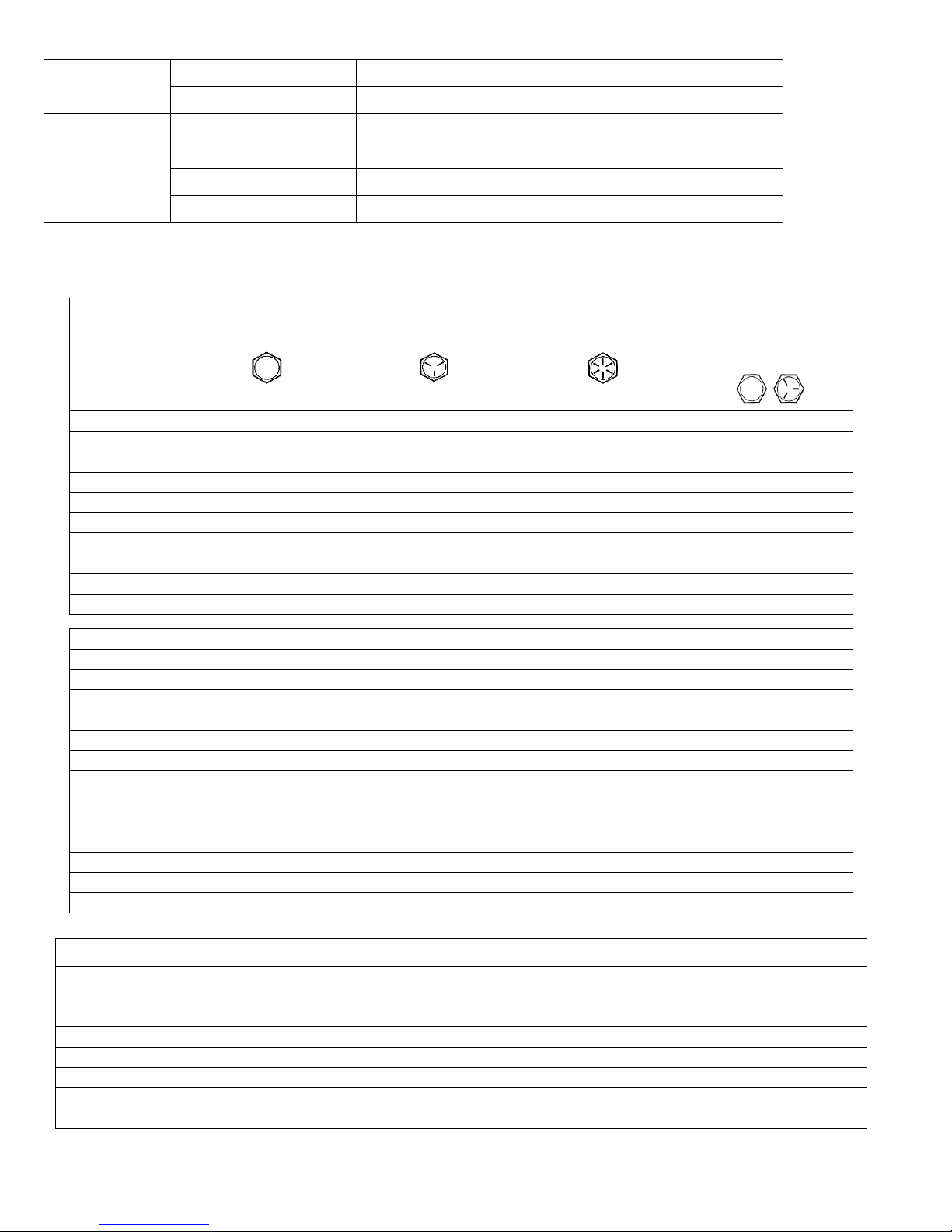

English Fastener Torque Recommendations for Standard Applications

Bolts, Screws, Nuts and Fasteners Assembled Into Cast Iron or Steel

Size Grade 2 Grade 5 Grade 8

Grade 2 or 5 Fasteners

Into Aluminum

Tightening Torque: N·m (in. lb.) ± 20%

8-32 2.3 (20) 2.8 (25) —

2.3 (20)

10-24 3.6 (32) 4.5 (40) —

3.6 (32)

10-32 3.6 (32) 4.5 (40) —

—

1/4-20 7.9 (70) 13.0 (115) 18.7 (165)

7.9 (70)

1/4-28 9.6 (85) 15.8 (140) 22.6 (200)

—

5/16-18 17.0 (150) 28.3 (250) 39.6 (350)

17.0 (150)

5/16-24 18.7 (165) 30.5 (270) —

—

3/8-16 29.4 (260) — —

—

3/8-24 33.9 (300) — —

—

Tightening Torque: N·m (ft. lb.) ± 20%

5/16-24 — — 40.7 (30)

—

3/8-16 — 47.5 (35) 67.8 (50)

—

3/8-24 — 54.2 (40) 81.4 (60)

—

7/16-14 47.5 (35) 74.6 (55) 108.5 (80)

—

7/16-20 61.0 (45) 101.7 (75) 142.5 (105)

—

1/2-13 67.8 (50) 108.5 (80) 155.9 (115)

—

1/2-20 94.9 (70) 142.4 (105) 223.7 (165)

—

9/16-12 101.7 (75) 169.5 (125) 237.3 (175)

—

9/16-18 135.6 (100) 223.7 (165) 311.9 (230)

—

5/8-11 149.5 (110) 244.1 (180) 352.6 (260)

—

5/8-18 189.8 (140) 311.9 (230) 447.5 (330)

—

3/4-10 199.3 (147) 332.2 (245) 474.6 (350)

—

3/4-16 271.2 (200) 440.7 (325) 637.3 (470)

—

Metric Fastener Torque Recommendations for Standard Applications

Property Class

Size

4.8 5.8

8.8 10.9 12.9

Noncritical

Fasteners

Into Aluminum

Tightening Torque: N·m (in. lb.) ± 10%

M4 1.2 (11) 1.7 (15) 2.9 (26) 4.1 (36) 5.0 (44)

2.0 (18)

M5 2.5 (22) 3.2 (28) 5.8 (51) 8.1 (72) 9.7 (86)

4.0 (35)

M6 4.3 (38) 5.7 (50) 9.9 (88) 14.0 (124) 16.5 (146)

6.8 (60)

M8 10.5 (93) 13.6 (120) 24.4 (216) 33.9 (300) 40.7 (360)

17.0 (150)

GENERAL TORQUE VALUES

Page 9

Maintenance

Tightening Torque: N·m (ft. lb.) ± 10%

M10 21.7 (16) 27.1 (20) 47.5 (35) 66.4 (49) 81.4 (60)

33.9 (25)

M12 36.6 (27) 47.5 (35) 82.7 (61) 116.6 (86) 139.7 (103)

61.0 (45)

M14 58.3 (43) 76.4 (56) 131.5 (97) 184.4 (136) 219.7 (162)

94.9 (70)

Torque Conversions

N·m = in. lb. x 0.113 in. lb. = N·m x 8.85

N·m = ft. lb. x 1.356 ft. lb. = N·m x 0.737

Page 10

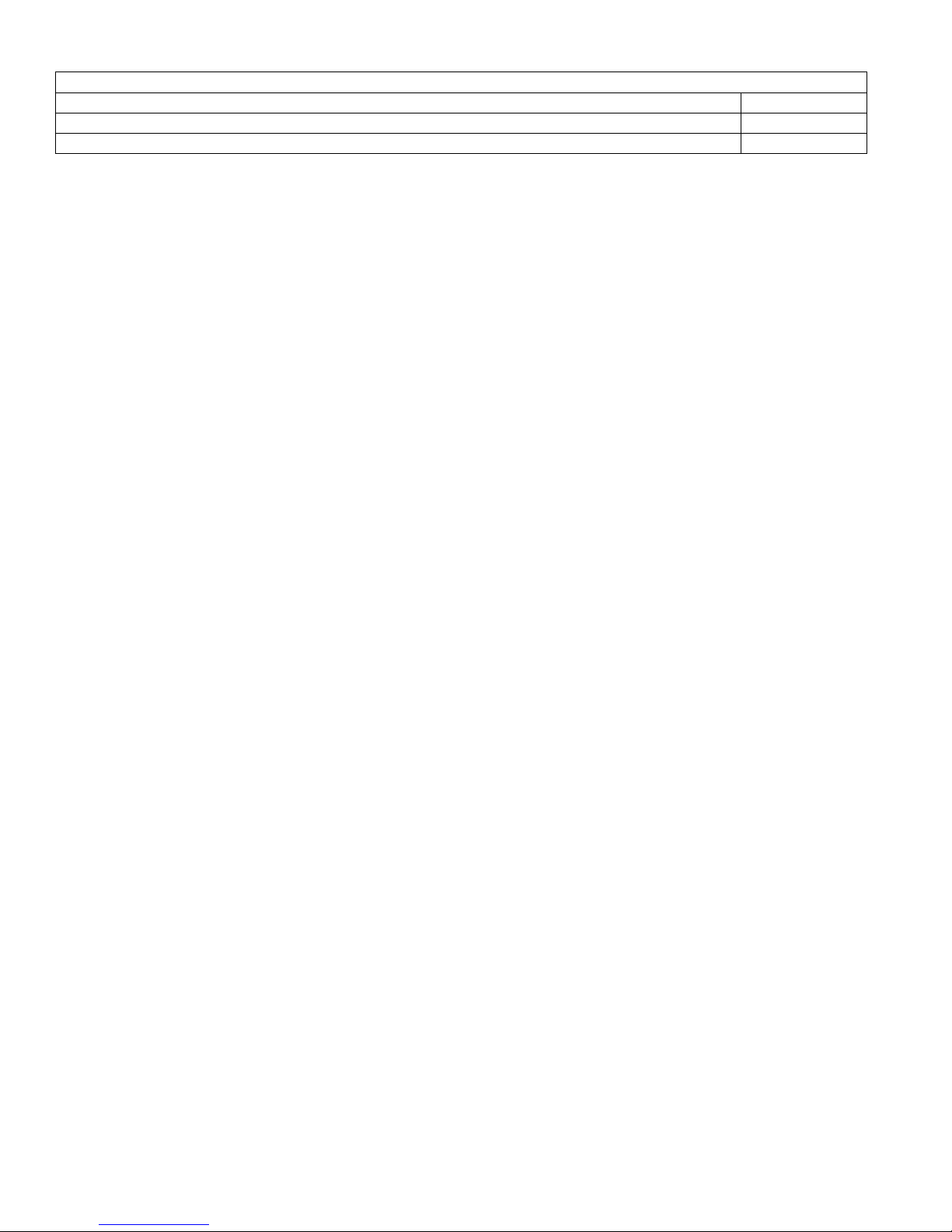

Maintenance

2-1

2. Specifications

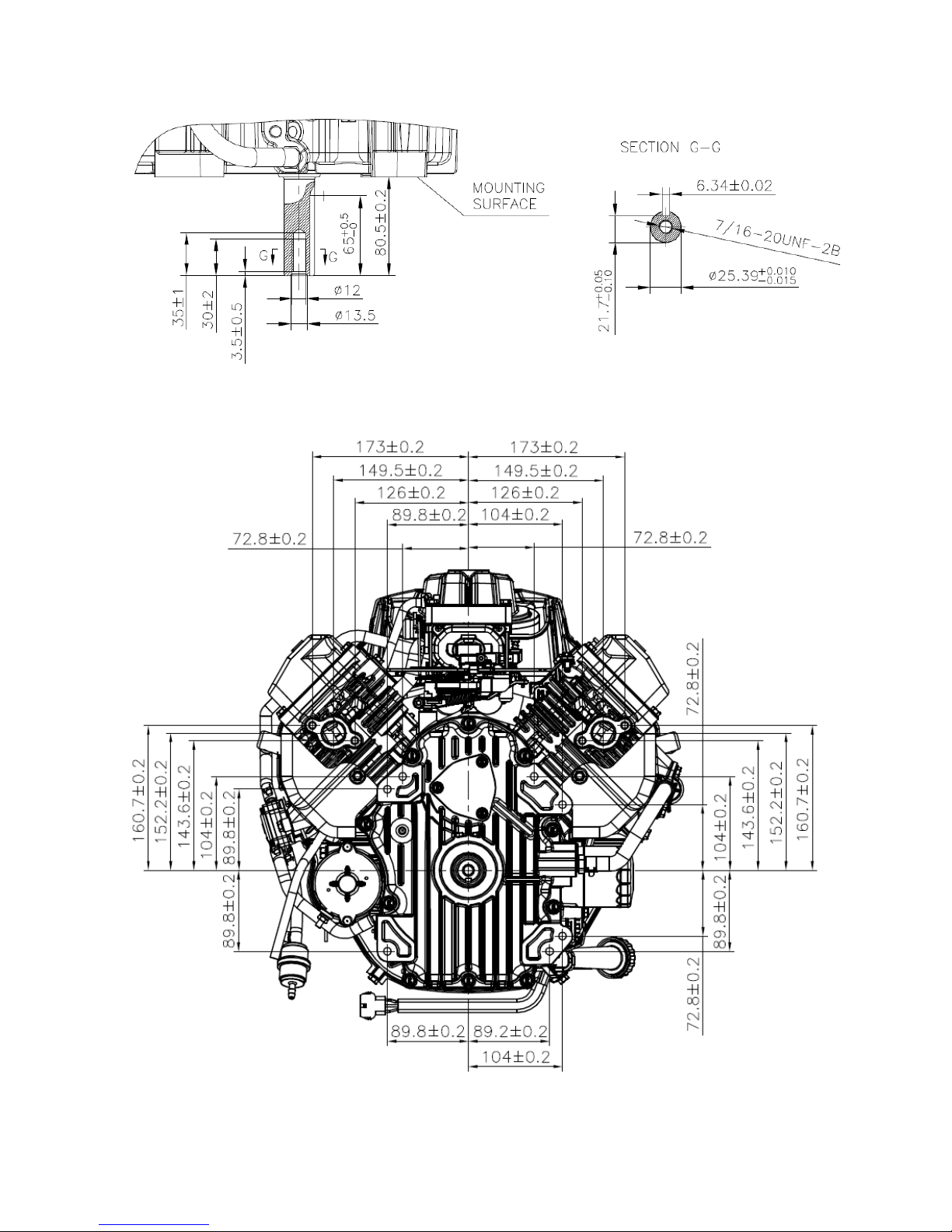

2.1 Specifications--------------------------------------------------2—2

2.2 Dimensional drawings----------------------------------------2—2

2.1 Specifications

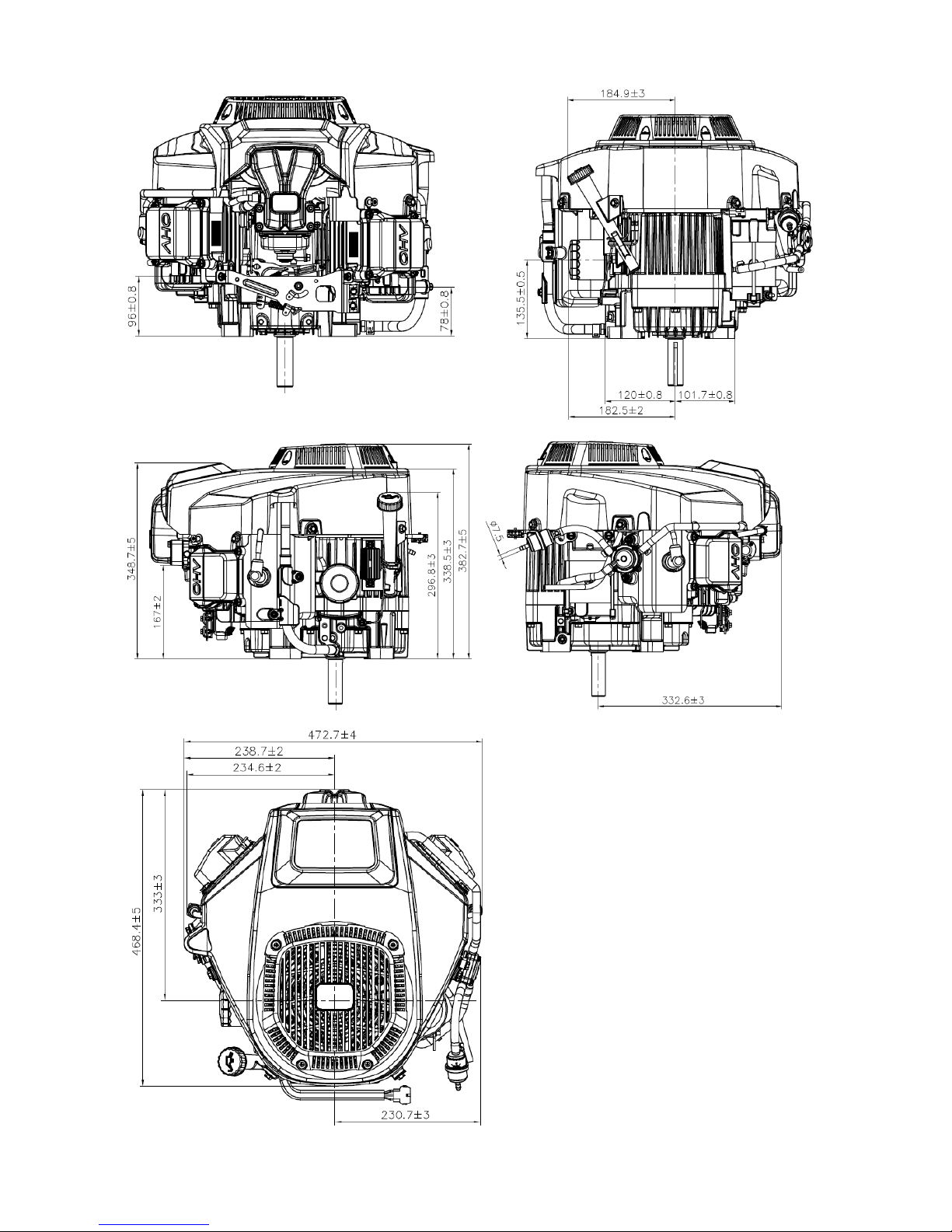

2.2 Dimensional Drawings in Millimeters

Model

P/N 127-9041 - 708 CC

Type

OHV, V-twin –Air Cooled 4-Stroke

Idle speed

1800 ± 50 rpm

Bore X Stroke

3.03” x 2.99” (77×76mm)

Displacement(cc)

43.20 Cubic Inches (708 cc)

Compression Ratio

8.7 :1

Lubricating mode

Full pressure

Starting mode

Electric

Rotation

Counter Clockwise(from P.T.O. side)

Valve clearance

Intake valve:0.004” - 0.006” , Exhaust valve:0.006” – 0.008”

Spark plug clearance

0.0027” - 0.0031” (0.7~0.8mm)

Igniting mode

Transistorized Magneto Ignition

Air cleaner

Foam & paper

Fuel type

Unleaded gasoline, minimum 87 Octane

Oil capacity

2.1 Quarts (2.0 liters)

Dimension(L×W×H)

18.44” x 18.61” x 15.06” (468.4×472.7×382.7 mm)

Net weight

89.95 lbs. (40.8 kg)

2

Page 11

Maintenance

2-2

Page 12

Maintenance

2-3

Page 13

Maintenance

2-4

Page 14

Maintenance

3-1

3 Maintenance

3.1 Maintenance schedule-----------------------------------------3-2

3.2 Engine oil ------------------------------------------------------ 3-2

3.3 Air cleaner ------------------------------------------------------3-3

3.4 Spark plug ------------------------------------------------------3-4

3.5 Valve clearance ------------------------------------------------3-4

3.6 Carburetor ----------------------------------------------------- 3-5

3.7 Governor -----------------------------------------------------3-5

3

Page 15

Maintenance

3-2

3.1 Maintenance Schedule

(1)Service more frequently when used in dusty condition areas.

(2)These items are to be maintained by designated dealers unless the user has special tools

and skills for maintenance.

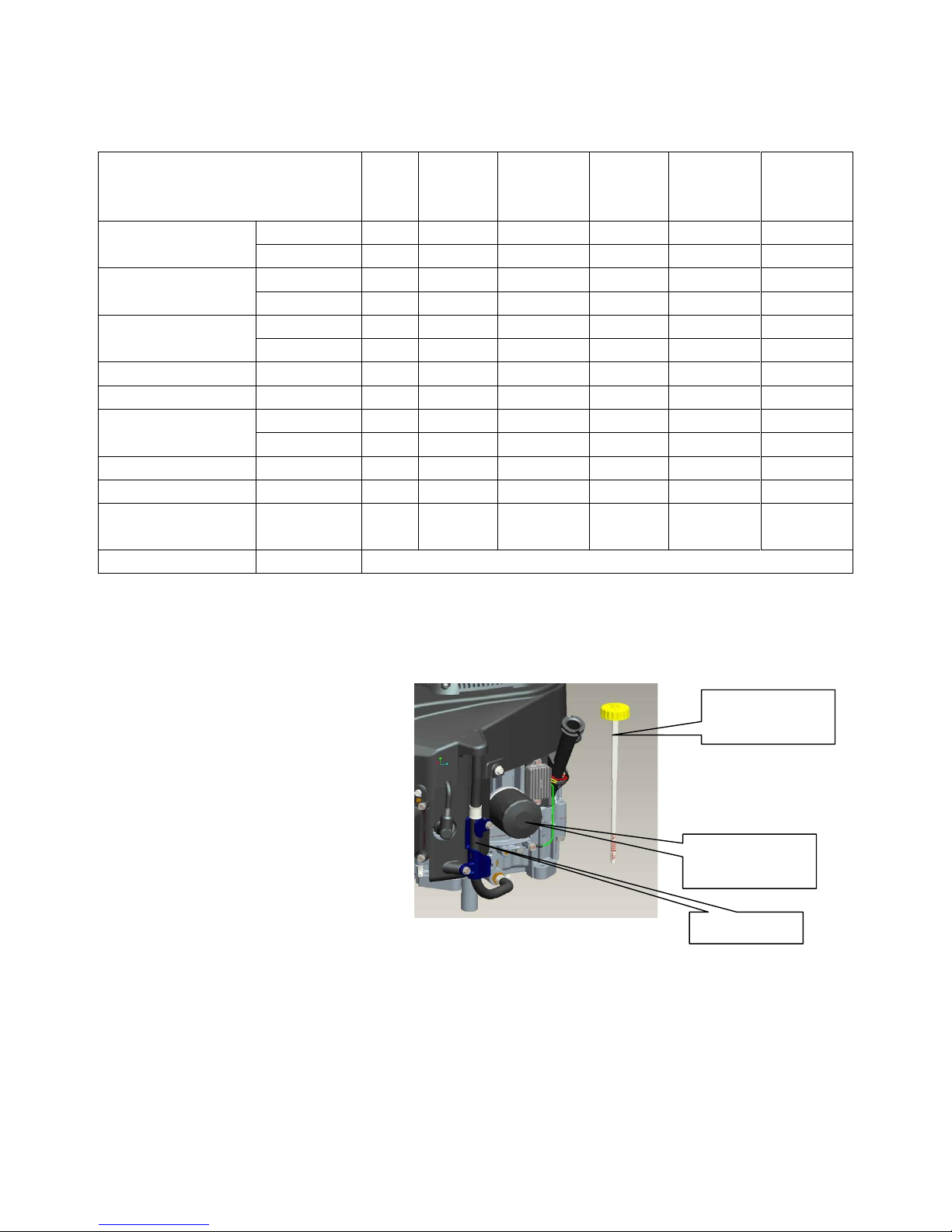

3.2 Engine Oil

Drain the oil while the engine is warm to

assure rapid and complete draining.

1. Clean the area around the oil filler

cap/dipstick. Remove

the oil filler cap/dipstick.

2. Drain the engine oil into a suitable

container using one of the following

methods.

Oil Drain:

a. Unwind the tube from the cleat

b. Pull hose down from the fitting

c. Allow the oil to drain into a suitable container.

d. Replace hose fully

Maintenance schedule

Each

Use

First 1

month

or 5 hours

Every 3

months or

25 hours

Every 6

months or

50 hours

Every year

or 100

hours

Every 2

years or

200 hours

Engine oil

Oil level ●

Change

● ●

Air cleaner foam

element

Clean

●(1)

Change

●(1)

Air cleaner paper

element

Clean

●(1)

Change

●(1)

Oil Filter

Change

●

Fuel filter

Replace

Spark plug

Replace

●

Check-adjust

●(2)

Valve clearance

Check-adjust

●(2)

Combustion chamber

Clean

●(2)

Remove engine

shroud and clean

Compressed

Air

●

Fuel hose

Every 3 years (Replace sooner if necessary) (2)

OIL FILLER

CAP/DIPSTICK

DRAIN LINE

OIL FILTER

Page 16

Maintenance

3-3

Engine Oil Capacity: 2.1 quarts (2.0 L)

Use a high-detergent, premium quality 4-stroke engine oil certified to meet or exceed US.

Automobile manufacturers’ requirements for API Service Classification SG, SF.

SAE 15W-40 is recommended for general, all-temperature use. Other viscosities shown in the chart may be

used when the average temperature in your area is within the indicated range.

3. Insert the oil filler cap/dipstick into the

oil filler tube. Remove the oil filler cap/dipstick

and check the oil level. Bring the level

to the upper mark on the dipstick.

after running the engine, recheck the oil

level and adjust if necessary.

Wash your hands thoroughly with soap

and water as soon as possible after

contact with used oil which contains

Carcinogenic substances.

Please dispose of used motor oil and the oil

containers in a manner that is compatible with the environment. We suggest you take it in a sealed container to

your local recycling center or service station for reclamation. Do not throw it in the trash, or pour it on the

ground.

UPPER LIMIT

LOWER LIMIT

Page 17

Maintenance

3-4

3.3 Air Cleaner

1. Lift open door

2. Rotate filter out from rear.

3. Clean the foam element by squeezing it in warm soapy water, rinsing it, and allowing it to dry. You may also

use a nonflammable solvent and then allow it to dry.

4. Clean the paper element by tapping it on a hard surface to knock off dirt, never used compressed air. Never

try to brush off the dirt. Brushing will force dirt into the filter fibers.

5. Use a damp rag to wipe any dirt from the inside of the air cleaner base and cover. Be careful not to allow dirt

into the duct leading to the carburetor.

6. Install filter in reverse order of removal

7. Close door

CAUTION: Operating the engine without an air filter, or with a damaged air filter, will

allow dirt to enter the engine, causing rapid engine wear. This type of damage is not covered by

the Distributor’s Limited Warranty.

3.4 Spark Plug

CLEANER

COVER

ELEMENT

AIR CLEANER BASE

Page 18

Maintenance

3-5

Recommended types: BOSCH F7RTC NHSP BP7RES CHAMPION RN9YC

NOTICE

Spark plugs of the wrong size or incorrect heat range

can cause engine damage.

1. Disconnect the spark plug lead and remove any dirt

from around the spark plug area.

2. Remove the spark plug with a spark plug wrench.

3. Inspect the spark plug for excessively worn electrodes,

chips or cracks in the insulator, or excessive deposits.

Replace the spark plug if you have any doubts about

its condition.

4. Measure the electrode gap with a wire gap gauge. Adjust

the gap to 0.025 – 0.030” by carefully bending

the ground electrode.

5. Use a spark plug wrench to tighten the plug enough to compress the washer. For a used plug, tighten 1/8 to

1/4 of a turn after the spark plug seats. For a new plug, tighten 1/2 turn after the spark plug seats. 18 – 22 ft.

lbs.

NOTICE

A loose spark plug can become hot enough to damage the engine. Over tightening a spark

plug can damage the threads in the engine.

6. Install the spark plug lead on the plug.

3.5 Valve Clearance

Valve clearance inspection and adjustment must be done with the engine cold.

1. Remove the valve cover, and set the first cylinder

piston at top dead center of the compression

stroke (both valves will be fully closed).

2. Measure the clearance between the rocker

arm and the valve stem with a feeler gauge.

Intake: 0.040” to 0.060” (0.10~0.15 mm)

Exhaust: 0.060” to 0.075 (0.15~0.20 mm)

3. To adjust valve clearance, hold the rocker arm

pivot and loosen the pivot lock nut.

4. Turn the rocker arm pivot to obtain the

specified clearance.

5. Hold the rocker arm pivot and tighten the pivot

lock nut.

6. Recheck the clearance and readjust if necessary.

7. Install the cylinder head cover.

8. Repeat procedure for the other side.

0.025” – 0.030”

0.70~0.80 mm

Page 19

Maintenance

3-6

3.6 Carburetor

Idle speed

1. Start the engine and allow the engine to

warm to normal operating temperature.

2. With the engine idling, adjust the throttle

stop screw to obtain the recommended

engine idle speed.

Recommended idle speed: 1800 ± 50 rpm

3.7 Governor

1. Loosen the governor arm pinch bolt nut.

but do not remove it.

2. Move the governor arm anti clockwise to

fully open the throttle and hold it in this

position.

3. Rotate the governor arm shaft fully

clockwise and hold it there with a pair

of pliers. Tighten the governor arm

pinch bolt nut to 8 ft. lbs. (11N·m) to secure the

governor arm to the governor arm shaft.

4. Check to be sure the governor arm and

throttle valve move free

Stop screw

Page 20

Maintenance

4-1

4 Disassembly and Service

4.1 Air cleaner --------------------------------------------------4-2

4.2 Engine cover --------------------------------------------------4-3

4.3 Control lever -------------------------------------------------4-4

4.4 Air Intake -----------------------------------------------------4-5

4.5 Carburetor ----------------------------------------------------4-5

4.6 Ignition coil --------------------------------------------------4-6

4.7 Flywheel/breather--------------------------------------------4-7

4.8 Cylinder head & valves -------------------------------------4-8

4.9 Crankcase cover/ governor --------------------------------4-11

4.10 Crankshaft /piston / camshaft ---------------------------4-14

4

Page 21

Maintenance

4-2

4.1 Air Cleaner

Page 22

Maintenance

4-3

4.2 Engine Cover

Page 23

Maintenance

4-4

4.3 Control Lever

Removal / Installation

Page 24

Maintenance

4-5

4.4 Air Intake

Page 25

Maintenance

4-6

4.5 Carburetor

NOTICE

No.

Process Description

Bolt Specification

Torque Range

N.m

In.lb.

1

Solenoid Valve

M12

6~9

53.1~79.6

2

Fuel Cup

Screw M4

1.5~2.0

13.3~17.7

3

Fuel Plug

Flange Bolt M6

6~9

53.1~79.6

4

Pin,Float

Screw M3

1.8~3.0

15.9~26.5

5

Main Jet

1.2~1.7

10.6~15

Page 26

Maintenance

4-7

4.6 Ignition Coil

Igniting coil gap adjustment

When reinstalling ignition coils, adjust the air

gap to: (0.015” – 0.020”)

1) Lightly tighten the igniting coil mounting bolt.

2) Insert the feeler gauge or a piece of paper of the same

thickness between the flywheel and coil as shown.

3) Push the coil against the flywheel by hand and tighten

the two bolts.

NOTICE

a) Adjust both ends of the coil to the same gap.

b) Avoid the magnet portion of the flywheel

when adjusting.

c) Inspect your work

Ignition Coil:

<Primary coil>

Put the tester terminal and lead terminal to contact with iron core of coil, and measure the primary coil resistance.

Primary coil resistance

1.6-1.9 Ω

<Secondary coil>

Put the tester terminal and removed spark plug cap’s high tension

cord to contact with iron cord and measure the secondary coil resistance.

Secondary coil resistance

6.2-7.1 KΩ

Adjustment

Adjustment is required only when the ignition coil or the flywheel has been removed.

1. Loosen the ignition coil mounting bolts.

2. Insert the thickness gauge or a piece of paper of the proper thickness between the ignition coil and the

flywheel, both gaps should be adjusted simultaneously. Avoid the magnet when adjusting the air gap.

3. Push the ignition coil firmly toward the flywheel and tighten the mounting bolts.

Specified clearance

0.015” – 0.020” (0.4 mm +/- 0.1mm)

Page 27

Maintenance

4-8

4.7 Flywheel /Breather

Removal / installation

NOTICE:

Disassembly:

Do not hit the flywheel with a hammer. Remove with a commercially available puller.

Avoid the magnet section when attaching the puller.

Reassembly:

Make certain there are no metal objects stuck to the magnet.

Adjust the ignition coil air gap after reassembly.

Page 28

Maintenance

4-9

4.8 Cylinder Head & Valves

Removal / Installation:

Remove the following:

1. engine cover

2. carburetor

3. Shroud Comp

Cylinder Head-Right

Page 29

Maintenance

4-10

Cylinder Head-Left

NOTICE:

Removal /Installation

Loosen and tighten Bolt, Cylinder Head in a crisscross pattern in 2~3 steps;

Before installation, remove any carbon deposits from the combustion chamber and

inspect the valve seats;

Measure the cylinder compression after reassembly.

Page 30

Maintenance

4-11

Disassembly / Reassembly

Inspection

Cylinder Head-Right

Page 31

Maintenance

4-12

Cylinder Head-Left

Valve Spring Free Length

Measure the free length of the valve springs.

Standard

Service limit

1.55” – 1.60”

1.53”

Replace the spring if they shorter than the service limit.

Valve Seat Width

Remove carbon deposits from the combustion

chamber. Inspection the valve seats for pitting or

other damage. Measure the valve seat width.

Standard

Service limit

0.028” – 0.030”

0.040”

If the valve seat width is under the standard, or

over the service limit, recondition the valve seat

Page 32

Maintenance

4-13

Cylinder Head

1、Remove carbon deposits from the combustion

chamber. Clean off any gasket material from the

cylinder head surface.

2、Check the spark plug hole and valve areas for cracks.

3、Check the cylinder head for warpage with a straight

edge and a feeler gauge as shown.

Service limit

0.002”

Valve Stem OD

Inspect each valve for face irregularities, bending

or abnormal stem wear. Replace the valve if necessary.

Measure and record each valve stem OD.

Standard

Service limit

IN

0.258” – 0.259”

0.255”

EX

0.257” – 0.258”

0.255”

Replace the valves if their OD is smaller than the service limit.

Valve Guide ID

Ream the exhaust valve guide to remove any

carbon deposits before measuring.

Measure and record each valve guide ID.

Standard

Service limit

0.259” – 0.260”

0.262”

Stem –to- Guide Clearance

Subtract each valve stem OD from the corresponding

guide ID to obtain the guide-to-stem clearance.

Standard

Service limit

IN

0.0008” – 0.0019”

0.0050”

EX

0.0015” – 0.0027”

0.0067”

If the stem-to-guide clearance exceeds the service limit, determine if the

new guide with standard dimensions would bring the clearance within

tolerance. If so, replace the guide (or cylinder head ) as necessary and

ream to fit. If the stem-to-guide clearance exceeds the service limit with

new guides, replace the valves as well.

Recondition the valve seat whenever the valve guide is replaced.

STRAIGHT EDGE

FEELER GAUGE

Page 33

Maintenance

4-14

Exhaust Valve Guide Reaming

For best results, be sure the cylinder head is at

room temperature before reaming the exhaust valve guide.

1. Coat the reamer and valve guide with cutting oil.

2. Rotate the reamer clockwise through the valve

guide the full length of the reamer.

3. Continue to rotate the reamer clockwise while

removing it from the valve guide.

4. Thoroughly clean the cylinder head to remove

any cutting residue.

5. Check the valve guide bore; it should be straight,

round and centered in the valve guide. Insert the valve

and check operation. If the valve does not operate

smoothly, the guide may have been bent during

installation. Replace the valve guide if it is bent or

damaged.

6. Check the valve stem-to-guide clearance

Valve Seat Reconditioning

1. Thoroughly clean the combustion chambers

and valve seats to remove carbon deposits.

2. Apply a light coat of Prussian Blue or erasable

felt-tipped marker ink to the valve faces.

3. Insert the valve, and then lift them and snap

them closed against their seats several times. Be

sure the valve does not rotate on the seat. The

transferred marking compound will show any

area of the seat that is not concentric.

4. Using a 45°cutter, remove enough material to

produce a smooth and concentric seat. Follow the

valve seat cutter manufacture’s instructions.

Turn the cutter clockwise, never counterclockwise.

Continue to turn the cutter as you lift it from the

valve seat.

5. Using the 30°~32° and 60° cutter to narrow

and adjust the valve seat so that it contacts the

middle of the valve face. The 30°~32° cutter removes

material from the top edge. The 60° cutter removes

material from the bottom edge. Bu sure that the width

of the finished valve seat is within specification.

CONTACT TOO LOW

CONTACT TOO HIGH

VALVE GUIDE

REAMER 0.259”

Page 34

Maintenance

4-15

Valve Seat Width

Standard

Service limit

0.0275” – 0.0315”

0.050”

1. Make a light pass with the 45° cutter to remove

any possible burrs at the edges of the seat.

2. After resurfacing the seats, inspection for even

valve seating.

3. Apply a light coat of Prussian Blue or erasable

felt-tipped marker ink to the valve faces.

4. Insert the valves, and then lift them and snap

them closed against their seats several times. Be

sure the valve does not rotate on the seat. The

seating surfacing, as shown by the transferred

marking compound, should have good contact all

the way around.

NOTICE

To avoid severe engine damage, be sure to

remove all lapping compound from the head

before reassembling.

5. Check the valve clearance after reassembly.

HAND VALVE LAPPER

Page 35

Maintenance

4-16

4.9 Crankcase Cover / Governor

Disassembly / Reassembly

Governor

NOTICE:

Check that the governor moves smoothly.

Page 36

Maintenance

4-17

Crankcase cover

Page 37

Maintenance

4-18

4.10 Crankshaft / Piston / Camshaft

Remove /installation

Page 38

Maintenance

4-19

Disassembly / Reassembly

Piston connecting rod

Assembly:

. Put the piston ring sign facing up when assembling.

. Don’t wrongly assemble the top ring and the second

ring.

. After assembling, be sure the piston can freely

move.

. Stagger the open of the piston to piston pin hole

with 120 degree.

Top ring

The second ring

Oil ring

Piston

Sign

Top ring

The second ring

Oil ring

Check, refer to

Piston pin

Piston ring clip

Assembly: Put the one end into the

piston slot, clamp other end by

sharp nose pliers and revolve into

slot. Don’t let the open of clip

aiming at the piston pin slot..

Connecting rod

Assembly: Put the long end of the

connecting rod aiming at the triangular

mark when assembling.

CLIP

CUT-OUT

Page 39

Maintenance

4-20

Piston Pin OD

Model

Standard

Service limit

LC2P77F

0.6689” – 0.6692”

0.6653”

Page 40

Maintenance

4-21

Cylinder Inside Diameter

Measure three points on the “X” and “Y” shaft

and record cylinder inside diameter(“X” shaft is vertical

to crankshaft and “Y” shaft parallel to crankshaft).

Take maximum reading as the wearing and tapering of

the cylinder.

Model

Standard

Service limit

708 CC

X: 3.0315”-3.0318”

Y: 3.0315”-3.0318”

3.0354”

3.0354”

Piston Skirt Outside Diameter

Measure and record the piston skirt outside diameter

at the 10mm from piston skirt maximum lower side

making 90°to piston pin hole.

Model

Standard

Service limit

708 CC

3.0301”-3.0351”

3.0218”

Piston- to – Cylinder Clearance

Standard

Service limit

0.0009”-0.0017”

0.010”

Piston Ring Side Clearance

Standard

Service limit

Top/

Second

0.0007” – 0.0023”

0.0043”

Piston Ring Width

Standard

Service limit

Top

00382”-0.0390”

0.0354”

Second

0.0460”-0.0468”

0.0433”

Page 41

Maintenance

4-22

Piston Ring End Gap

Standard

Service limit

0.0078” – 0.0157”

0.0177”

Before measuring end gap, use the piston top to position

the ring so it will not be cocked in the cylinder bore.

Connecting Rod Small End ID

Model

Standard

Service limit

708 CC

0.6695” – 0.6699”

0.6712”

Connecting Rod Large End ID

Original size

Model

Standard

Service limit

708 CC

1.5754” – 1.5757”

1.5773”

Crankshaft Pin OD

Model

Standard

Service limit

708 CC

1.5734” – 1.5744”

1.5551”

Page 42

Maintenance

4-23

Connecting Rod Large End Axial Clearance

Standard

Service limit

0.0177” – 0.0374”

0.0413”

Connecting Rod Large End Oil Clearance(Radial)

1) Clean all oil from the crankshaft neck journal

and inside side.

2) Place a piece of plastic gauge on the crankshaft

neck journal, assemble connecting rod, and tighten

the bolts to specified torque.

Bolt torque:9 ft. lbs. (12.5 N·m)

ATTENTION

3) Remove the connecting rod and measure the plastic

gauge.

4) If the clearance exceeds the service limit, replace

the connecting rod and recheck the clearance.

After using new connecting rod, the clearance still

exceeds the service limit, lap the neck journal and

use a connecting rod lower than standard value.

Camshaft Cam Height

Standard

Service limit

IN

1.179” – 1.183”

Replace under

1.171”

EX

1.179” – 1.183”

Replace under

1.171”

Camshaft OD

Standard

Service limit

0.6285” – 0.6293”

0.6266”

Note the location of the decompression mechanism,

check to be sure it moves freely.

Standard

Service limit

0.0015” – 0.0024”

0.0032”

Do not rotate the crankshaft while the

tightening connecting rod bolt

12.5 N·m

Page 43

Maintenance

4-24

Chapter 5 – Electrical System Information

Ignition Coil Gap Adjustment 1

Ignition Coil Resistance Inspection 1

Spark Testing 2

Fuel Solenoid 2

Charging System Specifications 3

AC Output Test 3

DC Output Test 4

5

Page 44

Maintenance

4-25

Ignition Coil Gap Adjustment

High Voltage Ignition Systems can be Dangerous - Use Caution when Servicing Ignition Systems

4) Install the ignition coil and lightly tighten the ignition coil mounting bolts.

5) Rotate engine so ignition coil is aligned with the magnet portion of the flywheel.

6) Insert the feeler gauge between the flywheel and coil.

7) Adjust the ignition coil gap at both sides of the coil.

8) Sufficiently tighten the mounting bolts.

Ignition Coil Resistance Inspection

Primary Coil

Place Ohm meter leads between the harness connection

lead and the exposed metal coil leg.

Secondary Coil

Place Ohm meter leads between exposed metal coil leg

and the spark plug terminal connection.

Ignition Coil Gap

0.011- 0.019”

(.3-.5 mm)

A - Primary Coil Resistance

1.0-1.6 Ω

B Secondary Coil Resistance

8.9 k Ω – 12.1 k Ω

A

B

Page 45

Maintenance

4-26

Spark Testing

- Fuel is Extremely Flammable - Use Extreme Caution When Servicing the Fuel System

- High Voltage Ignition Systems can be Dangerous - Use Caution when Servicing Ignition Systems

1. Remove spark plug cap from the spark plug.

2. Remove the spark plug from the engine.

3. Connect the negative (-) electrode of the spark plug (threaded area) to ground (cylinder head cover).

4. Crank the engine and view the electrode gap. Spark should be present when engine is turning over.

5. Reinstall the spark plug and torque to specification - 22 ft-lbs (30 Nm).

6. Properly install the spark plug boot.

Fuel Solenoid

Fuel Solenoid Resistance

Place Ohm meter leads between the harness connections,

Fuel Solenoid Resistance

35 - 45Ω

4

35 - 45Ω

Page 46

Maintenance

4-27

Charging System Specifications

AC Output Test

1. Insert RED

test

lead into

VC

receptacle

in meter.

2.

Insert BLACK

test lead into COM receptacle.

3. Rotate selector to

V-

(AC

VOLTS)

position.

4. Attach RED test lead clip (1) to AC output terminal(5),

Fig.18.

5. Attach BLACK test lead clip (2) to engine ground.

6. With engine

running

at 3600 RPM output should be no less than 14 volts

AC.

7. NOTE: The battery MUST be in good condition to

perform

this test.

Charge Coil(s) Air Gap

Measure Between the Magnet Area of the Flywheel and the

Charge Coil Legs

0.011- 0.019” (.3-.5 mm)

No Load DC Voltage Output @ 3000 RPM

Measure Across Battery Terminals

14.5 +/- .5 Volts DC

No Load AC Voltage Output @ 3000 RPM

Measure Across Stator Leads – Stator Leads Disconnected

30 VAC

Charge Coil / Stator Resistance

Measure Resistance Across the Two Stator Leads

0.16 Ohms +/- 15%

Page 47

Maintenance

4-28

DC Output Test

1.

Insert RED test

lead into

1

OA

receptacle in

meter.

2. Insert BLACK test lead into COM receptacle

in

meter.

3. Rotate selector to A== (DC AMPS) position.

4. Attach RED test lead clip (1) to DC

output

pin (6)in connector (4),

Fig.16. If NO or LOW output is found,

replace stator.

Loading...

Loading...